Oil fume purification method

An oil fume and atomizer technology, applied in the field of oil fume purification, can solve the problems of high operating and maintenance costs, high cost, and unsuitable for large-scale promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

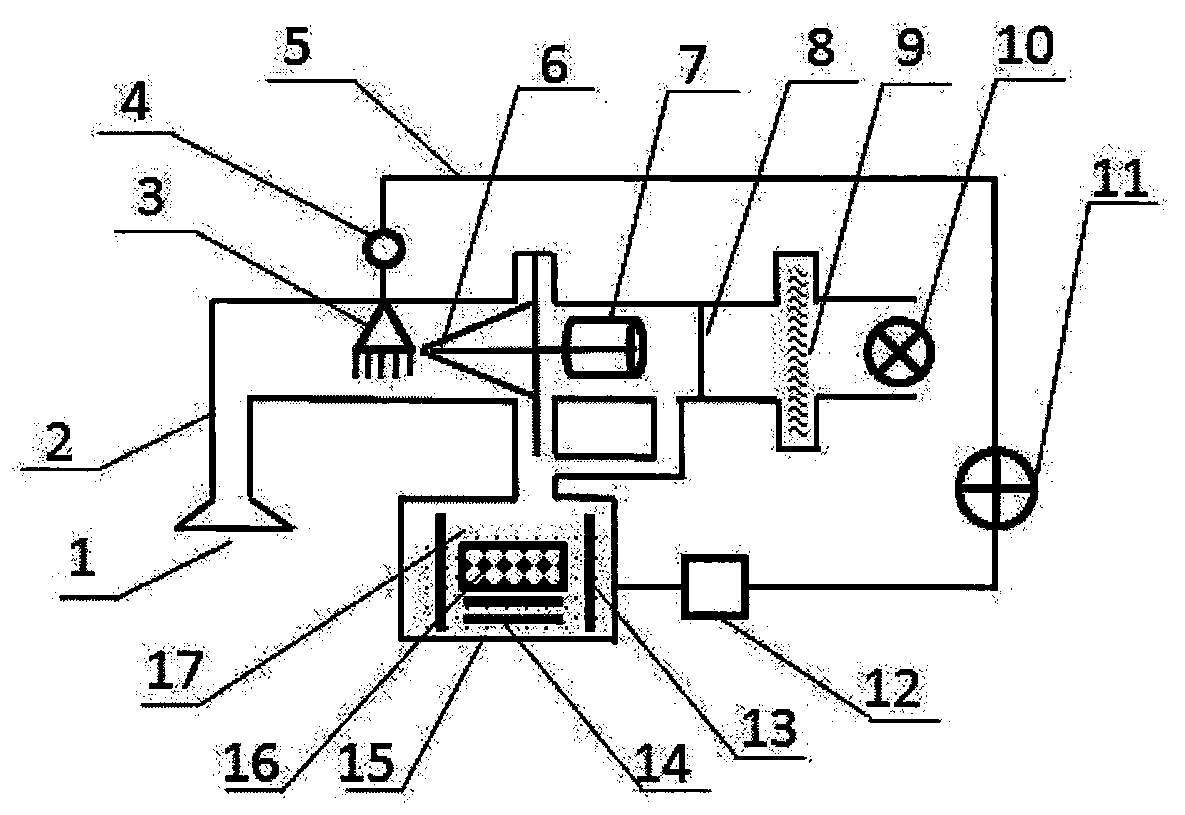

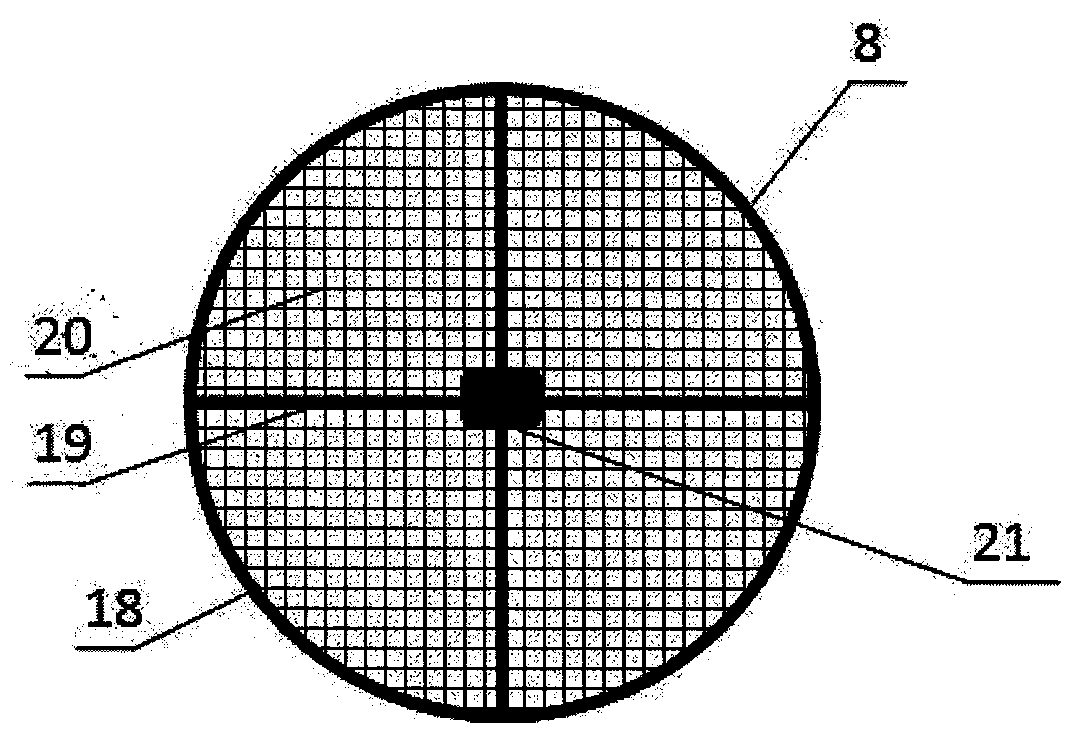

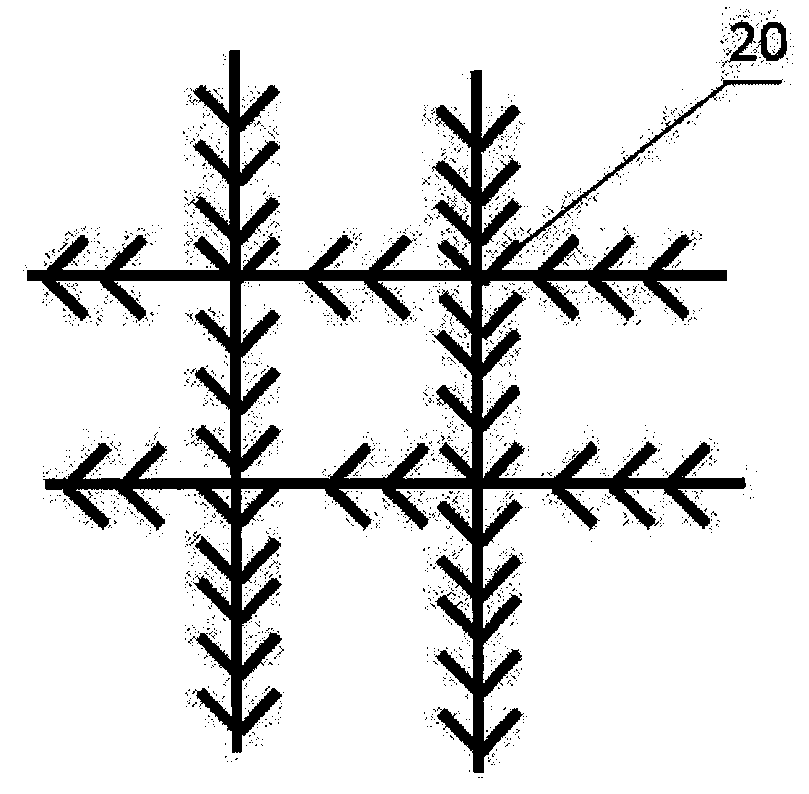

[0019] A method for purifying oily fume according to the present invention, the method involves a device consisting of a gas collecting hood, an oil fume channel, an atomizer, a heating ring, a water pipe, a cone catcher, a motor, an adsorption net, activated carbon, a fan, and a dissolved air pump , filter, electrode plate, ultraviolet lamp tube, liquid reservoir, photocatalyst, capture liquid, frame, bracket, grid, vibrator, outer ring and silk screen, around the inner wall of the oil fume channel 2 above the gas collecting hood 1 The atomizer 3 is set, the atomizer 3 is composed of multiple groups of nozzles, the atomizer 3 is connected to one end of the water pipe 5, the heating ring 4 is looped on the water pipe 5, and the other end of the water pipe 5 is connected to the liquid reservoir 15, And fix the dissolved air pump 11 and the filter 12 on the water pipe 5 respectively, and the middle part of the oil fume passage 2 is respectively provided with a cone catcher 6, a m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com