Patents

Literature

673results about How to "Improve bonding efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

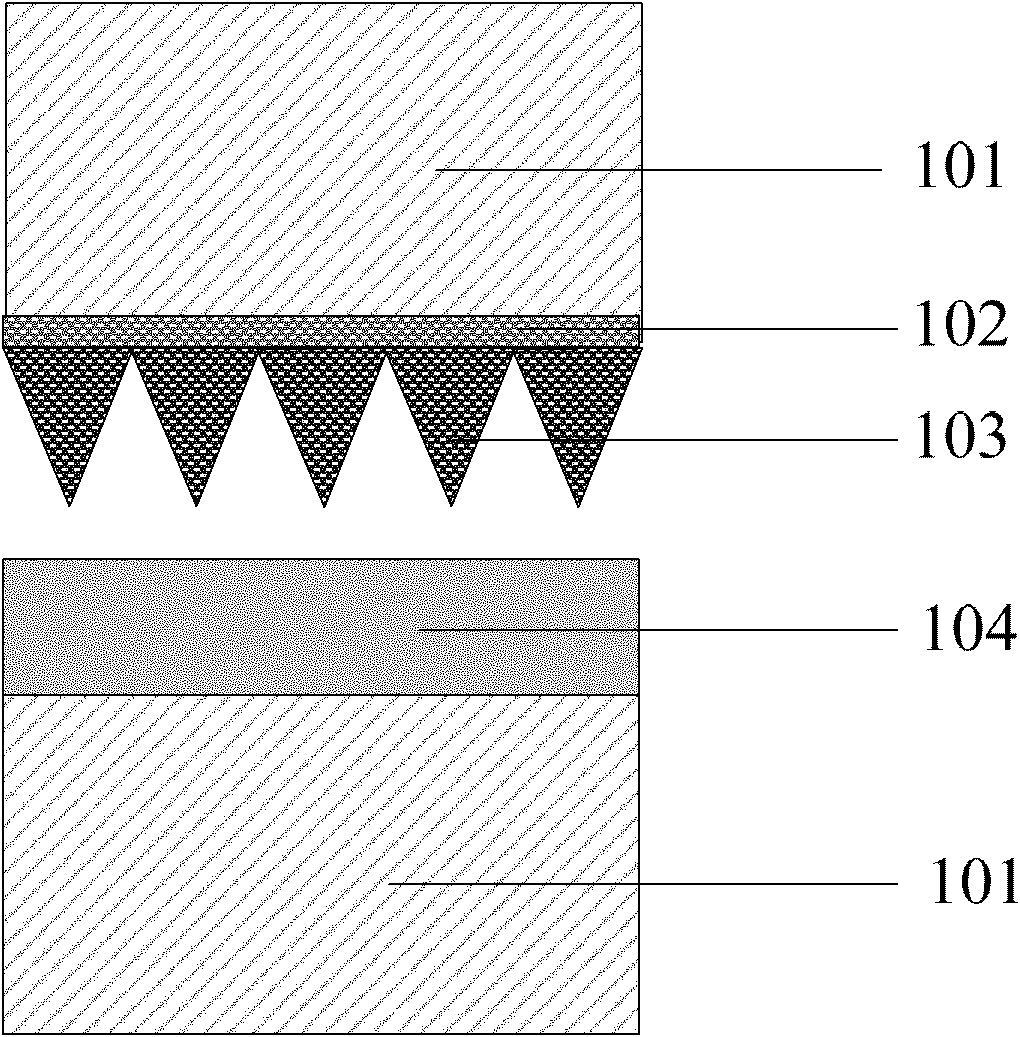

Multi-layer mixed synchronization bonding structure and method for three-dimensional packaging

ActiveCN102169845AGuaranteed accuracy requirementsSave time and costSemiconductor/solid-state device detailsSoldering apparatusDielectricHard metal

The invention relates to a multi-layer mixed synchronization bonding structure and a method for three-dimensional packaging. The method comprises the following steps of: forming a hard metal conical array on a surface of a metallic pad of a substrate to be mixed and bonded; forming a soft metal layer on the surface of the metallic pad of the other substrate to be mixed and bonded; forming dielectric adhesion layers on surfaces of non-metallic pads of the two substrates to be mixed and bonded; aligning the hard metal conical array with the soft metal layer, heating and pressurizing to make thehard metal conical array inserted into the soft metal layer, and combining the dielectric adhesion layers with each other to form a mixed pre-bonding structure; and then heating, forming an intermetallic compound in the hard metal conical array which is inserted into the soft metal layer, and solidifying and combining the dielectric adhesion layers. Compared with the conventional bonding method, the method provided by the invention has the advantages that: yield is high; bonding time is saved; cost is reduced; and the reliability of a product is improved at the same time.

Owner:NAT CENT FOR ADVANCED PACKAGING

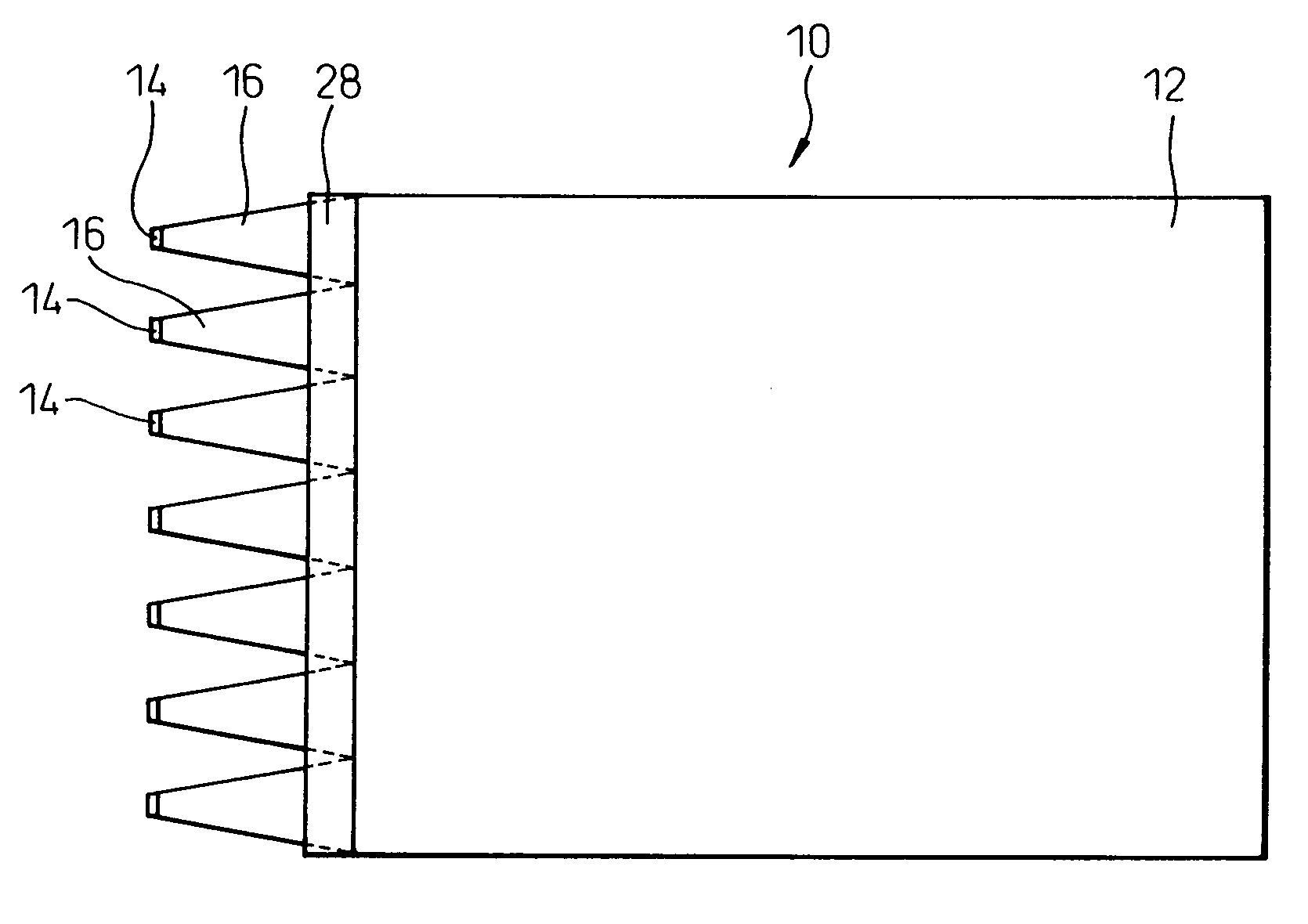

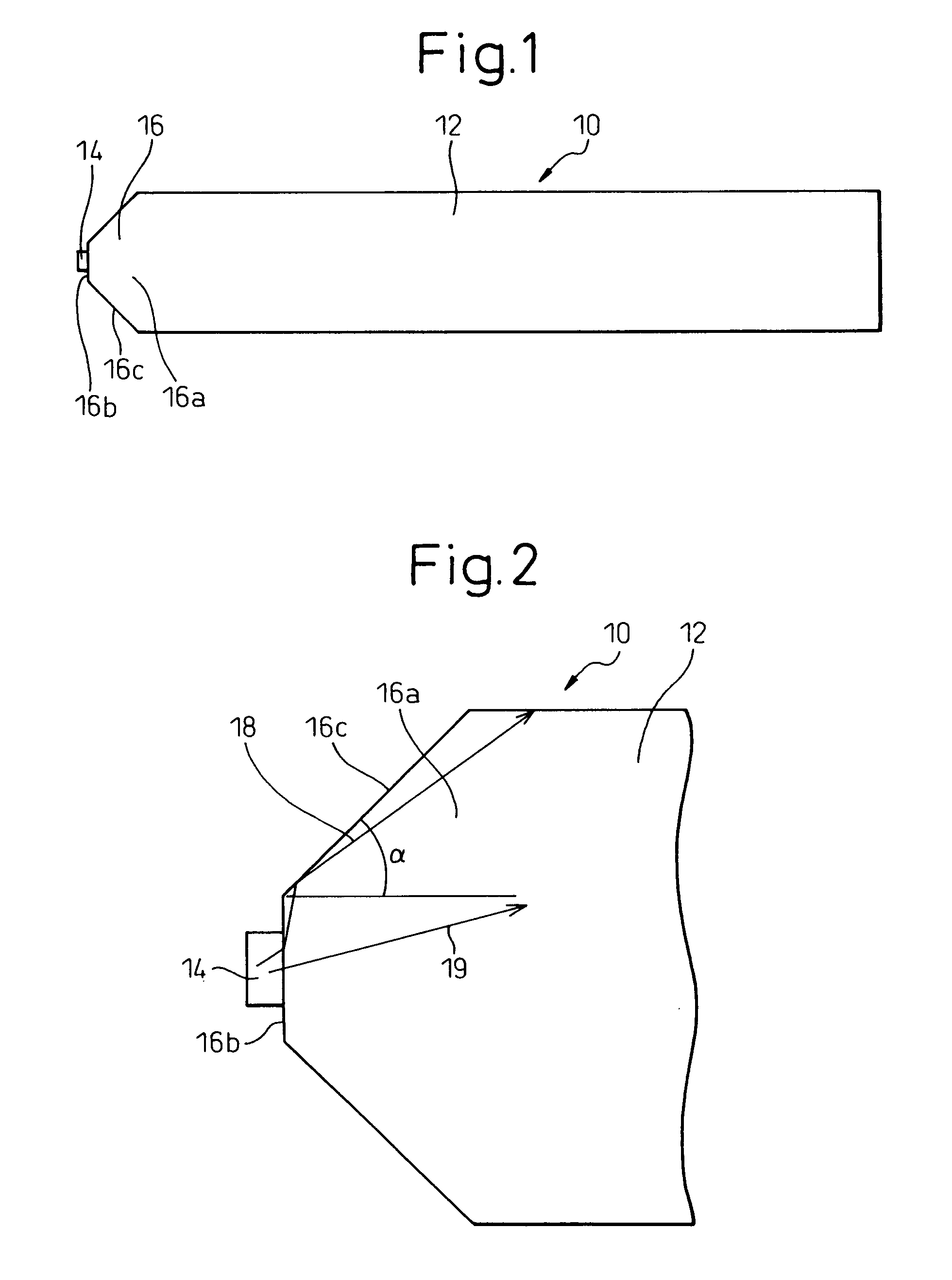

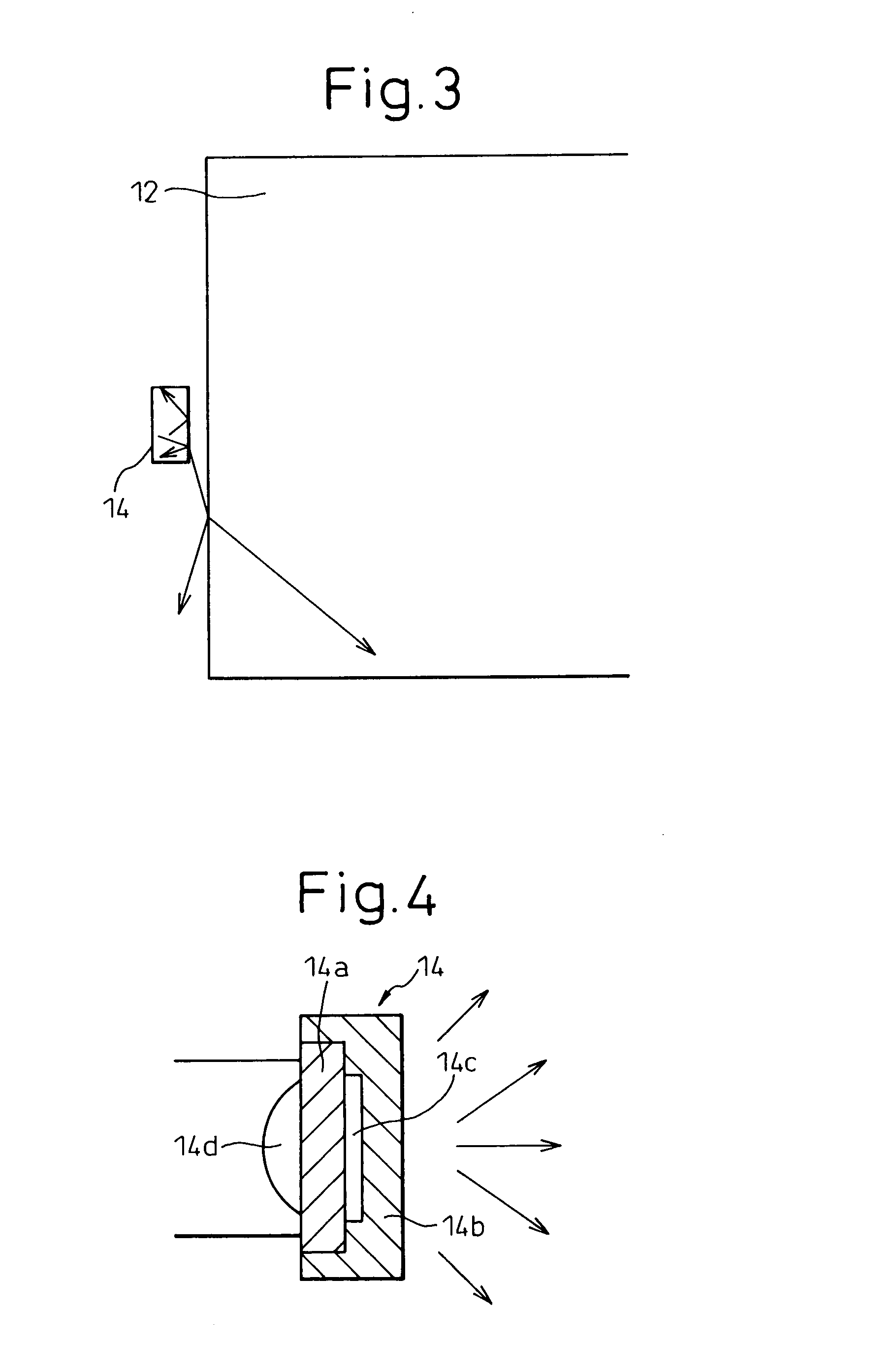

Lighting unit and display device

ActiveUS7163331B2Excellent bonding efficiencyImprove bonding efficiencyShow cabinetsMechanical apparatusLiquid-crystal displayLight guide

A lighting unit and a liquid crystal display device which can improve the efficiency of usable light. The lighting unit includes a light source, a light guide plate, and a truncated pyramid located between the light guide plate and the light source. The truncated pyramid has a base, a top smaller than the base, and a slope linking the base and the top. The light source is placed in close contact with the top of the truncated pyramid, and the light guide plate is placed in close contact with the base of the truncated pyramid. Light is propagated from a light emitting part of the light source to the light guide plate without passing through any air layer. Also, an unnecessary light removing structure is provided in the light guide plate near the incidence surface thereof.

Owner:SHARP KK

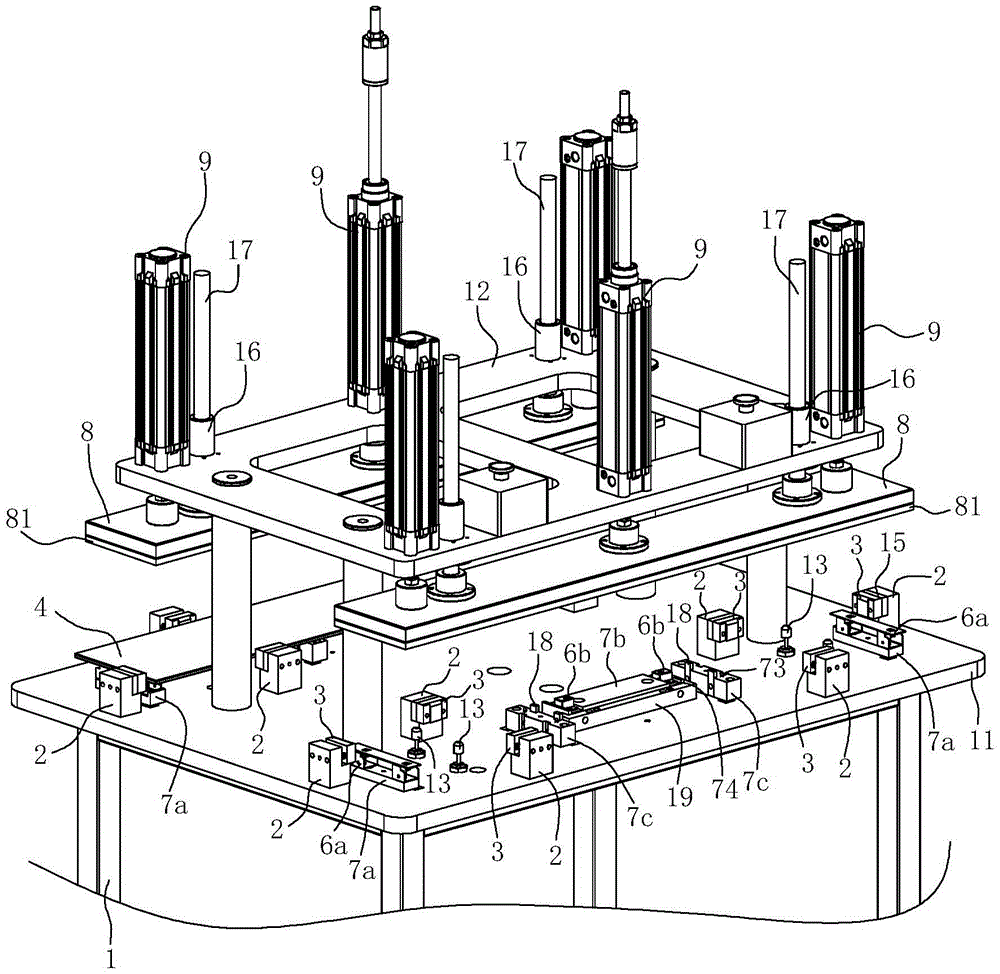

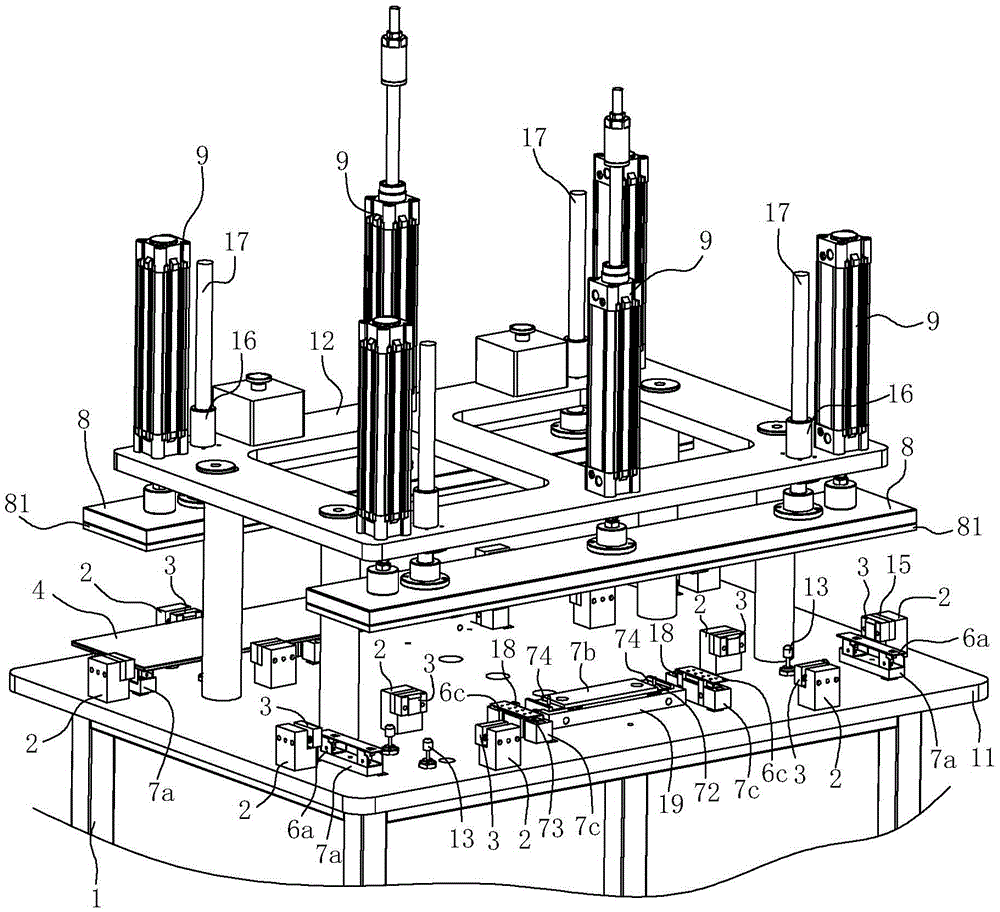

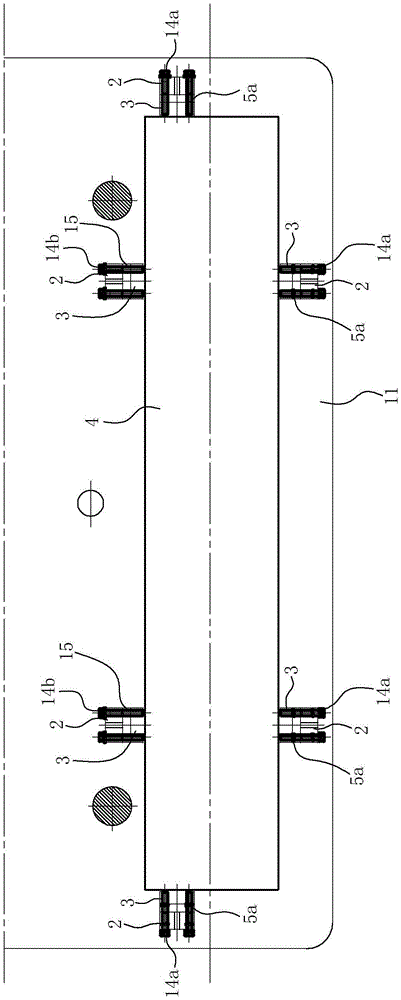

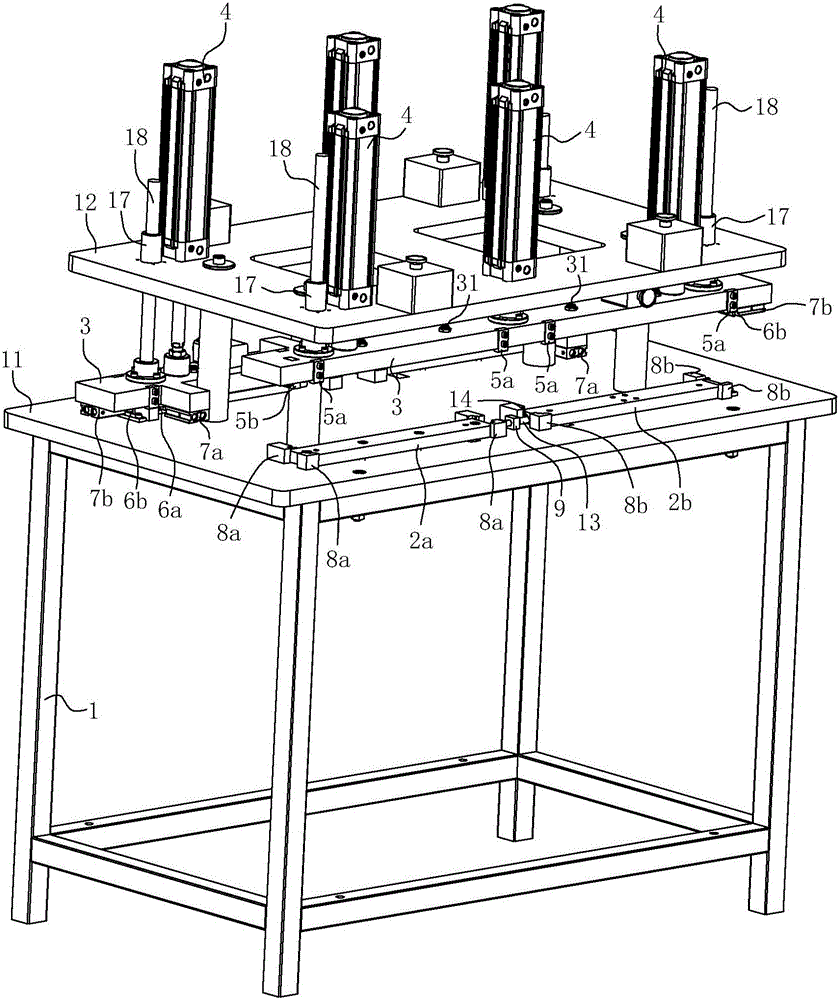

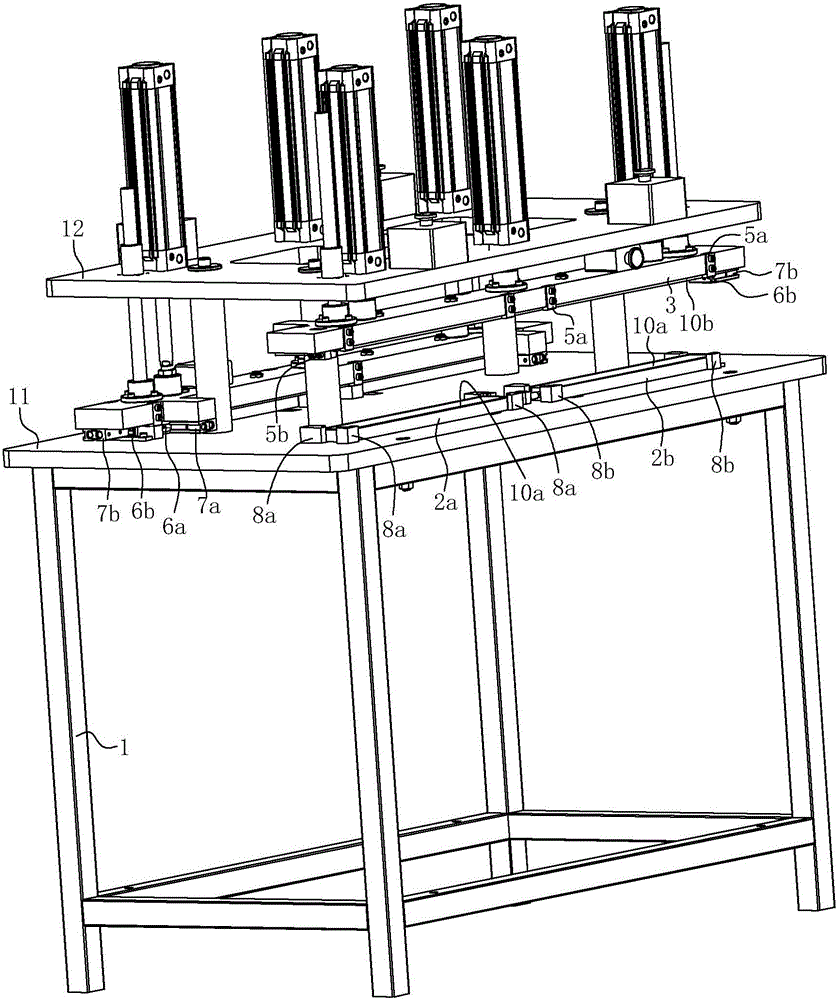

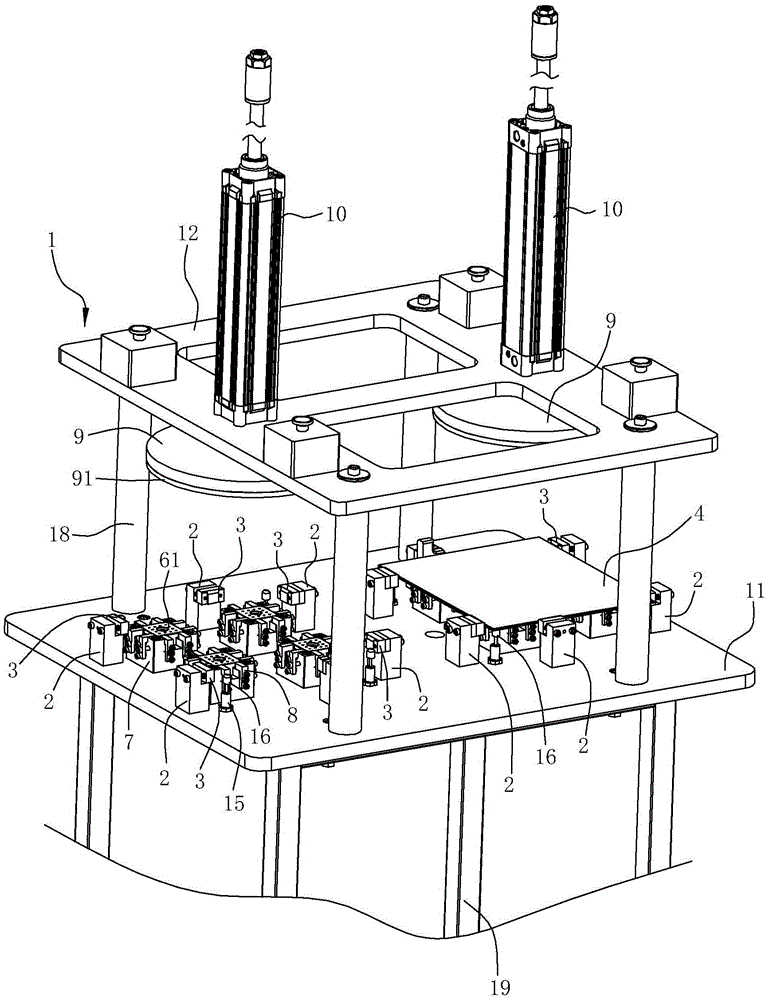

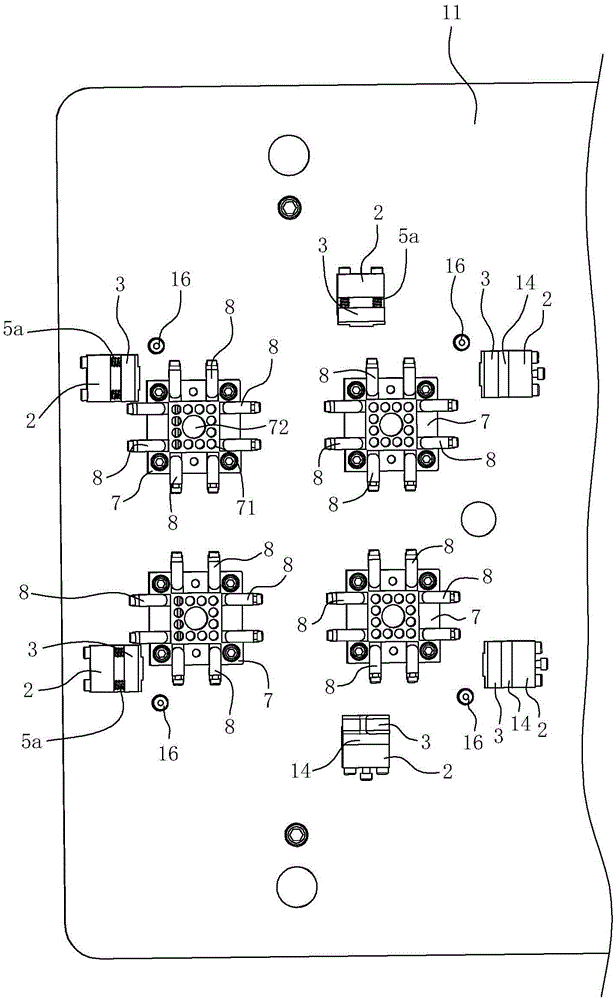

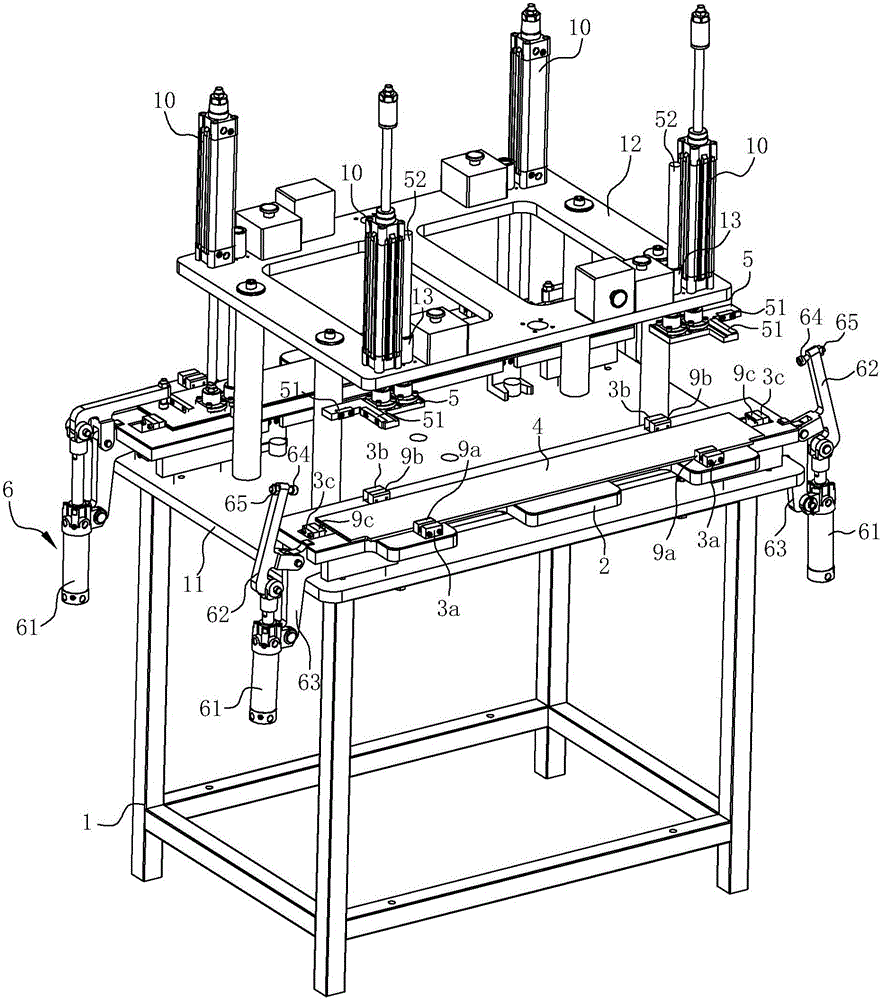

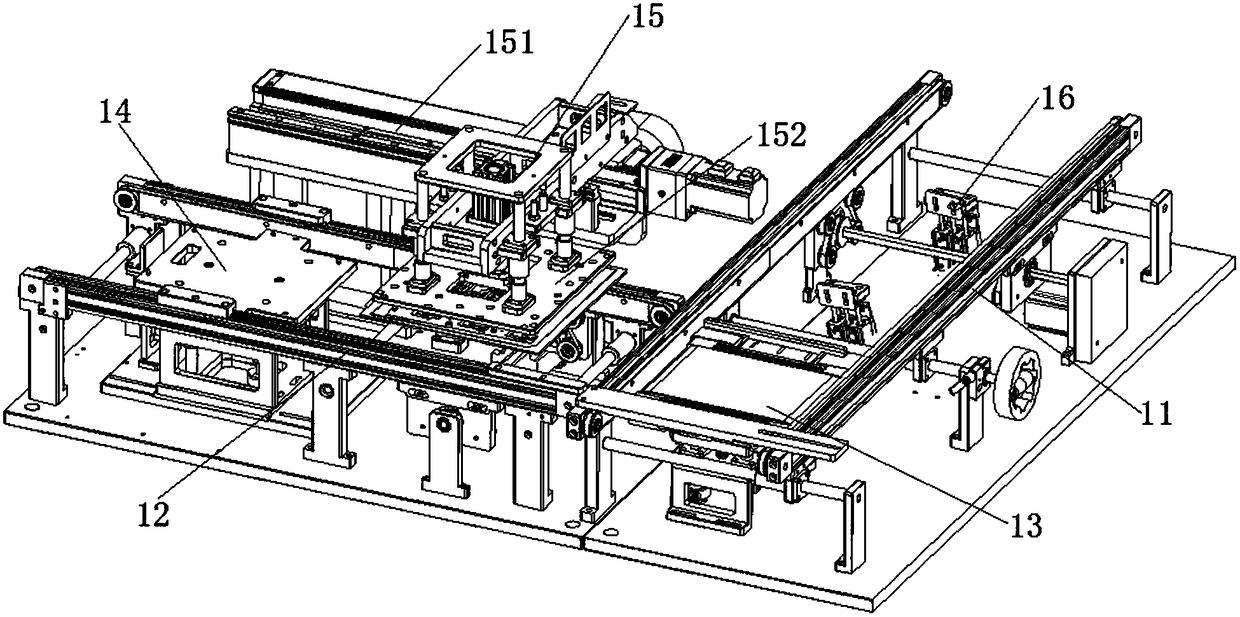

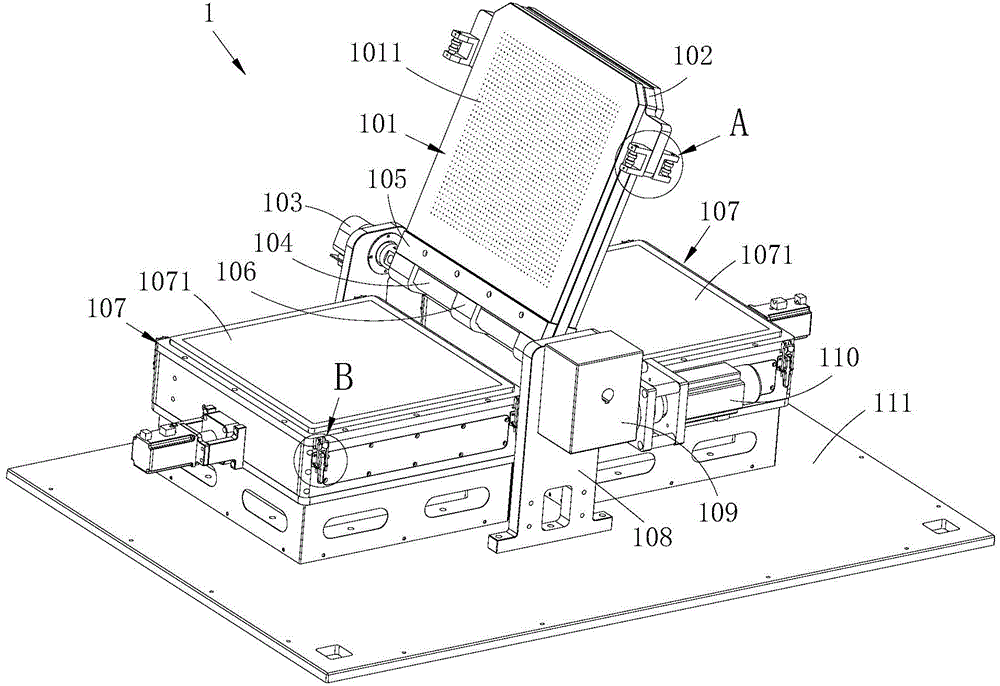

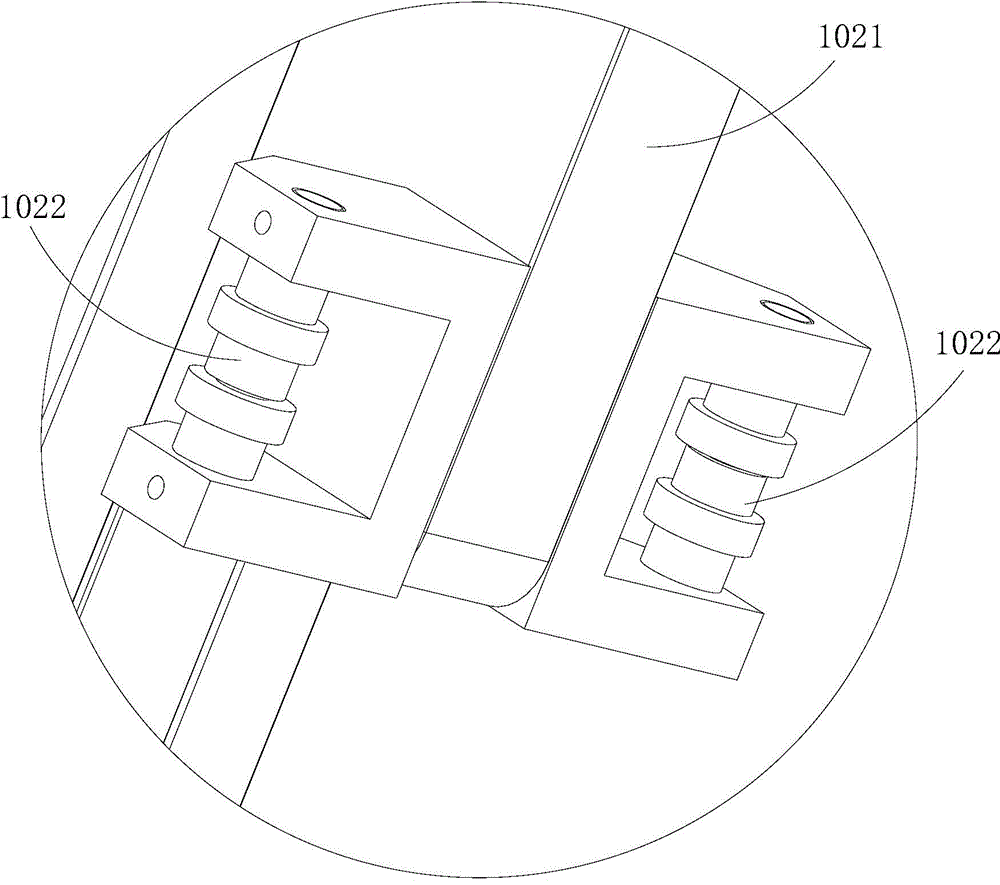

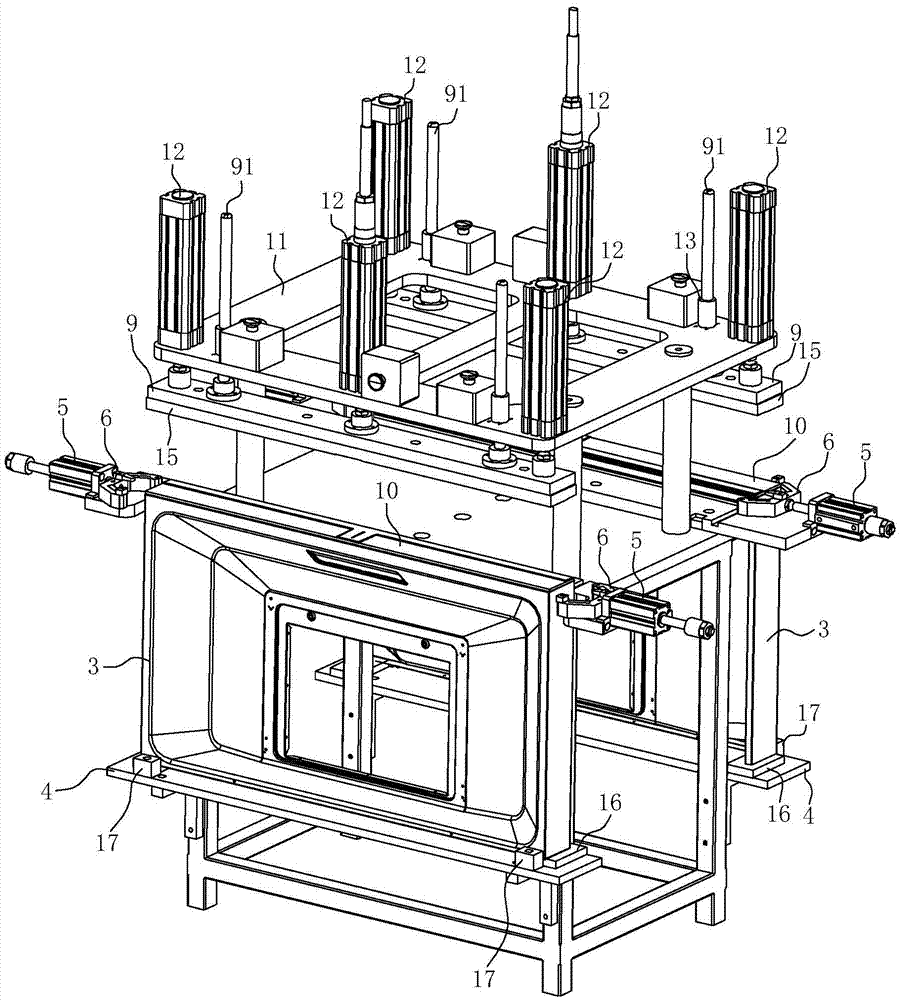

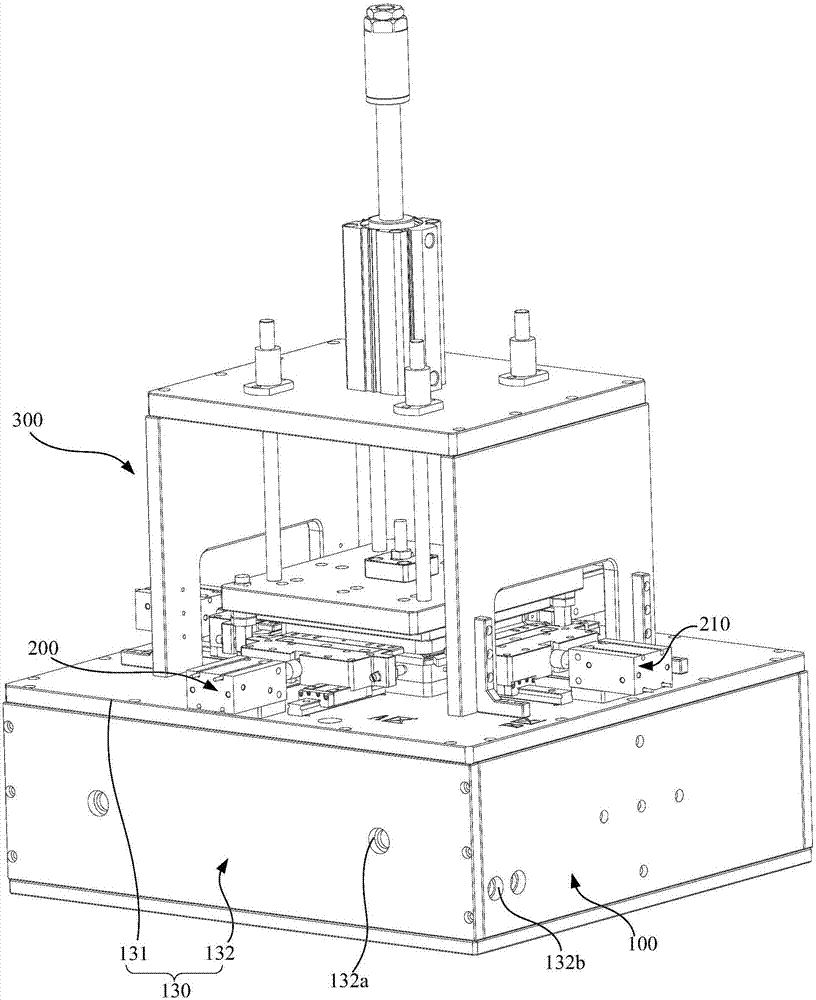

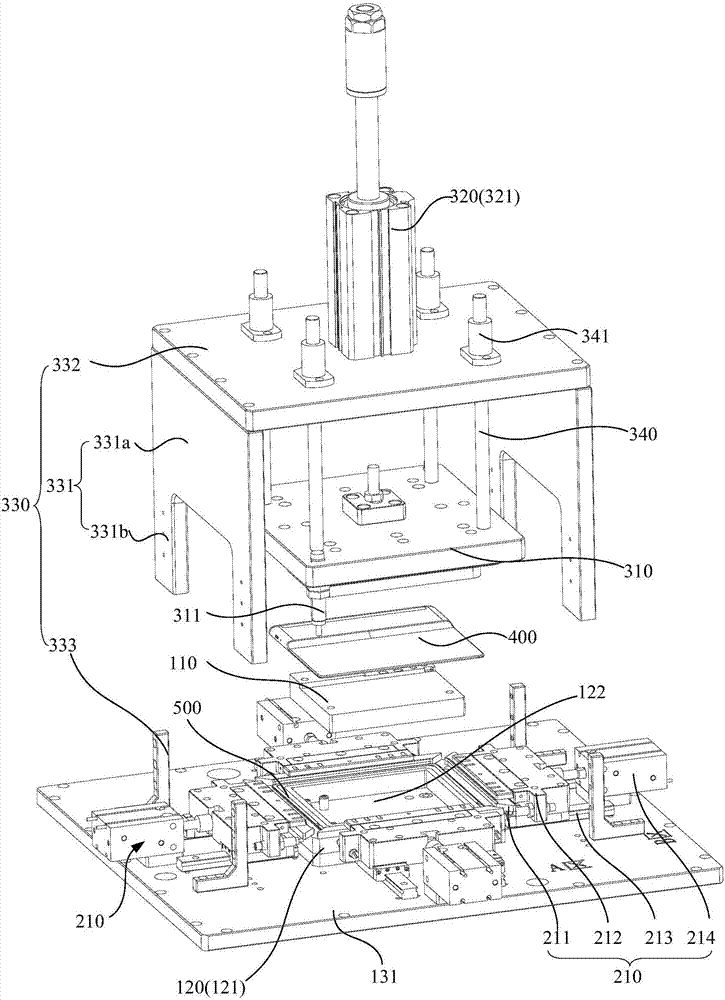

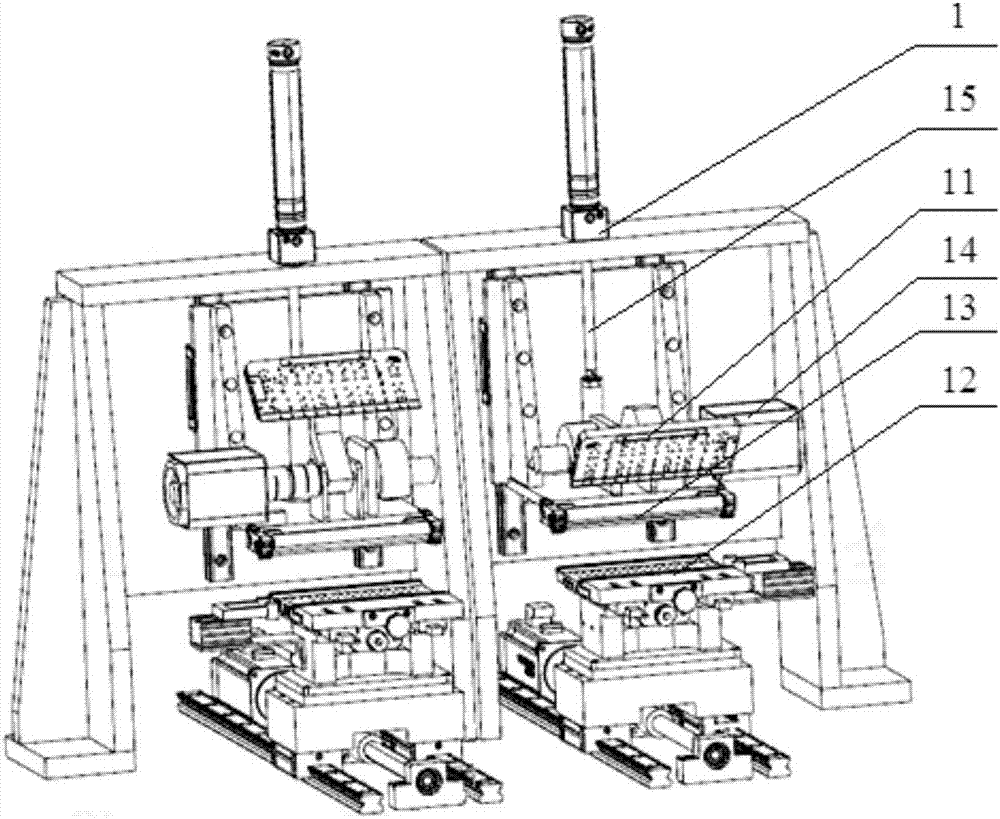

Bonding tool capable of simultaneously bonding various parts onto glass panel

ActiveCN105422567AImprove bonding efficiencyHigh bonding precisionMaterial gluingElectrical junctionEngineering

The invention relates to a bonding tool capable of simultaneously bonding various parts onto a glass panel. The bonding tool comprises a frame body which is provided with a table board and an upper mounting plate, and at least one set of a bonding structure. The bonding tool is characterized in that the bonding structure comprises a peripheral limiting structure for peripherally restraining the glass panel, a first lay-up block which is fixed on the table board for restraining a glass panel bracket, a second lay-up block which is fixed on the table board for restraining a first switch bracket, a third lay-up block which is fixed on the table board for restraining a second switch bracket, and a pressure maintaining block which is arranged above the table board, is driven by a pressure maintaining air cylinder mounted on the upper mounting plate to move up and down vertically, wherein the pressure maintaining block is pressed for pressing the glass panel to the bonding surface of each bracket to carry out pressure maintaining. The tool works once, so that not only can the glass bracket and the switch bracket be bonded onto the glass panel, but also bonding mounting of switch brackets of different models on the glass panel can be adapted, and therefore, the tool has the advantages of high bonding efficiency and high bonding precision, less processes, and convenient operation.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Splicing tool used for splicing decoration panel to glass faceplate

ActiveCN106050853AGood adhesionSolve the problem of bonding misalignmentMaterial gluingSurface plate

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

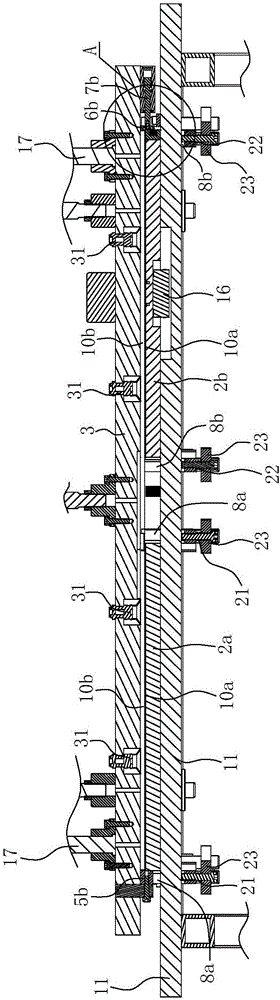

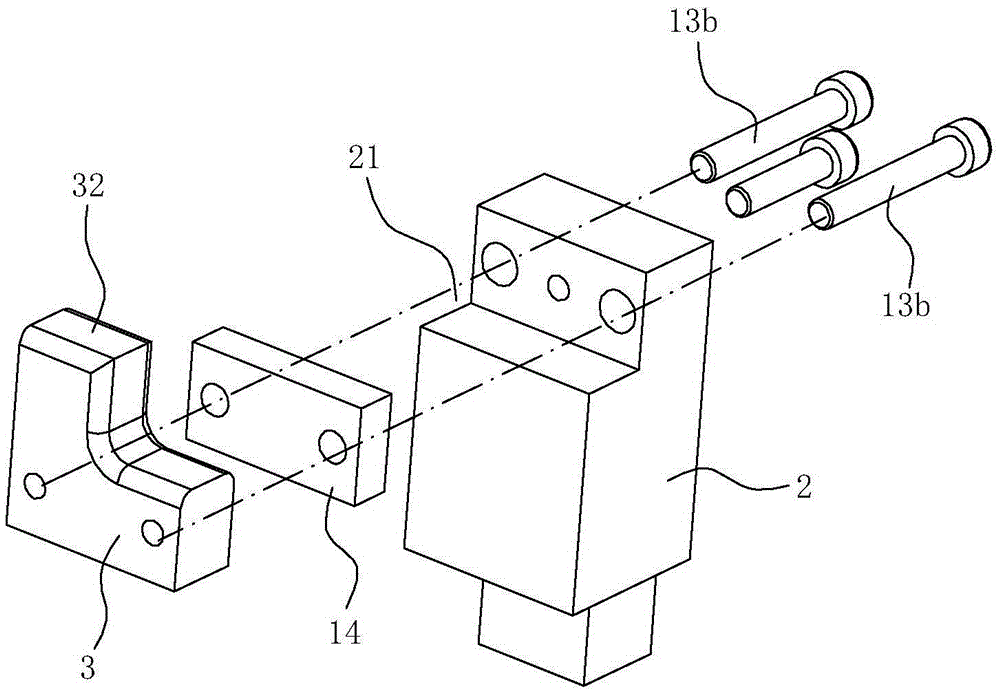

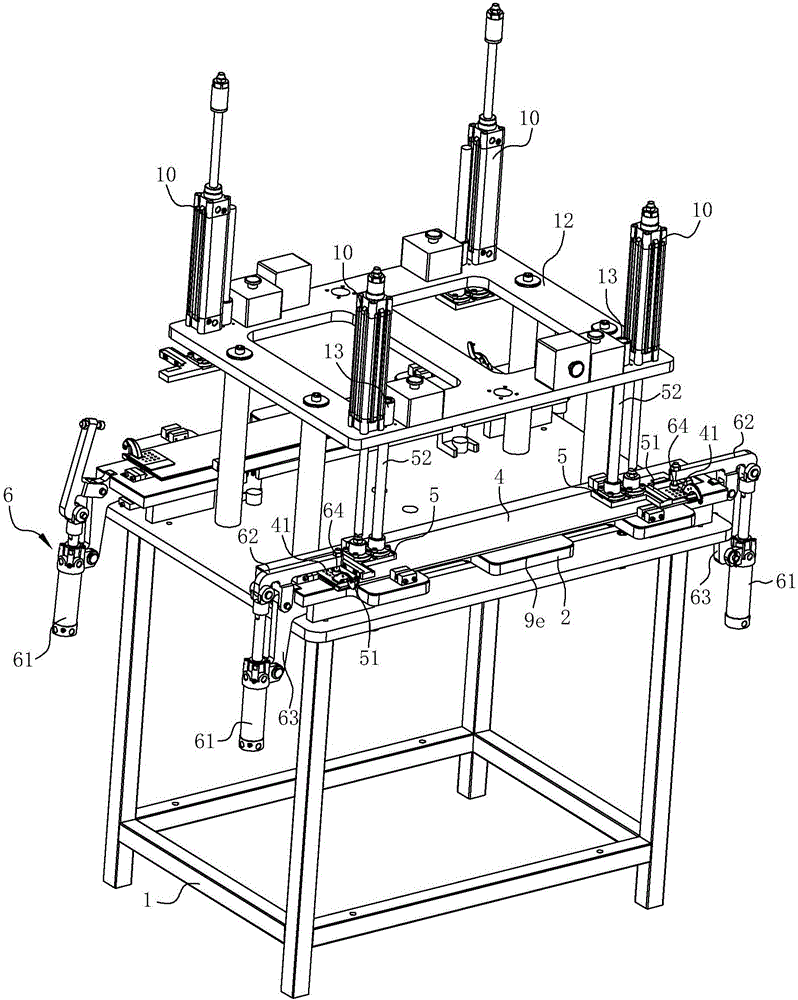

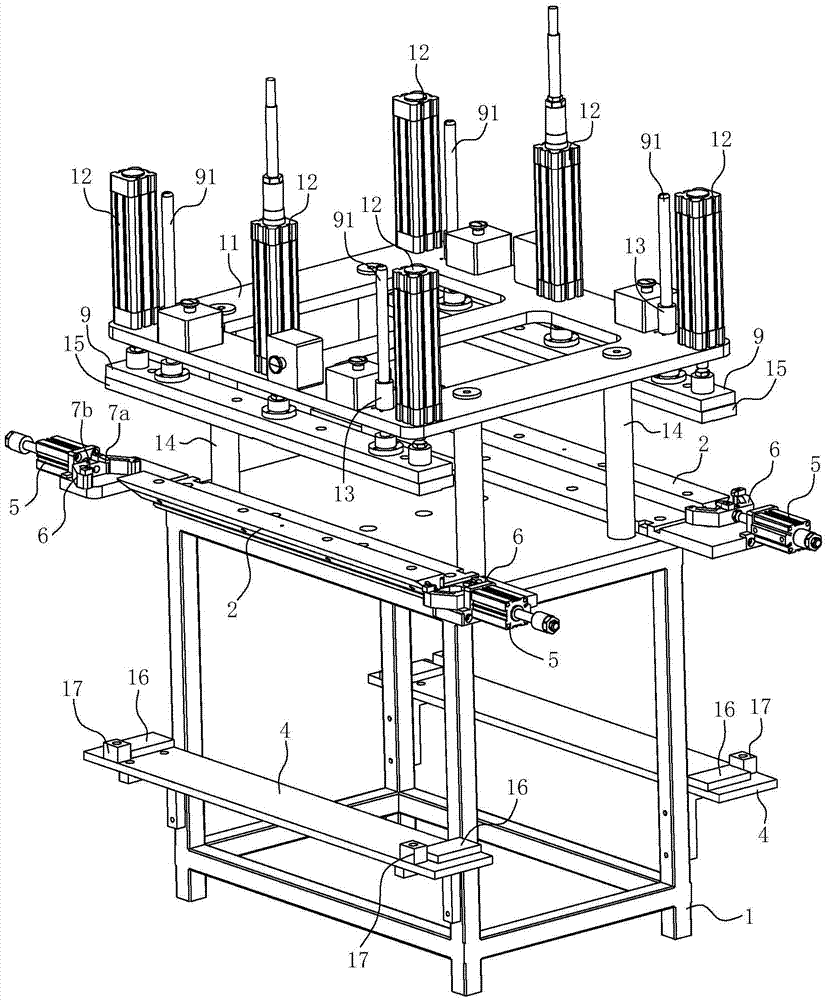

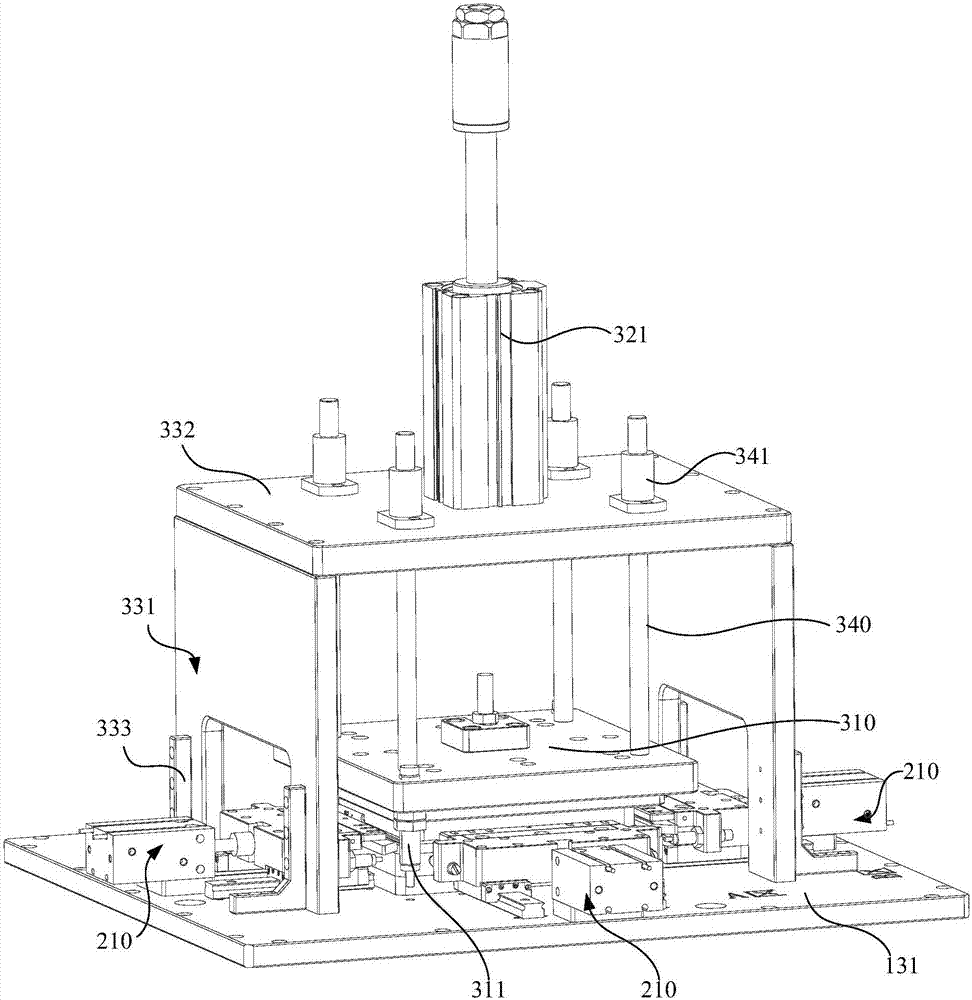

Bonding tool for mounting part on glass assembly and capable of adjusting dimensions in any direction

ActiveCN105538187AHigh bonding precisionHigh bonding efficiency and precisionWork holdersElectrical junctionEngineering

The invention relates to a bonding tool for mounting a part on a glass assembly and capable of adjusting dimensions in any direction. The bonding tool is characterized in that the tool comprises a rack body, glass panel limiting structures, support limiting structures and pressure maintaining blocks; the rack body is provided with a table board and an upper mounting plate; the glass panel limiting structures are used for limiting glass panels; the support limiting structures are used for limiting buckle supports; the pressure maintaining blocks are located above the glass panel limiting structures, and are driven by pressure maintaining cylinders mounted on the upper mounting plate to vertically move up and down; and the down pressing of the pressure maintaining blocks enables the glass panels to be tightly pressed on the bonding faces of the buckle supports to conduct pressure maintaining. In the bonding process, the relative position relation of the buckle supports and the glass panels is kept unchanged through the limiting of the glass panel limiting structures to the glass panels and the restraint of the support limiting structures to the buckle supports, and the bonding precision is high; the pressure maintaining blocks are driven by the action of the pressure maintaining cylinders to press the glass panels to the bonding faces, coated with glue, of the buckle supports and conduct pressure maintaining for a certain time, so that the buckle supports and the glass panels are firmly fixed.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

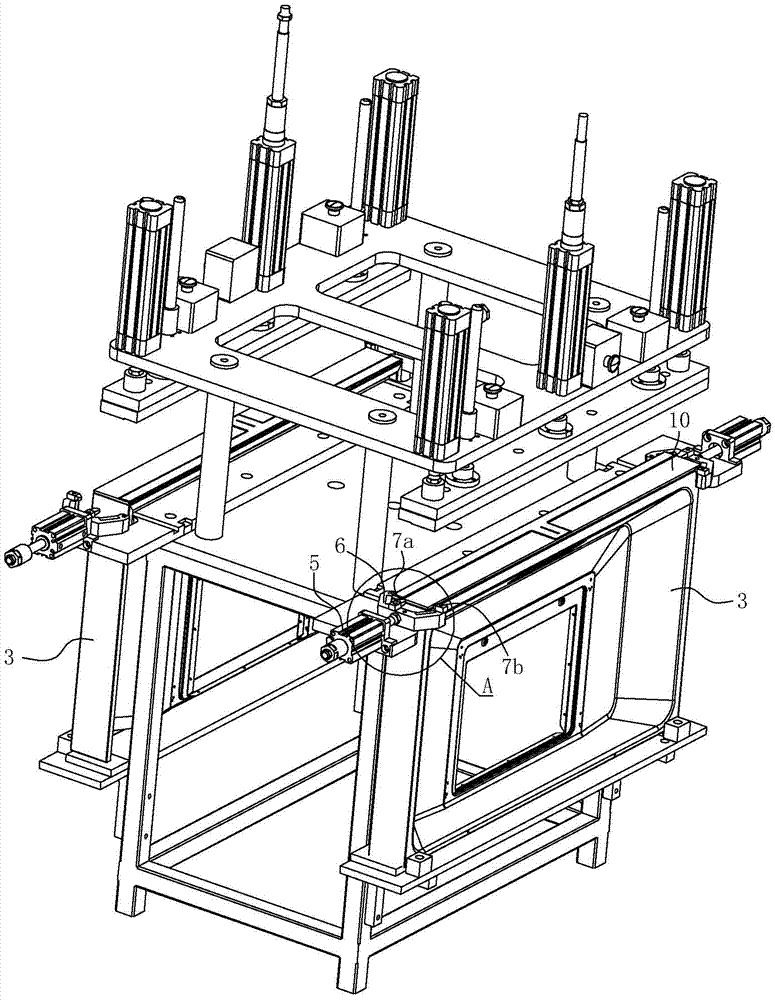

Adhesion clamp for smoke baffle

ActiveCN105818020AEasy to operateGood adhesionMaterial gluingWork holdersMechanical engineeringSmoke

The invention relates to an adhesion clamp for a smoke baffle. The adhesion clamp for the smoke baffle comprises a frame. The frame is provided with a table top, an upper mounting plate and at least one set of adhesion structure. The adhesion clamp for the smoke baffle is characterized in that the adhesion structure comprises a shelf, a circumferential limiting structure, two L-shaped limiting blocks and two pressing mechanisms; the circumferential limiting structure is used for restraining the smoke baffle in the circumferential direction, and comprises a front positioning block, a rear positioning block, a left positioning block and a right positioning block; the front positioning block and the rear positioning block are fixed to the shelf; the left positioning block and the right positioning block are restrained on the shelf and can slide left and right synchronously; the two L-shaped limiting blocks are used for limiting rotary shaft components, and can move vertically under driving of an air cylinder mounted on the upper mounting plate; and the two pressing mechanisms can press the rotary shaft components onto the upper end face of the smoke baffle to maintain the pressure for adhesion. By means of the adhesion clamp, the rotary shaft components can be accurately and firmly mounted onto the smoke baffle, the dimensions of the rotary shaft components at the two ends of the smoke baffle can be accurate, the both sides are balanced in error, and the situation that errors are lumped at one end is avoided.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

FPC flexible printed circuit board automatic processing equipment

PendingCN108323016AImprove feeding effectImprove work efficiencyLaminating printed circuit boardsPunchingAutomatic test equipment

The invention relates to the automation equipment field, and especially relates to FPC flexible printed circuit board automatic processing equipment; a convey structure transports a carrier carrying acircuit board to a first transplant unit; the first transplant unit conveys the circuit board to a punching structure for punching; a second transplant unit conveys the punched circuit board to a positioning feed structure for secondary positioning discharge; a turning structure turns the discharged circuit board; a detection structure detects the turned circuit board to realize precise feeding and blanking; the circuit board is processed by the automatic processing equipment; the positions between the convey structures can be automatically placed; each station can simultaneously realize feeding and blanking functions, thus greatly improving the material piece conveying speed; in addition, instead of using CCD, the automatic processing equipment uses a machinery structure to position, thus improving the positioning efficiency, greatly improving the attaching efficiency, and effectively preventing oxidation influence and non-uniform working strength problems caused by using fingers topaste chips.

Owner:SUZHOU JIERUISI INTELLIGENT TECH CO LTD

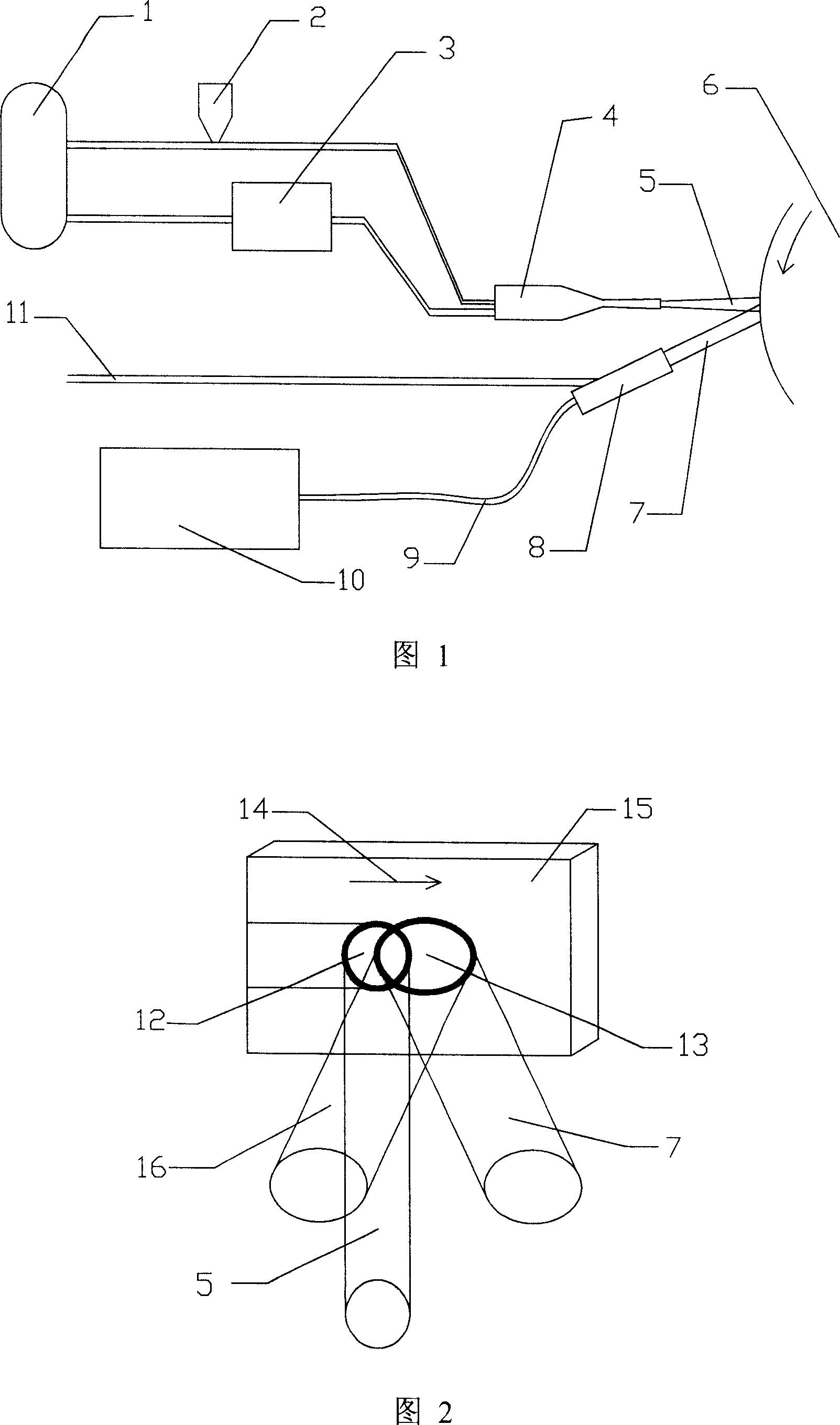

Cold air power spraying and coating method containing laser irradiation

ActiveCN101153393ALow critical speedReduce hardnessHeat inorganic powder coatingOptoelectronicsLaser beams

The invention relates to the cold gas dynamic spray technology and the laser technology, in particular to a cold gas dynamic spray method comprising laser irradiation, wherein, compressed gas which carries with metallic powder impacts against the surface of a plaque at supersonic speed to form a circular spray spot on the surface of the plaque; meanwhile, an elliptic irradiation laser speckle is formed directly ahead of the circular spray spot through laser beam irradiation; moreover, the elliptic irradiation laser speckle and the circular spray spot are partly overlapped. The invention can substantially reduce the particle critical speed during cold gas dynamic spray and increases splicing efficiency and strength to ensure structural stability of spray particles, thereby improving coating performance.

Owner:BAOSHAN IRON & STEEL CO LTD

Spray coating apparatus and spray coating method

InactiveUS20050181142A1Convenient coatingAdhesion efficiency is reducedSpraying power supplySpray nozzlesSpray nozzleSpray coating

By forming an air flow in which a quantity and a blowoff angle of the air supplied toward an atomized spray paint flow don't influence a coating pattern, there are provided a coating apparatus and a coating method, each of which does not disturb the coating pattern, does not require conditions such as wind speed and temperature of a conventional coating booth, and can perform remarkable reduction in an air conditioning energy of the coating booth, prevention of scatter of a paint, and an improvement in a paint adhesion efficiency. In a spray coating apparatus which possesses a casing and an injection nozzle provided in a tip side of the casing and which forms a coating pattern by injecting paint and shaping air from the injection nozzle to thereby form a coating film on a coated object, a first adapter which blows off the air in an injection direction of the injection nozzle is provided on an substantially concentric circle of the injection nozzle, and the first adapter covers, by blowing off the introduced air while giving it a blowoff angle slanting toward a circumferential direction, an outer periphery of the coating pattern near the injection nozzle with the air.

Owner:NIPPON PAINT CO LTD +1

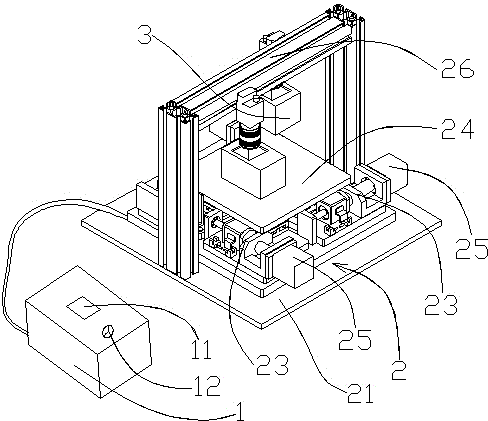

Multipurpose attaching machine for 3D glass curved screens

The invention discloses a multipurpose attaching machine for 3D glass curved screens. The multipurpose attaching machine comprises a rack, and two vacuum cavities, a vacuumizing mechanism, a glass conveying mechanism and two turning mechanisms are arranged in the rack; the vacuum cavities are used for containing Film protection films, and each vacuum cavity comprises a Film protection film positioning mechanism and a Film protection film fine tuning mechanism; the vacuumizing mechanism is used for vacuumizing the vacuum cavities; the glass conveying mechanism is used for automatically conveying 3D glass, and CCD vision inspection units matched with the Film protection film fine tuning mechanisms are arranged at the bottom of the glass conveying mechanism; the turning mechanisms are used for positioning and turning the glass, and each turning mechanism comprises a cavity cover plate, a glass positioning fixture, a pneumatic clamping mechanism and a rotating shaft; after the 3D glass is manually placed in the glass positioning fixtures in parallel to be clamped, driving mechanisms drive the 3D glass to turn along with the cavity cover plates to the position over the Film protection films to complete attaching of the glass and the Film protection films. The multipurpose attaching machine for the 3D glass curved screens has the advantages of being in precise in glass positioning and Film protection film positioning, good in cavity sealing and vacuumizing effect, high in attaching efficiency, good in attaching effect and the like.

Owner:HUIZHOU LONGHAI TECH

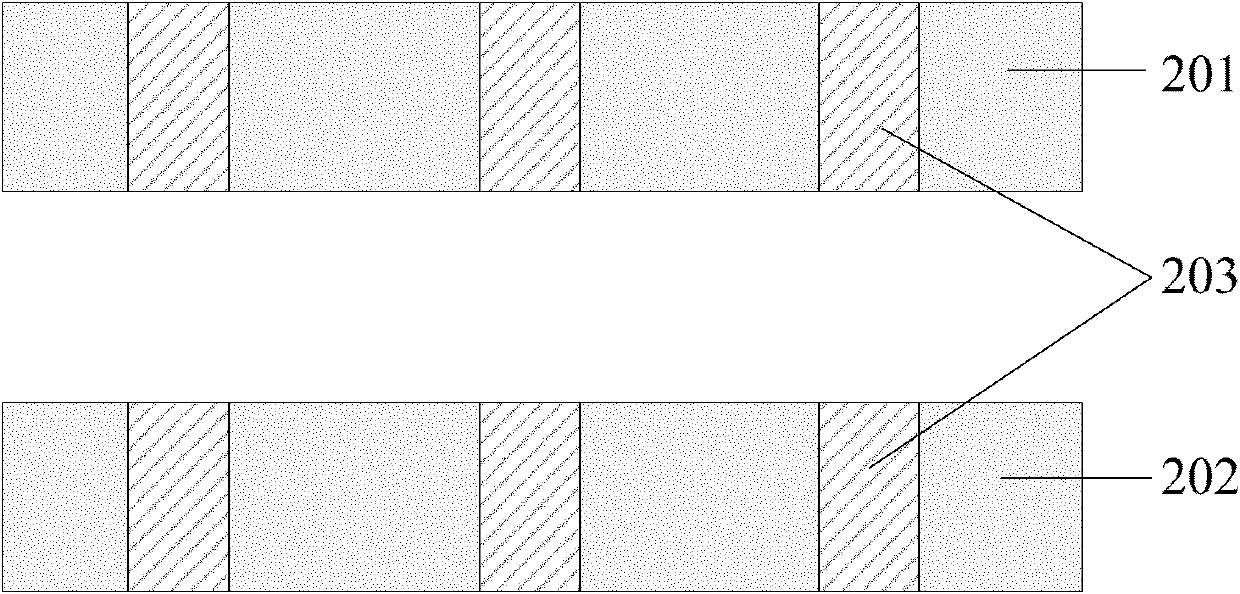

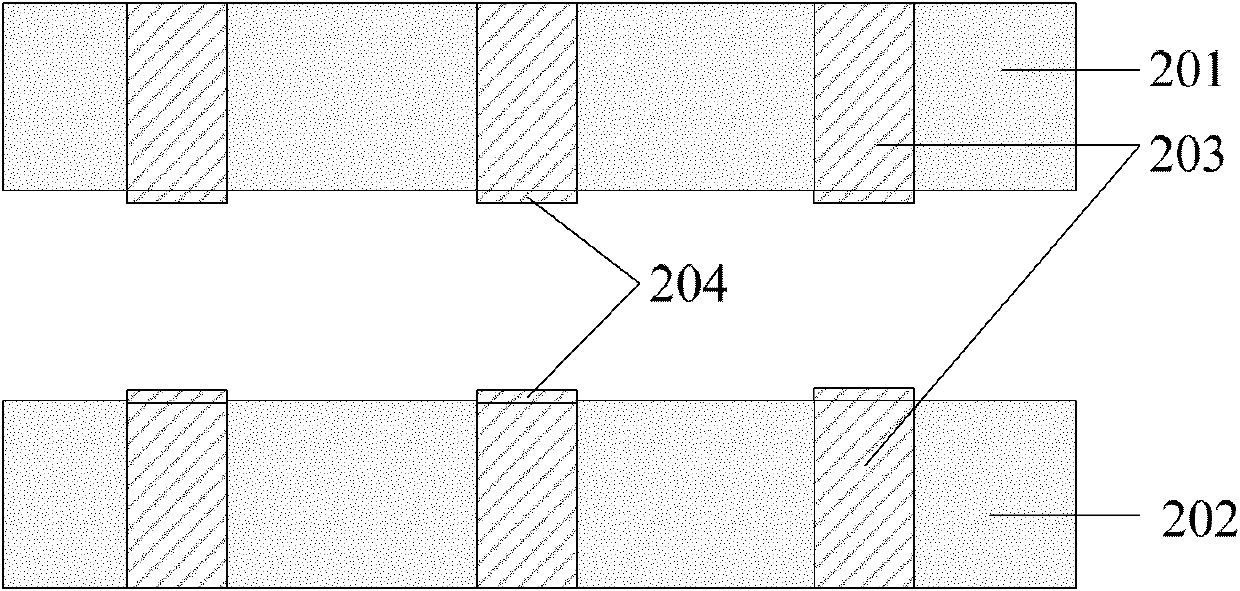

Metal bonding method of three-dimensional chip structure and bonding structure

ActiveCN103107128AStop the spreadImprove bonding qualitySemiconductor/solid-state device detailsSolid-state devicesBond qualityThin layer

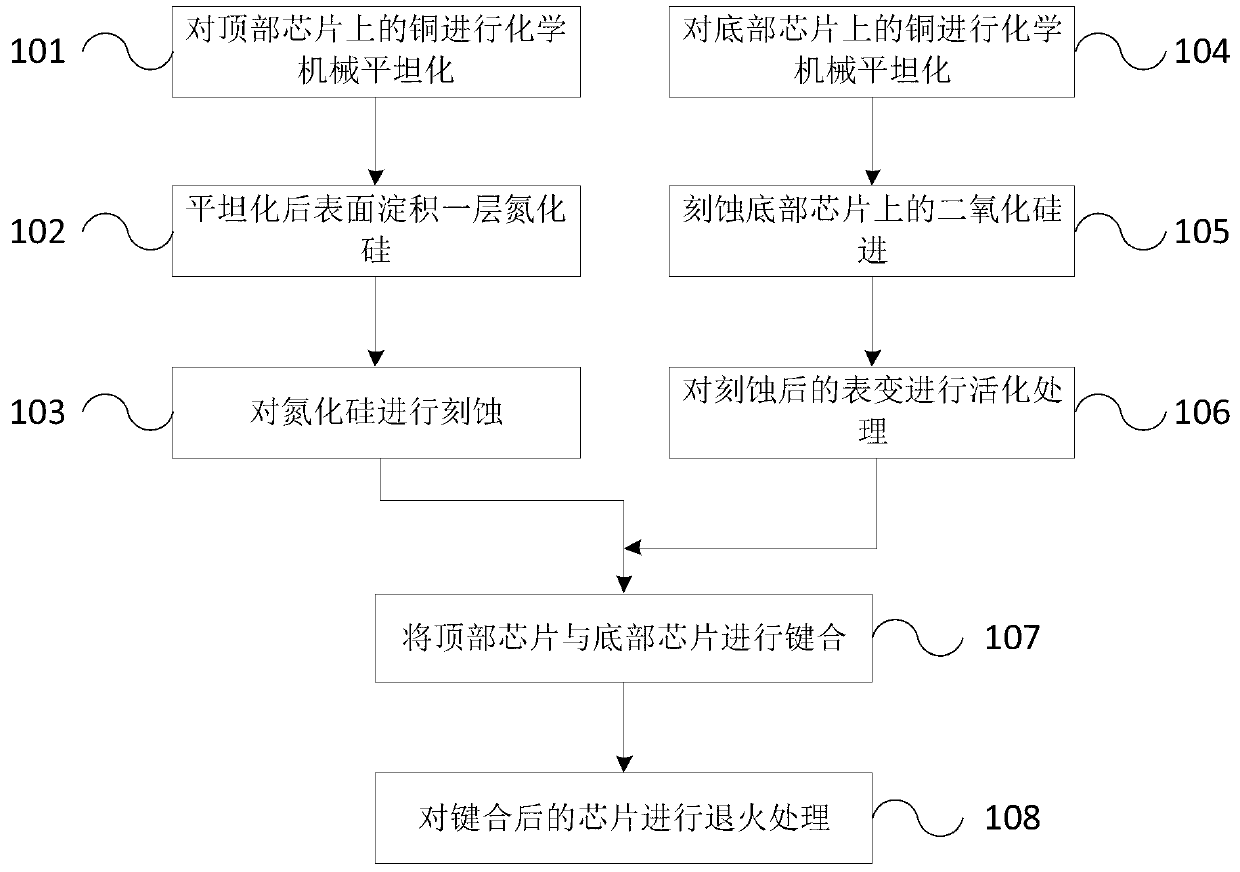

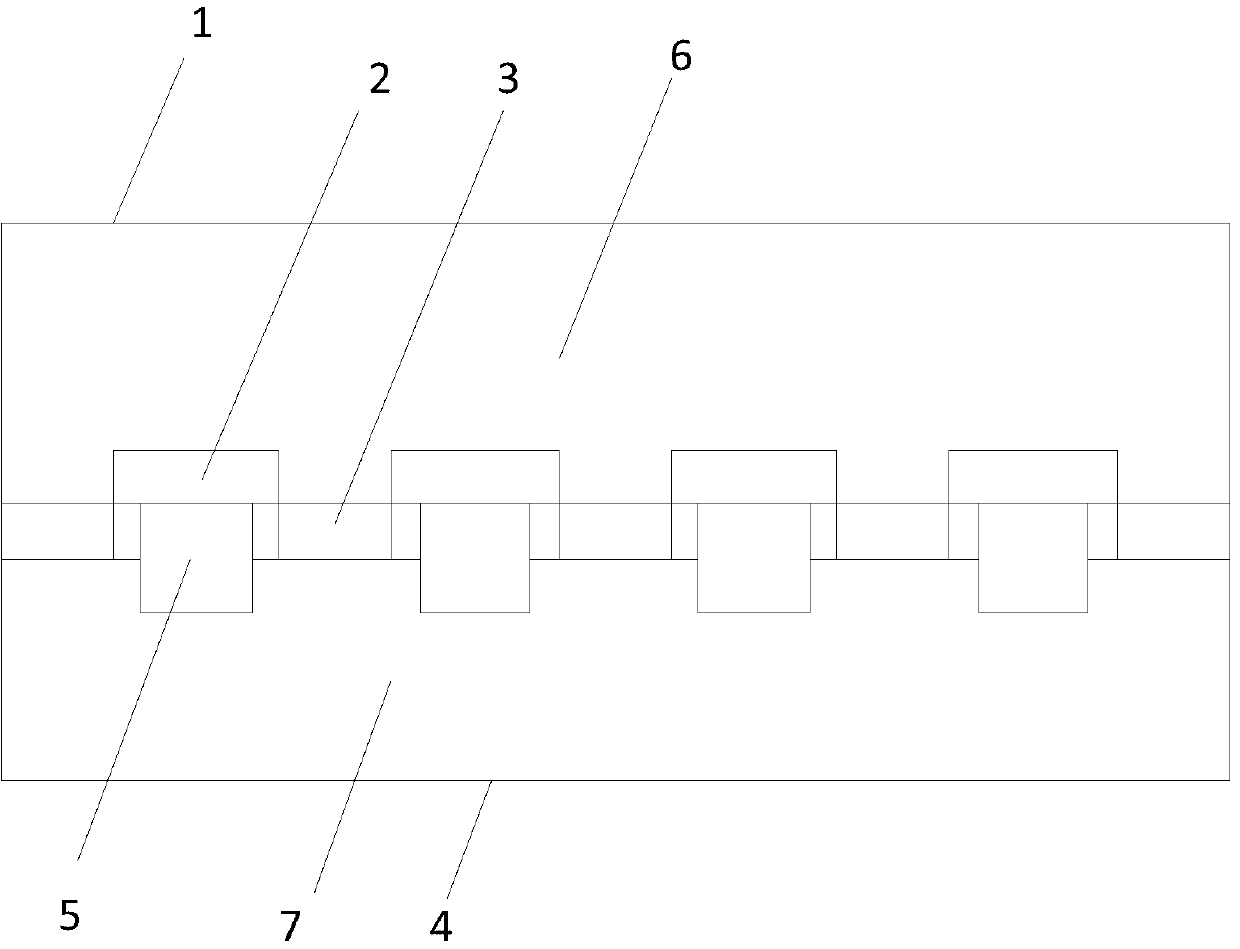

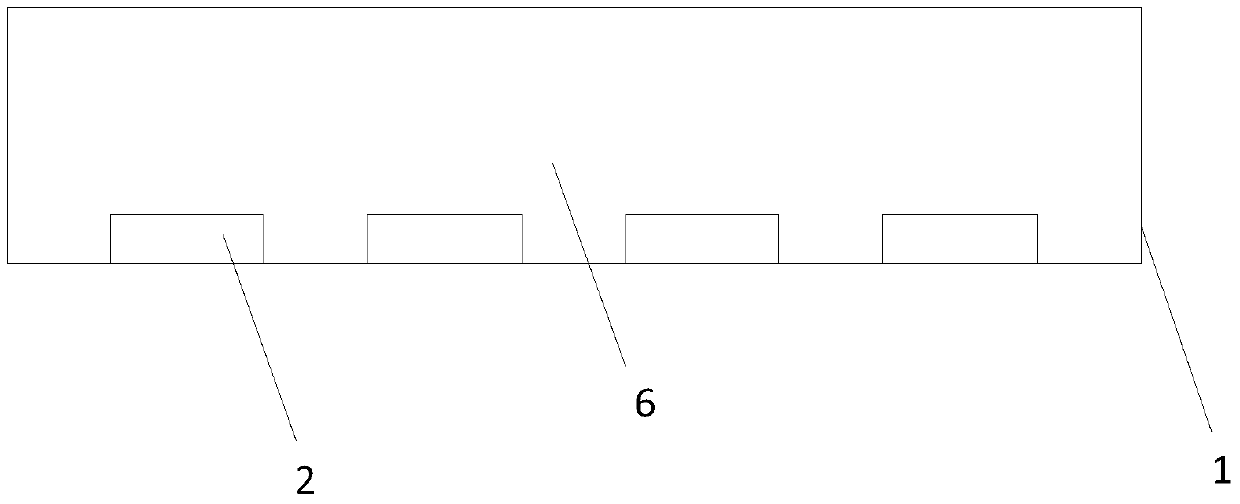

The invention relates to the field of semiconductor fabrication, in particular to a metal bonding method of a three-dimensional chip structure and a bonding structure. The method comprises that copper of a top chip is processed in a chemical machinery planarization mode, a silicon nitride layer is deposited on the surface after being processed in a chemical machinery planarization mode, the silicon nitride layer attached to the copper of the top chip is etched, a groove is formed, the bottom of the groove is the copper of the top chip, copper of a bottom chip is processed in a chemical machinery planarization mode, a bottom silica layer is etched, the copper is enabled to be protruded, activating treatment is carried out to the surface after etch of the copper of the bottom chip is achieved, the copper of the top chip and the copper of the bottom chip are aligned and bonded, and annealing treatment is carried out to the chips after being bonded. According to the metal bonding method of the three-dimensional chip structure and the bonding structure, silicon oxide and silicon nitride are used for being matched with metal and metal bonding, bonding quality is enabled to be better, a silicon nitride layer thin layer can prevent the metal from diffusing into around materials, and goals that a technology process is simplified, temperature needed by bonding is reduced, bonding reliability is improved, bonding efficiency is improved, and bonding cost is reduced can be achieved.

Owner:WUHAN XINXIN SEMICON MFG CO LTD

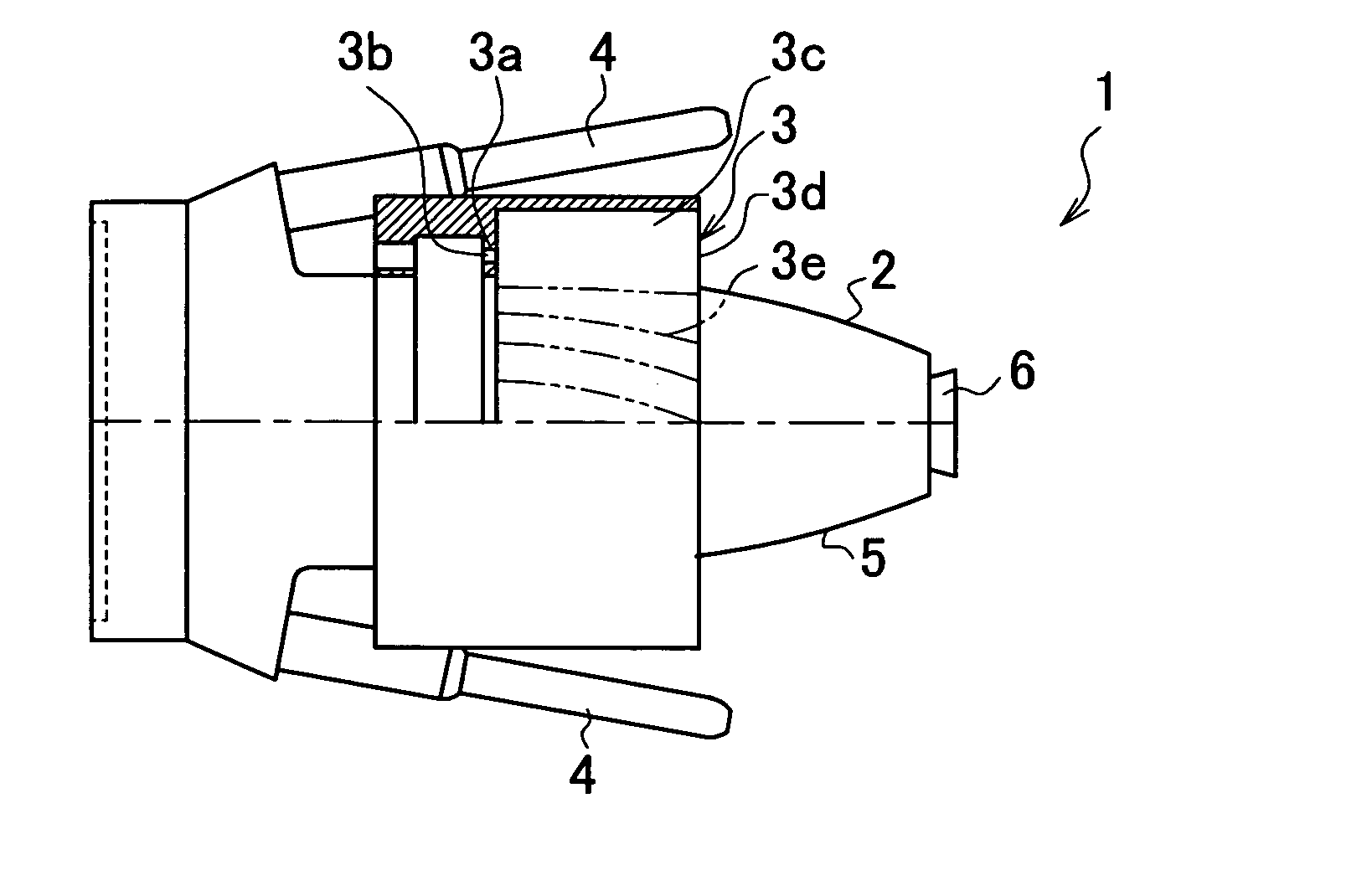

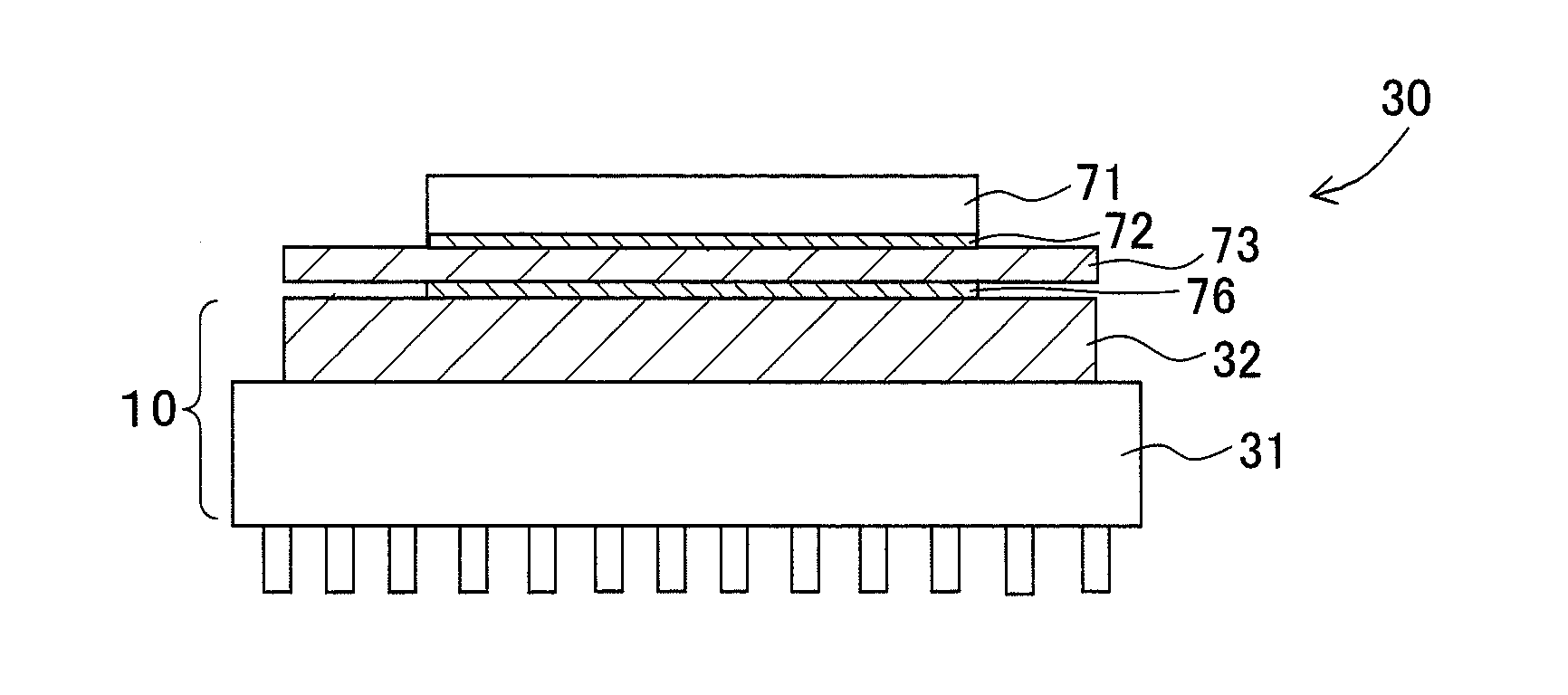

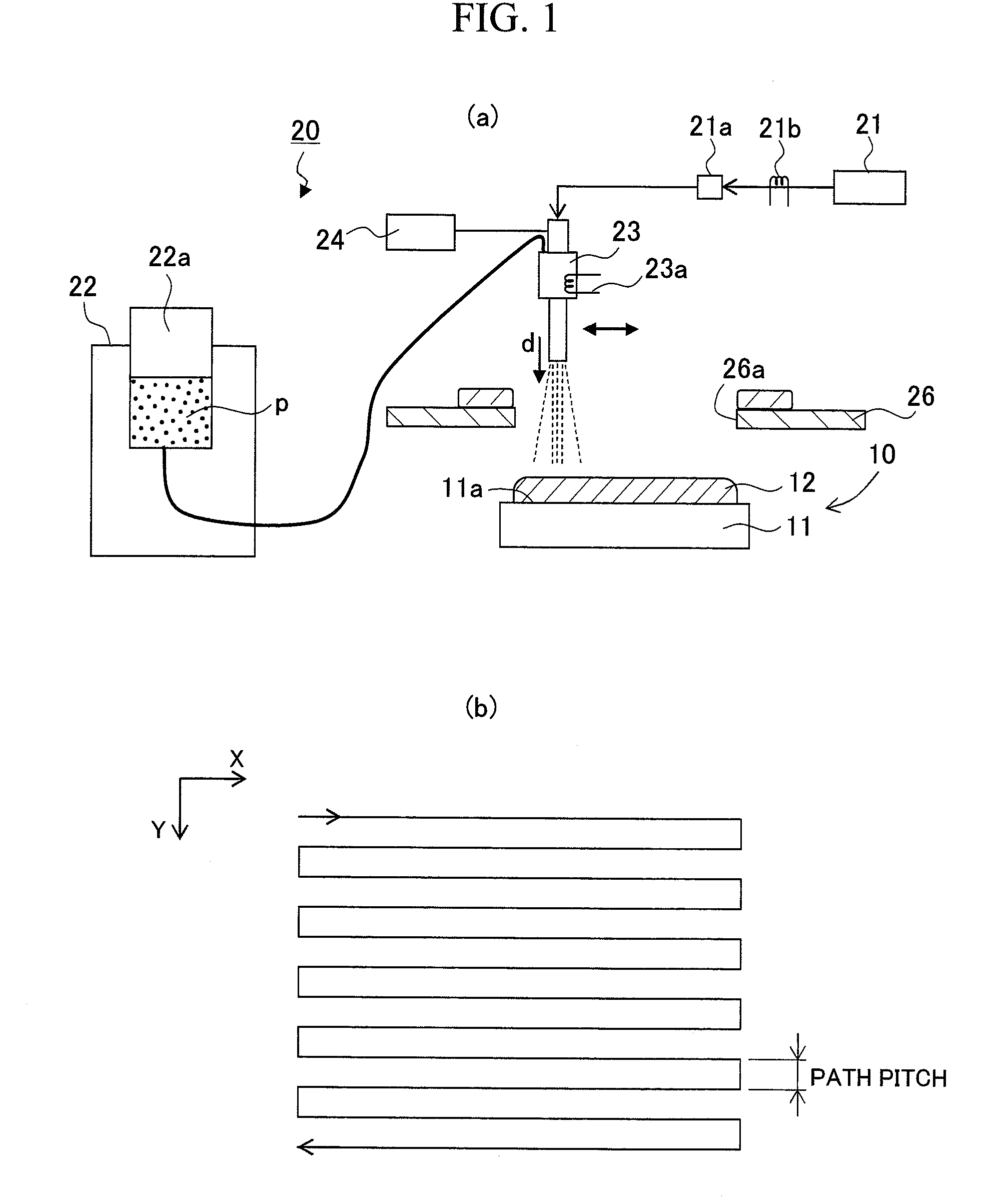

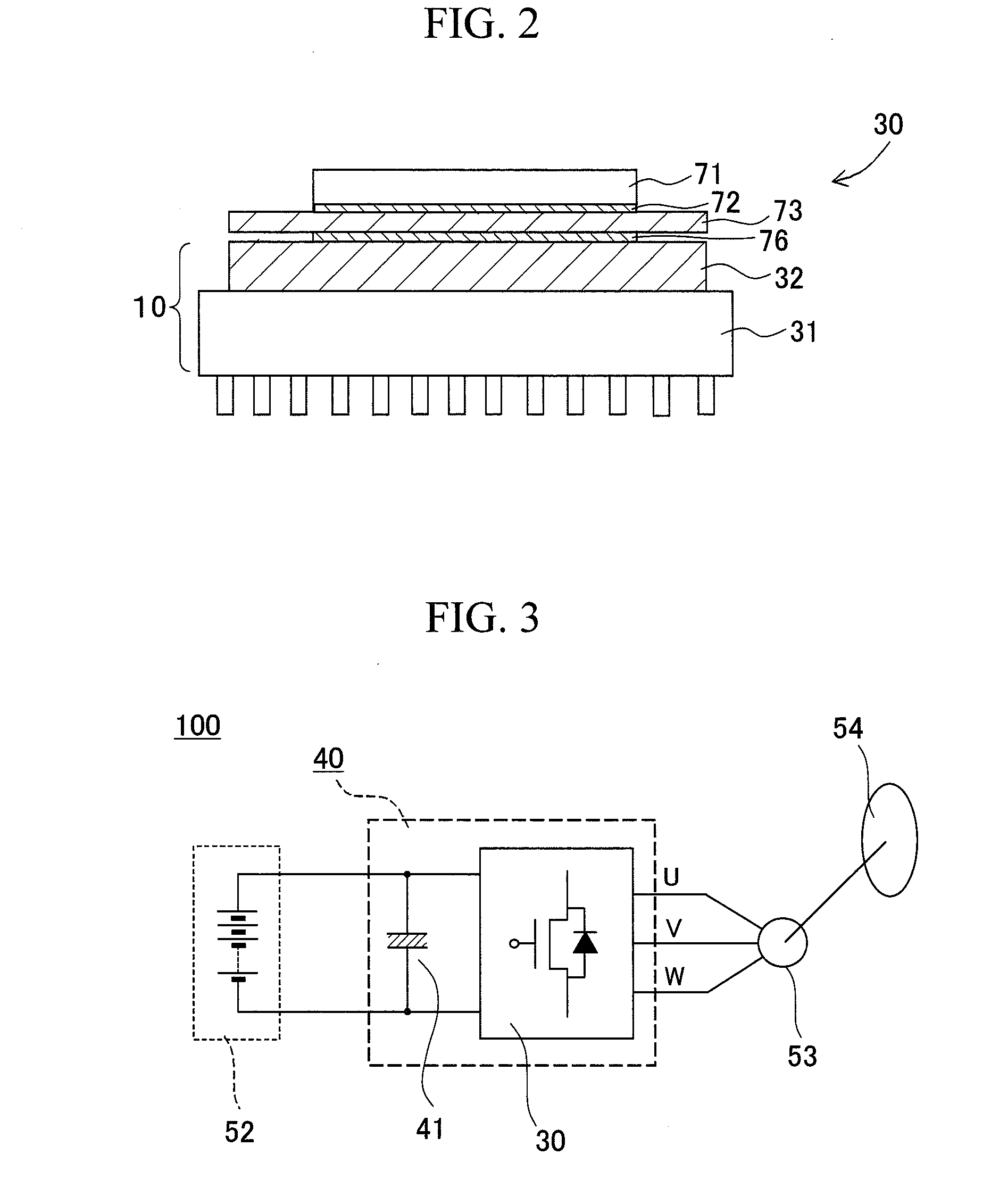

Film forming method, thermal conduction member, power module, vehicle inverter, and vehicle

ActiveUS20100073883A1Improve bonding efficiencyAdhesion efficiency is lowLayered productsSemiconductor/solid-state device detailsSolid phasesApparent density

There is provided a film forming method capable of enhancing adhesion efficiency of a metal powder by use of a low-pressure compressed gas even in the case of spraying the metal powder remaining in a solid-phase state to a substrate, to form a film, the method being a film forming method of spraying a metal powder p in a solid-phase state to a surface 11a of a substrate 11 along with a compressed gas, to form a film 12 of the metal powder p on the surface 11a of the substrate 11, wherein a powder, which at least contains a powder for film formation having an apparent density of 1.4 to 2.0 g / cm3 and an average grain size of not larger than 25 μm, is used as the metal powder p.

Owner:TOYOTA JIDOSHA KK

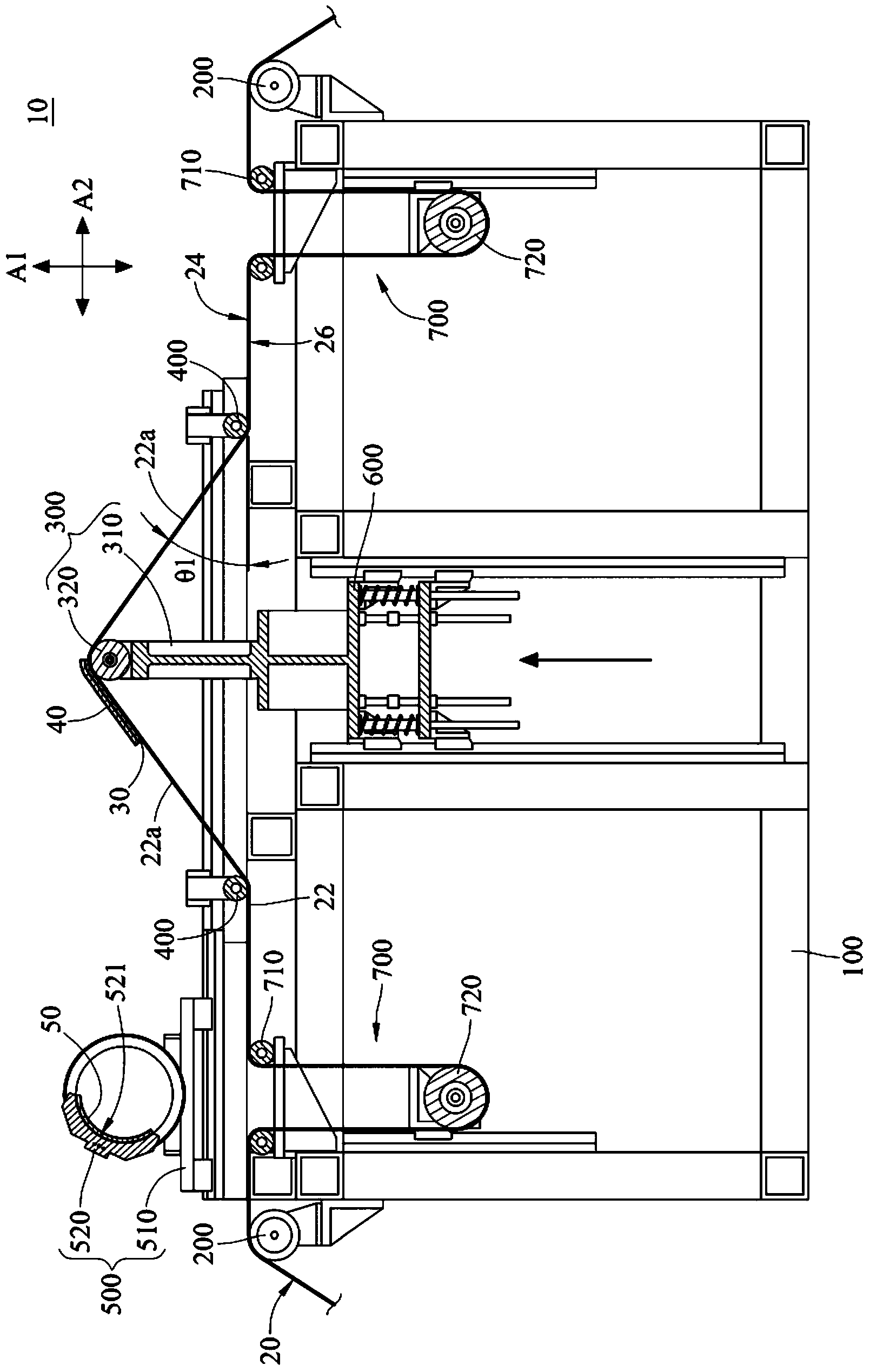

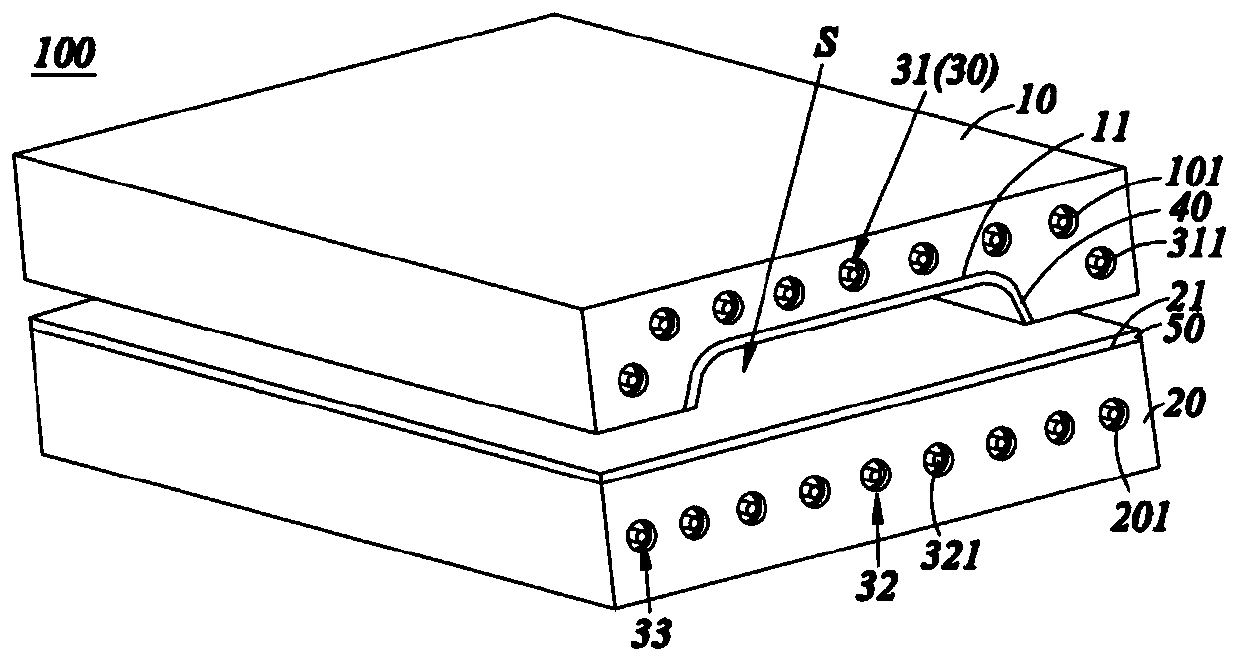

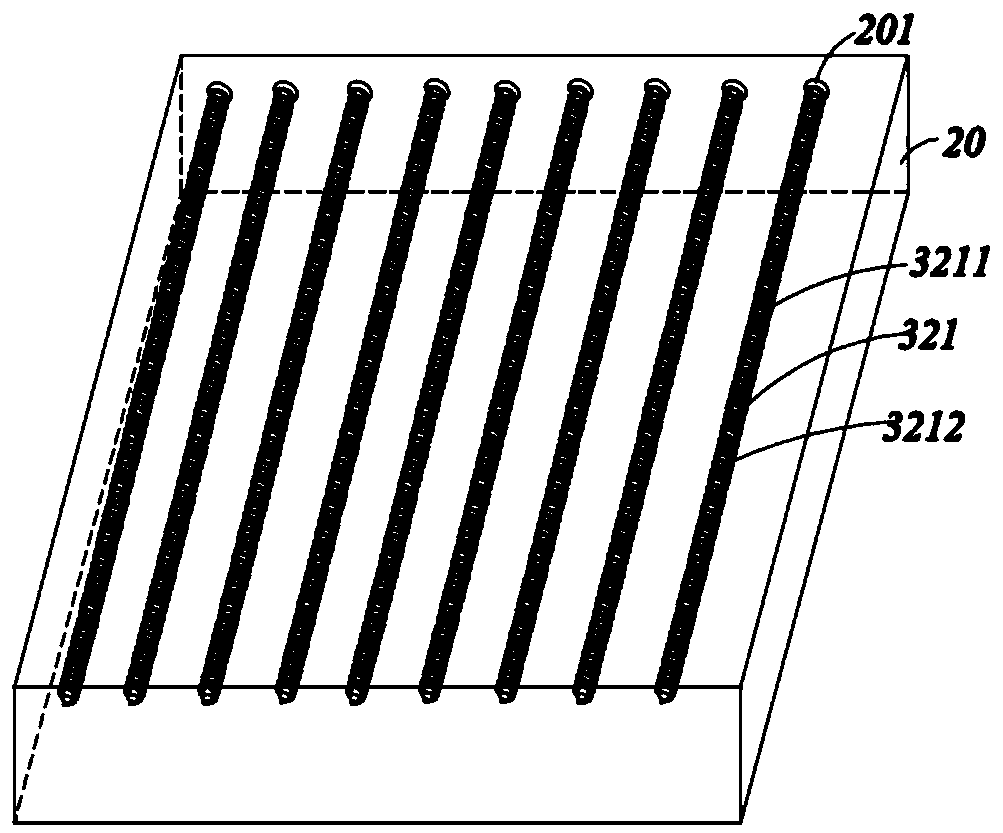

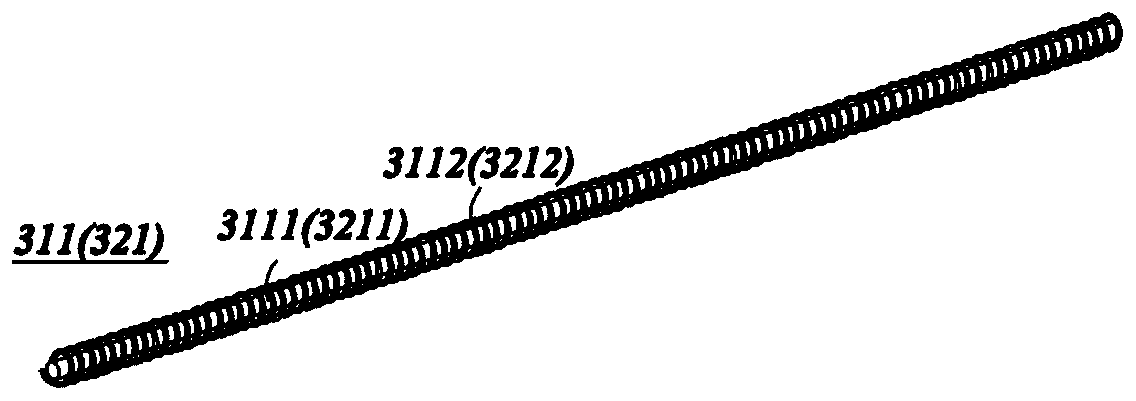

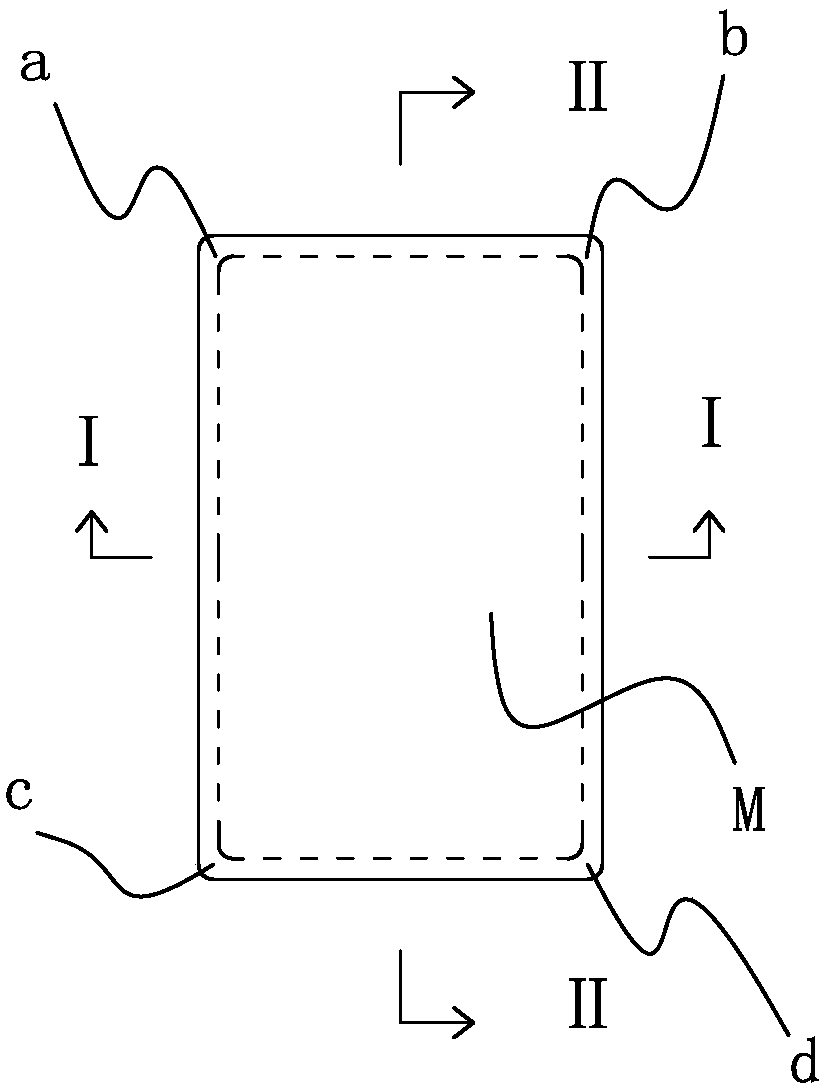

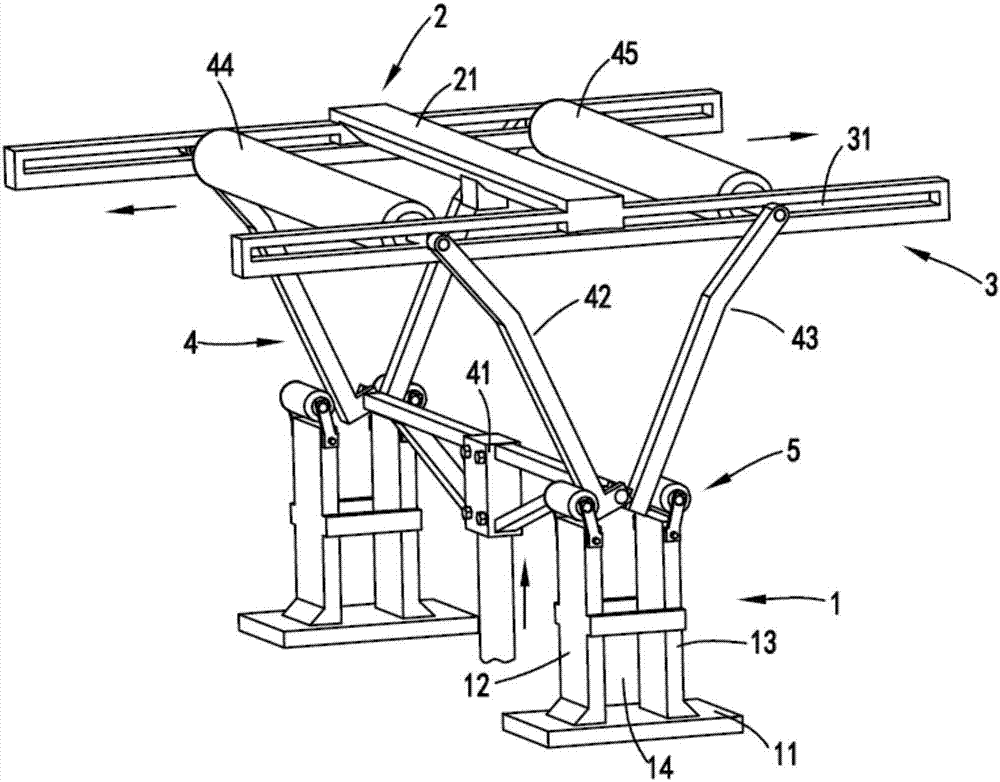

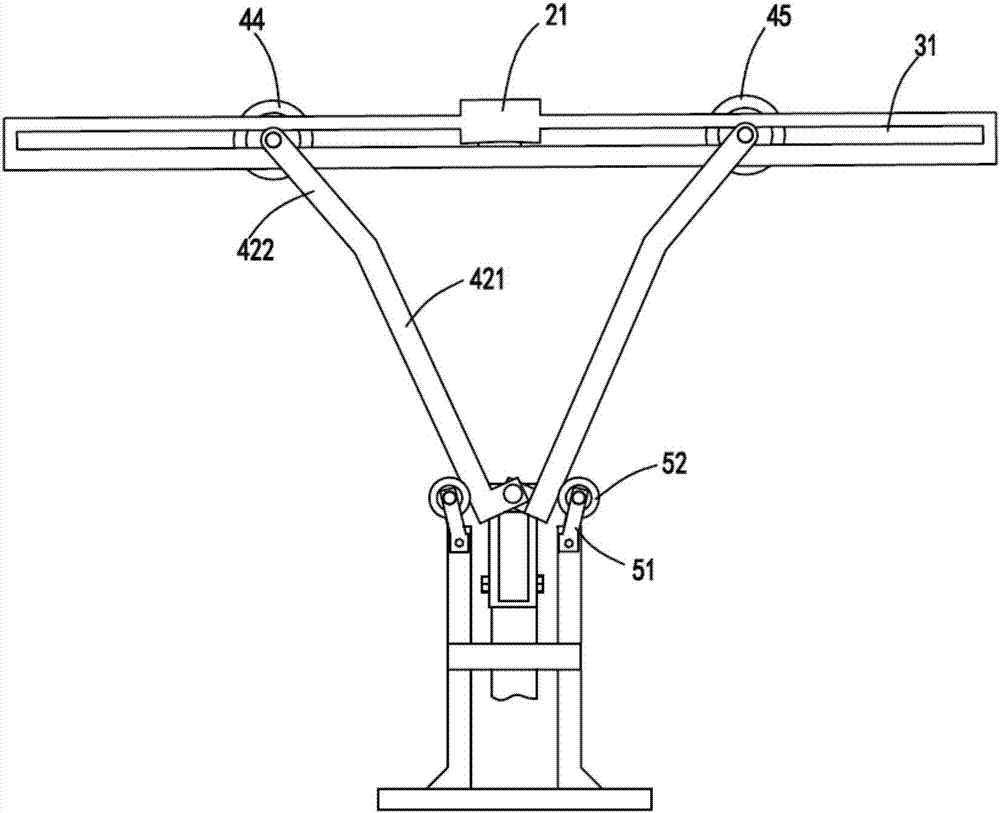

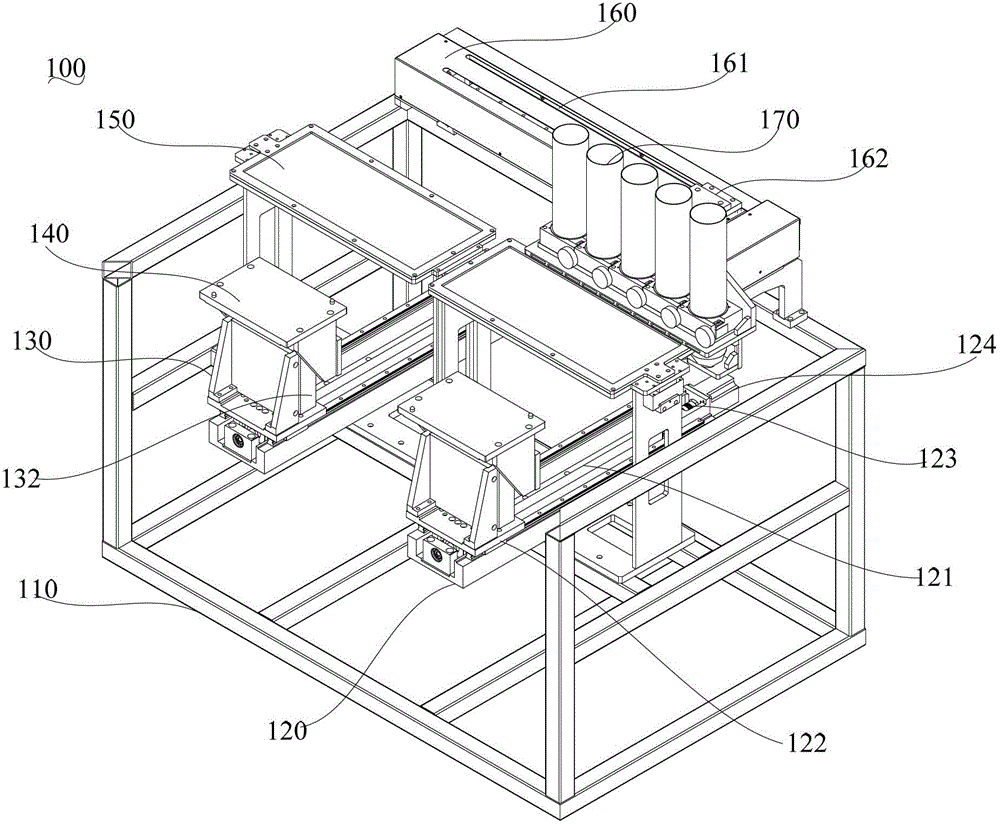

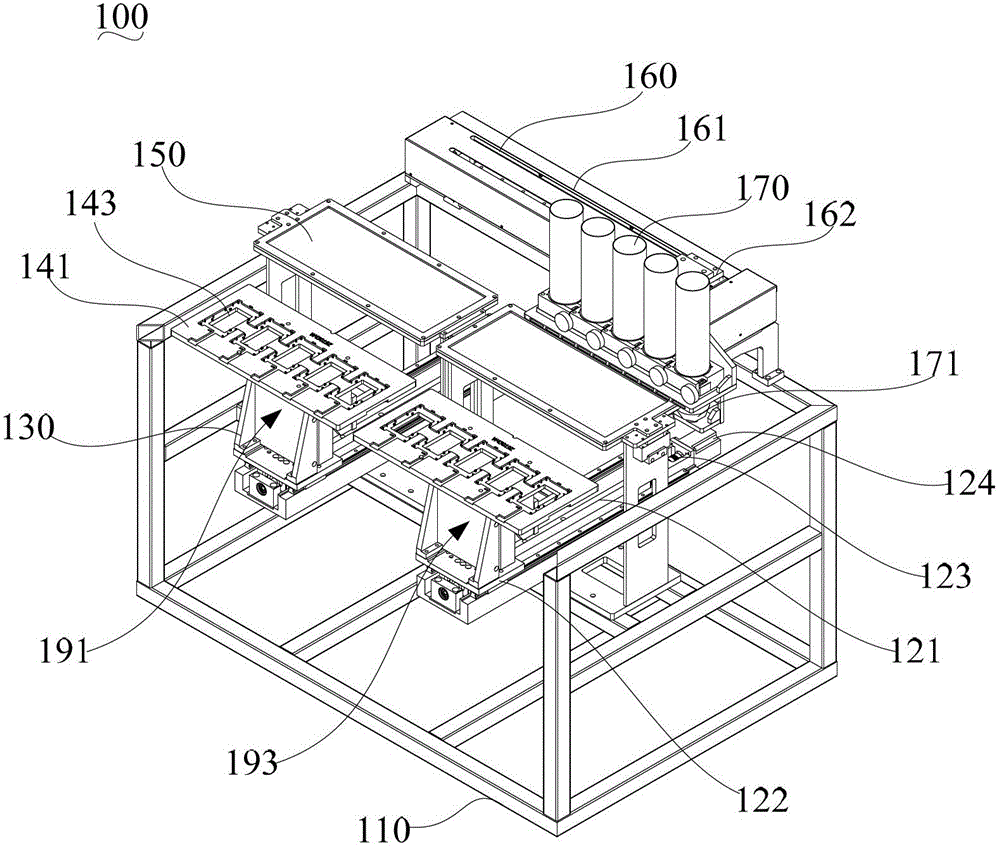

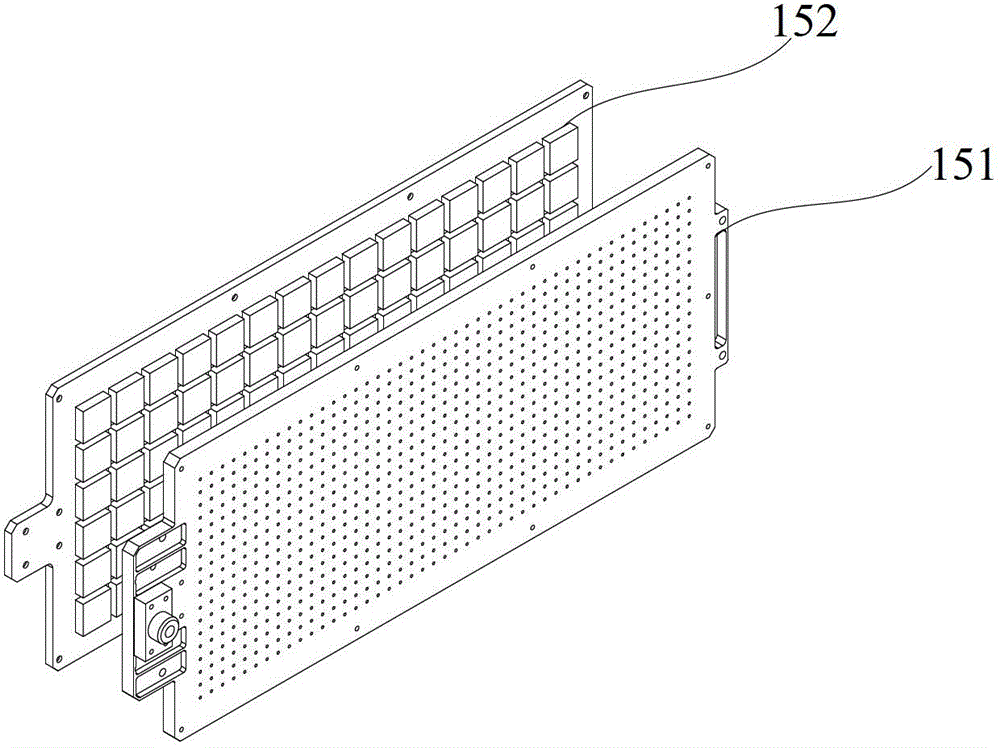

Double-station overturning lamination structure

ActiveCN104670945AImprove bonding efficiencyImprove fitting accuracyOverturning articlesLaminationPulp and paper industrySuction surface

The invention relates to the technical field of alignment lamination, and discloses a double-station overturning lamination structure, which comprises two vacuum net cages, a rotating shaft, a sealing plate and two overturning plates, wherein the two vacuum net cages are arranged at an interval, and an arrangement interval is formed between the two vacuum net cages; the upper end faces of the vacuum net cages form platform surfaces; the rotating shaft is positioned above the arrangement interval; the lower end of the sealing plate is connected to the rotating shaft; the two overturning plates are connected to the two lateral surfaces of the sealing plate respectively, and are provided with suction surfaces. According to the double-station overturning lamination structure, the rotating shaft rotates to drive the overturning plates on the sealing plate to swing between the two vacuum net cages, products are laminated to the suction surfaces and the platform surfaces respectively, the platform surfaces ascend to laminate the two products when the suction surfaces are parallel to the platform surfaces, and when the products are laminated on one station, the products can be arranged on the other station to realize double-station operation under the driving of the rotating shaft, so that the product lamination efficiency and accuracy are greatly improved, and convenience in operation is achieved.

Owner:SHENZHEN SKING INTELLIGENT EQUIP

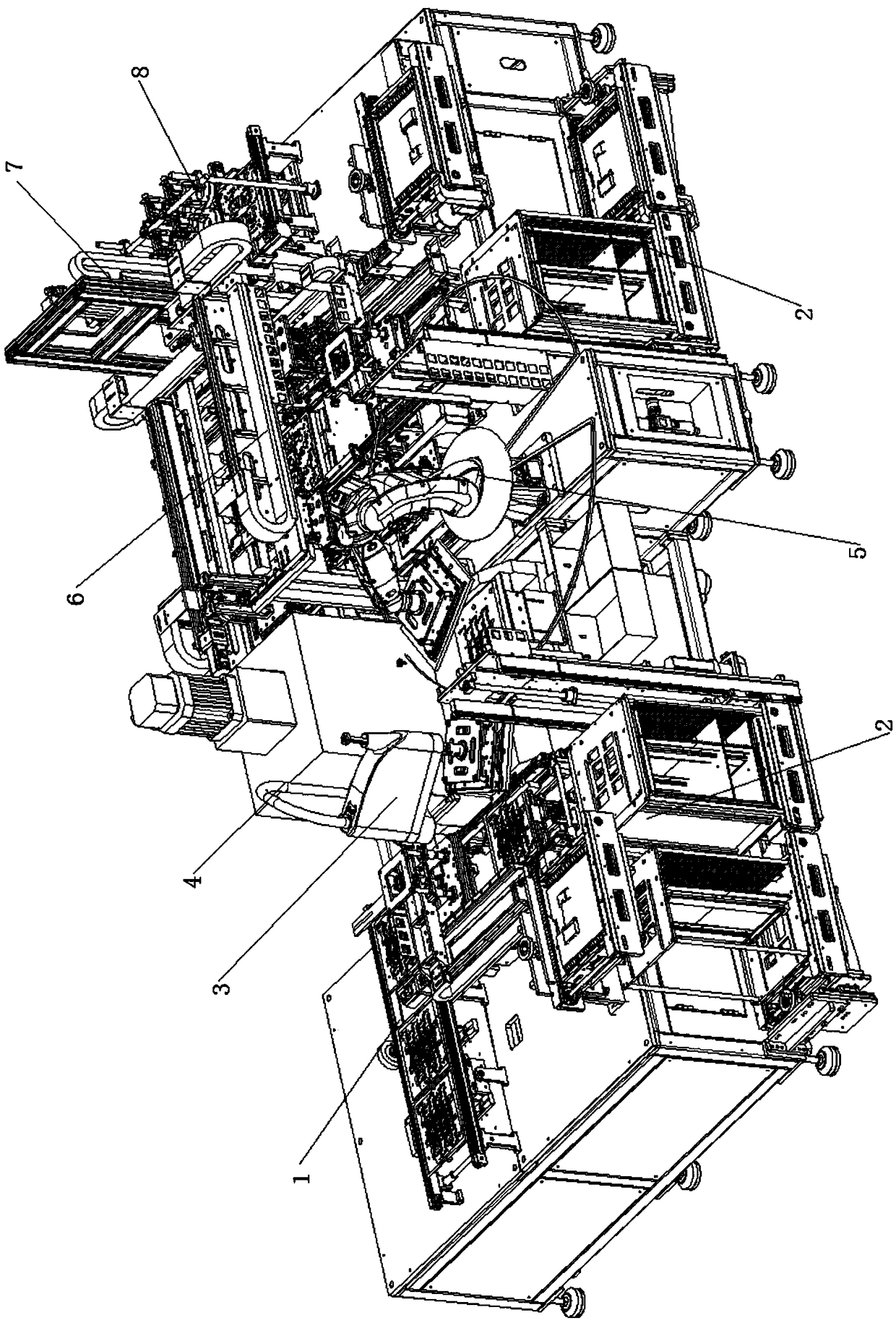

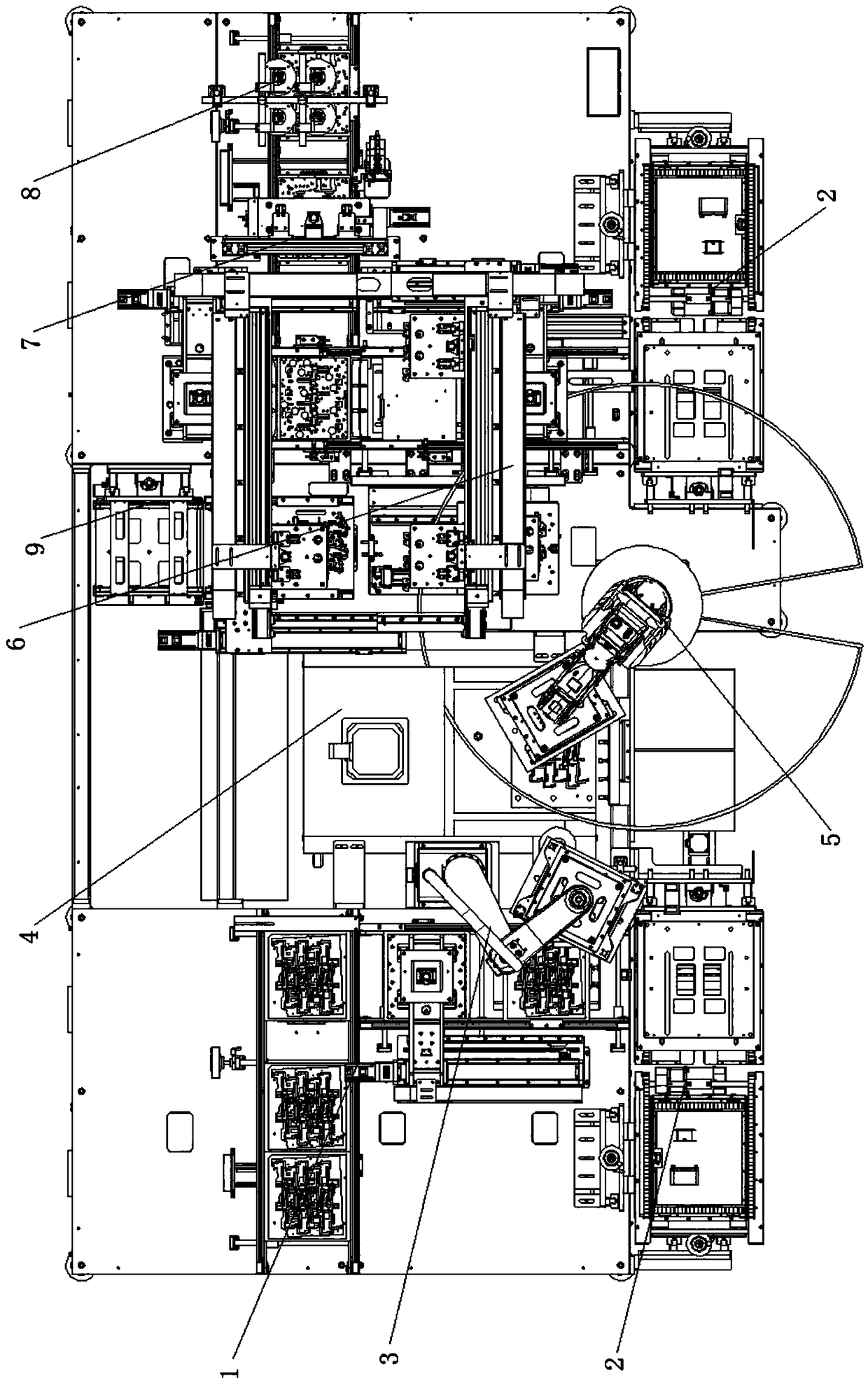

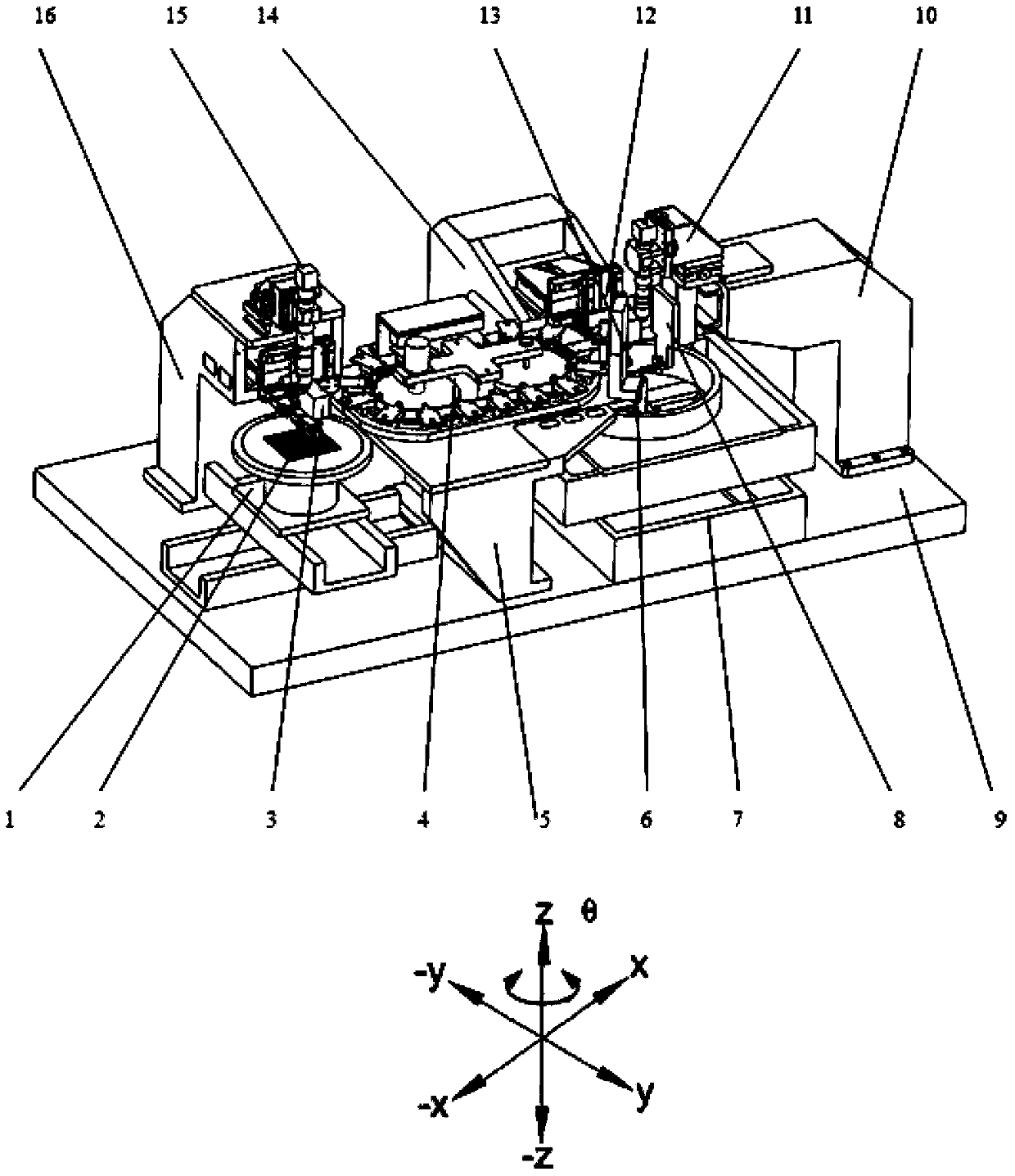

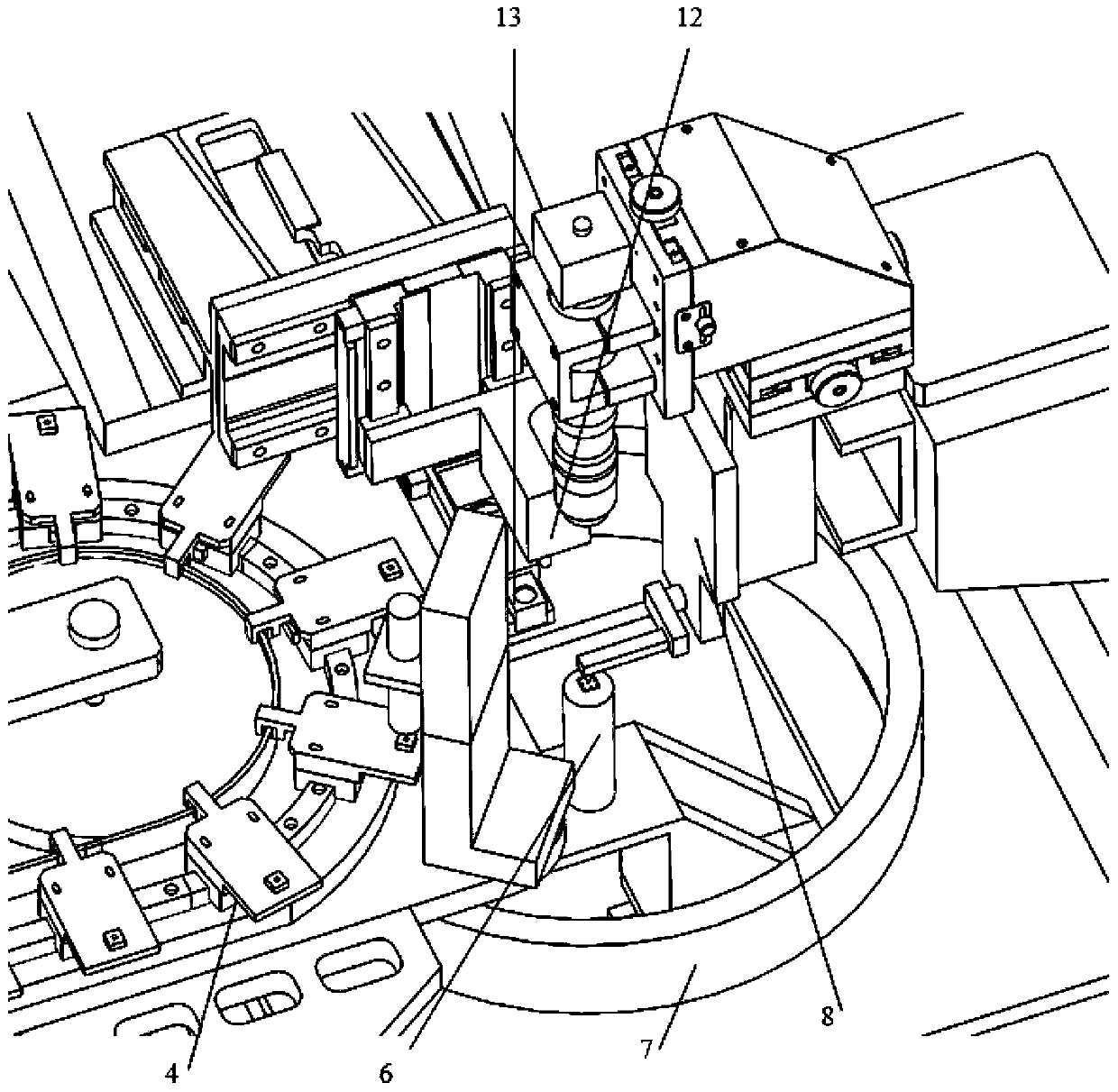

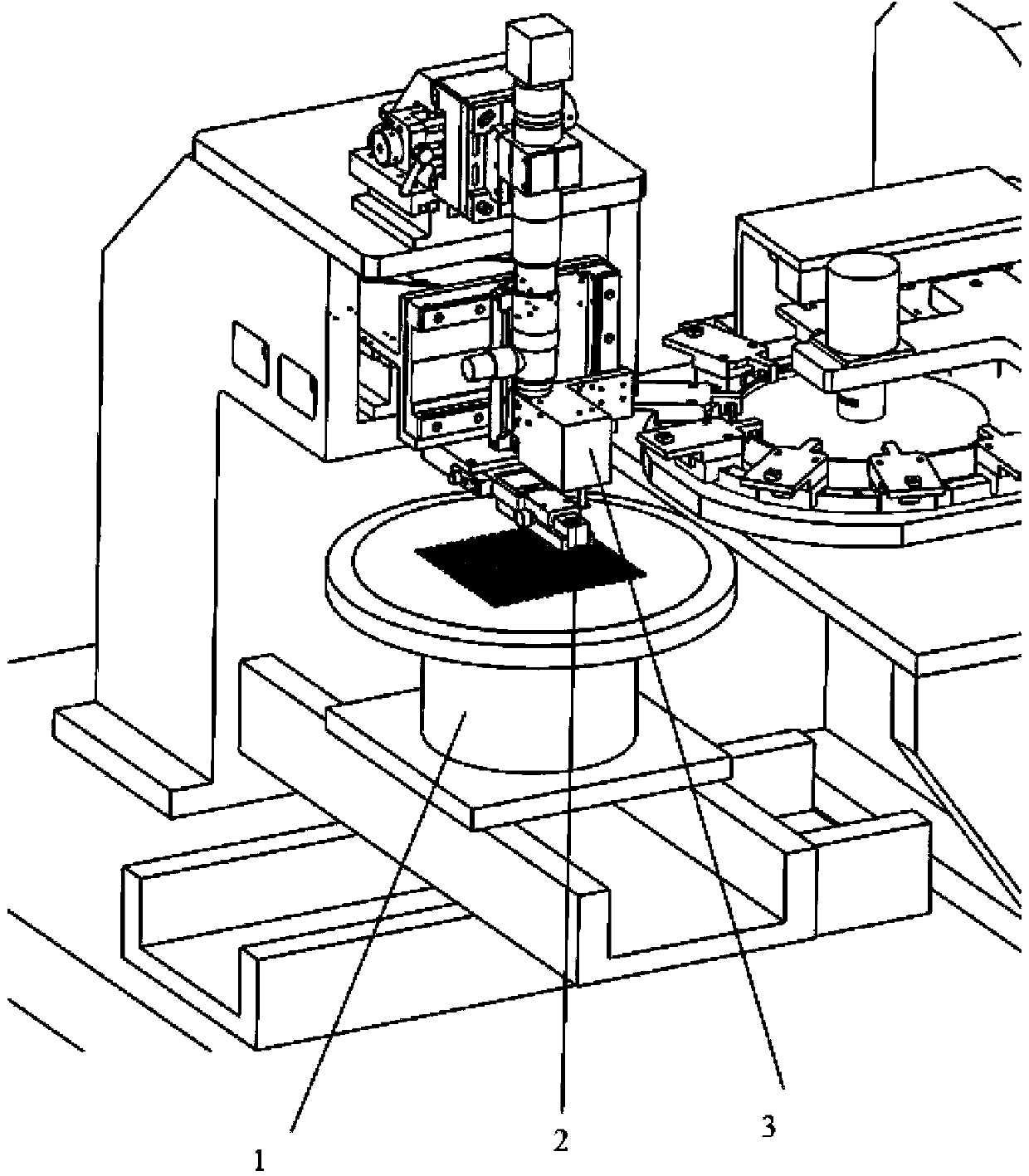

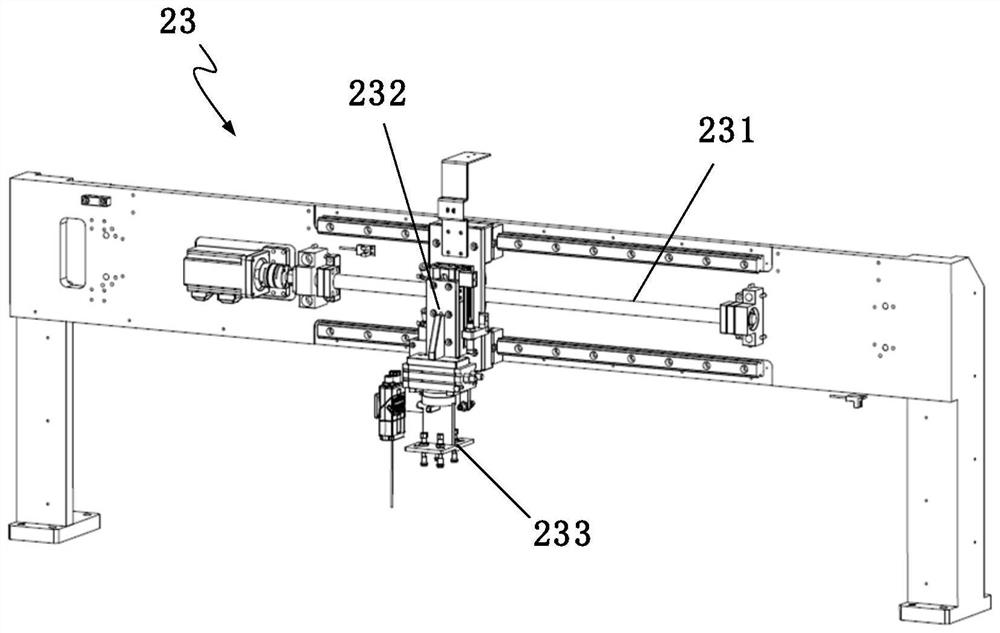

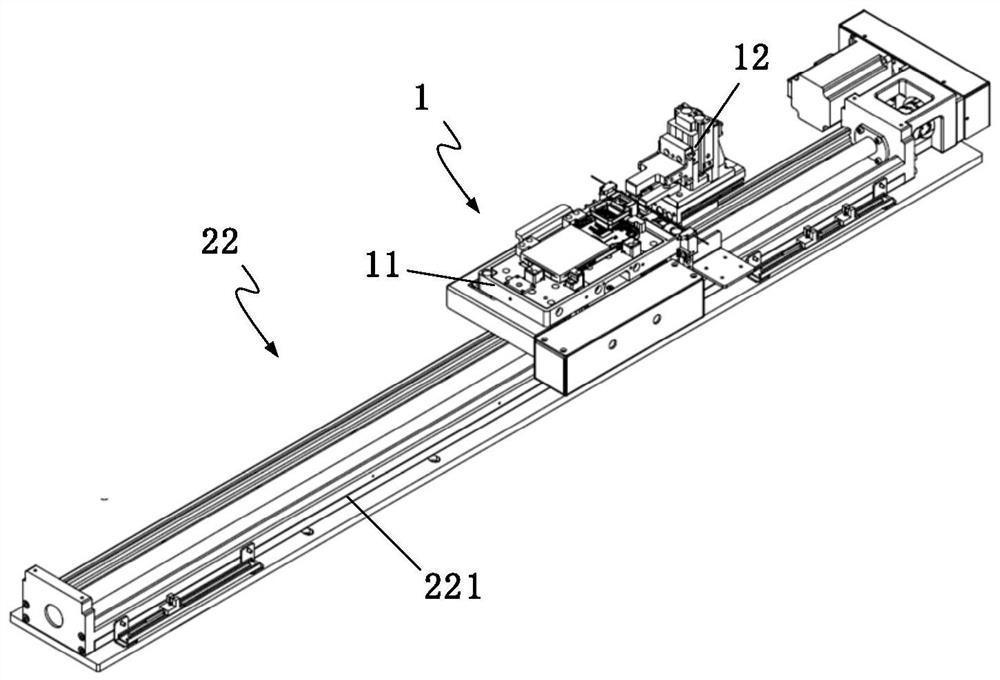

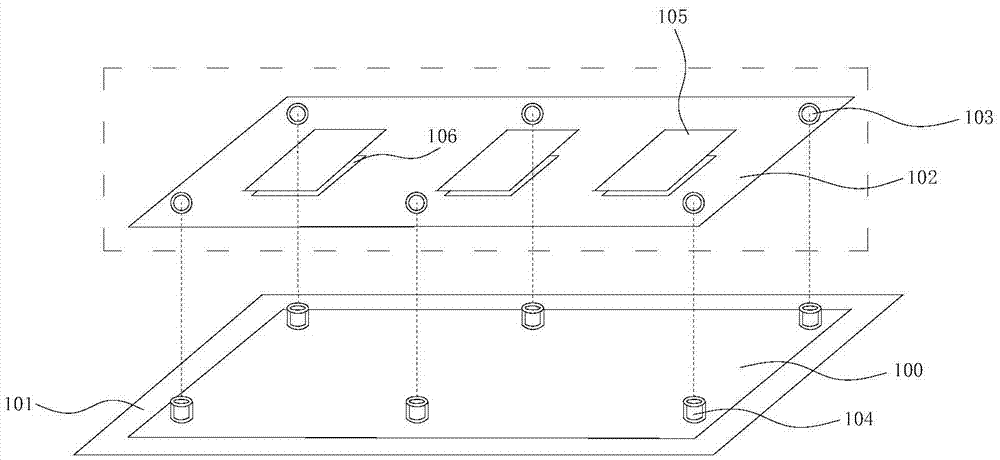

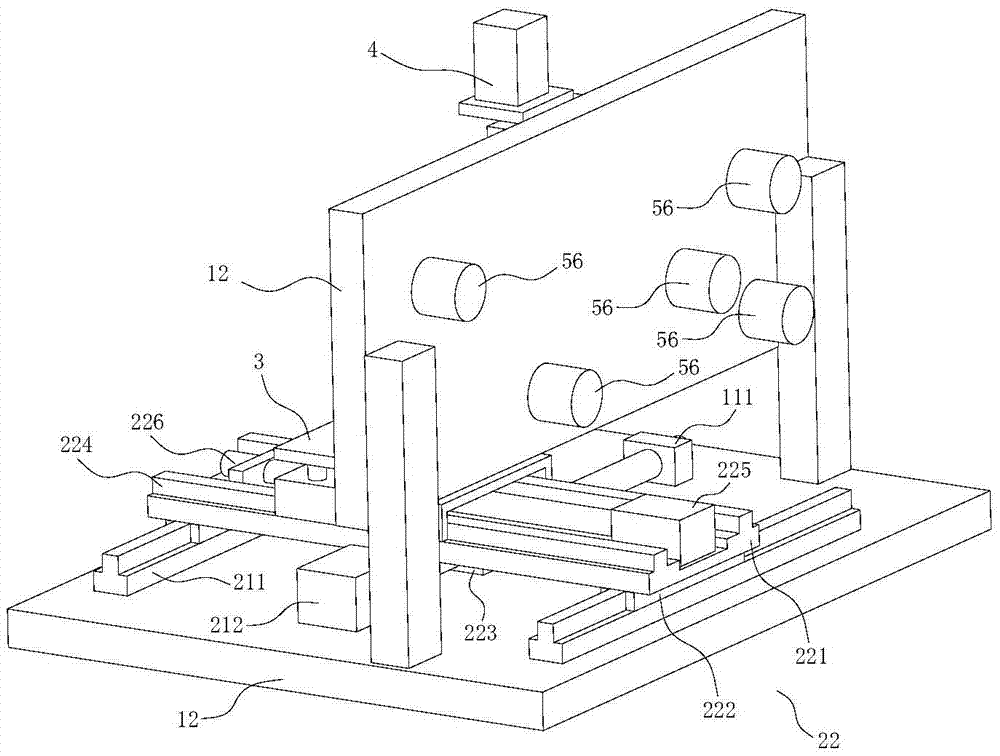

Workpiece bonding system

InactiveCN104183527AShorten delivery timeImprove bonding efficiencySolid-state devicesSemiconductor/solid-state device manufacturingManufacturing technologyEngineering

The invention provides a workpiece bonding system, and relates to the technical field of semiconductor processing and manufacturing. The workpiece bonding system is used for completing bonding processing of a semiconductor workpiece. The workpiece bonding system includes a workpiece providing device, a workpiece conveying device and a workpiece processing device. The workpiece providing device is used for obtaining a workpiece to be processed from a workpiece bearing device and conveying the workpiece to be processed to the workpiece conveying device; the workpiece conveying device is used for connecting the workpiece providing device and the workpiece processing device, obtaining the workpiece to be processed form the workpiece providing device, and conveying the workpiece to be processed to the workpiece processing device; and the workpiece processing device is used for obtaining the workpiece to be processed from the workpiece conveying device, and completing bonding of the workpiece. The workpiece conveying device can also be used for performing various preprocessing operation on the workpiece in the process of conveying the workpiece. The technical scheme of the workpiece bonding system in the invention can reduce consumption of time for workpiece delivery and preprocessing, and improve the overall efficiency of workpiece bonding.

Owner:CETC BEIJING ELECTRONICS EQUIP

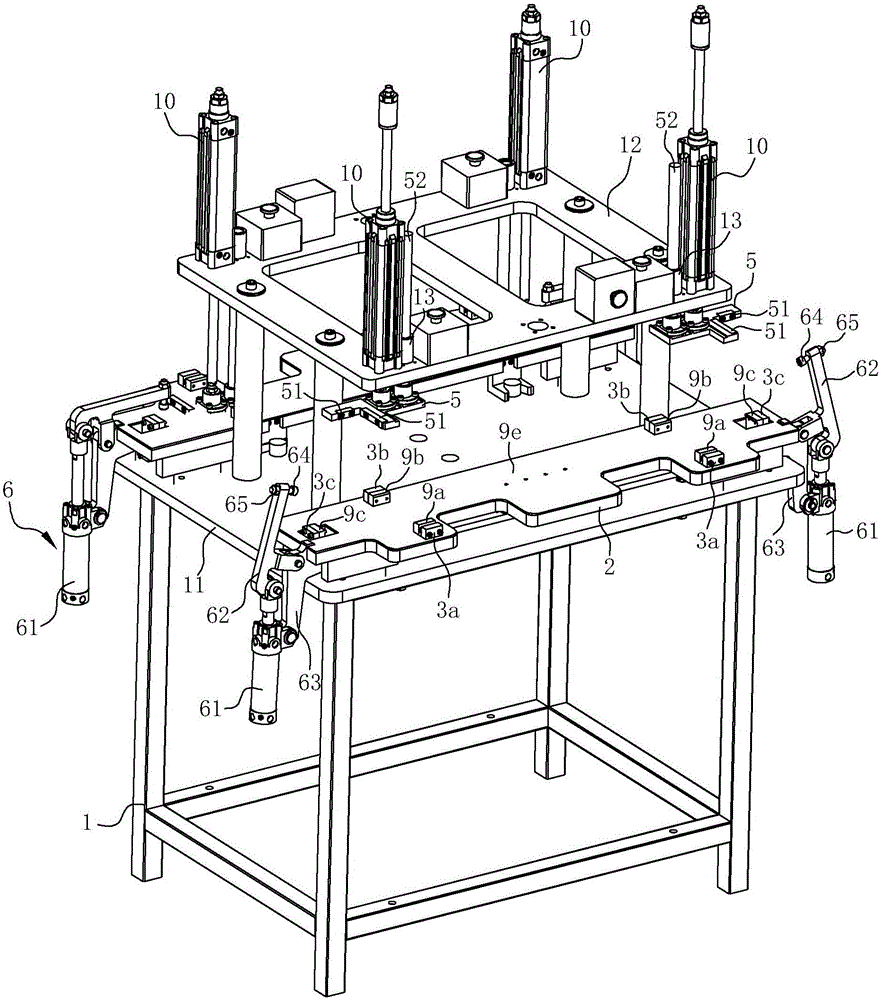

Adhering tool for adhering glass panel to exhaust fume collecting hood

The invention relates to an adhering tool for adhering a glass panel to an exhaust fume collecting hood. The adhering tool comprises a support, and an adhering structure is at least arranged on one side of the support. The adhering tool is characterized in that the adhering structure comprises an upper bearing board, a lower bearing board, two positioning air cylinders, an upper installation board and compression blocks, wherein locating detents are installed on piston rods of the positioning air cylinders and provided with horizontal arms and inclined arms; first positioning blocks are fixed to the horizontal arms; second positioning blocks are fixed to the ends of the inclined arms on at least one side; the upper installation board is fixed above the support; the upper installation board and a top board of the support are spaced vertically; the compression blocks are located over the upper bearing board and driven by a compression air cylinder to vertically and perpendicularly move; the compression blocks press downwards to compress the glass panel to the front end face of the exhaust fume collecting hood for pressure maintaining. The adhering tool has the advantages that structural design is reasonable, the glass panel adheres to the exhaust fume collecting hood accurately and firmly, the binding efficiency and precision are high, a few procedures are needed, and operation is convenient.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

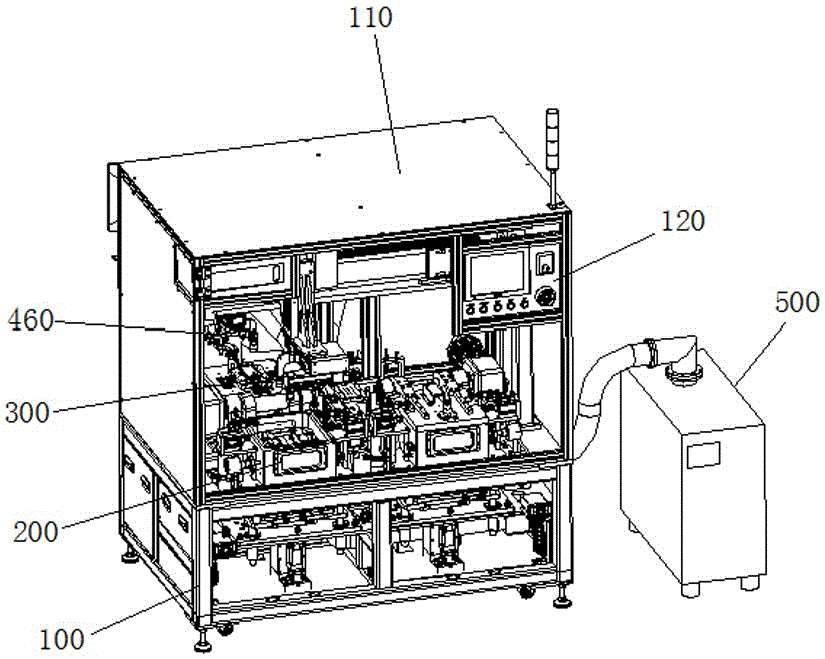

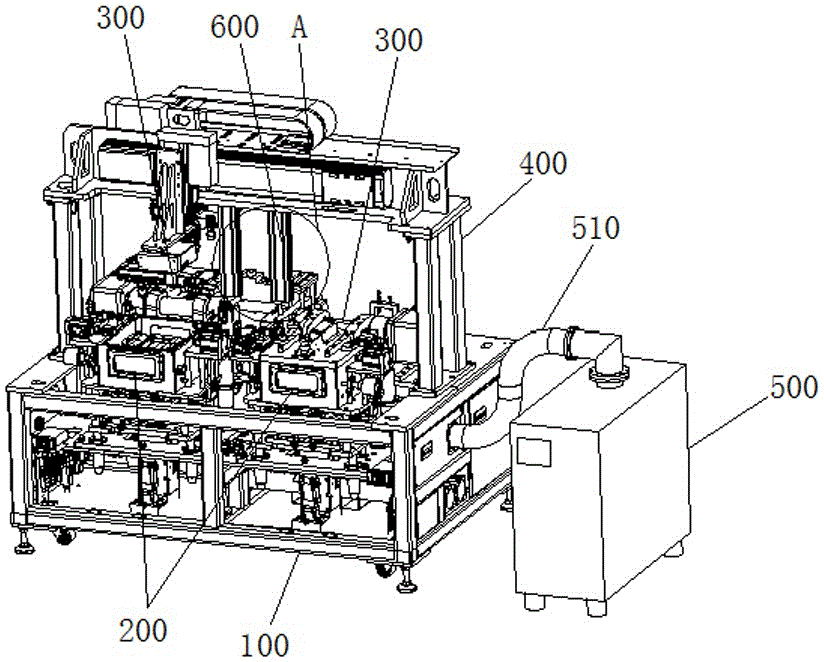

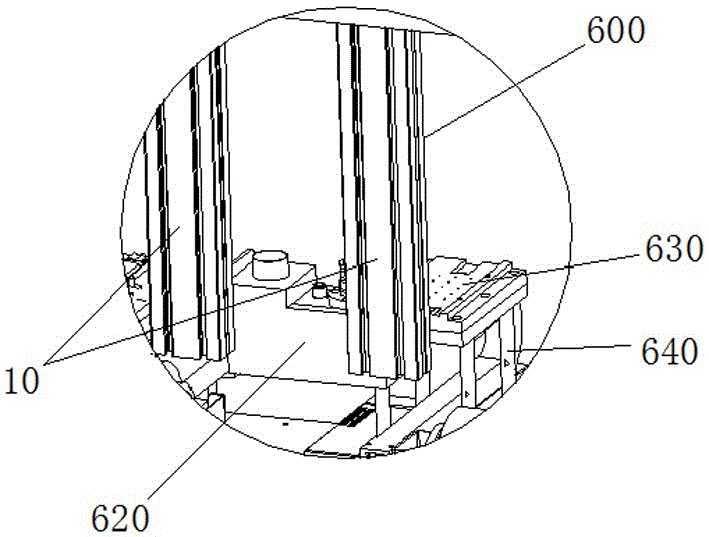

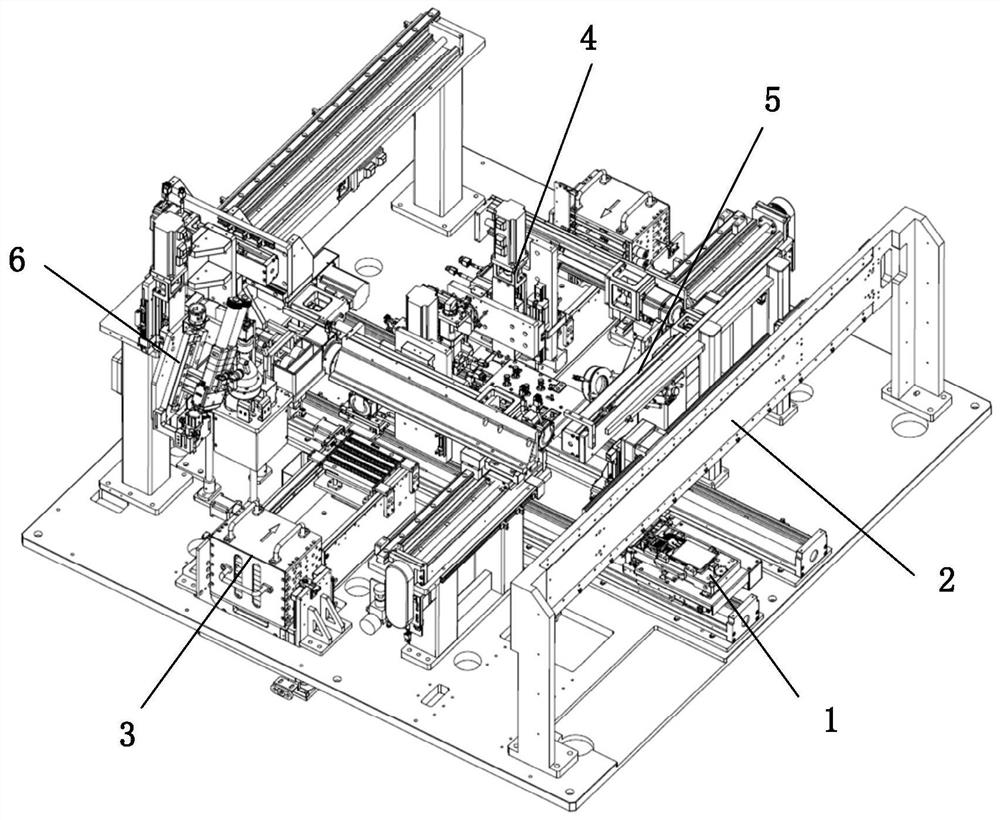

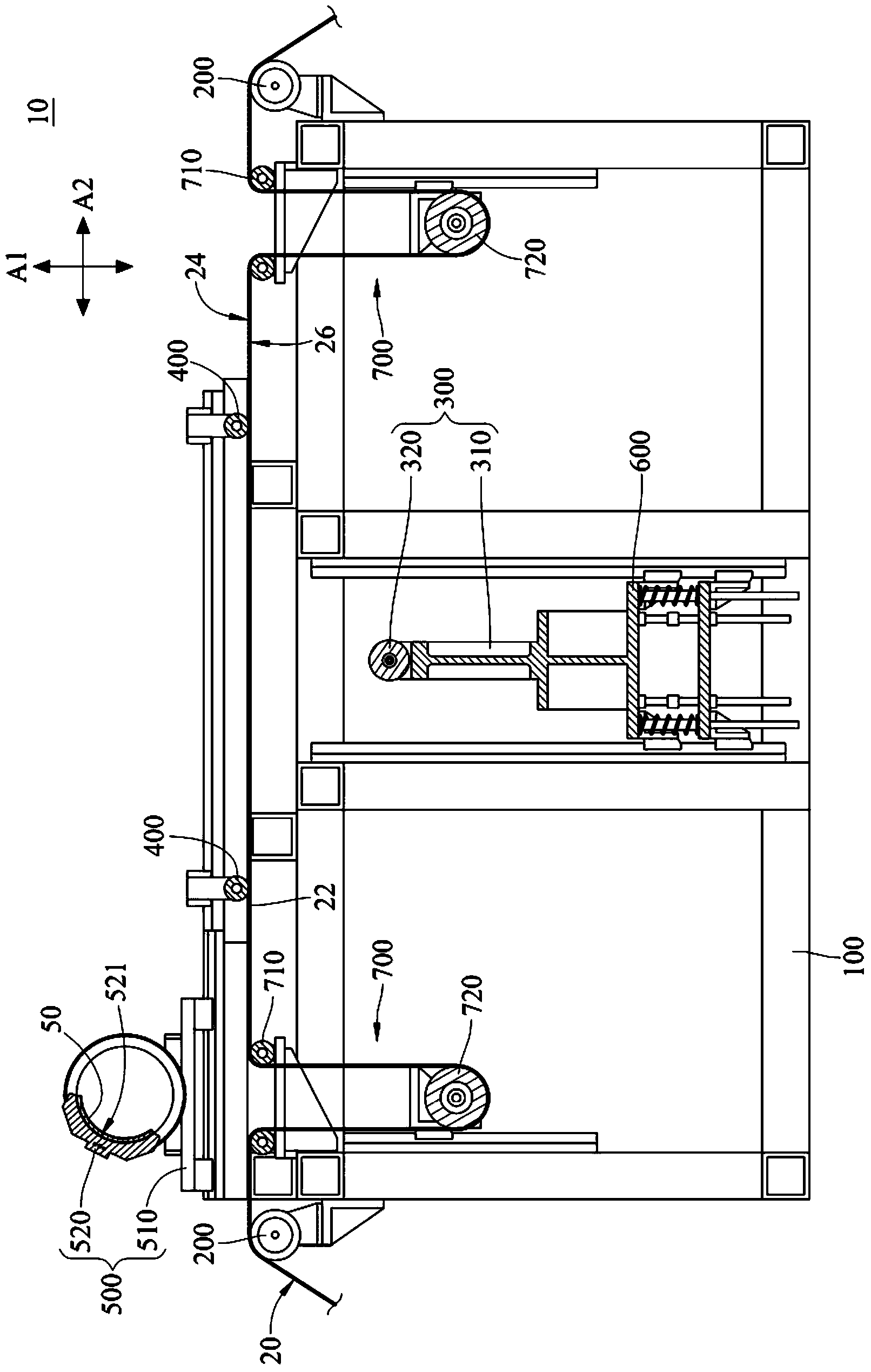

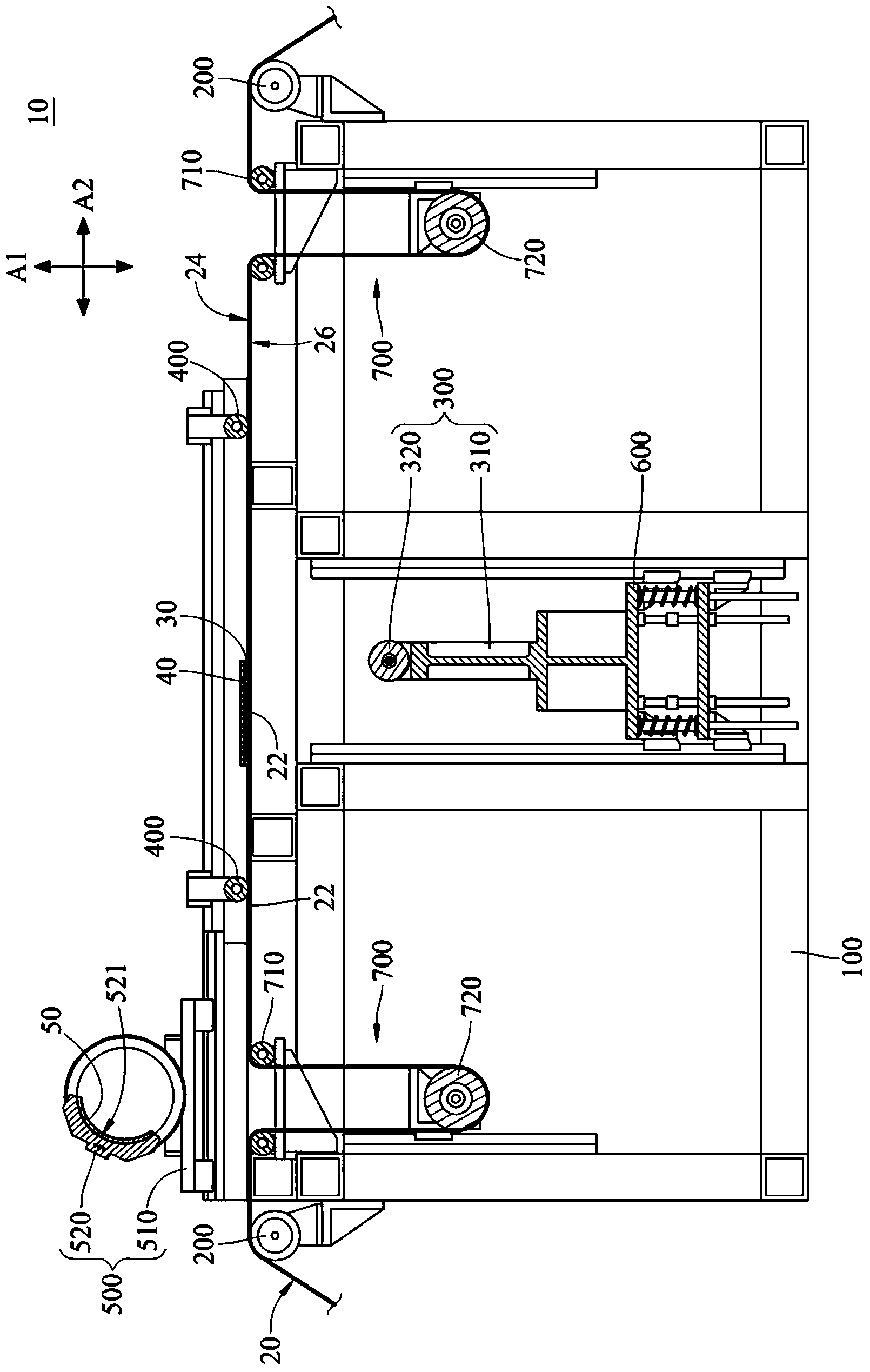

Bonding assembly equipment

InactiveCN112076947AReduce the number of targetingImprove bonding efficiencyLiquid surface applicatorsMaterial gluingEngineeringMechanical engineering

The invention belongs to the technical field of automatic assembly, and discloses bonding assembly equipment which is used for bonding assembly of a first workpiece and a second workpiece. The bondingassembly equipment comprises a jig, a first feeding device, a second feeding device, an assembling device and a glue dispensing device. The jig is configured to clamp the first workpiece. The first feeding device is configured to receive the jig input from the outside and can further transfer the jig to an assembling station and a discharging station. The second feeding device is configured to store and output the second workpiece. And the assembling device can be moved to the position among the second feeding device, the assembling station and the glue dispensing mechanism so as to pick up the second workpiece provided by the second feeding device, and after the glue dispensing device coats glue onto the bonding part of the second workpiece, the second workpiece can be bonded and assembled to the first workpiece located at the assembling station. The bonding assembly equipment provided by the invention can be used for efficiently carrying out bonding assembly operations.

Owner:BOZHON PRECISION IND TECH CO LTD

Curved surface laminating device

ActiveCN104309264AImprove bonding efficiencyAvoid damageLaminationLamination apparatusDrive wheelEngineering

Owner:AU OPTRONICS CORP

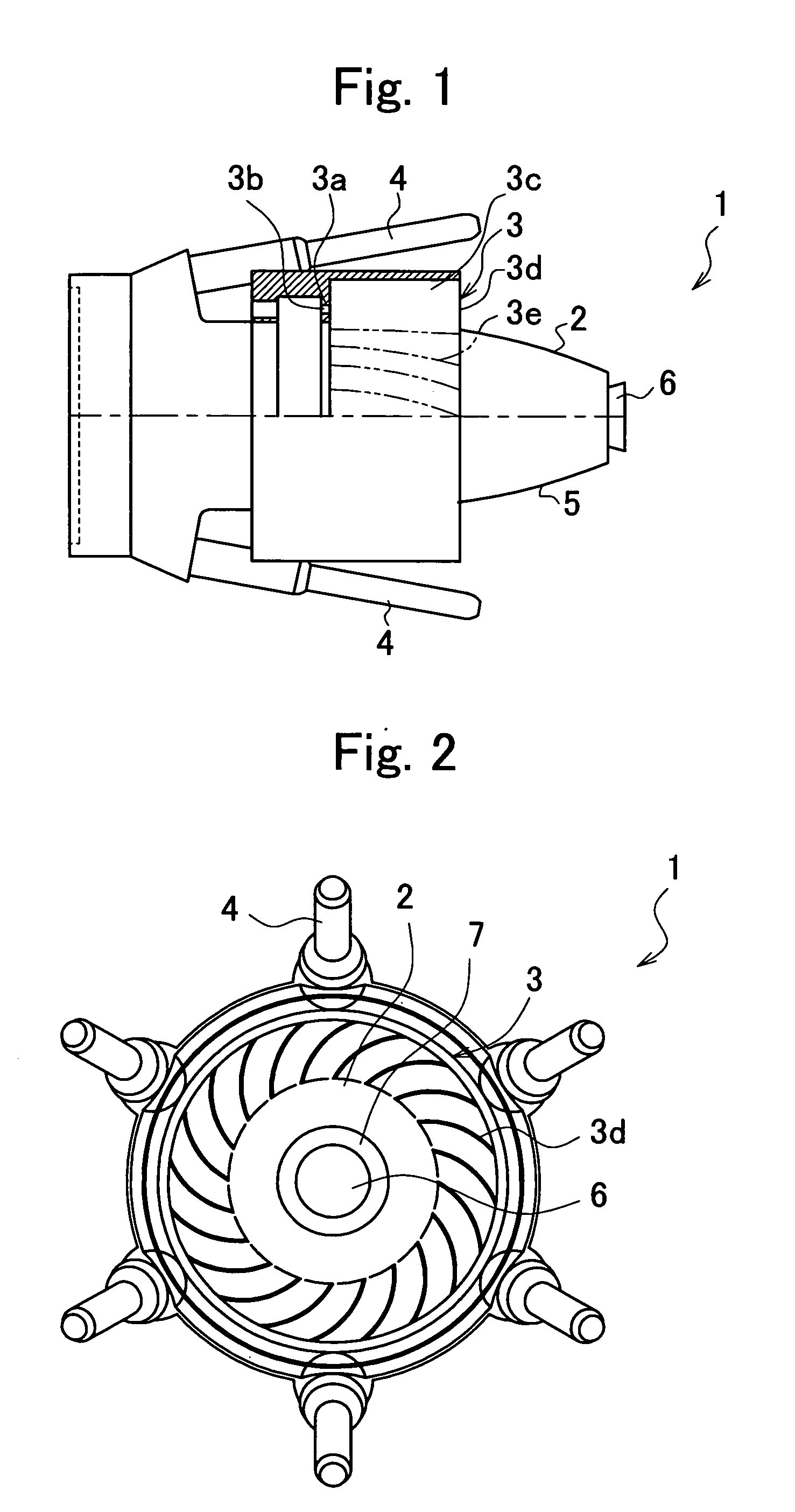

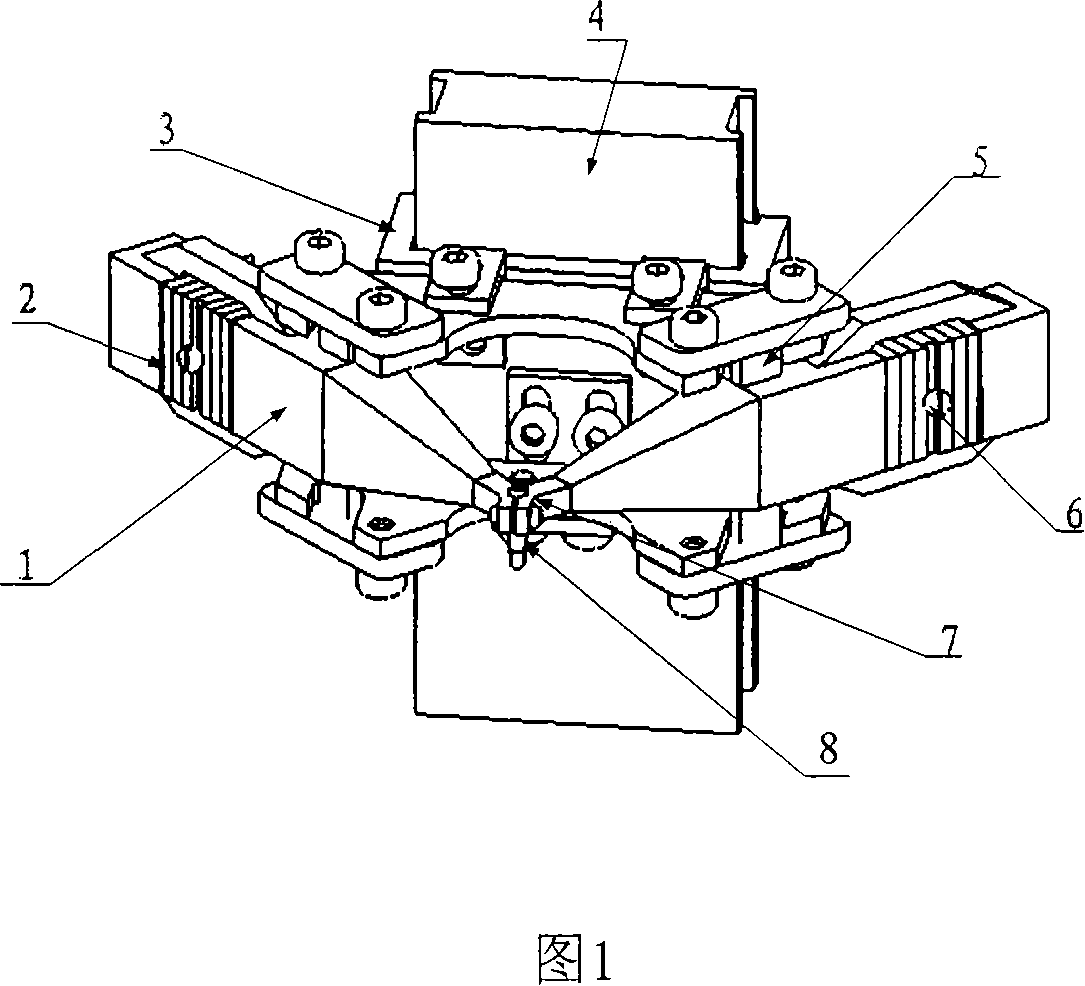

Parallel compound ultrasonic energy transmission device

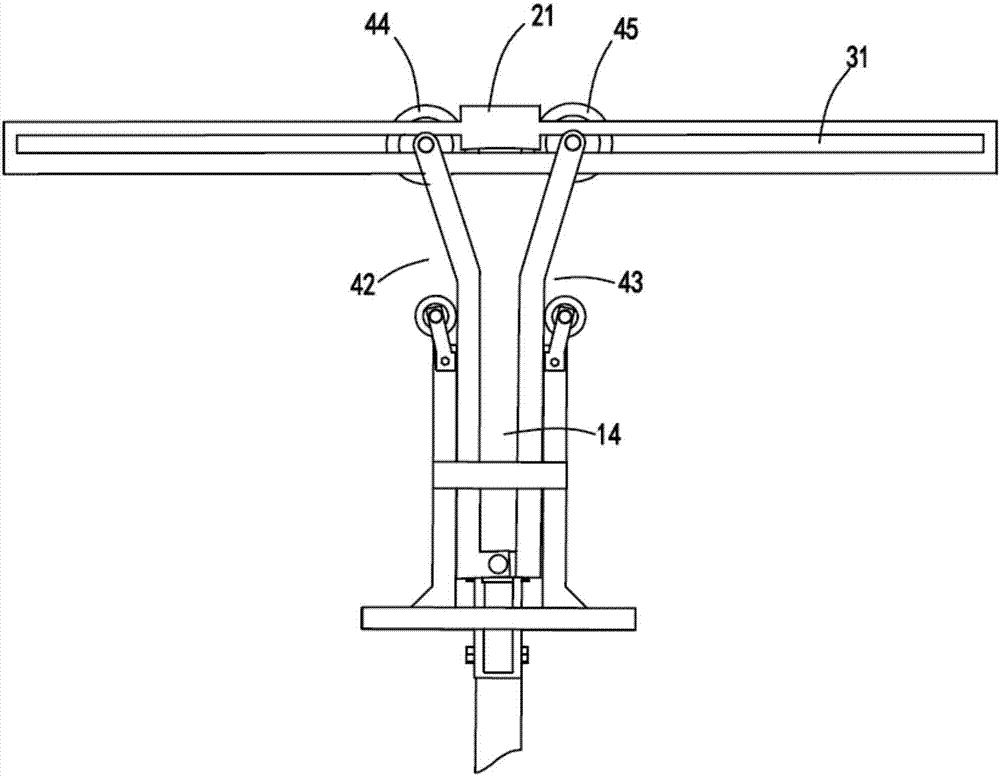

InactiveCN101053864ALarge coverage areaReduced lateral deflection stiffnessSemiconductor/solid-state device manufacturingMechanical vibrations separationEnergy transferVibration amplitude

The invention provides a parallel connection combined type ultrasonic energy transferring device, which comprises a parallel connection combined type supersonic wave amplitude transformer, a piezoelectricity ultrasonic transducer as well as a working cleaver on front end of the amplitude transformer. Two sets of unidirectional vibration amplitude transformer are rigidly connected with each other on working end, and the parallel connection combined type supersonic wave amplitude transformer is fixed on a movable flatform via an elastic beam. The invention provides a novel parallel connection combined type ultrasonic energy transferring device, which is used to increase lead bond efficiency, wherein, the requirement of increasing supersonic wave lamplitude transformer end cleaver track cover area is satisfied, at the same time, ultrasonic energy density is increased, bond time is reduced, and bond efficiency is increased.

Owner:HARBIN INST OF TECH

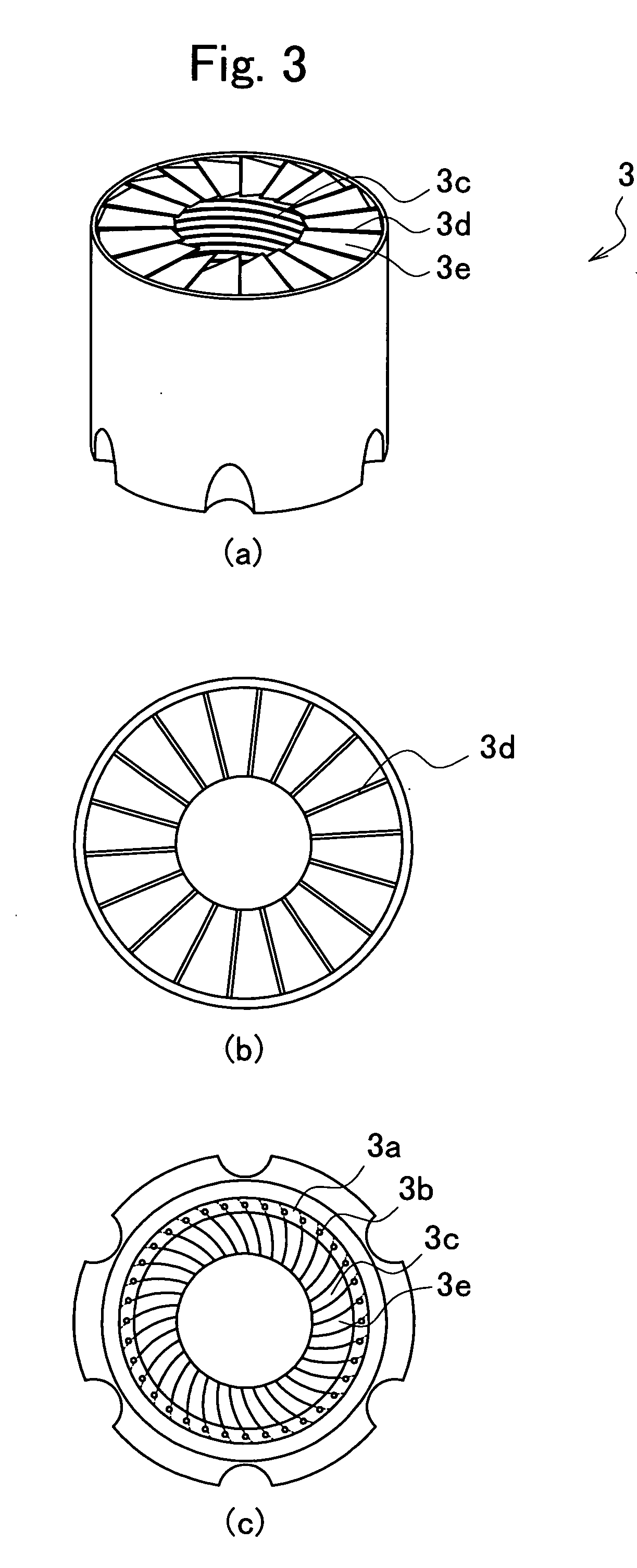

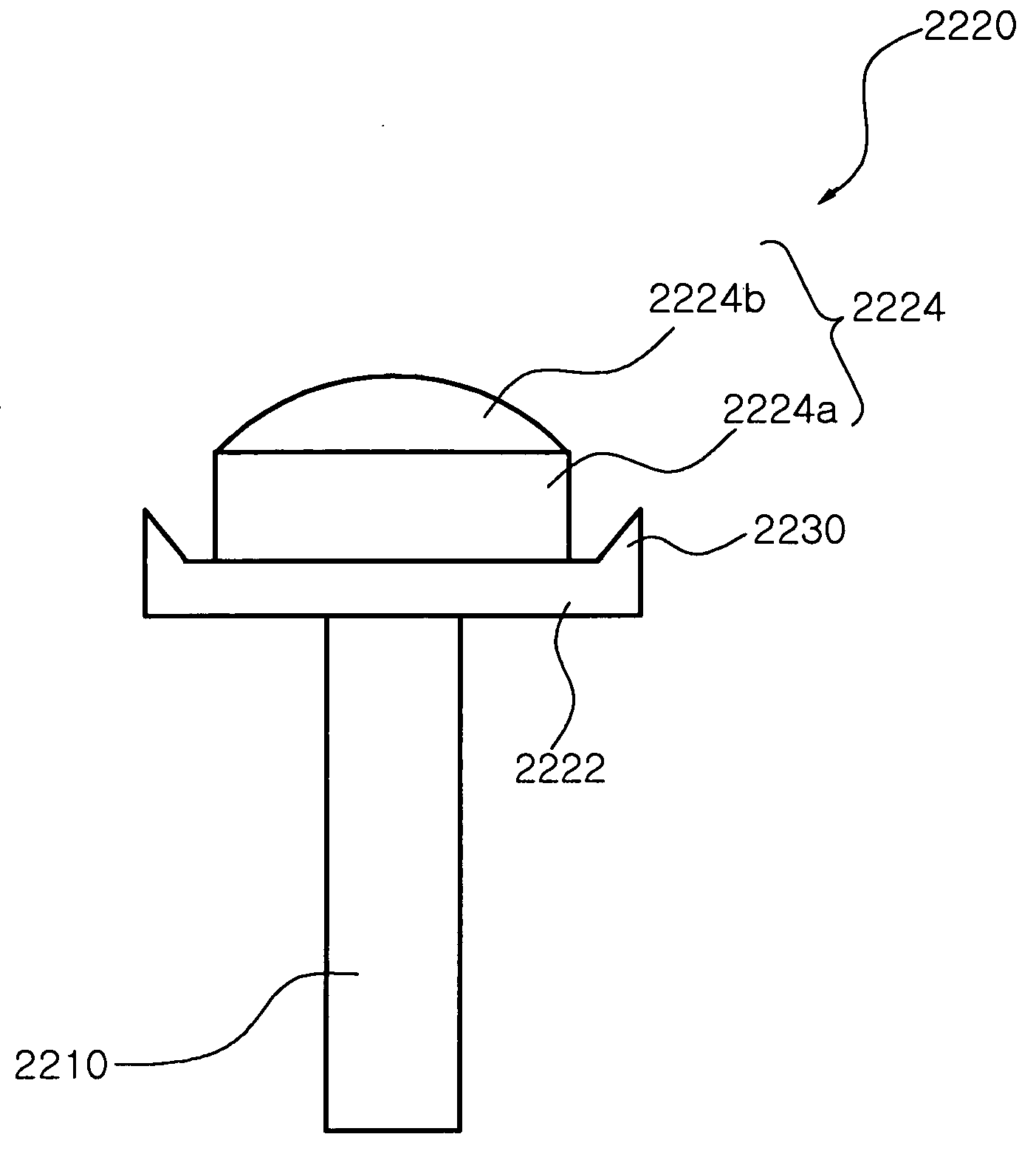

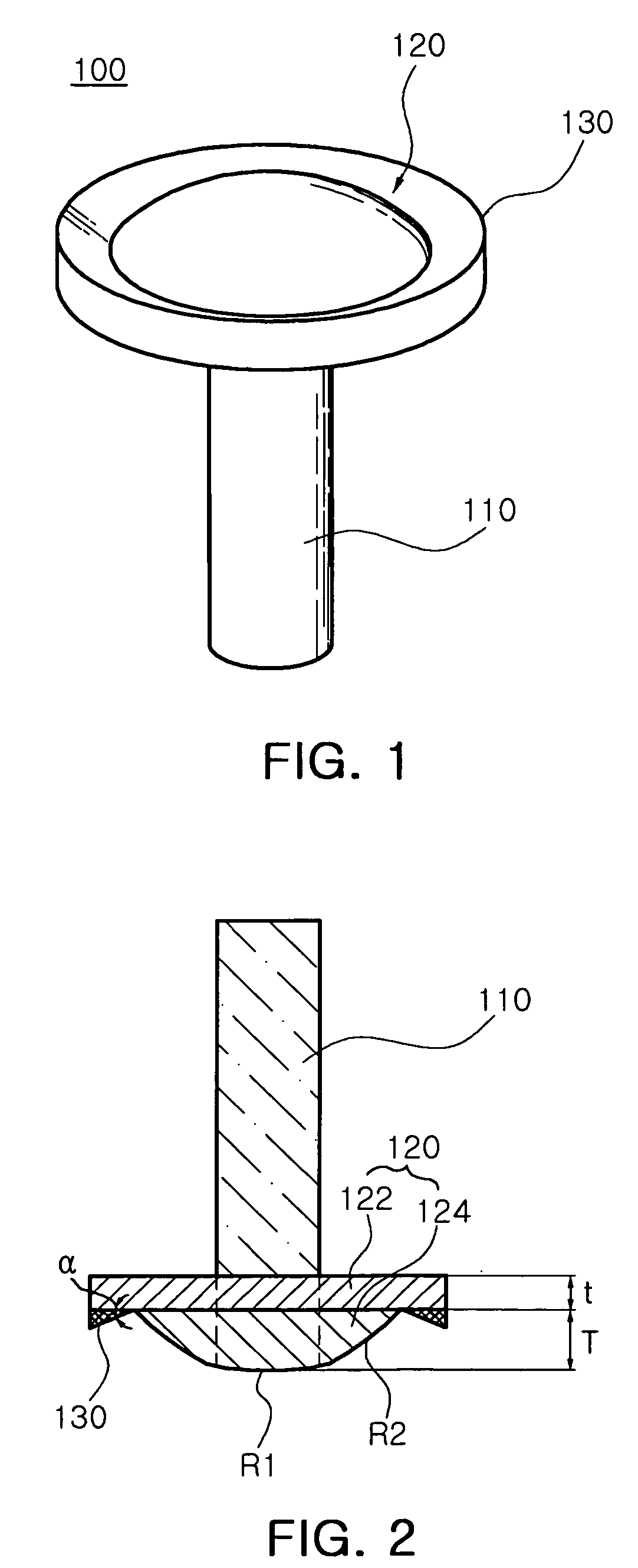

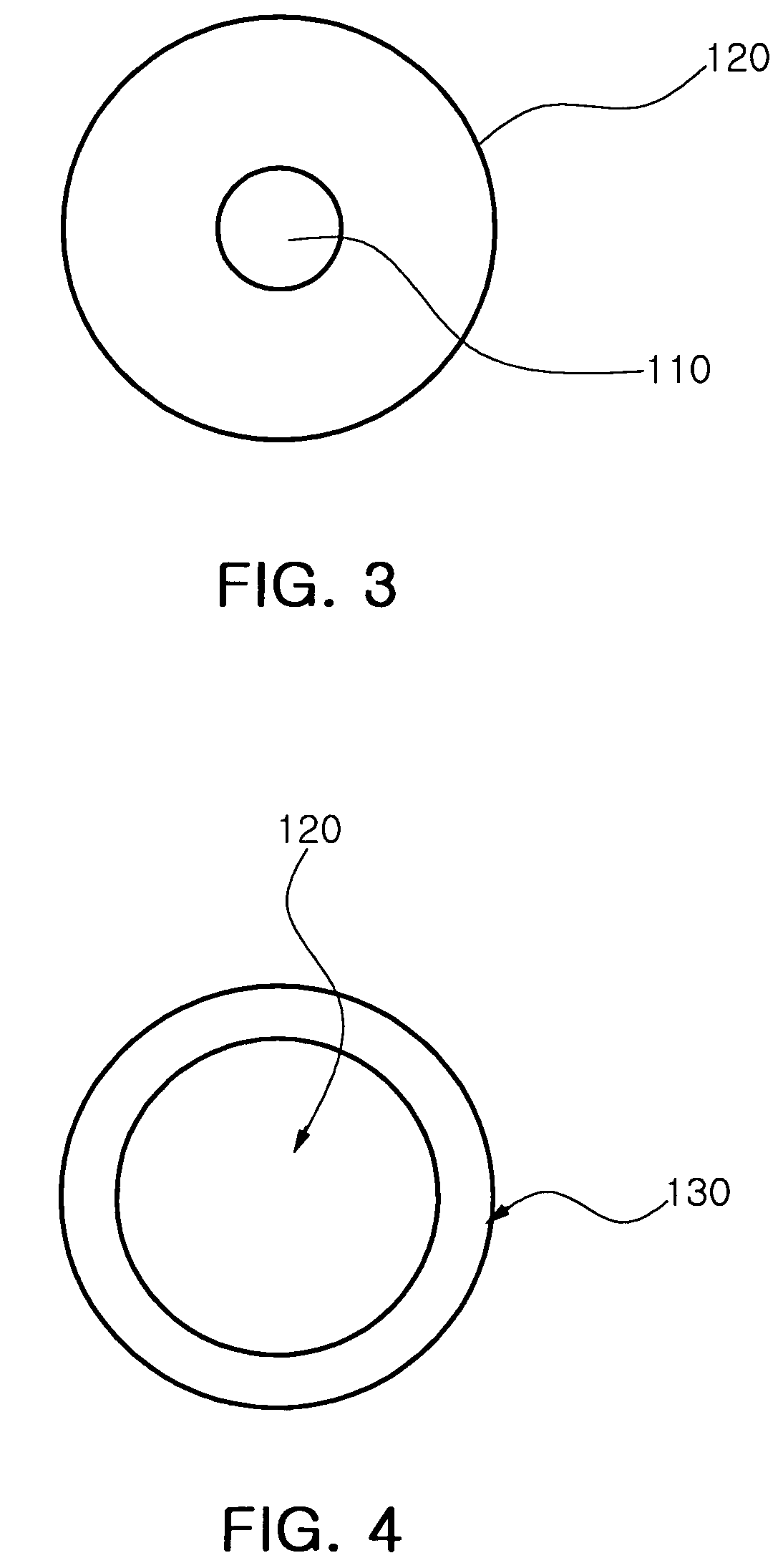

Lead pin for package substrate

InactiveUS20110068473A1Avoid pollutionImprove bonding efficiencyNon-insulated conductorsSemiconductor/solid-state device detailsEngineeringSolder paste

There is provided a lead pin for a package substrate including: a connection pin being inserted into a hole formed in an external substrate; a head part formed on one end of the connection pin; and a barrier part formed on one surface of the head part in order to block the path of a solder paste so that the solder paste is prevented from flowing so as to cover the upper portion of the head part when the head part is mounted on the package substrate.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

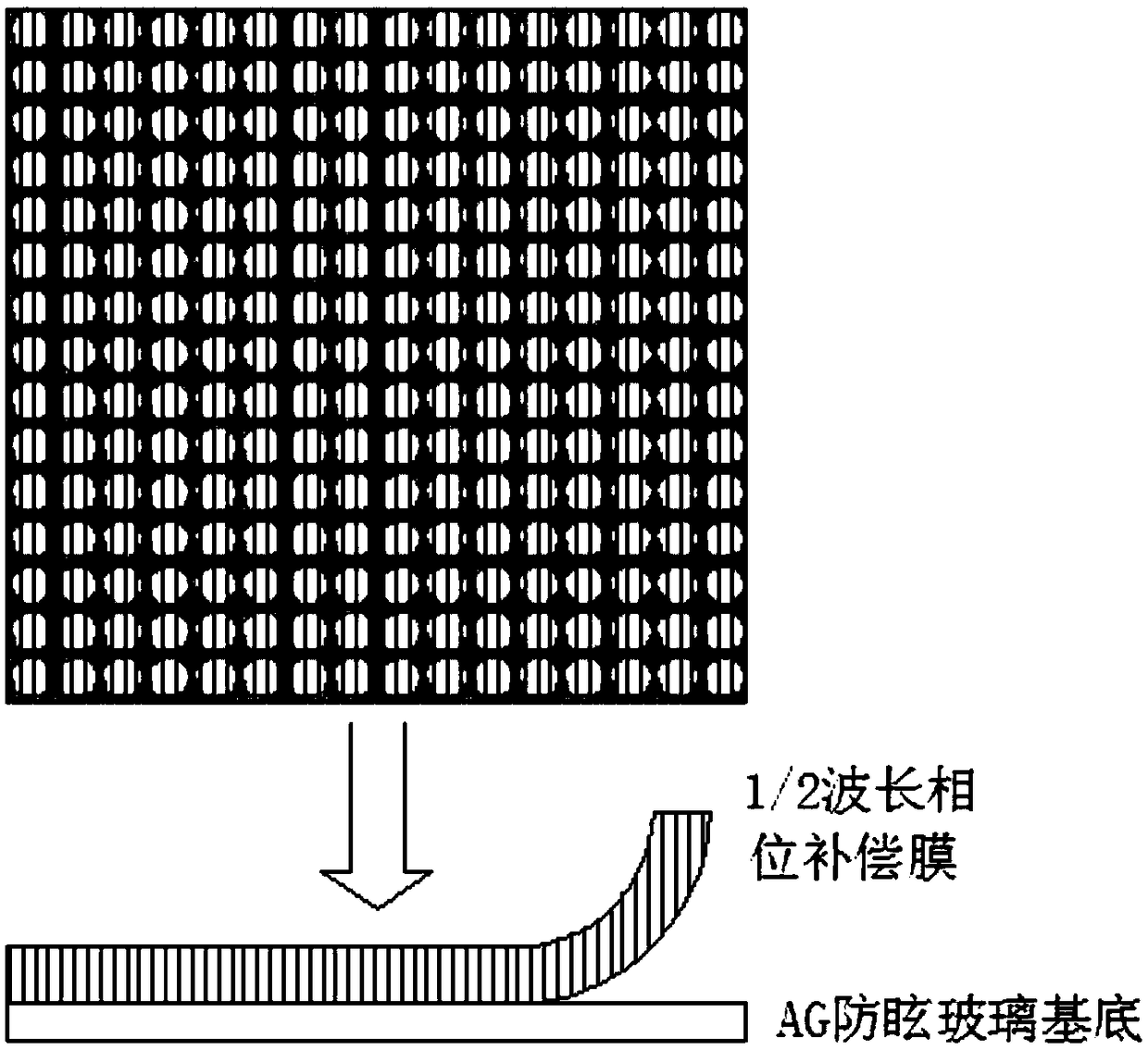

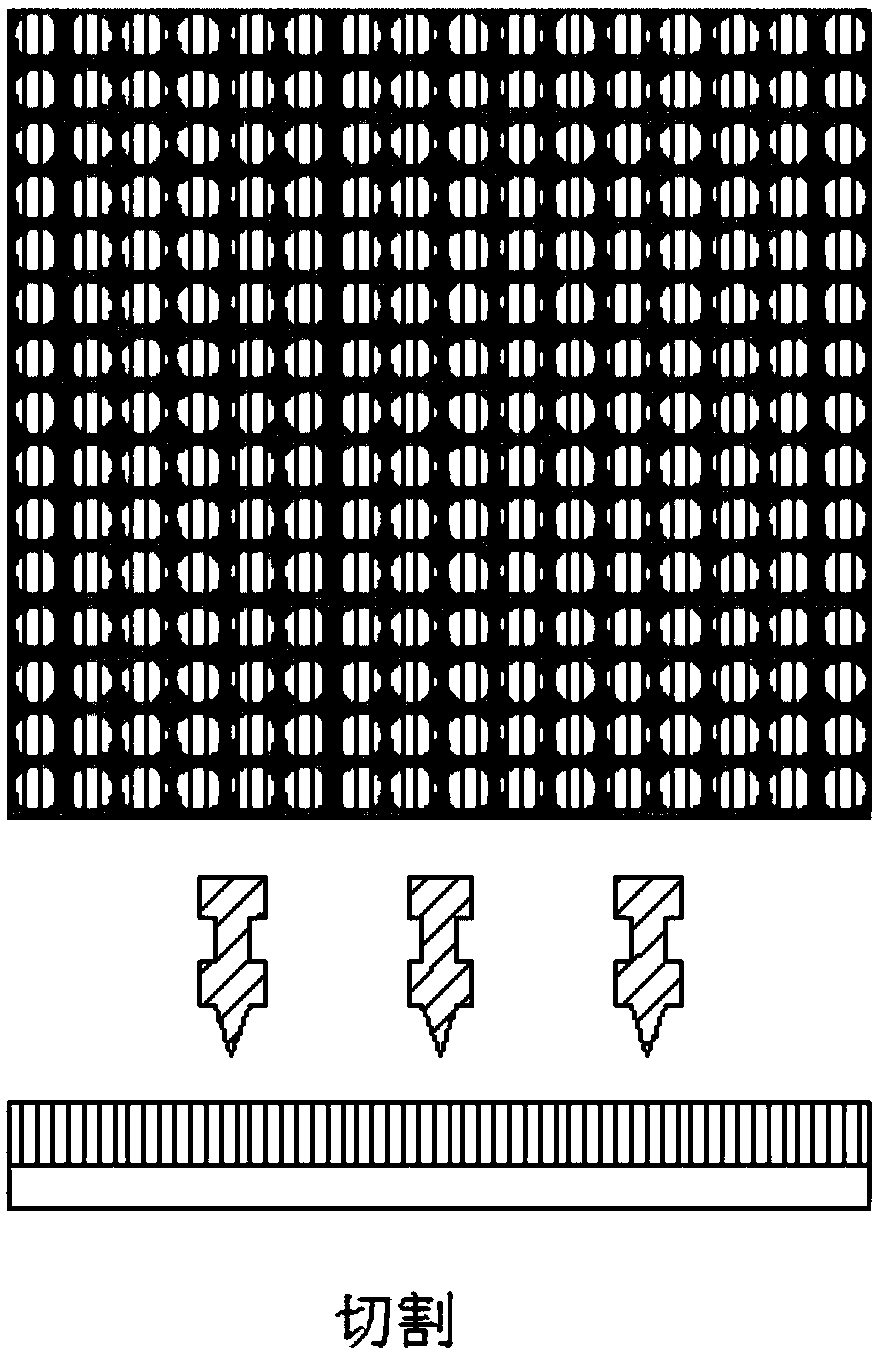

Low-reflectivity 3D polarized light film, low-reflectivity polarized light LED and preparation method

ActiveCN108919406AAchieve precise preparationSolve the difficulties that splicing is difficult to achievePolarising elementsPhase differenceOptoelectronics

The invention relates to a low-reflectivity 3D polarized light film, a low-reflectivity polarized light LED and a preparation method. The low-reflectivity 3D polarized light film, the low-reflectivitypolarized light LED and the preparation method aim to solve the problems that a traditional polarized light film preparation method has large accumulative seam splicing error, large crosstalk interval and poor flatness and high reflectivity of a manufactured product. The preparation method of the low-reflectivity 3D polarizing film comprises the following steps that patterned AG anti-glare glassis manufactured; 1 / 2 wavelength phase difference compensation film is attached to the non-AG surface of an AG anti-glare glass layer; cutting is carried out to form a patterned structure; invalid areastripping is carried out; filling is carried out to form a planarization layer; a polarizer is aligned and attached to the planarization layer or a black shading layer of AG anti-glare glass to prepare the low-reflectivity 3D polarized light film; and furthermore, glue is applied to the patterned AG anti-glare glass, polarizer or an LED module of the 3D polarized light film, and the 3D polarizedlight film and the LED module are aligned and attached to prepare the low-reflectivity polarized light LED.

Owner:NINGBO VISION DISPLAY TECH

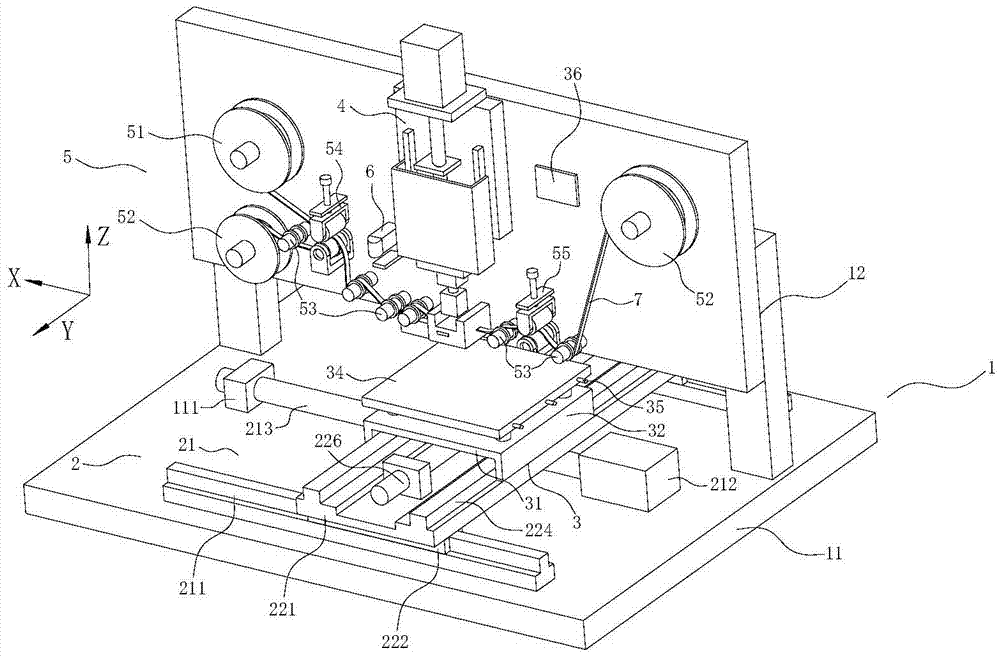

Automatic stamping and laminating machine

InactiveCN107116612AImprove bonding efficiencyReduce use costMetal working apparatusControl systemAutomatic testing

The invention discloses an automatic stamping and laminating machine. The automatic stamping and laminating machine comprises a supporting frame, a carrying table moving assembly, a carrying table assembly located on the carrying table moving assembly and moving in the X direction and the Y direction through the carrying table moving assembly, a stamping assembly, a receiving and releasing assembly and a control system; gum penetrates the stamping assembly, is stamped by the stamping assembly and is laminated on a laminated object, two ends of gum are located on the receiving and releasing assembly, and are collected and released by the receiving and releasing assembly, and the control system is connected with the carrying table moving assembly, a carrying table assembly, the stamping assembly and the receiving and releasing assembly. Back laminating work is carried out by replacement of jig manual combination, the aim that the gum is automatically peeled from a release film is achieved, automatic stamping and automatic laminating are achieved, the gum laminating efficiency is improved, the laminating quality is ensured, and the use cost and the laminating cost of the gum are reduced.

Owner:SUZHOU DAXIANG NEW MATERIAL

Locating assembling tool

ActiveCN106964951ARealize large-scale productionImprove bonding efficiencyWork holdersMetal working apparatusMechanical engineeringBallast

The invention relates to a locating assembling tool. The locating assembling tool is used for fit of a workpiece and an annular accessory. The locating assembling tool comprises a bearing mechanism, a locating mechanism and a pressure mechanism. The bearing mechanism comprises a base assembly, a first bearing platform which is arranged on the base assembly and used for bearing the workpiece and has elasticity and a second bearing platform which is connected with the base assembly, used for bearing the annular accessory and surrounds the first bearing platform, wherein the height of the surface of the first bearing platform is larger than the set height of the second bearing platform. The locating mechanism comprises multiple locating assemblies, wherein the locating assemblies are symmetrical about the second bearing platform and used for locating the workpiece and the annular accessory. The pressure mechanism comprises a supporting assembly fixed to the base assembly, a drive piece arranged on the supporting assembly and a ballast piece which is connected with the drive piece and used for exerting pressure on the workpiece and the first bearing platform. By the adoption of the locating assembly tool, on the basis of guaranteeing the fit quality of the workpiece and the annular accessory, the fit efficiency between the workpiece and the annular accessory is improved.

Owner:GUANGDONG EVERWIN PRECISION TECH

Attaching method of steel sheet enhancing sheets of flexible circuit board, jigs of flexible circuit board, and strip attaching steel sheets of flexible circuit board

ActiveCN103731991AAdvantages of bonding methodAvoid fitPrinted circuit detailsPrinted circuit manufactureFlexible circuitsEngineering

The invention discloses an attaching method of steel sheet enhancing sheets of a flexible circuit board, jigs of the flexible circuit board, and strip attaching steel sheets of the flexible circuit board. The method includes the first step of arranging pure glue, covering enhancing sheet attaching positions located on the upper portion inside all regions surrounded by all grooves, on all rows of grooves of the flexible circuit board, the second step of enabling position fixing stop dogs corresponding to the jigs to be sleeved with all the rows of grooves of the flexible circuit board, and enabling upper positioning pins to be sleeved with first positioning holes above all the rows of grooves, the third step of attaching the steel sheet enhancing sheets of the strip attaching steel sheets corresponding to all the rows of grooves to the pure glue in the enhancing sheet attaching positions, and enabling each positioning pin to be sleeved with the corresponding strip attaching steel sheet through a second positioning hole of a connecting rib, the fourth step of placing the jigs into a false attaching machine along with the flexible circuit board and the strip attaching steel sheets to be pressed in advance, pressing the pure glue through a hot press after pressing is conducted through the false attaching machine in advance, and enabling all the steel sheet enhancing sheets to be attached to the enhancing sheet attaching positions of the flexible circuit board, and the fifth step of stripping all the connecting ribs of the strip attaching steel sheets from the steel sheet enhancing sheets on the connecting ribs. According to the method, the multiple enhancing sheets can be simultaneously attached, the attaching efficiency is improved, and the operation is convenient.

Owner:SHENZHEN HUALIN CIRCUIT TECH

Film pasting device for 3D glass with two opposite edges as curved edges and film pasting method

ActiveCN107323726AGuaranteed non-interferenceEasy accessPackagingGlass productionEngineeringMechanical engineering

Owner:LENS TECH CHANGSHA

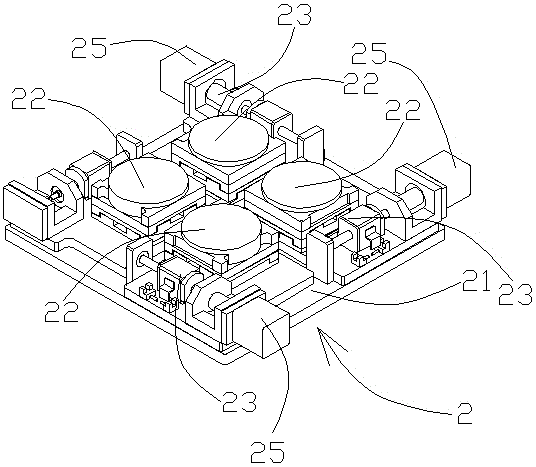

Vision alignment platform

InactiveCN104859888AQuick alignmentAlignment quick preparationPackaging automatic controlElectric machineryEngineering

The invention discloses a vision alignment platform. The platform comprises a controller, an alignment mechanism and a photographing unit, wherein a display screen is arranged on the controller, analysis and calculation software is embedded in the controller, the controller is in signal communication with the alignment mechanism through a signal line, the alignment mechanism comprises a base, four XYtheta sliding platforms, three adjusting screw rods and a working platform, the four XYtheta sliding platforms are evenly distributed in the center of the base, the three adjusting screw rods are arranged on outer sides of the four XYtheta sliding platforms and act under the driving of three external motors respectively to drive the XYtheta sliding platforms to act, and the photographing unit is fixed above the working platform through a fixing support; positions of products are acquired by the photographing unit, position deviations are calculated accurately by the analysis and calculation software in the controller, the products are moved to accurate positions by the alignment mechanism, so that quick and accurate alignment is realized, the alignment accuracy is high, the error is very small, the yield of the products produced through aligned lamination is high, the lamination efficiency is improved, and the lamination quality is guaranteed.

Owner:厦门坚端精密机械有限公司

Attaching device and attaching method

ActiveCN109795201AImprove bonding efficiencyIncrease productivityLaminationLamination apparatusElectrical and Electronics engineering

The invention discloses an attaching device and an attaching method. The attaching device comprises a first carrier table, a second carrier table and a driving assembly, and the first carrier table isused for carrying a first component; the second carrier table is used for carrying a second component, and the second component and the first component are arranged in a face-to-face manner; and thedriving assembly is used for driving the first carrier table and the second carrier table to magnetically attract to enable the first component and the second component to be attached to each other. According to the attaching device disclosed by the invention, the first component and the second component are respectively carried by the carrier tables, and then the first component and the second component are attached to each other through a magnetic attraction effect, so that the attaching efficiency can be effectively improved, the device is simple to operate, and the production efficiency isgreatly improved.

Owner:BAZHOU YUNGU ELECTRONICS TECH CO LTD

Mobile phone cover plate attachment mold and process

The invention provides a mobile phone cover plate attachment mold. The mobile phone cover plate attachment mold is used for enabling a glass cover plate to be attached to a protection film so as to form a mobile phone cover plate. The mobile phone cover plate attachment mold comprises an upper mold, a pad film and a lower mold. A groove is formed in the upper mold. The lower mold comprises a substrate, a bearing part and elastic parts. The substrate comprises a bottom plate and a side plate, and containing space is formed between the bottom plate and the side plate. The pad film is located between the upper mold and the lower mold and comprises a bearing portion. The upper surface of the bearing portion faces the upper mold and is used for containing the to-be-attached protection film. Thelower surface of the bearing portion is borne on the bearing part and the side plate of the substrate of the lower mold. The bearing part gives first supporting to the middle area of the bearing portion, and the side plate gives second supporting to the corner areas of the periphery of the bearing portion. When the upper mold and the lower mold are compounded, second supporting pressure providedfor the corners of the periphery of the bearing portion is larger than first supporting pressure of the middle area of the bearing portion. The invention further provides an attachment process for carrying out attachment of the glass cover plate and the protection film through the attachment mold. The protection film and the glass cover plate are attached closely, and the effect is better.

Owner:DONGGUAN GUANHE OPTICAL GLASS CO LTD

Rolling type leveling mechanism

InactiveCN107031905AImprove film application efficiencyPrevent prone toPackagingEngineeringAir bubble

The invention relates to a rolling smoothing mechanism, which includes a limit device, a support device for supporting a film, guide devices arranged on both sides of the support device, and a device for driving the guide device, the support device and the film along the support device. The limiting device moves upward to make the film contact with the workpiece to be filmed, and then moves along the guide device to both sides so that the film is completely attached to the surface of the workpiece; the invention overcomes the problems of low film sticking efficiency and many bubbles in the film sticking process.

Owner:长兴昊太机械有限公司

Device for dispensing and gluing and method for dispensing and gluing of touch screen

InactiveCN102716836AImprove bonding efficiencyLow costLiquid surface applicatorsLaminationEngineeringMechanical engineering

A device for dispensing and gluing is used for dispensing and gluing a first workpiece and a second workpiece. The device includes a support, a first translational structure arranged on the support, a second translational structure connected with the first translational structure, a loading stage for loading the first workpiece and the second workpiece, a vacuum adsorption module and a dispensing structure. The loading stage is connected with the first translational structure. The vacuum adsorption module is connected with the support. When the loading stage moves to the vacuum adsorption module, the vacuum adsorption module can adsorb the first workpiece. The dispensing structure is arranged on the support and near an end where the first translation structure is arranged, and the loading stage moves to the dispensing structure for performing dispensing on the second workpiece. The first translational structure drives the loading stage to move, and the first translational structure drives the second translational structure to move. The above dispensing structure provided in the invention, avoiding the use of a turning shaft, is advantaged in simple structure, lower cost, avoidance of twice-turnover processing in a process, easiness in operation as well as improved dispensing and gluing efficiency. Further provided is a method for dispensing and gluing of a touch screen.

Owner:SHENZHEN TAIYI MECHANICAL & ELECTRICAL EQUIP

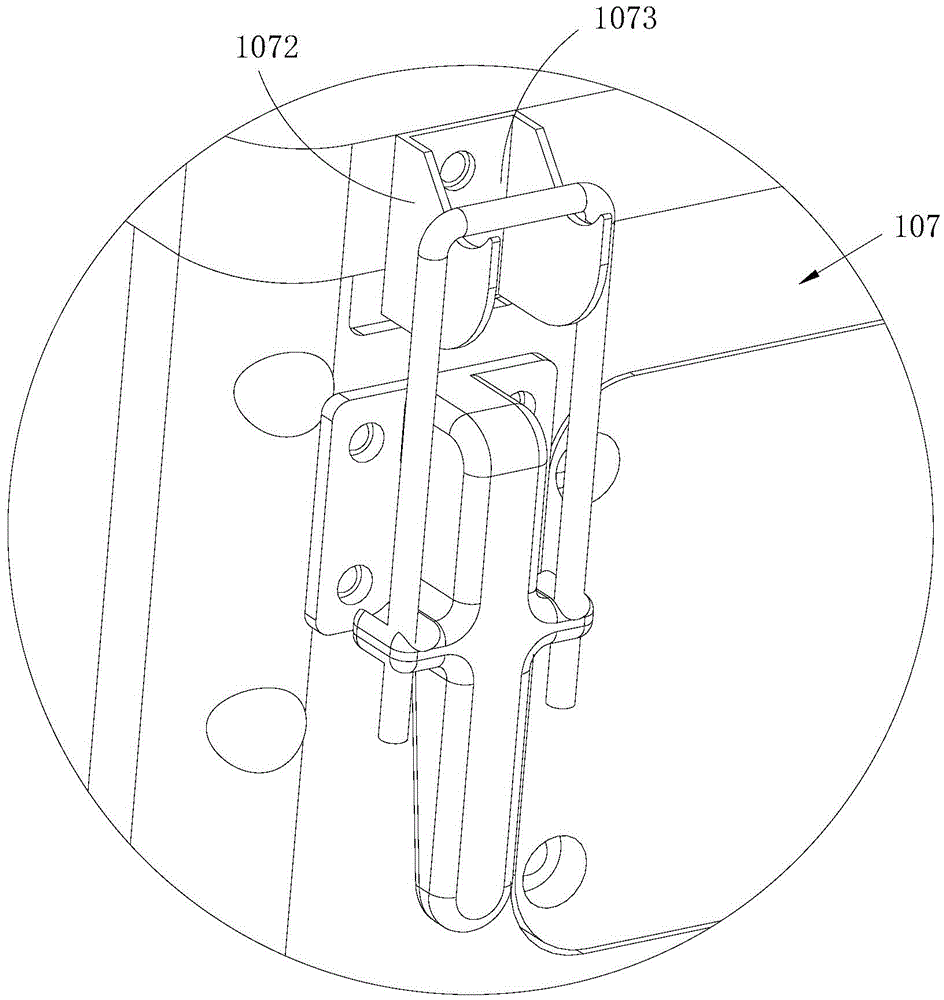

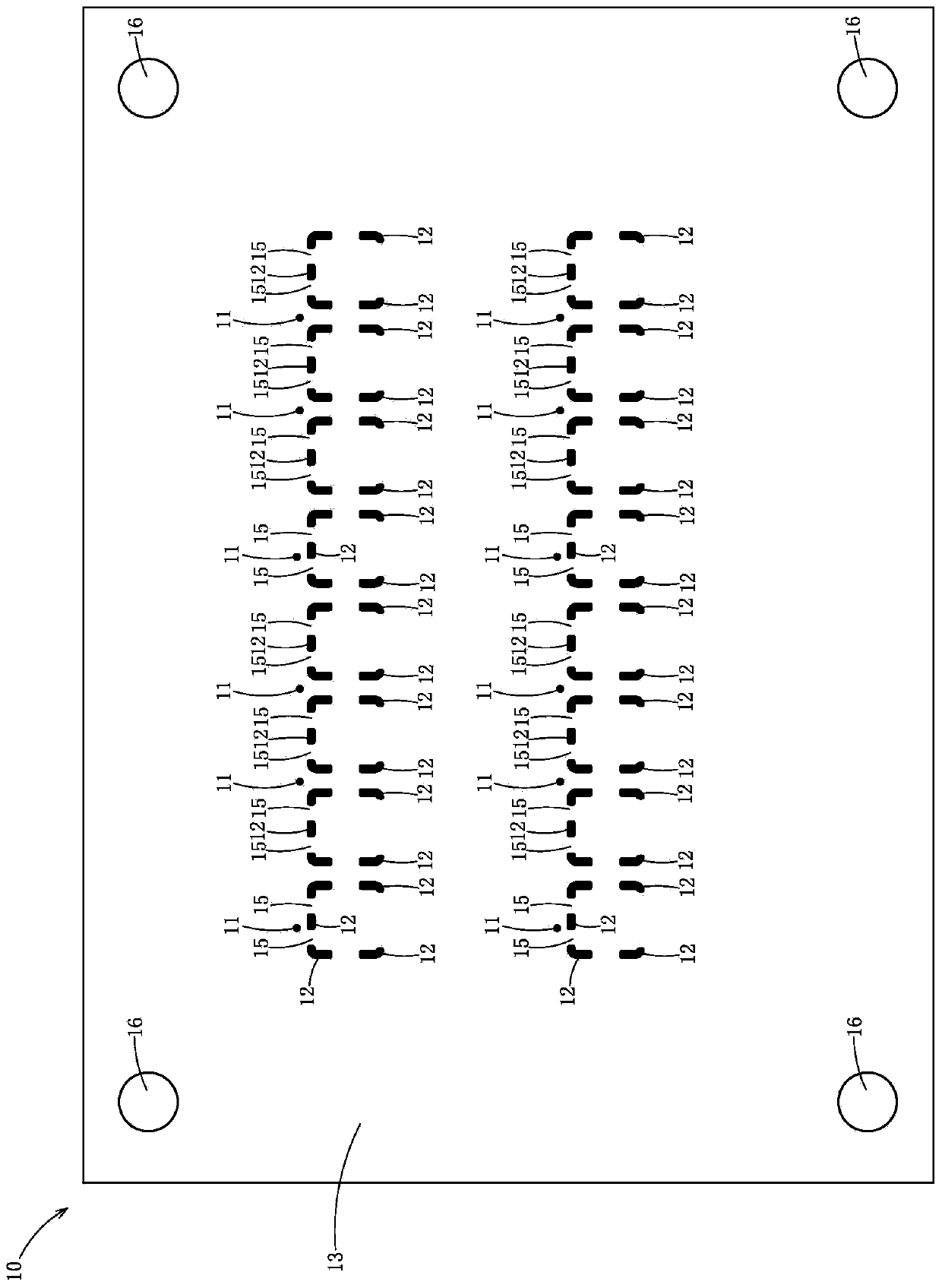

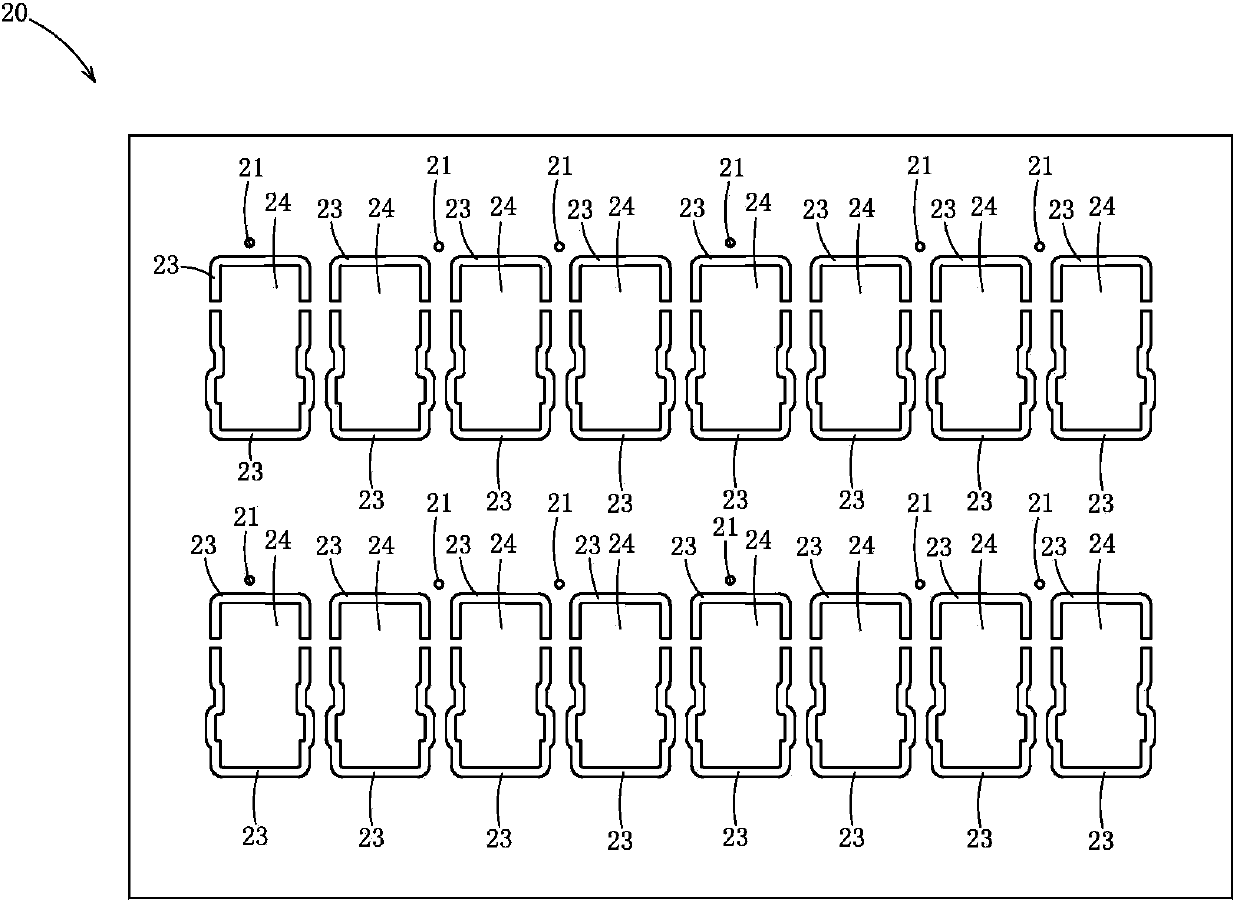

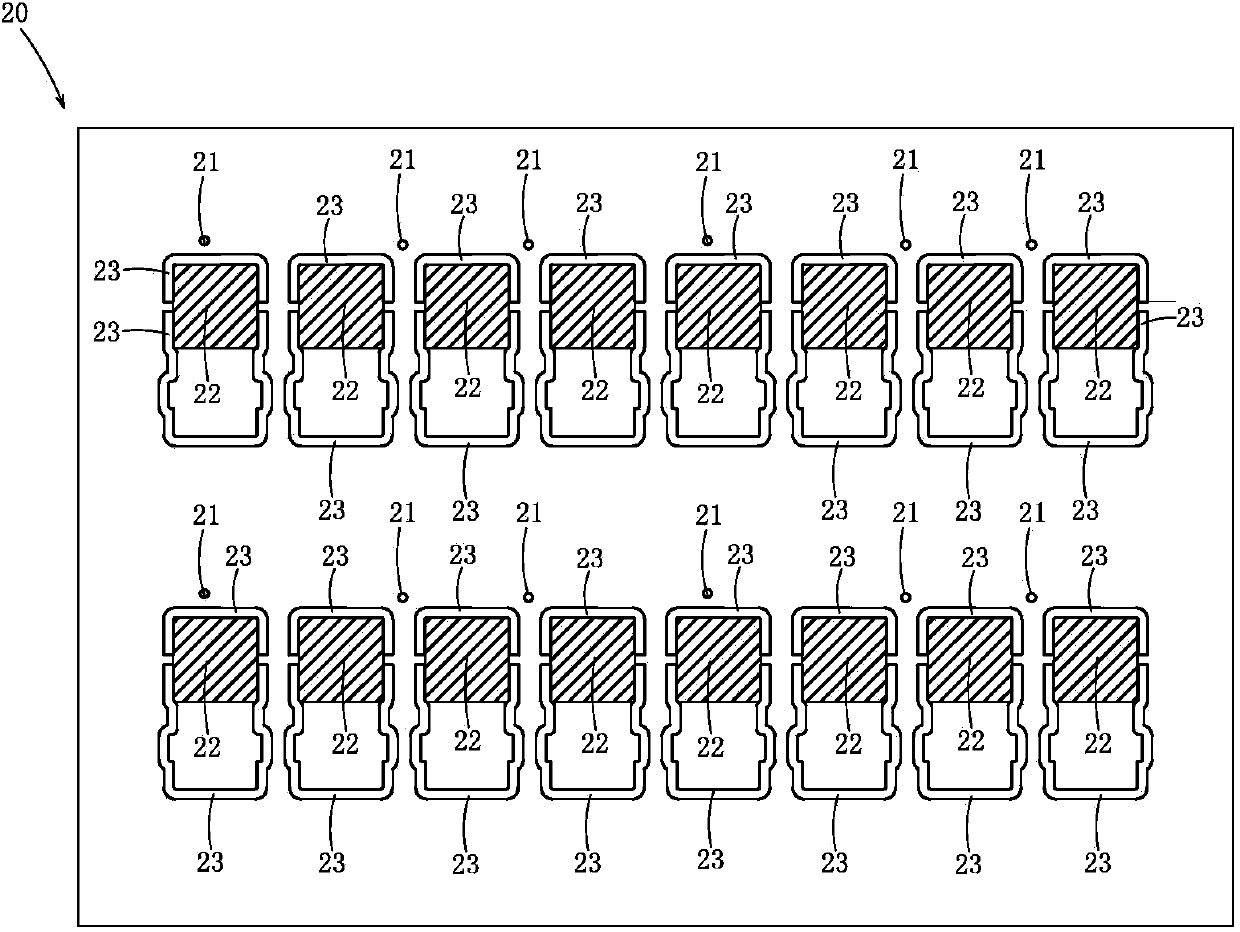

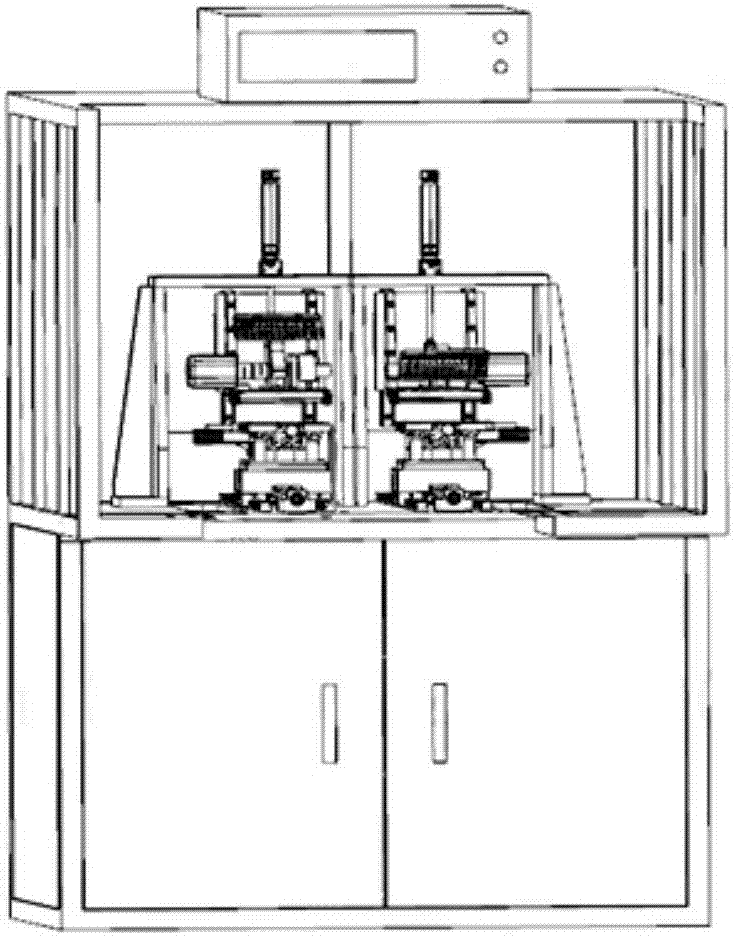

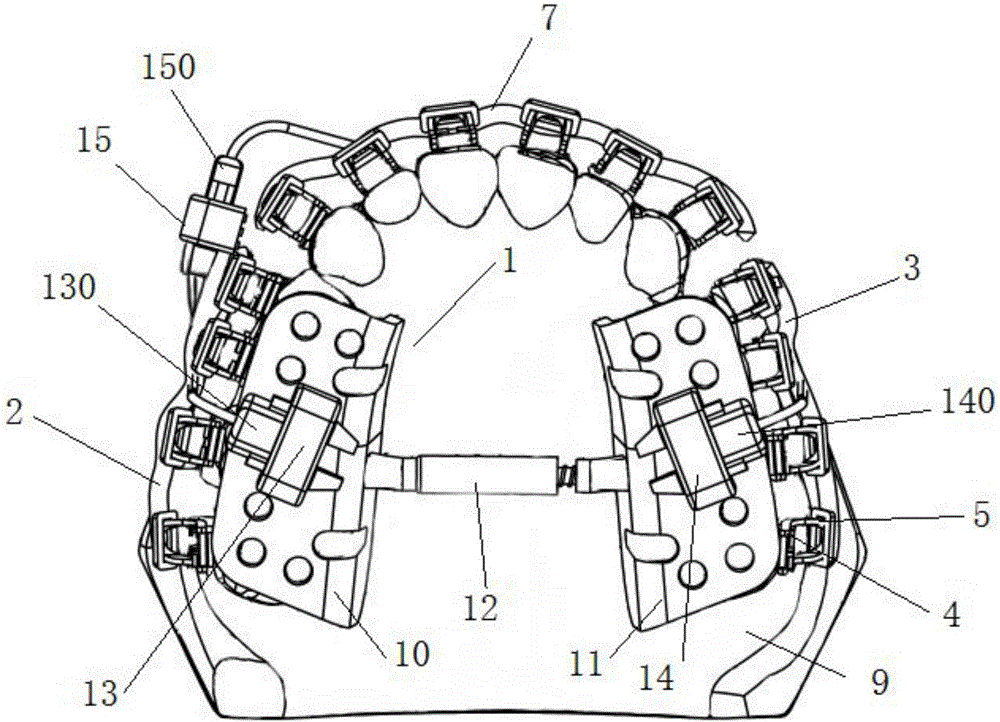

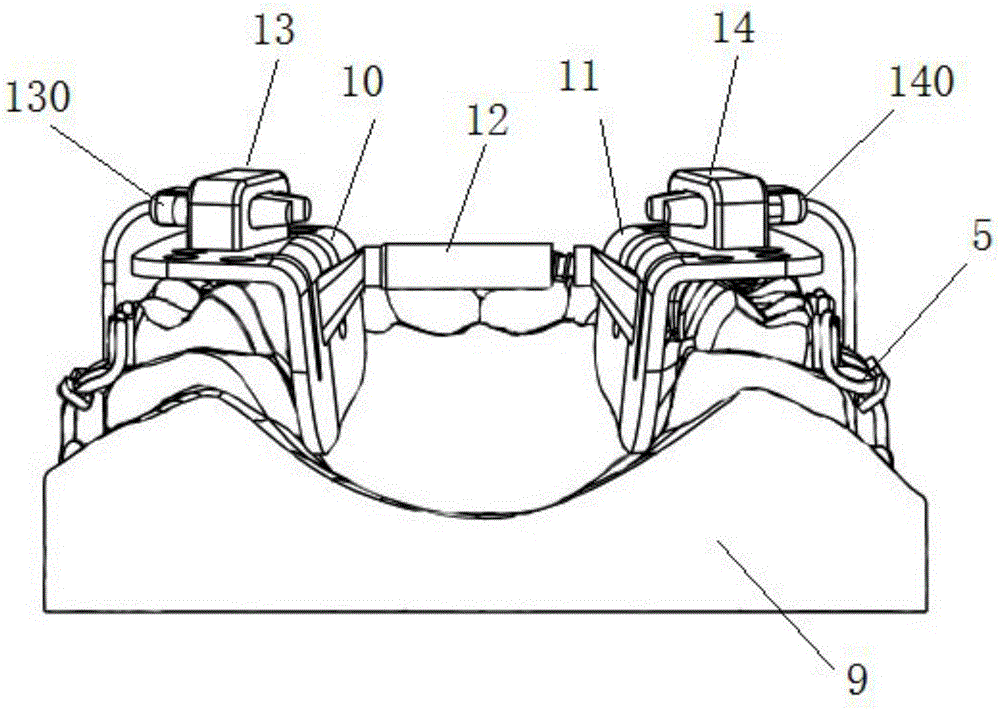

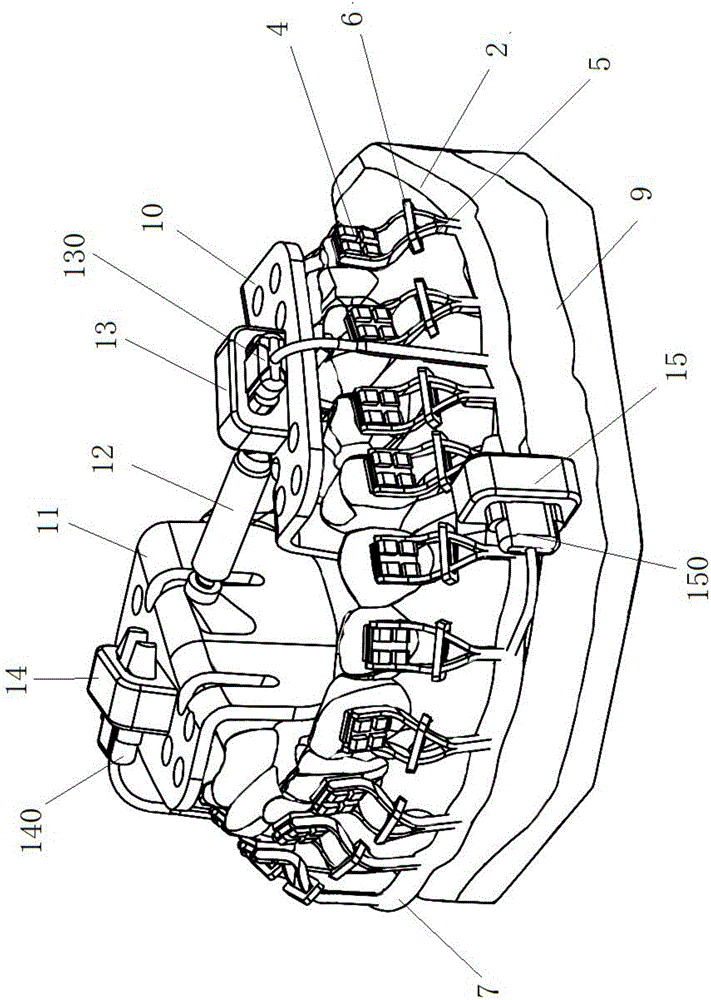

Orthodontic bracket indirect bonding precise positioning system and application method

The invention relates to an orthodontic bracket indirect bonding precise positioning system and an application method. The orthodontic bracket indirect bonding precise positioning system comprises a local positioning tray (1), a rear right tooth transfer arch-shaped rod (2), a rear left tooth transfer arch-shaped rod (3) and a front tooth transfer arch-shaped rod (7). The local positioning tray (1) comprises a first single side positioning local tray body (10) and a second single side positioning local tray body (11) which are symmetrically arranged, and a detachable spring ejecting rod (12) is installed between the first single side positioning local tray body (10) and the second single side positioning local tray body (11). By means of the orthodontic bracket indirect bonding precise positioning system and the application method, a bracket can be more precisely arranged; the bonding time is shortened; a patient feels more comfortable, and an upper bracket for intraoral teeth can be easily and quickly bonded clinically. In addition, healthier human engineering is achieved through indirect bonding, three-dimensional control over the teeth can be conveniently achieved, facial form improvement can be better achieved, and a good correction effect can be obtained.

Owner:赵计林

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com