Method for making biological organic fertilizer by utilizing urban domestic sludge and special-purpose leavening agent of method

A technology for urban domestic sludge and bio-organic fertilizer, applied in organic fertilizer, sewage/sludge fertilizer, application, etc., can solve the problems of ocean pollution, low operation cost, high treatment cost, achieve complete degradation treatment, and solve environmental protection problems. effect of the problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

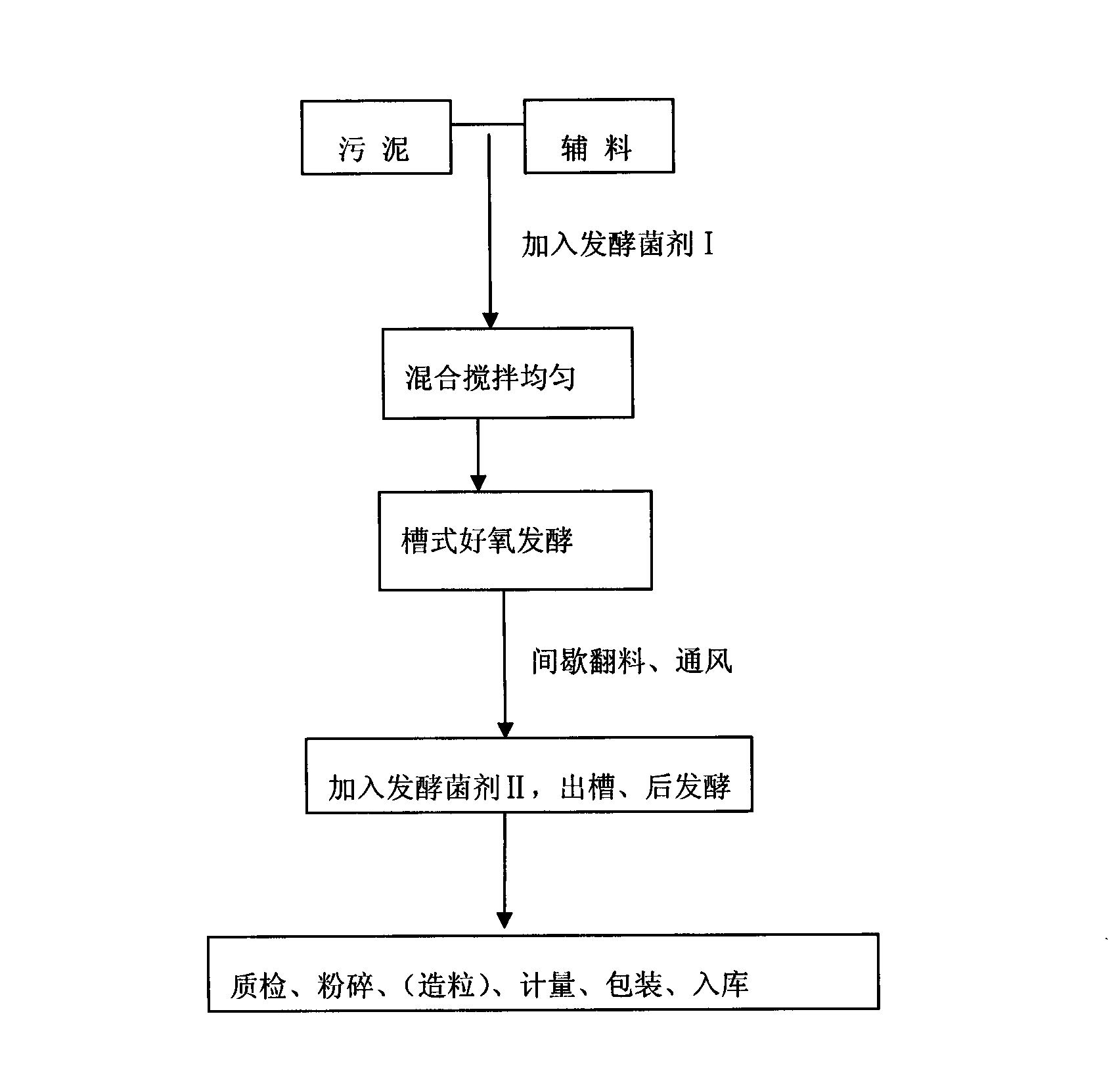

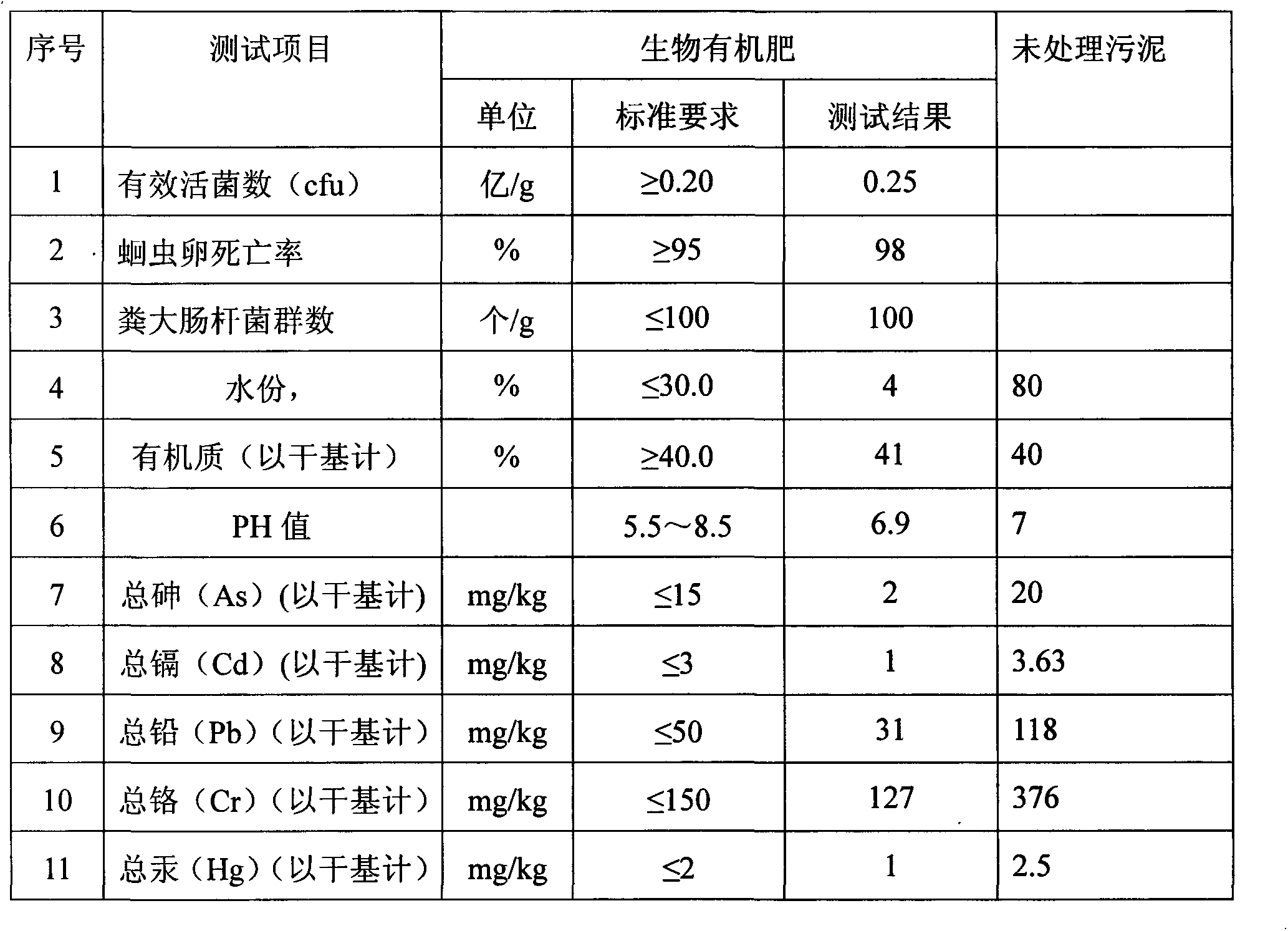

[0019] refer to figure 1 Shown, the present invention is further described.

[0020] A kind of method of utilizing municipal domestic sludge to manufacture bio-organic fertilizer of the present invention and special leavening agent thereof, its specific implementation method is as follows;

[0021] (1) First, measure the water content and various nutrient contents on the basis of the existing sludge and auxiliary materials (crop straw, mushroom residue, traditional Chinese medicine residue, etc.); adjust the sludge and auxiliary materials according to the measured water content and nutrient content ratio, so as to achieve a water content of 55-65% after mixing, and a C / N of 25-30;

[0022] (2) Add the prepared sludge and auxiliary materials into the microbial fermentation strain I (calculated on the basis of one ton of dry material) at a ratio of 2-3‰, mix them evenly, and put them into the bio-organic fertilizer fermentation tank , the height of the material should not exce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com