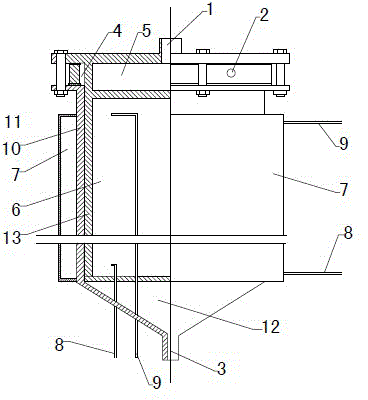

A microchannel reactor for large-scale production

A technology of microchannel reactor and microchannel reaction, which is applied in chemical instruments and methods, chemical/physical processes, chemical/physical/physical chemical processes, etc., can solve problems such as hidden dangers, great safety, and high production costs, and achieve the elimination of reactions The difference in effect, good cooling and heat dissipation capacity, and the effect of eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

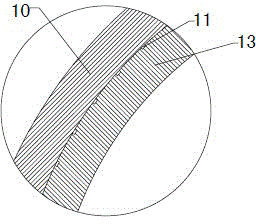

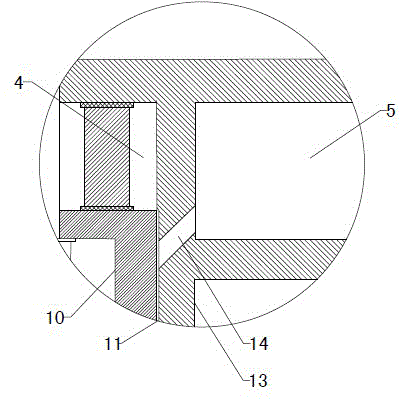

[0028] The basic structure and connection relationship are the same as the above attached figure 1 , 3 shown. Specifically, the arcs of the microchannel reaction lines 11 on the horizontal cross-sectional circumference of the inner shell 13 are 15°; the groove depth of the microchannel reaction line 11 is 0.5 mm, and the groove width is 0.5 mm. In this situation, it can adapt to the industrialized safe production of most dangerous chemical reactions such as strong exothermic and fast.

Embodiment 2

[0030] The basic structure and connection relationship are the same as the above attached figure 1 , 3 shown. Specifically, the arc of the microchannel reaction line 11 on the horizontal cross-sectional circumference of the inner housing 13 is 45°; the groove depth of the reaction line of the microchannel reaction line 11 is 0.3mm, and the groove width is 0.3mm. In this situation, it is suitable for industrialized safe production of more intense and faster exothermic chemical reactions.

Embodiment 3

[0032] The basic structure and connection relationship are the same as the above attached figure 1 , 3 shown. Specifically, the arcs of the microchannel reaction lines 11 on the horizontal cross-sectional circumference of the inner shell 13 are 90°; the groove depth of the microchannel reaction line 11 is 0.2 mm, and the groove width is 0.2 mm. Under this situation, the industrial production of dangerous chemical reactions with more intense heat release and faster control is more accurate and the safety guarantee is the strongest.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com