Entity wire frame modeling device

A wireframe and entity technology, applied in manufacturing auxiliary devices, coating devices, processing data acquisition/processing, etc., can solve troublesome and unsuitable problems such as integrated modeling of large solid wireframes, and achieve reduced friction and occupied volume small, stability-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

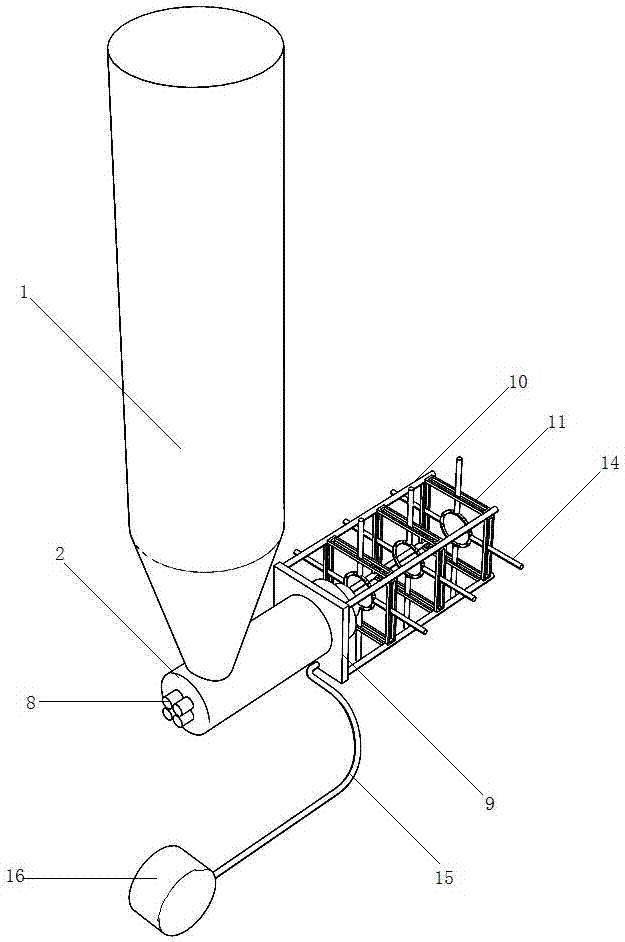

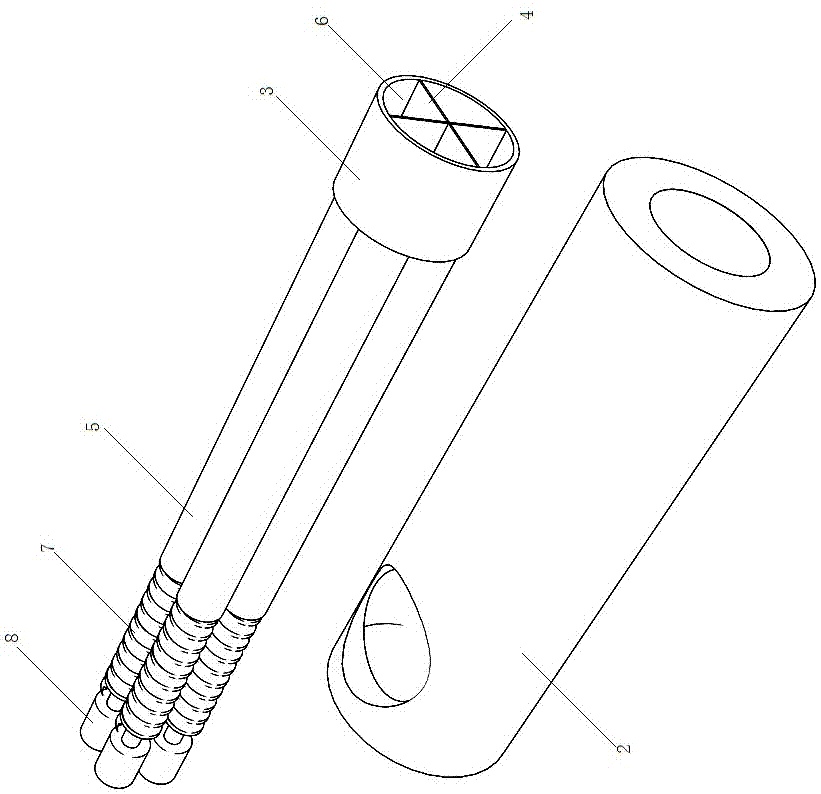

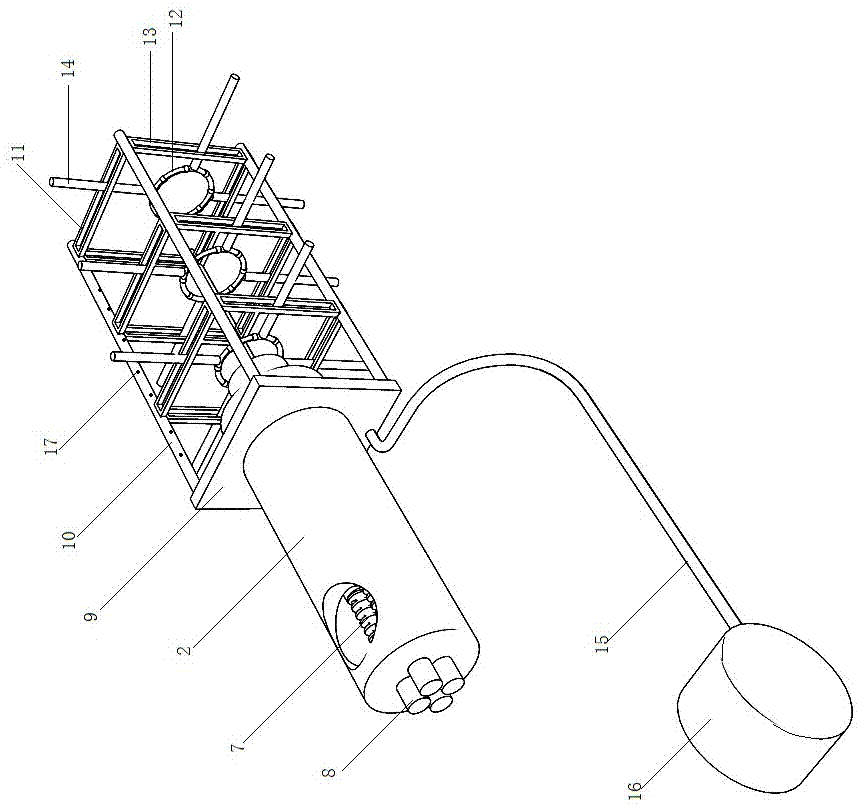

[0021] The present invention will be further described in detail below with reference to the drawings and specific embodiments.

[0022] Such as Figure 1-7 As shown, the physical wire-frame modeling device includes a melt supply device 1, an extrusion mechanism, and a shaping mechanism; the extrusion mechanism includes a housing 2, and the discharge port of the melt supply device 1 is connected to the rear of the housing 2; the housing 2 The front end is plugged and connected with the model head 3; the model head 3 is a tubular structure, and the partition 4 arranged in the radial direction is evenly distributed in the model head 3; the partition 4 divides the interior of the model head 3 into a plurality of fan-shaped holes 6 evenly; A screw extruding device is installed in the housing 2; the screw extruding device includes a plurality of stacked feeding pipes 5; the number of the feeding pipes 5 and the fan-shaped holes 6 are the same and they are connected in one-to-one corre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com