Semiconductor component and manufacturing method

A manufacturing method and semiconductor technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of high resistivity of bulk silicon, device burnout, and large conduction voltage drop of devices, so as to improve anti-surge effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

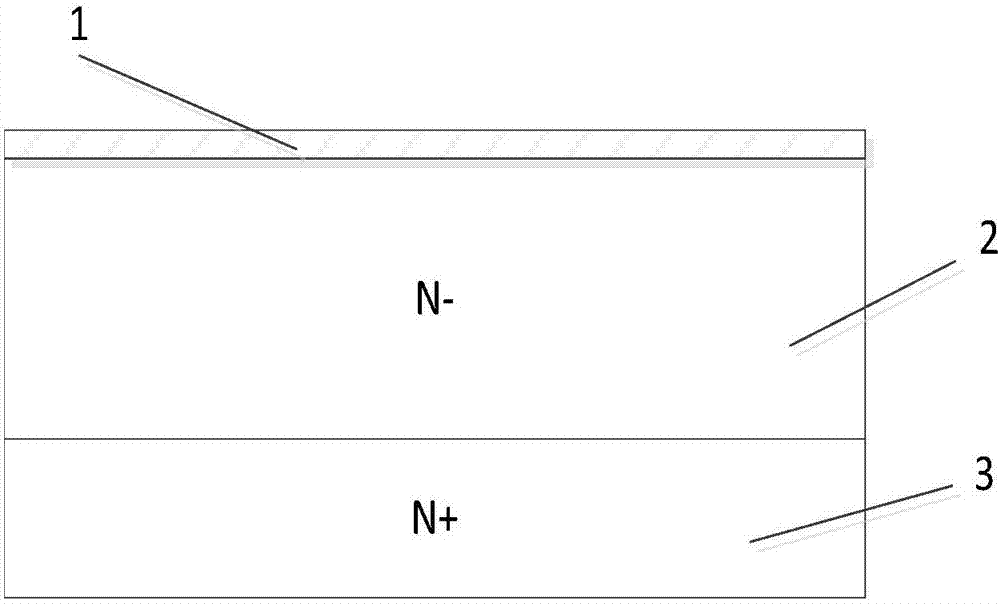

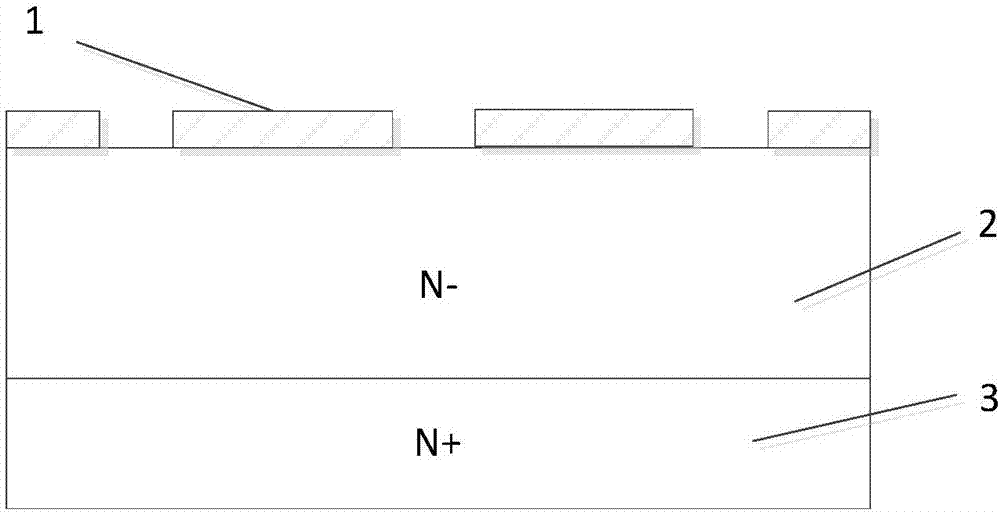

[0036] An embodiment of the present invention provides a method for manufacturing a semiconductor element, the method comprising:

[0037] Perform ion implantation at multiple preset implantation positions of the semiconductor material;

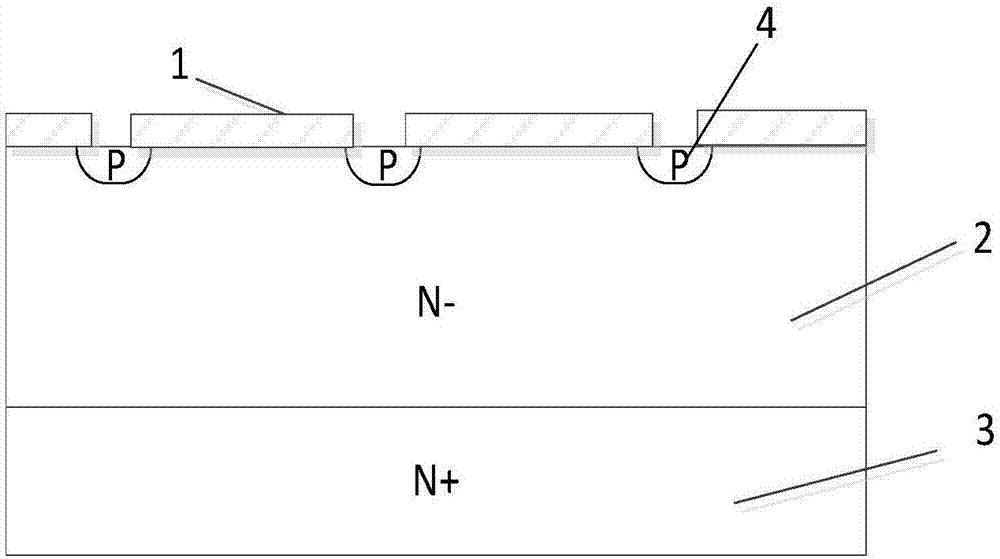

[0038] Forming a doped P-type region at each implantation position through the implanted ions, and a doped P-type diffusion region diffused from the doped P-type region;

[0039] Groove etching is performed at each implant position, and during the etching process, the doped P-type region is etched away, and the doped P-type diffusion region is retained, so that each cell of the formed semiconductor element The region has a doped P-type diffusion region.

[0040] In the embodiment of the present invention, ion implantation is performed at a plurality of preset implantation positions of the semiconductor material; through the implanted ions, a doped P-type region is formed at each implantation position, and the doped P-type region diffused in ...

Embodiment 2

[0072] Such as Figure 6 As shown, the embodiment of the present invention provides a semiconductor element, the semiconductor element is a trench structure; each trench of the trench structure corresponds to a cell region; the cell region has a doped P-type diffusion region 41 .

[0073] In the embodiments of the present invention, a doped P-type diffusion region is formed in each cell region of the semiconductor element, thereby neither reducing the device switching frequency nor the turn-on voltage drop, while effectively improving the anti-surge capability of the semiconductor element.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com