Patents

Literature

219results about How to "Improved pressure stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

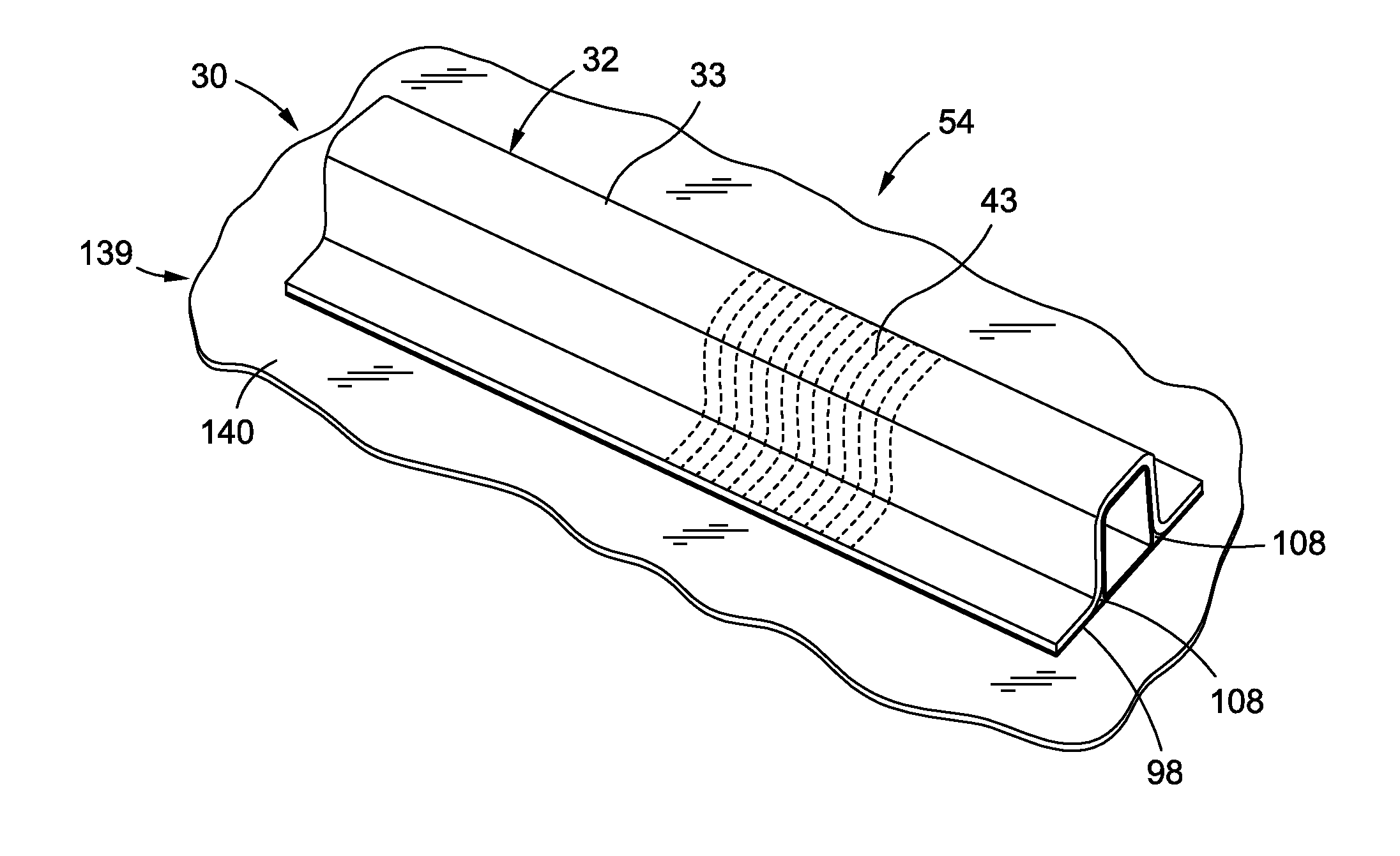

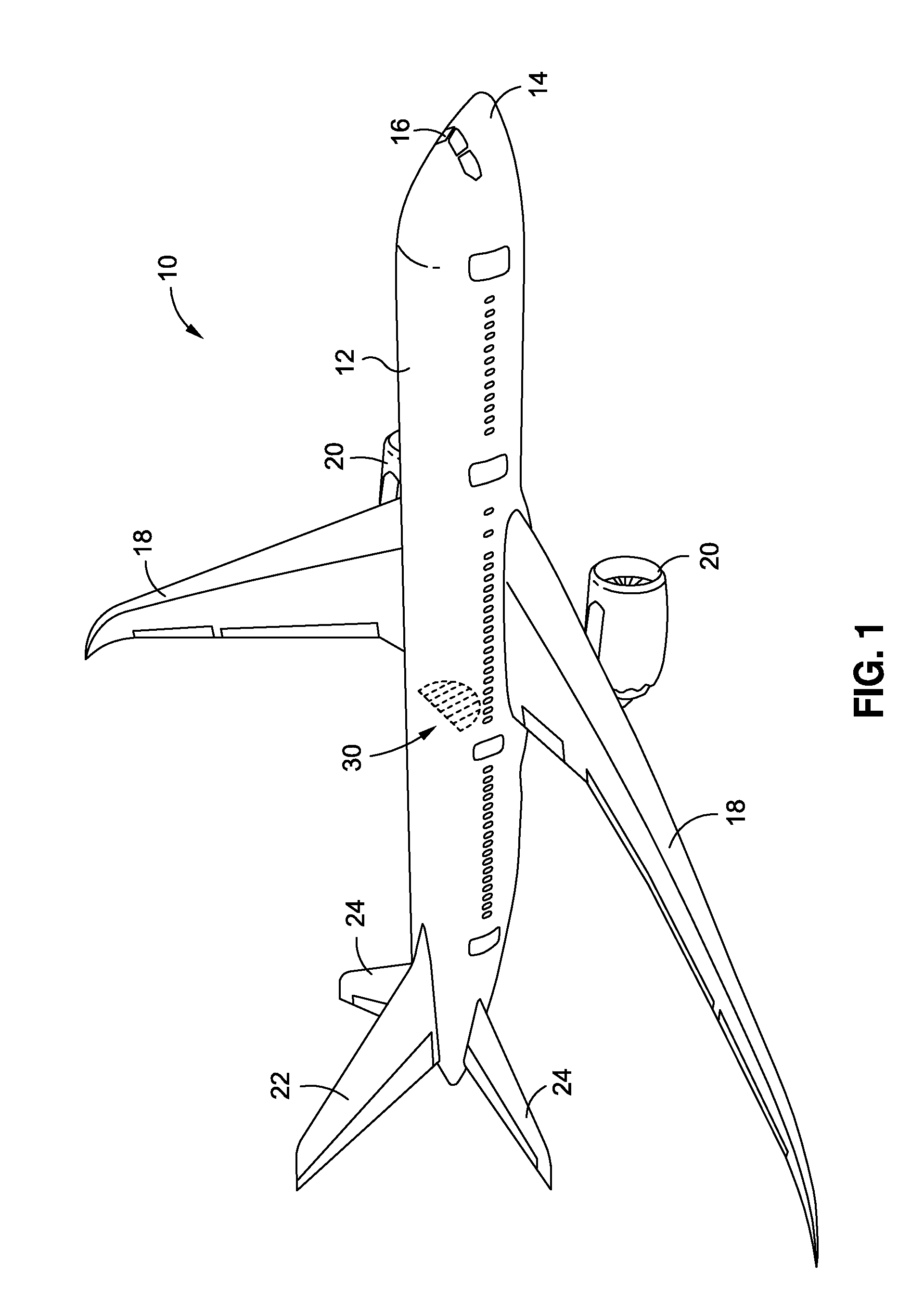

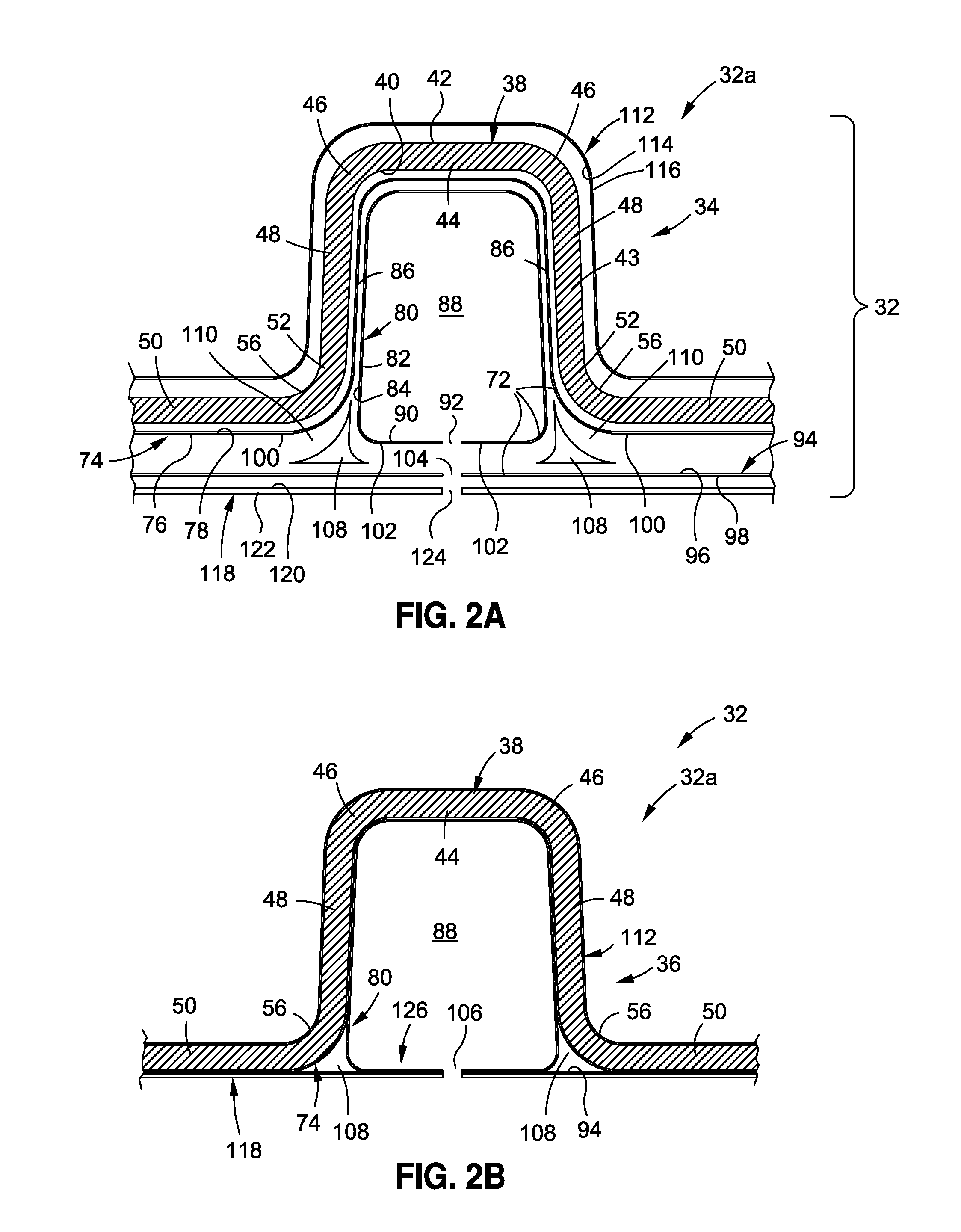

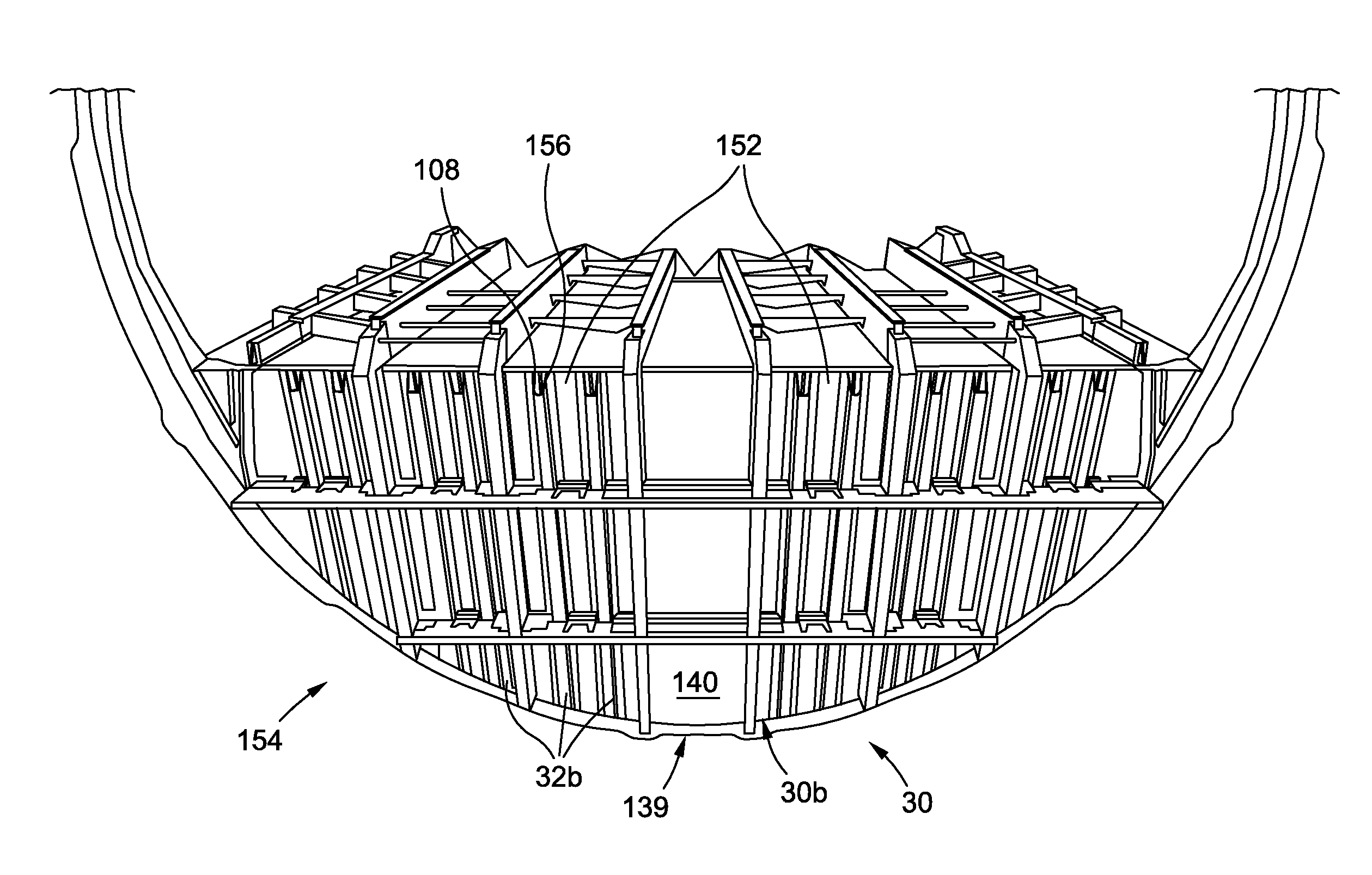

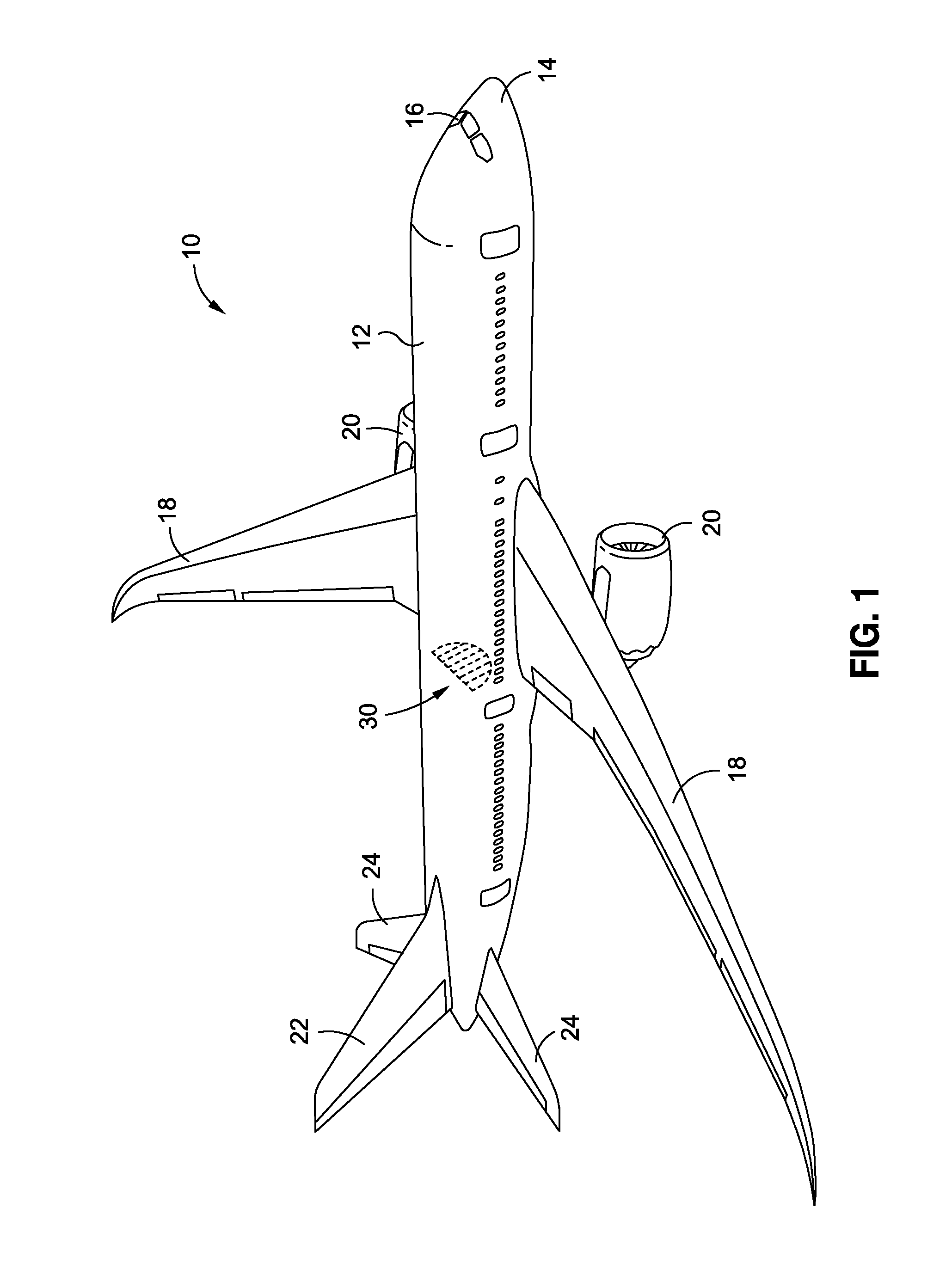

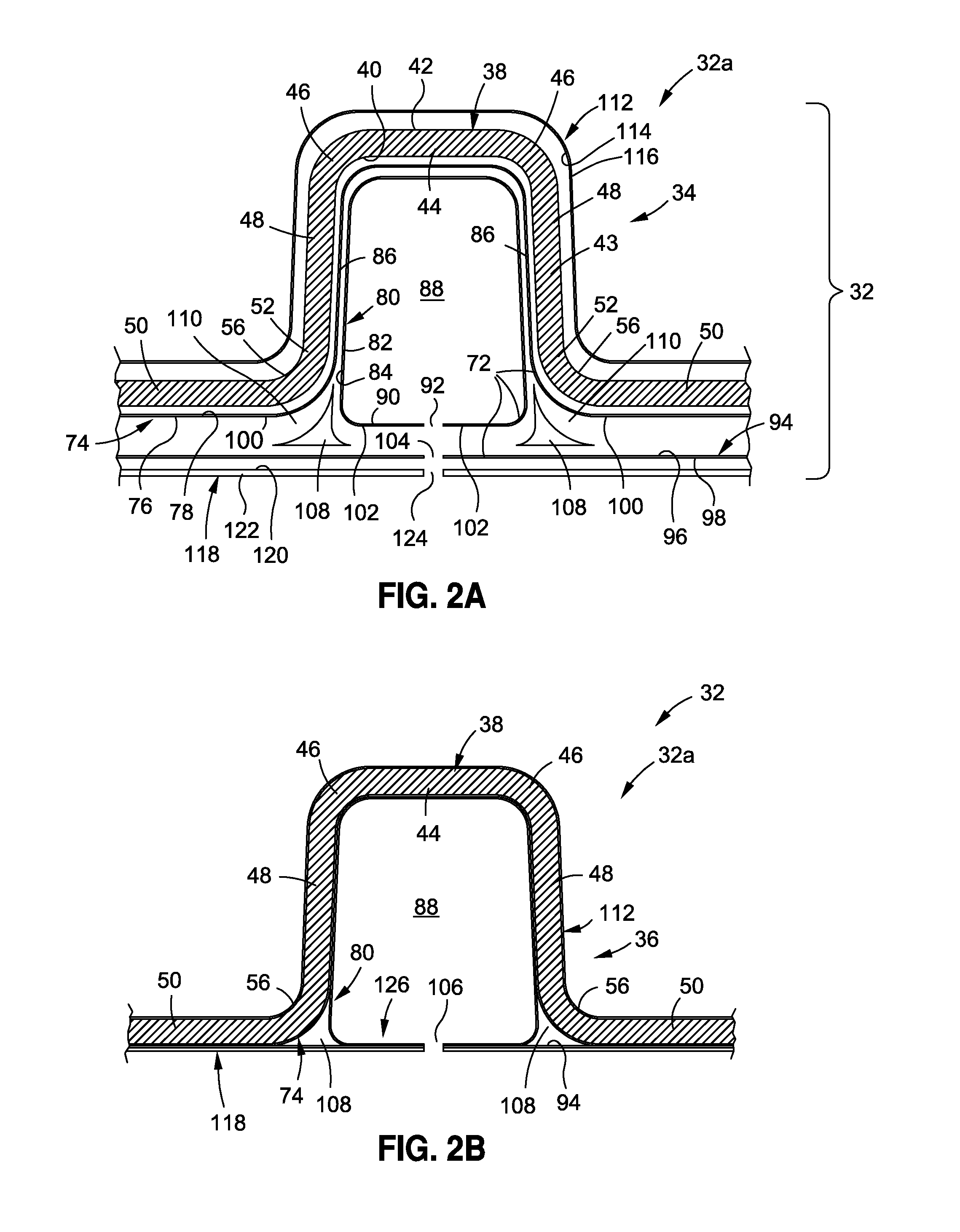

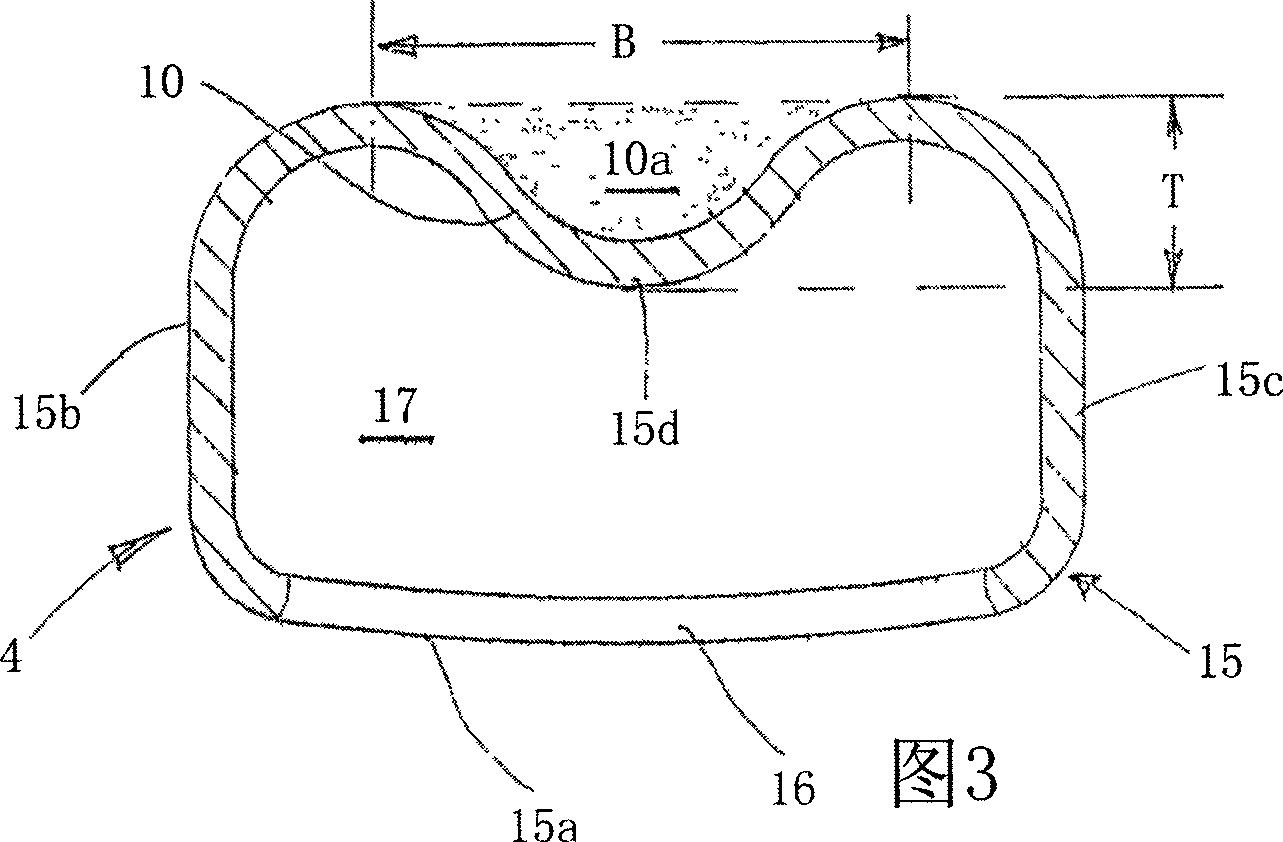

Composite Hat Stiffener, Composite Hat-Stiffened Pressure Webs, and Methods of Making the Same

ActiveUS20130344291A1Improved composite stiffenerSimple structureFuselage framesMilitary adjustmentMaterials science

There is provided a composite hat stiffener, a composite hat-stiffened pressure web, and a method of making the same. The composite hat stiffener has a composite hat section having a first side and a second side. The composite hat stiffener further has a plurality of composite stiffening plies coupled to the composite hat section. The plurality of composite stiffening plies include a body ply coupled to the first side of the composite hat section, a wrap ply coupled the body ply, and a base ply coupled to the body ply and the wrap ply. The composite hat stiffener further has a pair of radius filler noodles coupled to the composite hat section and disposed between the plurality of composite stiffening plies. The composite hat stiffener further has an outer ply coupled to the second side of the composite hat section.

Owner:THE BOEING CO

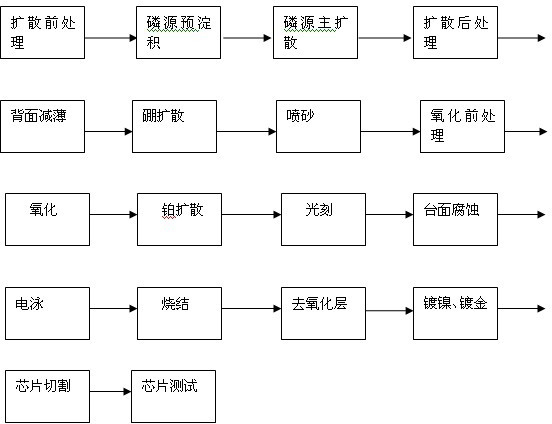

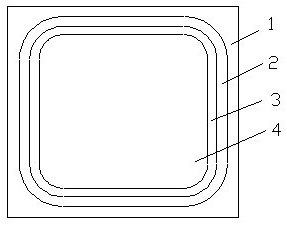

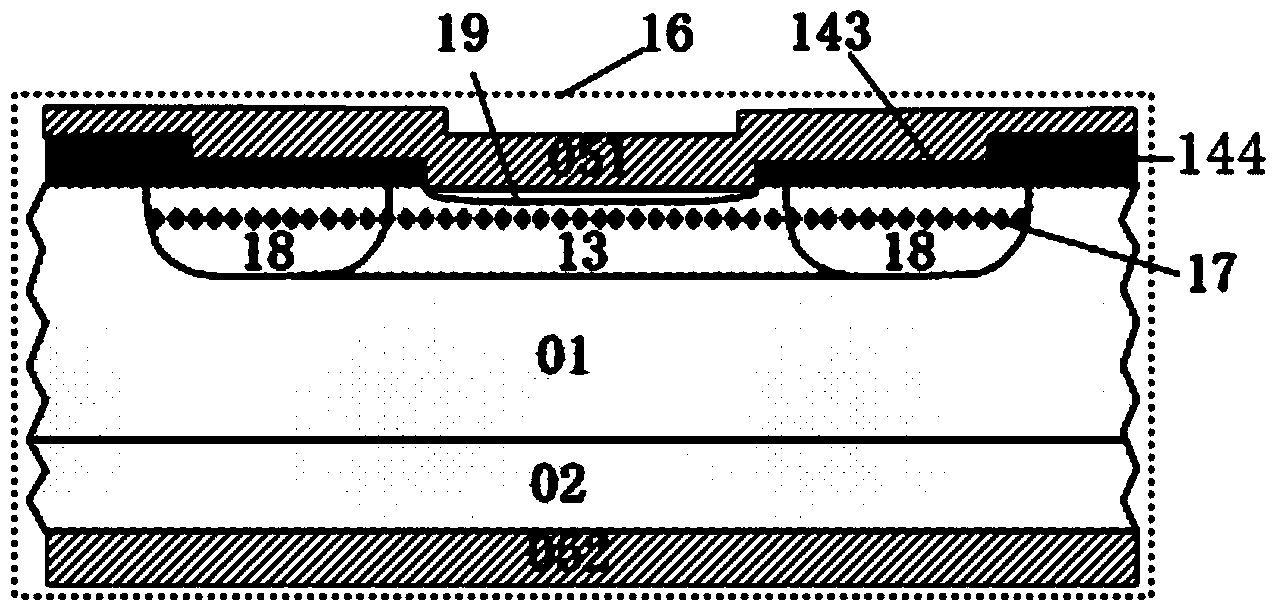

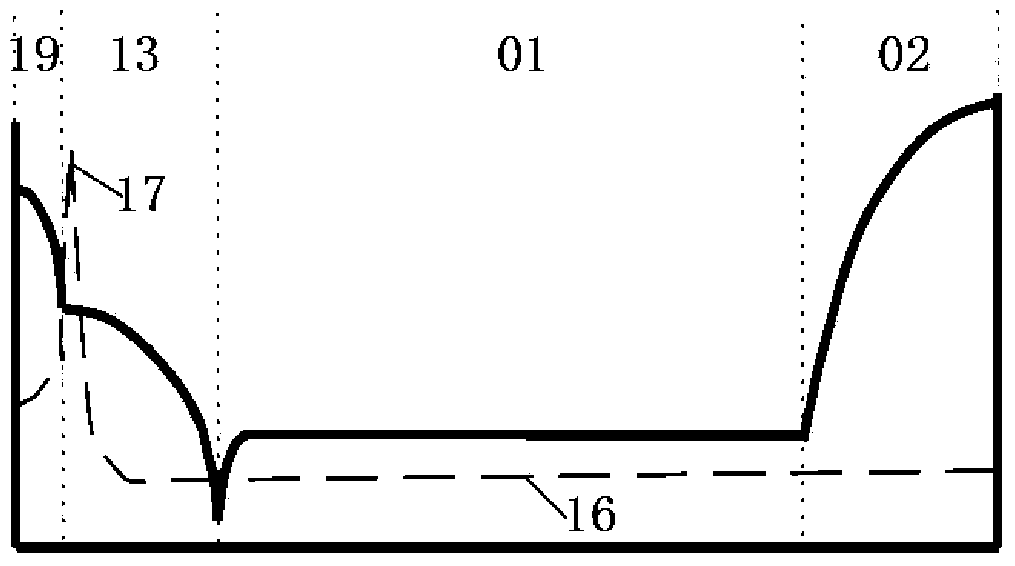

Fast recovery diode (FRD) chip and production process thereof

ActiveCN102087976AImprove anti-surge performanceImprove switching performanceSemiconductor/solid-state device manufacturingSemiconductor devicesElectrophoresesEtching

The invention relates to a fast recovery diode (FRD) chip and a production process thereof. A diode with a P+NN+ structure is produced by adopting the process steps of diffusion pretreatment, double diffusion of a liquid source, back thinning, oxidization, platinum diffusion, photoetching, mesa etching, electrophoresis, sintering, scribing and the like. In the chip production process, a method of carrying out deep junction diffusion by carrying a liquid phosphorous source is adopted, so that the flatness of a diffusion junction is improved and the homogeneity and the stability of a breakdown voltage are strengthened; a method of reducing the concentration of a boron diffusion source and improving the purity of the boron diffusion source is adopted, so that the surge resistance capacity of an FRD is improved; and an electrophoresis glassivation process is adopted, so that the voltage withstanding stability and reliability of a bidirectional voltage stabilizing diode are improved. In addition, the production process has the advantages that the reverse recovery time is shortened, the switching speed is improved, the voltage drop is reduced, the power consumption is reduced, the voltage withstanding stability is improved, and the reliability of the diode is improved.

Owner:TIANJIN ZHONGHUAN SEMICON CO LTD

Hollow column member with built-in high tensile steel bars and pipes for confinement of ultra high performance concrete

InactiveCN102296753AReduce section sizeImprove bearing capacityStrutsBuilding reinforcementsRebarHigh rise

The invention provides a hollow column member with built-in high tensile steel bars and pipes for a confinement of ultra high performance concrete, especially being suitable for the field of pier column member of high rise, heavy load and longspan structures. The member comprises a reinforcement cage consisting of outer steel pipes, longitudinal high tensile steel bars and stirrups, and hollow ultra high performance concrete poured on the internal surface of the outer steel pipes wrapping the reinforcement cage. The invention fully utilizes the advantages of the ultra high performance concrete, the high tensile steel bars, and the hoop confinement of the outer steel pipes, effectively reduces the cross section of the member, improves the bearing capacity and stretch ability of the member, so that the member has good earthquake resistant behavior, the materials are saved and the available space is increased at the same time. According to the invention, prestress is not needed, the construction technology is simple, and the construction speed is improved. The member is suitable for the precasting production, is good for application of the two high tensile materials in projects, and meets the design concepts of energy saving, environmental protection and new style.

Owner:BEIJING UNIV OF TECH

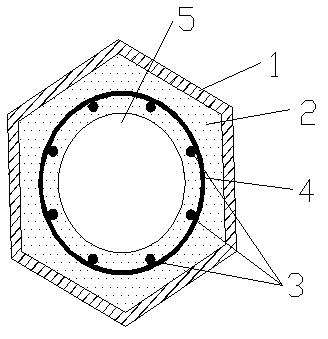

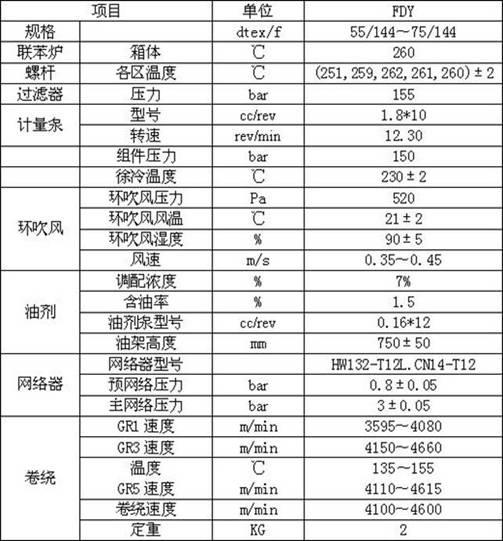

Porous superfine polyamide 6 fully-drawn yarn, preparation method thereof, and equipment thereof

InactiveCN102493016AImprove mixing uniformityImproved pressure stabilityFilament forming substance formingArtificial thread manufacturing machinesYarnAir velocity

The invention relates to a porous superfine polyamide 6 fully-drawn yarn, a preparation method thereof, and equipment thereof. According to the invention, existing FDY production equipment is adopted. A raw material polyamide 6 is sliced and dried; an additive is added on line; the material is subject to screw extrusion and melt extrusion; the material is then cured with a gradually cooling manner and a circular air blow cooling manner; with a reasonably selected spinning temperature of 259-262 DEG C, an air temperature in the circular air blowing process of 19-23 DEG C, a humidity of 85-95%, an air velocity of 0.35-0.45m / s, an oiling and clustering position of 700-800mm, and a winding speed of 4100-4600m / min, the porous superfine polyamide 6 fully-drawn yarn product with a specification of 55dtex / 144f-75dtex / 144f is prepared. Flexible operation is adopted in the preparation method. The preparation method is advantaged in simple technology and low production cost. The product is advantaged in stable performance, good yarn evenness, and good coloration property.

Owner:SUZHOU UNIV

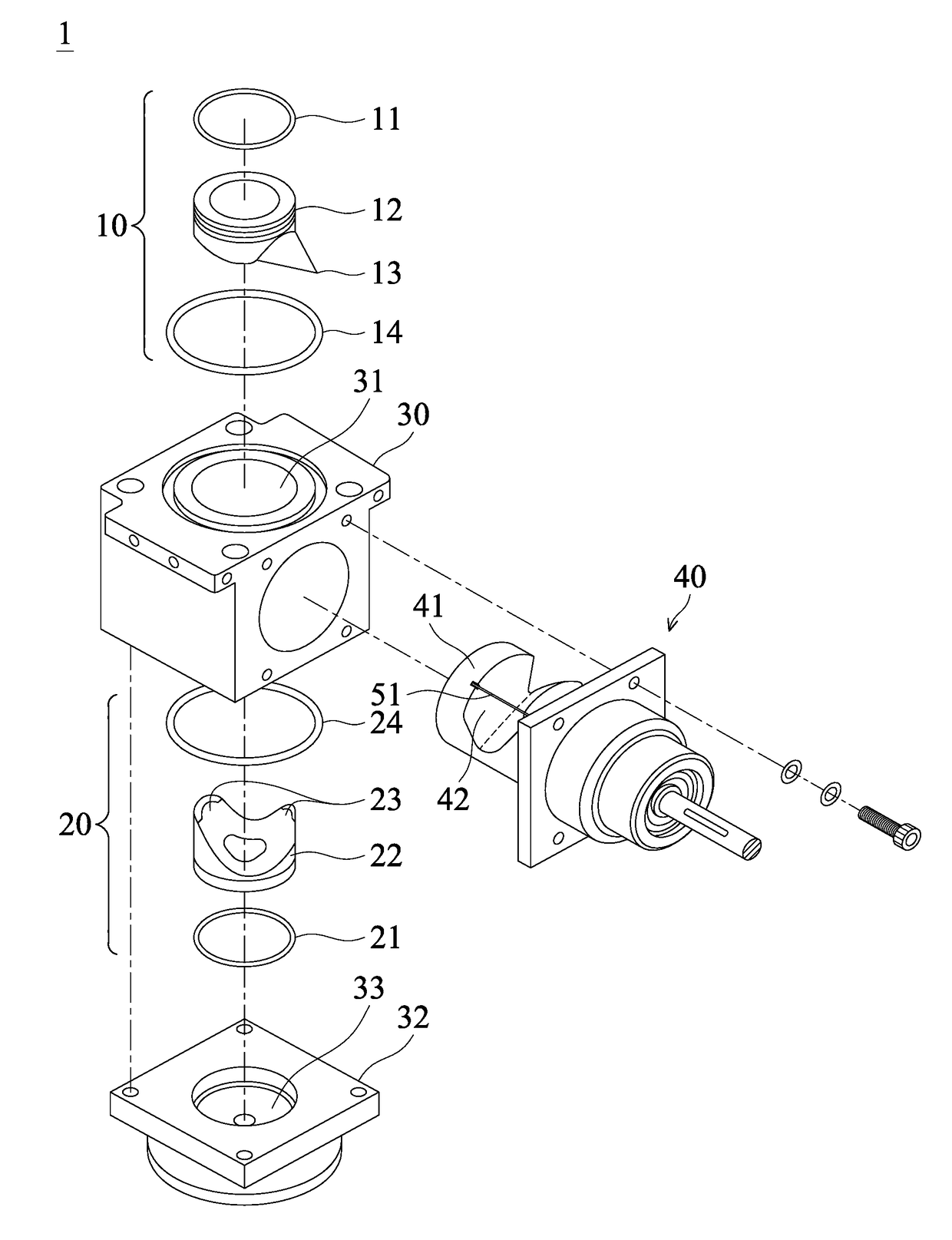

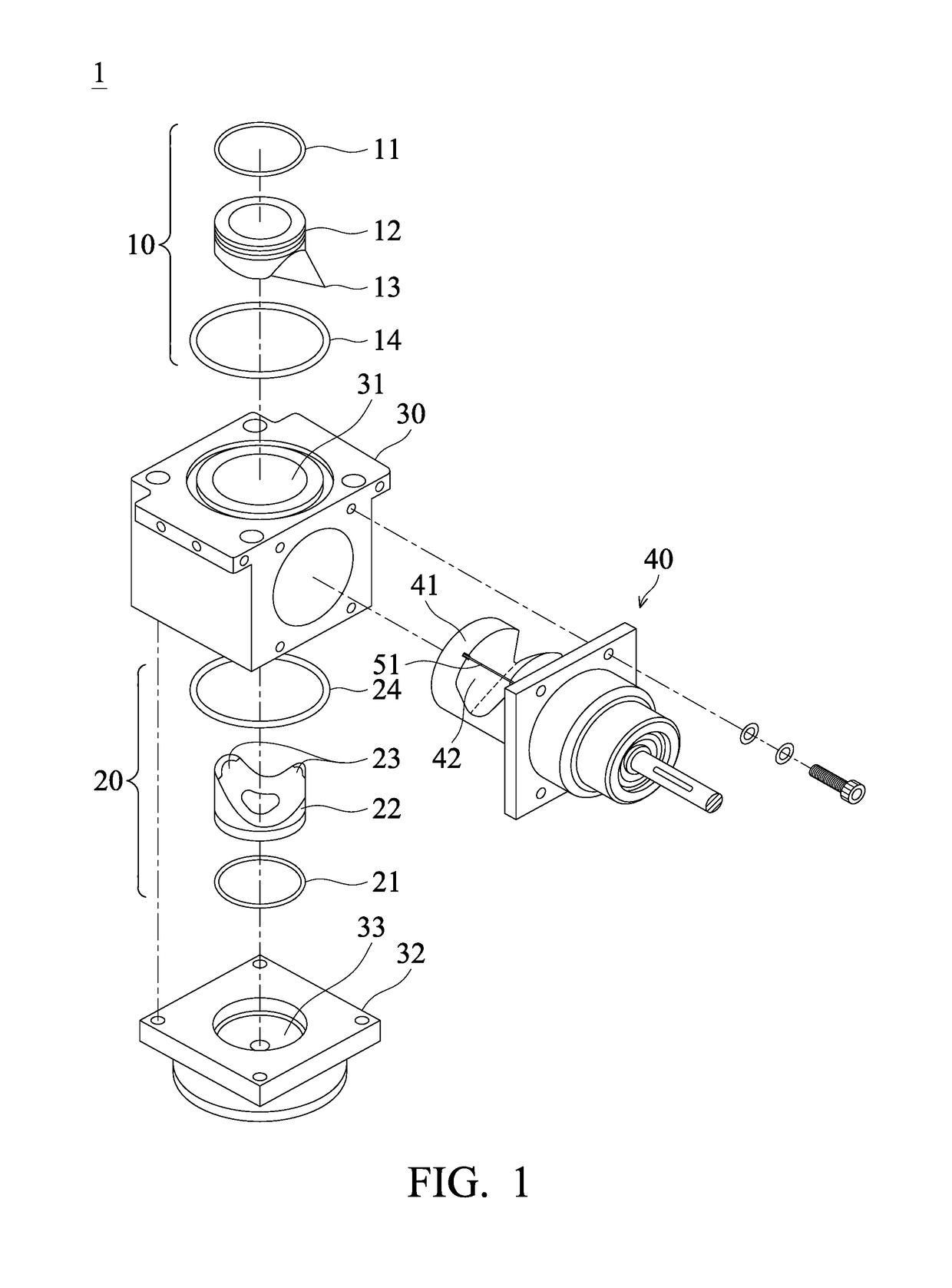

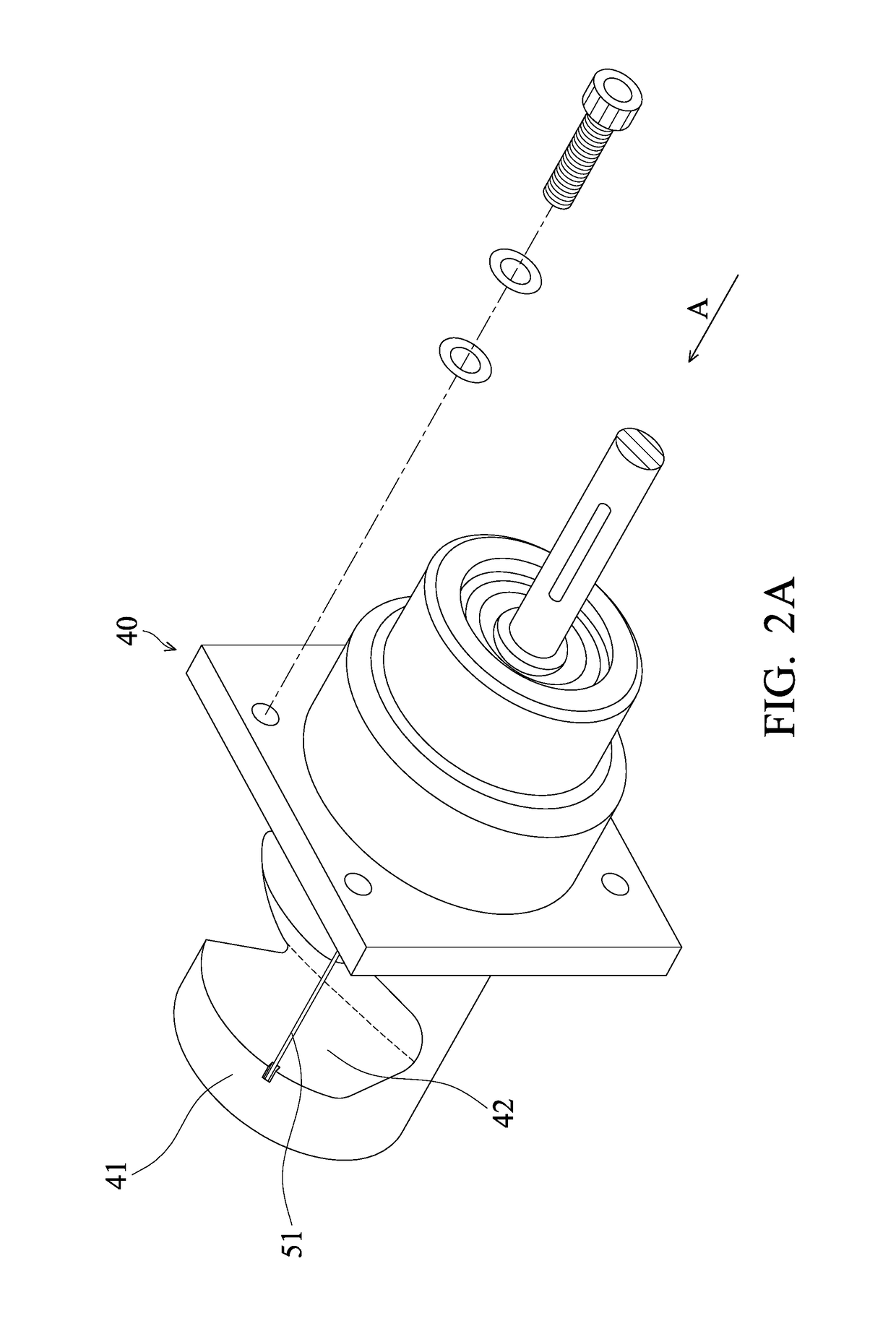

Throttle valve

ActiveUS9958073B2Degree of avoidanceImproved pressure stabilityPlug valvesValve housingsThrottleVALVE PORT

A throttle valve is provided. The throttle valve includes a throttle valve body, a valve plug, a hollow seal and a first scraper. A flow path is formed in the throttle valve body. The valve plug is disposed in the throttle valve body. A notch is formed on the valve plug. By rotating the valve plug, the position of the notch is changed, and the degree of opening of the flow path is modified. The hollow seal is disposed in the throttle valve body. An abutting portion is formed on the hollow seal, and the abutting portion sealably abuts the valve plug. The first scraper is disposed on the valve plug. When the valve plug is rotated, the first scraper abuts the abutting portion to clean the abutting portion.

Owner:VANGUARD INTERNATIONAL SEMICONDUCTOR CORPORATION

Nebulising device for use in a cpap-system

ActiveUS20110000487A1Easy to controlReducing losses/dilutionRespiratorsMedical devicesBiomedical engineeringCpap ventilation

The present invention relates to a modified nebulizing device for generating a nasal continuous positive airway pressure (CPAP) and addition of nebulized drug which can be carried out simultaneously and in synergy without loosing a substantial amount of nebulized drug. Further, the present invention also discloses a nebulizing device and a nebulizing attachment device usable in a system for generating continuous positive airway pressure (CPAP) and simultaneously and in synergy adding of nebulized drug without loosing a substantial amount of nebulized drug.

Owner:NEORES

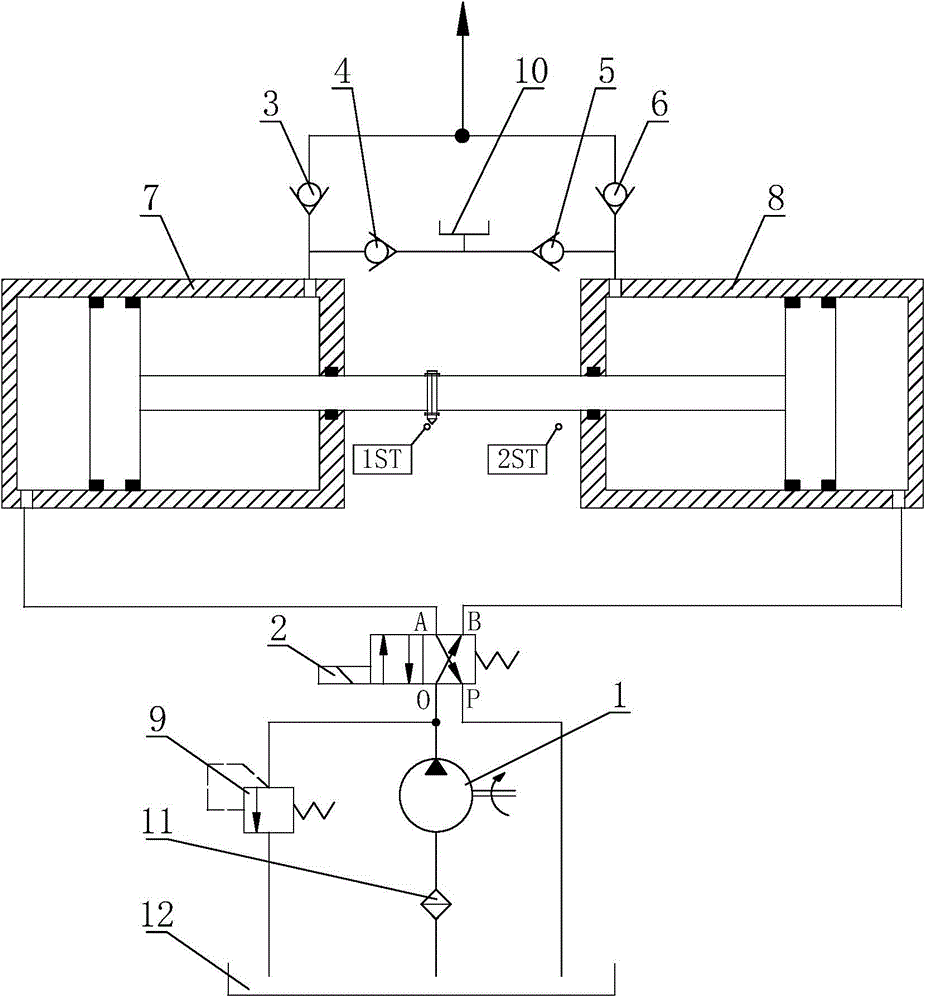

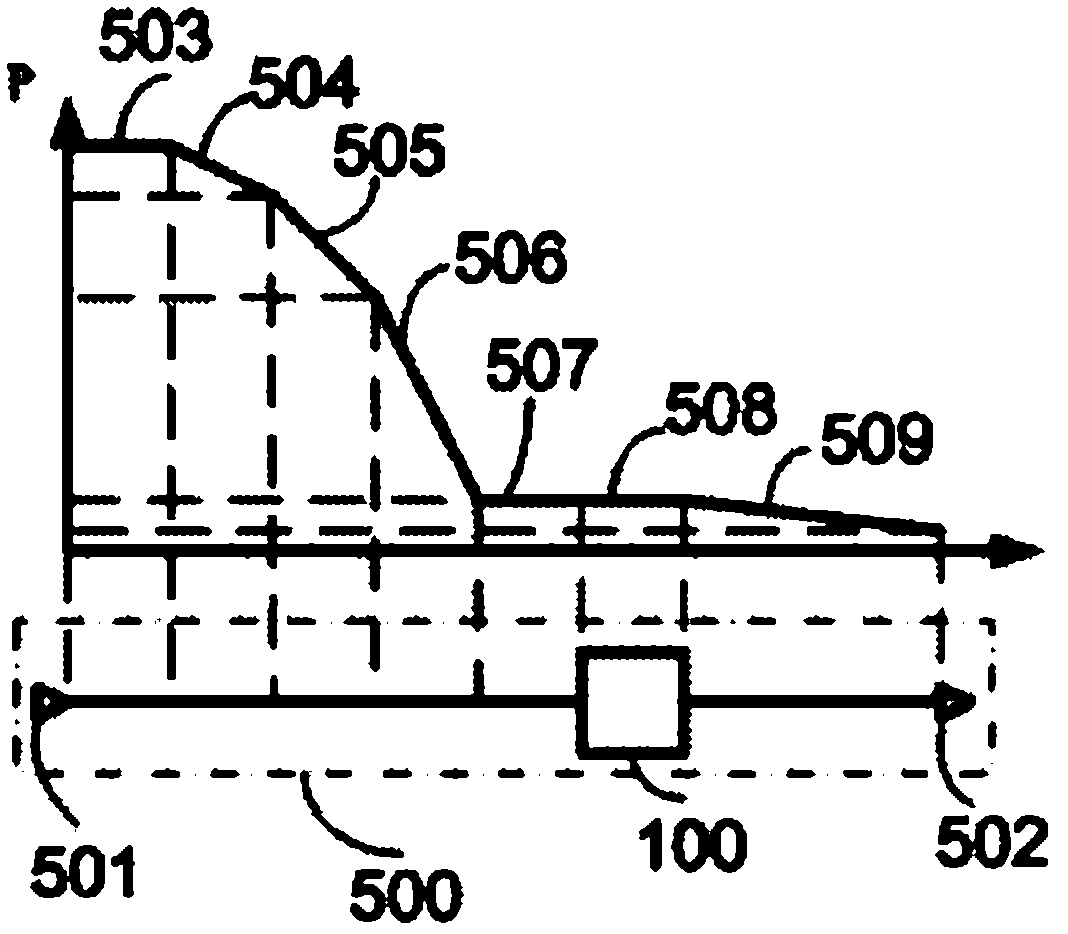

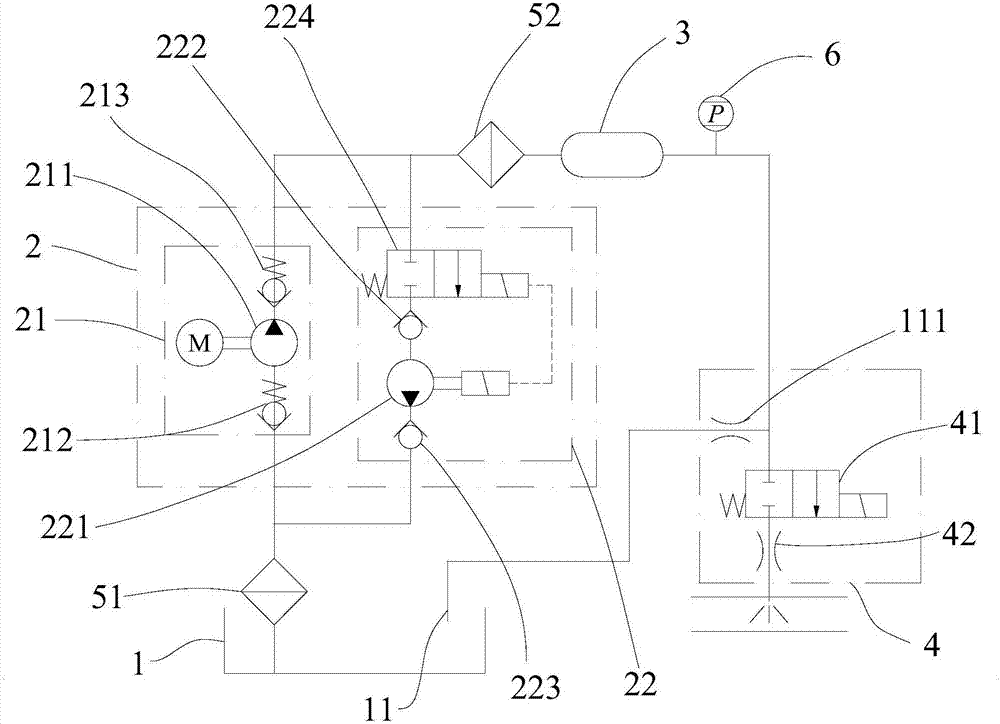

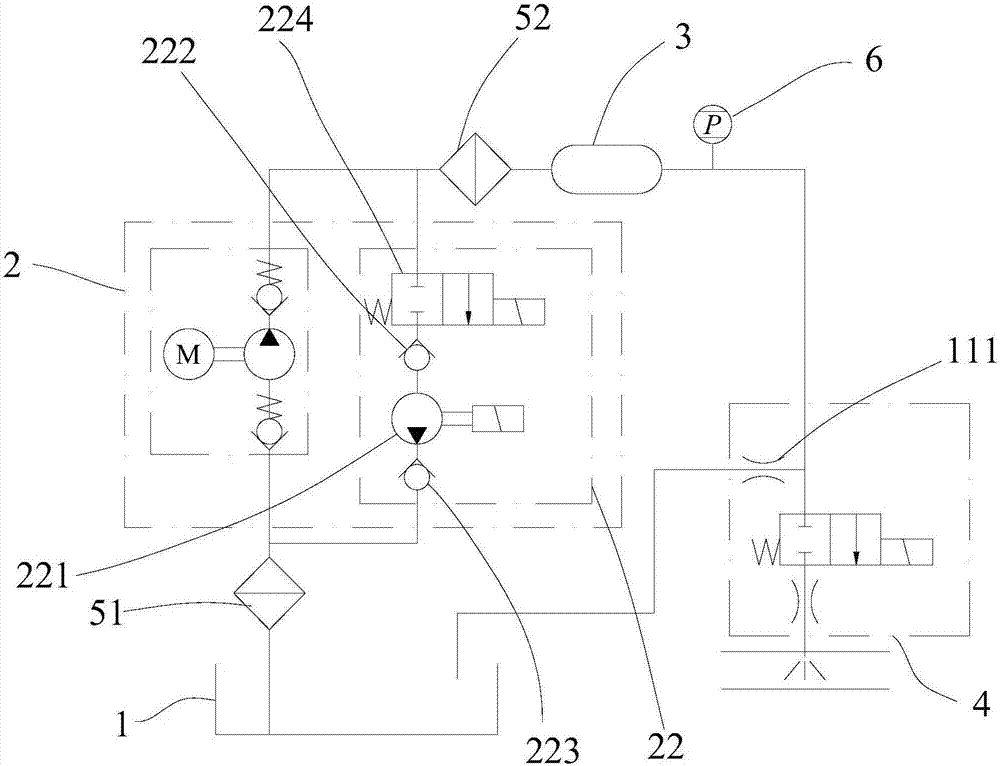

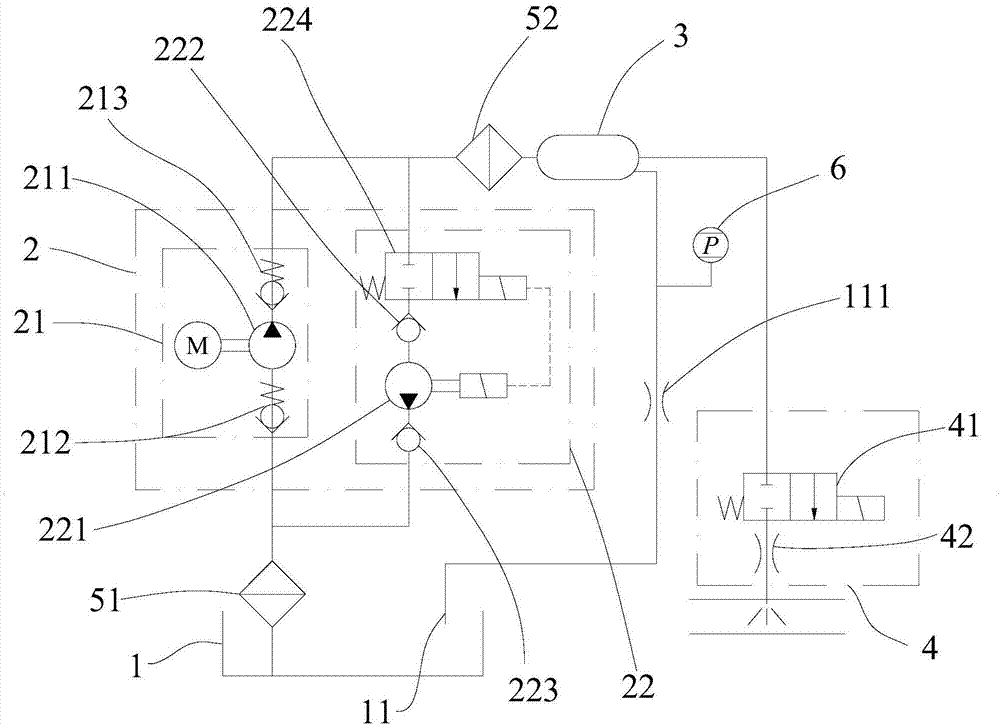

Double-acting hydraulic control system of supercharging device

InactiveCN105782147AReasonable designUninterrupted oil supplyServomotor componentsServomotorsHydraulic cylinderControl system

The invention discloses a double-acting hydraulic control system of a supercharging device. The double-acting hydraulic control system comprises a hydraulic pump, an oil storage tank, a control valve, a first hydraulic cylinder, a second hydraulic cylinder and an oil make-up tank, wherein a piston rod of the first hydraulic cylinder and a piston rod of the second hydraulic cylinder are in butt joint. A first work port of the control valve communicates with a rodless cavity of the first hydraulic cylinder, a second work port of the control valve communicates with a rodless cavity of the second hydraulic cylinder, a fourth work port of the control valve communicates with the oil storage tank, and a third work port of the control valve communicates with an oil outlet of the hydraulic pump. A first one-way valve, a second one-way valve, a third one-way valve and a fourth one-way valve are connected between a rod cavity of the first hydraulic cylinder and a rod cavity of the second hydraulic cylinder in parallel and are mounted symmetrically, and the oil make-up tank is arranged at the position, between the second one-way valve and the third one-way valve, of a pipeline. The double-acting hydraulic control system has the following beneficial effects that design is reasonable, practicality and convenience are achieved, equipment input is reduced, running energy consumption is low, the mechanic-electronic-hydraulic integrated design is adopted, and the intelligent degree is high.

Owner:XIAN ZHONGZHI HUIZE PHOTOELECTRIC TECH

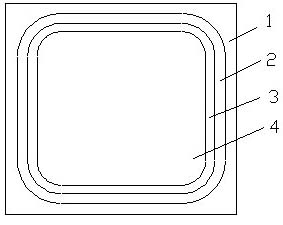

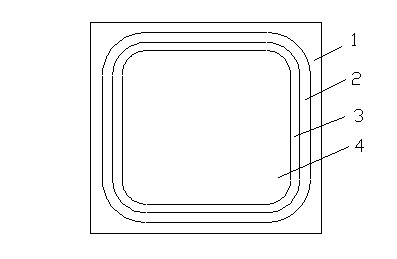

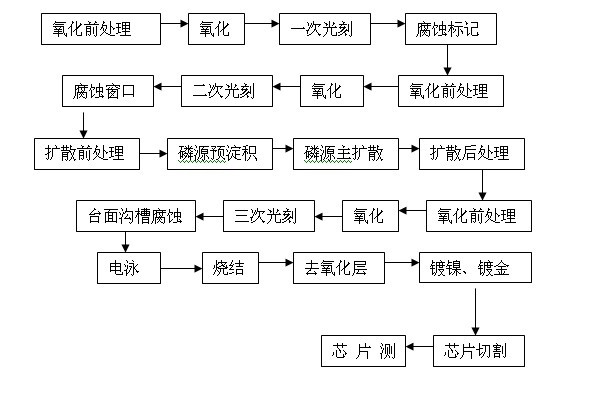

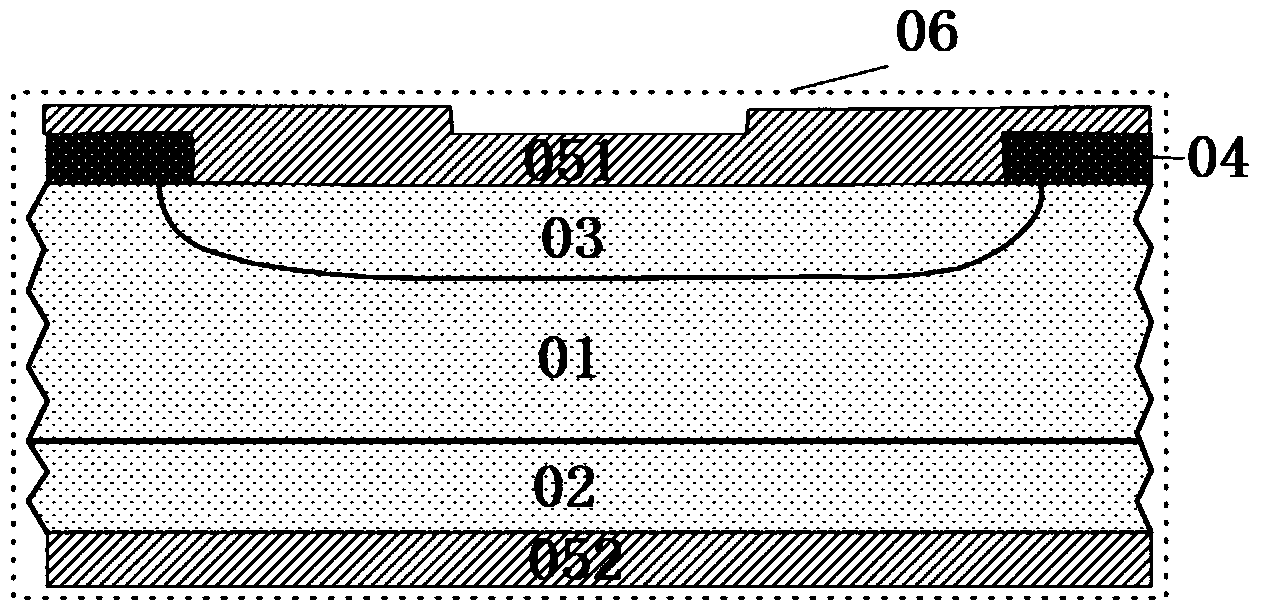

Chip for two-way voltage regulator diode DB3 and manufacturing technique thereof

ActiveCN102082093AImprove trigger abilityImproved pressure stabilityPhotomechanical apparatusSemiconductor/solid-state device manufacturingEtchingFragmentation rate

The invention relates to a manufacturing technique of a chip for a two-way voltage regulator diode DB3, wherein the two-way voltage regulator diode DB3 is a symmetrical diode with the structure of N<+> PN<+>. The resilience voltage is increased due to the adoption of a triple photolithographic process, the trigger capacity of the two-way voltage regulator diode is improved; due to the application of shallow mesa or trench etching, the fragmentation rate is reduced; and glass is passivated due to the adoption of an electrophoretic process, the withstand voltage stability and reliability of the two-way voltage regulator diode are improved. The manufacture technique of the chip for the two-way voltage regulator diode has the advantages of improving the breakdown voltage stability of the two-way voltage regulator diode DB3, enhancing the trigger capacity of the diode, reducing the high-temperature power consumption, prolonging the service life of the diode, and simultaneously improving the qualification rate.

Owner:TIANJIN ZHONGHUAN SEMICON CO LTD

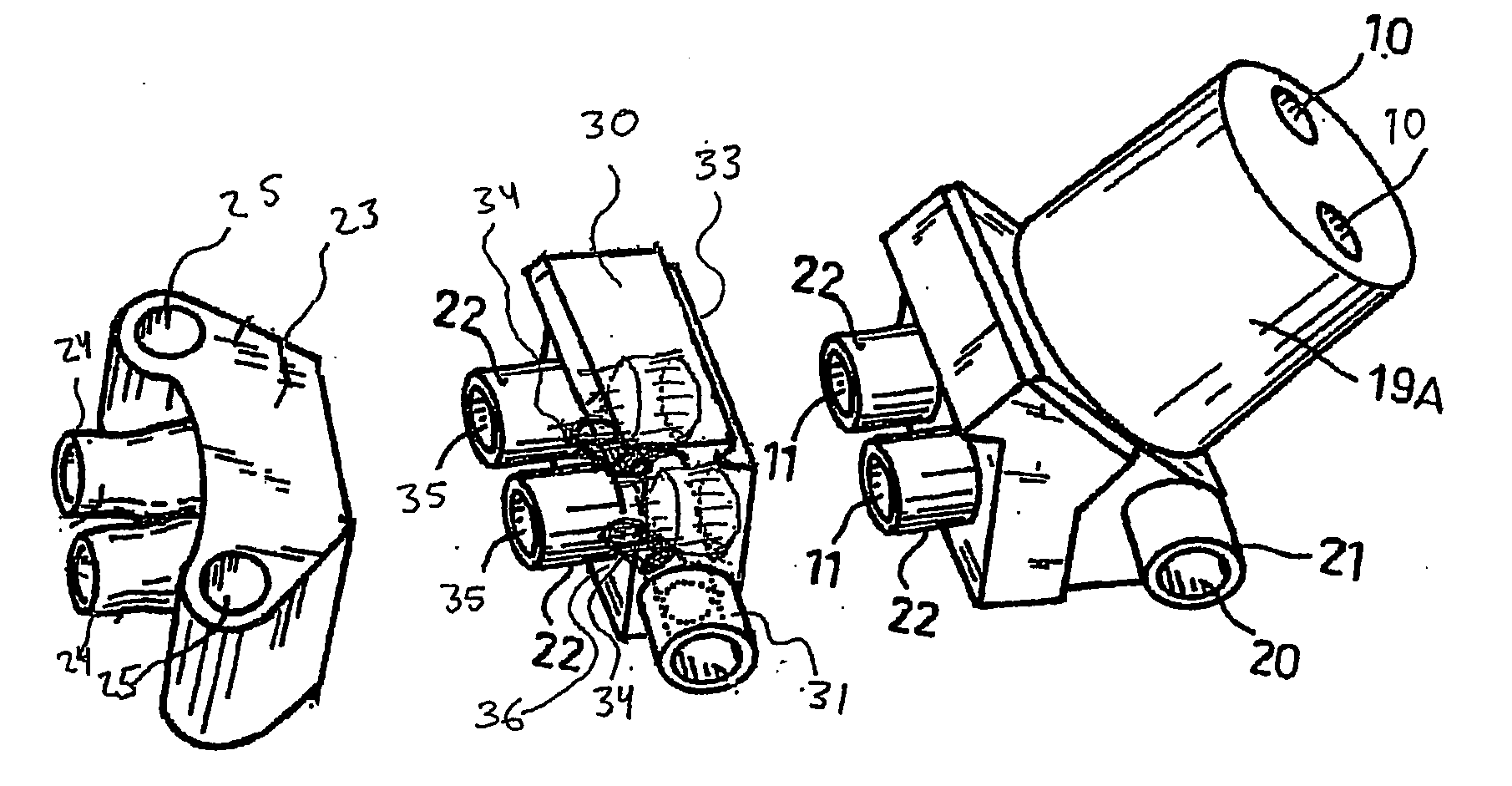

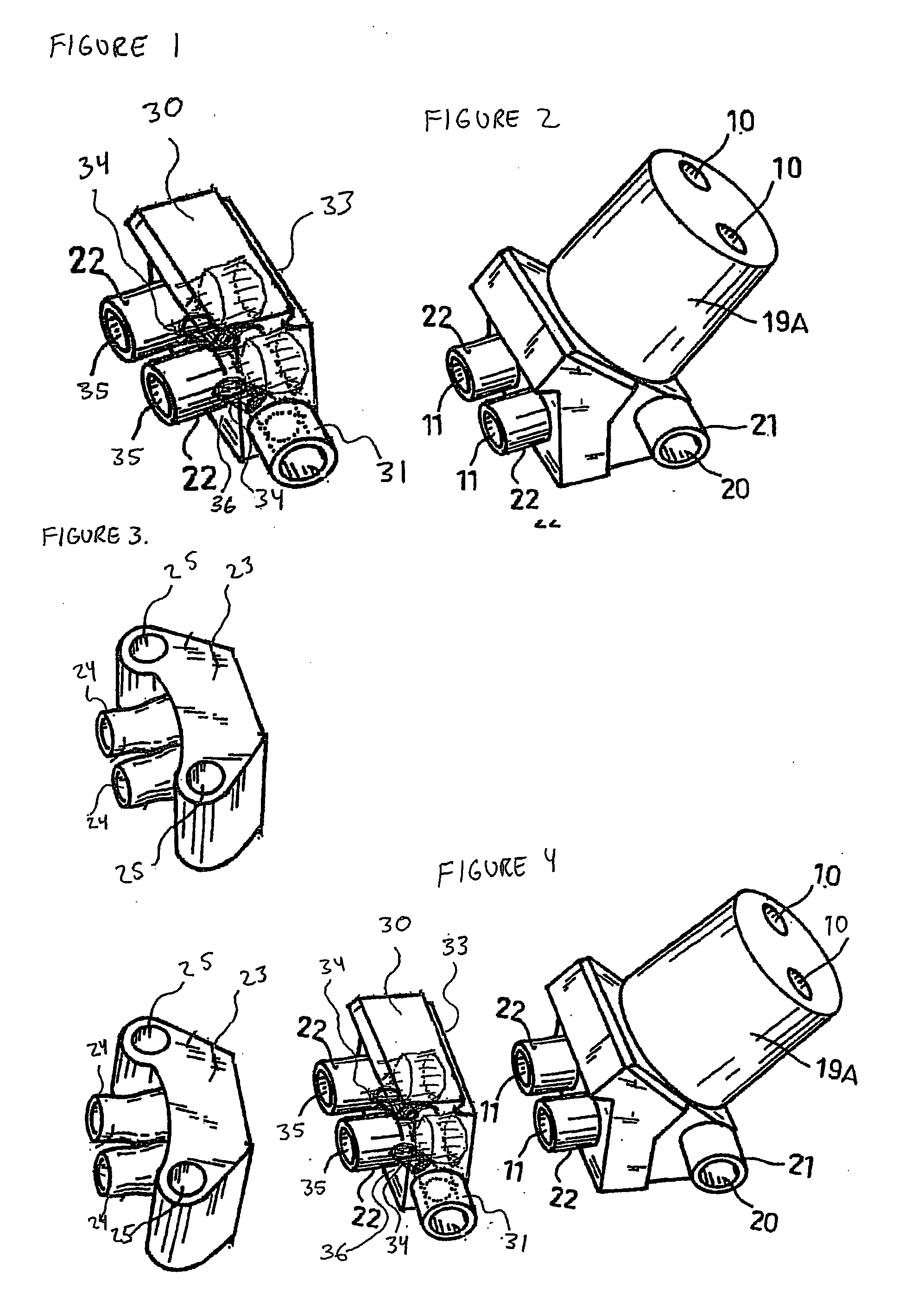

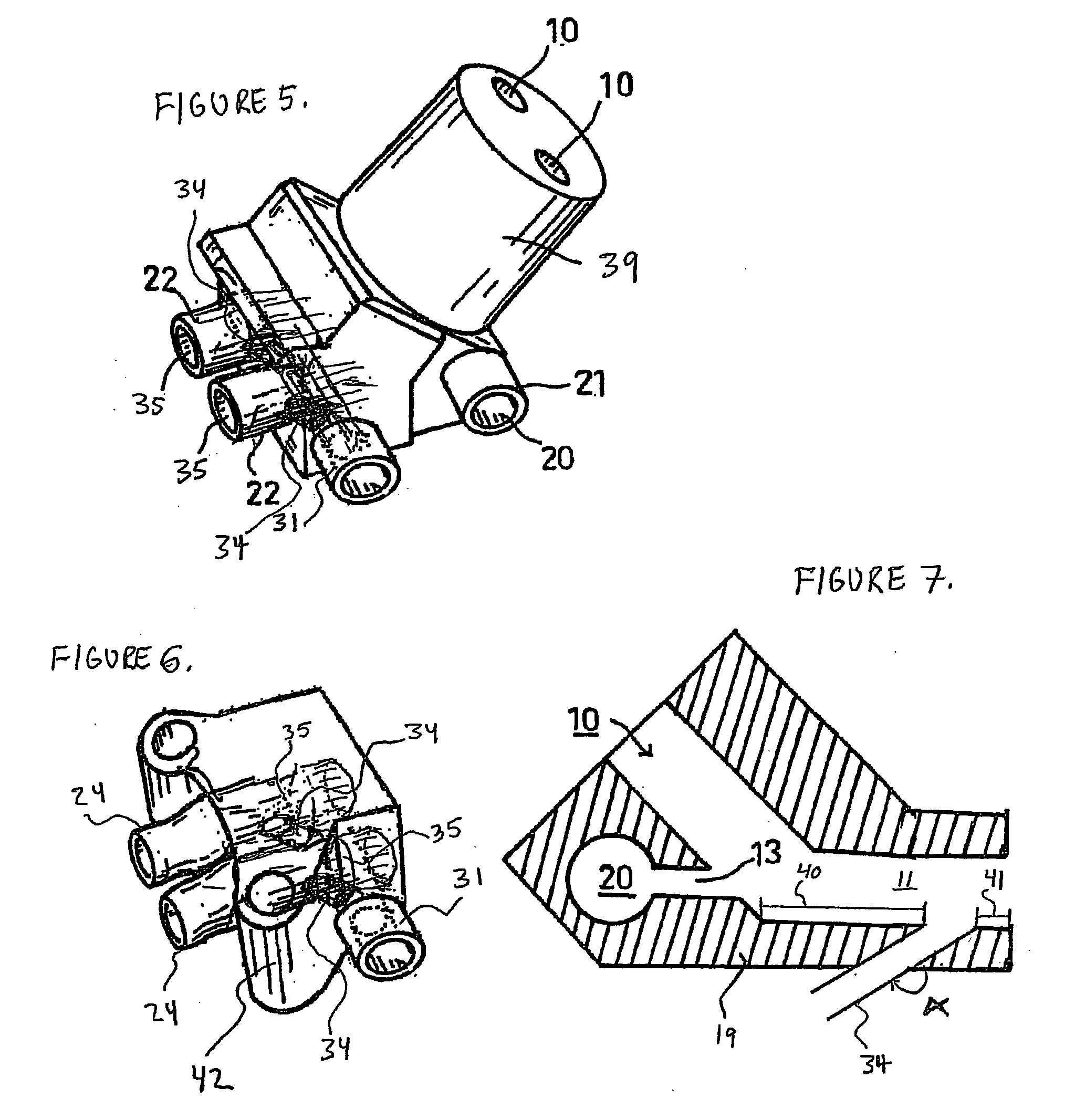

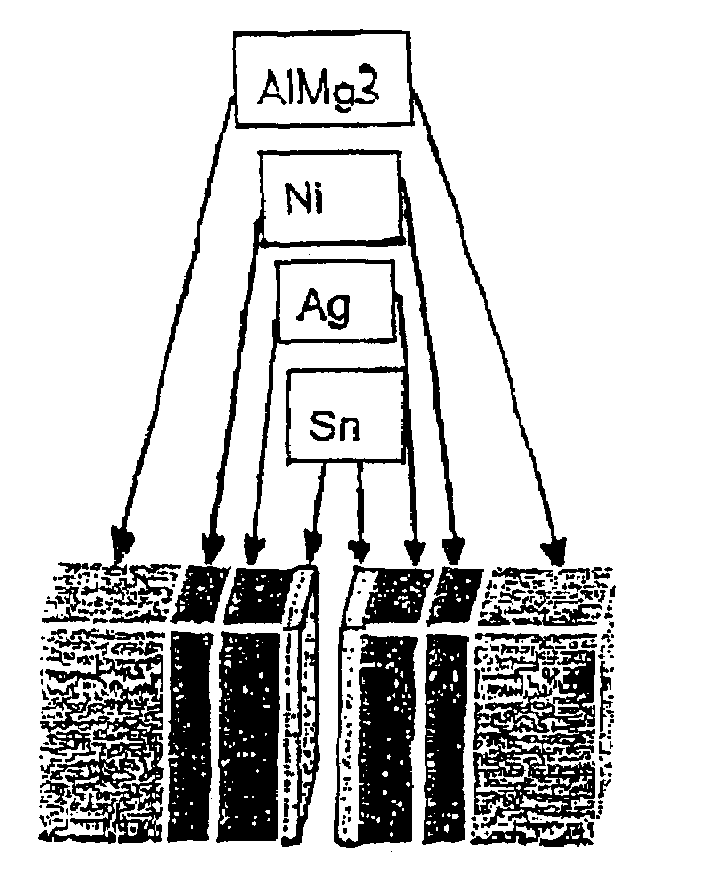

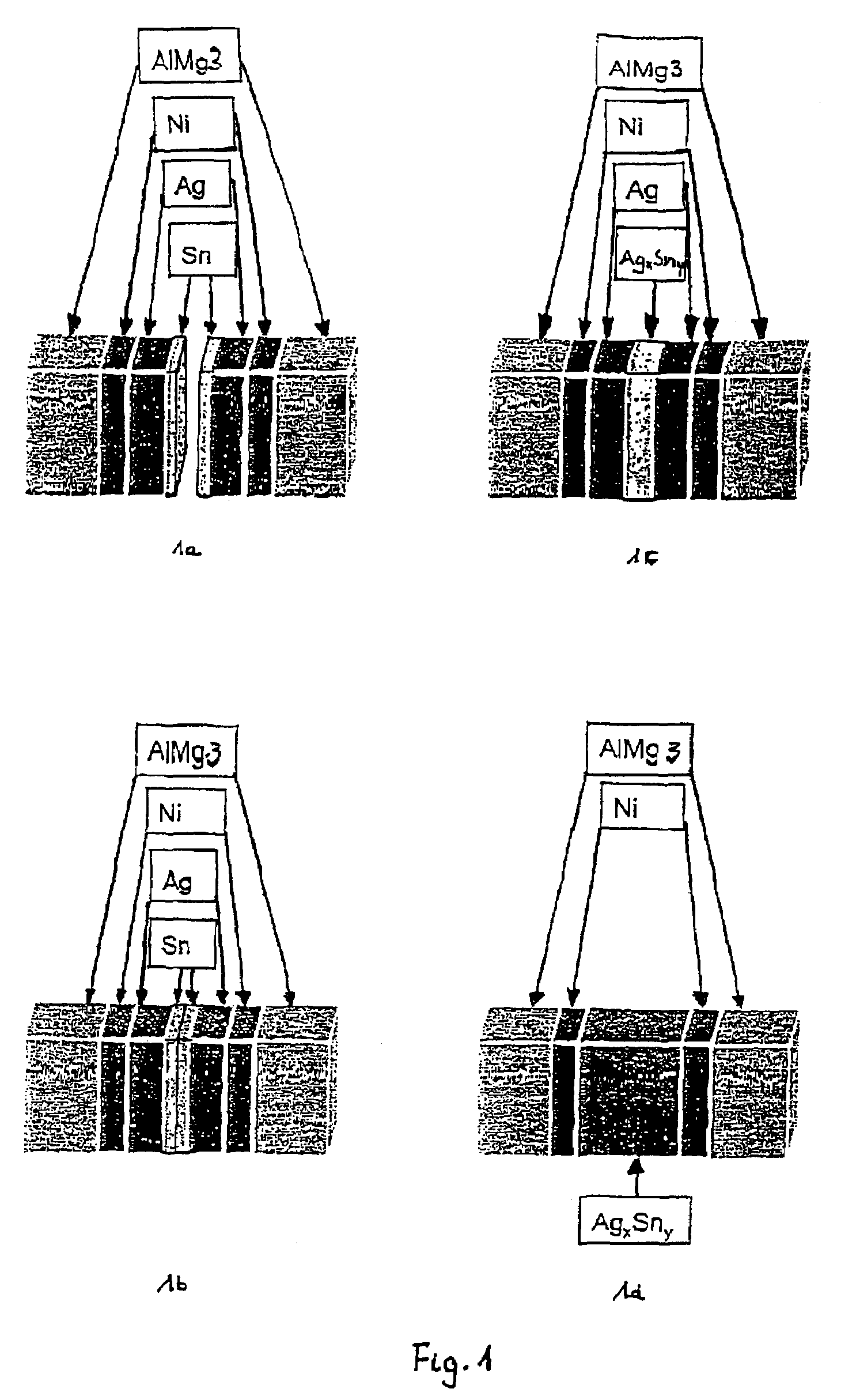

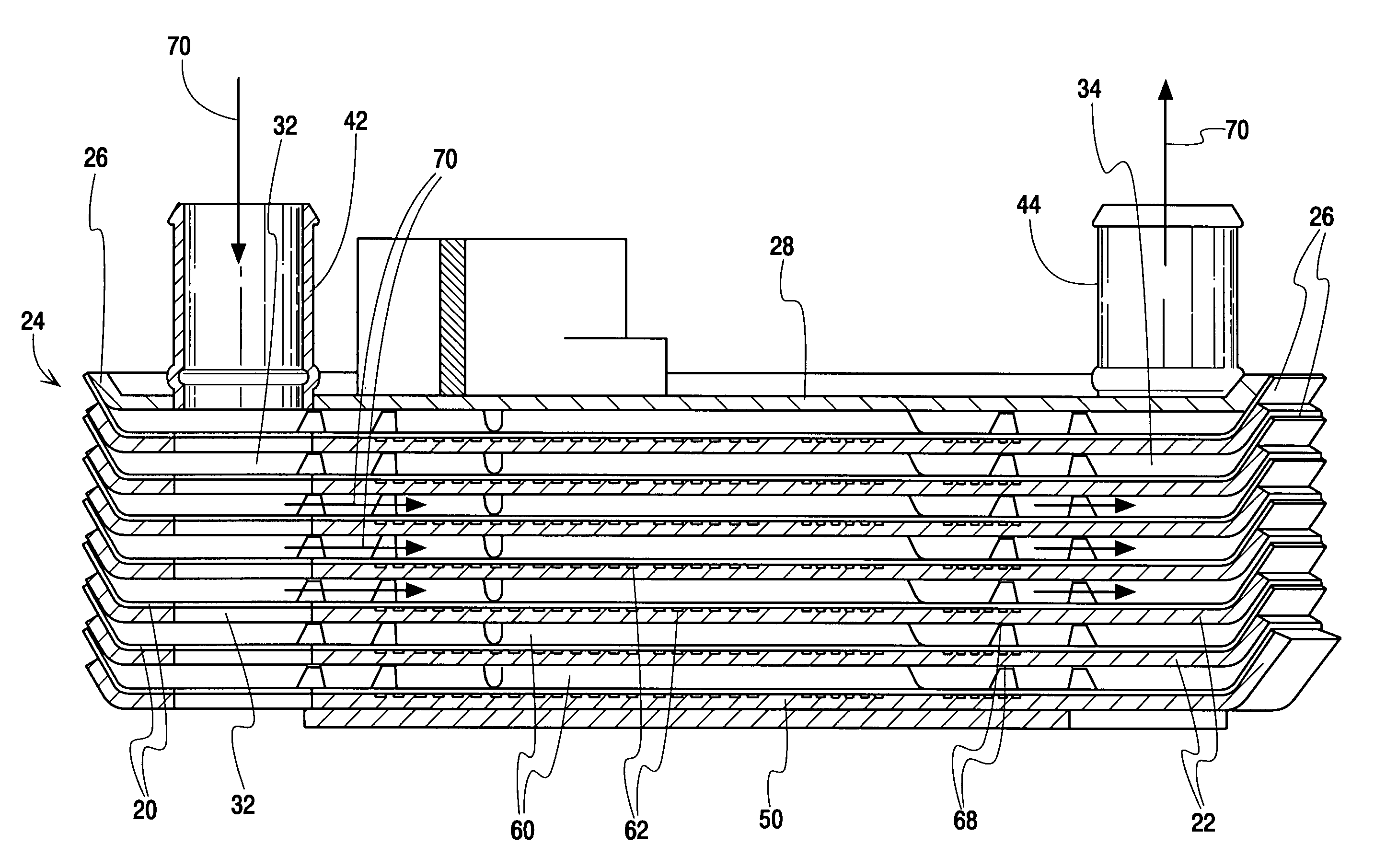

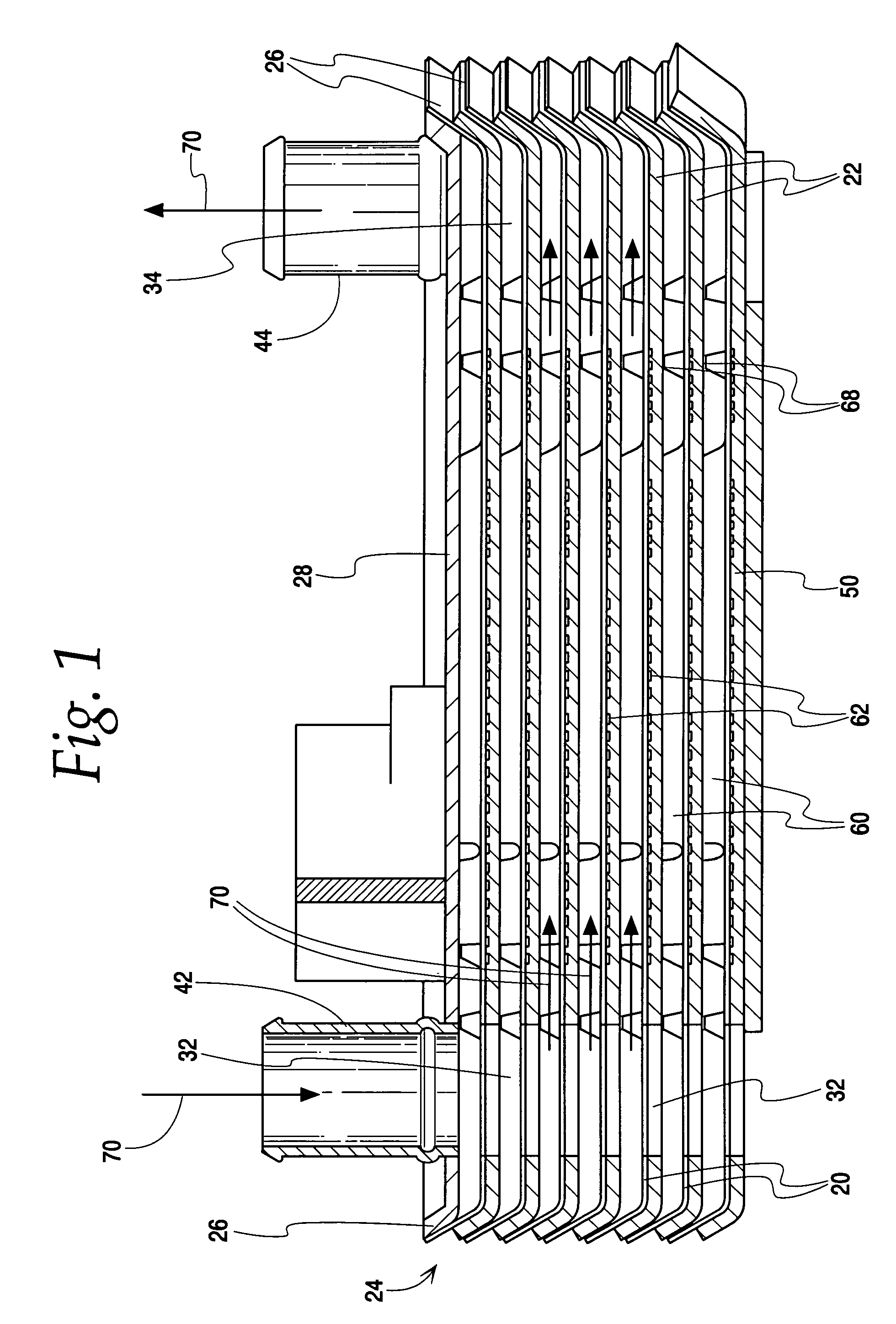

Method of connecting module layers suitable for the production of microstructure modules and a microstructure module

InactiveUS7380698B2Sufficient flectional strengthImproved pressure stabilityDecorative surface effectsWelding/cutting media/materialsMelting temperatureCopper alloy

A method for joining microstructured component layers and a method for manufacturing microstructure component layers and the microstructure component layer is provided. At least one multifunctional barrier coating is applied to the joining surfaces of a base material layer for the microstructured component layers. The layers are made of aluminum / aluminum alloys and / or copper / copper alloys, and / or noble steels. At least one solder / brazing coating is applied to each barrier coating. The coated base material layers comprising the component layers are stacked. The stacked component layers are joined by solder / brazing using heat. The melting temperature of the solder / brazing coating is higher after the heat joining than before same.

Owner:ATOTECH DEUT GMBH

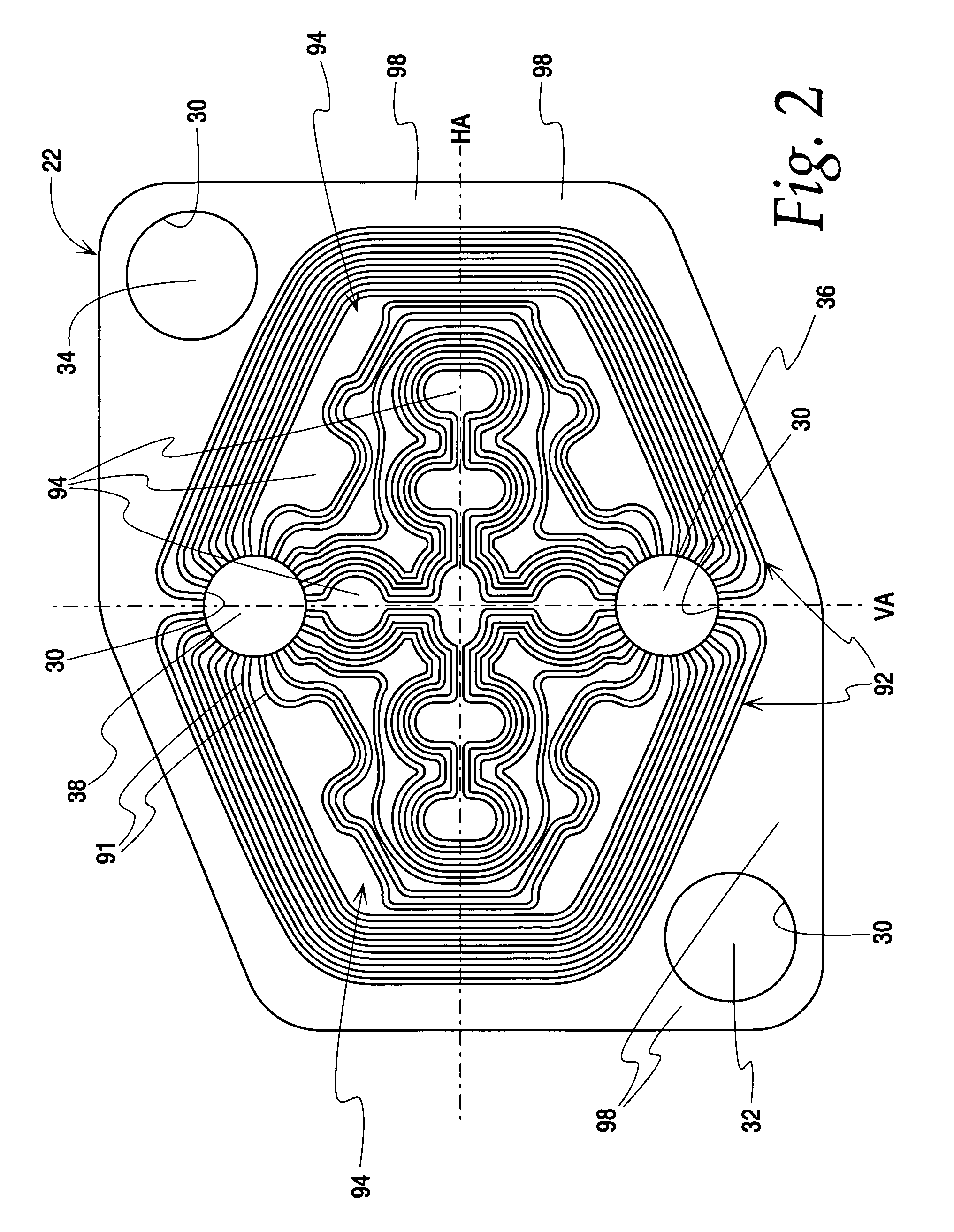

Composite hat stiffener, composite hat-stiffened pressure webs, and methods of making the same

ActiveUS20140299257A1Improved composite stiffenerSimple structureFuselage framesLamination ancillary operationsMaterials science

There is provided a method of making a composite hat stiffener. The method has the steps of curing a composite hat stiffener in a hat tool to form a pre-cured composite hat stiffener. The pre-cured composite hat stiffener has a composite hat section, a plurality of composite stiffening plies with a body ply, a wrap ply, and a base ply, all coupled to the composite hat section, wherein the body ply is coupled to a first side of the composite hat section, the wrap ply is coupled to the body ply, and the base ply is coupled to the body ply and the wrap ply, a pair of radius filler noodles coupled to the composite hat section and disposed between the plurality of composite stiffening plies, and an outer ply coupled to the composite hat section. The method further includes bonding the pre-cured composite hat stiffener to a structure surface.

Owner:THE BOEING CO

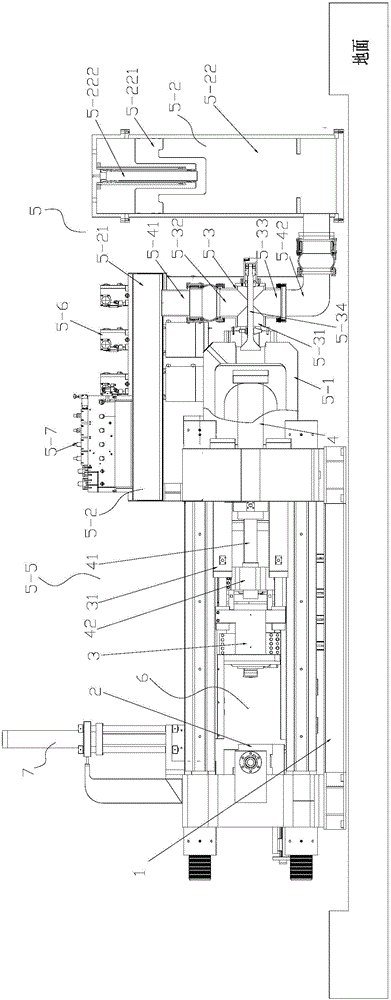

Energy-saving high-efficiency closed-type pressurizing oil supply sectional material extruder

ActiveCN104624691AShort work scheduleReduce no-load travelPump assembliesPressesProduction rateMaster cylinder

The invention relates to an energy-saving high-efficiency closed-type pressurizing oil supply sectional material extruder which comprises a base, a mould, an ingot containing barrel, an auxiliary cylinder, a shearing device and an oil supply system, wherein the mould, the ingot containing barrel and the auxiliary cylinder are sequentially arranged on the base; the oil supply system comprises a main cylinder and an oil storage tank; the main cylinder is provided with a plunger; the extruder is a short-stroke extruder; the ingot containing barrel of the extruder is arranged on the top position of an extrusion rod, and the ingot containing barrel forms a feed space with the mould during displacement; the oil storage tank includes a closed oil return tank and a closed pressurizing oil cylinder; the oil return tank is connected with the main cylinder through a reflux oil way connected into the main cylinder, and the oil return tank is connected with the pressurizing oil cylinder through an oil supply pipeline; the pressurizing oil cylinder is provided with a piston which acts on the pressurizing oil supply pipeline to supply oil to the main cylinder, and oil inside the pressurizing oil cylinder is extruded into the main cylinder or oil inside the main cylinder is refluxed into the pressurizing oil cylinder through a circulating oil way through the reciprocating motion of the piston; and the oil supply system is controlled by a plurality of servo motor oil pump sets. The energy-saving high-efficiency closed-type pressurizing oil supply sectional material extruder disclosed by the invention can be used for effectively enhancing the production rate, reducing the manufacturing cost of an integral machine, saving the material and reducing the oil consumption.

Owner:FOSHAN NANHAI MINGSHENG MACHINE MFR

Soft fast recovery diode and manufacturing method thereof

ActiveCN103872144AReduce EMIReduce lossSemiconductor/solid-state device manufacturingSemiconductor devicesHigh resistanceControl layer

The invention relates to a soft fast recovery diode and a manufacturing method thereof. The diode comprises an N type intrinsic region, a back N<+> buffer region, an anode metal layer and a cathode metal layer, wherein the back N<+> buffer region is formed on the back face of the N type intrinsic region; a P type emitting region is formed between the front face of the N type intrinsic region and the anode metal layer; mask oxide layers are formed symmetrically at the two ends of the anode metal layer; a P type high-resistance region is formed on the boundary of an active region; a P<+> ohmic contact layer is formed in the center of the active region; an overall lifetime control region is formed on the entire diode, and covers all structural layers of the diode; a localized lifetime control layer is positioned close to the P<+> ohmic contact layer in the P type emitting region along the axial direction of the diode; the localized lifetime control layer is positioned in a plane constructed by the P type emitting region and the P type high-resistance region along a direction which is vertical to the axial direction of the diode. The soft fast recovery characteristic of a device is realized by adopting an overall-localized lifetime control way; by arranging the high-resistance region, the snow slide resistance of the device is improved.

Owner:STATE GRID CORP OF CHINA +2

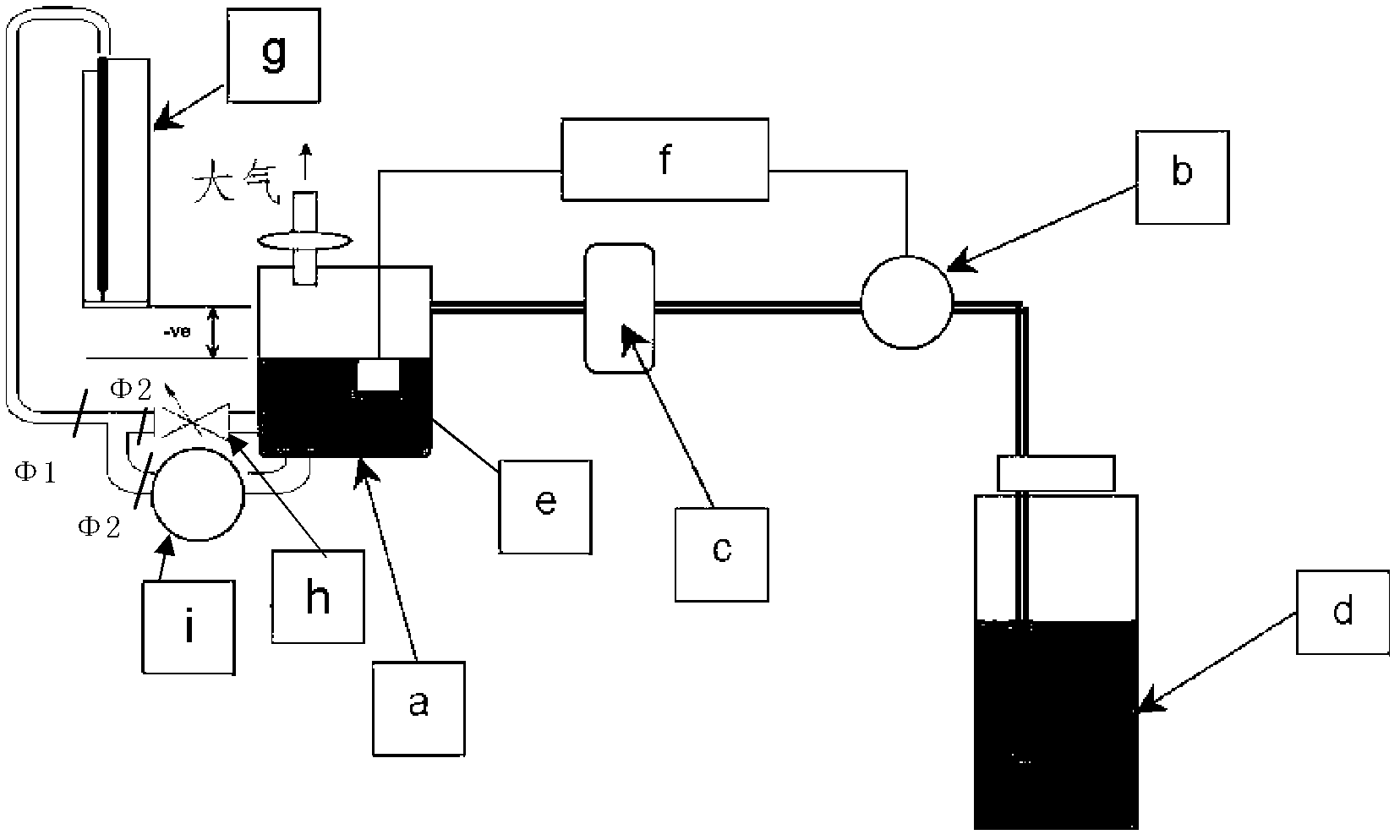

Plate heat exchanger

InactiveUS7600559B2Improved pressure stabilityHeat exhanger conduitsLaminated elementsPlate heat exchangerEngineering

Owner:MODINE MFG CO

Gelatinizing and pressing-fit device for plate

InactiveCN108722778APressing to achievePressing is beneficial to realizeLiquid surface applicatorsMaterial gluingThree stageEngineering

The invention provides a gelatinizing and pressing-fit device for a plate, and belongs to the technical field of plate processing. The gelatinizing and pressing-fit device comprises a pressing-fit mechanism, a gelatinizing mechanism and a glue liquid control mechanism. A gelatinizing support of the gelatinizing mechanism is arranged on a guide rail in a left-right sliding manner, and a gelatinizing roll is rotationally arranged between two gelatinizing roll supporting plates. A first lead screw and a first lead screw nut are in threaded connection, and a second lead screw and a second lead screw nut are in threaded connection. The pressing-fit mechanism is arranged over the gelatinizing mechanism, and first sliding sleeve plate, a second sliding sleeve plate and a third sliding sleeve plate of the pressing-fit mechanism are arranged from top to bottom and arranged on a pressing rod in a vertical sliding manner. The rigidity of a first spring is smaller than that of a second spring, andthe rigidity of the second spring is smaller than that of a third spring. The gelatinizing and pressing-fit device is fast and even in gelatinizing, pressing-fit force changes can be divided into three stages, the pressing-fit force is in a gradually increasing broken line type, the pressing-fit force stability is good, and the gelatinizing and pressing-fit effect of the plate is greatly improved.

Owner:费晓杰

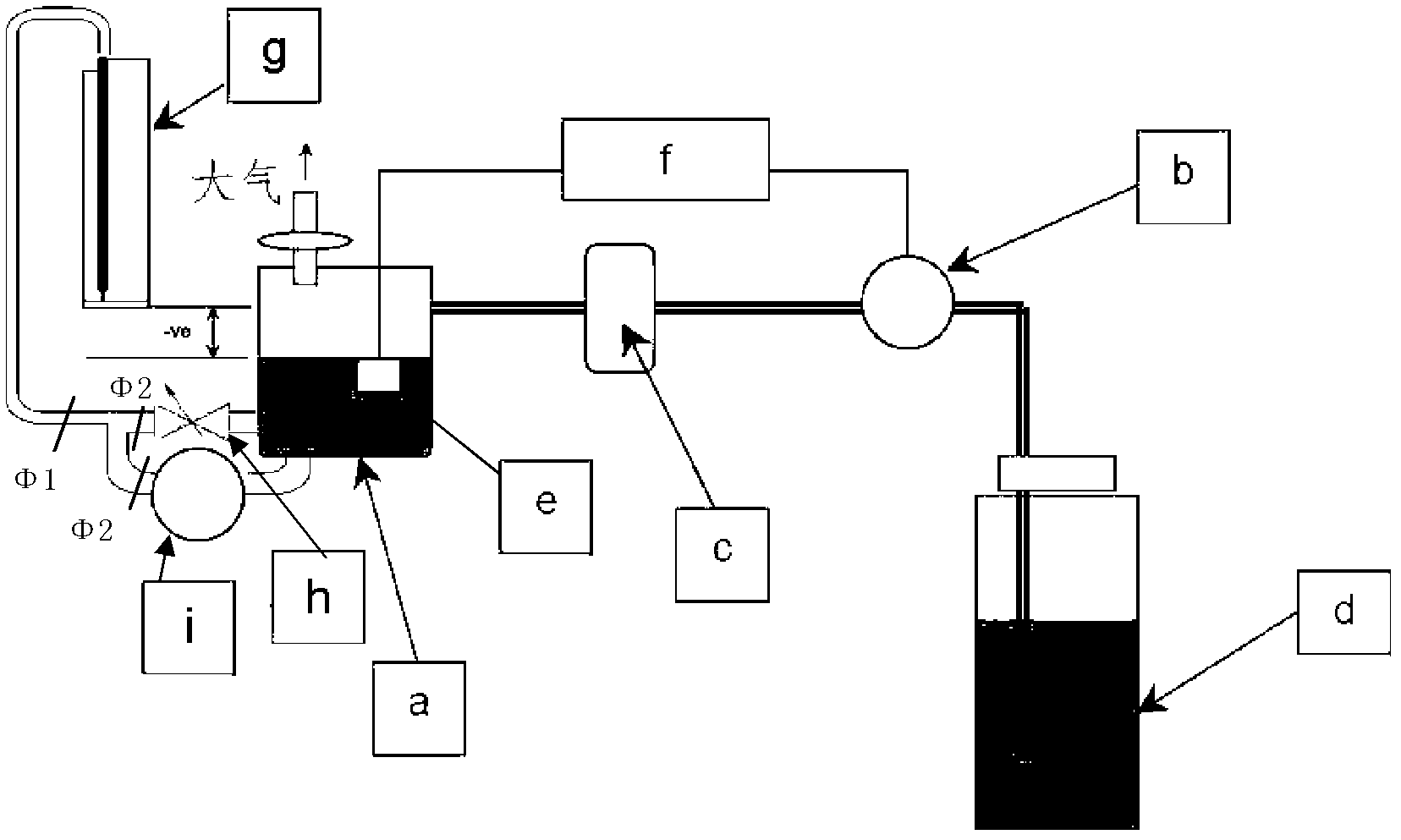

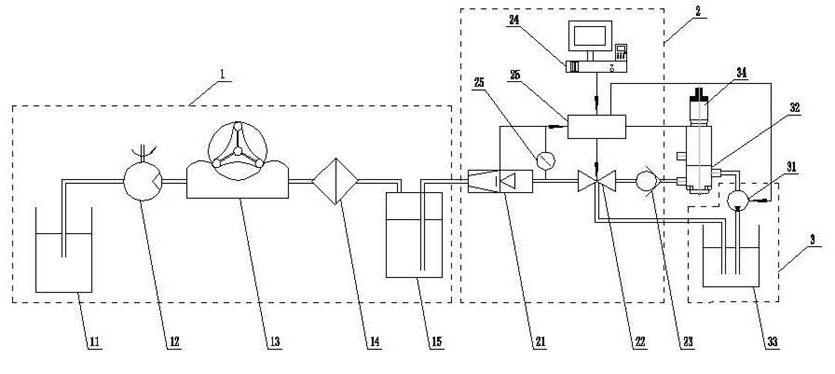

Ink supply and cleaning system for ink spraying and printing head

The invention provides an ink supply and cleaning system for an ink spraying and printing head, comprising a primary ink box, a secondary ink box and the ink spraying and printing head, wherein the primary ink box is communicated with a secondary ink box by virtue of a primary ink pump and a filter, the secondary ink box is internally provided with a liquid level sensor, the liquid level sensor is connected with a feedback control module, the feedback control module is connected with the primary ink pump, the secondary ink box is provided with a breather pipe communicated with the air, and a spray orifice of the ink spraying and printing head is higher than the highest liquid level of the secondary ink box; the bottom of the second ink box is provided with an auxiliary liquid outlet, the liquid outlet is connected with an auxiliary liquid outlet pipe, the auxiliary liquid outlet pipe is provided with an additional ink pump, an ink supply channel comprises an outlet pipe and an output pipe, the outlet pipe is provided with a solenoid valve, one end of the outlet pipe is communicated with the secondary ink box, the other end of the outlet pipe is communicated with one end of the output pipe, the other end of the output pipe is communicated with the ink spraying and printing head, the auxiliary liquid outlet pipe is communicated with the other end of the outlet pipe, and diameters of the auxiliary liquid outlet pipe and the outlet pipe are larger than the diameter of the output pipe. The ink supply and cleaning system disclosed by the invention can enhance reliability and has a good cleaning effect.

Owner:厦门鹿匠科技股份有限公司

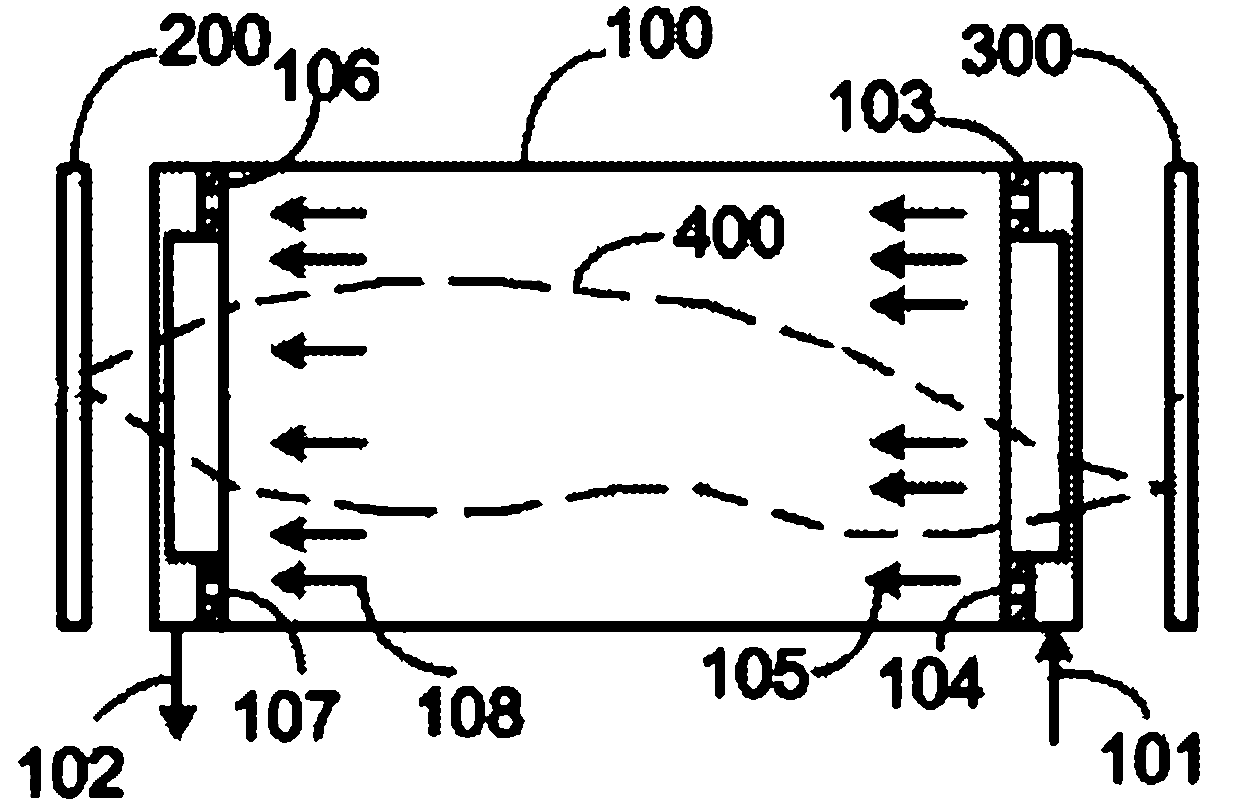

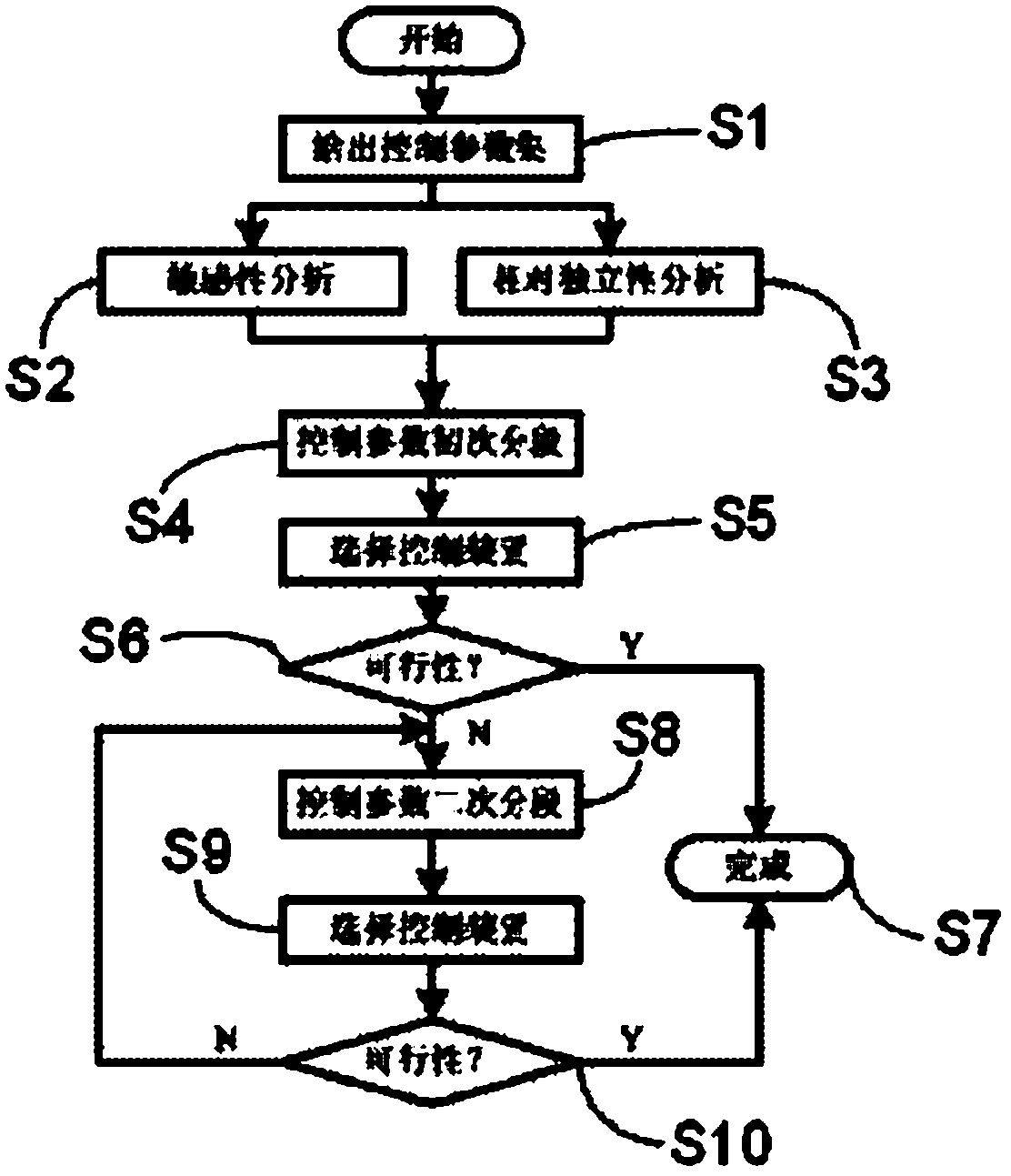

Optical system internal chamber precision gas control method and device thereof

ActiveCN103309369AAchieve precision gas controlOnline adjustableFluid pressure control without auxillary powerLoop controlEngineering

The invention provides an optical system internal chamber precision gas control device. The device comprises an optical system and a gas control loop which is designed by adopting a control parameter decoupling method. An optical system internal chamber precision gas control method comprises a gas control loop control parameter decoupling method. The method specifically comprises the steps of giving a control parameter set; carrying out sensitivity analysis on the control parameter set; carrying out relative independence analysis on the control parameter set; carrying out first sectioning on control parameters; selecting a control device; judging the feasibility of the control device; if the control device is feasible, completing the building of the gas control loop; if the control device is not feasible, carrying out secondary sectioning; selecting a control device; judging the feasibility of the control device of each section; if the control device is feasible, completing the building of the gas control loop; and if the control device is not feasible, carrying out sectioning again until the control device is feasible. According to the invention, multi parameter decoupling can be carried out on the gas loop to realize high power depressurization; secondary pollution can be inhibited; the pressure stability is great; the parameters are adjustable online; and the method and the device have the advantages of simple structure, high reliability and convenient maintenance.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

Urea pumping system

PendingCN107246302AResolve residual crystalsSolve the problem of blocked pipesExhaust apparatusSilencing apparatusRefluxElectromagnetic valve

The invention discloses a urea pumping system. The urea pumping system comprises a urea box, a urea pump module, an energy accumulator and a nozzle module which are sequentially connected through a pipeline, wherein the urea pump module comprises a main pump used for pumping a liquid in the urea box to the nozzle module, and an auxiliary pump used for reversely sucking a liquid in the pipeline back into the urea box; the nozzle module comprises a first electromagnetic valve and an atomization nozzle; the first electromagnetic valve is connected with the energy accumulator and the atomization nozzle through the pipeline; a reflux pipeline which communicates with the urea box is arranged on the pipeline between the first electromagnetic valve and the energy accumulator; and a first damping hole is formed in the reflux pipeline. According to the urea pumping system, an airfree auxiliary structure is adopted, double-pump parallel connection is adopted, when a urea solution is injected, the main pump is started, the urea solution is pumped from the urea box to the nozzle module, after injection, the auxiliary pump sucks the urea solution remaining in the system back into the urea box, and the problems of urea crystallization and pipeline blocking are solved.

Owner:HUST WUXI RES INST +1

Polymer dispersion comprising particles of polyurethane and a copolymer or terpolymer produced by emulsion polymerization of olefinically unsaturated monomers

InactiveUS6924336B2Reduce usageImprove balanceOrganic non-macromolecular adhesiveCellulose adhesivesAdhesiveCrystallinity

A polymer dispersion comprising an aqueous, continuous phase and dispersed particles of polyurethane, which is based on organic, non-aromatic isocyanates with a functionality of at least 2, said polyurethane having a high degree of crystallinity and whose crystalline phase has a melting point between 25 and 70° C., and a copolymer and / or terpolymer having a Tg (glass transition temperature) between −20 and +50° C. obtainable by emulsion polymerization of ethylenically unsaturated monomeric materials containing only C, H, O and / or N atoms, which monomeric materials comprise from 0.5 to 15 percent on the total of monomeric materials of monomers containing at least one nitrile group, in a weight ratio between 50:50 and 10:90 (polyurethane to emulsion polymer), in which the particles of the dispersion are in the form of multiphase particles comprising said polyurethane and said copolymer and / or terpolymer and which dispersion is obtainable by emulsion polymerization of the monomeric materials in the presence of the polyurethane dispersion, said eventual polymer dispersion having a solids content of 30 to 70%. The invention also comprises the use of these dispersions as an adhesive, especially for heat seal laminating, preferably for 3-D(imensional) Laminating. The dispersion is also useful as a size for glass fibers.

Owner:CELANESE INT CORP

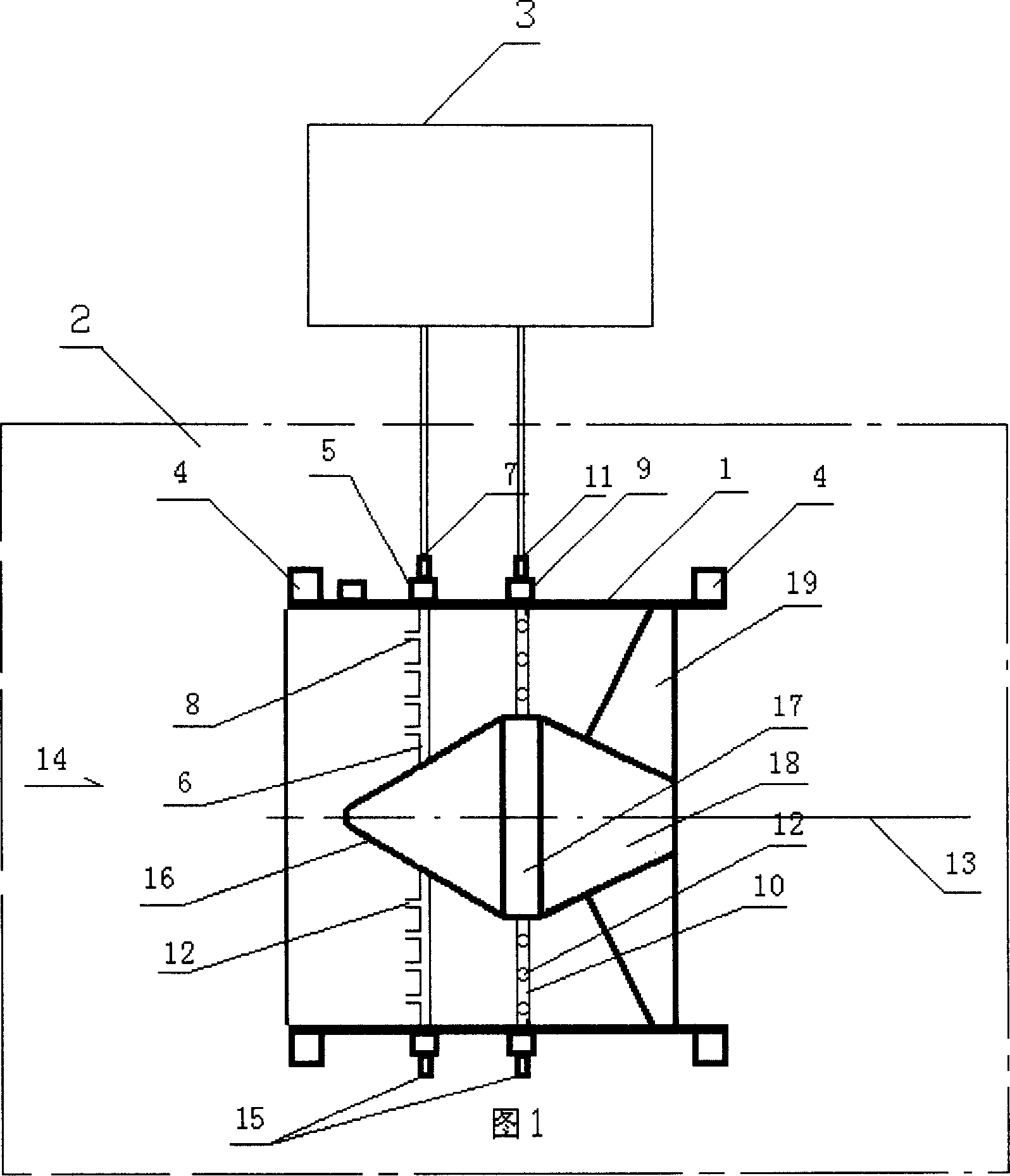

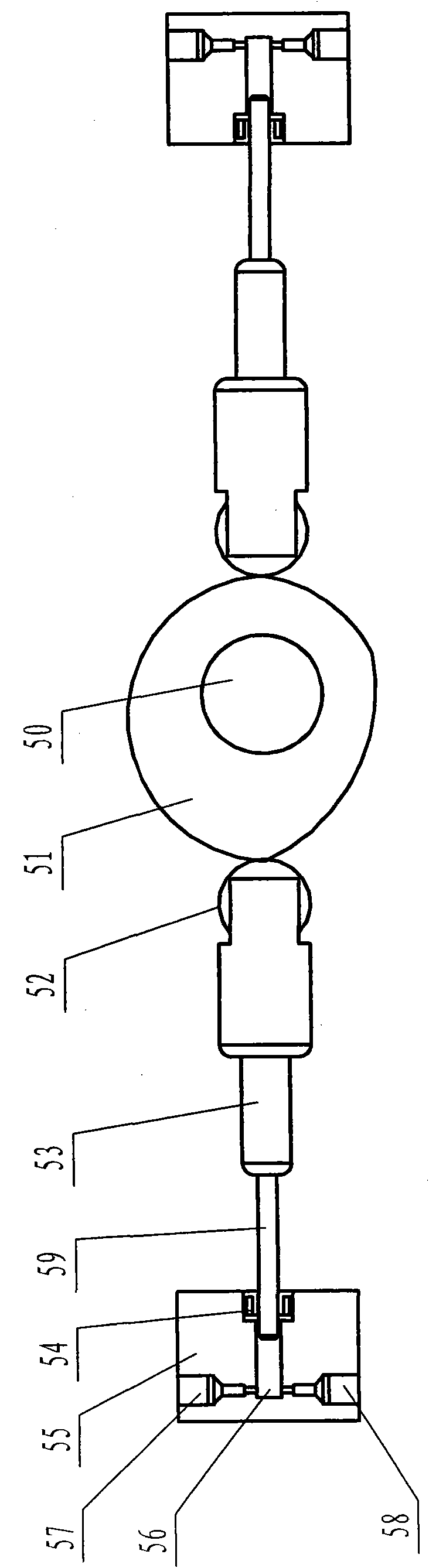

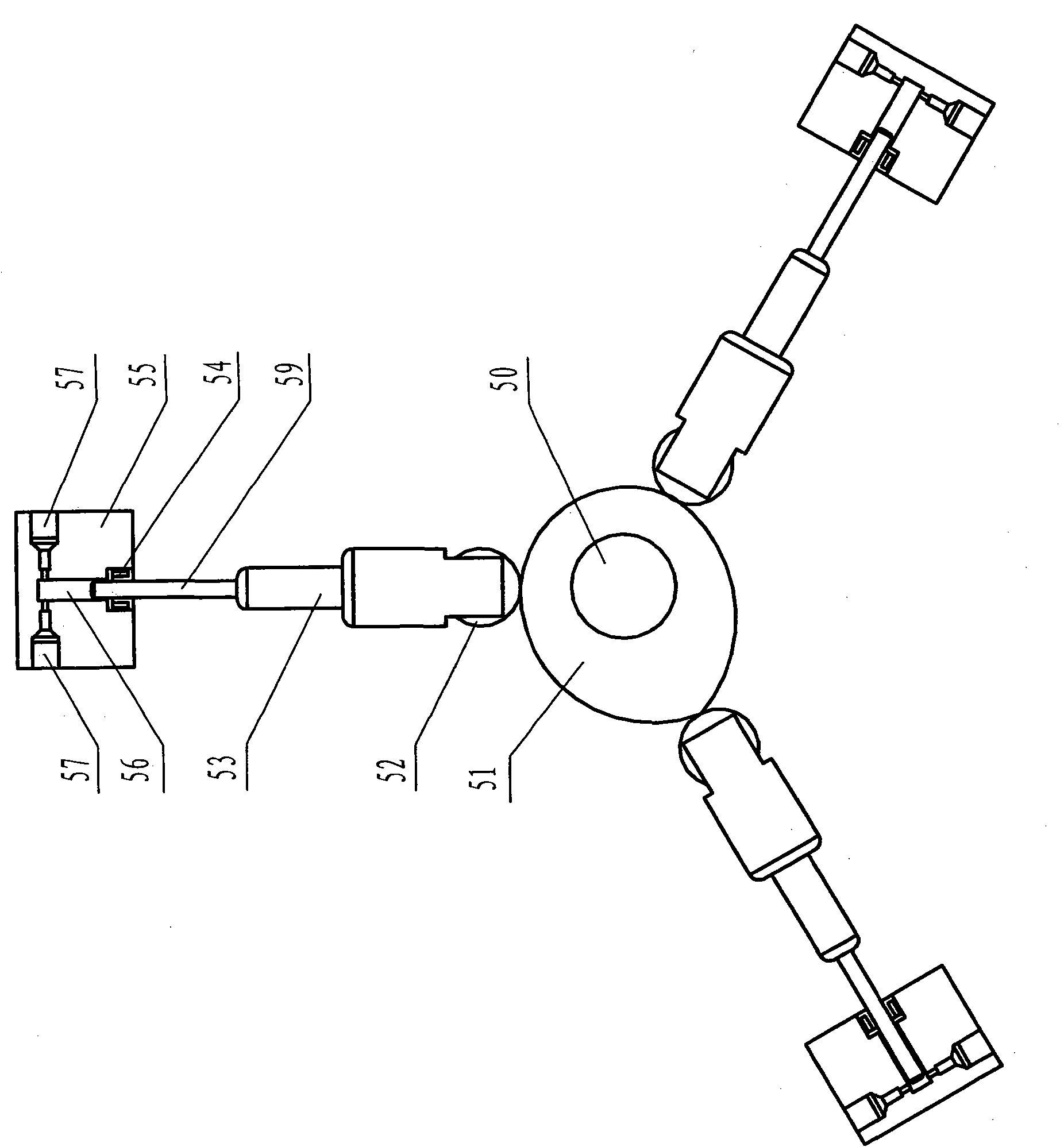

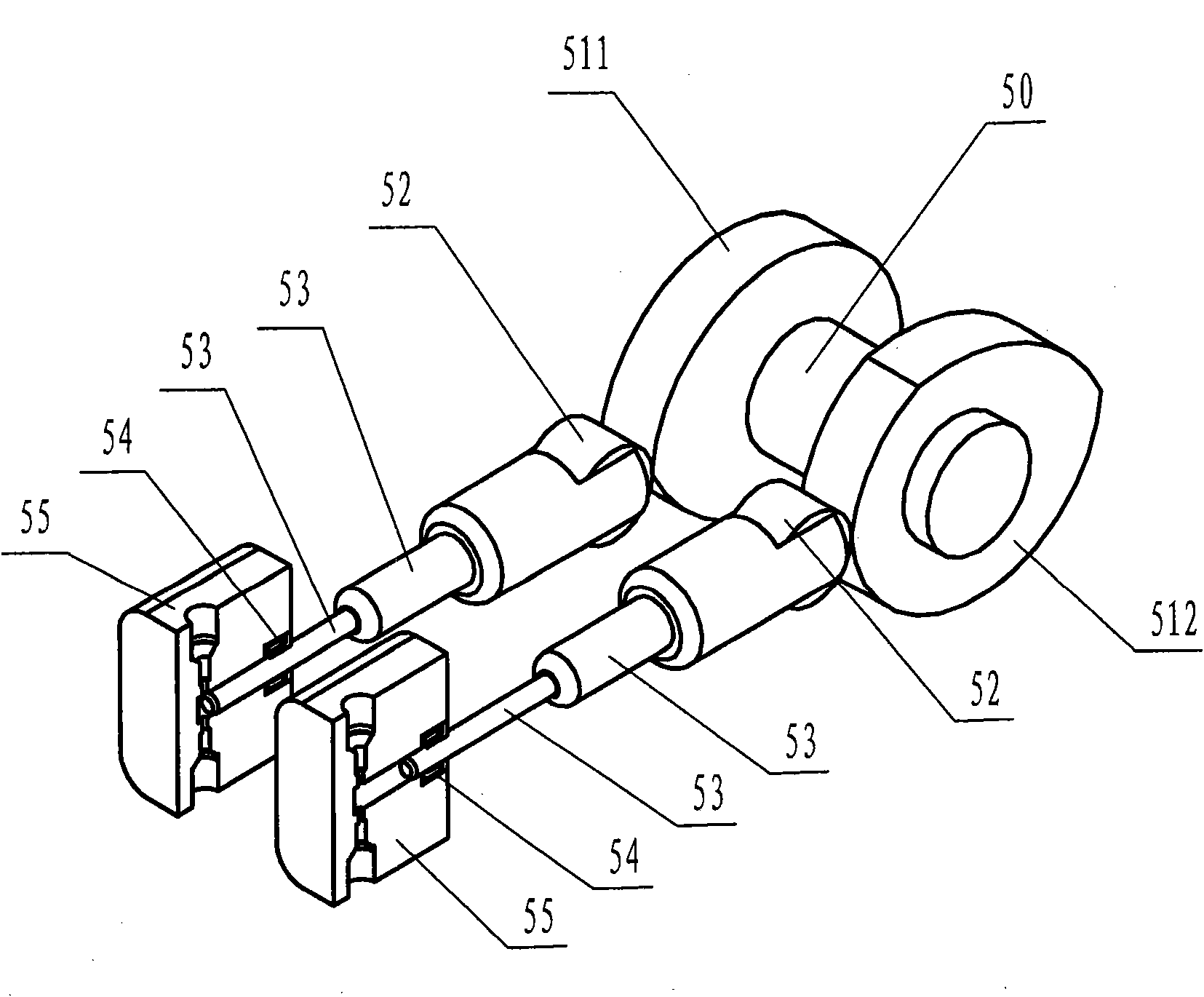

Built-in conical throttling gear

InactiveCN1834591ALarge rangeHigh resolutionVolume/mass flow by differential pressureEngineeringWide dynamic range

The invention relates to a flux meter, especially a inner concealing cone throttling set that includes a sensor device, and flow guiding cone, front pressure collecting pipe, front pressure measuring pipe, front pressure measuring head. It has low request to the straight pipe section and could measure wide dynamic range high accuracy flow and is suitable to kinds of liquid.

Owner:西安中望流量仪表有限公司

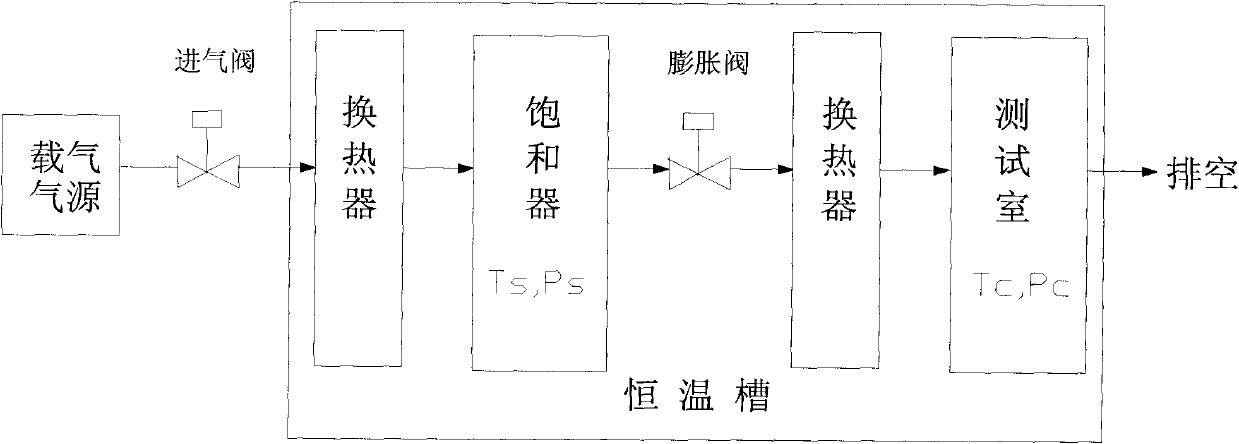

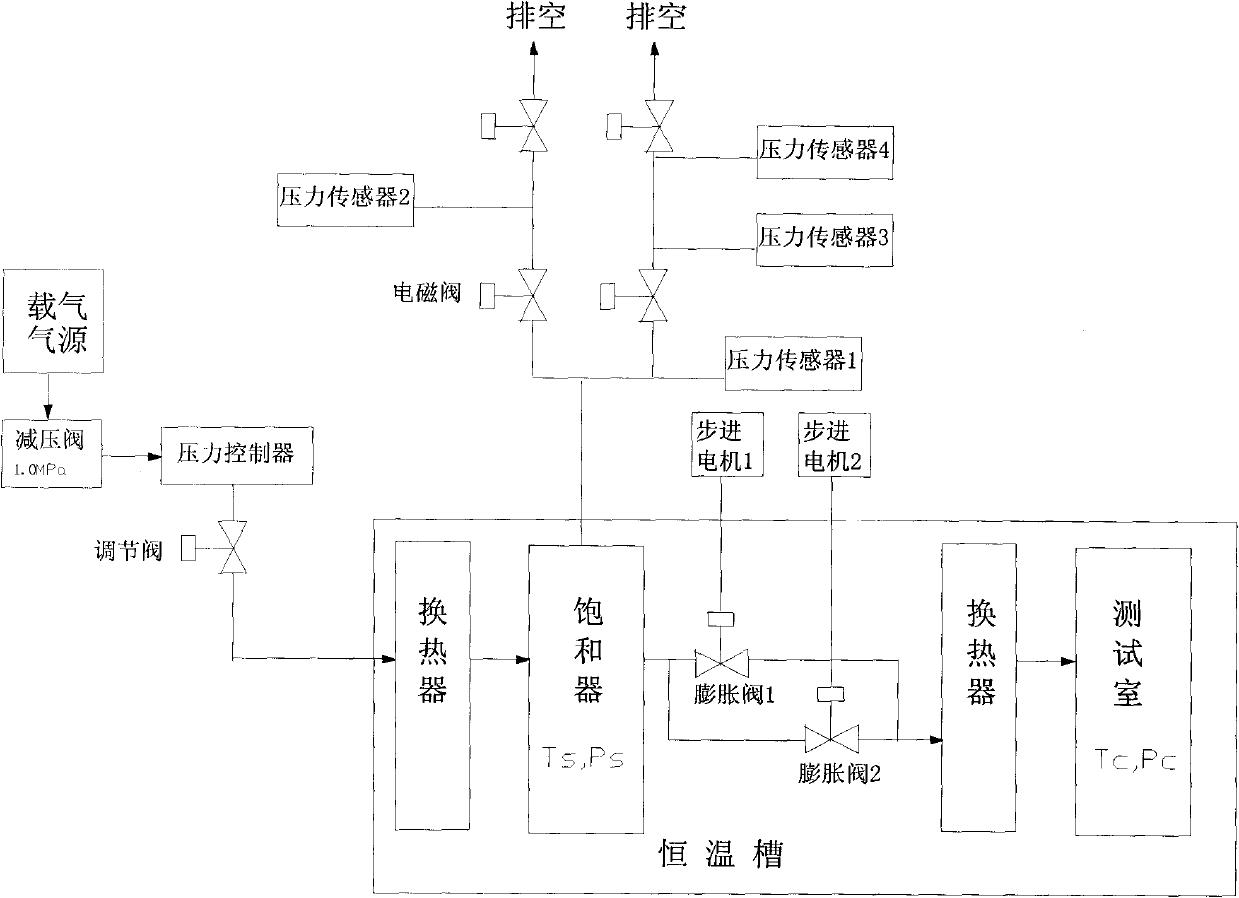

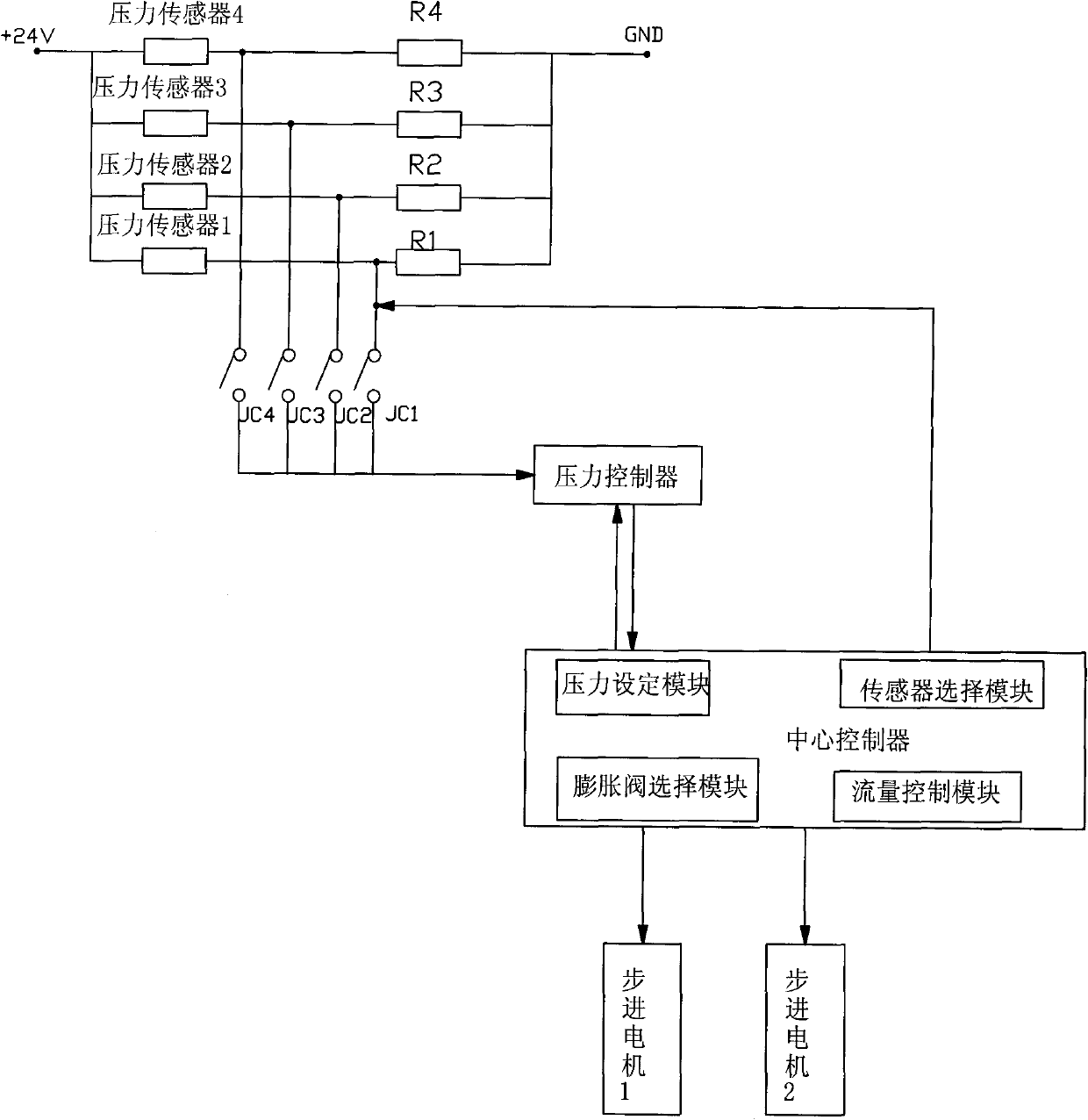

Gas pressure and flow control device of humidity generator

InactiveCN101794158AHigh-resolutionAvoid pressure instabilitySimultaneous control of multiple variablesGas passingEngineering

The invention relates to a humidity generator, belonging to the field of two-pressure humidity generators. A gas pressure and flow control method of the humidity generator is characterized by comprising the following steps: arranging a pressure sensor on a saturator of the humidity generator to monitor and transfer the pressure in the saturator in real time; setting voltage according to the gas pressure required to be reached; comparing the value of the set voltage with the value of the feedback voltage transferred by the pressure sensor in real time, and controlling gas of gas sources to enter the saturator according to the comparison result; and when the pressure in the saturator reaches the set value, controlling the flow of the gas passing through a testing room of the humidity generator to reach the set value. The invention also relates to a device for controlling pressure and flow of gas by using the method. The invention enables the pressure to always stabilize at the set valueautomatically, avoids the current phenomenon of unstable pressure, and realizes the high stability of pressure control.

Owner:SHANGHAI INST OF MEASUREMENT & TESTING TECH

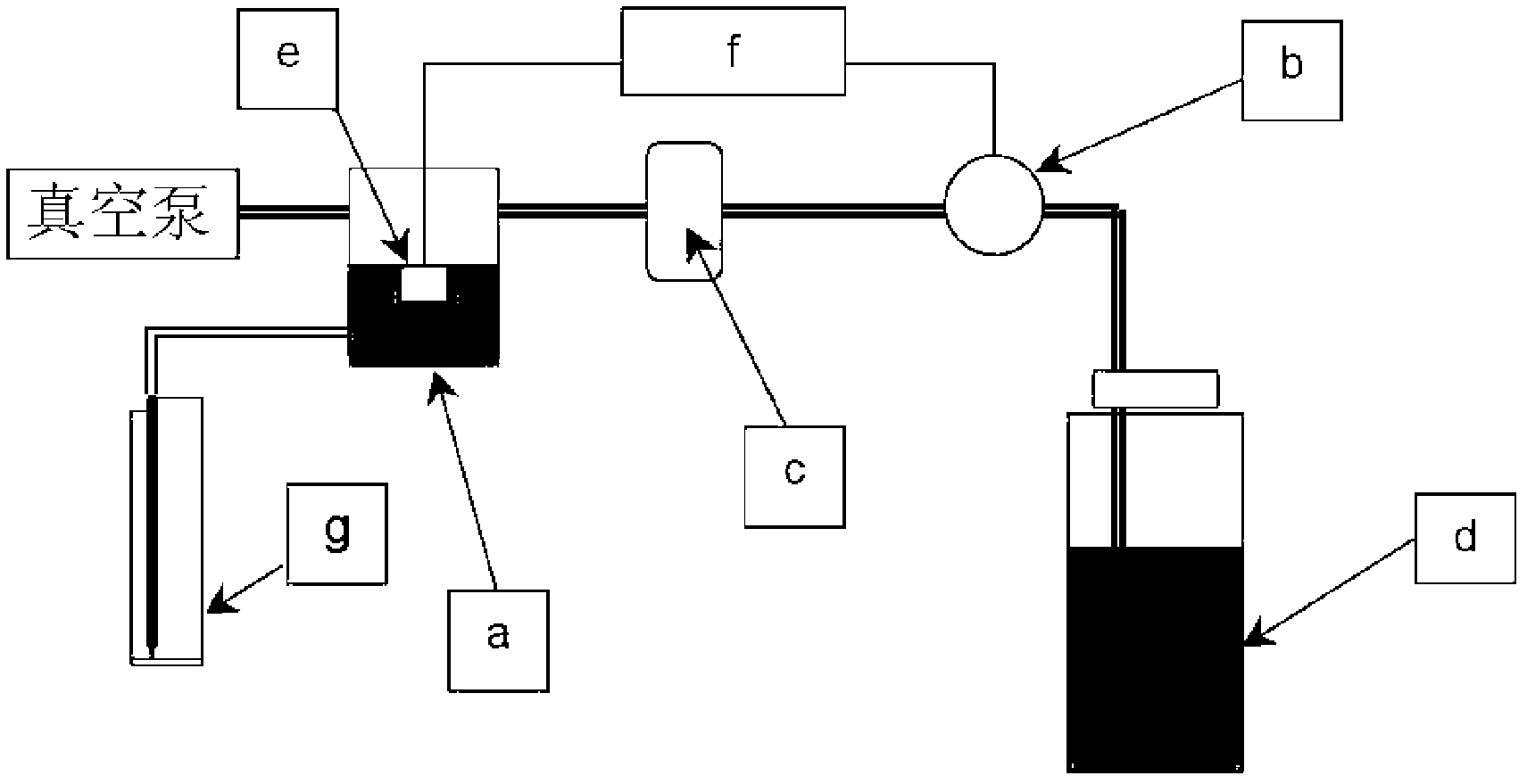

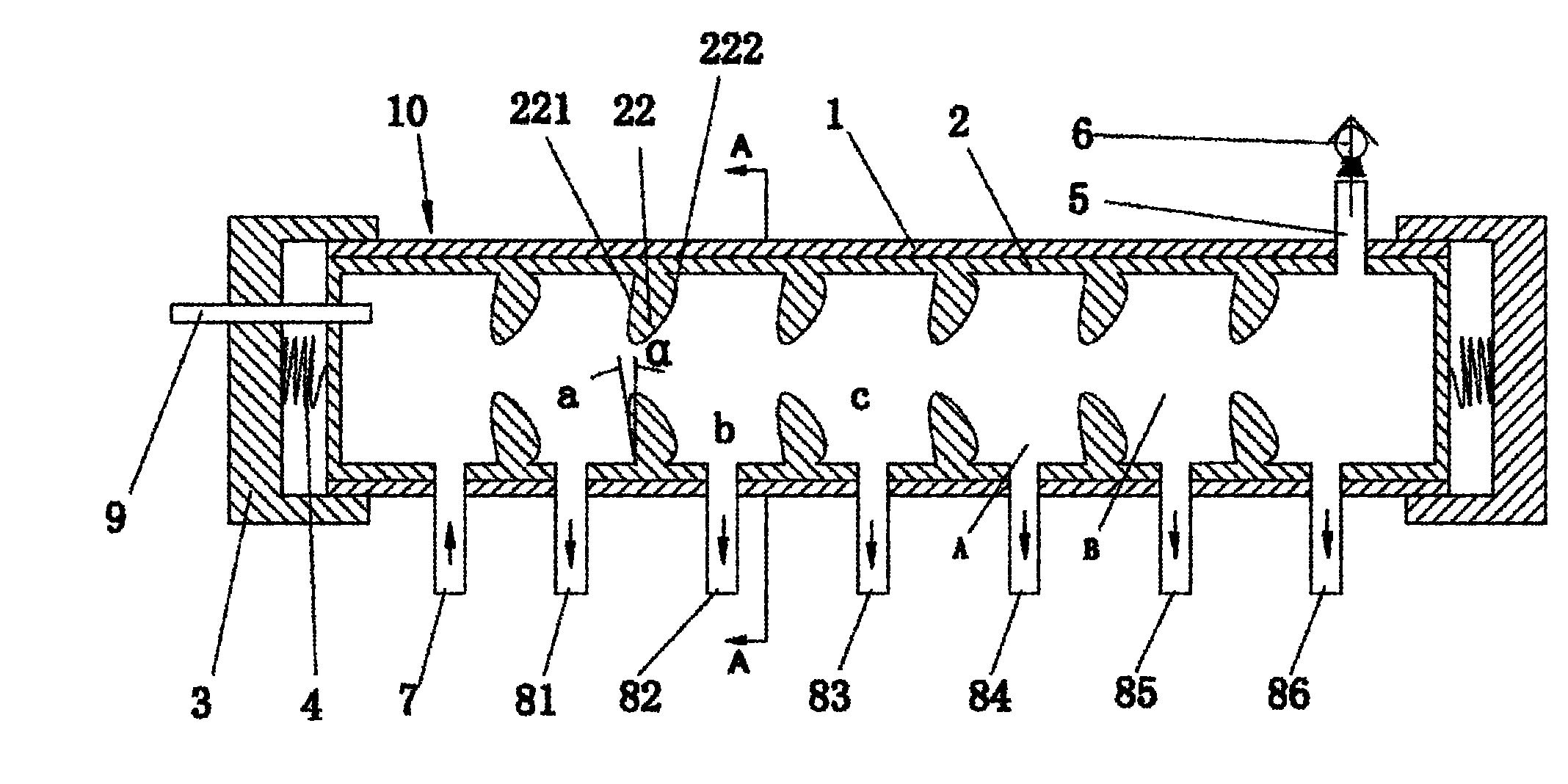

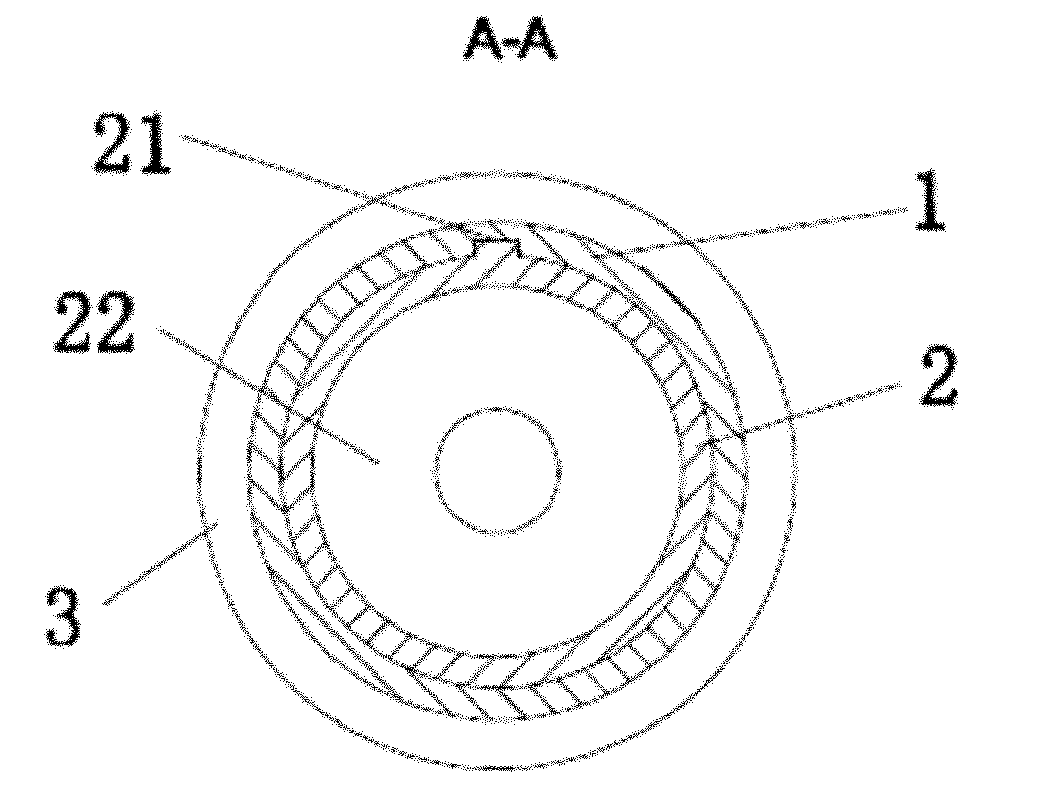

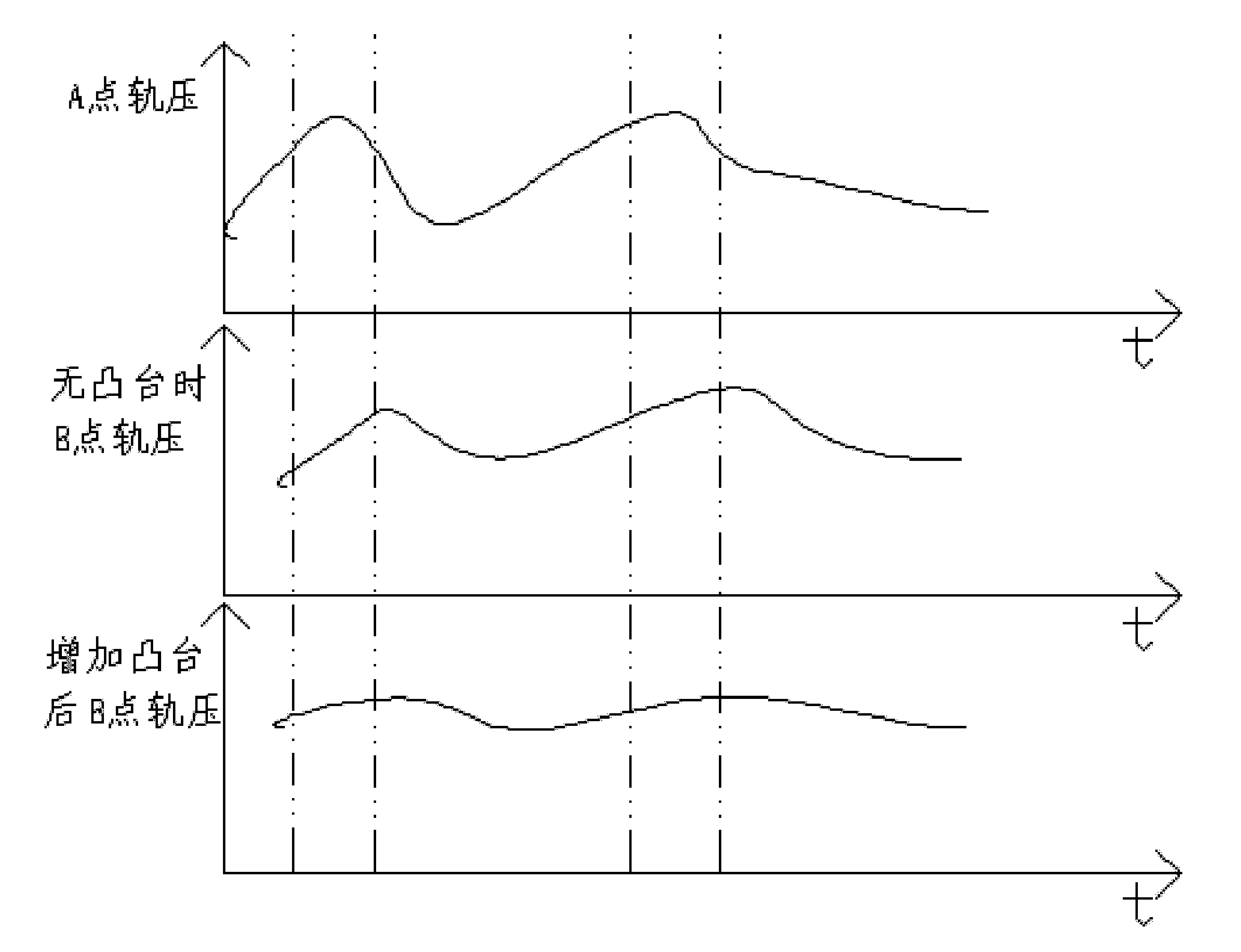

Component type high-pressure common rail device

InactiveCN102174918AReduces the effects of pressure fluctuationsSmall pressure fluctuationsFuel injection apparatusMachines/enginesCommon railComponent type

The invention discloses a component type high-pressure common rail device. A common rail pipe is provided with a pressure sensor and a pressure limiter. The common rail pipe comprises an inner pipe and an outer pipe; a circumferential limit device is arranged between the inner pipe and the outer pipe; the two ends of the outer pipe are fixedly sleeved with a seal cover and the seal covers are used for sealing the two ends of the outer pipe; the circumferential surface of the common rail pipe is provided with an oil inlet and multiple oil outlets; and on the inner circumferential surface of the inner pipe, an annular inward-convex table stretching along the circumferential direction of the inner pipe is respectively arranged between the oil inlet and an oil outlet adjacent to the oil inlet and between two adjacent oil outlets. The component type high-pressure common rail device disclosed by the invention can improve the pressure stability in the common rail pipe, reduce the fluctuation of pressure, and guarantee stability of fuel injection of the high-pressure common rail system.

Owner:北京建筑工程学院

Water pressure reducing valve

InactiveCN1967031AReasonable connectionReasonable connectivityEqualizing valvesSafety valvesPore water pressureWorking environment

It relates to a current pressure reducing valve. It comprises a valve, valve core bar, pressure regulating cover, involucra, spring, spring base, regulating pressure screw, nut, epithelial pressure plate, O type ring of valve core bar, O type rings behind and before the pressure reducing valve base, pressure reducing valve base, seal gasket, seal gasket pressure plate, hexagonal cap, block and return hole, with inner thread on the valve fitting with the outside thread of the pressure regulating cap. It is reasonable, reliable in connection, convenient in installation, clean in working environment, endurable, good in performance and low in cost.

Owner:浙江艾默樱零部件有限公司

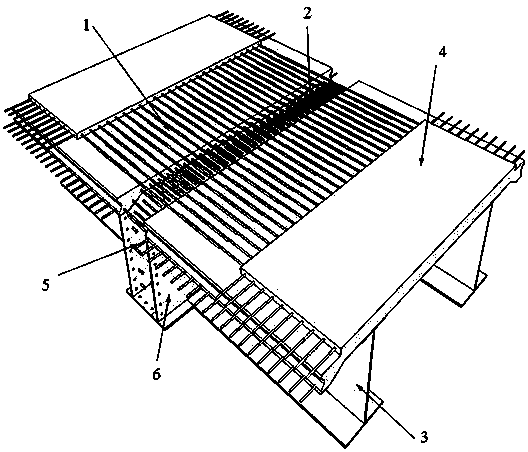

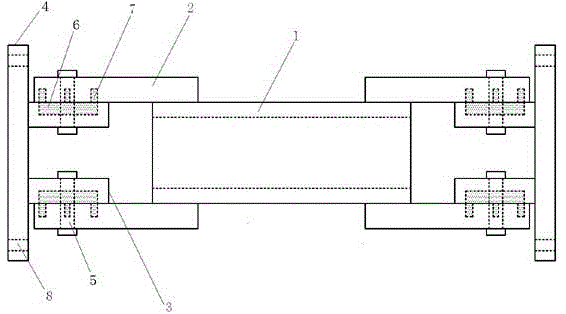

Fabricated light composite beam simply-supported variable-structure continuous structure and construction method thereof

PendingCN108385503AImprove integrityReduce dosageBridge structural detailsBridge erection/assemblyBridge deckContinuous beam

The invention provides a fabricated light composite beam simply-supported variable-structure continuous structure and a construction method thereof. The fabricated light composite beam simply-supported variable-structure continuous structure comprises two oppositely-arranged span steel-ultrahigh performance concrete light composite simply-supported beam prefabricated units, and a cast-in-place ultrahigh performance concrete pier top crossbeam arranged between the two oppositely-arranged span steel-ultrahigh performance concrete light composite simply-supported beam prefabricated units; the prefabricated units comprise a plurality of I-shaped steel beams, bridge deck slabs arranged on the I-shaped steel beams, and connecting parts arranged at the ends of the I-shaped steel beams; each connecting part comprises a first connecting part body arranged at the end of one prefabricated unit, and a second connecting part body arranged on the other prefabricated unit; and ultrahigh performance concrete is poured at the matched areas of the first connecting part bodies and the second connecting part bodies in place to form the pier top crossbeam. According to the fabricated light composite beam simply-supported variable-structure continuous structure and the construction method thereof, the problem that a traditional steel-concrete composite continuous beam hogging-moment-area bridge deckslab is prone to cracking when being pressed, and steel beams are prone to losing stability due to being pressed is solved; a continuous bridge is better in durability and longer is service life, meanwhile, on-site zero welding can be achieved, the on-site operation amount is reduced, the fabricating efficiency of the structure is improved, and fabricated and rapid construction is facilitated.

Owner:HUNAN UNIV

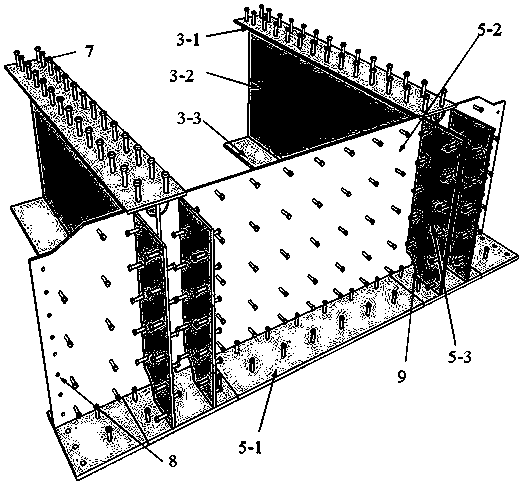

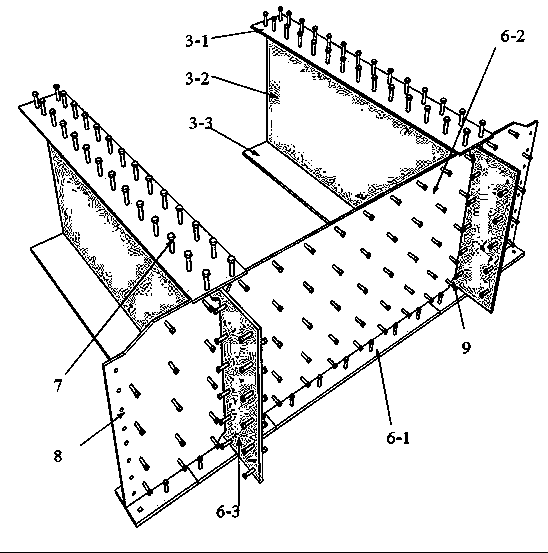

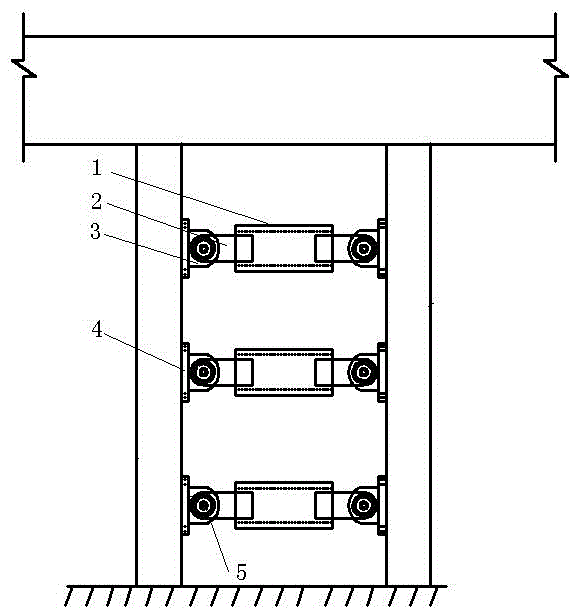

Replaceable shock-absorbing and energy-dissipating type double-leg high-pier system beam

InactiveCN105568845AReduce calculation heightImproved pressure stabilityBridge structural detailsEarthquake resistanceReinforced concrete

The invention discloses a replaceable shock-absorbing and energy-dissipating type double-leg high-pier system beam and relates to the technical field of earthquake resistance and shock absorption of bridge structures. The replaceable shock-absorbing and energy-dissipating type double-leg high-pier system beam comprises a rigid rod and connection structures at the two ends of the rigid rod; each connection structure comprises a rotating plate, a lug plate and an end plate; the end plates are fixedly connected with double-leg high piers on the two sides; the lug plates are welded to the plate faces of the end plates; one end of each rotating plate is welded to the rigid rod; the other end of each rotating plate is connected with the corresponding lug plate through a concentric shaft; annular grooves are formed in the contact faces of the lug plates and the rotating plates around the concentric shafts; a plurality of groove holes are evenly formed in the contact faces of the rotating plates and the lug plates in the circumferential direction of the grooves. The groove holes are communicated with the grooves. Soft lead solidified into a whole is poured in the grooves and the groove holes. The system beam can replace a reinforced concrete system beam which is traditionally used, the calculating height of the piers can be reduced, static force stability is improved, energy dissipation can be performed in an earthquake, the earthquake resistance of the piers is improved, and the replaceable shock-absorbing and energy-dissipating type double-leg high-pier system beam is easy to replace after an earthquake.

Owner:SHIJIAZHUANG TIEDAO UNIV

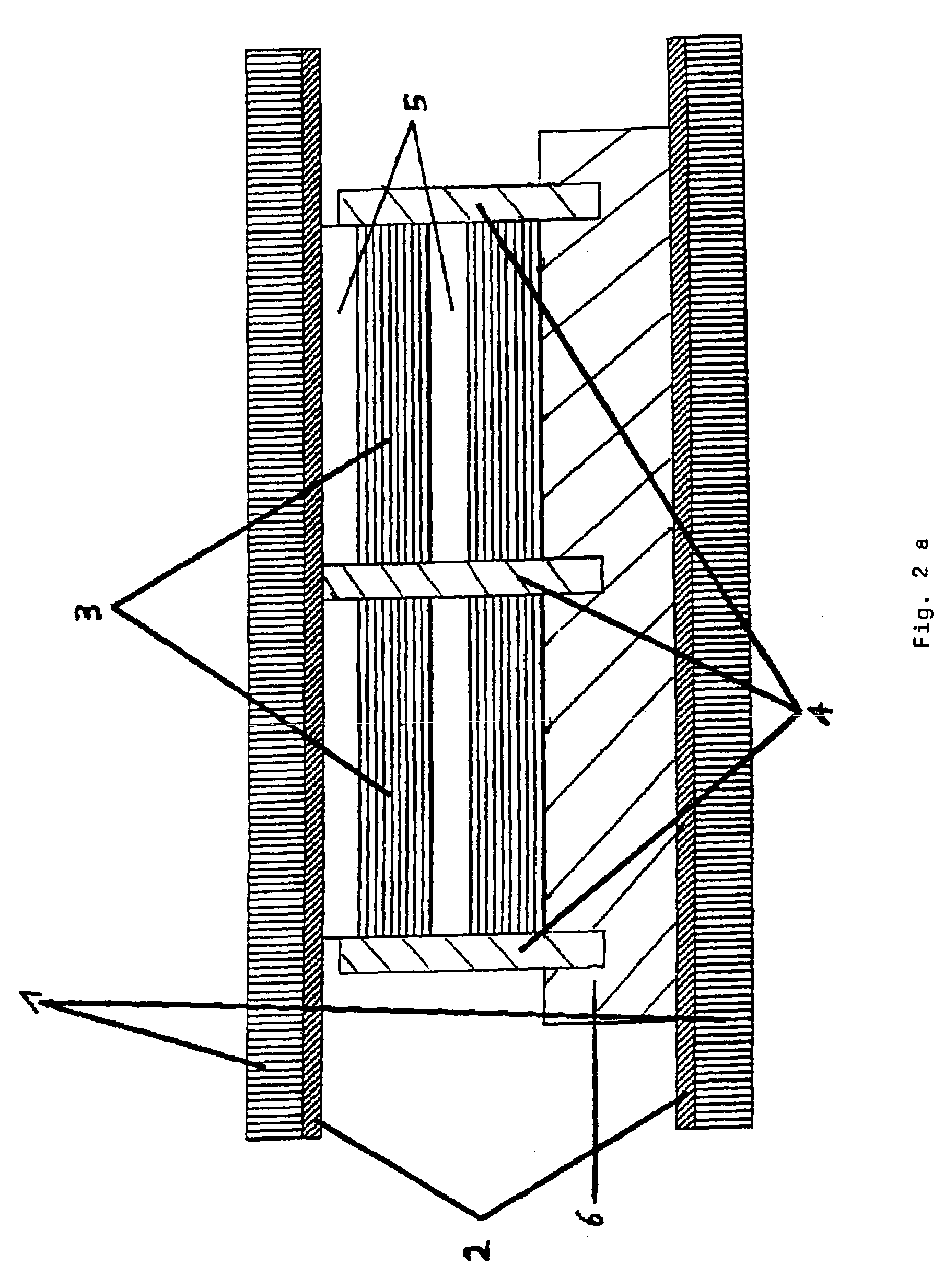

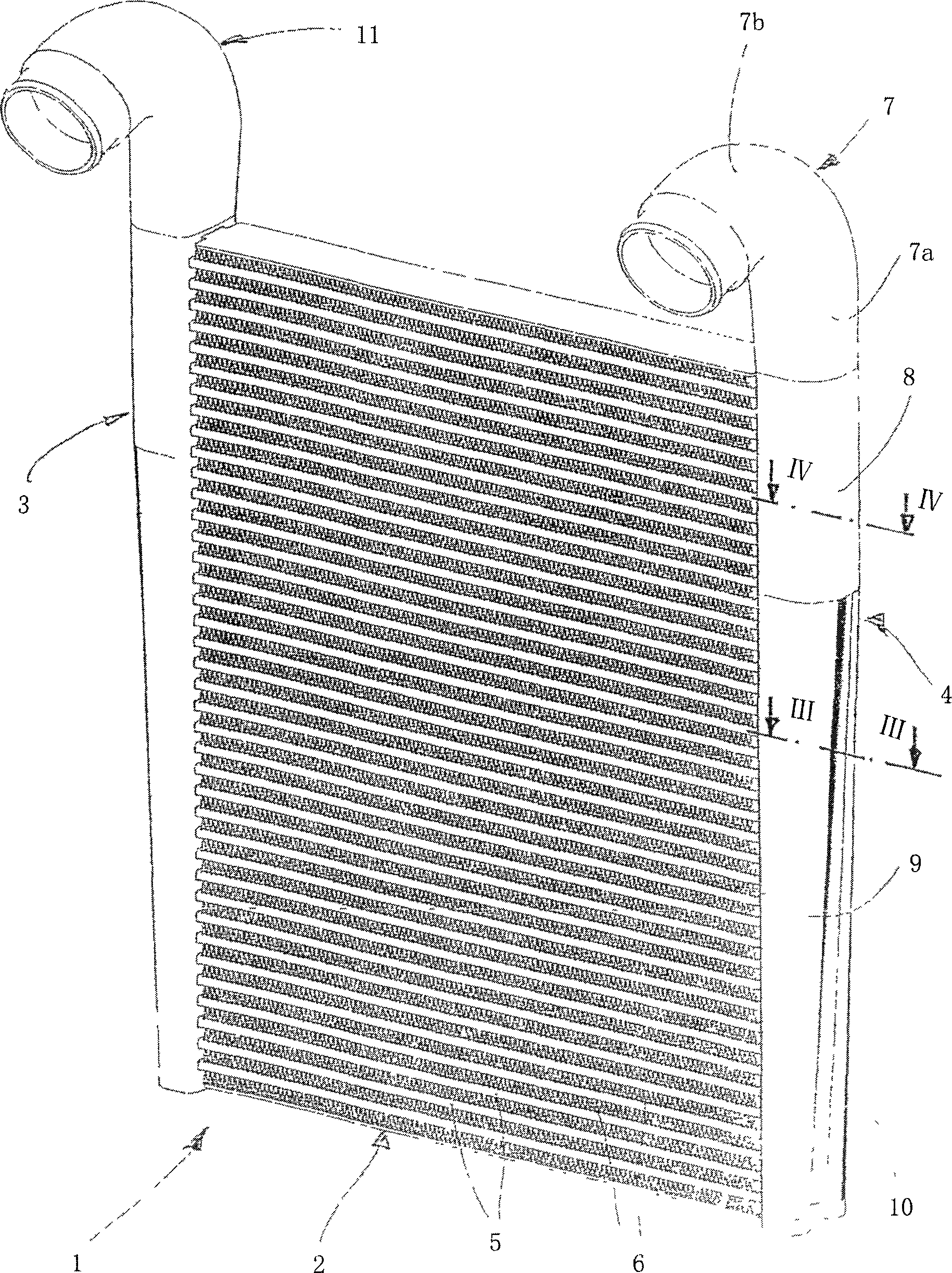

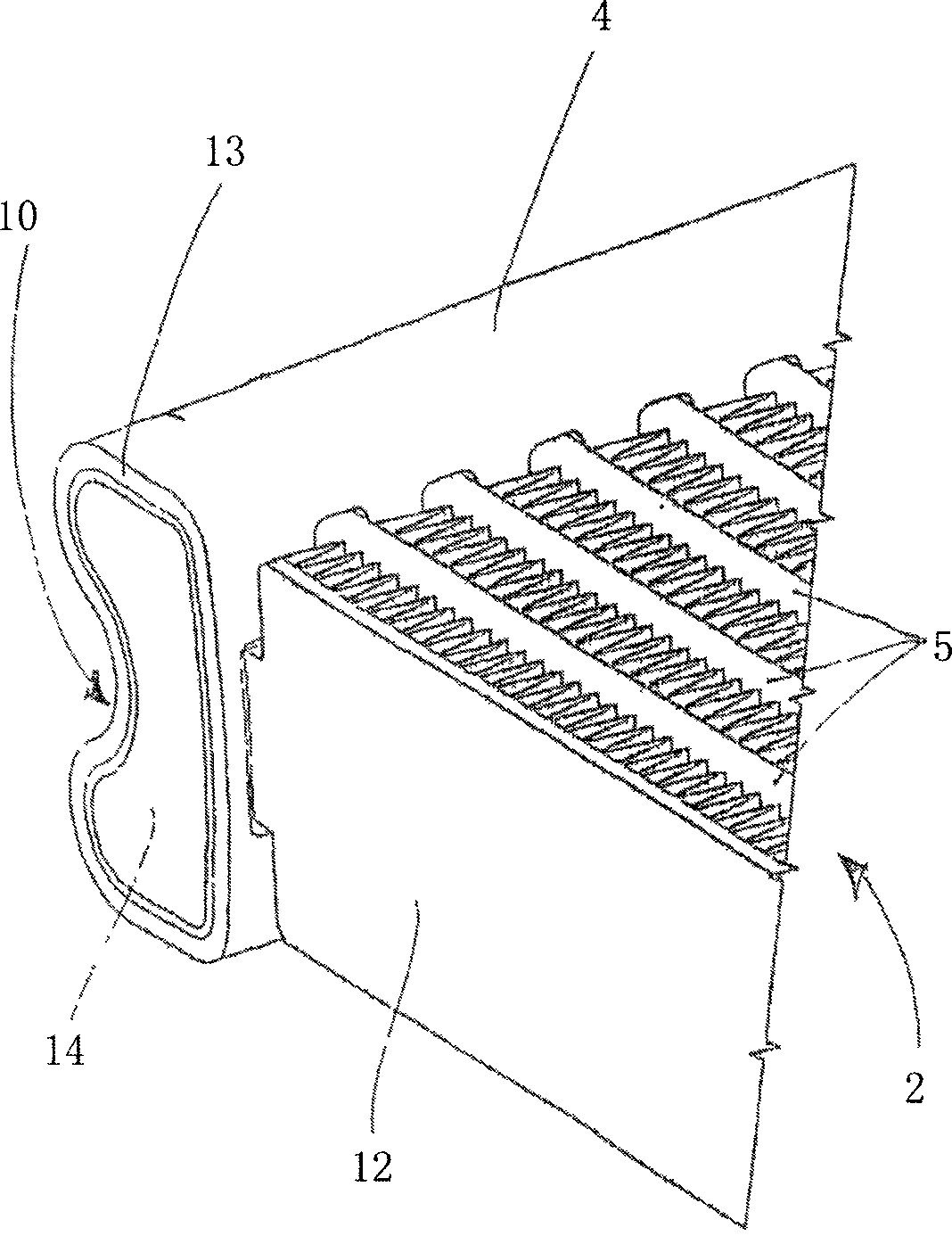

Charge-air cooler for motor vehicles

InactiveCN1860341AThe manufacturing process is applicable to a wide rangeReduce manufacturing costInternal combustion piston enginesIndirect heat exchangersEngineeringHigh pressure

The invention relates to a heat exchanger for motor vehicles, especially for utility vehicles. Said heat exchanger comprises a heat exchanger unit (2), constituted of tubes (5) having tube ends and ribs (6) disposed between said tubes (5), and collecting tanks (3, 4), disposed on both ends and produced by internal high pressure forming for introducing and discharging a medium. Said collecting tanks (3, 4) comprise bottoms with openings for receiving the tube ends, covers and inlet and outlet tubes (7, 11).

Owner:BEHR GMBH & CO KG

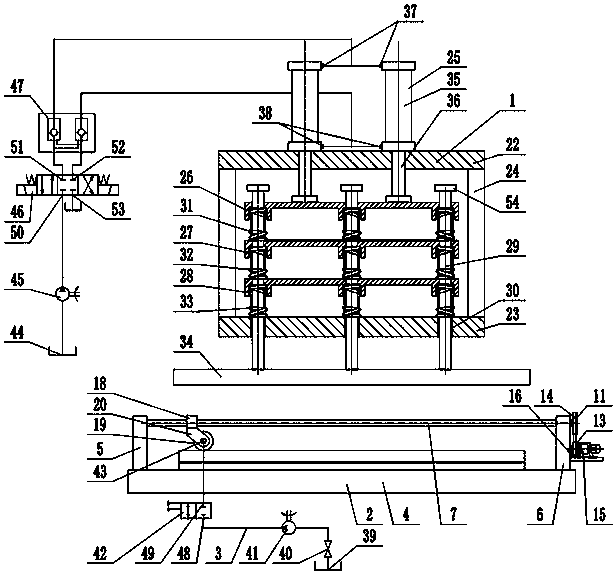

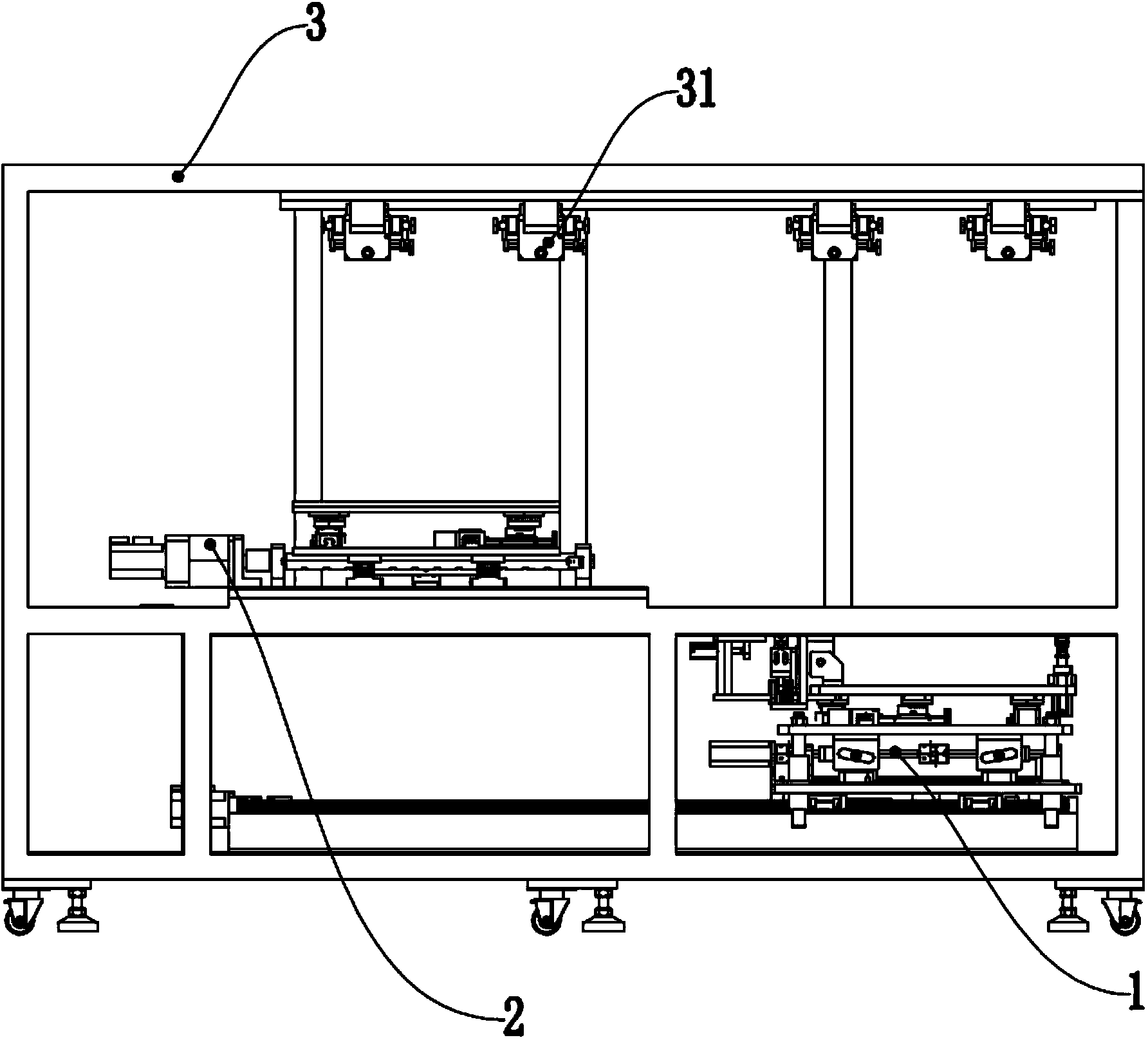

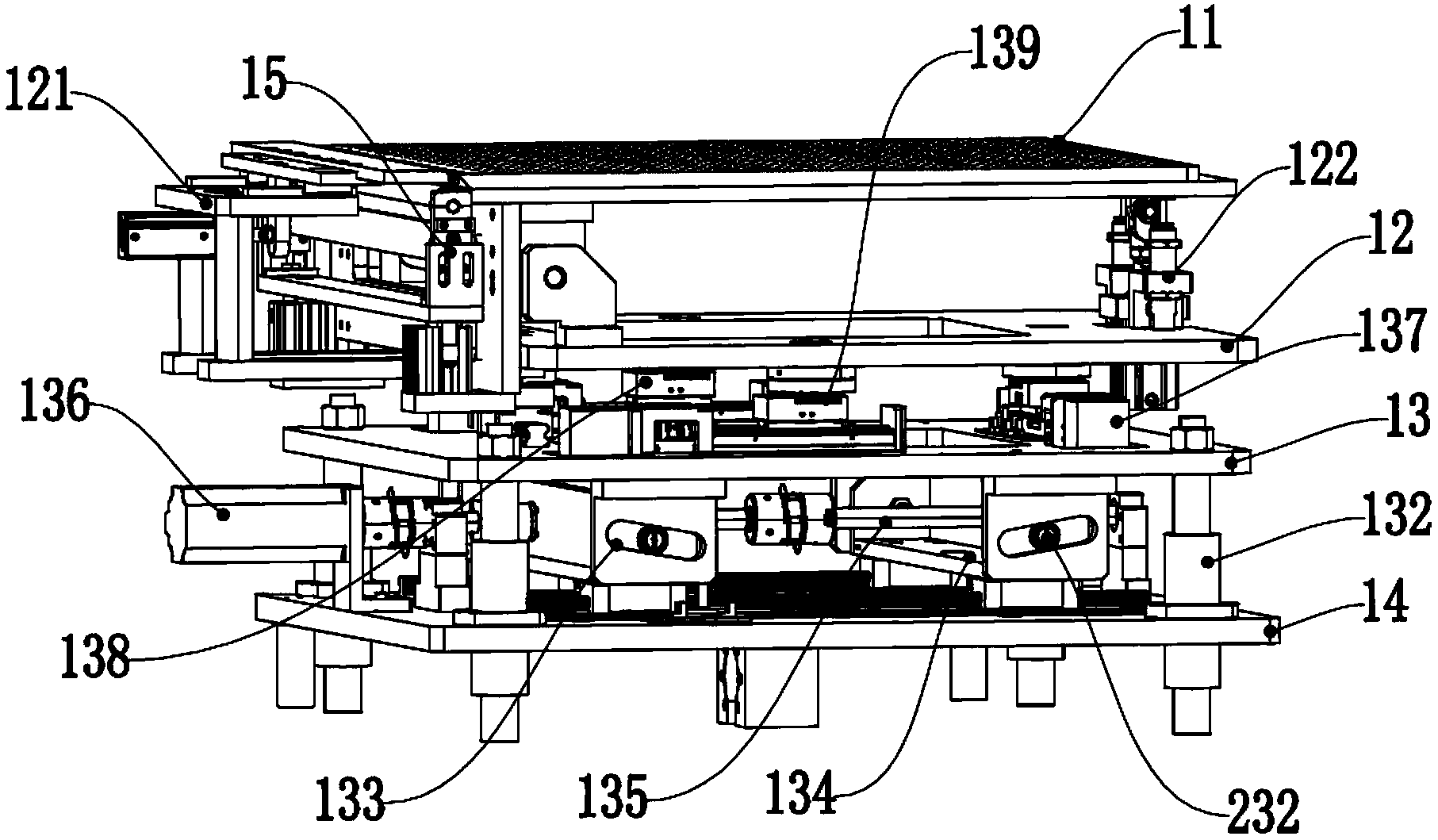

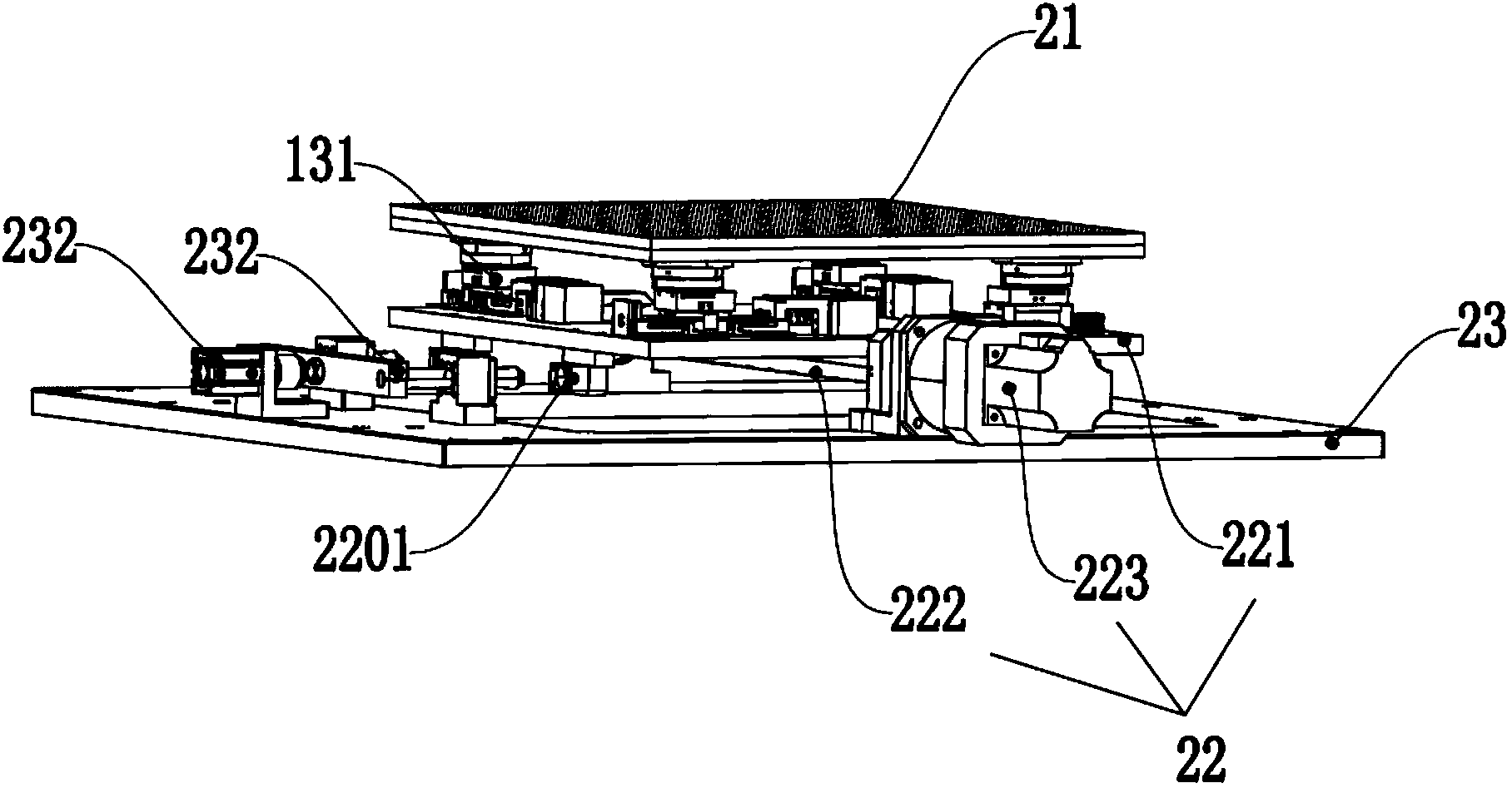

Automatic position-adjustment laminating machine

ActiveCN103895309AImproved pressure stabilityImprove bonding efficiencyLamination ancillary operationsLaminationAgricultural engineeringControllability

The invention discloses an automatic position-adjustment laminating machine. The automatic position-adjustment laminating machine comprises a membrane platform mechanism, a plate platform mechanism, a circuit board and a machine frame, wherein the membrane platform mechanism comprises a membrane platform, an upper frame, a middle frame and a bottom frame; the membrane platform is arranged right above the upper frame; the bottom surface of the upper frame is connected with the middle frame through a horizontal adjustment component; the bottom frame is arranged on the machine frame through a rail in the X-axial direction; a horizontal adjustment component is also arranged between the plate platform and a rotating plate; a camera is arranged on the machine frame above the membrane platform and the plate platform. According to the automatic position-adjustment laminating machine, a membrane and the plate are not required to be aligned manually; the laminating efficiency is improved; the positions of the membrane platform and the plate platform are adjusted automatically; the laminating accuracy is improved; the smoothness after the membrane is laminated is improved; an independently controlled rubber roller frame is arranged; the stability of pressure provided for laminating the membrane is high; the operation is convenient; the controllability is high.

Owner:SHENZHEN YANCHUANG PRECISION EQUIP MACHINERY

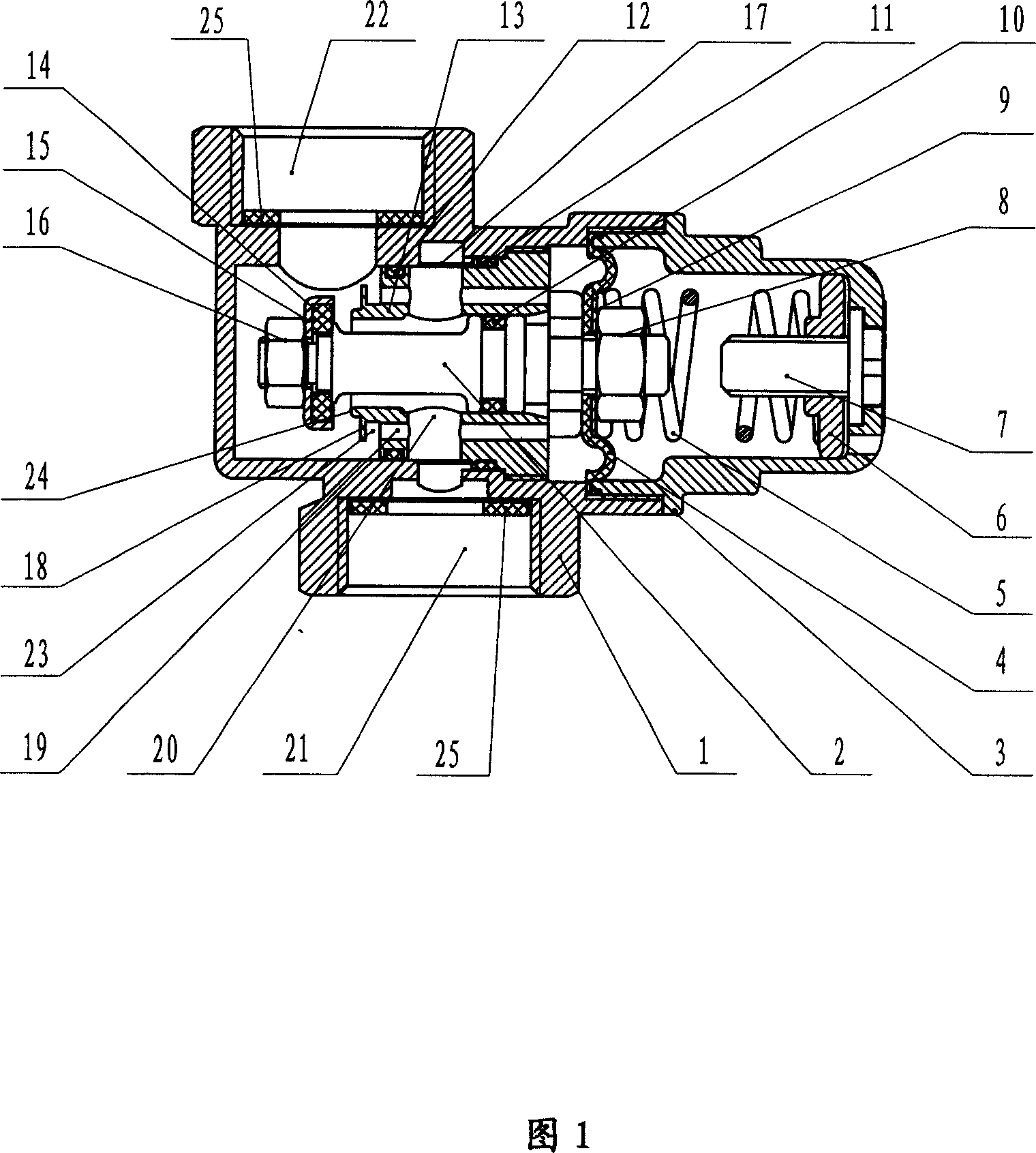

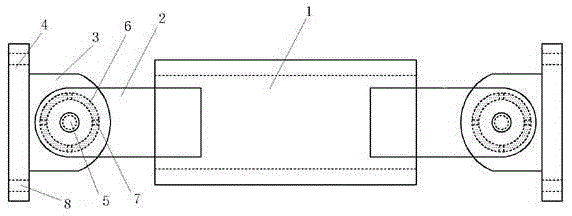

Parallel liquid phase chromatographic pump

ActiveCN102052275AReduce the difficulty of industrial designReduce volumeComponent separationPiston pumpsEngineeringCam

The invention provides a parallel liquid phase chromatographic pump. The parallel liquid phase chromatographic pump comprises a cam with a camshaft, a pump head, at least two reciprocating fluid delivery mechanisms and a cam driving mechanism; the cam is an end cam; a cam curve comprises 1 to 5 curve units; and each curve unit comprises an ascending curve which can convert the rotating motion of the cam into the uniform linear motion of a plunger and a recession curve which enables the plunger to return in situ. Leads r of the ascending curve and the recession curve are both equal to 4v / npiD<2>, and a lead angle theta of the ascending curve is equal to 360 degrees / n, wherein v is the delivery volume of the parallel liquid phase chromatographic pump when the cam rotates a circle; D is the diameter of the plunger; n is the number of the plungers; and n is an integer of 2 to 10. A supporting roller has a conic shape; and the ratio of the circumference of one of any two cross sections of the supporting roller to the perimeter of the cam curve at the corresponding position is equal to the ratio of the circumference of the other of any two cross sections of the supporting roller to the perimeter of the cam curve at the corresponding position. The parallel liquid phase chromatographic pump has a simple structure and high fluid pressure stability, and is easy to design and process.

Owner:BEIJING PURKINJE GENERAL INSTR

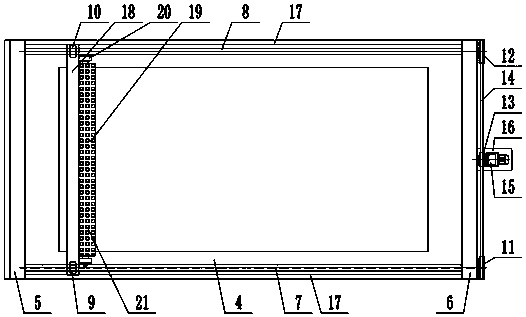

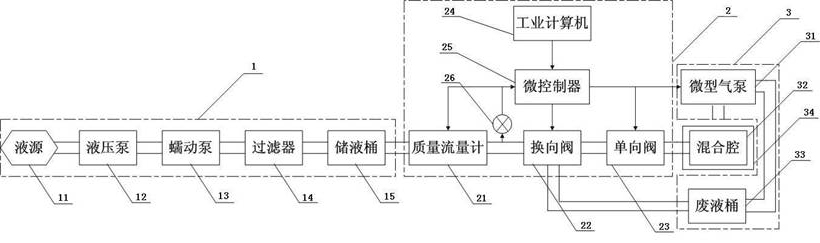

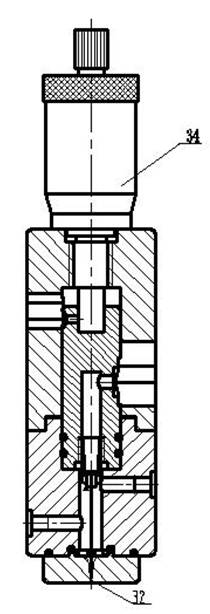

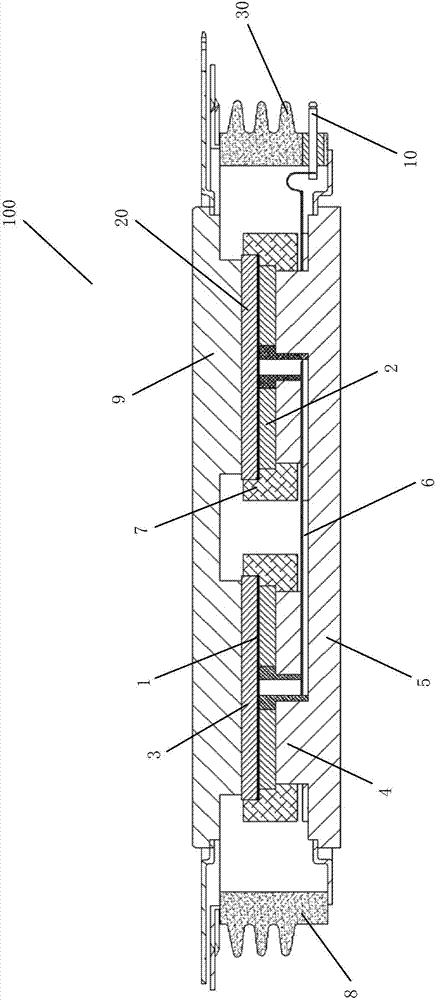

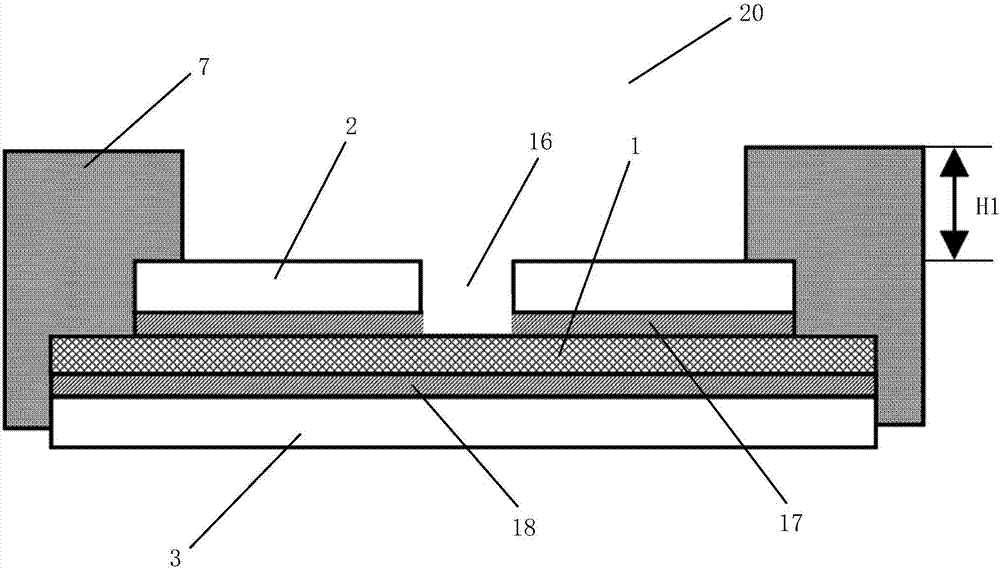

Liquid control system for double-fluid injector

ActiveCN102151627AImprove continuityImproved pressure stabilityLiquid surface applicatorsLiquid spraying apparatusPeristaltic pumpHydraulic pump

The invention relates to a liquid control system for double-fluid injection, which comprises a liquid source device, a liquid control device, a return suction device and a double-fluid injector, wherein the liquid source device, the liquid control device, the double-fluid injector and the return suction device are connected by hoses in turn, and liquid supply and recovery of the double-fluid injector are realized. In a liquid source device, a hydraulic pump is adopted to convey liquid to the system, and a peristaltic pump is used to reduce impulse. In the liquid control device, a liquid electromagnetic valve is adopted to supply continuous or impulse liquid flow to downstream equipment, a liquid one-way valve is arranged in the path of liquid before entering a mixing chamber to prevent liquid backflow caused by overhigh pressure in the mixing chamber, a return suction opening is formed on the other side of the mixing chamber, and a micro air pump is used to suck liquid before the system stops working to avoid trailing, wire drawing and other phenomena. The system can be used in ink injection, glue injection and welding processes and other processes, particularly a double-fluid injection spot gluing process.

Owner:SHANGHAI UNIV

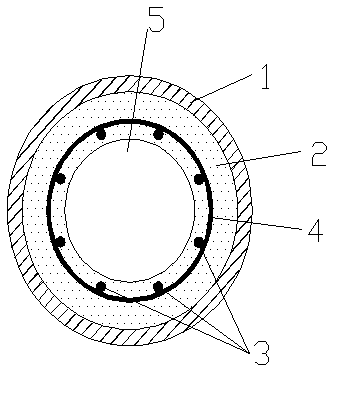

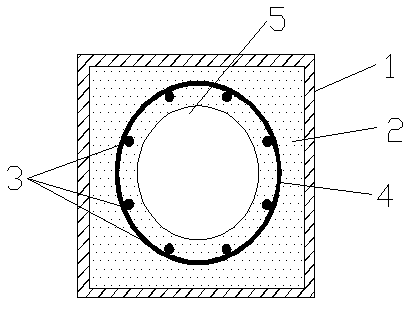

Power semiconductor chip, sub-module comprising the chip and crimping-type packaging module

ActiveCN107240571AImprove area utilization efficiencyAchieve preparationSemiconductor/solid-state device detailsSolid-state devicesPower semiconductor deviceSemiconductor chip

The invention discloses a power semiconductor chip, a sub-module comprising the chip and a crimping-type packaging module. The chip comprises: a terminal area and an effective area arranged inside the terminal area. The effective area is provided therein with an emitting electrode area and a grating electrode area. The grating electrode area comprises a grating electrode, a grating electrode bus, and a plurality of peripheral grating electrodes arranged on the circumference of the grating electrode. The grating electrode is arranged at the center of the peripheral grating electrode surrounding area; and the grating electrode is connected with the peripheral grating electrodes through the grating electrode bus. The peripheral grating electrode surrounding area is divided into a plurality of sub-areas in the same size by the grating electrode bus with emitting electrodes arranged in the sub-areas. Among the peripheral grating electrodes, break points are arranged. The break points are distributed in center symmetrical or axial symmetry. The emitting electrodes inside and outside the peripheral grating electrode surrounding area are communicated with each other via the break points. With the invention, the problem with balanced contact of the interfaces among the sub-modules that can be hardly achieved in the prior art can be realized. The technical problems with complex structure and technology as well as with achieving a high finished product rate can be resolved. In addition, batch production also becomes possible.

Owner:ZHUZHOU CRRC TIMES SEMICON CO LTD

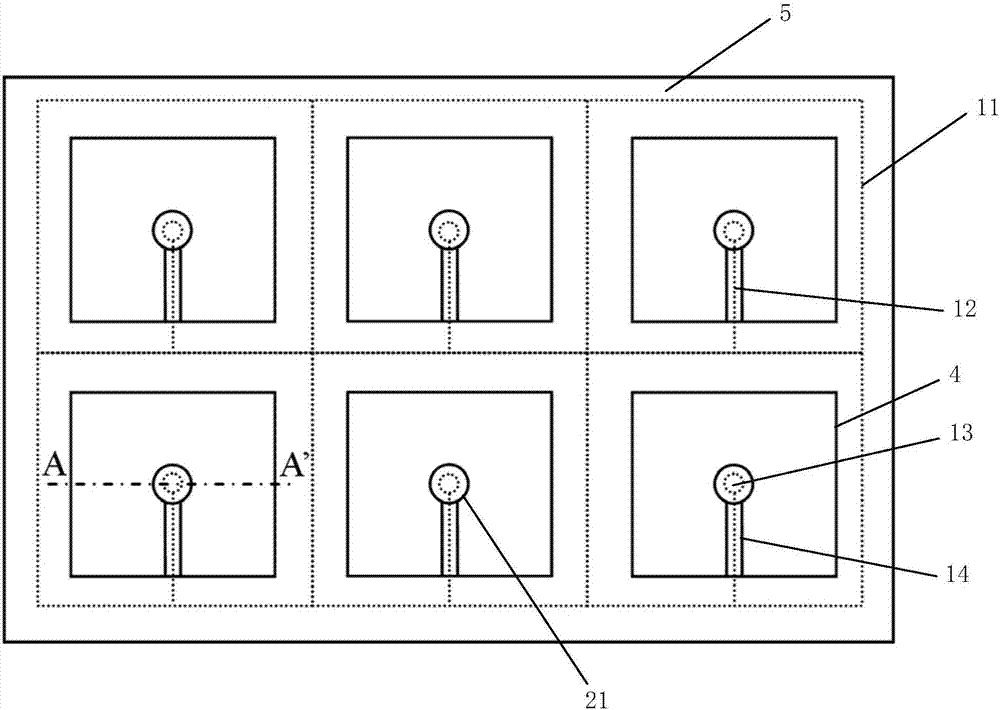

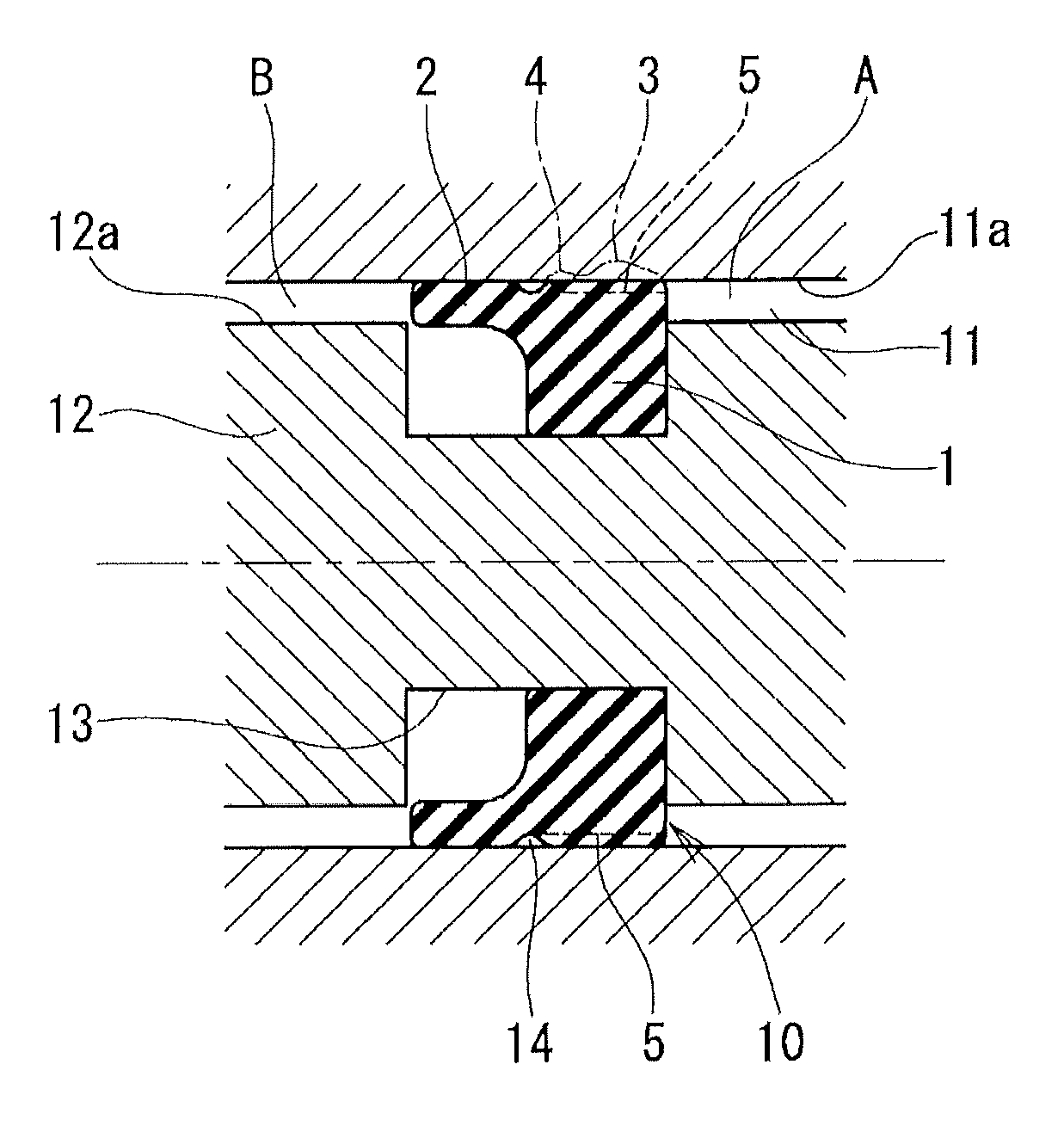

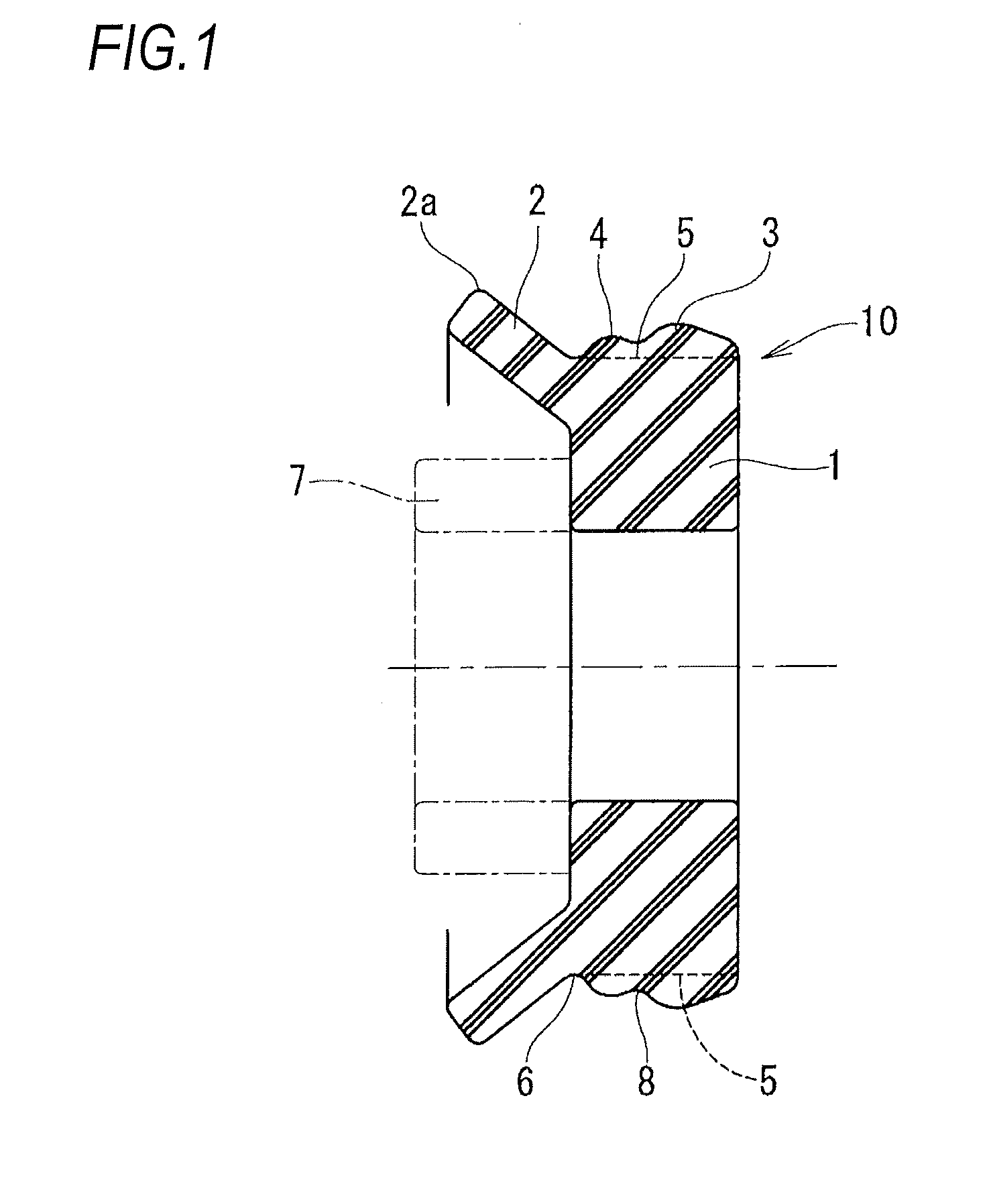

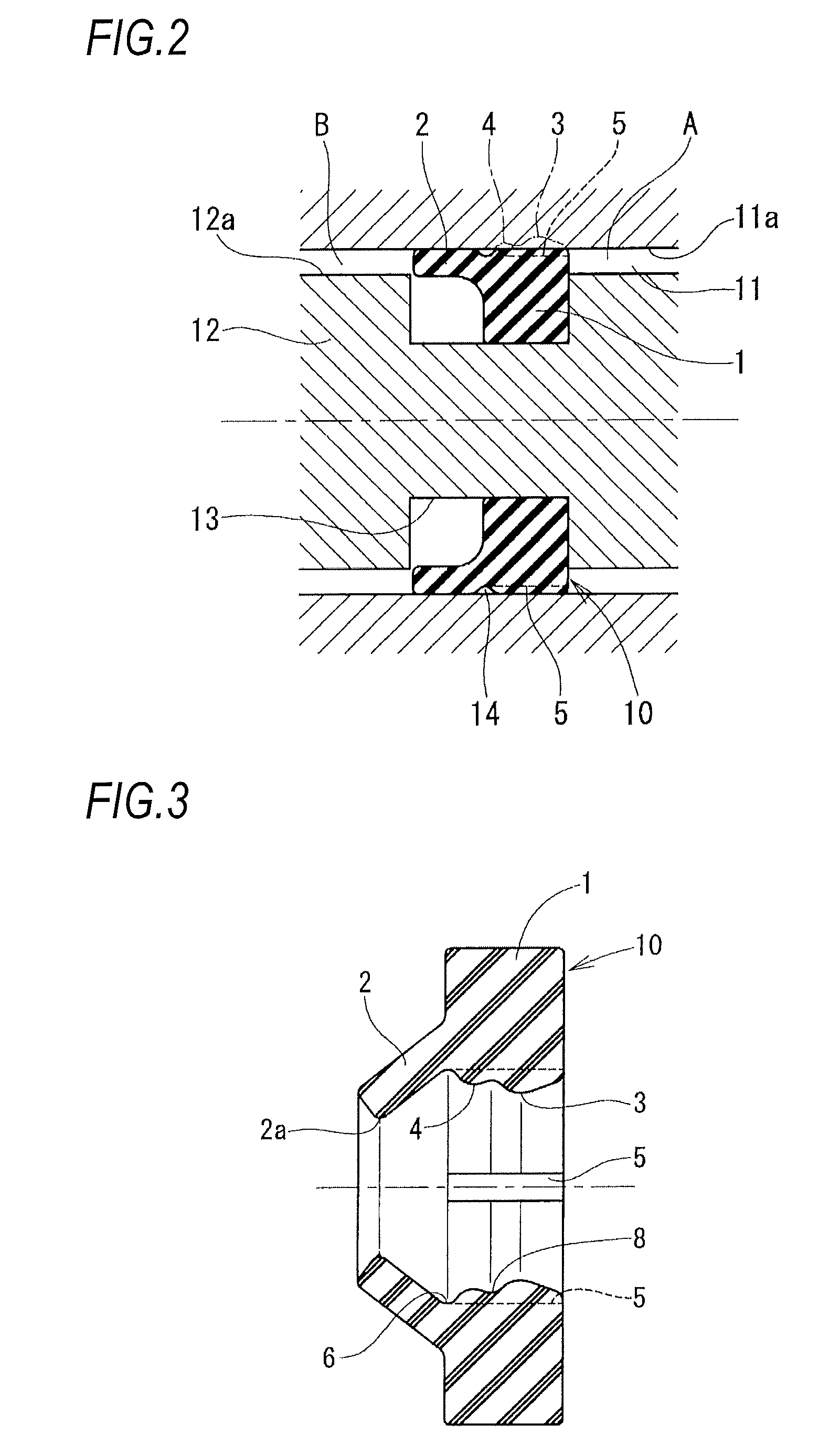

Annular seal member

InactiveUS8814170B2Improved pressure stabilityImprove stabilityEngine sealsPiston ringsEngineeringMechanical engineering

An annular seal member configured to seal a gap between a shaft hole and a shaft inserted into the shaft hole, the annular seal member comprises: an annular base part; an annular lip, which includes a lip edge that is configured to be contact with one of a hole face of a shaft hole and an outer periphery of a shaft, the one of which is a seal mating face; a first convex part, a second convex part and a passage recess, which is provided at a face of the base part facing the seal mating face; a concave part, which is formed at a position between the second convex part and the base end portion of the annular lip, and which has a circumferential size larger than a recess width of the passage recess.

Owner:ADVICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com