Horizontal axis micromechanical gyroscope and its preparation method

A technology of micro-mechanical gyroscope and horizontal axis, applied in gyroscope/steering sensing equipment, gyro effect for speed measurement, instrument and other directions, it can solve the problem that it is difficult to realize variable-area sensitive capacitance, capacitance is difficult to detect differentially, and it is difficult to obtain Sensitive capacitance and other issues, to achieve the effect of mass production, reduce processing costs, and improve sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

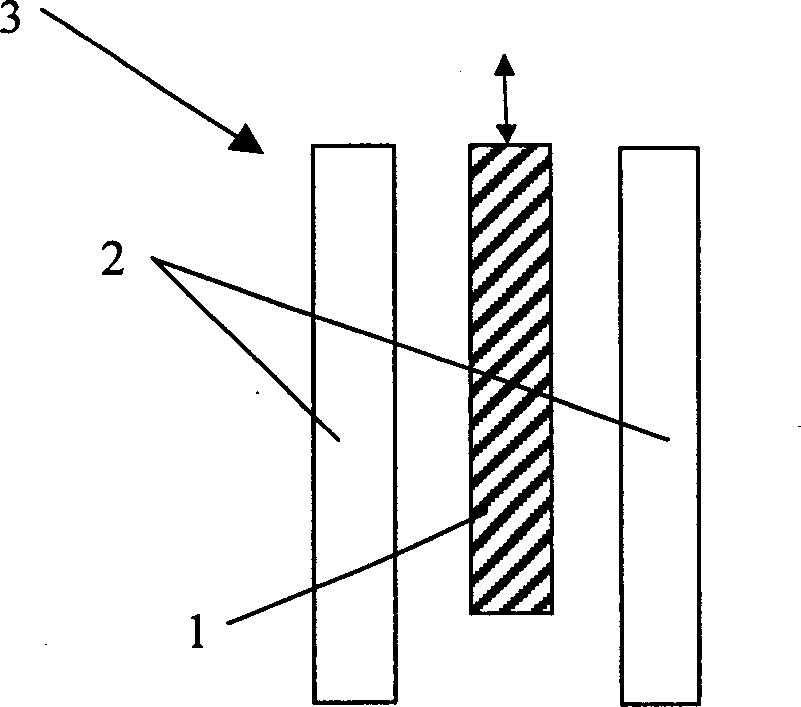

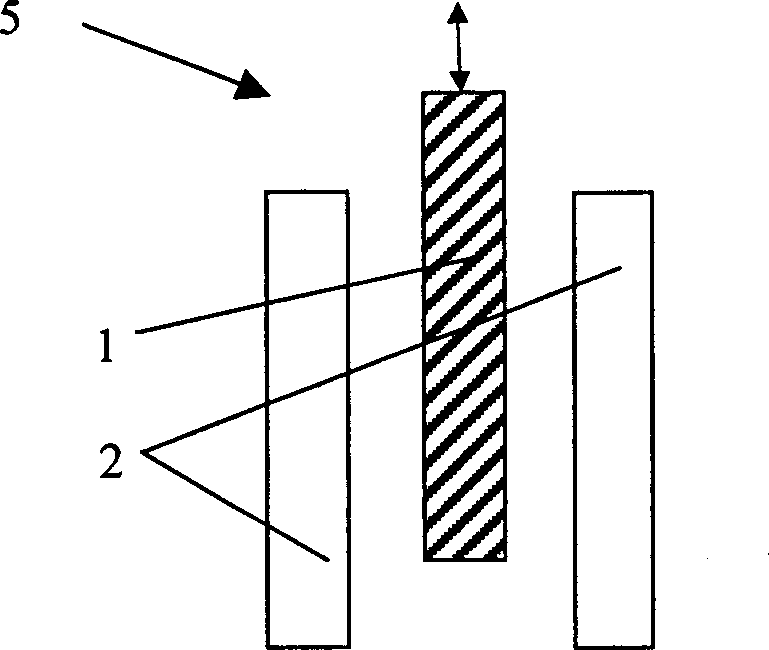

[0026] Embodiment 1: The following steps are adopted when making a single-ended unequal-height comb-tooth capacitance horizontal-axis micromechanical gyroscope:

[0027] 1. The starting material is double-throwing N-type (100) silicon wafer 18 (such as Figure 5a shown), the thickness is 400±10 microns;

[0028] 2, at first form silicon oxide 19 mask on silicon wafer 18, then on silicon wafer 18, form the compound mask (as shown in Figure 5 b) that photoresist 20 and silicon oxide 19 form, then use photoresist 20 as The deep groove 21 is etched by the mask, and the depth of the deep groove 21 determines the height difference between the lower ends of the fixed electrode 2 and the movable electrode 1;

[0029] 3. As shown in FIG. 5c, the photoresist mask 20 is removed, and the shallow groove 22 is etched using the silicon oxide 19 as a mask. The depth of the shallow groove 22 determines the gap between the movable electrode 1 and the glass substrate;

[0030] 4. If Figure 5...

Embodiment 2

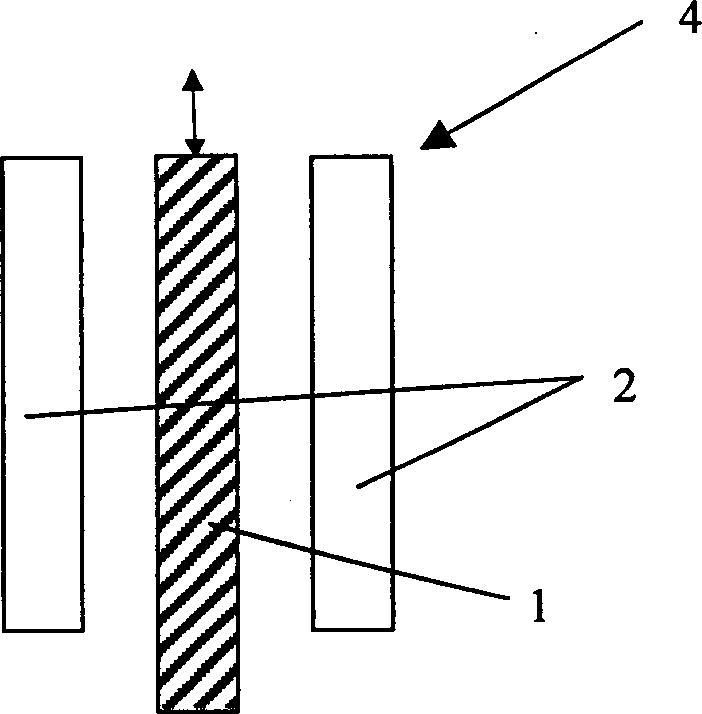

[0034] Embodiment 2: The following steps are adopted when making a double-ended unequal-height comb capacitor horizontal axis micromechanical gyroscope:

[0035] 1. The initial process is consistent with the above single-end unequal-height comb micromechanical gyroscope process, that is, steps 1 to 6 in Example 1 are used, and then the following steps are carried out;

[0036] 2. If Figure 6a As shown, a composite mask composed of a photoresist mask 27 and an aluminum mask 28 is formed on the surface of the silicon wafer 18, and the photoresist is used as a mask to etch deep grooves 29;

[0037] 3. If Figure 6b As shown, the photoresist mask 27 is removed, the silicon wafer 18 is etched with the aluminum mask 28 as a mask, and the movable electrode 1 and the fixed electrode 2 of the capacitor are formed to complete the horizontal-axis micromachine of the double-terminal unequal-height comb capacitor. Gyro preparation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com