Patents

Literature

591 results about "Elastic beam" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

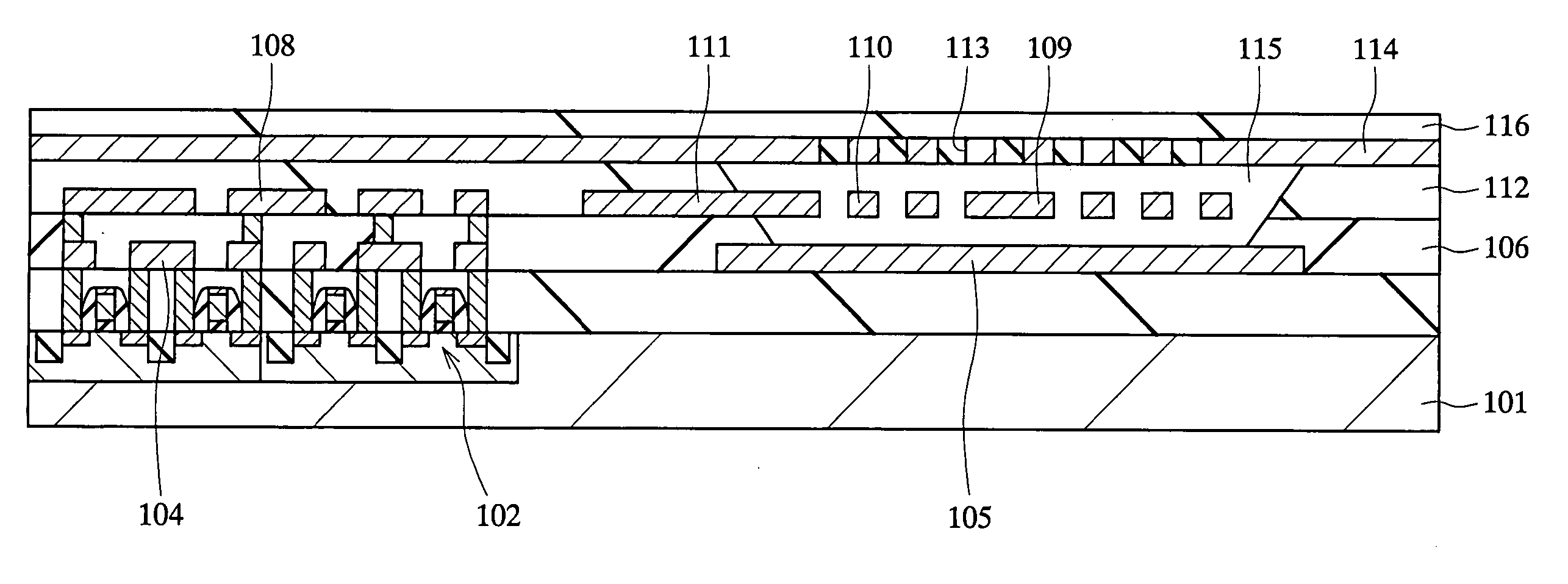

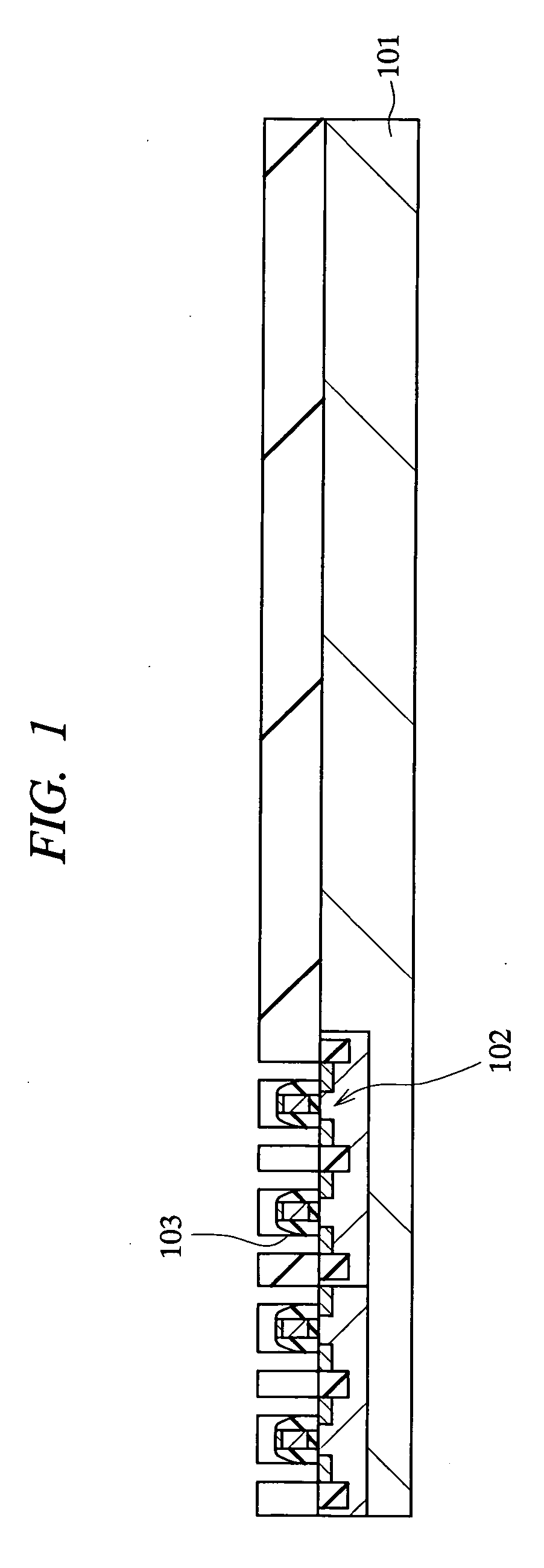

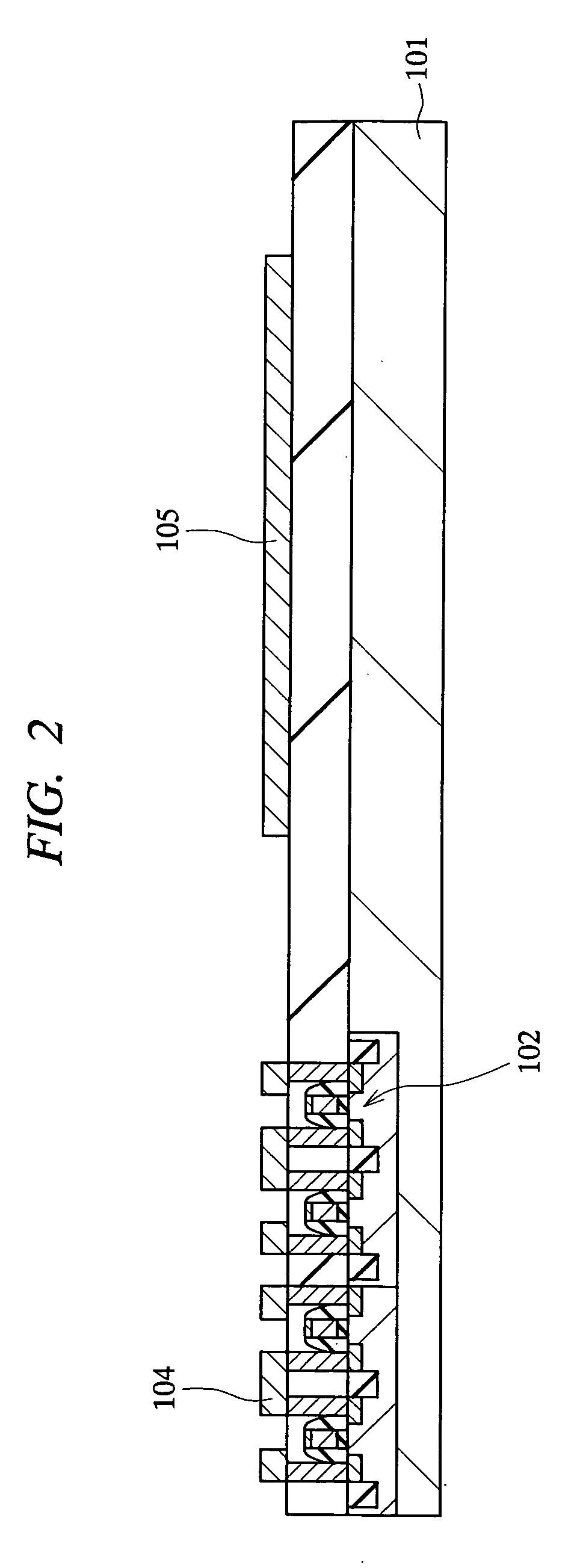

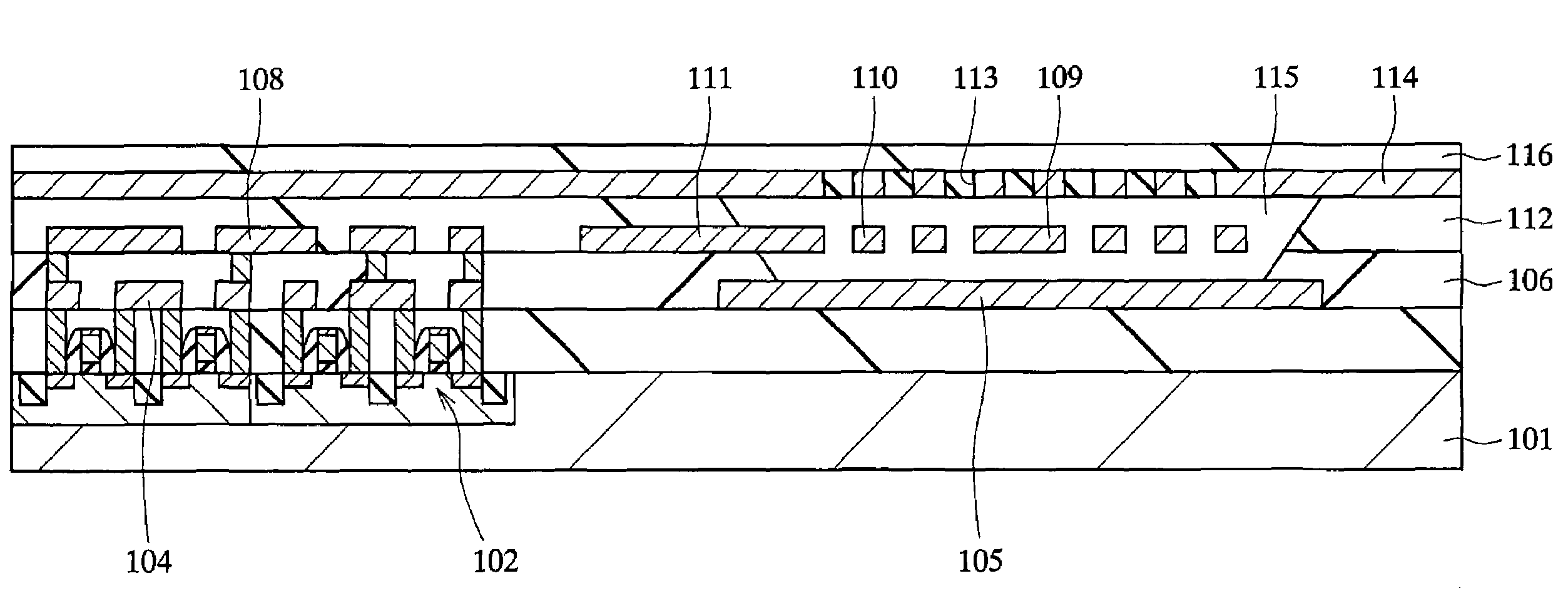

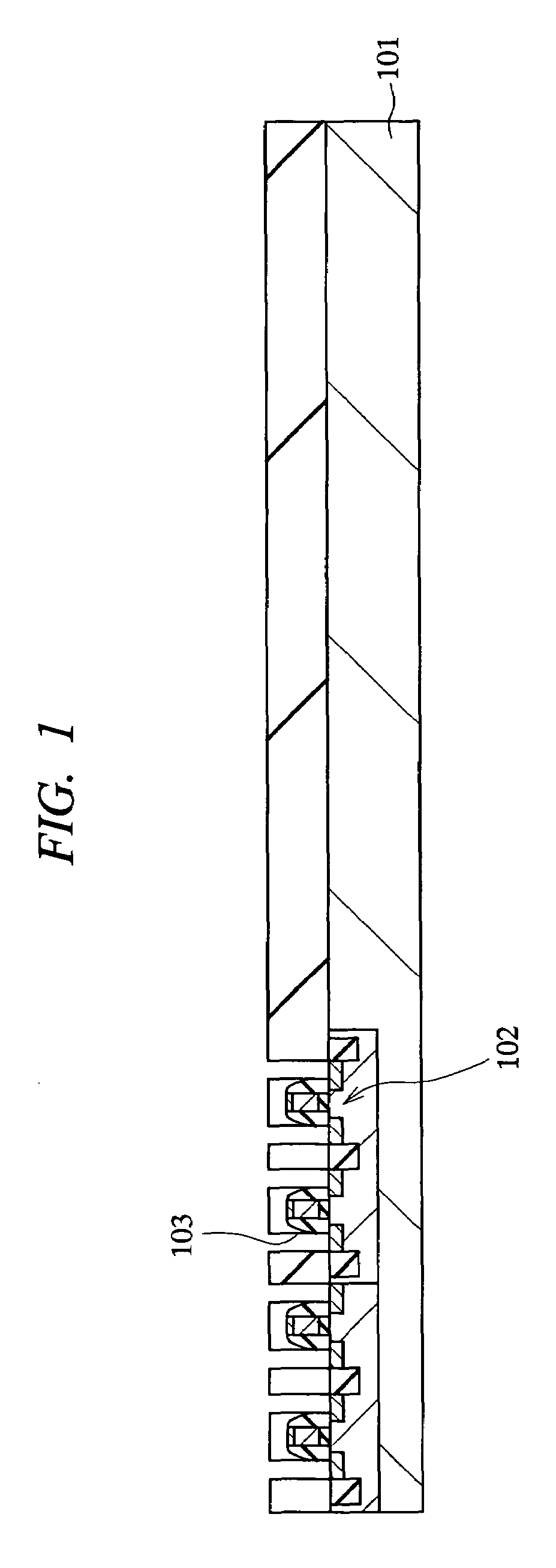

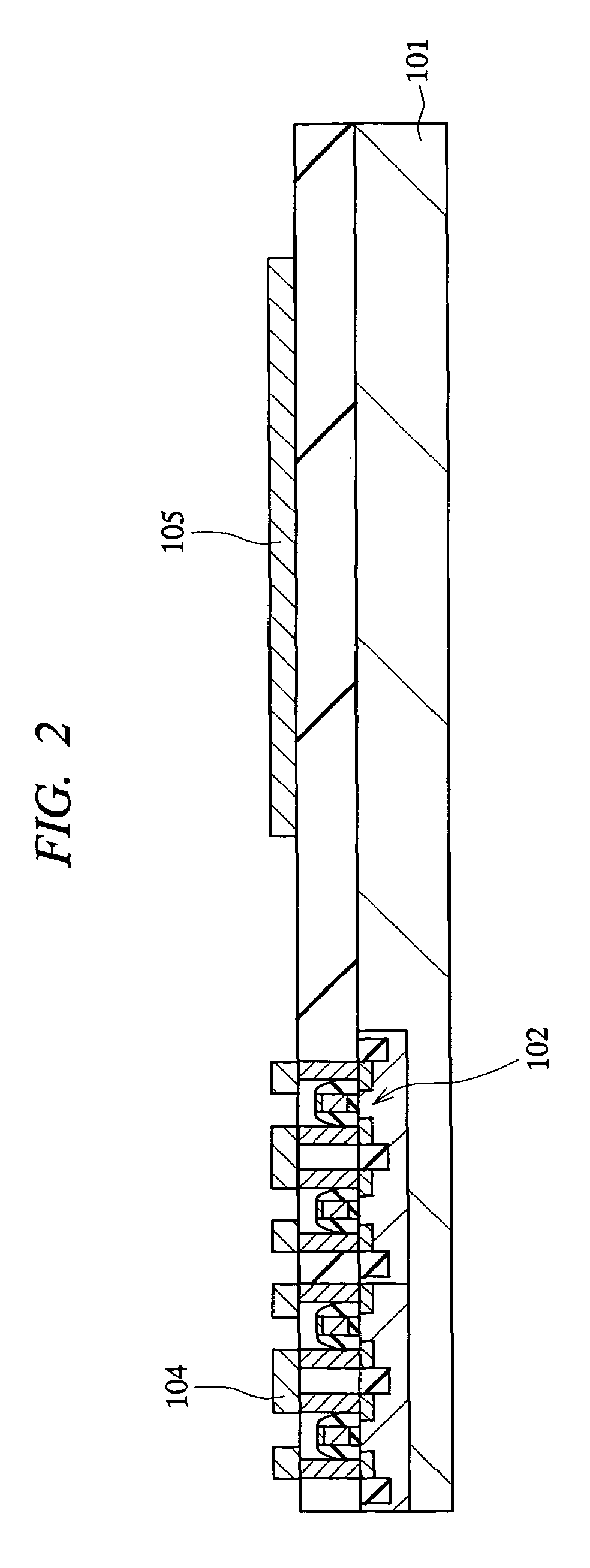

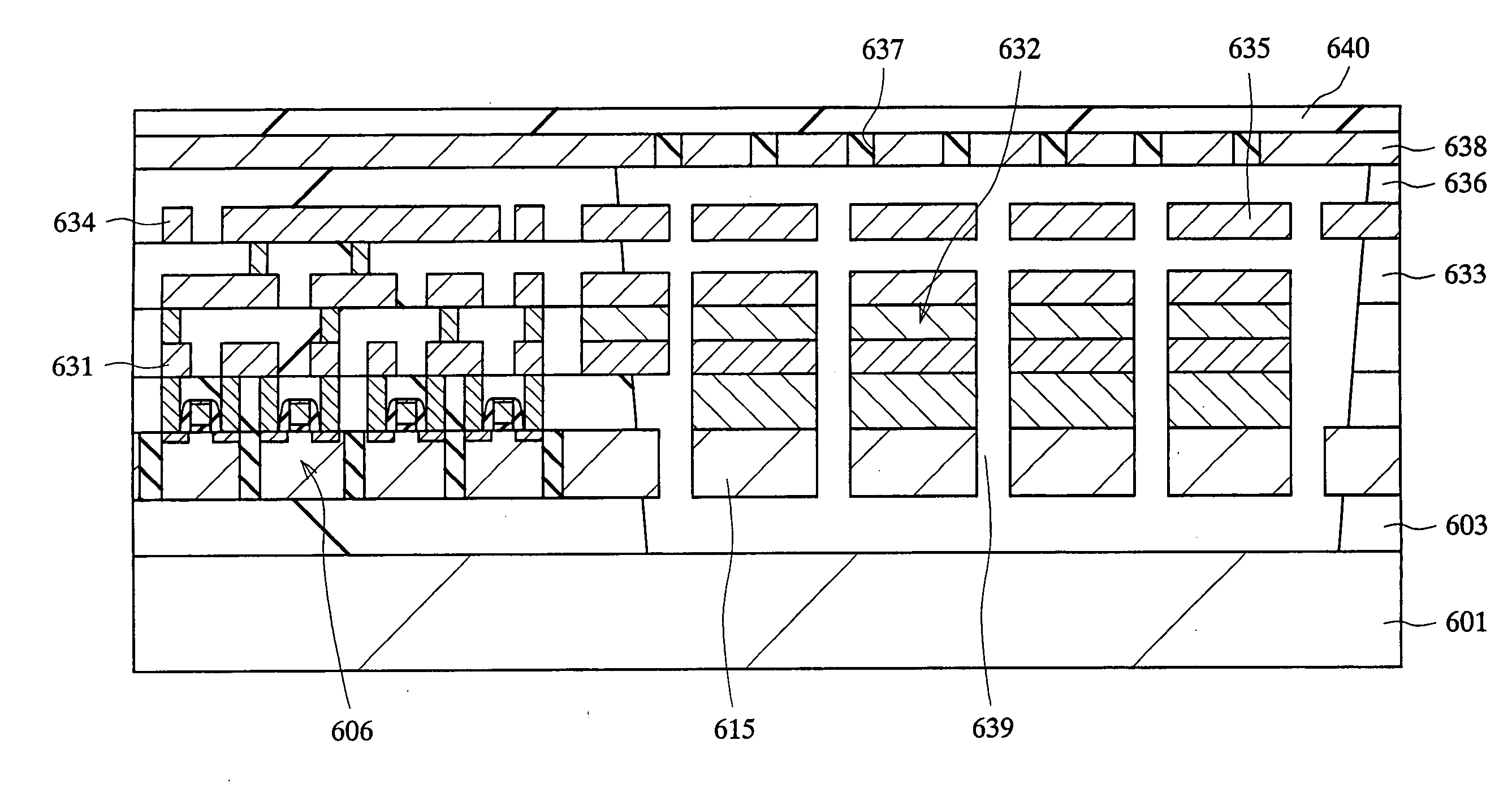

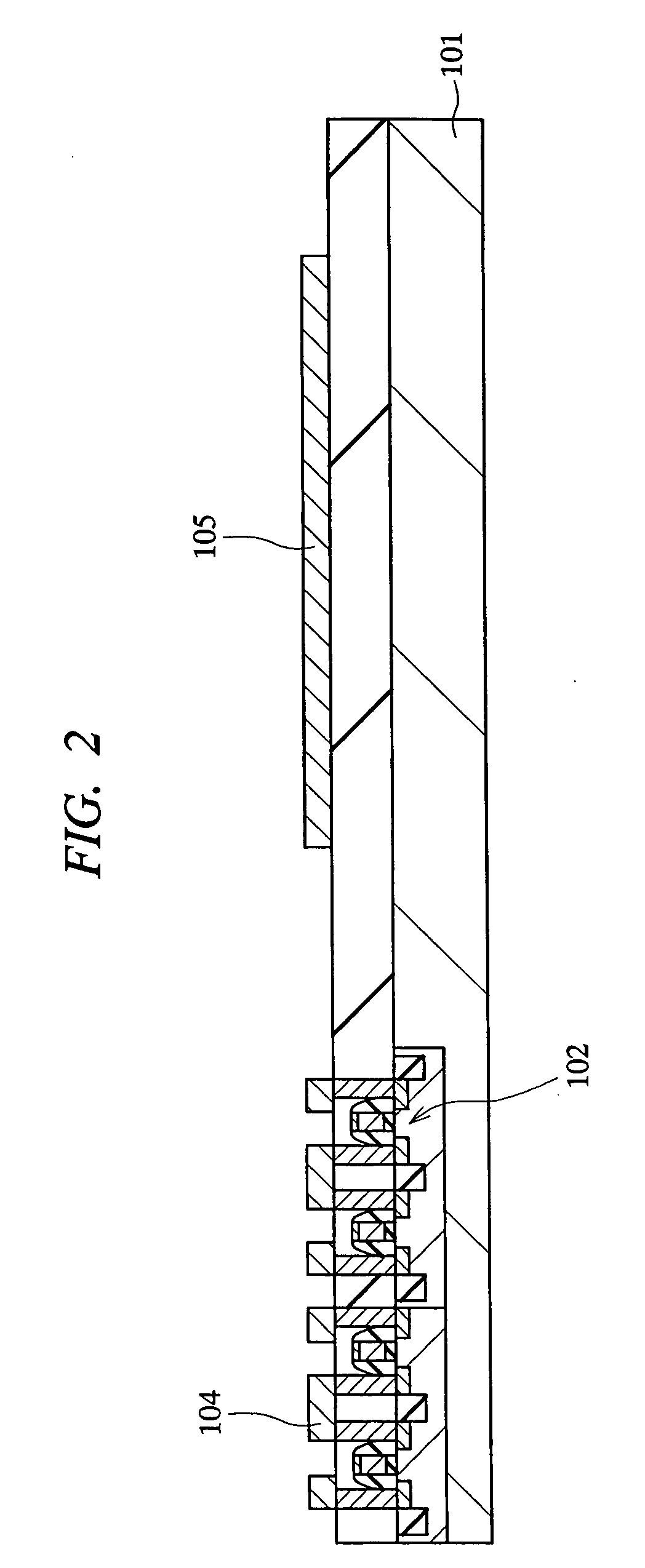

Integrated micro electro-mechanical system and manufacturing method thereof

ActiveUS20060205106A1Accurate representationHigh dimensional accuracyTelevision system detailsInflated body pressure measurementDielectricEtching

In the manufacturing technology of an integrated MEMS in which a semiconductor integrated circuit (CMOS or the like) and a micro machine are monolithically integrated on a semiconductor substrate, a technology capable of manufacturing the integrated MEMS without using a special process different from the normal manufacturing technology of a semiconductor integrated circuit is provided. A MEMS structure is formed together with an integrated circuit by using the CMOS integrated circuit process. For example, when forming an acceleration sensor, a structure composed of a movable mass, an elastic beam and a fixed beam is formed by using the CMOS interconnect technology. Thereafter, an interlayer dielectric and the like are etched by using the CMOS process to form a cavity. Then, fine holes used in the etching are sealed with a dielectric.

Owner:HITACHI ASTEMO LTD

Integrated micro electro-mechanical system and manufacturing method thereof

ActiveUS7402449B2Easy to manufactureSufficient massTelevision system detailsInflated body pressure measurementDielectricEtching

In the manufacturing technology of an integrated MEMS in which a semiconductor integrated circuit (CMOS or the like) and a micro machine are monolithically integrated on a semiconductor substrate, a technology capable of manufacturing the integrated MEMS without using a special process different from the normal manufacturing technology of a semiconductor integrated circuit is provided. A MEMS structure is formed together with an integrated circuit by using the CMOS integrated circuit process. For example, when forming an acceleration sensor, a structure composed of a movable mass, an elastic beam and a fixed beam is formed by using the CMOS interconnect technology. Thereafter, an interlayer dielectric and the like are etched by using the CMOS process to form a cavity. Then, fine holes used in the etching are sealed with a dielectric.

Owner:HITACHI ASTEMO LTD

Integrated micro electro-mechanical system and manufacturing method thereof

InactiveUS20090049911A1Easy to manufactureSufficient massTelevision system detailsInflated body pressure measurementDielectricEtching

In the manufacturing technology of an integrated MEMS in which a semiconductor integrated circuit (CMOS or the like) and a micro machine are monolithically integrated on a semiconductor substrate, a technology capable of manufacturing the integrated MEMS without using a special process different from the normal manufacturing technology of a semiconductor integrated circuit is provided. A MEMS structure is formed together with an integrated circuit by using the CMOS integrated circuit process. For example, when forming an acceleration sensor, a structure composed of a movable mass, an elastic beam and a fixed beam is formed by using the CMOS interconnect technology. Thereafter, an interlayer dielectric and the like are etched by using the CMOS process to form a cavity. Then, fine holes used in the etching are sealed with a dielectric.

Owner:HITACHI LTD

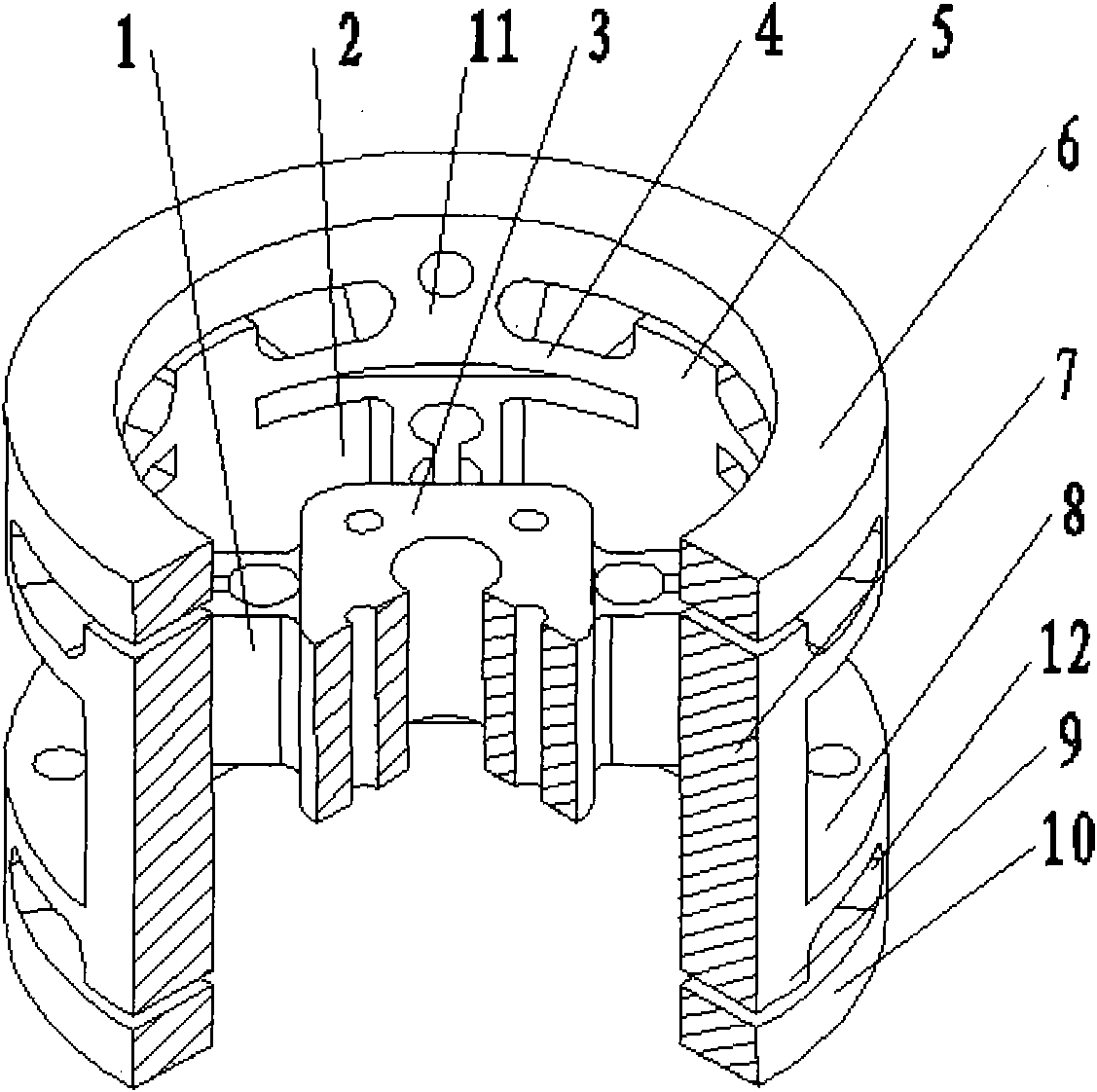

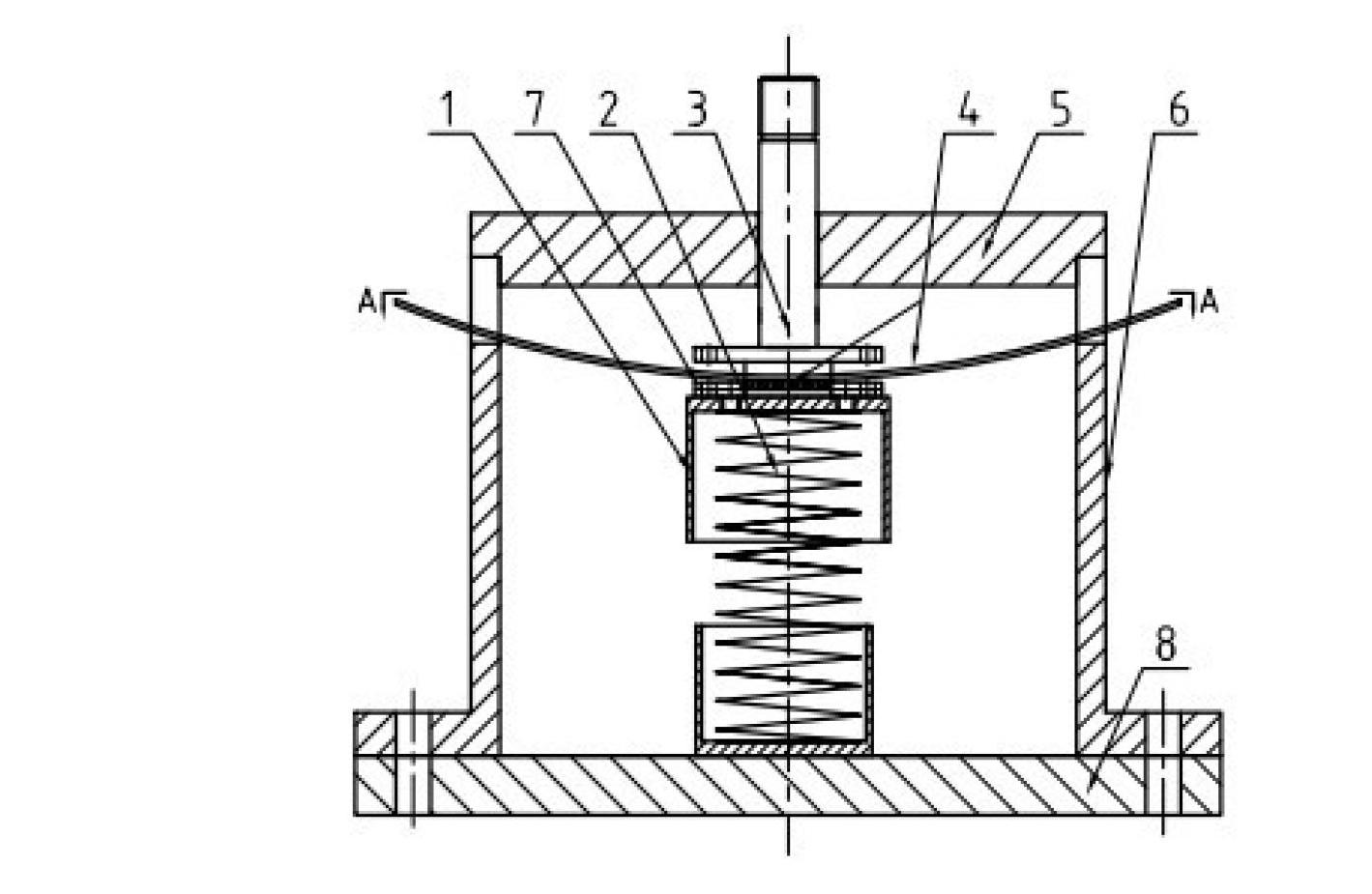

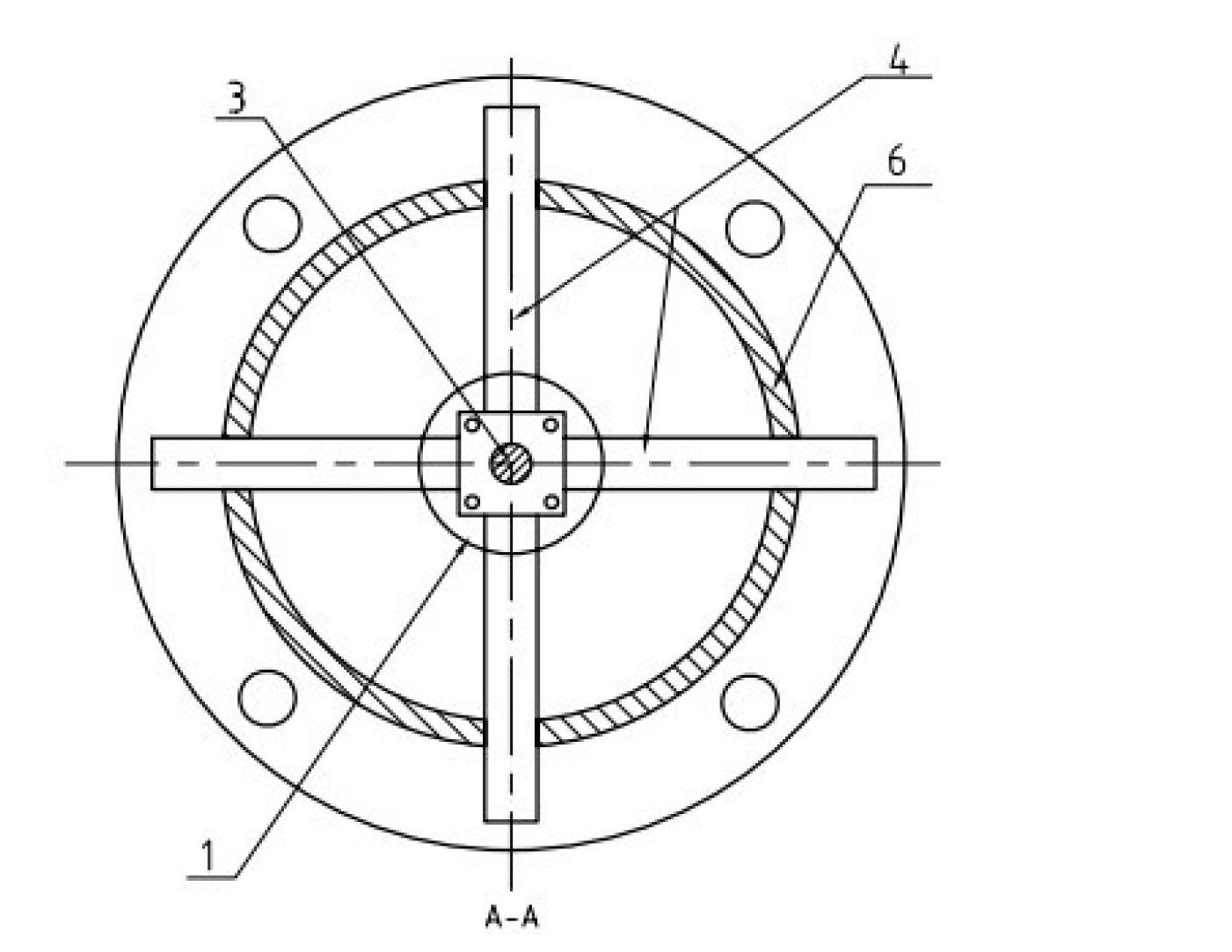

Six-dimensional force sensor

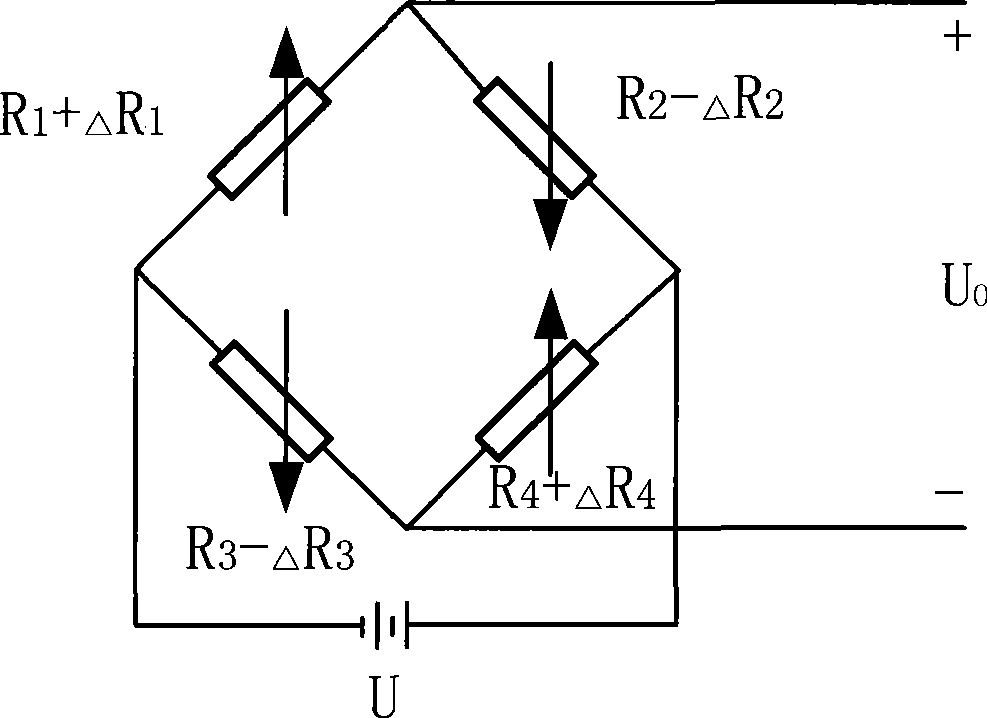

InactiveCN101672705ARealize overload protectionIncrease stiffnessForce measurementElastomerElectrical resistance and conductance

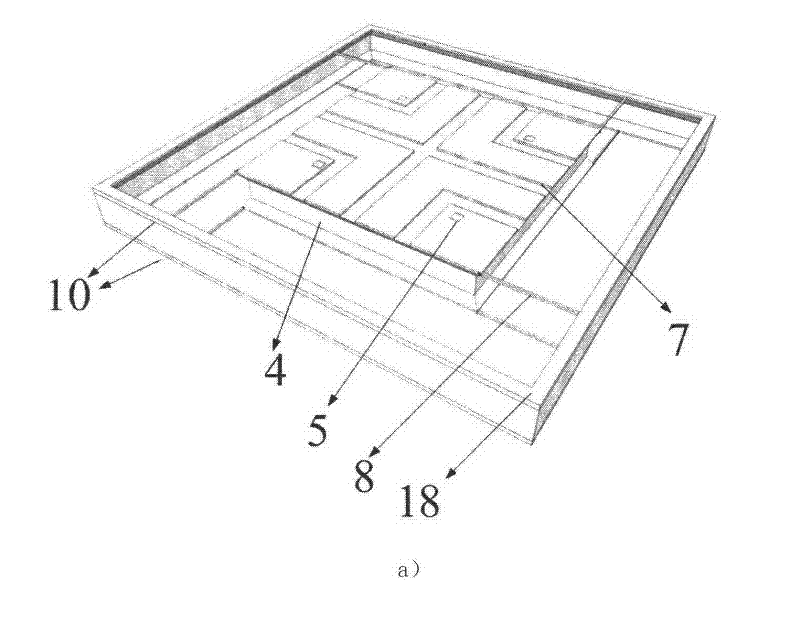

The invention relates to a six-dimensional force sensor which comprises a sensor elastomer and resistance strain gages, wherein the sensor elastomer comprises a cylindrical shell and a crossed elasticbeam; the crossed elastic beam is positioned in the center in the shell and comprises a strain beam (1) and a loading platform (3); an upper base (6) and a lower base (10) are respectively positionedat both ends of the shell; force transmission columns (7) are positioned in the middle of the shell and connected with an upper elastic beam (4) and a lower elastic beam (8); a flexible beam (2) is positioned between the force transmission columns, and the inner side of the flexible beam (2) is connected with the strain beam. A sensor force sensing element comprises the upper elastic beam, the lower elastic beam and the strain beam, and 28 resistance strain gages are attached to the proper position on the force sensing element, wherein 24 strain gages form six groups of full-bridge detectingcircuits for realizing the acquisition of six-dimensional force information, and other four strain gages are reserved. The invention has the characteristics of compact structure, large rigidity, lessdimensional coupling, high precision and good dynamic performance and can be used for the research of an intelligent robot, automated detection and control, bionic motion analysis and sports research.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

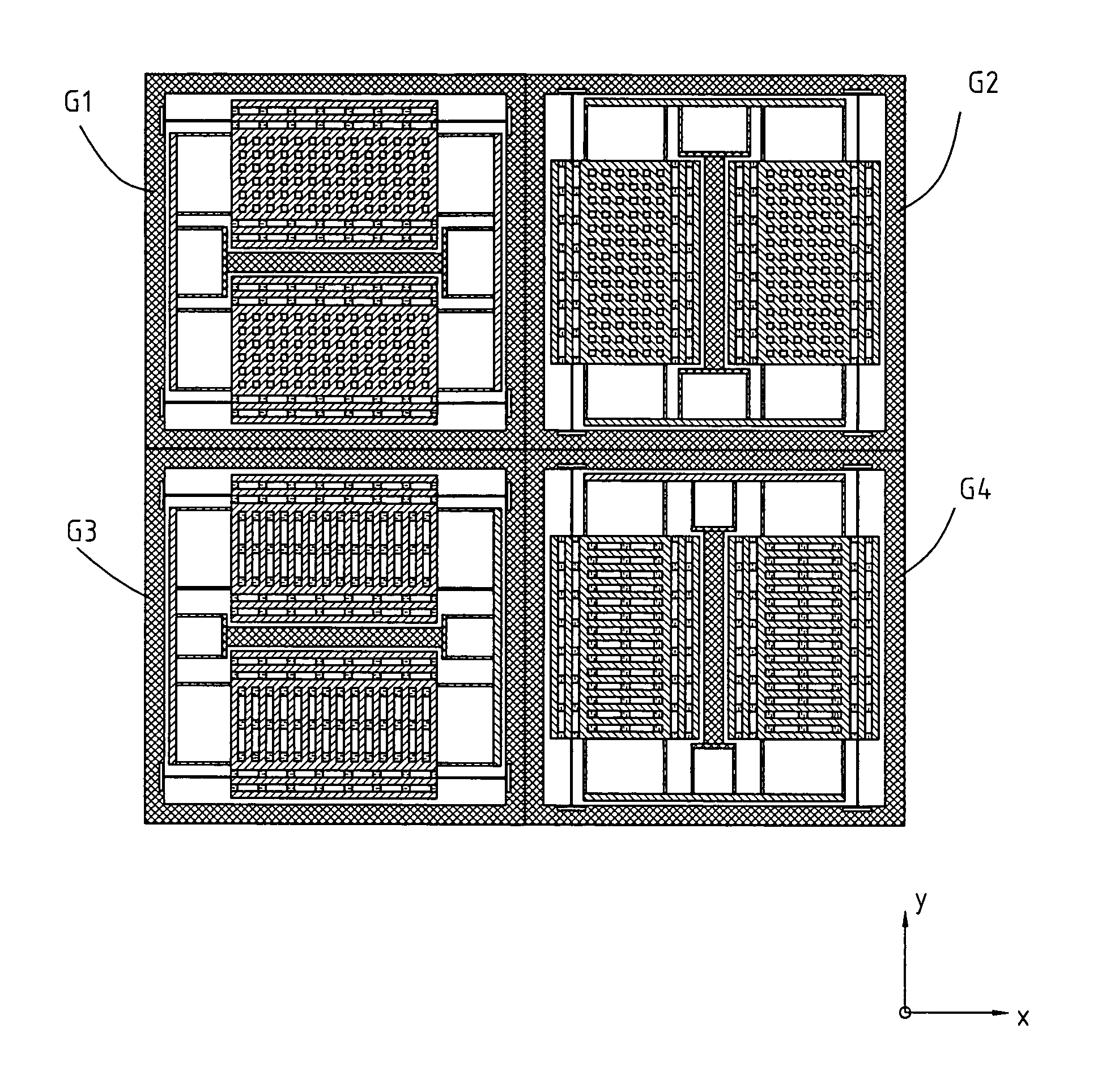

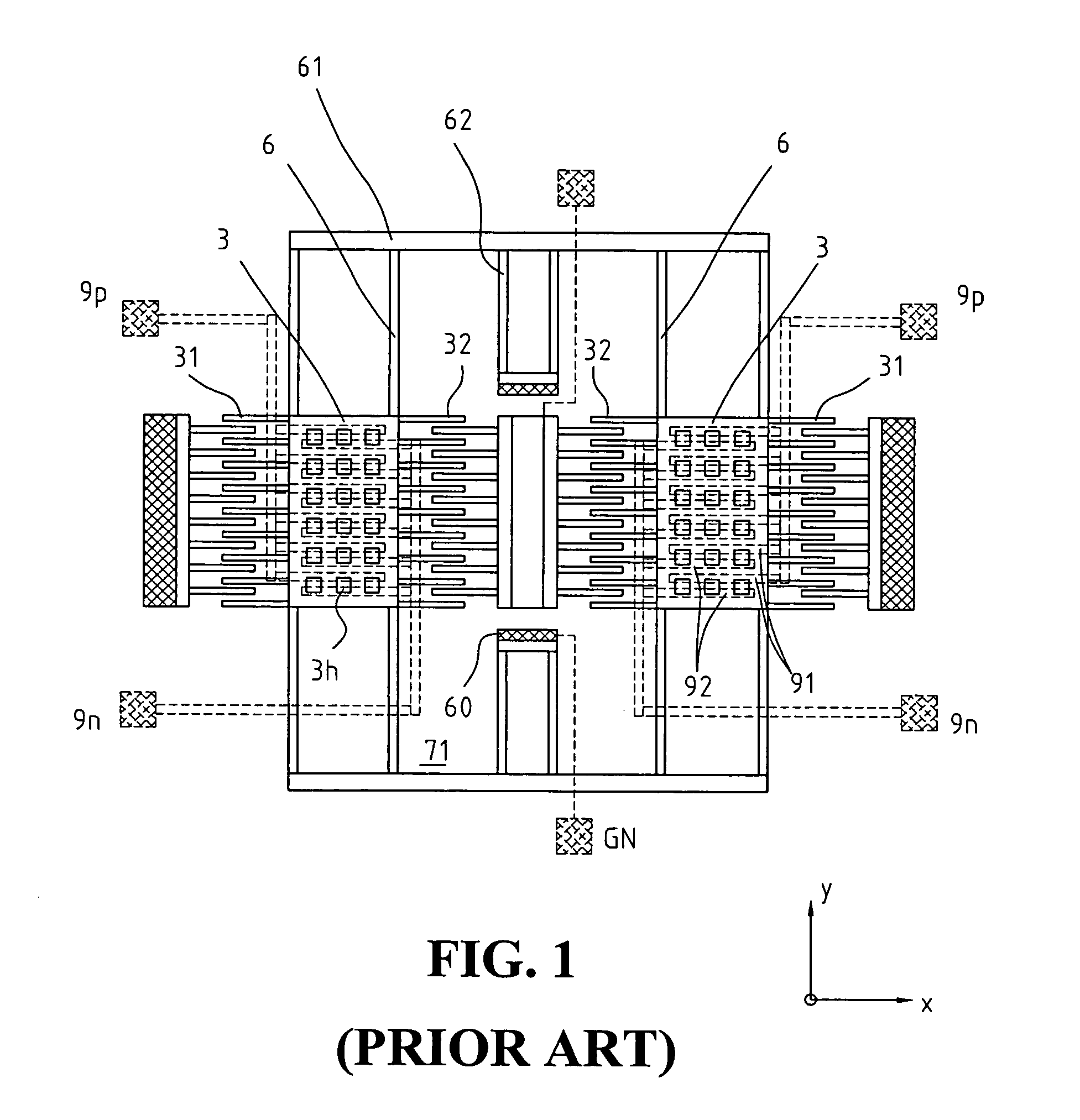

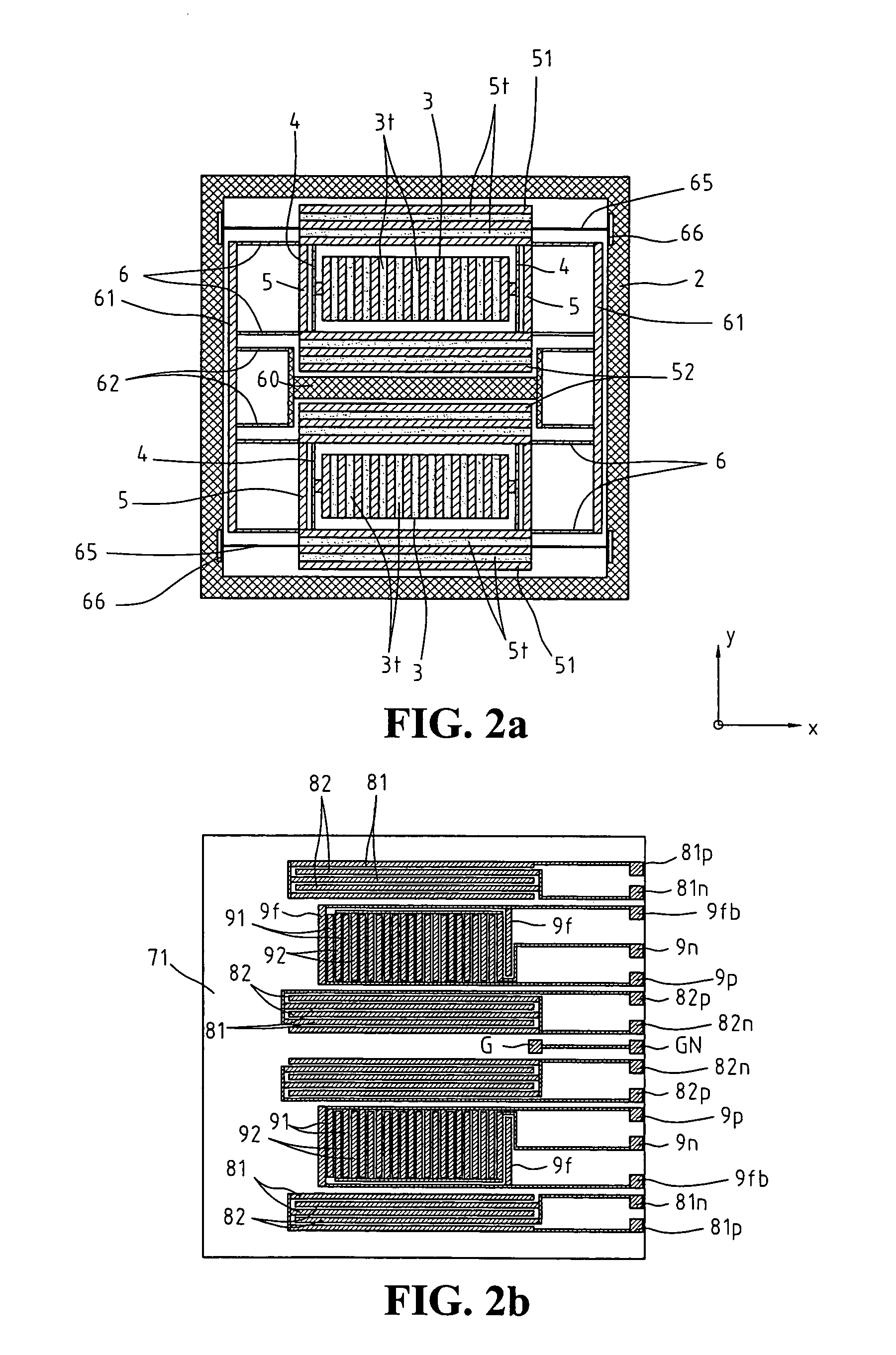

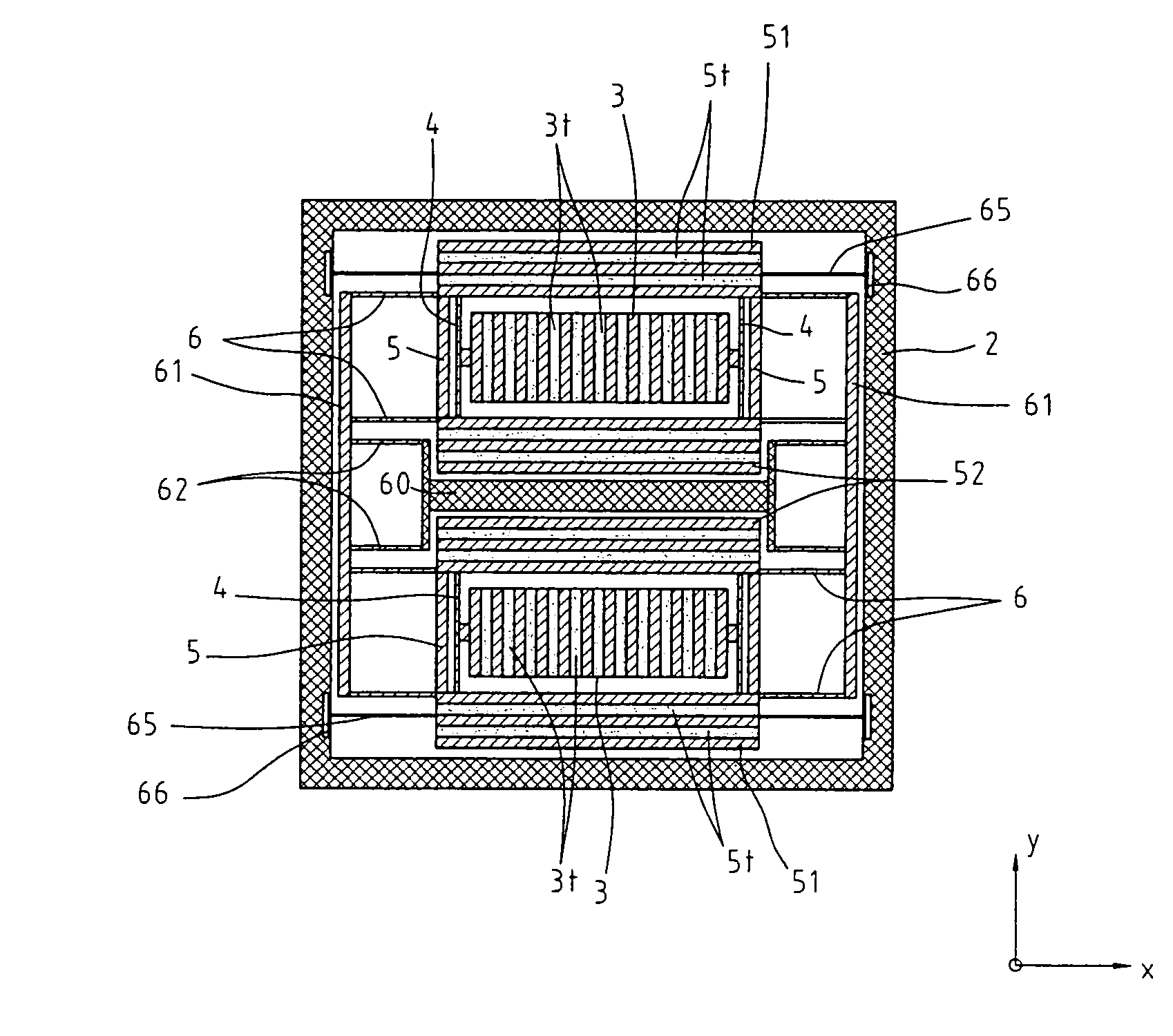

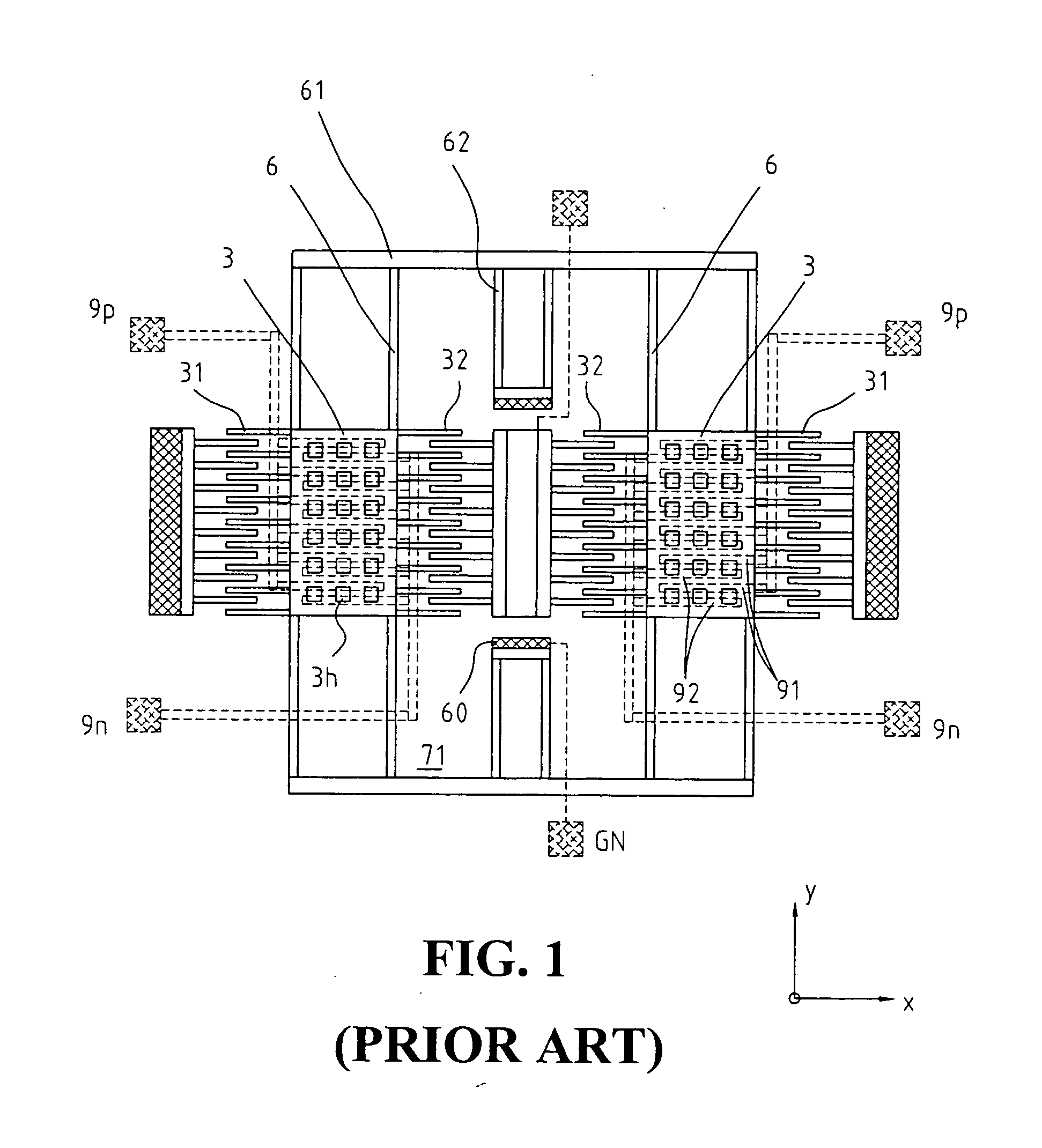

Planar 3-axis inertial measurement unit

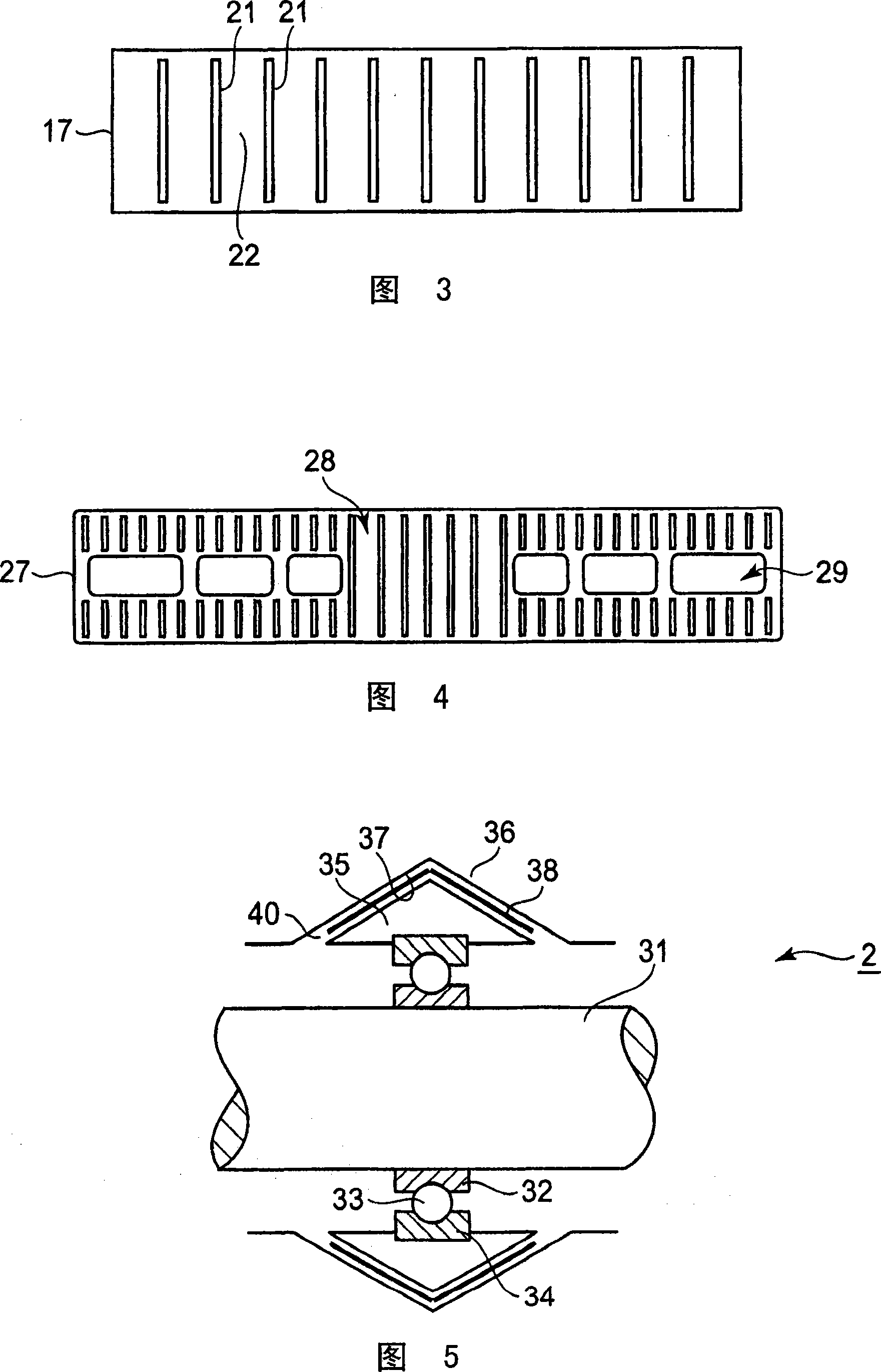

ActiveUS7168317B2Simple manufacturing processLow costAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsIn planeCapacitance

The present invention relates to a z-axial solid-state gyroscope. Its main configuration is manufactured with a conductive material and includes two sets of a proof mass and two driver bodies suspended between two plates by an elastic beam assembly. Both surfaces of the driver bodies and the proof masses respectively include a number of grooves respectively perpendicular to a first axis and a second axis. The surfaces of the driver bodies and the proof masses and the corresponding stripe electrodes of the plates thereof are respectively formed a driving capacitors and a sensing capacitors. The driving capacitor drives the proof masses to vibrate in the opposite direction along the first axis. If a z-axial angular velocity input, a Coriolis force makes the two masses vibrate in the opposite direction along the second axis. If a first axial acceleration input, a specific force makes the two masses move in the same direction along the first axis. If a second axial acceleration input, a specific force makes the two masses move in the same direction along the second axis. Both inertial forces make the sensing capacitances change. One z-axial solid-state gyroscopes and two in-plane axial gyroscopes can be designed on a single chip to form a complete three-axis inertial measurement unit.

Owner:MIN OF NAT DEFENSE

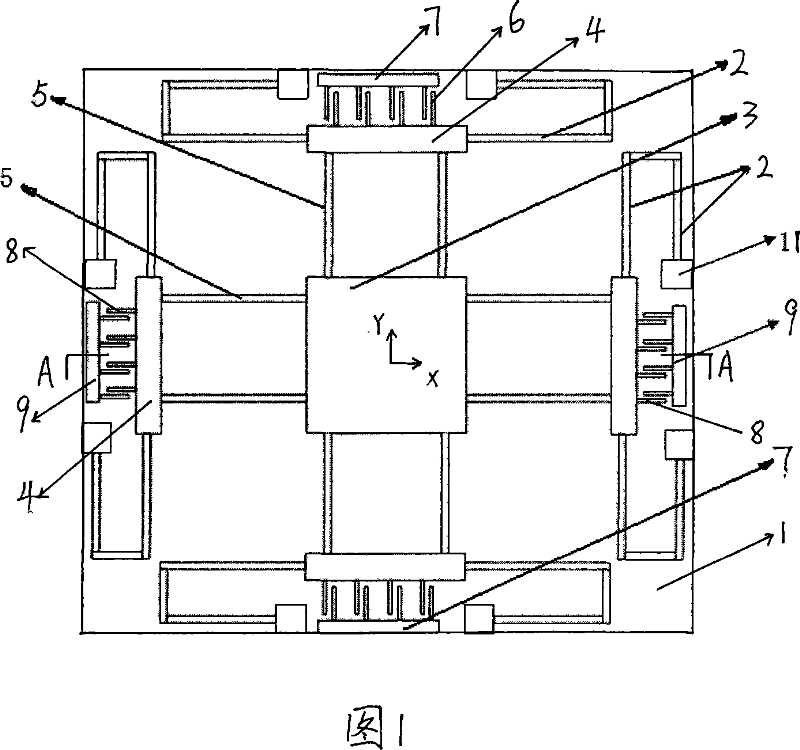

Uniaxle integrated inertia measurement device based on single mass-block

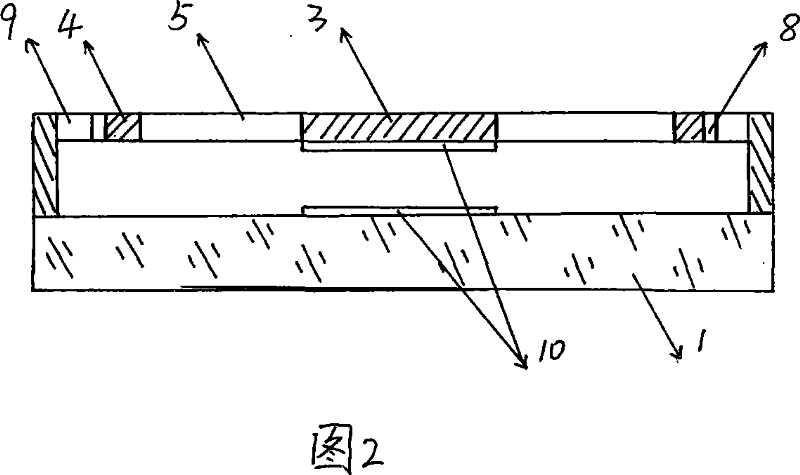

InactiveCN101038299AReduce the difficulty of separationSimple designSpeed measurement using gyroscopic effectsGyroscopes/turn-sensitive devicesCapacitanceGlass cover

The present invention which relates to the micro-mechanism electric technology provides a single-shaft and integrated device for measuring the inertia based on the single quality block. And the present solves the problems of the prior single-shaft and integrated assembly for measuring the inertia that the structure is complex, the volume and quality are big, etc. The single-shaft and integrated device for measuring the inertia includes a quality block and a glass cover bottom. The quality block which is hang on the upper of the glass cover bottom through a supporting beam includes a quality chip and four supporting bodies that are fixed with the four sides of the quality chip through the elastic beam. A moveable comb for detecting is fixed on the external of the supporting body relative to the Y direction and a moveable comb for driving is fixed on the external of the supporting body relative to the X direction. A fixed comb for detecting and a fixed comb for driving are fixed on the glass cover bottom, and electrodes for forming the capacitance are fixed on the lower end surface and the glass cover bottom of the quality chip. The device in the present invention has advantages of a reasonable structure, an easy processing, a high reliability, a small volume, a strong ability of resisting the interference, a high precision, a high precision of measuring the paralleling and orthogonality of the vectors, etc.

Owner:ZHONGBEI UNIV

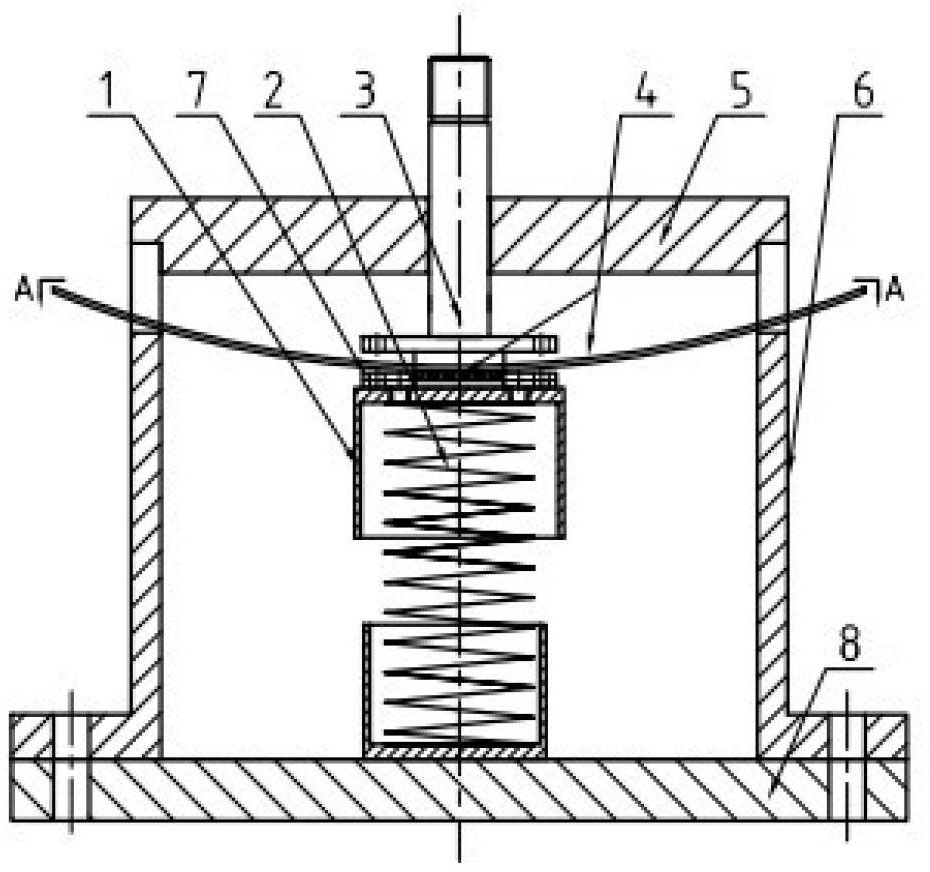

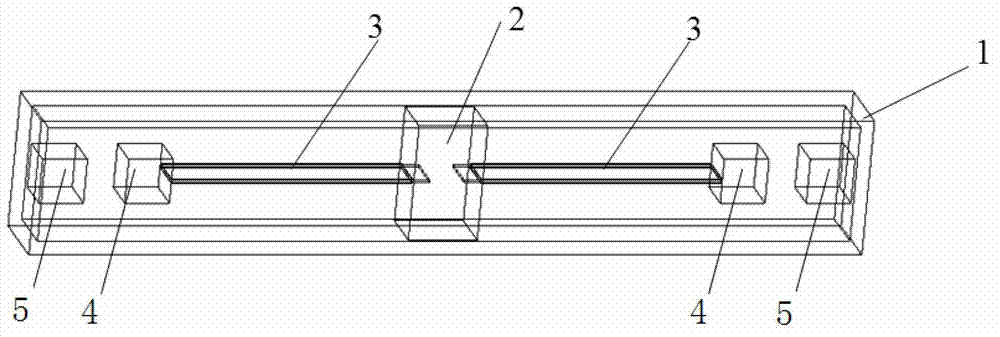

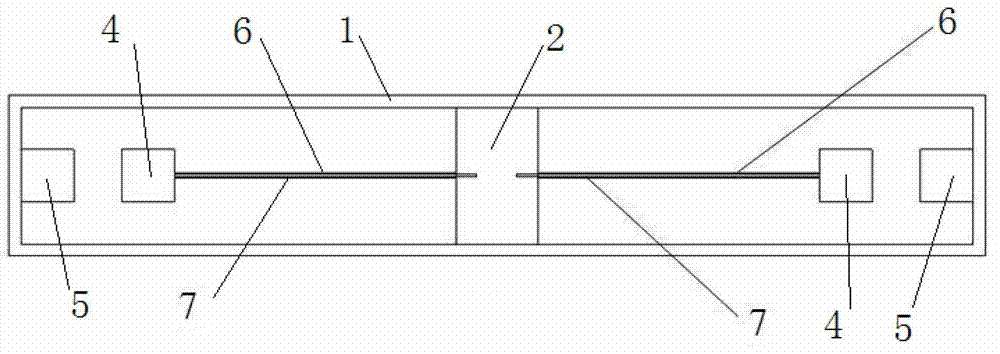

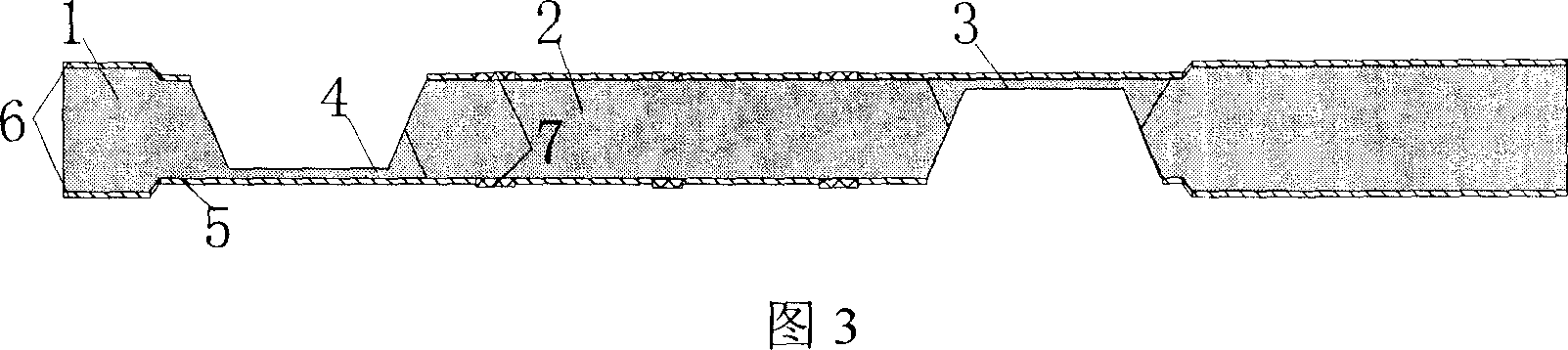

Sliding beam and spring combined nonlinear ultra-low frequency vibration isolator

InactiveCN102678804AExtended Effective Vibration Isolation RangeWith anti-shock effectShock absorbersEngineeringUltra low frequency

The invention discloses a sliding elastic beam and spring combined nonlinear ultra-low frequency vibration isolator, which mainly comprises a sliding elastic beam with negative rigidity and a spring with positive rigidity, and is provided with a connection component and a supporting structure, wherein the spring is connected below the sliding elastic beam; the connection component is used for connecting the sliding elastic beam; the supporting structure is used for supporting the sliding elastic beam; the sliding elastic beam has negative rigidity during deformation; the spring is of positive rigidity; and the entire vibration isolator has the characteristic of near zero rigidity because of combination of the two elastic elements. The entire system, namely the sliding beam and spring combined nonlinear ultra-low frequency vibration isolator provided by the invention has the characteristic of approximately dynamic quasi zero rigidity, can be used for isolating vibration of ultra-low frequency and has an anti-impact effect.

Owner:SHANGHAI JIAO TONG UNIV

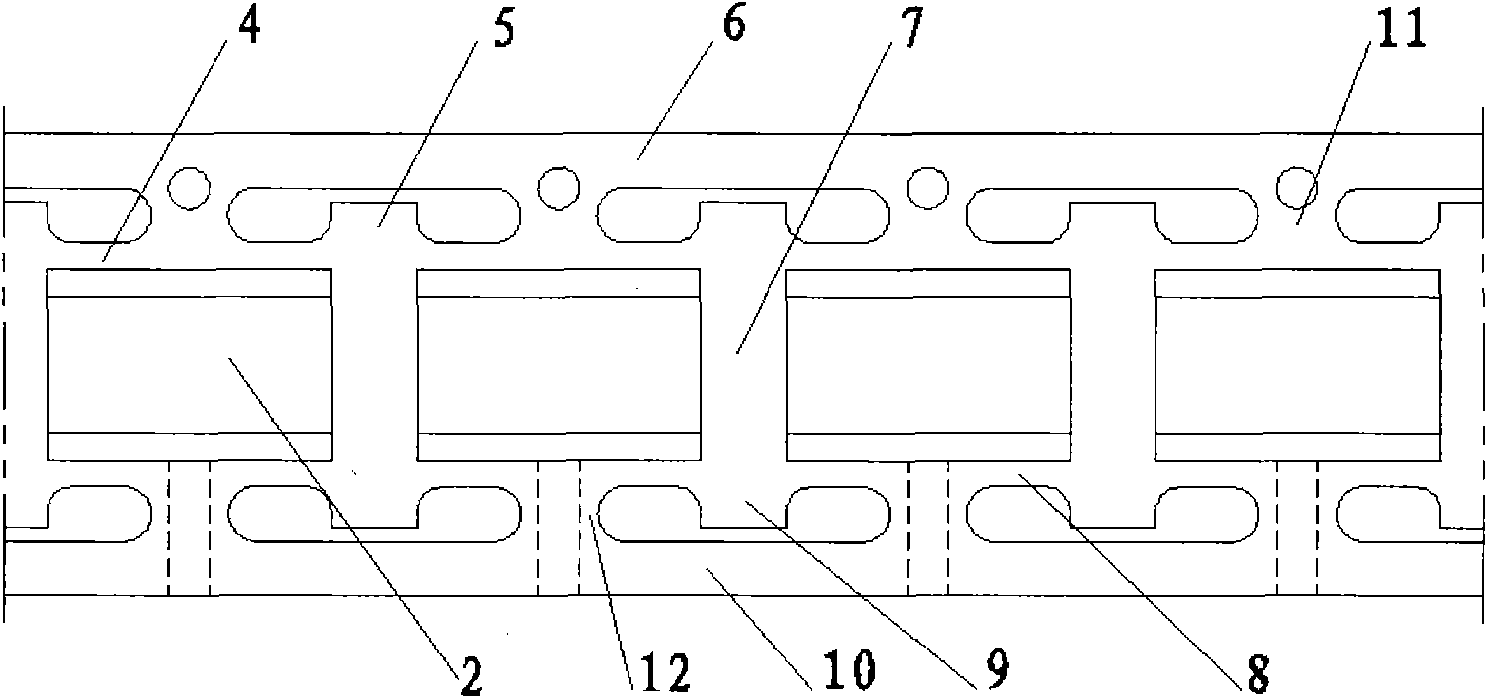

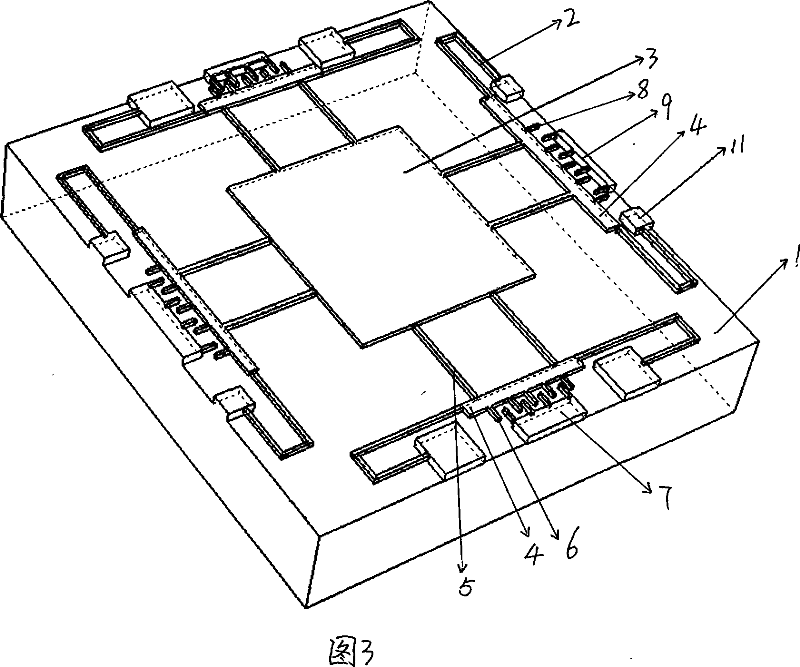

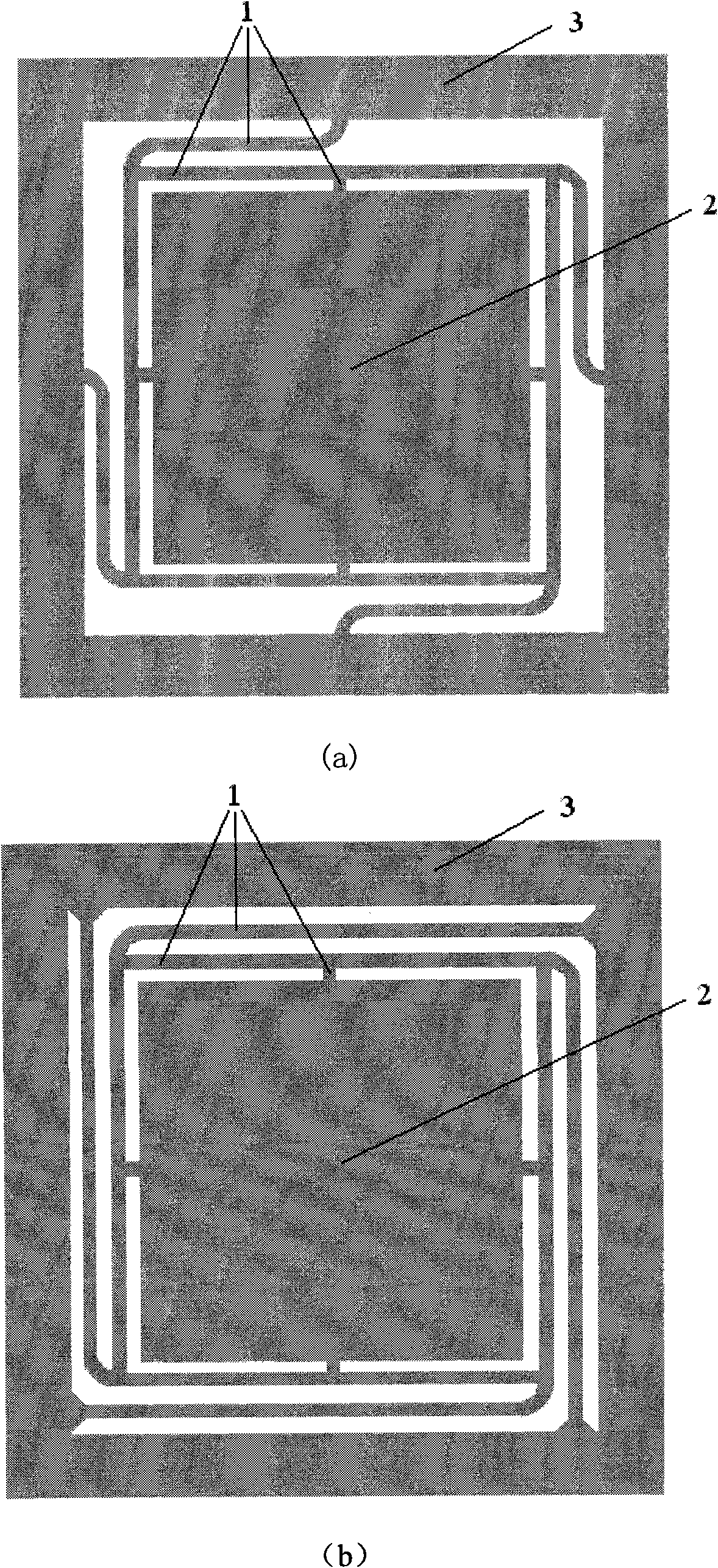

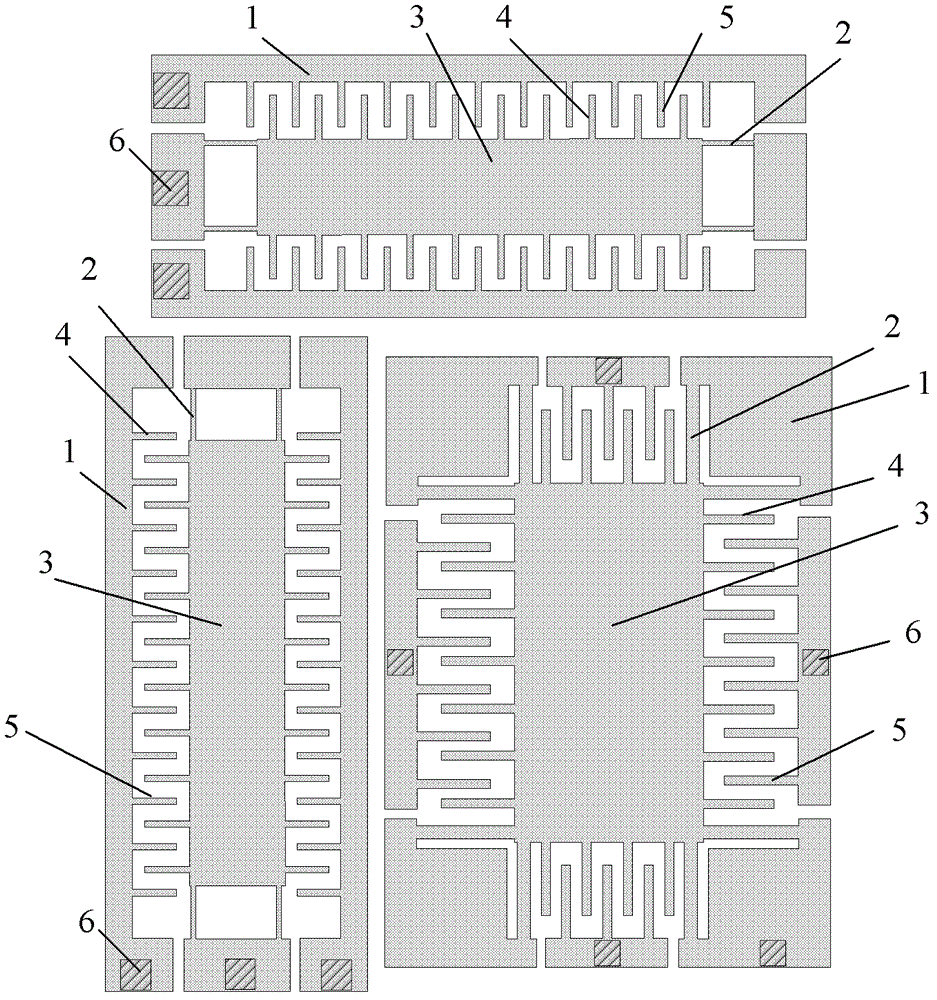

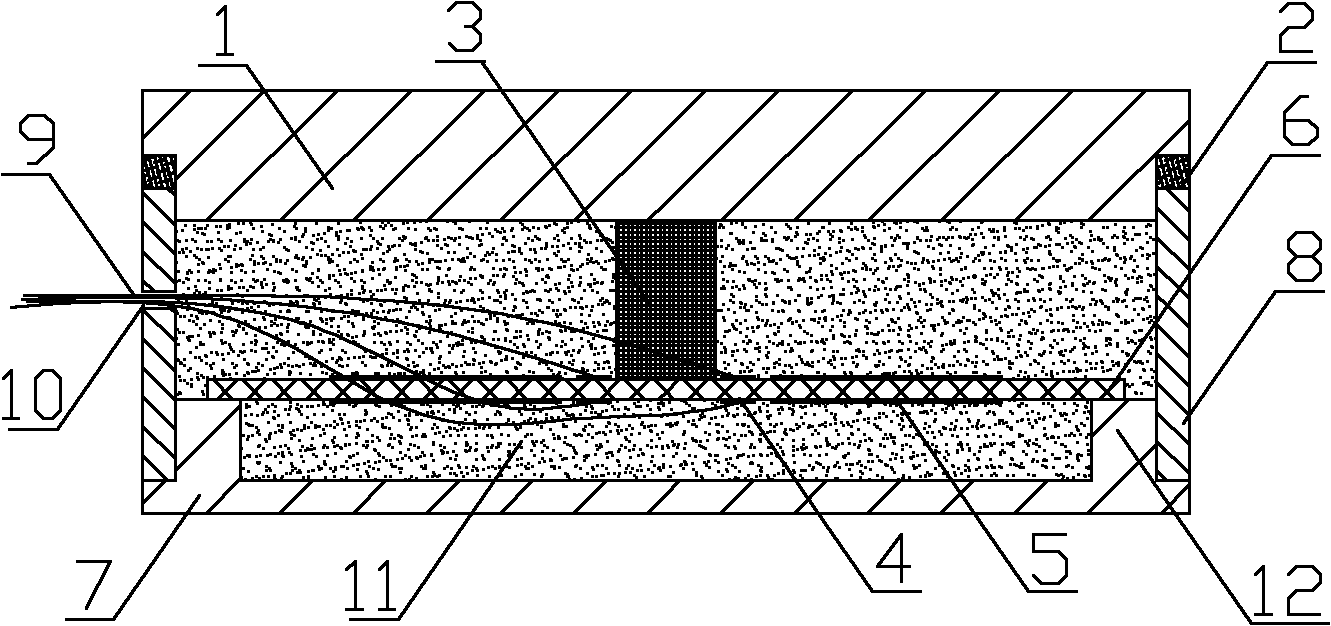

Capacitive micro-acceleration sensor with symmetrically combined elastic beam structure and production method thereof

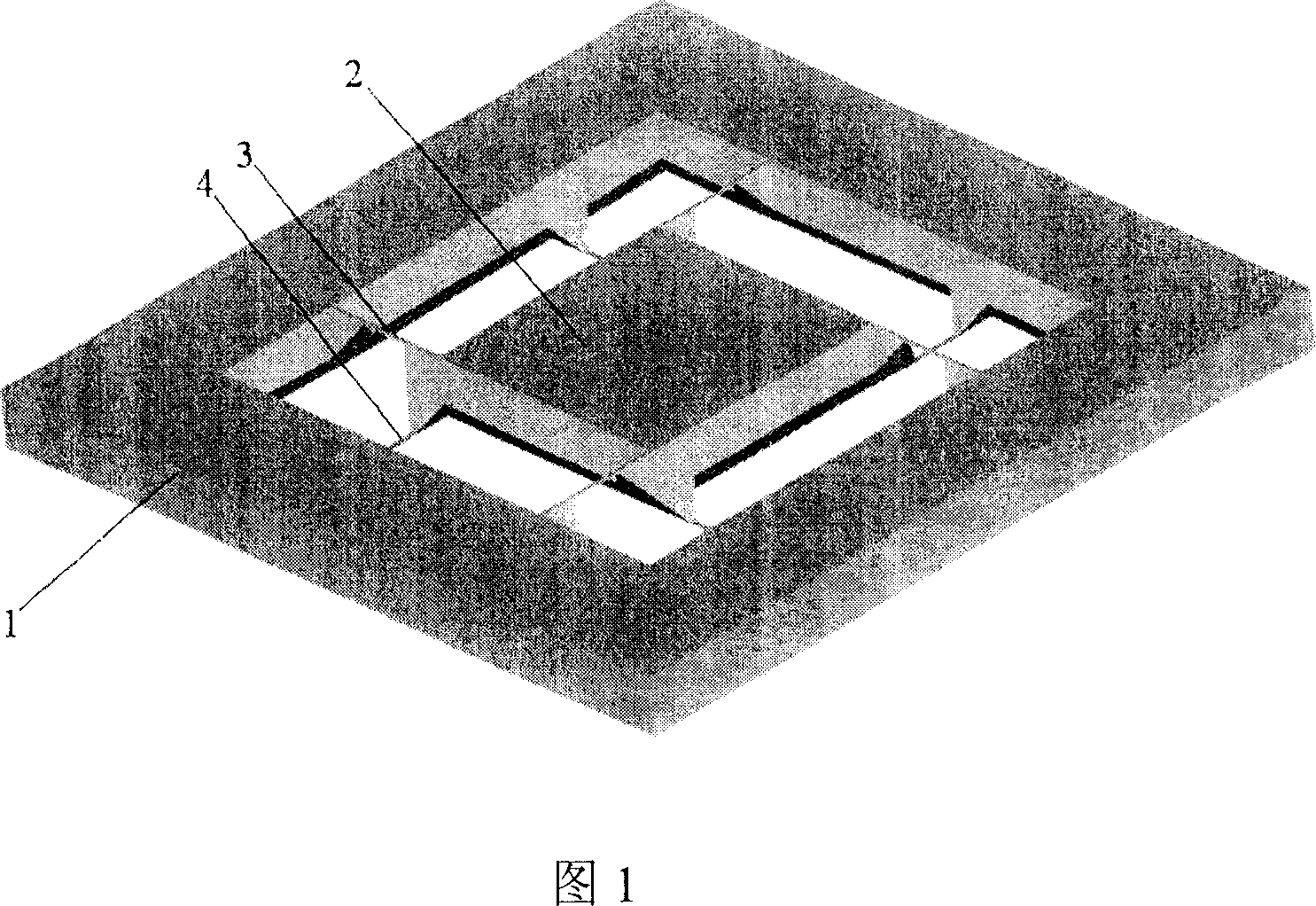

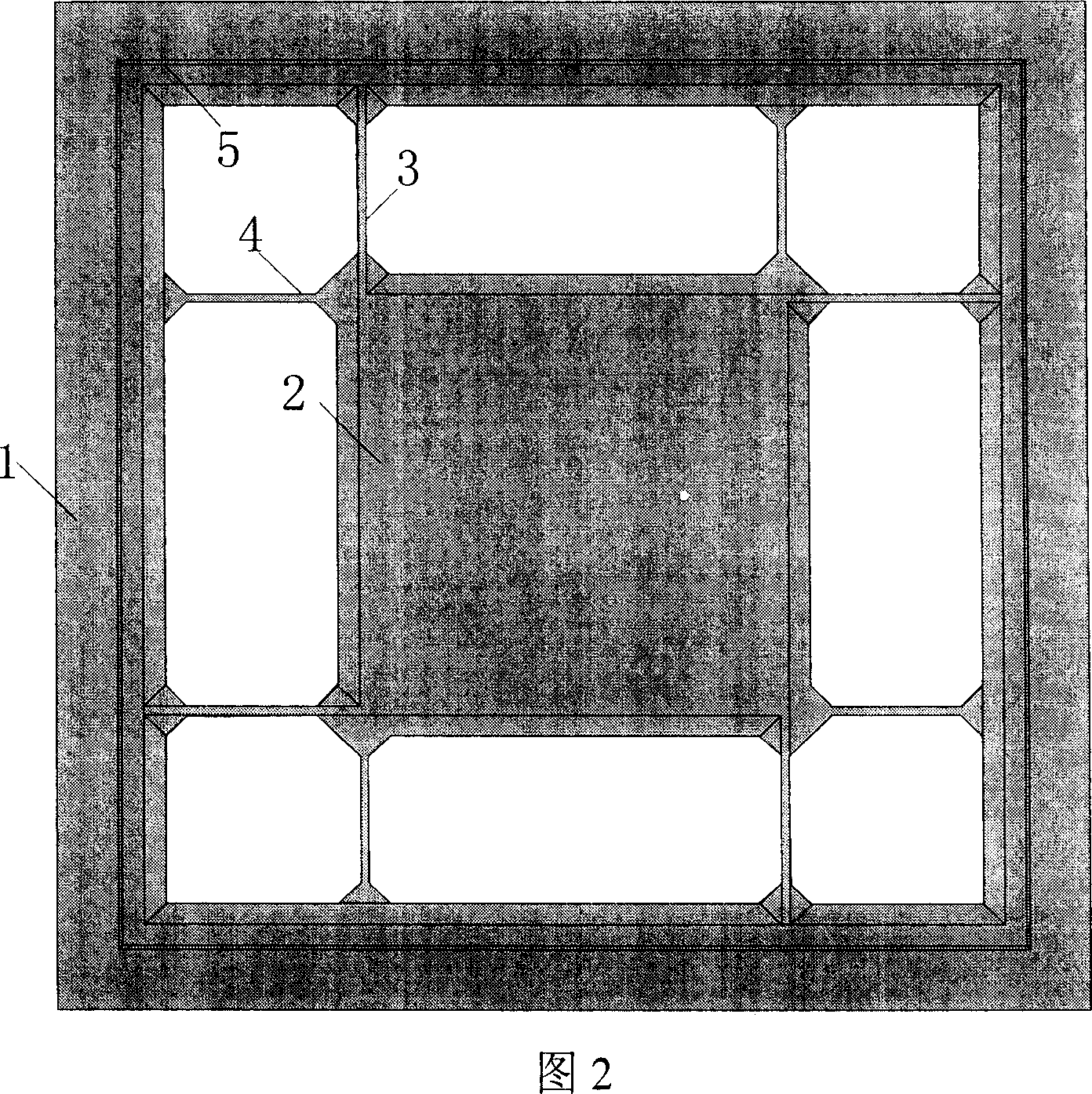

ActiveCN101858929AReduce sensitivityGreat lateral sensitivityPrecision positioning equipmentPiezoelectric/electrostriction/magnetostriction machinesCross sensitivityShaped beam

The invention relates to a capacitive micro-acceleration sensor with a symmetrically combined elastic beam structure and a production method thereof. The acceleration sensor comprises a symmetric center mass block, an external support frame, eight symmetric straight beams, two symmetric frame beams, a combined elastic beam structure, an upper cover plate and a lower cover plate, wherein the eight symmetric straight beams are used for connecting the center mass block with the external support frame, and the combined elastic beam structure is formed by connecting eight symmetric L-shaped beams together; and the other end of each straight elastic beam connected with the frame beams is connected to the middle or a vertex angle at the top end and the bottom end of the lateral face of the center mass block, and the other end of each L-shaped beam connected with the frame beams is connected to the inner side face of the external support frame. The acceleration sensor adopts the combined elastic beam structure which is formed by connecting the symmetric straight beams, the frame beams and the L-shaped beams together, has high symmetry and can remarkably reduce the cross-sensitivity of the sensor; and the sensor is produced by adopting a microelectronic mechanical system technology and is the capacitive micro-acceleration sensor with high sensitivity.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

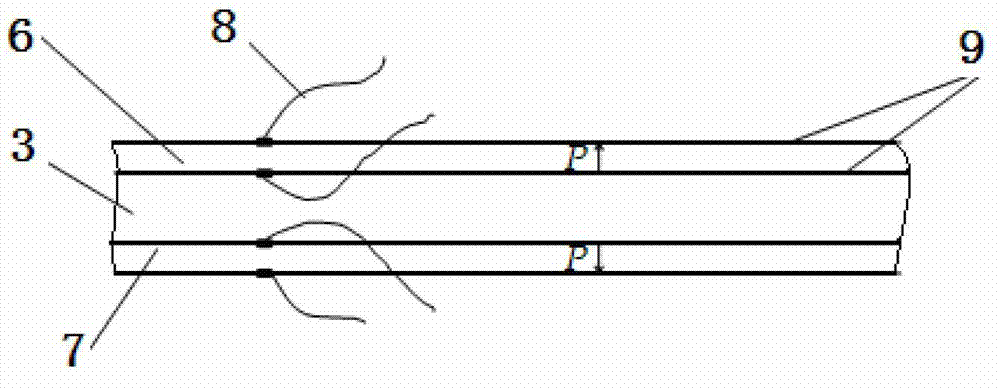

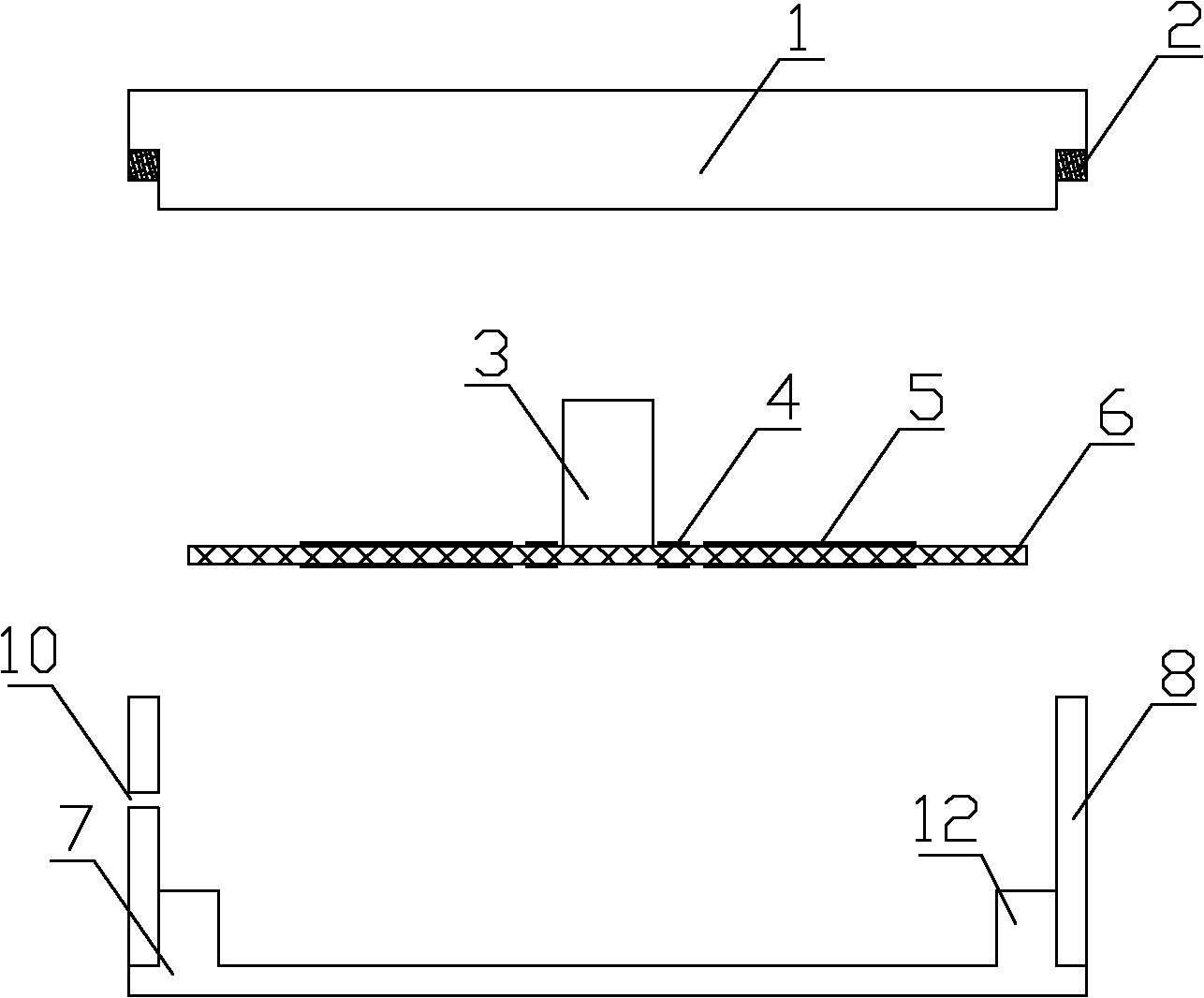

Bistable and double cantilever beam piezoelectric power generating device

InactiveCN102790547AOvercome the limitations of resonanceImprove power generation efficiencyPiezoelectric/electrostriction/magnetostriction machinesElectricityMagnetic poles

The invention discloses a bistable and double cantilever beam piezoelectric power generating device. A clamp is fixed in a casing; two bistable piezoelectric cantilever oscillator structures are respectively arranged at two ends of the clamp and the inner wall of the casing at the same side of the clamp; each bistable piezoelectric cantilever oscillator structure comprises a twin crystal bistable piezoelectric cantilever beam fixed with the clamp; a first permanent magnet is arranged at the free end of the twin crystal bistable piezoelectric cantilever beam; a second permanent magnet is fixed on the inner wall of the casing of the same side of the clamp and positioned at the same horizontal position of the first permanent magnet; two permanent magnets are oppositely arranged according to magnetic poles; the twin crystal bistable piezoelectric cantilever beam comprises an elastic beam and piezoelectric layers which are attached to an upper surface and a lower surface of the elastic beam; the elastic beam is respectively equal to the piezoelectric layers in width and length; and electrodes are respectively arranged on the upper surface and the lower surface of each piezoelectric layer. According to the coherent nonlinear characteristic of the bistable and double cantilever beam piezoelectric power generating device disclosed by the invention, the great motion under wide-narrow frequency excitation can be realized, environment vibration can be effectively utilized for generating power and the power generating efficiency is increased. Two groups of piezoelectric cantilever beams are combined so as to effectively increase the power generation amount of the device in unit time.

Owner:TIANJIN UNIV

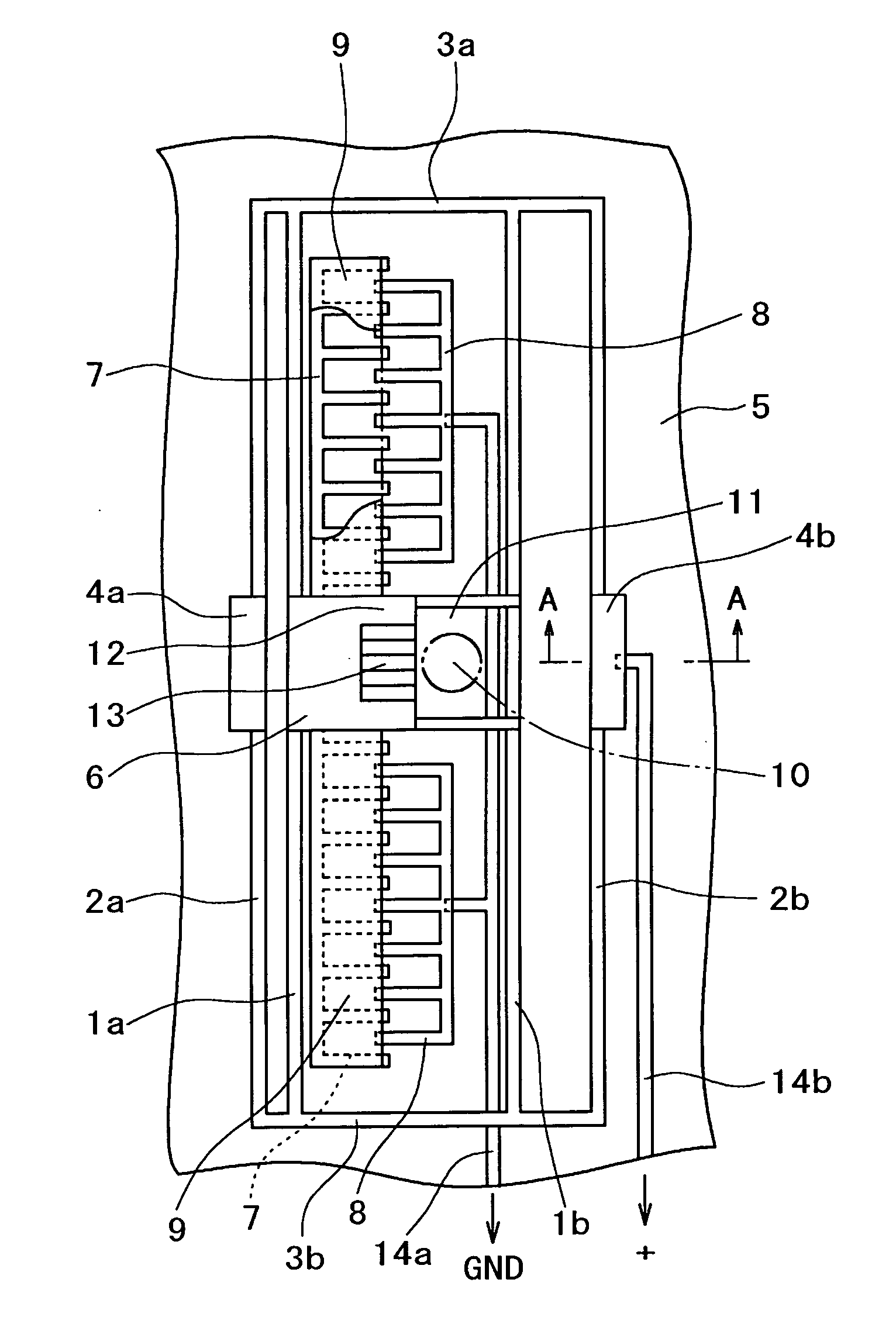

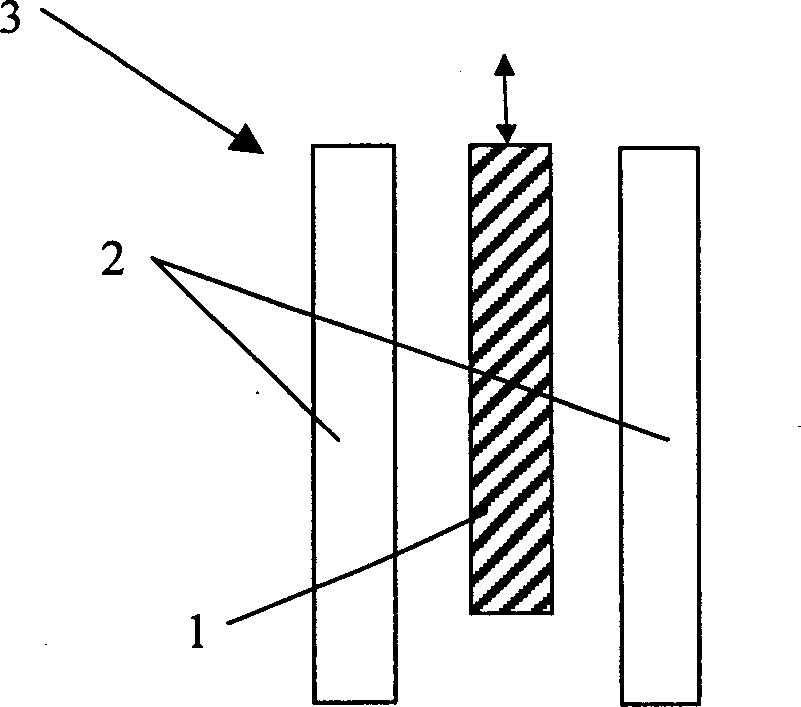

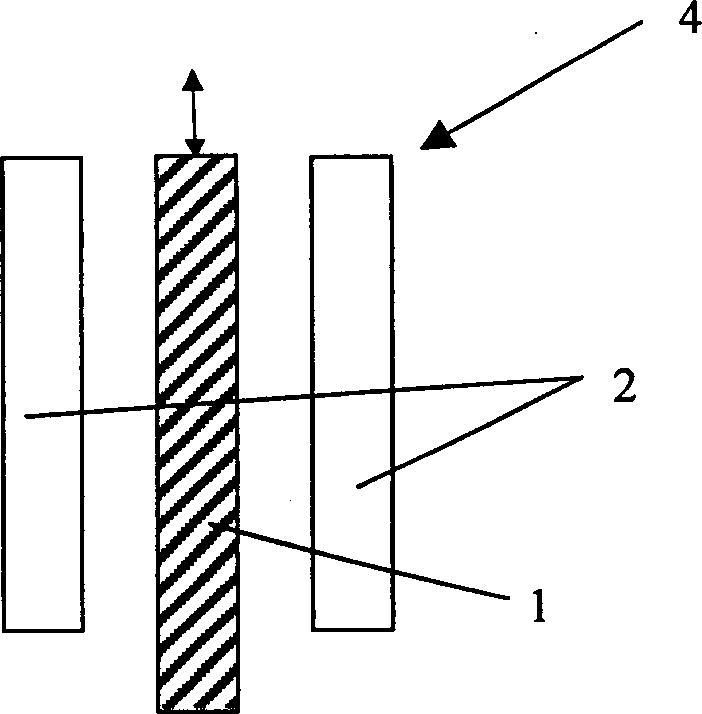

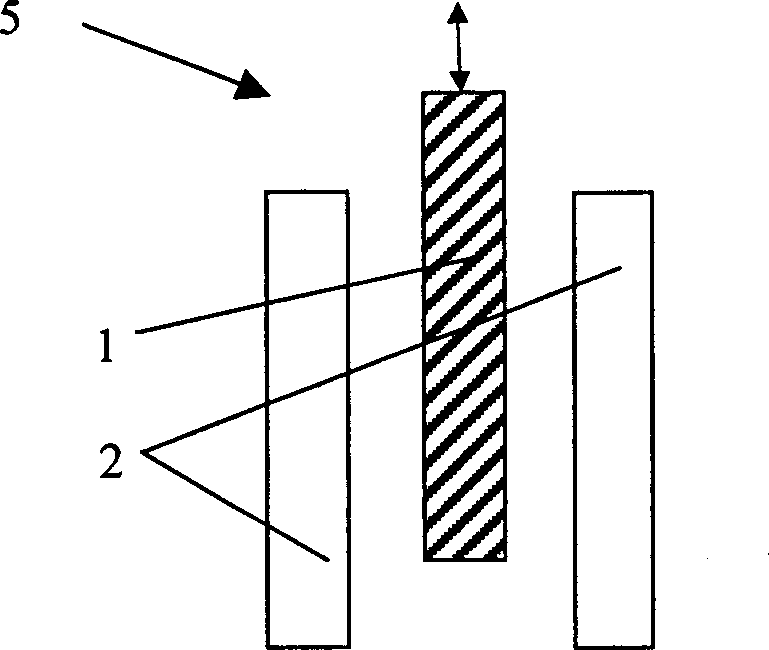

Electrostatic comb drive actuator, and optical controller using the electrostatic comb drive actuator

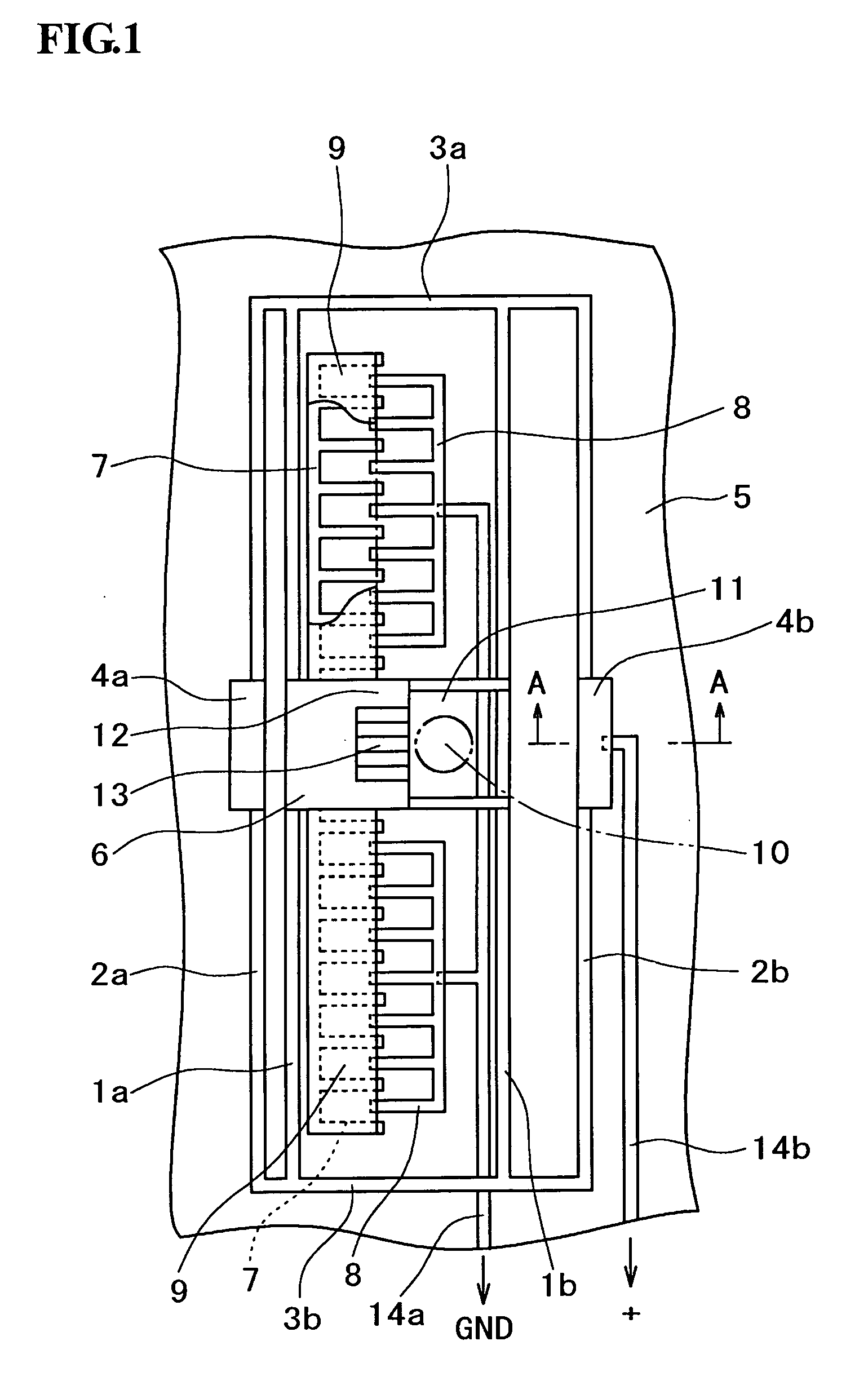

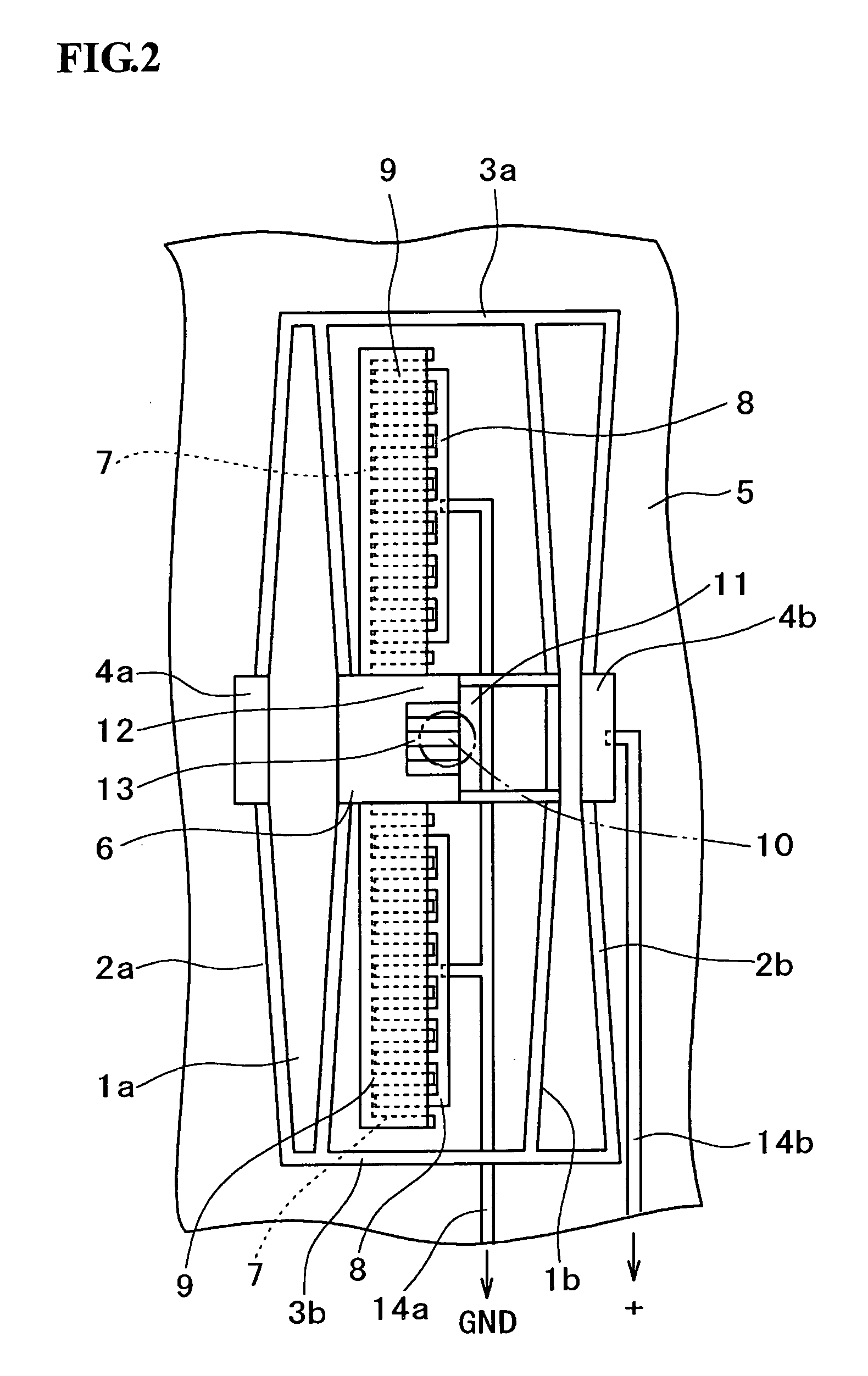

InactiveUS20050052723A1Preventive effectIncreased bending stiffnessPiezoelectric/electrostrictive devicesFlexible microstructural devicesComb driveEngineering

An electrostatic comb drive actuator, characterized in that plural outer suspended elastic beams 2a and 2b are disposed in parallel to and outside plural inner suspended elastic beams 1a and 1b disposed in parallel to each other; the ends of the inner suspended elastic beams and the outer suspended elastic beams on both sides are connected with end connecting beams 3a and 3b; the outer suspended elastic beams are supported at their centers on a board 5; the inner suspended elastic beams are connected with each other at their centers by means of a working section 6; a movable comb electrode 7 is supported on the working section; and a fixed comb electrode 8 is supported on the board.

Owner:MORITEX CORP +1

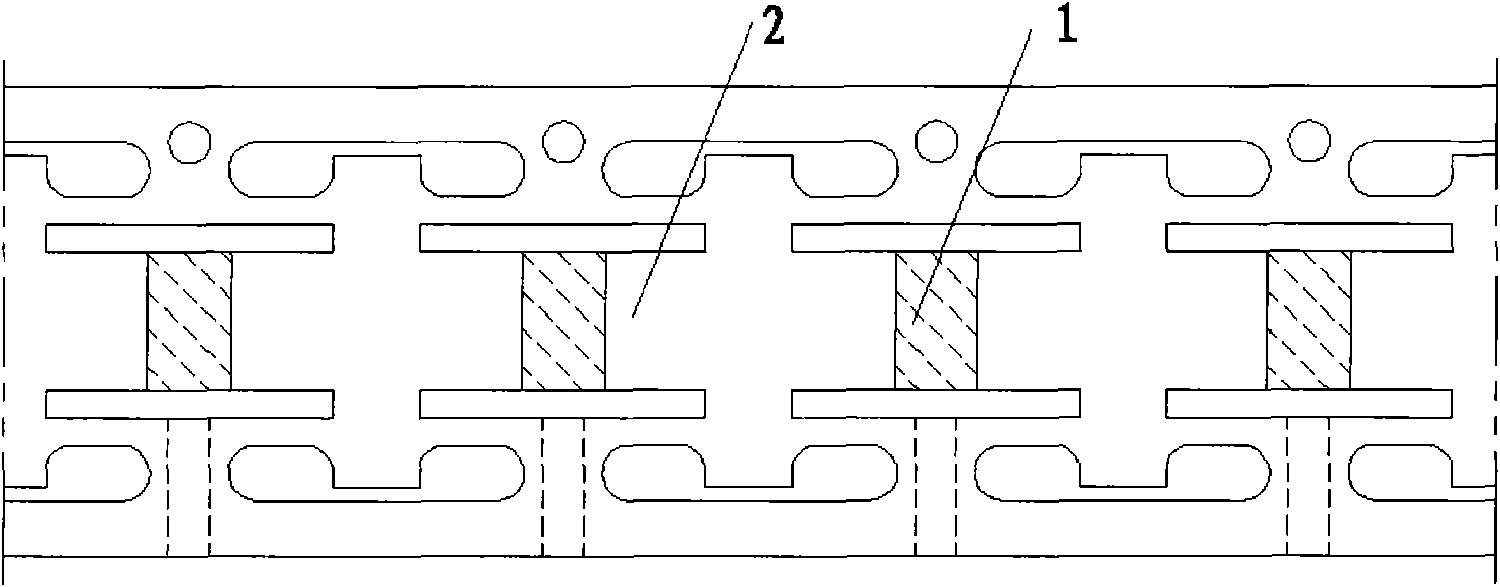

Micro mechanical capacitance type acceleration transducer, and fabricating method

A method for preparing acceleration transducer of micromechanical capacity type includes forming rectangular mass block with no lobe compensation on single crystal silicon pellet by utilizing aeolotropic corrosion technique based on elastic beams being alternatively distributed at top and bottom surfaces of active mass block, forming straight elastic beam at two said surfaces of mass block, applying silicon-silicon bond technique to realize bond of three-layers silicon pellet, depositing lead wire pad of top electrode and active electrode and realizing electric signal isolation between two said electrodes.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

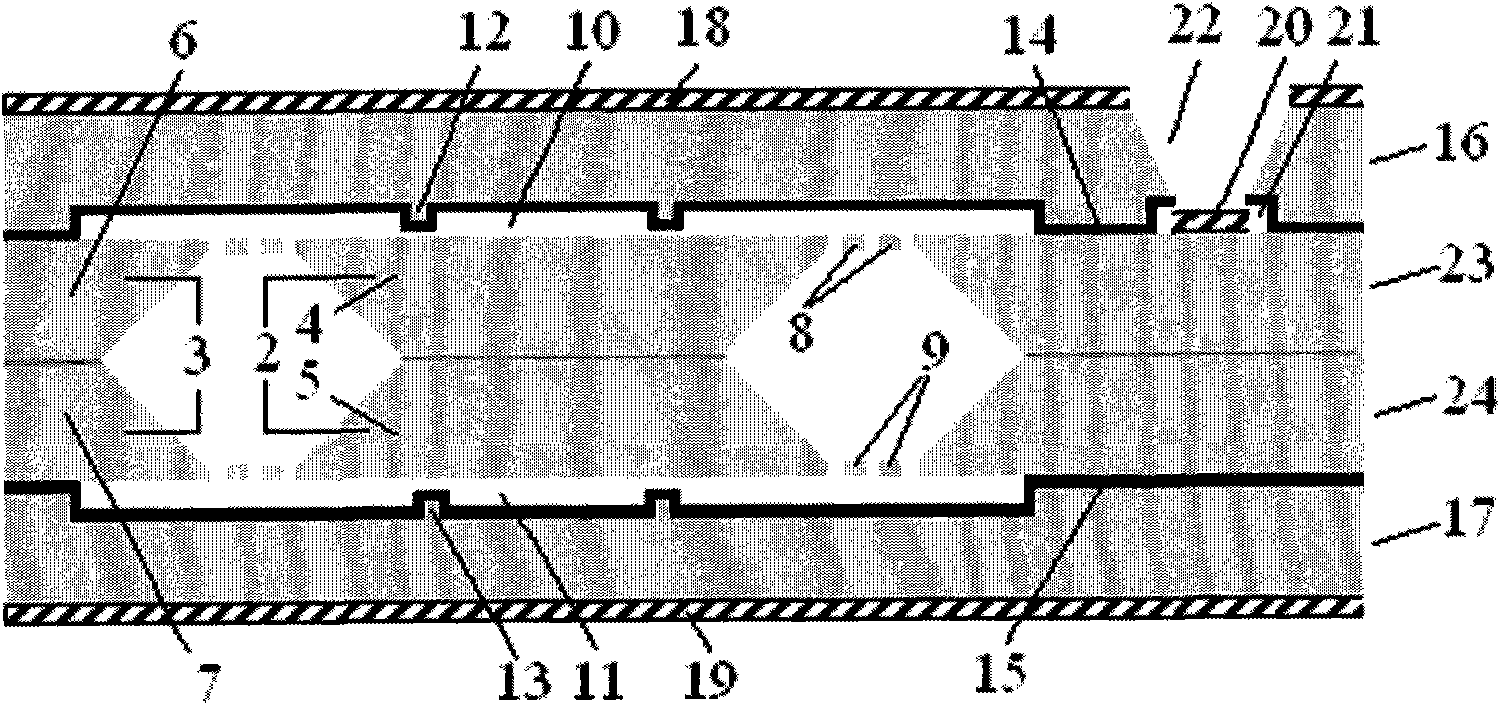

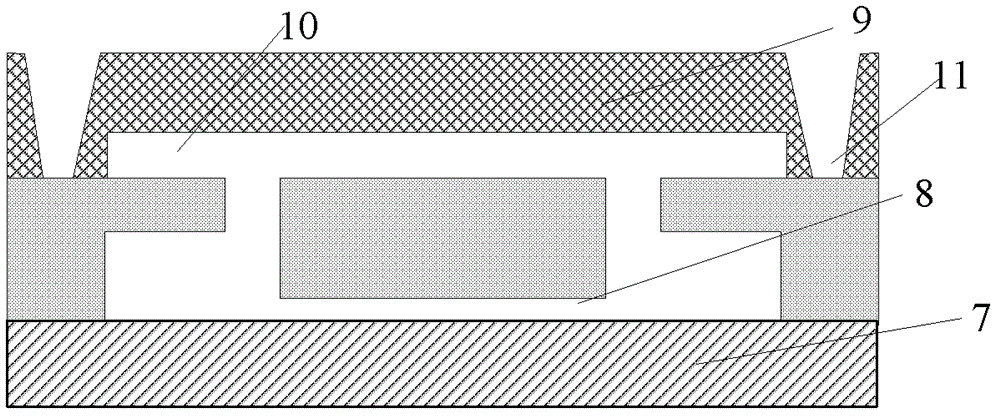

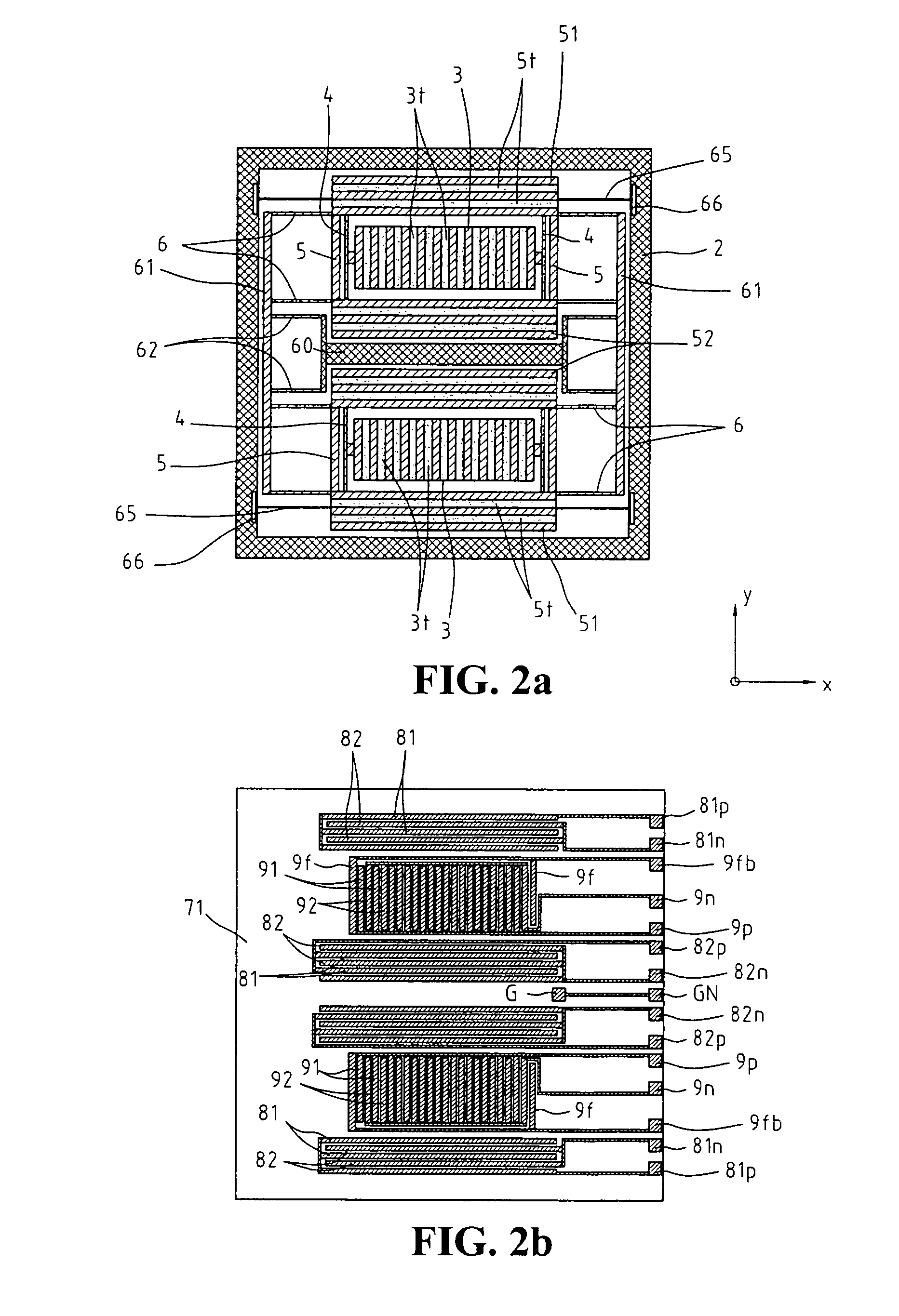

Micro-electromechanical system (MEMS) triaxial accelerometer and manufacturing method thereof

ActiveCN102798734ASolve problemsSolve the costAcceleration measurement using interia forcesDecorative surface effectsCapacitanceTriaxial accelerometer

The invention provides a micro-electromechanical system (MEMS) triaxial accelerometer and a manufacturing method thereof. The MEMS triaxial accelerometer comprises a sensitive device layer, an upper cover board layer and a lower supporting body layer, wherein clearances are reserved between the sensitive device layer and the upper cover board layer as well as between the sensitive device layer and the lower supporting body layer; the sensitive device layer comprises a supporting frame body, an elastic beam, three independent sensitive mass blocks, movable comb teeth, fixed comb teeth and an electrode; the three independent sensitive mass blocks in the sensitive device layer are used for detecting acceleration signals of three axes X, Y and Z respectively; an acceleration sensor in each direction is hung in the supporting frame body through the corresponding sensitive mass block by the elastic beam which is only sensitive to the detection direction; a plurality of pairs of movable comb teeth are formed on each sensitive mass block by using a body silicon processing technology; a plurality of pairs of fixed comb teeth are correspondingly formed on the supporting frame body to form a pair of differential capacitors serving as sensitive capacitors; and the differential comb tooth capacitors in different directions generate a differential capacitance change in response to the acceleration signals in the corresponding directions.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Solid-state gyroscopes and planar three-axis inertial measurement unit

ActiveUS20060156815A1Simple manufacturing processLow costAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsCapacitanceIn plane

The present invention relates to a z-axial solid-state gyroscope. Its main configuration is manufactured with a conductive material and includes two sets of a proof mass and two driver bodies suspended between two plates by an elastic beam assembly. Both surfaces of the driver bodies and the proof masses respectively include a number of grooves respectively perpendicular to a first axis and a second axis. The surfaces of the driver bodies and the proof masses and the corresponding stripe electrodes of the plates thereof are respectively formed a driving capacitors and a sensing capacitors. The driving capacitor drives the proof masses to vibrate in the opposite direction along the first axis. If a z-axial angular velocity input, a Coriolis force makes the two masses vibrate in the opposite direction along the second axis. If a first axial acceleration input, a specific force makes the two masses move in the same direction along the first axis. If a second axial acceleration input, a specific force makes the two masses move in the same direction along the second axis. Both inertial forces make the sensing capacitances change. One z-axial solid-state gyroscopes and two in-plane axial gyroscopes can be designed on a single chip to form a complete three-axis inertial measurement unit.

Owner:MIN OF NAT DEFENSE

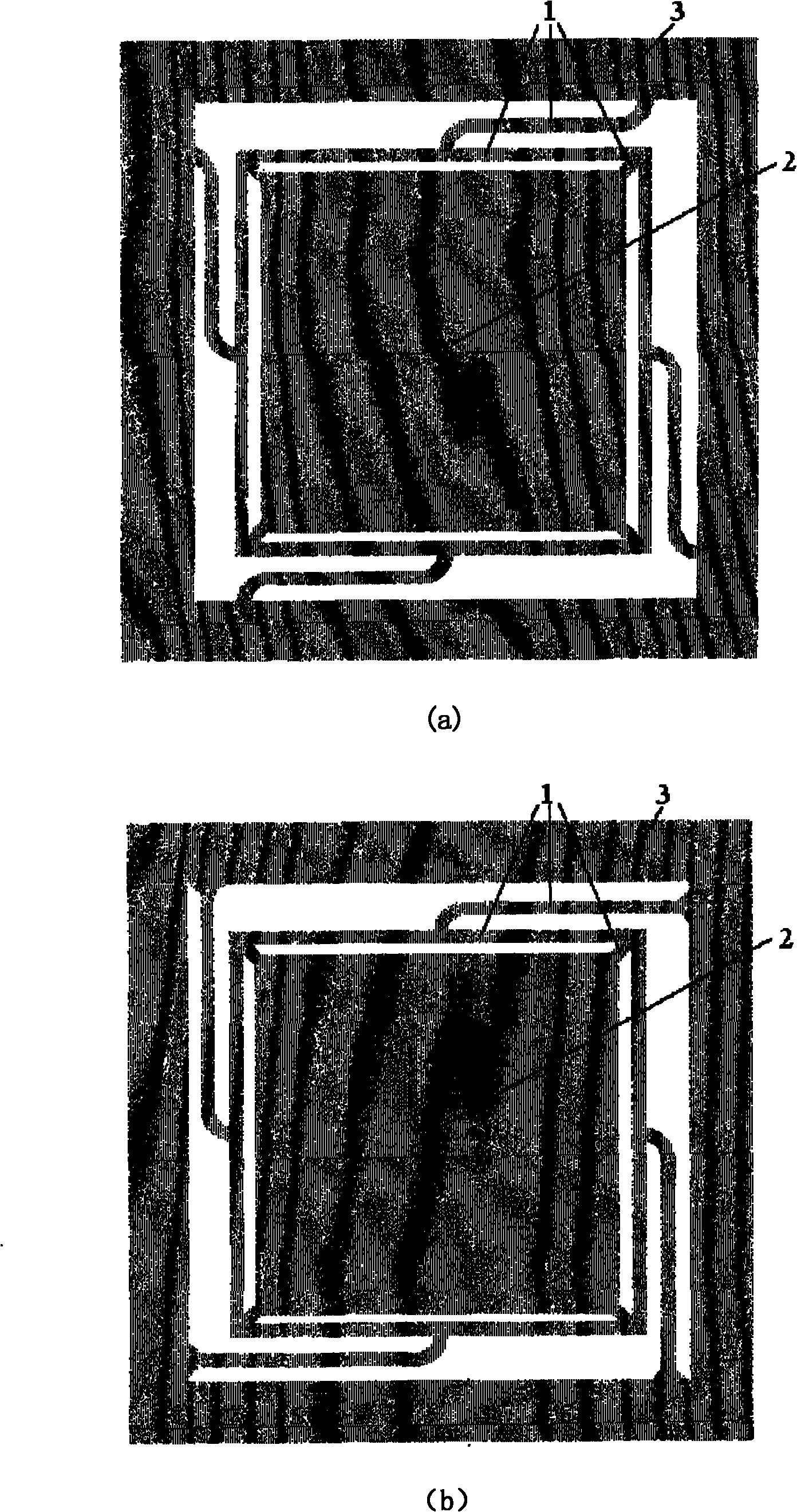

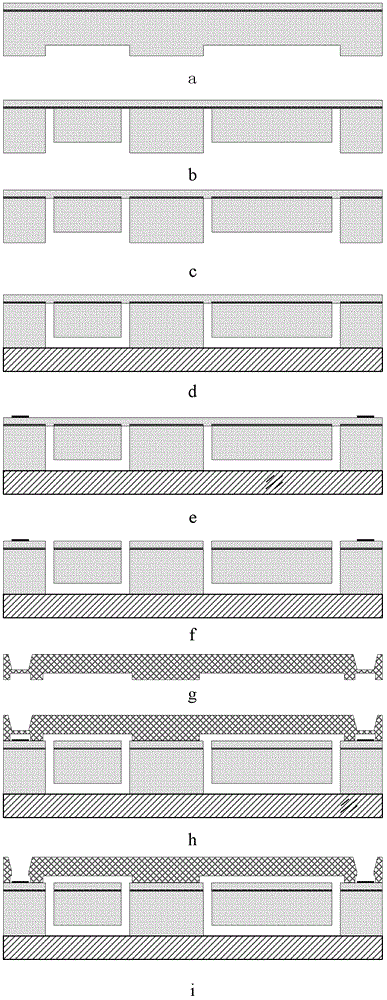

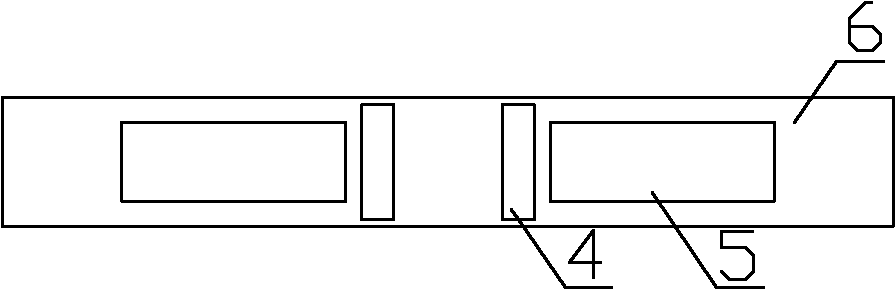

Capacitive type micro-acceleration sensor with double-sided symmetrical elastic beam structure and manufacturing method

ActiveCN102495234AImprove performanceHigh sensitivityDecorative surface effectsAcceleration measurementEtchingBlock structure

The invention relates to a capacitive type micro-acceleration sensor with a double-sided symmetrical elastic beam structure and a manufacturing method. The capacitive type micro-acceleration sensor is characterized in that: (1) an SOI silicon wafer of a double-device layer is a substrate with an elastic beam-mass block structure; (2) a fixed upper electrode and a fixed lower electrode are respectively located on the upper and lower sides of the mass block; (3) the elastic beam is a straight beam of which one end is connected with the mass block, and the other end is connected with a support frame; (4) overload protection salient points are formed on the upper and lower surfaces of the mass block; (5) damping regulation grooves are formed on the upper and lower surfaces of the mass block; and (6) an electrode leading through hole of the mass block is located above the support frame. By adopting the wet etching self-stop technology, the elastic beam-mass block structure which is the most important in the acceleration sensor is processed and formed once in the wet etching; and the bonding of three layers of silicon wafers is realized by a silicon-silicon direct bonding method, and the electrode leading through hole of the mass block is formed on the fixed upper electrode through infrared aligned photoetching. According to the invention, the cross-axis sensitivity is reduced while the device sensitivity is improved.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

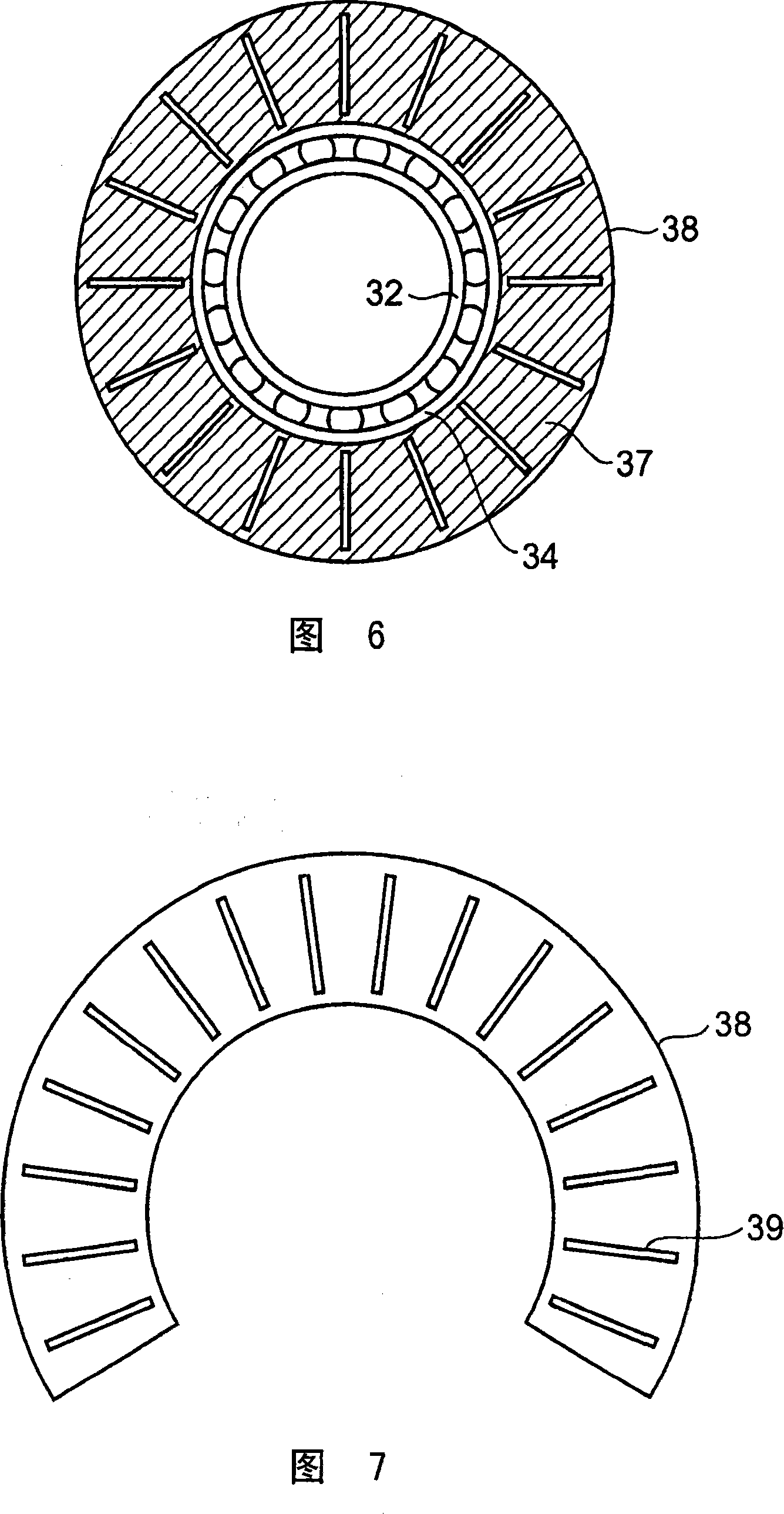

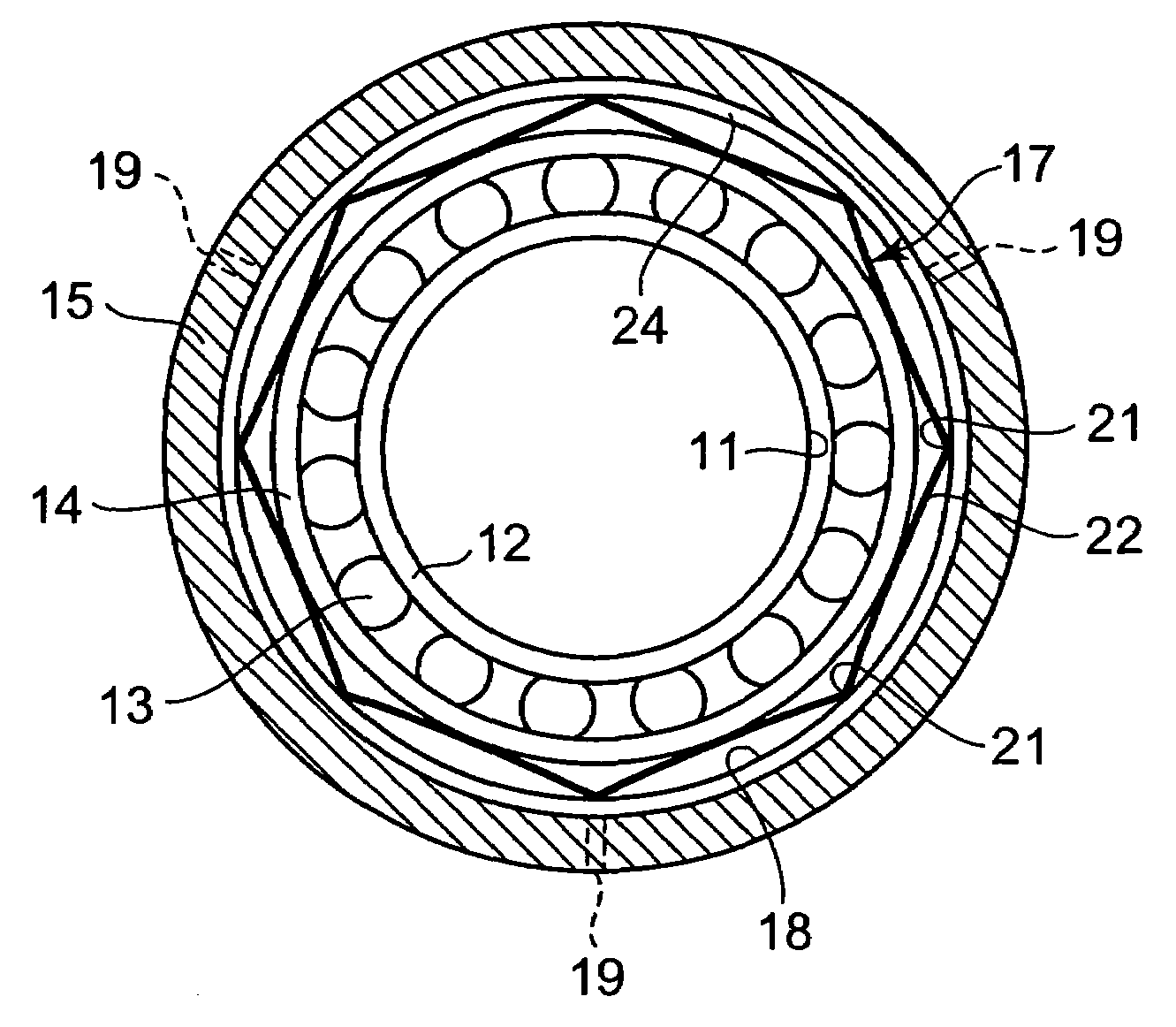

Vibration damping mechanism for bearing

ActiveCN101010521AInhibit sheddingInhibition releaseLeaf springsShaftsRolling-element bearingEngineering

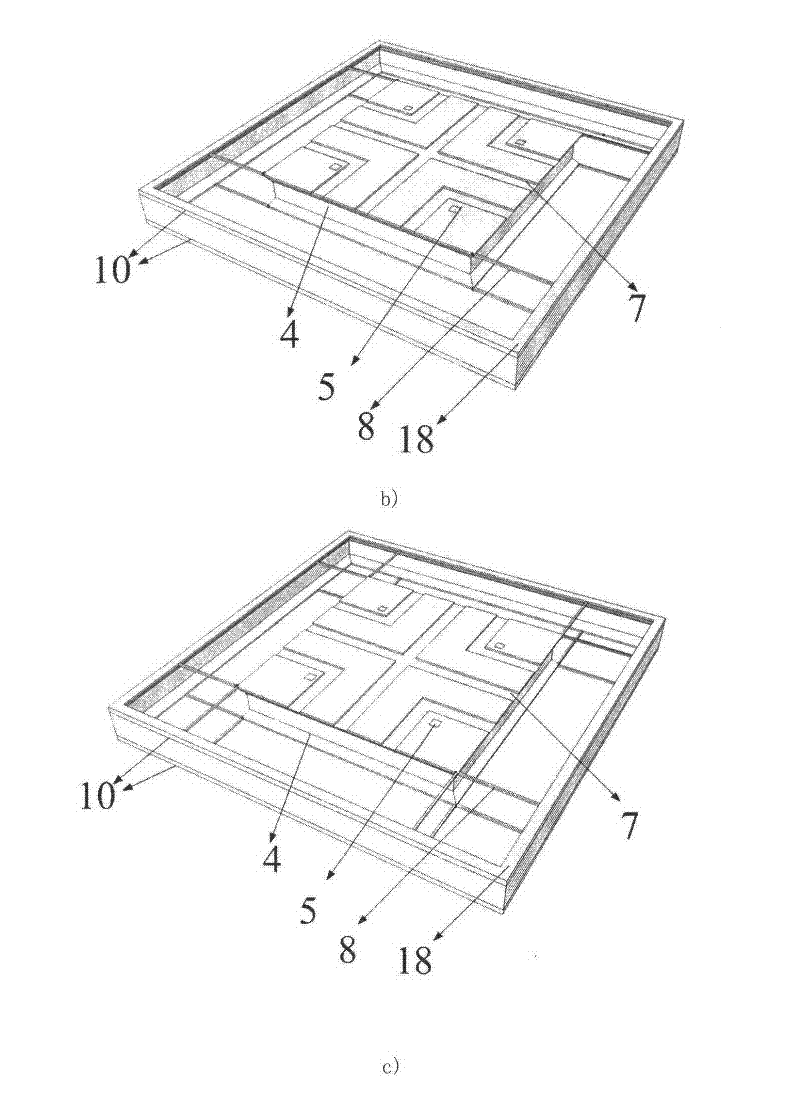

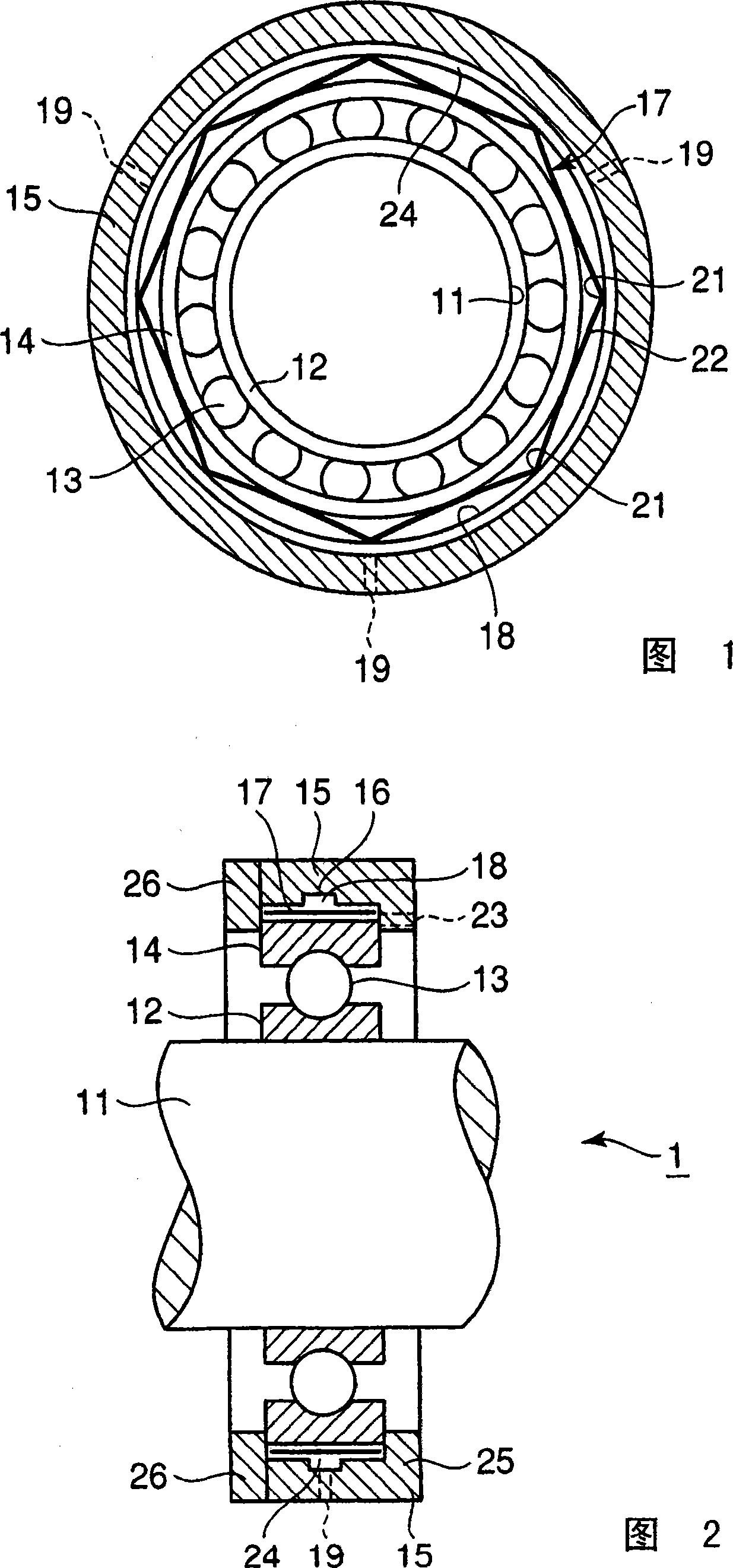

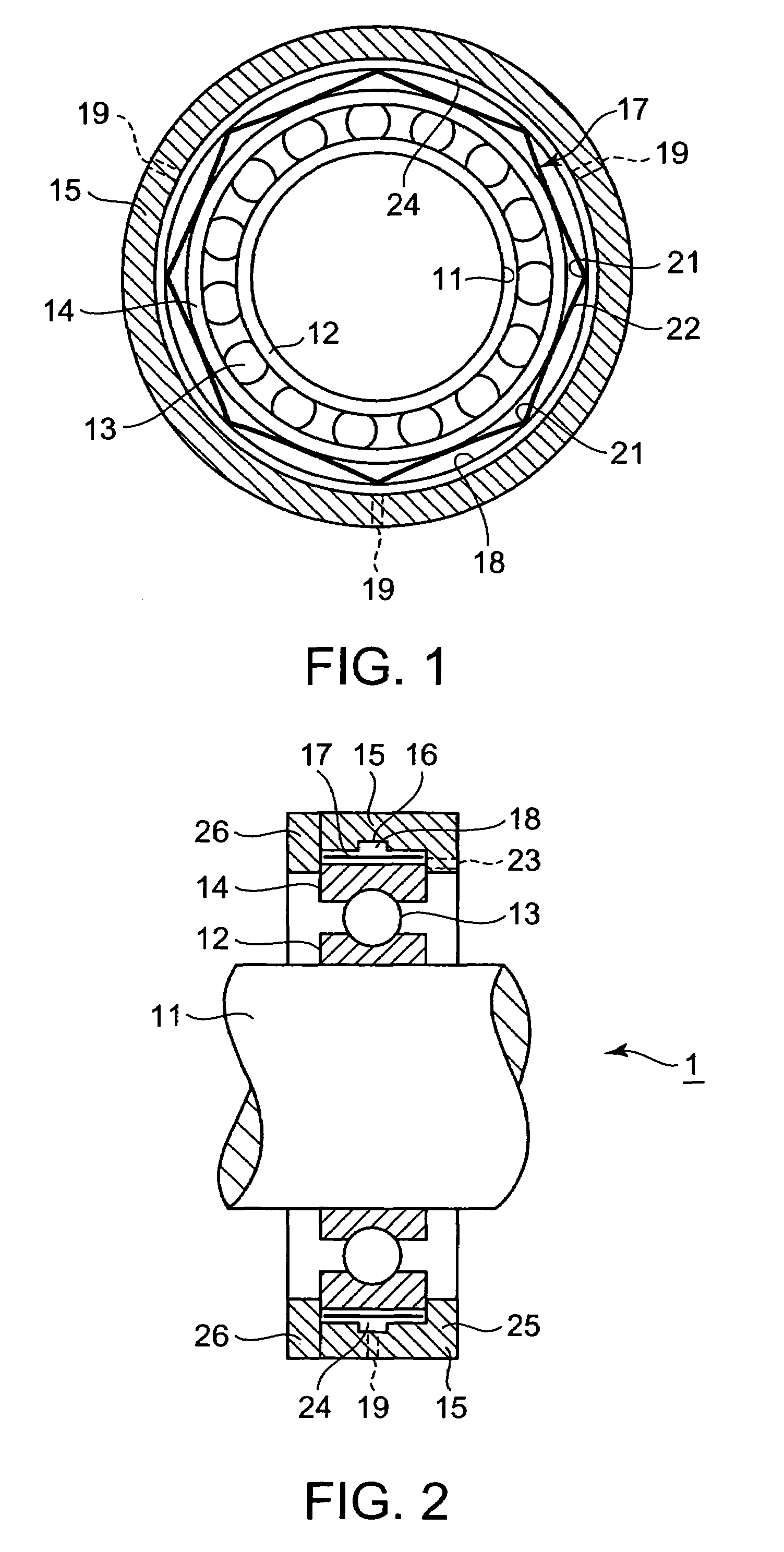

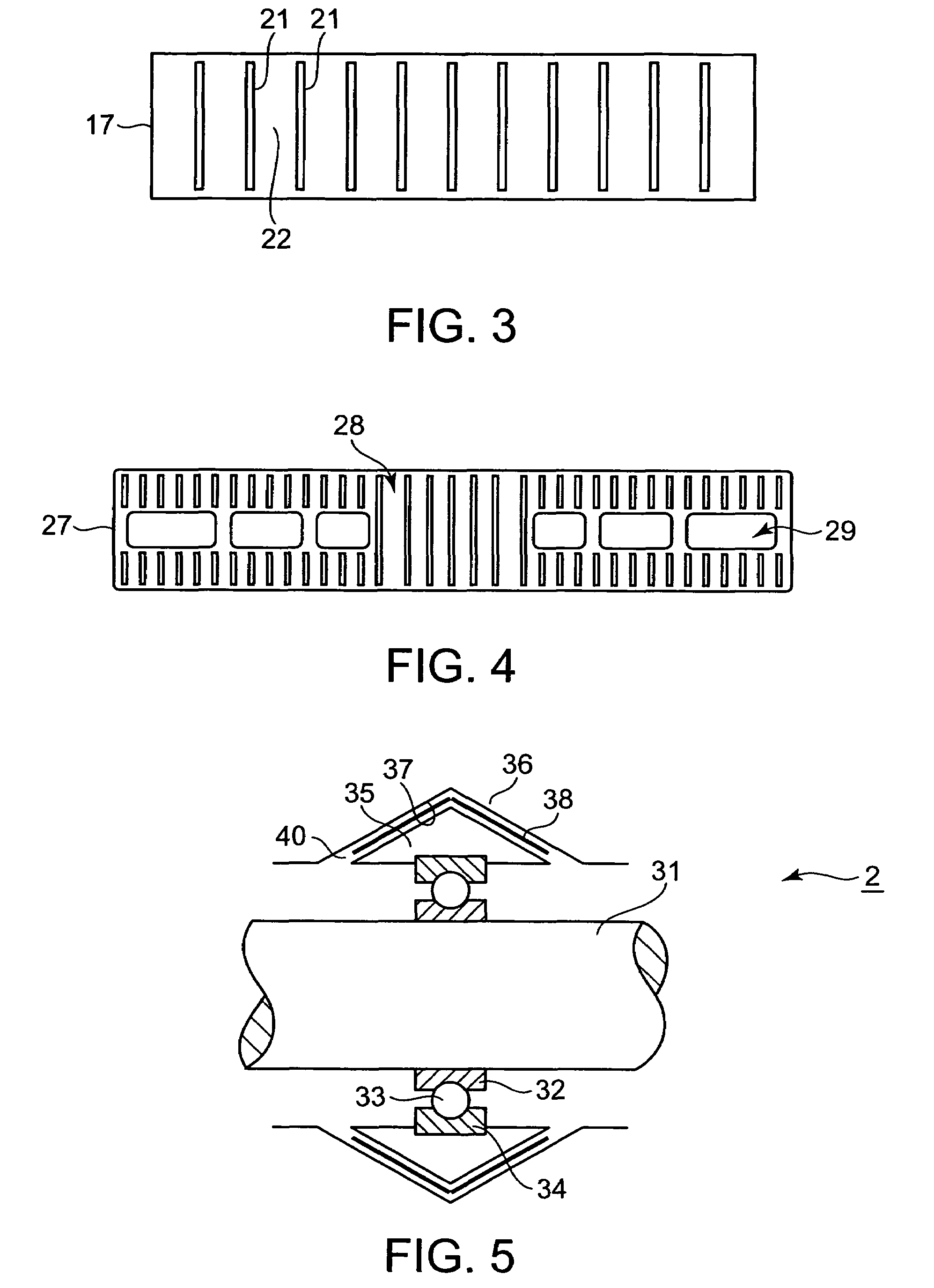

A squeeze film damper bearing easily manufacturable, having excellent productivity, and reduced in size and a vibration damping mechanism for the rolling bearing capable of having an effect on loads in two of radial and thrust directions. In the vibration damping mechanism (1) for the rolling bearing, a storage hole (16) having a diameter larger than the diameter of the outer periphery (14) of the bearing is formed on the inside of a housing (15) and an oil supply hole (19) supplying an oil into the storage hole is formed in the wall of the housing (15), the bearing is inserted into the storage hole to form an annular clearance (18) on the outer periphery of the bearing, and a thin flat plate (17) having a plurality of slits is inserted into the annular clearance along the circumferential direction. The portions of the thin flat plate held by the slits are formed in an elastic beam to elastically support the bearing at a center position, and the vibration of the bearing is damped by a squeeze film action caused by an oil film generated by supplying the oil into the annular clearance.

Owner:KAWASAKI JUKOGYO KK

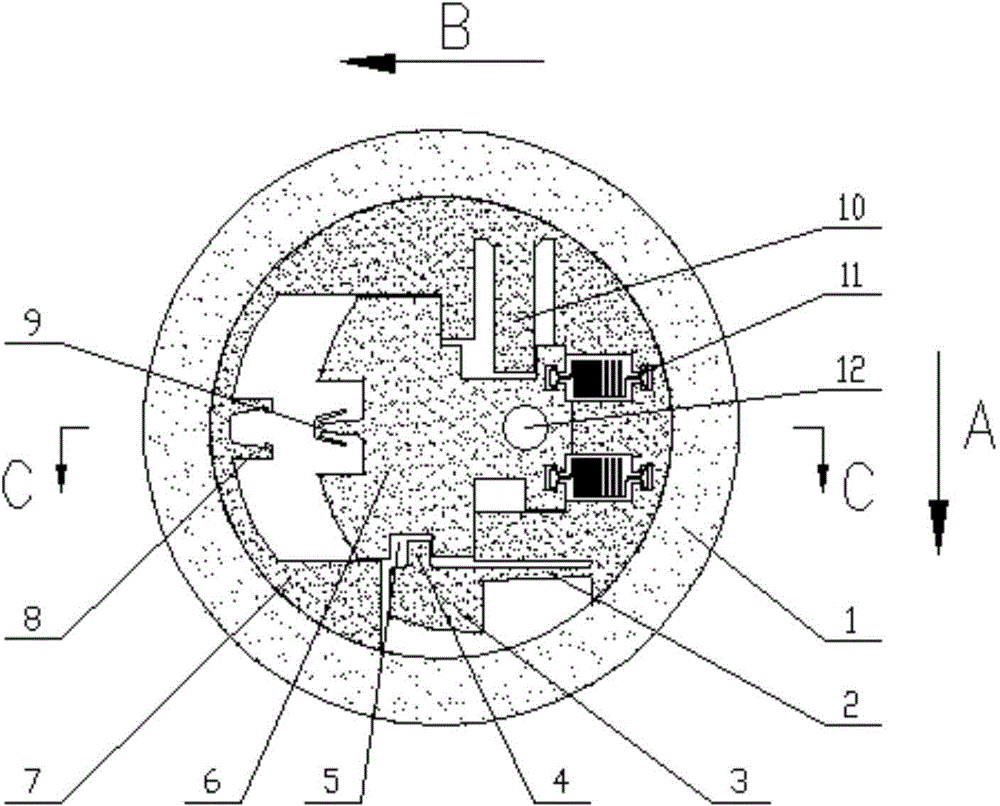

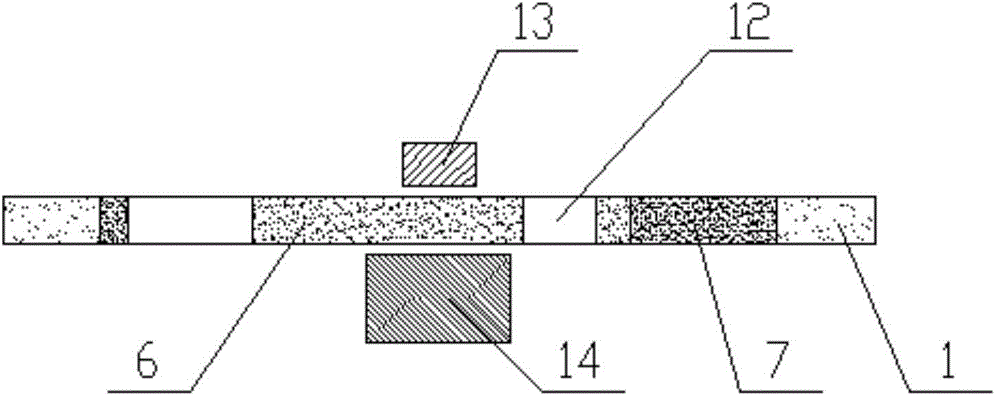

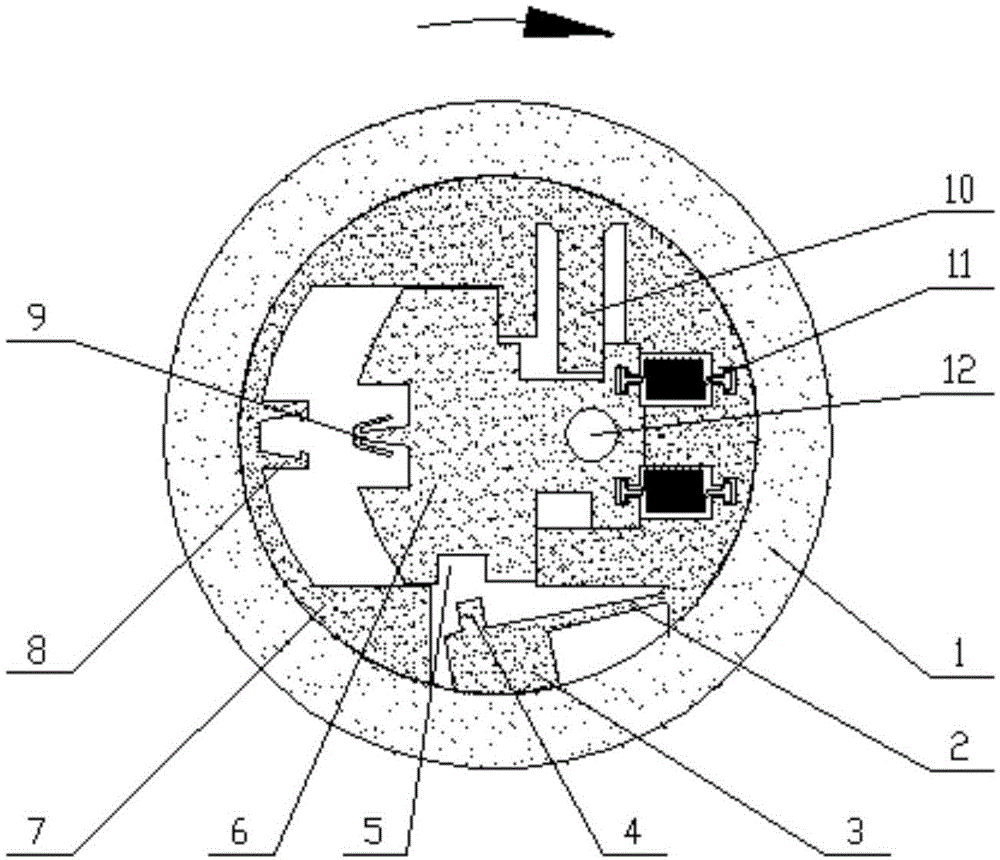

Micro electro mechanical system (MEMS) centrifugal safety mechanism for rotating ammunition and safety method thereof

The invention discloses a micro electro mechanical system (MEMS) centrifugal safety mechanism for rotating ammunition and a safety method of the MEMS centrifugal safety mechanism. An elastic beam processed on a base plate integrally is connected with a centrifugal mass block, a centrifugal baffle plate fixedly connected on the centrifugal mass block is embedded into a groove in the bottom of a sliding block for restraining the sliding block, when the rotating ammunition falls off accidentally or rolls during order dealing, the elastic beam can ensure that the centrifugal mass block and the centrifugal baffle plate fixedly connected with the centrifugal mass block are at initial position, the centrifugal baffle plate can restrain the sliding block, an explosion propagation hole is isolated from an explosion propagation channel and a safety device is safe; if the launching operation is abnormal, the elastic beam still can drive the centrifugal baffle plate fixedly connected with the centrifugal mass block to return to the initial position to restrain the sliding block, so that the safety of the ammunition after misfiring accidentally is ensured. The MEMS centrifugal safety mechanism is wide in applicability, is suitable for various MEMS safety devices for rotating ammunition, and is integrally processed with the base plate, so that the assembling links are reduced; and the MEMS centrifugal safety mechanism is convenient for modular and generalized design, and is easy for batch production and low in cost.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

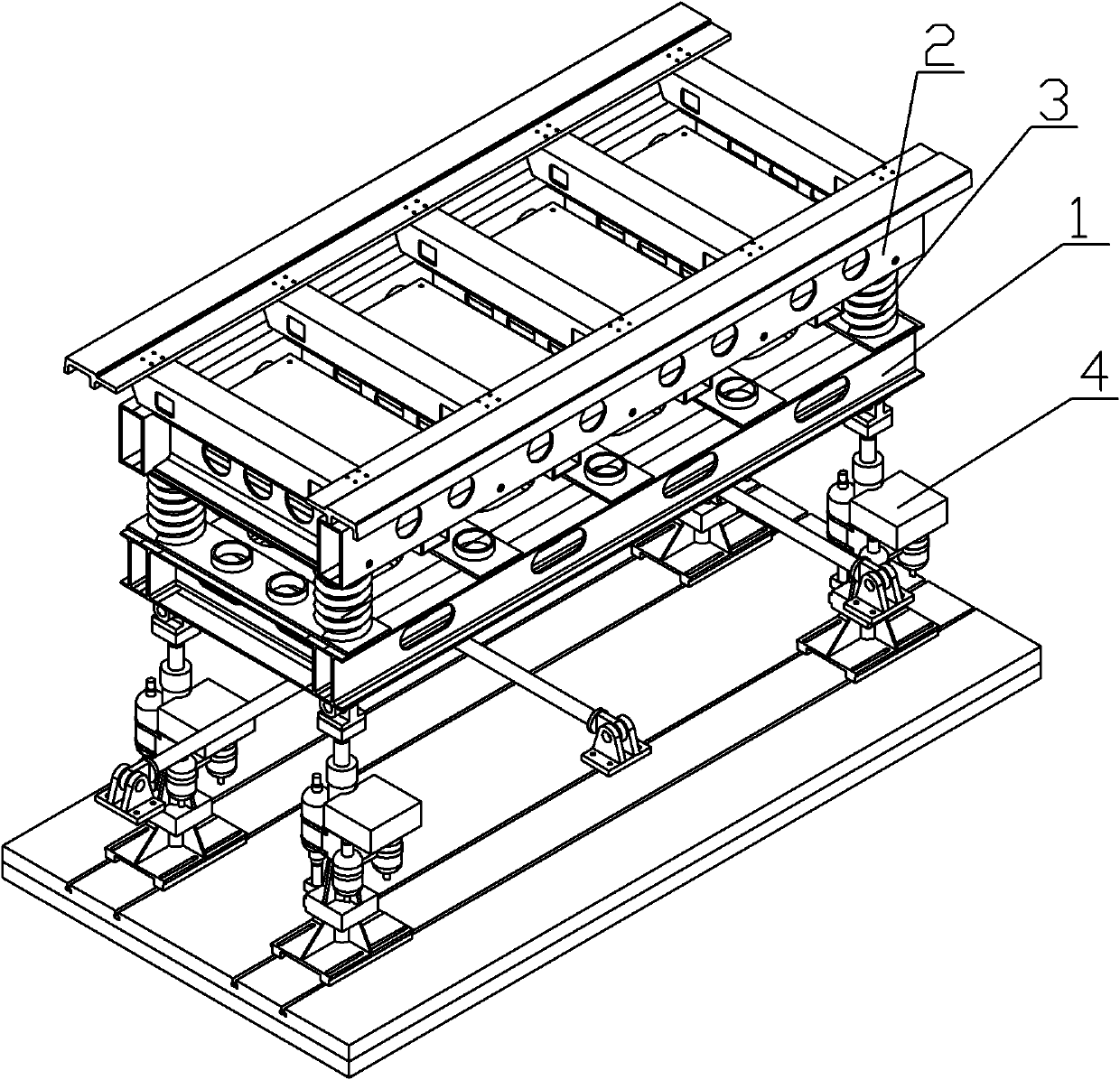

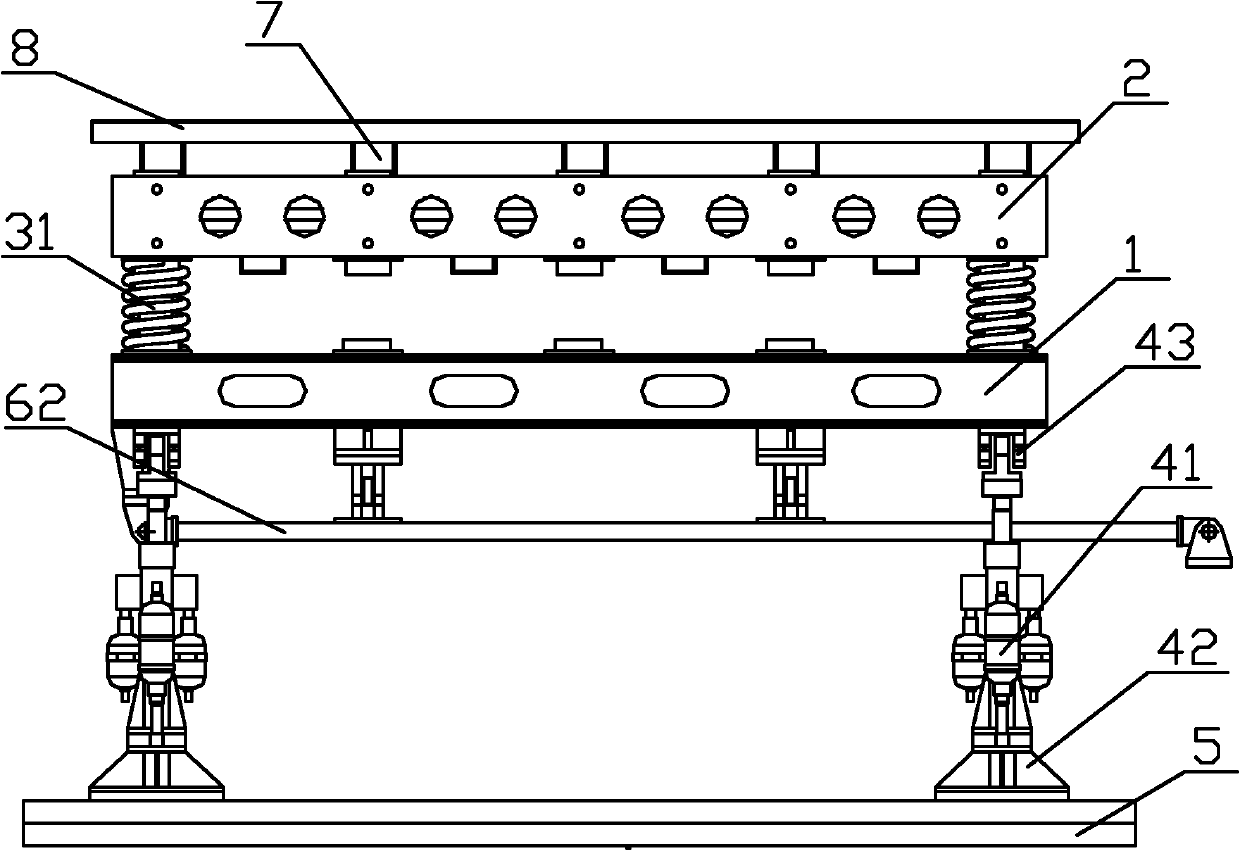

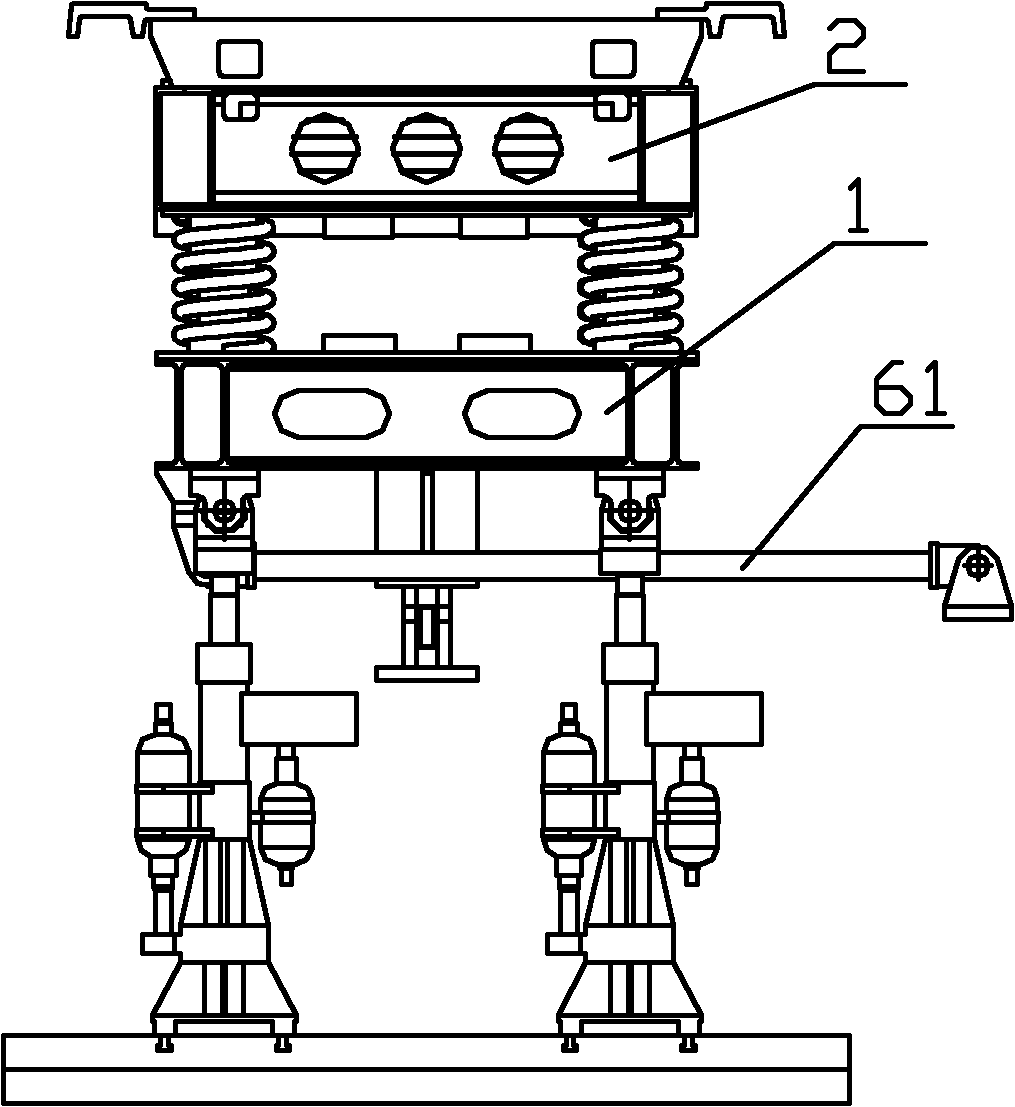

Electromechanical coupling vibration test device for maglev train

ActiveCN101995322ASimple structureLight weightMechanical vibrations separationVibration testingLevitationControl system design

The invention relates to the technical field of single levitation chassis testing for a maglev train, in particular to an electromechanical coupling vibration test device for the maglev train. The device comprises a primary platform for simulating ground support, a secondary platform which is positioned above the primary platform and simulates a track beam, and a track beam rigidity adjusting system for connecting the primary platform and the secondary platform, wherein the track beam rigidity adjusting system and the secondary platform supported by the track beam rigidity adjusting system form simulated maglev train track beam characteristics; and a hydraulic shock excitation system which applies excitation to the primary platform so as to simulate geometrical irregularity of track ground is fixed under the primary platform. The defects of the simplified single-point test or complete-vehicle debugging test for the conventional maglev train are overcome, the complex laboratory simulation of levitation control, elastic beam and coupling vibration environment of a levitation chassis mechanism for the maglev train is realized, the gap in research of key technology for domestic and overseas maglev trains is filled, and a scientific test means is provided for design of a levitation control system of the maglev train, the track beam characteristics and design of the mechanical structure of the levitation chassis.

Owner:常州西南交通大学轨道交通研究院 +1

Bearing vibration damping mechanism

ActiveUS7628542B2Easy to produceReduce vibrationLeaf springsShaftsRolling-element bearingEngineering

A squeeze film damper for a bearing and a vibration damping mechanism capable of damping the vibration of a rolling bearing are provided. The squeeze film damper is small in construction and can be easily made by mass production. The vibration damping mechanism is capable of damping both radial and axial vibrations. A bearing housing 15 is provided with a bearing holding bore 16 of a diameter greater than the outside diameter of the outer ring 14 of a bearing, and an oil hole 19 through which oil is supplied into the bearing holding bore 16. A vibration damping mechanism 1 is formed by inserting a thin, flat sheet 17 provided with slits into an annular space formed between the inner wall of the bearing holding bore 16 and the outside surface of a bearing held in the bearing holding bore 16 so as to surround the bearing. Parts of the thin, flat sheet extending between the adjacent slits serve as elastic beams. The elastic beams center the bearing and support the centered bearing elastically. The vibration of the bearing is damped by the squeeze film effect of an oil film formed by supplying oil into the annular space.

Owner:KAWASAKI HEAVY IND LTD

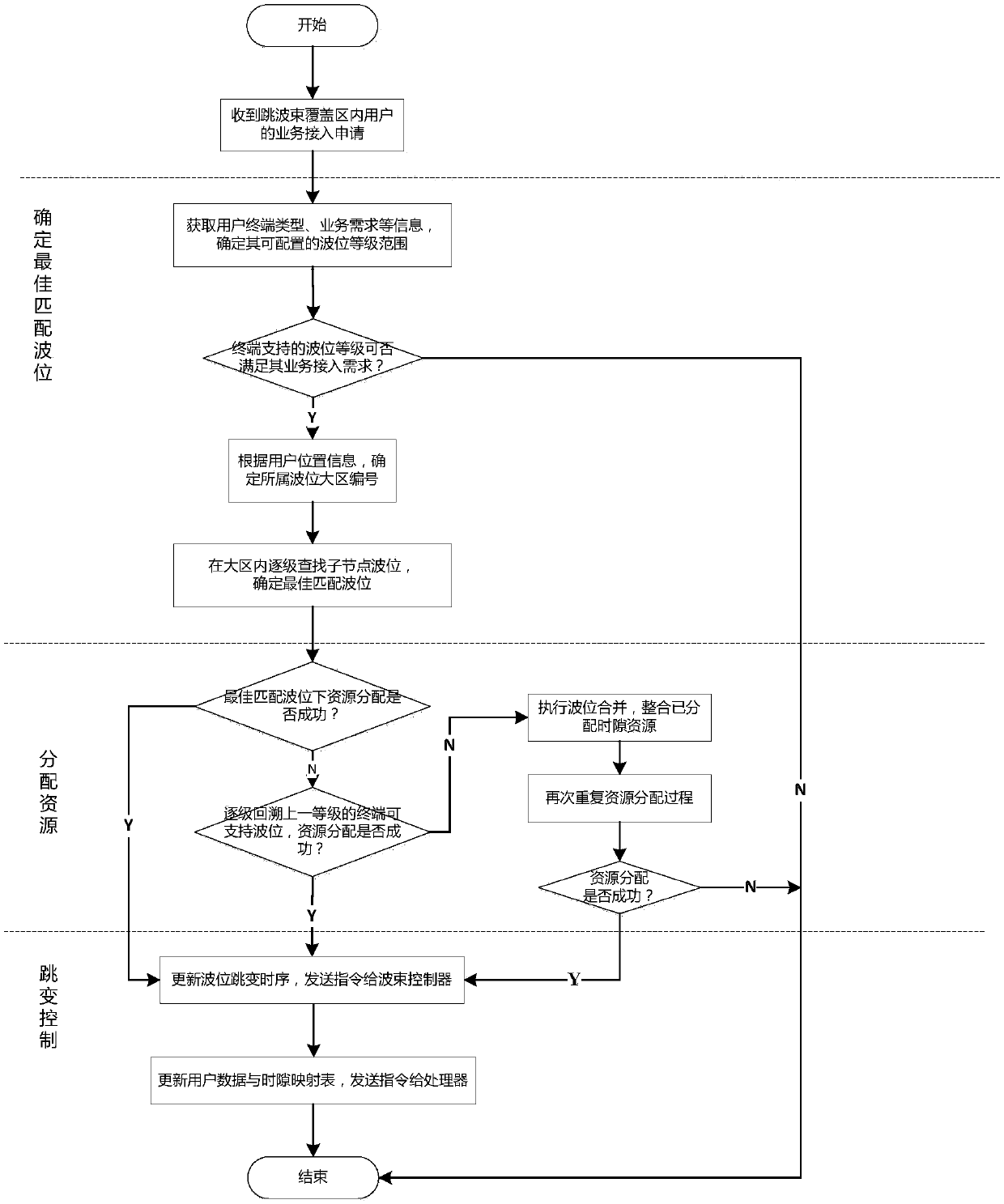

Elastic beam position resource scheduling system and scheduling method for jump beams

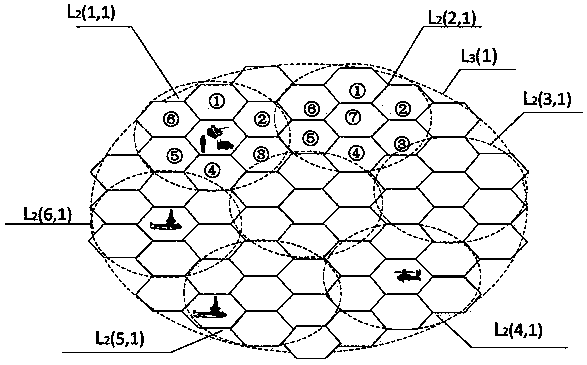

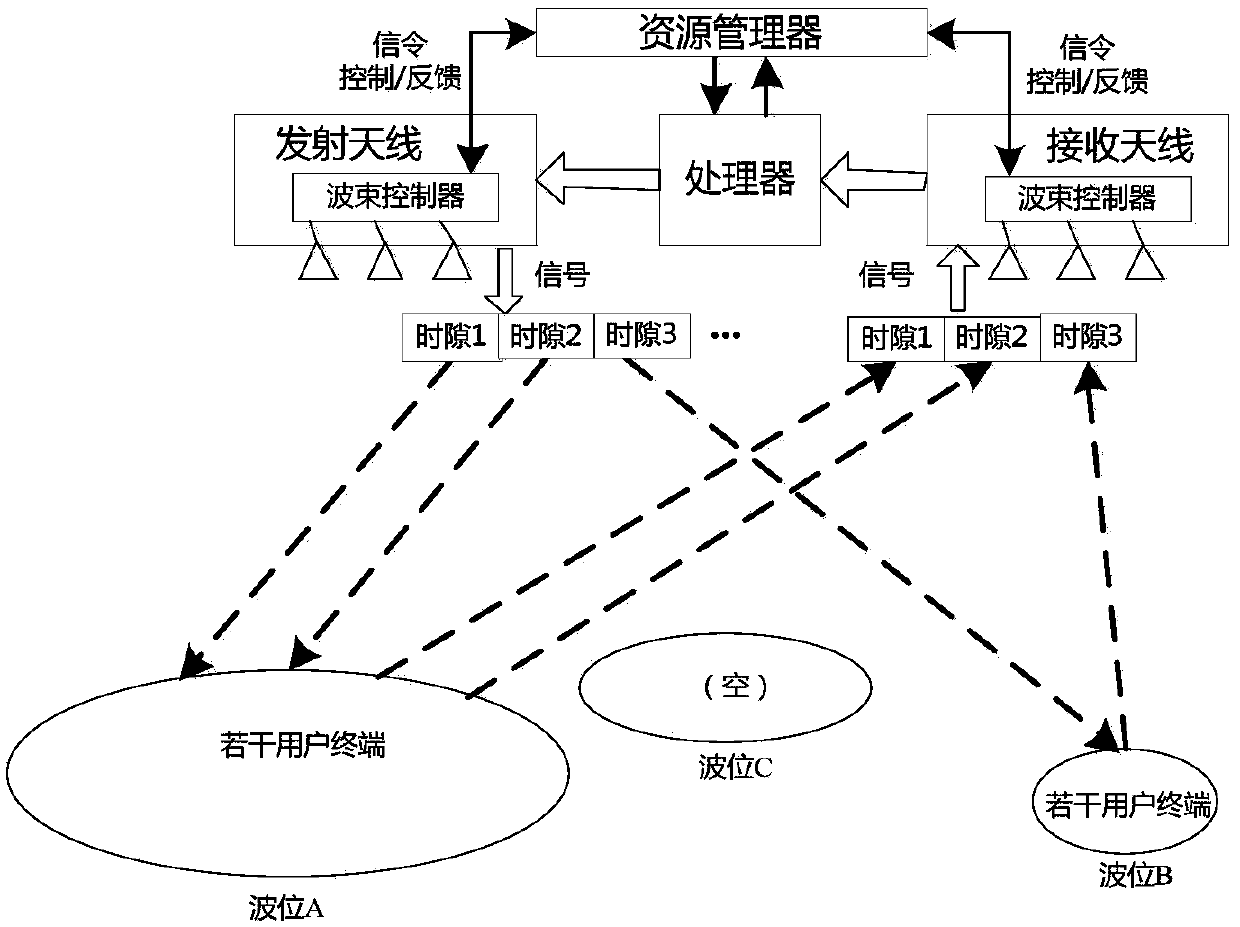

ActiveCN107949066ASolve resource optimization problemsImprove experienceSignal allocationWireless communicationResource utilizationResource management

The invention provides an elastic beam position resource scheduling system and scheduling method for jump beams. A beam position refers to a coverage area of a jump beam on the earth surface on a specific direction, and the availability is subject to the allocation of time slots. The elastic beam position resource scheduling system comprises: a resource manager, a processor, a beam controller, a transmitting antenna and a receiving antenna, the resource manager completes an elastic beam position resource scheduling process according to service access request signaling and sends an instructionto the receiving antenna and the beam controller in the sending antenna so as to control the jump timing sequence of the jump beam, and sends scheduling information to the processor to ensure the synchronous cooperation of the transmitted data and the beam position. The elastic beam position resource scheduling method, that is, a processing and control operation flow of the resource manager, mainly comprises determining an elastic beam position, resource optimization distribution and the jump control. Based on the high dynamics of the user demand distribution and the shaping variability of thejump beam, the utilization ratio of jump beam resources and the flexible anti-interference capability can be effectively improved.

Owner:XIAN INSTITUE OF SPACE RADIO TECH

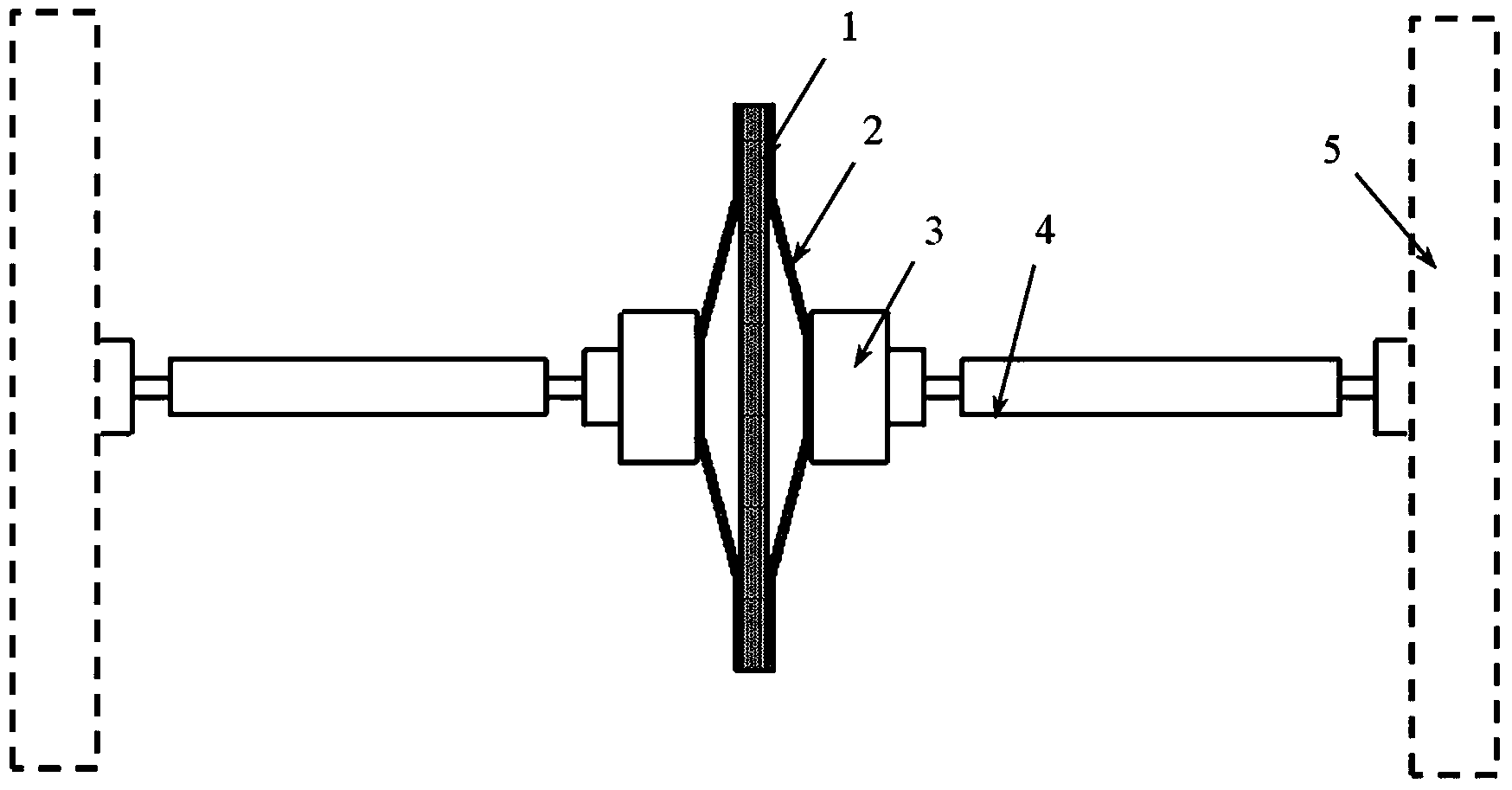

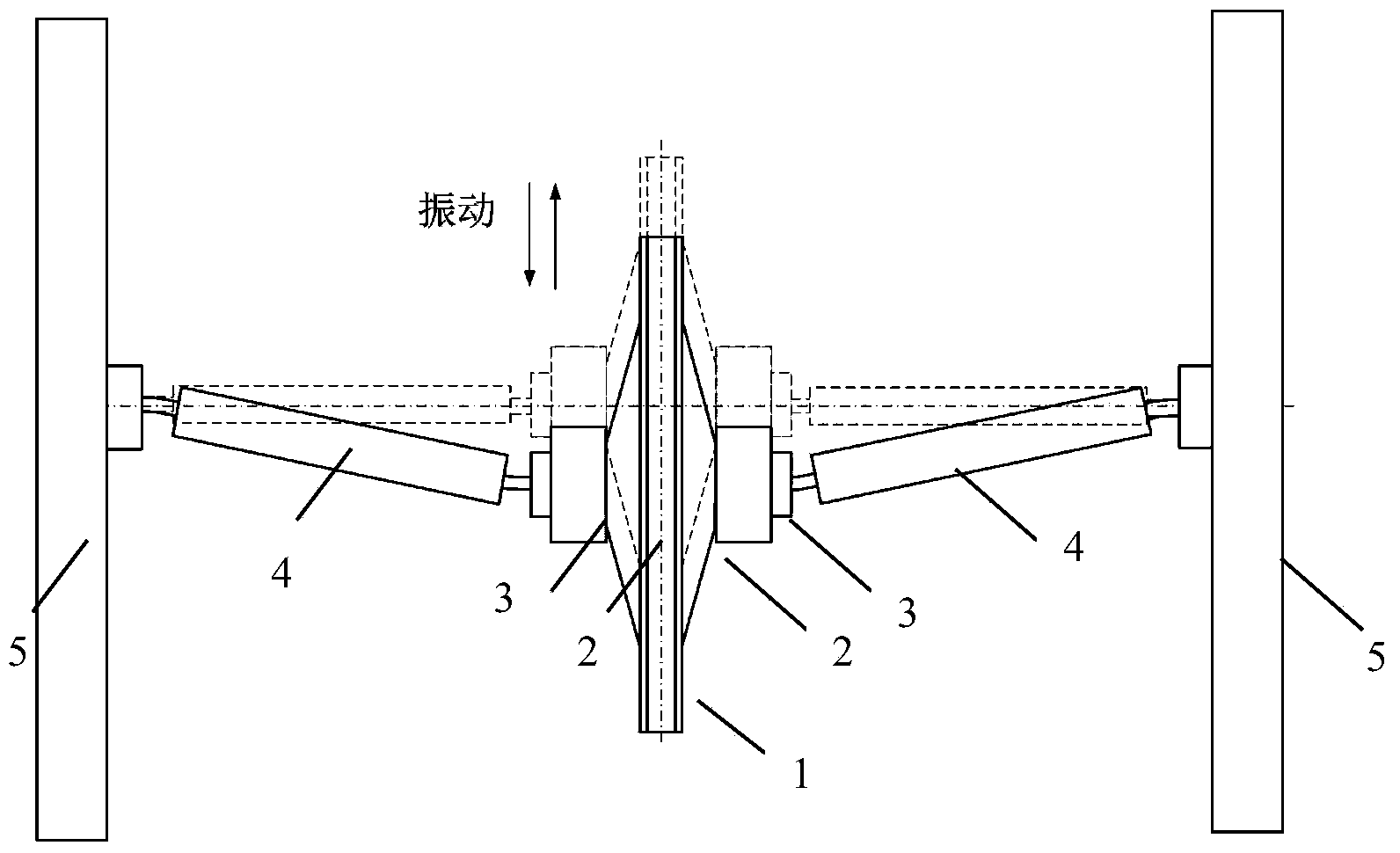

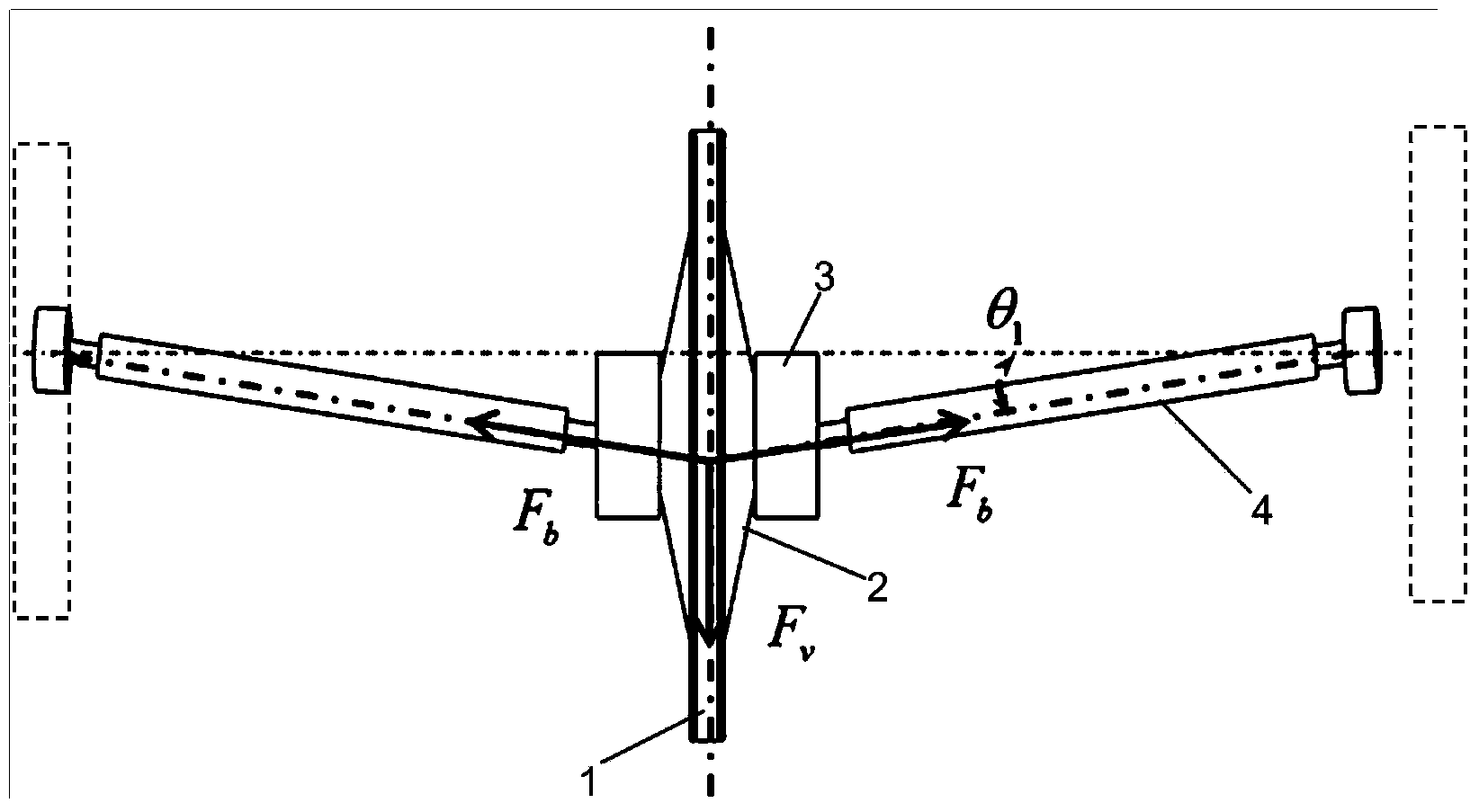

High-efficiency multidirectional vibration energy collection device

InactiveCN104283460AImprove reliabilityHigh strengthPiezoelectric/electrostriction/magnetostriction machinesElectricitySpherical joint

A high-efficiency multidirectional vibration energy collection device comprises a piezoelectric material, arch-shaped plates, mass blocks, elastic beams and bases. According to the structure of the high-efficiency multidirectional vibration energy collection device, the piezoelectric material serves as a symcenter, and the arch-shaped plates, the mass blocks, the elastic beams and the bases are symmetrically distributed on the two sides of the piezoelectric material. The piezoelectric material is connected with the mass blocks on the two sides of the piezoelectric material through the arc-shaped plates, each mass block is connected with the corresponding base through the corresponding elastic beam, and first-level magnification of force is completed through the elastic beams. The elastic beams are connected with the mass blocks and the bases in a fixed mode or in a hinged mode or through spherical joints. Second-level magnification of the force is completed through the arch-shaped plates. The high-efficiency multidirectional vibration energy can generate one more order of magnitude of electric energy than a transmission energy collector under the same environment. Vibration energy in different directions can be collected.

Owner:BEIJING UNIV OF TECH

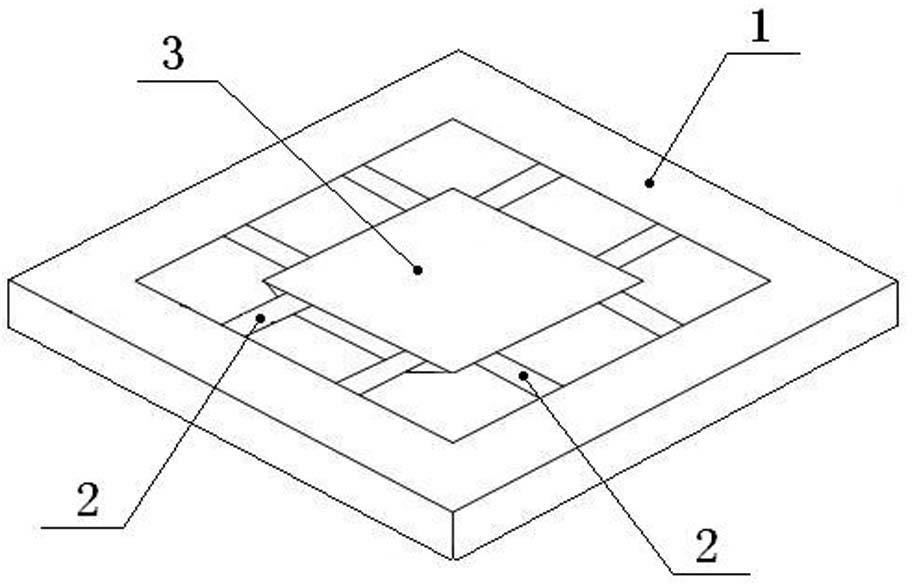

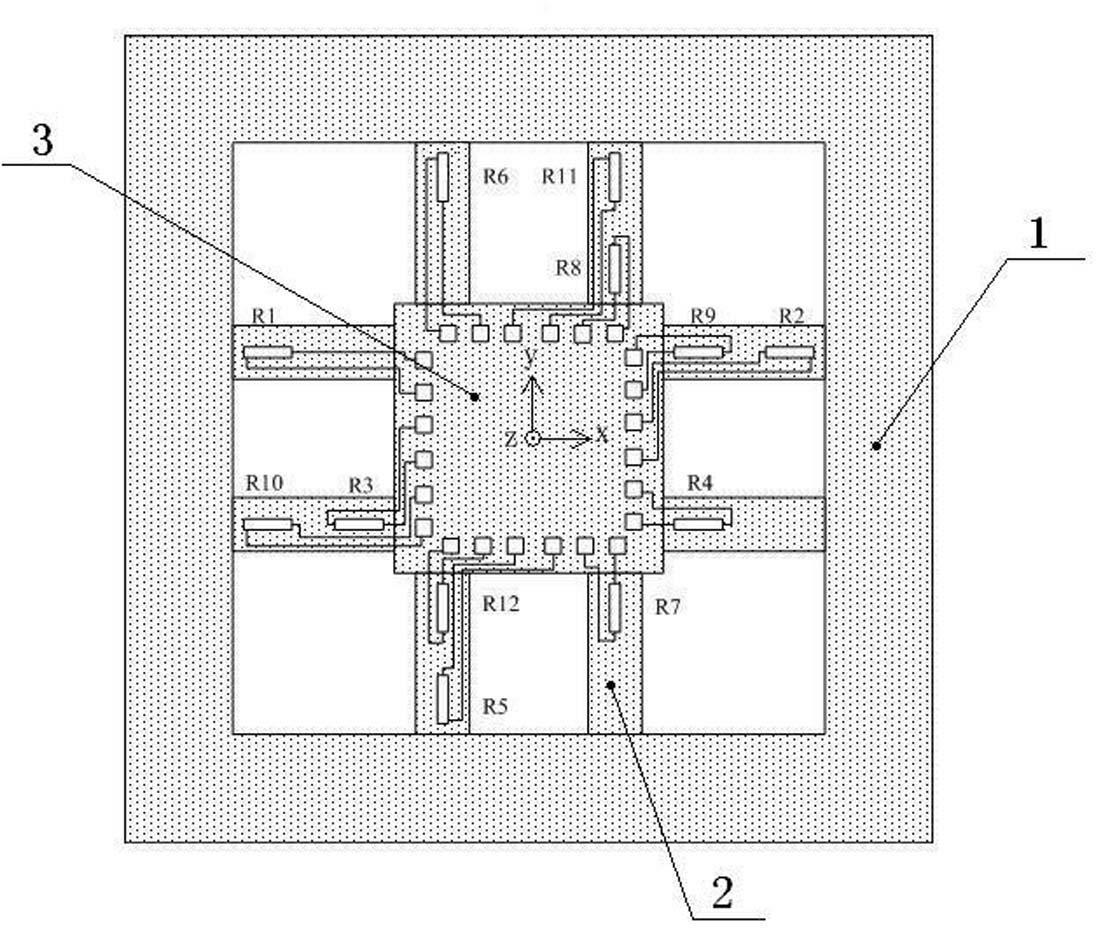

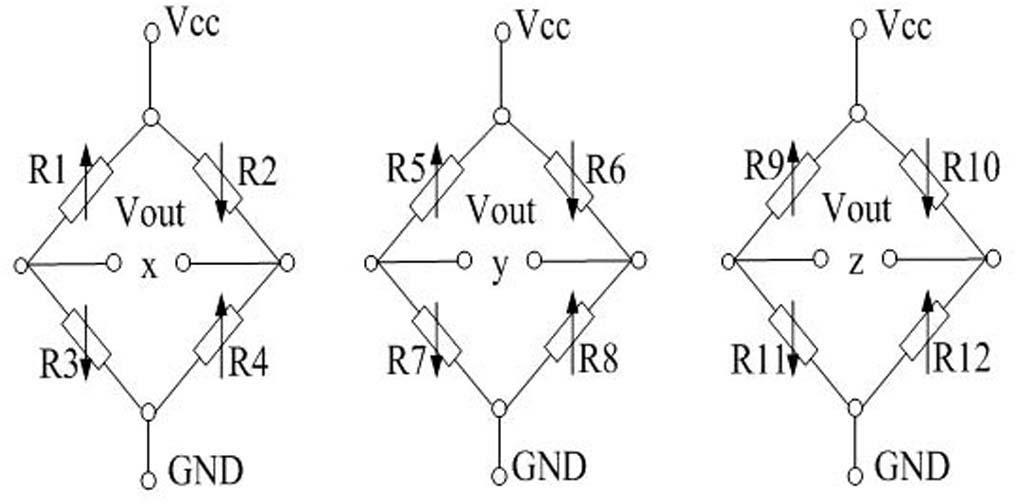

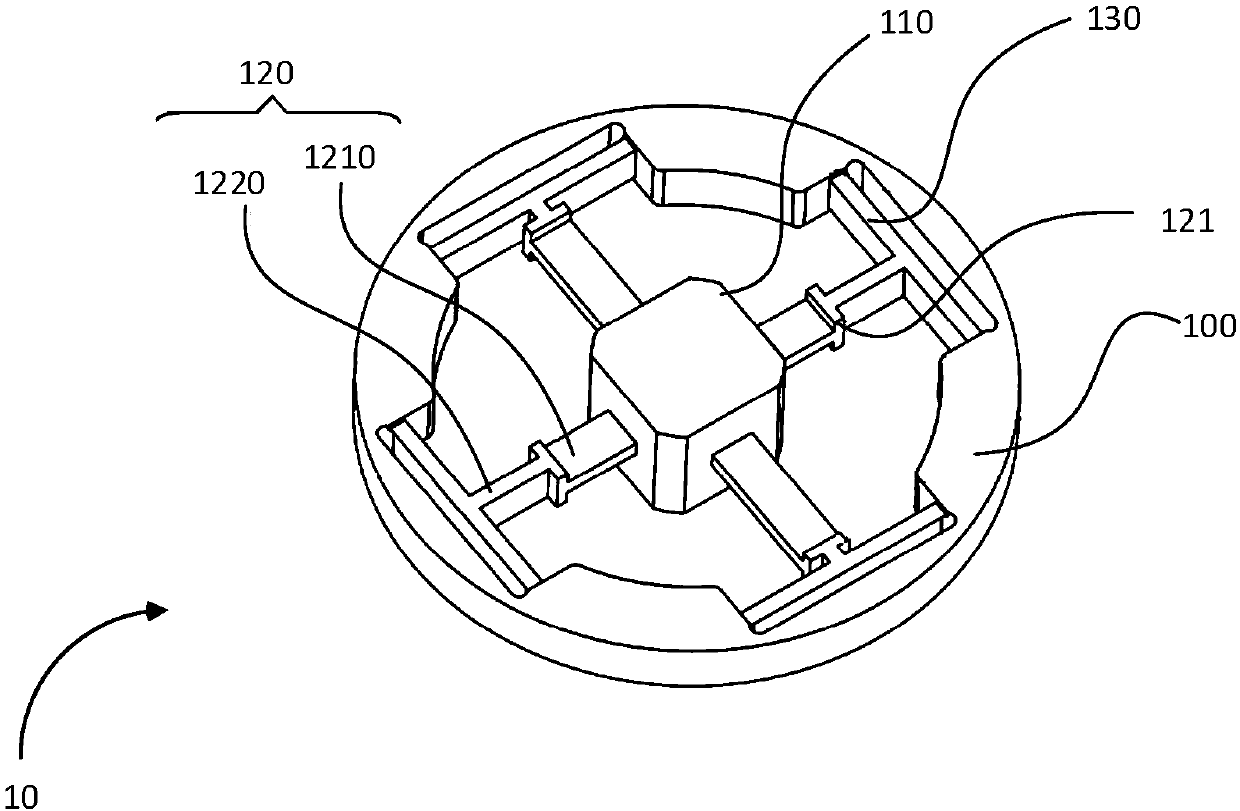

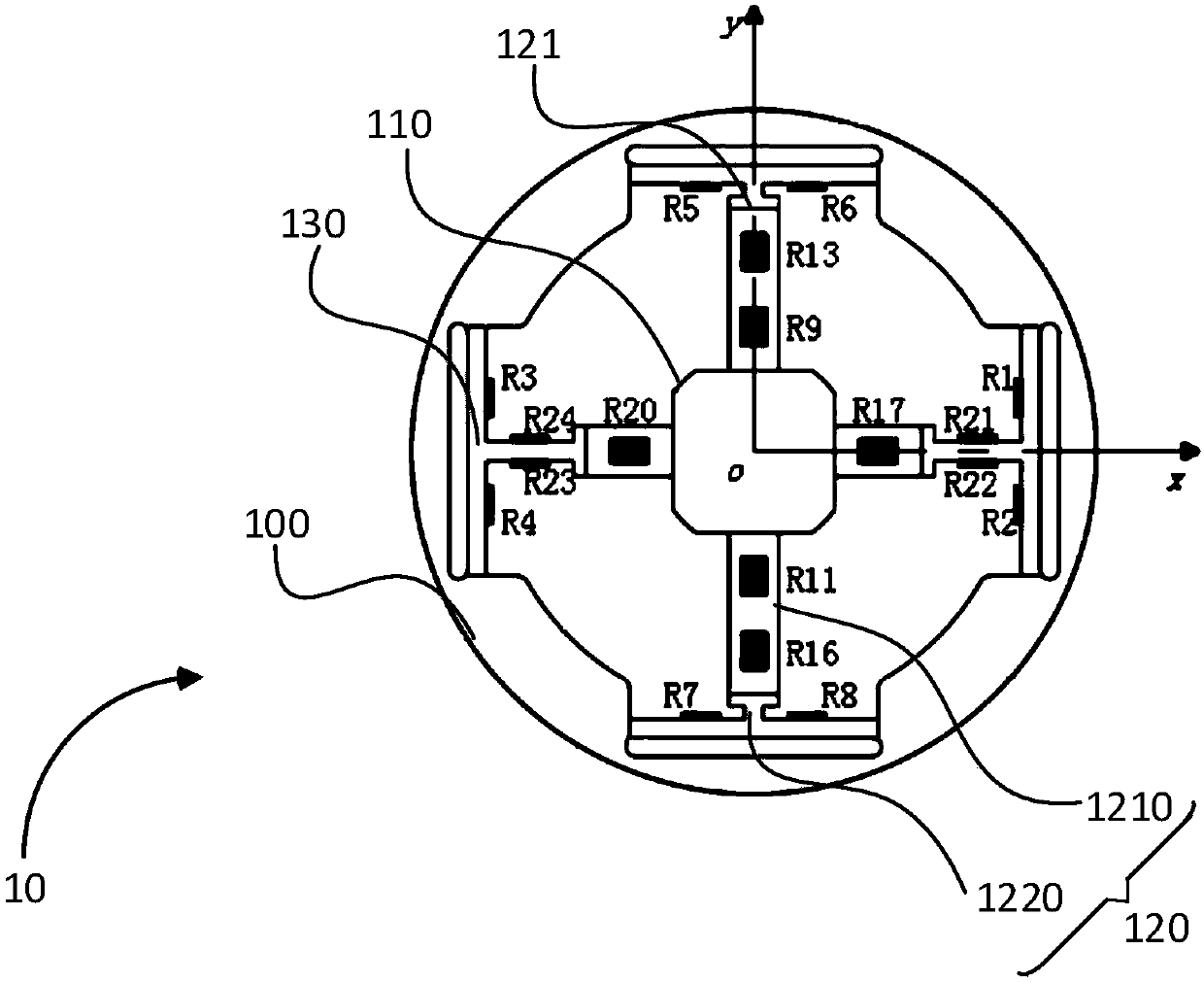

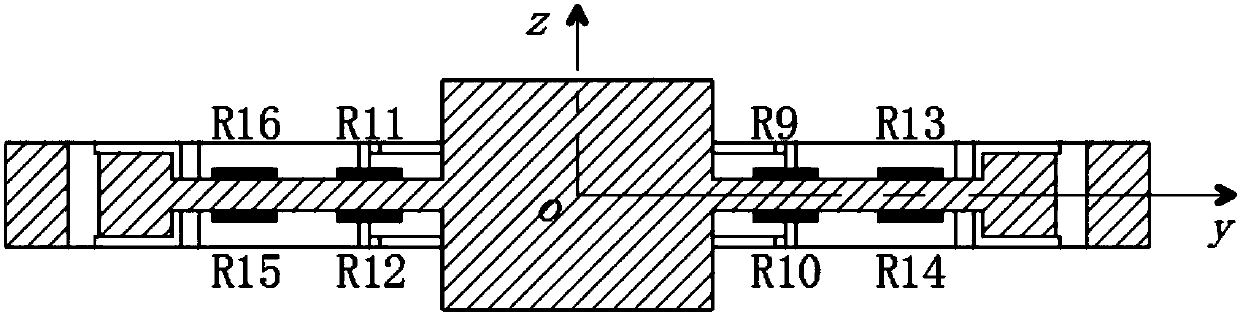

Single-chip integrated eight-beam-arm triaxial accelerometer

InactiveCN102435776AHigh sensitivityImproved shaft couplingAcceleration measurement using interia forcesPiezoelectric/electrostrictive devicesElectrical resistance and conductanceTriaxial accelerometer

The invention relates to an acceleration sensor in the field of sensors of a micro electro mechanical system (MEMS), in particular to a single-chip integrated eight-beam-arm triaxial accelerometer, and solves the problems of low sensitivity, high degree of inter-axial coupling, complicated packaging structure, inconvenience for installation test and poor high-temperature resistance of the conventional accelerometer. The single-chip integrated eight-beam-arm triaxial accelerometer comprises eight elastic beam arms, a central clamped block and mass block frames, wherein the surrounding mass block frames are respectively fixed with the central clamped block through the elastic beam arms; a lower bottom surface of the central clamped block is bonded with a glass bottom cover through an electrostatic coupling technology; twelve piezoresistors having equal resistance are symmetrically distributed at both ends of the eight elastic beam arms; and the piezoresistors are connected to respectively form three Wheatstone bridges for respectively testing three axial accelerations. The single-chip integrated eight-beam-arm triaxial accelerometer is high in sensitivity, simple in packaging structure, high in reliability, low in cost, easy to integrally process, and wide in application range.

Owner:ZHONGBEI UNIV

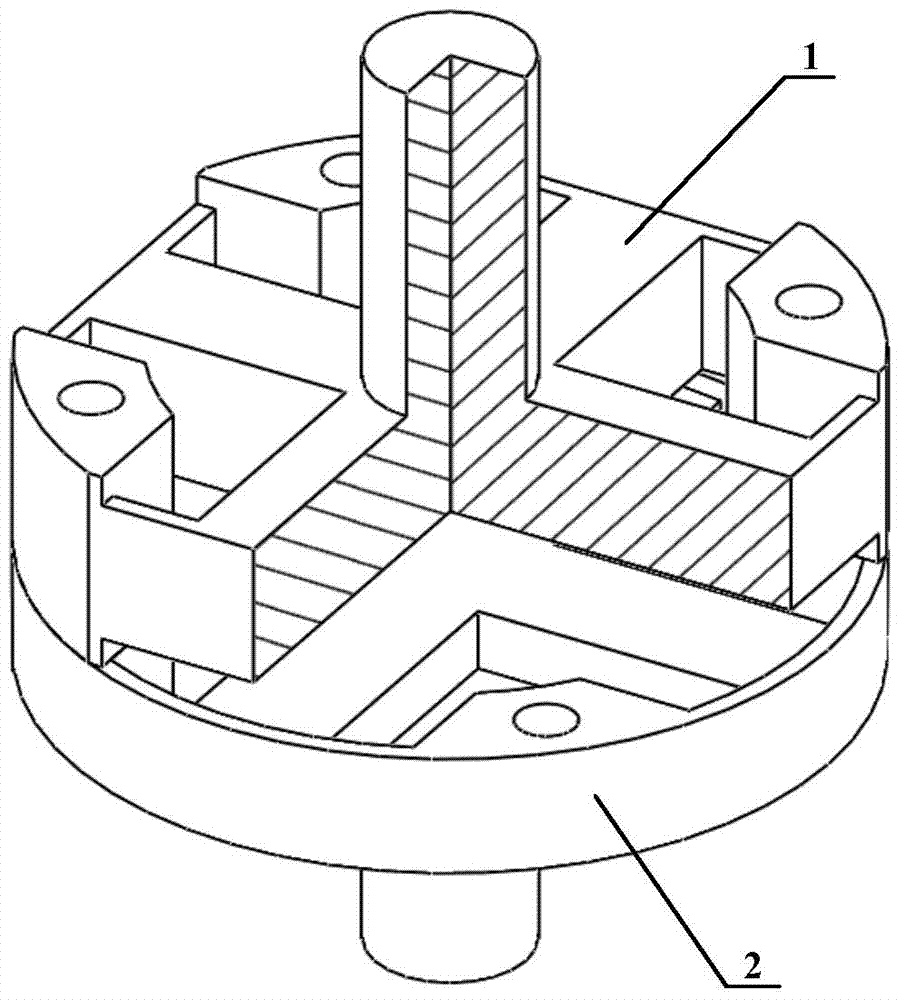

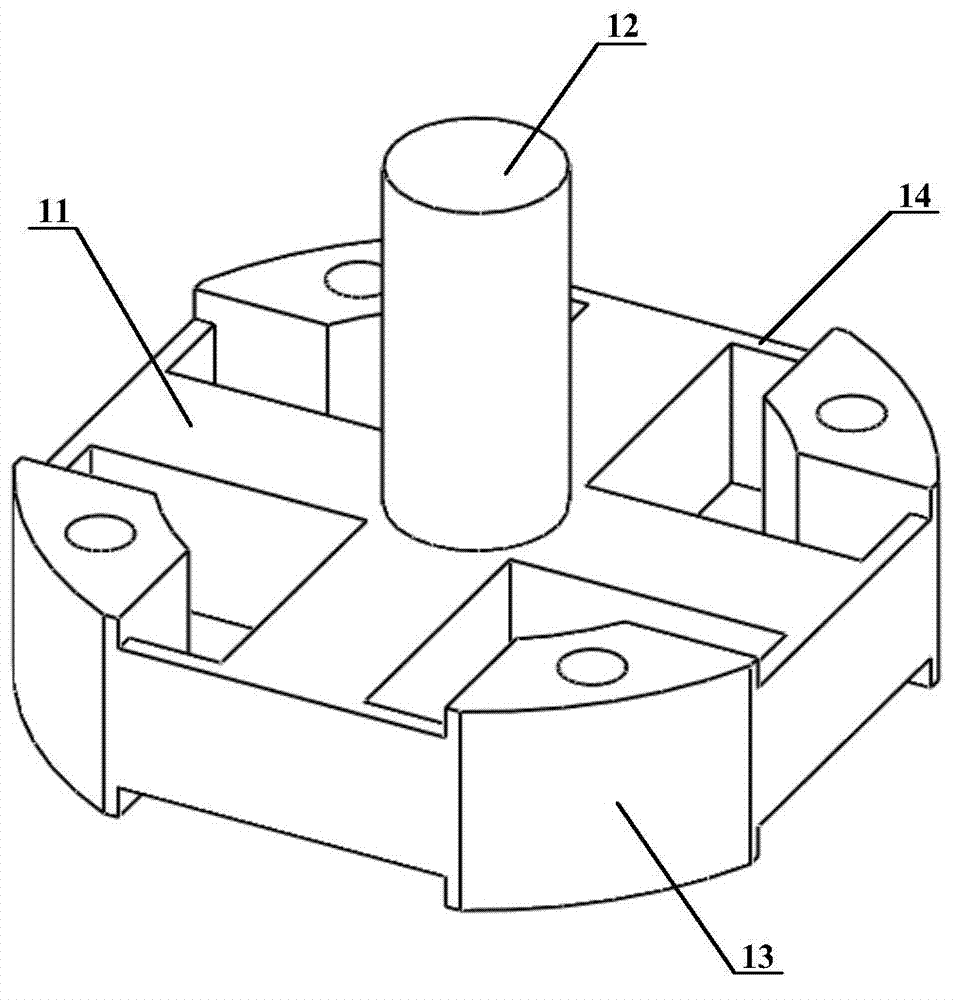

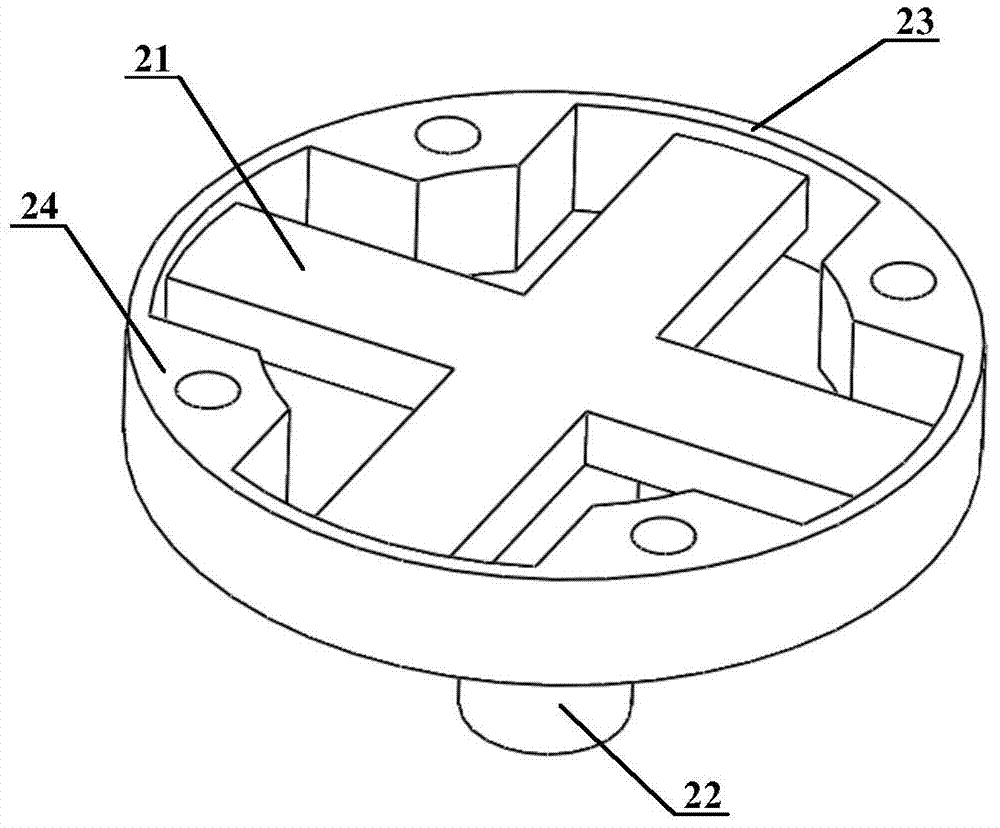

Double crossed beam combination type finger joint six-dimensional force sensor

ActiveCN103940544AMiniaturizationBreak through the volume bottleneckMeasurement of force componentsFixed frameFinger joint

The invention discloses a double crossed beam combination type finger joint six-dimensional force sensor. The double crossed beam combination type finger joint six-dimensional force sensor is formed by combining an upper elastic crossed beam body and a lower elastic crossed beam body. The upper elastic crossed beam body comprises four upper elastic beams, an upper center loading shaft, four upper fixing tables and four upper floating beams. The lower elastic crossed beam body comprises four lower elastic beams, a lower center loading shaft, a fixing frame and four lower fixing tables. The upper elastic crossed beam body and the lower elastic crossed beam body are fixed through the four upper fixing tables and the four lower fixing tables corresponding to the four upper fixing tables in a one-to-one mode, and form a double crossed beam structure. Compared with an existing multi-dimension force sensor, the double crossed beam combination type finger joint six-dimensional force sensor is higher in sensitivity and is suitable for multi-dimension force measurement in the field of finger joints of robots.

Owner:SOUTHEAST UNIV

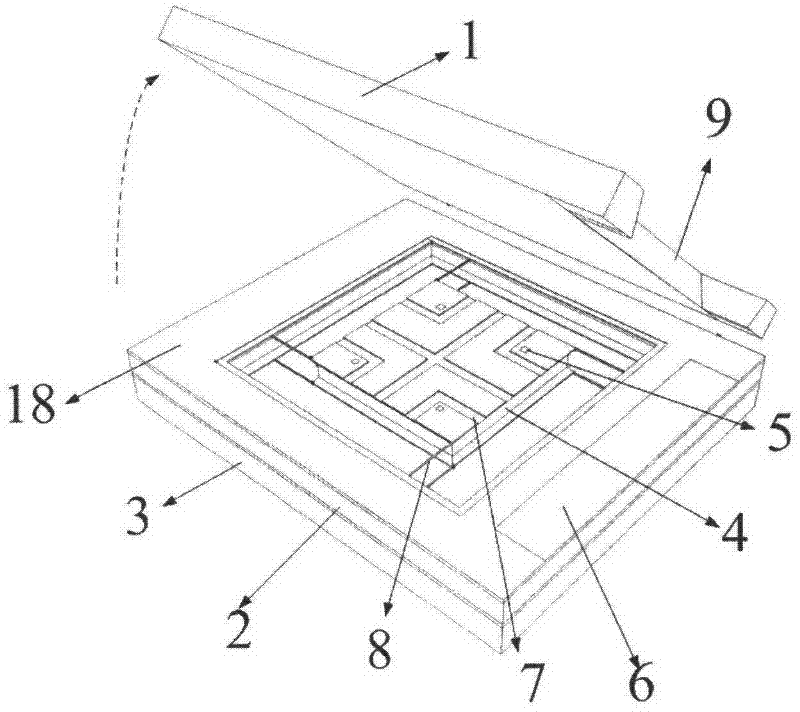

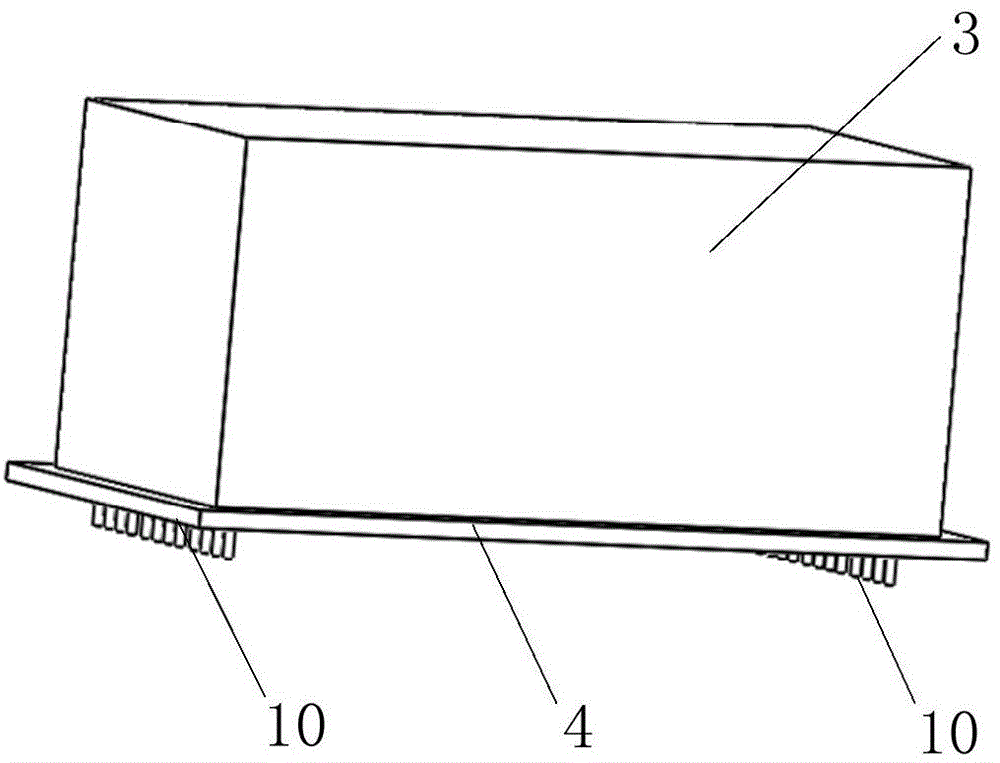

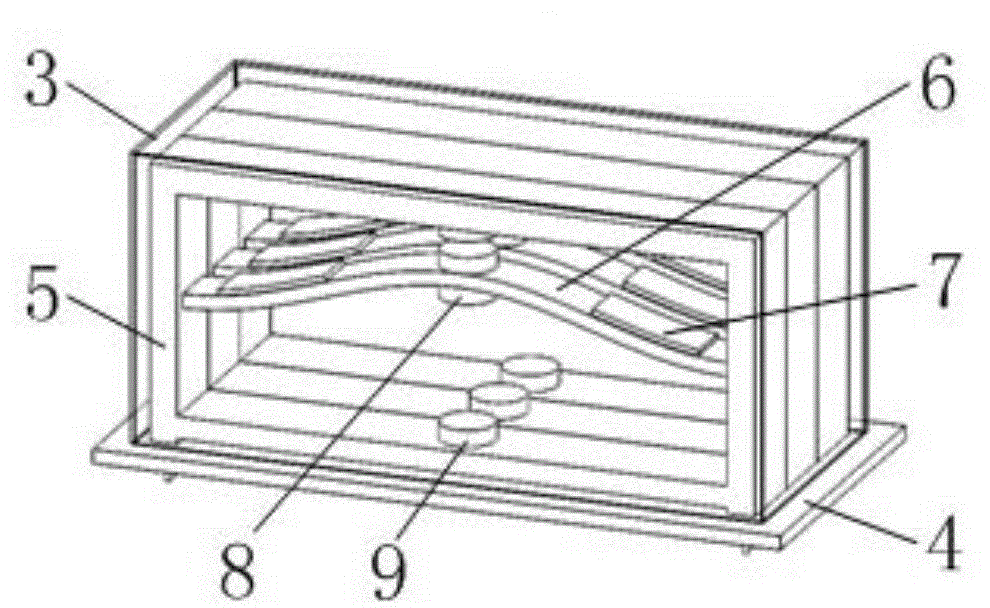

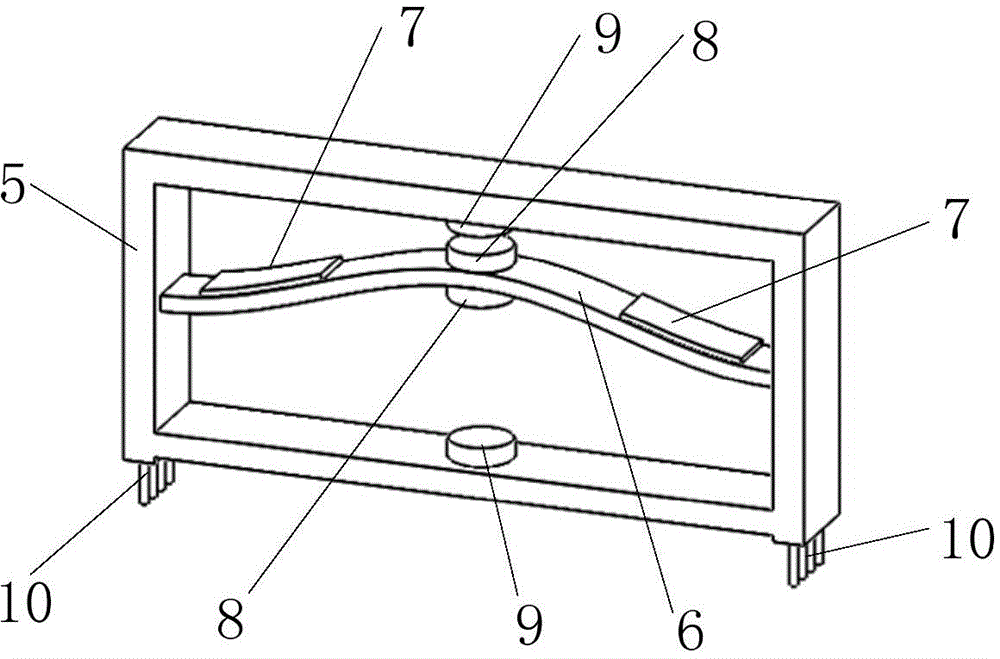

Electronic device posture adjustment device based on bistable-state structure

InactiveCN104536534ANovel structureSimple structurePiezoelectric/electrostriction/magnetostriction machinesDigital data processing detailsElectricityEngineering

The invention relates to an electronic device posture adjustment device based on a bistable-state structure. The electronic device posture adjustment device comprises a shielding cover (3) and a PCB bottom plate (4), a posture adjustment unit is packaged in the shielding cover (3) and comprises a frame (5), bistable-state elastic beams (6) and piezoelectric units (7), the bistable-state elastic beams (6) are fixed to the inner side of the frame (5) and has the upwards-convex state and the downwards-concave state, the piezoelectric units (7) are symmetrically spliced to the left sides and the right sides of the bistable-state elastic beams (6), permanent magnets (8) are fixed to the middles of the bistable-state elastic beams (6), and electromagnets (9) are arranged above and below the permanent magnets (8) and fixed to the frame (5). By means of the electronic device posture adjustment device, the external vibration energy can be collected, the in-air posture of a portable electronic device in the falling process can be further adjusted, and an impacting resistant portion of the portable electronic device is in contact with the ground firstly so that the effect of protecting a fragile part can be achieved.

Owner:张文明 +2

Horizontal axis micromechanical gyroscope and its preparation method

InactiveCN1828223ASmall dampingHigh sensitivitySpeed measurement using gyroscopic effectsGyroscopes/turn-sensitive devicesElectricityCapacitance

The product comprises: an outer / inner frame, a drive electrode and a drive feedback electrode both with two group of lateral comb-tooth capacitors and movable electrodes connected to the outer frame, a drive-modal elastic beam, a detection electrode with two group of unequal vertical comb-tooth capacitors for difference detection with movable electrode connected to the inner frame, a detect-modal elastic beam as four group of combined torsion beams everyone with ends connected to former inner / outer frame respectively, and an anchor point fixed on substrate bottom and connected to the outer frame through the drive-modal beam. This invention is simple and fit to large-scale production, compatible to Z-axis gyro and accelerometer, and can be used for MIMU.

Owner:PEKING UNIV

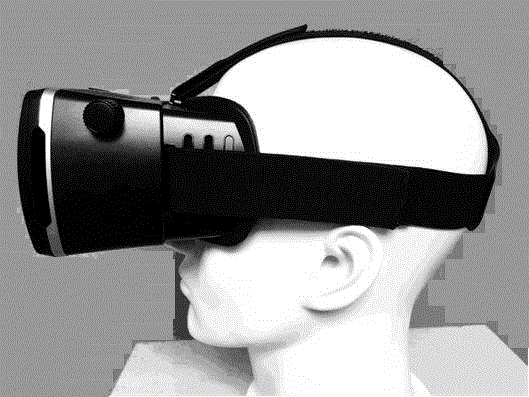

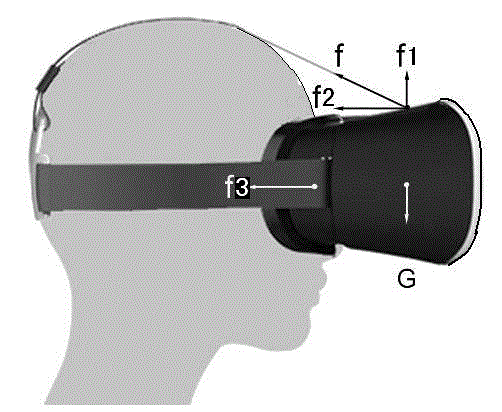

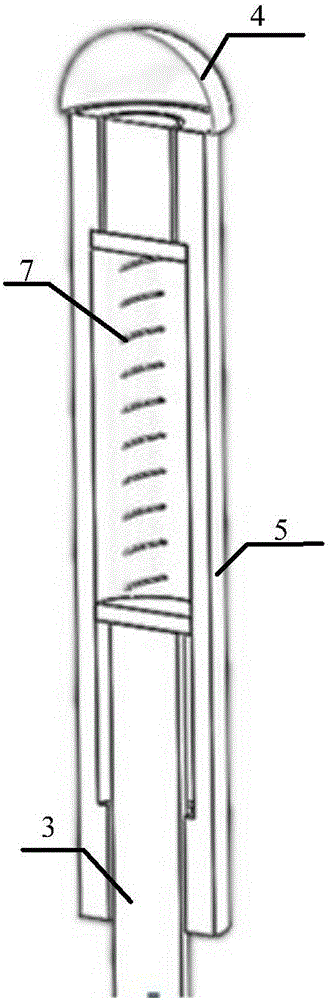

Telescopic cantilever elastic beam head-wearing mechanism

The invention discloses a telescopic cantilever elastic beam head-wearing mechanism which comprises an overhead lifting force adjuster and a supporting seat adjuster, wherein the overhead lifting force adjuster, a cantilever elastic beam and an elastic steel band form a telescopic cantilever; the telescopic cantilever can perpendicularly lift virtual reality glasses or a virtual reality helmet to suspend in front of a wearer; the hanging force can be directly transmitted to triangular pivots at the top of the head and the afterbrain of the wearer through the telescopic cantilever, a nylon flat band and the supporting seat adjuster, so that the pressure on the face, the forehead and the nose bridge of the wearer can be relieved. The virtual reality glasses or the virtual reality helmet can be directly hung by the lifting force of the telescopic cantilever which is reasonable in design and convenient to adjust, and the lifting gravity is directly transmitted to the triangular pivots at the afterbrain of the wearer, so that the pressure on the face, the forehead and the nose bridge of the wearer can be relieved; therefore the wearer can wear the virtual reality glasses or the virtual reality helmet more practically, easily and comfortably.

Owner:上海宏镜科技有限公司

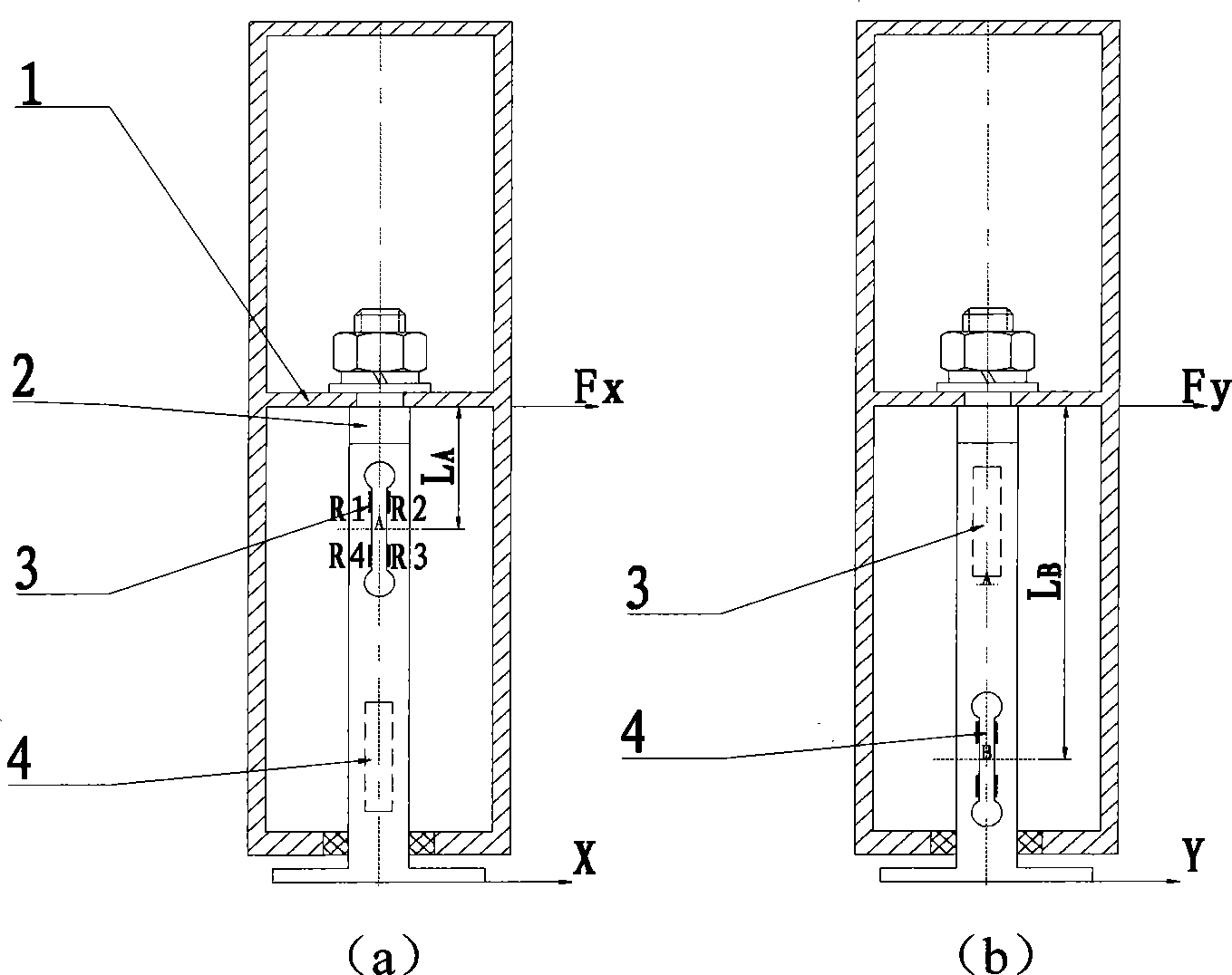

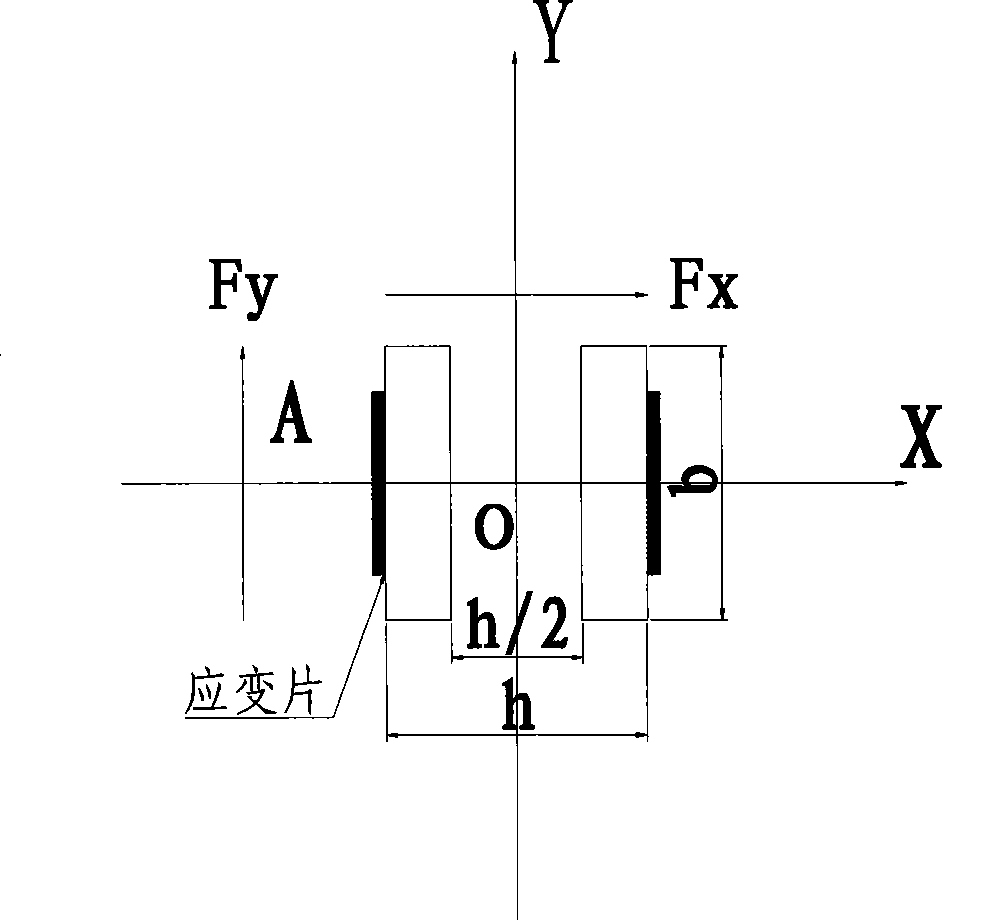

Force sensor and air measurement method thereof

InactiveCN101509816AQuick responseThe overall structure is simple and reliableFluid pressure measurement using ohmic-resistance variationIndication/recording movementEngineeringStrain gauge

The invention discloses a force sensor and a wind speed measuring method thereof. The force sensor includes a wind-engaging body, an elastic beam, a first strain gauge group and a second strain gauge group. The measuring method adopts the strain gauges to measure the wind load of the elastic beam and obtains wind speed and direction through measurement. Without moving elements, the invention has quick response, simple and reliable structure and strong environment applicability.

Owner:SOUTHEAST UNIV

Multidimensional force/torque sensor

InactiveCN107782482AReduce the effect of elasticityIncrease the number ofMeasurement of force componentsCouplingEngineering

The invention relates to a multidimensional force / torque sensor, which comprises a hollow framework, a loading platform, a plurality of laminar first elastic beams, a plurality of laminar second elastic beams, a force transferring block and a strain gage group, wherein the loading platform is suspended in the framework, the two ends of each second elastic beam are connected with the framework, thesecond elastic beams and the corresponding first elastic beams are connected at a preset angle, the corresponding first elastic beam is divided into two mutual perpendicular parts in width directionby the force transferring block, two sides of the force transferring block are respectively connected the two parts of the first elastic beam correspondingly, and the distances of the force transferring block away from the center of the first elastic beams are different. The thickness of the first elastic beams is thinned, thus reducing the influence on other beams; the first elastic beams are divided into two parts through the force transferring block, so that the elastic deformation of the first elastic beams can be effectively generated on any one of the two parts, and the detection dimension can be increased while the multi-component coupling is reduced. The distances of the force transferring block away from the center of the first elastic beams are different, so that the pasting positions and quantity of strain gages can be increased, and the detection dimension can be increased.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI +1

Strain beam type soil pressure sensor

InactiveCN102135458ALimit maximum deformationAvoid damageForce measurementElectrical resistance and conductanceEngineering

The invention provides a strain beam type soil pressure sensor comprising a hollow shell and a cover plate for sealing the shell, wherein the internal chamber of the shell is internally provided with an elastic beam and a transmission shaft; a circle of steps that extend upwards are arranged at the bottom of the shell; the elastic beam is arranged on the steps; the upper surface and the lower surface of the elastic beam are provided with resistance strain gauges with the same resistance and terminal boards that are matched with the resistance strain gauges; the resistance strain gauges are connected with one another by conducting wires so as to form a Wheatstone bridge that is connected with a strain gauge by a connecting wire; the shell is provided with a through hole that can allow the connecting wire to pass out; the transmission shaft is arranged between the elastic beam and the cover plate; one end of the transmission shaft is contacted with the cover plate; and the other end of the transmission shaft is contacted with the elastic beam. The strain beam type soil pressure sensor has the advantages of being applicable to soil pressure measurement on the soil of various stiffness, and being capable of eliminating the temperature influence.

Owner:ZHEJIANG UNIV

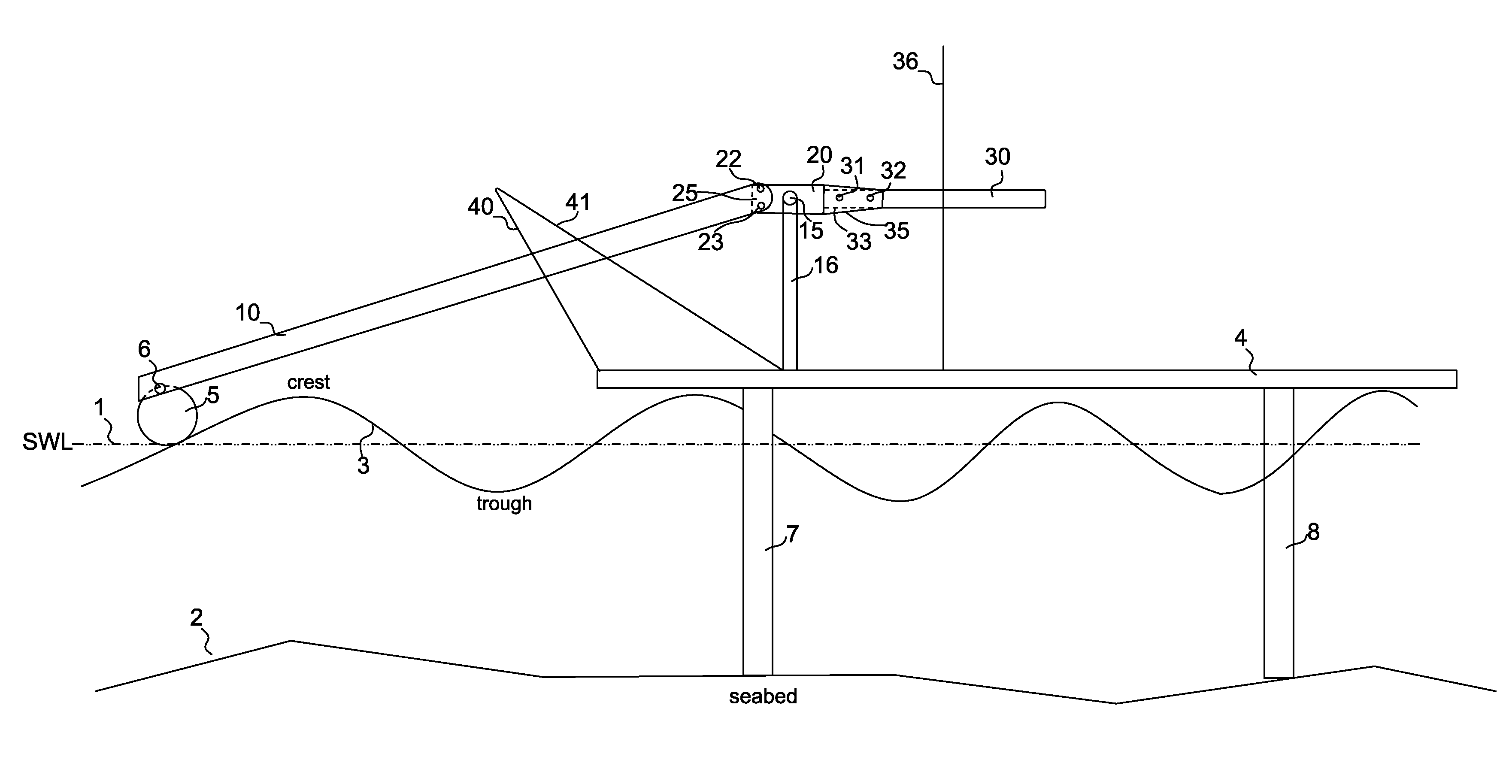

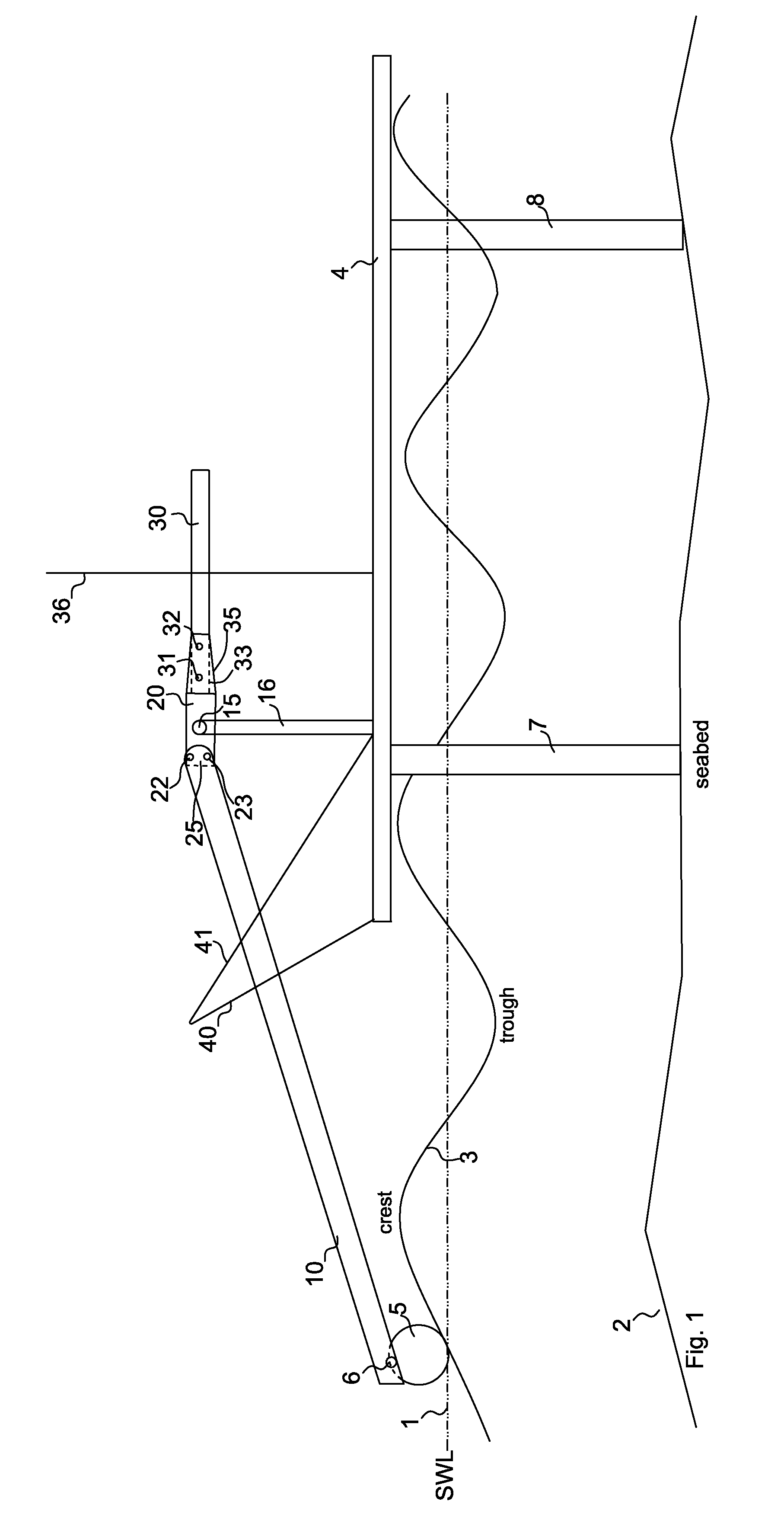

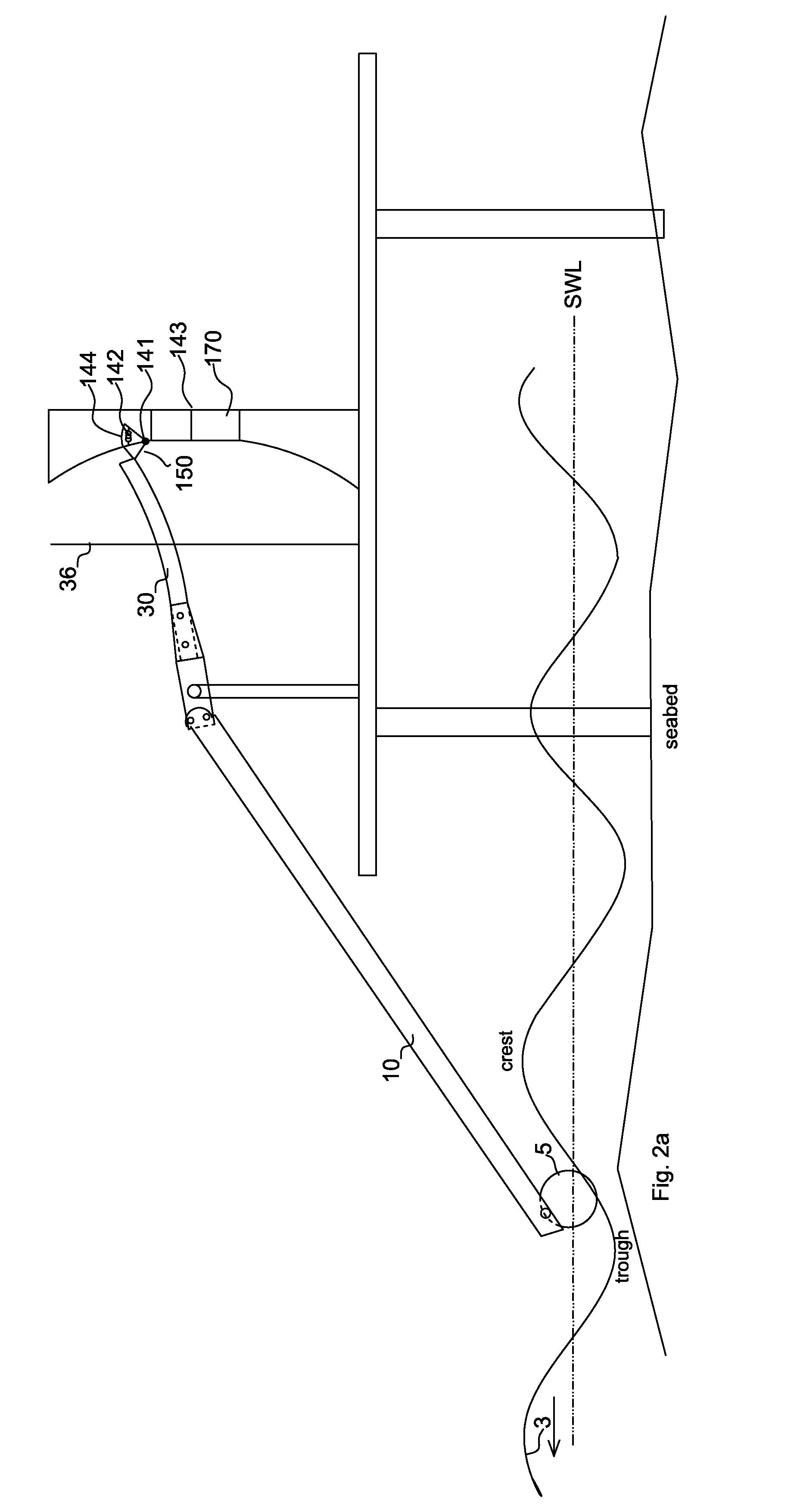

Ocean wave energy converter and method of power generation

A device comprising a float (5) and a pivoting assembly of a rigid beam (10) and an elastic beam (30, firmly connected to each other, pivoting about a stationary point (15). The device transforms the rise and falls of the ocean waves into usable mechanical energy. In one embodiment, the elastic beam is latched into a latch mechanism (150). The latch mechanism obstructs the elastic beam to continue moving. The elastic beam deflects and accumulates potential power. When the elastic beam is released, it moves with a high speed and momentum. In another embodiment this momentum is utilized to counter-rotate an electric generator's two rotors (251, 252).A method of transforming the energy of a mass in reciprocating motion to electrical power.

Owner:VASSILIOS VAMVAS

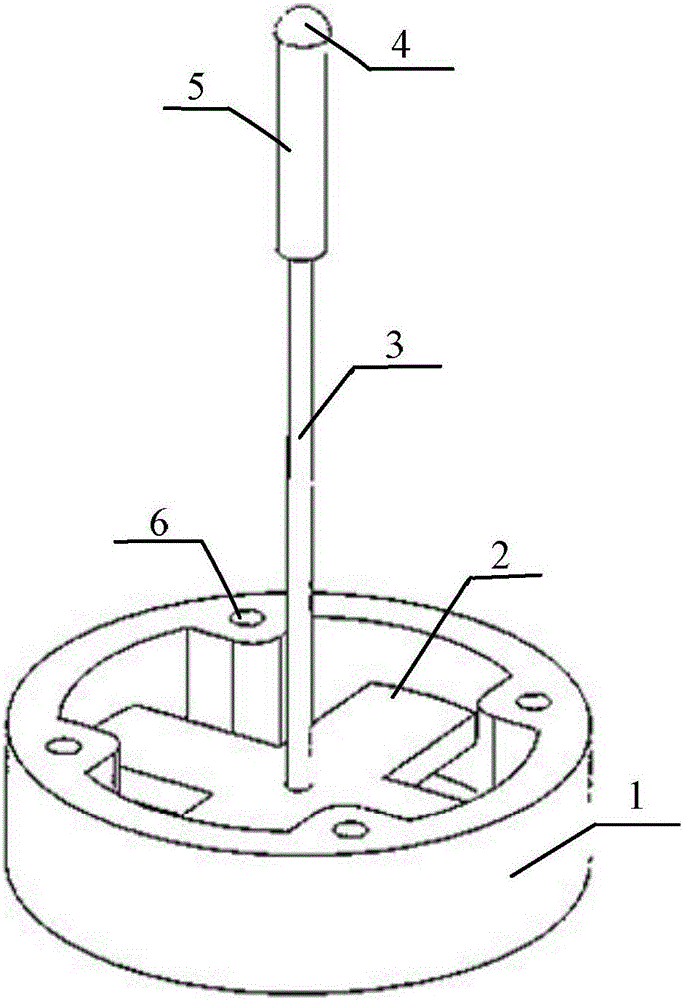

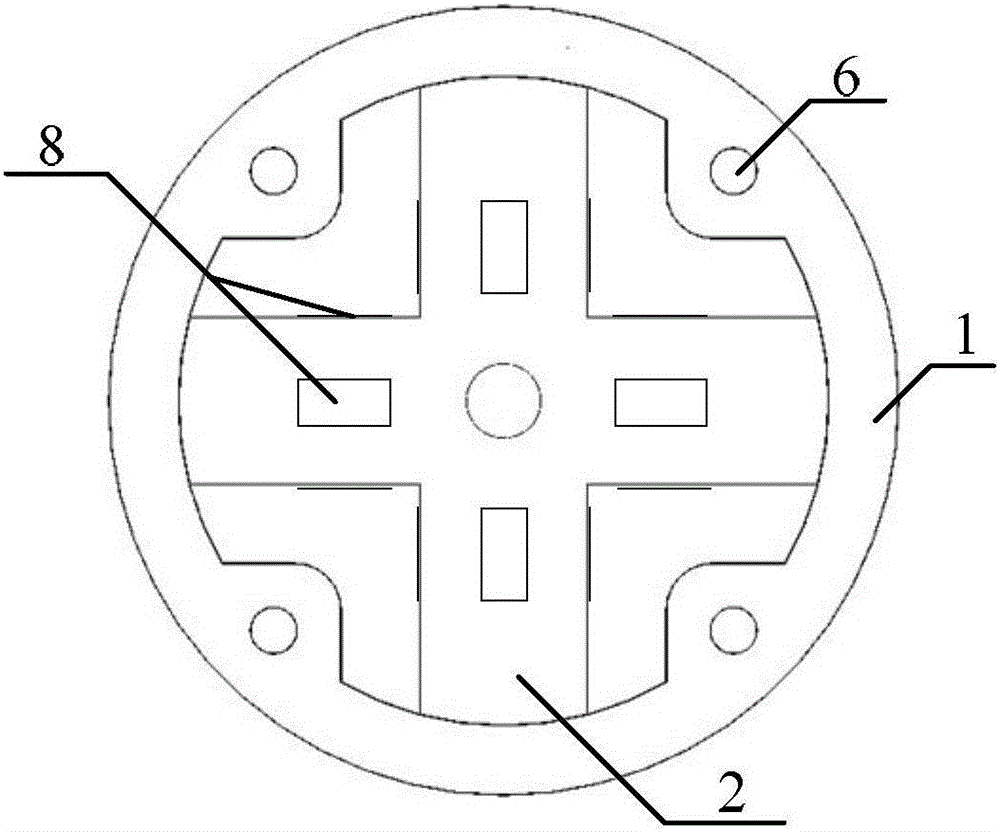

Whisker sensor for perceiving three-dimensional force displacement and three-dimensional force of contact point

The invention discloses a whisker sensor for perceiving three-dimensional force displacement and a three-dimensional force of a contact point. The whisker sensor is installed on a robot body, the whisker sensor comprises a cross elastic beam (1), strain gauges (8), a flexible whisker (3), a contact ball (4), a spring (7) and a sleeve (5), wherein the cross elastic beam (1) is of a hollow structure and comprises four elastic beams (2) arranged inside, a wheel rim and four wheel rim screw holes (6), the four elastic beams (2) are intersected in pairs to form an angle of 90 degrees and thus form a cross shape, and the upper surface, the lower surface, the left side surface and the right side surface are each provided with a strain gauge (8) in an adhesive mode; the four wheel rim screw holes (6) are symmetrically distributed at the upper surface of the cross elastic beam (1) for fixing the position of the sensor; and the flexible whisker (3) is installed at the center of the cross elastic beam (1). According to the invention, accurate positioning of a target object can be realized.

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com