Three-layer efficient high-speed gas-liquid mass transfer tower board

A gas-liquid mass transfer and tray technology, applied in the field of mass transfer trays, can solve the problems of lowering the upper limit of tower equipment operation, large tray pressure drop, energy loss, etc., and achieve the effect of improving tray efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

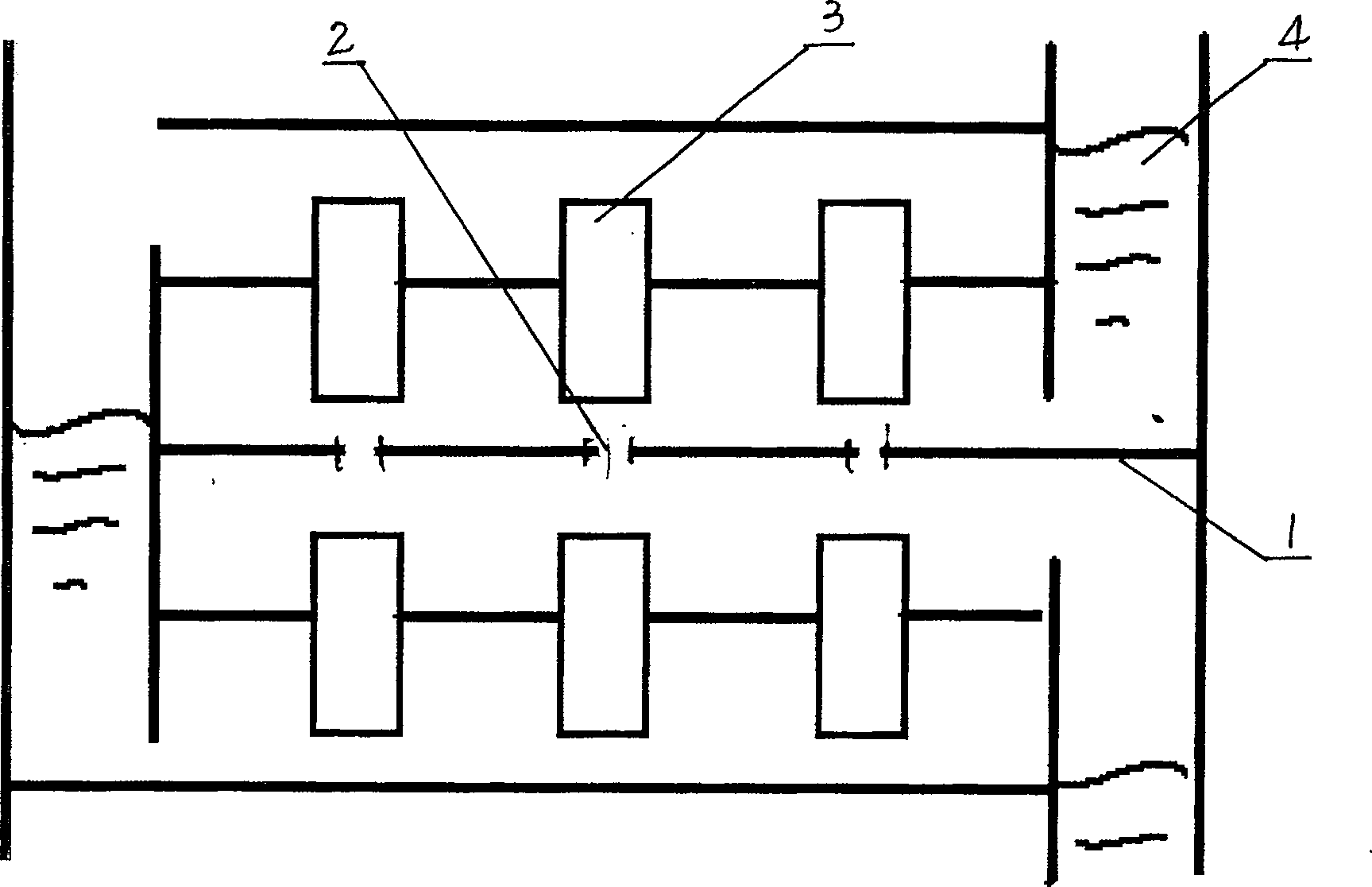

[0028] As shown in the drawings, the present invention relates to a three-layer high-efficiency high-speed gas-liquid mass transfer tray. The tray 1 includes three layers. These three layers together constitute the gas-liquid mass transfer part. The first layer of tray is a gas-liquid mass transfer tray. The dispersing plate has a plate hole 2 on the gas-liquid dispersing plate, and the second layer of tray adjacent to the gas-liquid dispersing plate is a liquid collecting plate, which is connected to the lifting cylinder 3, and the liquid collecting plate is connected to the downcomer The pipe 4 is connected, and there is no top cover on the lifter 3, but a layer of liquid foam collection plate is set, which is the third layer of tray above the liquid collection plate, and the mist collection plate There is a gap with the lifter 3. Its characteristic is that the gas-liquid phase is fully in contact with the mass transfer in the element, while on the tray 1 there is only a sin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com