Parallel compound ultrasonic energy transmission device

An energy transmission and composite technology, applied in the field of processing tools, can solve problems such as difficult to output and difficult to realize, and achieve the effects of ensuring consistency, increasing coverage area, and compact overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is described in more detail below in conjunction with accompanying drawing example:

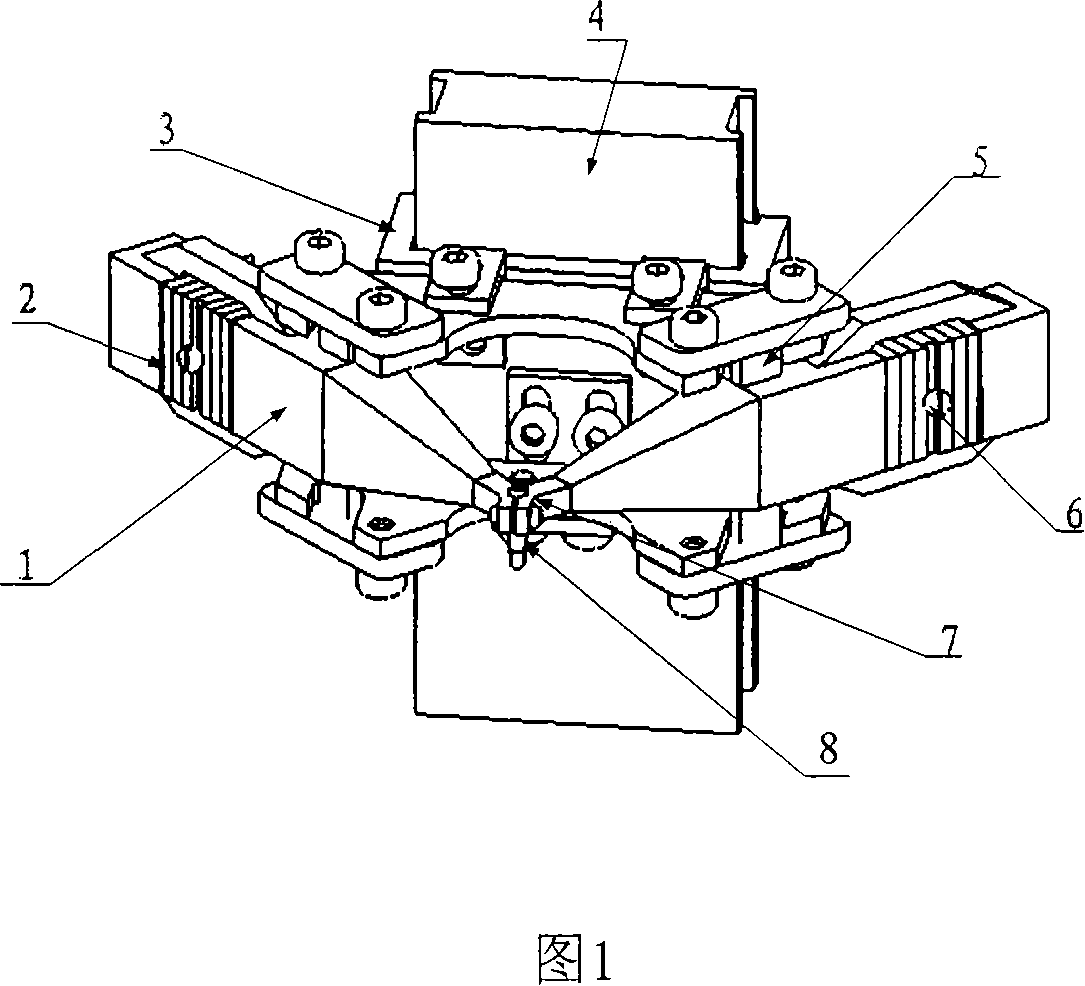

[0028] Combining Figures 1, 8, 9 and 10, the composition of the parallel composite ultrasonic energy transmission device includes a parallel composite ultrasonic horn 1, a working chopper 7 is installed at the end of the horn, and a The piezoelectric ultrasonic transducer 2 and the working ends of two sets of unidirectional vibration horns are rigidly connected in parallel, and the horns are fixed on the moving platform 3 of the voice coil motor 4 through the elastic beam 5 . The section of the horn is rectangular or square. The piezoelectric ultrasonic transducer is piezoelectric ceramic wafers stacked in parallel, a pre-tightening wedge is arranged in the middle of the parallel stacking piezoelectric ceramic wafers, and a pre-tightening bolt 6 is provided on the pre-tightening wedge. There are three pre-tightening wedges, namely wedge 10, wedge 11 and wedge 12,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com