Ultra-large high-efficiency high-operation-flexibility high-throughput anti-blocking composite flow-through tray

A through-flow tower and through-flow technology, which is applied in the field of large-scale composite through-flow trays, can solve the problems of short vapor-liquid contact time, high space utilization rate, and low mass transfer efficiency, so as to increase the gas-liquid contact area and time, Improve efficiency and reduce tray pressure drop effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

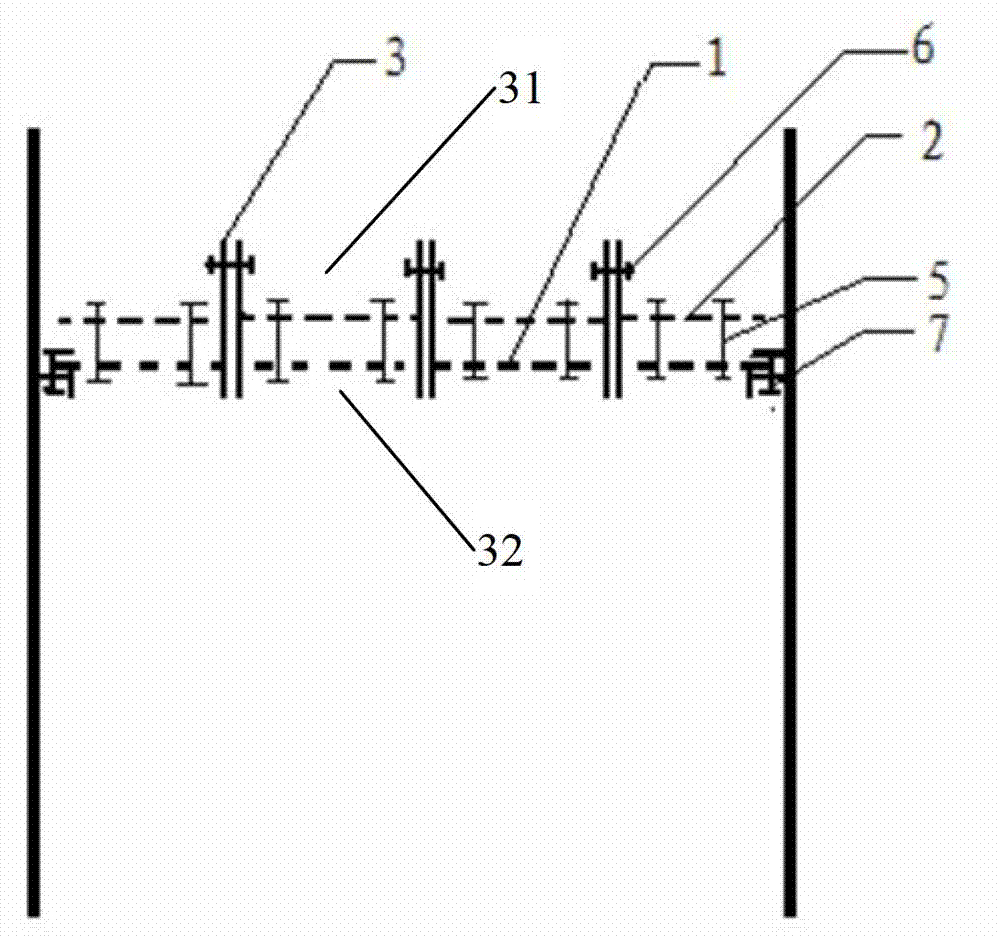

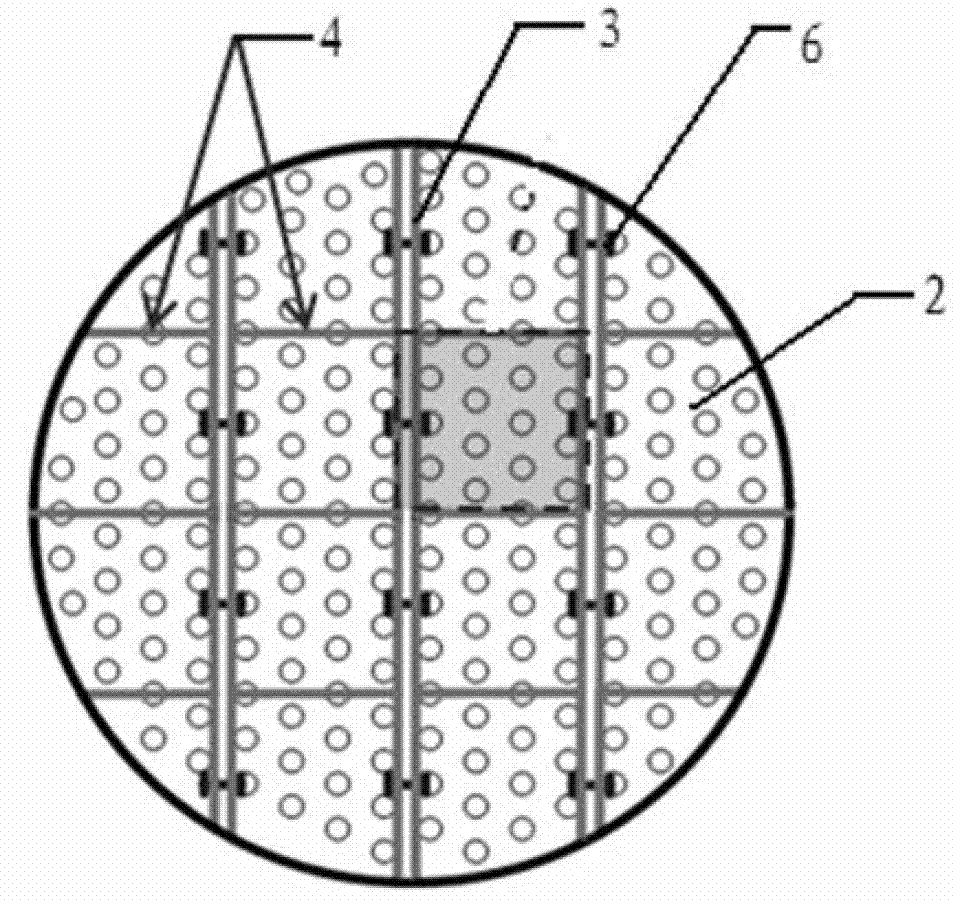

[0014] Example 1, such as figure 1 , figure 2 As shown, the present invention is assembled into a tray by several strip composite through-flow trays. The composite through-flow tray is composed of a through-flow tray 1, a through-flow sieve tray 2, an H-shaped vertical edge 3 and a partition 4. The through-flow tray 1 is a flat plate with a thickness of 2 to 10 mm, and there are holes on it. 20 to 60% of the diameter or equivalent diameter of 15 to 20 mm round hole or rhombus hole; at a distance of 3 to 8 mm in the upper part of the through-flow tray 1, a plurality of fixed columns 5 are used to fix the through-flow with the same opening ratio and hole shape The sieve plate 2, the fixed column 5 and the through-flow tray 1 and the through-flow sieve plate 2 can be welded or bolted. The plate thickness of the through-flow sieve plate 2 is 2-10 mm; the sieve holes or diamond-shaped holes on the through-flow sieve plate 2 and the through-flow tray 1 are staggered or partially ...

Embodiment 2

[0016] Embodiment 2, can refer to figure 1 , figure 2 , the present invention is made up of through-flow tray 1, through-flow sieve plate 2, H-shaped vertical edge 3 and dividing plate 4, and through-flow tray 1 is the flat plate with the thickness of 2~10mm, has opening ratio 20~ 60% of strip-shaped holes with a width of 6-20mm and a length of 30-200mm; a through-flow sieve plate with the same opening ratio and hole shape fixed by multiple fixing columns 5 at a distance of 3-8mm high on the upper part of the through-flow tray 1 2. The fixed column 5 and the through-flow tray 1 and the through-flow sieve plate 2 can be welded or bolted. The plate thickness of the through-flow sieve plate 2 is 2-10 mm; the strip holes on the through-flow sieve plate 2 and the through-flow tray 1 are staggered or partially staggered; the H-shaped vertical edge 3 is vertically fixed on the through-flow tray 1 and the Both ends of the through-flow sieve plate 2, the upper and lower ends of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com