Controllable damping molecule spring vehicle suspension

A molecular spring, vehicle suspension technology, applied in the direction of spring, spring/shock absorber, shock absorber, etc., can solve the problems of insufficient bearing capacity, poor vibration isolation performance, high price, etc., to reduce weight, improve performance, The effect of simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

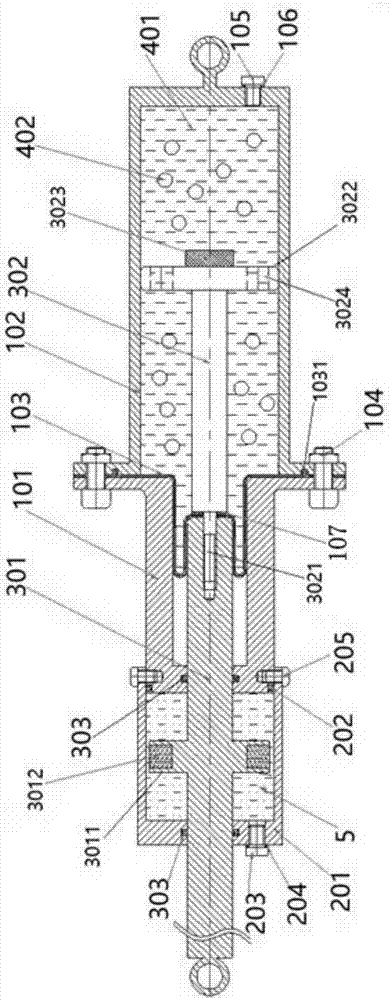

[0028] The present invention will be further explained below in conjunction with the accompanying drawings.

[0029] Such as figure 1 Shown is a controllable damping molecular spring vehicle suspension of the present invention, including a compressible hydraulic cylinder, an incompressible auxiliary cylinder, a piston, a molecular spring mixed medium and a magnetorheological fluid 5; the inside of the compressible hydraulic cylinder is filled with a molecular spring mixed Medium, the piston compresses the molecular spring mixed medium in the compressible hydraulic cylinder to provide elasticity; the incompressible auxiliary cylinder is filled with magnetorheological fluid, and the magnetorheological fluid flows through the damping hole to produce controllable damping when the piston moves. in:

[0030] The compressible hydraulic cylinder includes an end cover 101 and a cylinder body 102 which are connected to each other. A diaphragm 103 is arranged at the connection between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com