Suspension type floating plate vibration isolation system

A technology of vibration isolation system and floating slab, which is applied in the direction of roads, building components, rails, etc. It can solve the problems of inconsistent vertical deformation, inconvenient construction of floating slabs, and difficult maintenance of floating slabs, so as to save materials and facilitate construction , easy to replace the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

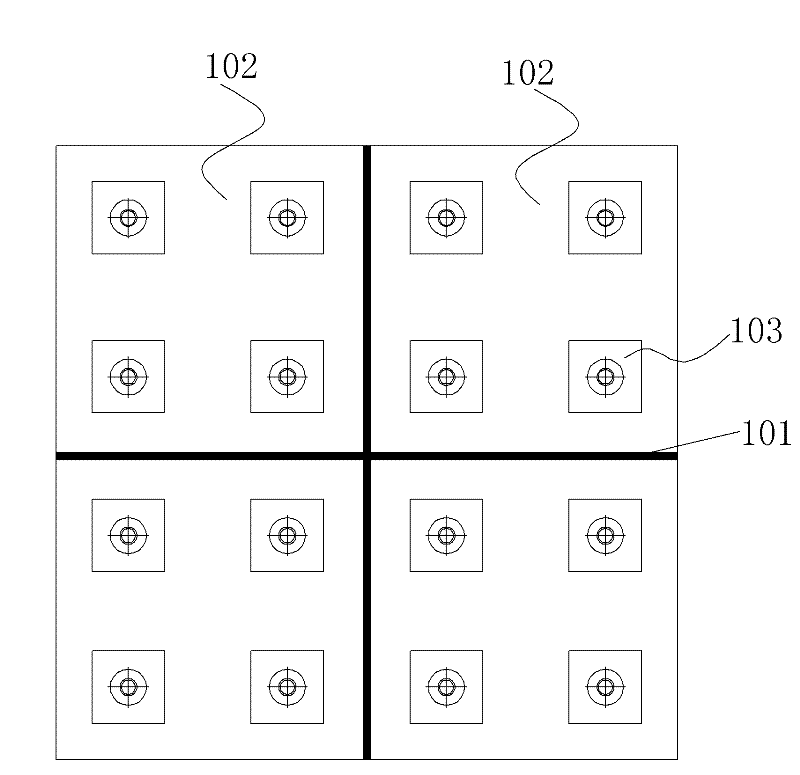

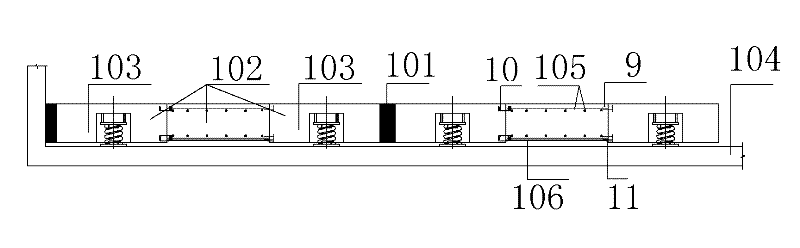

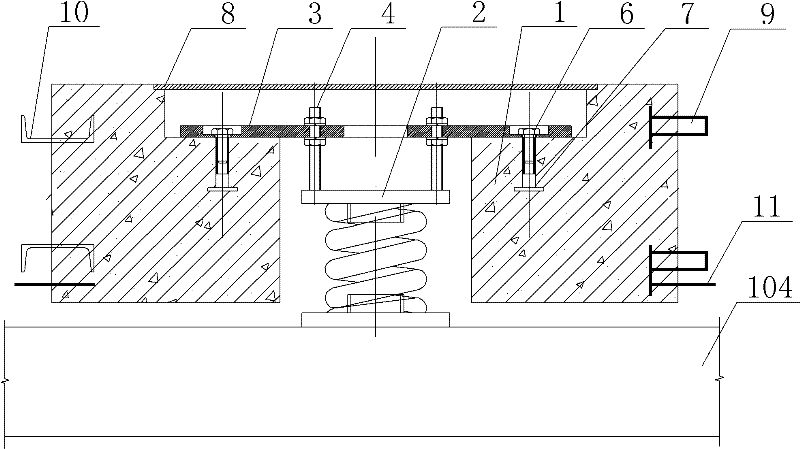

[0045] Such as Figure 1 to Figure 6 A suspended floating plate vibration isolation system is shown, the vibration isolation system includes a regional floating plate 102, a rubber vibration-absorbing belt 101 and a plurality of prefabricated vibration-isolation units 103, there are multiple regional floating plates 102, and the rubber damping belt Vibration belts 101 are arranged between floating slabs 102 in different areas to limit the horizontal transmission of vibration. Prefabricated vibration isolation units 103 and cast-in-place concrete slabs form regional floating slabs 102. Multiple prefabricated vibration isolation units 103 are placed on floors or On the ground, the regional floating slab 102 is supported on the floor or the ground through the vibration isolator of the prefabricated vibration isolation unit 103, forming a gap with the ground or the floor to isolate vibration and noise, that is, the regional floating slab 102 is suspended in the There is a vertical g...

Embodiment 2

[0055] Figure 7 to Figure 10 It is the second embodiment of the suspension floating plate vibration isolation system of the present invention, which is different from the first embodiment in that the floating floating plate in this embodiment is constructed by jacking.

[0056] The construction method of the second embodiment is to clean up the structural floor first, and keep the structural floor smooth, and level the uneven floor; before pouring concrete, lay PE film on the corresponding floor of the floating slab to avoid the concrete from colliding with the original The floor slab is stuck to the ground, so that the solidified concrete can be separated from the original ground smoothly when it is lifted; then the prefabricated vibration isolation unit 103 is placed on the floor according to the design, and the floating slab steel bars are bound, and the concrete is poured, and finally the The area floating floor 102 is lifted.

[0057] For the lifting method of the regio...

Embodiment 3

[0059] Figure 11 to Figure 13 It is the third embodiment of the suspended floating plate vibration isolation system of the present invention, which is different from the first embodiment in that the embedded part adopts the connecting sleeve 7 and the embedded plate 5 . The connecting sleeve 7 can also be pre-embedded in the concrete block 1 together with the embedded plate 5, and the embedded plate 5 and the connecting sleeve 7 are connected. Figure 12 As shown, the internal thread is processed at the corresponding position of the embedded plate 5. Of course, the embedded plate 5 and the connecting sleeve 7 in the embedded part can be connected by welding. The embedded board 5 is arranged horizontally and is located below the jacking function board 3 . The jacking function plate 3 adopts a circular plate with a square hole in the middle. The other structures of this embodiment are the same as those of the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com