Fast recovery diode (FRD) chip and production process thereof

A technology for recovering diodes and production processes, which is applied to electrical components, semiconductor/solid-state device manufacturing, circuits, etc. It can solve problems such as unstable breakdown voltage, easy burnout of diodes, and poor anti-surge capability, and achieve enhanced withstand voltage stability performance and reliability, improve anti-surge capability, and prolong life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to understand the present invention more clearly, describe the present invention in detail in conjunction with accompanying drawing and embodiment:

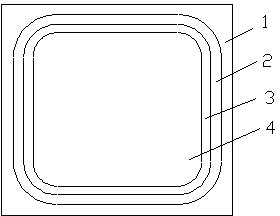

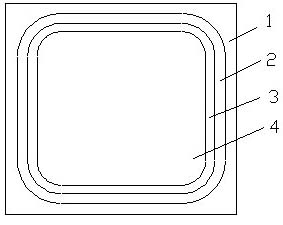

[0027] Such as figure 1 The chip structure of the fast recovery diode FRD shown is "P + NN + . Chip sections are FRD chip 1, mesa groove 2, glass layer 3, and metal surface 4 in sequence.

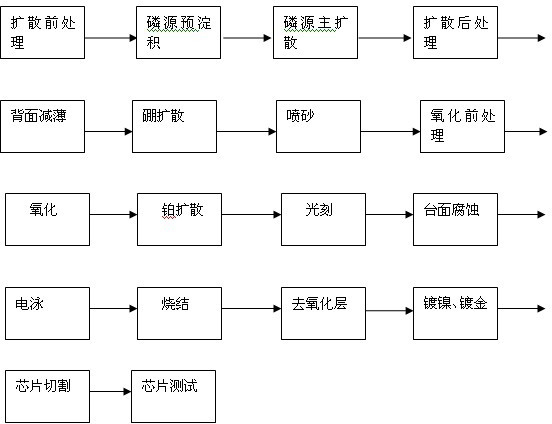

[0028] Such as figure 2 The chip process flow of the shown fast recovery diode FRD is as follows:

[0029] 1) Pre-diffusion treatment: chemically treat the surface of the silicon wafer through acid, alkali, deionized water ultrasonic cleaning and other processes.

[0030] 2) Phosphorus source pre-deposition: pre-deposit the cleaned silicon wafers in a diffusion furnace at a temperature of 1100-1200 °C by passing gas into a liquid phosphorus source.

[0031] 3) Main diffusion of phosphorus source: Diffusion advance is carried out on the pre-deposited silicon wafer in a diffusion furnace at 1200-1250 °C.

[0032] 4) P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com