Patents

Literature

56results about How to "Improve heat and aging resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multimode organic filler/polymer composite damping material and manufacturing method thereof

InactiveCN103897287AImprove shock absorptionImprove heat and aging resistanceSound energyRelaxation effect

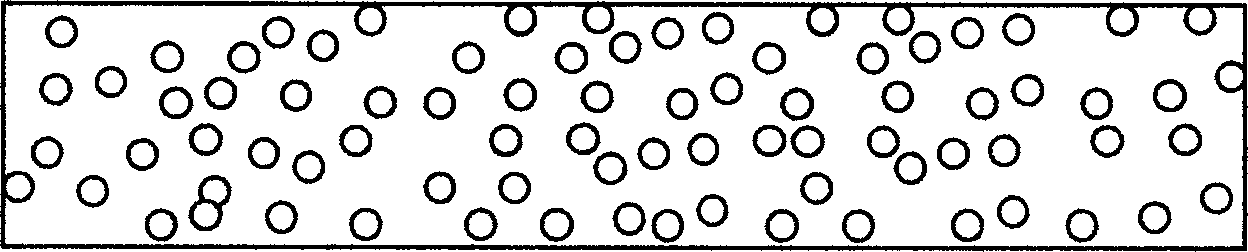

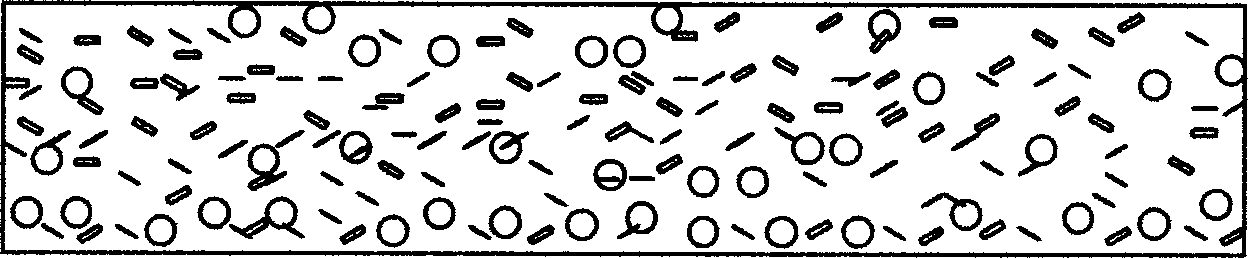

The invention relates to a multimode organic filter / polymer composite damping material and a manufacturing method thereof, relates to the field of soundproof materials, aims to solve the problems that in the prior art high efficient soundproof materials do not have a prominent effect, and generate harmful gas, which harms the human health; and provides a multimode inorganic filler / polymer composite damping material. The damping material comprises the following materials: thermoplastic resin and an inorganic filler, which has been subjected to a surface treatment with a coupling agent processing fluid; wherein the inorganic filter accounts for 15 to 80 wt% of the total weight of the damping material, and the balance being thermoplastic resin. In the damping material, the binding between each particle is abnormal, thus the internal friction between incident sound waves in this structure is effectively increased, thus a relaxation effect is generated, and the sound is absorbed. Fillers with different particle sizes are corresponding to sound waves in different bandwidths or frequencies, so sounds in different frequencies can all be absorbed by the damping material, and moreover the damping material has a good soundproof effect, and is suitable for promotion and application.

Owner:浙江艾迪雅科技有限责任公司

Efficient sound insulation material and manufacturing method thereof

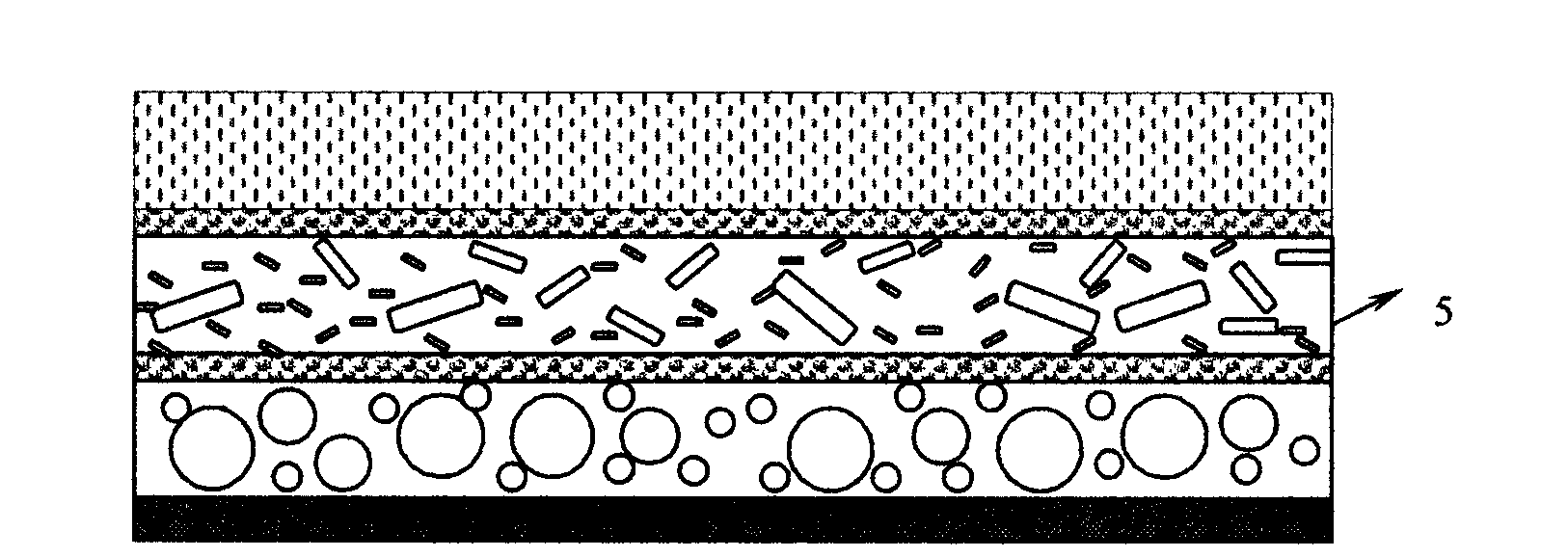

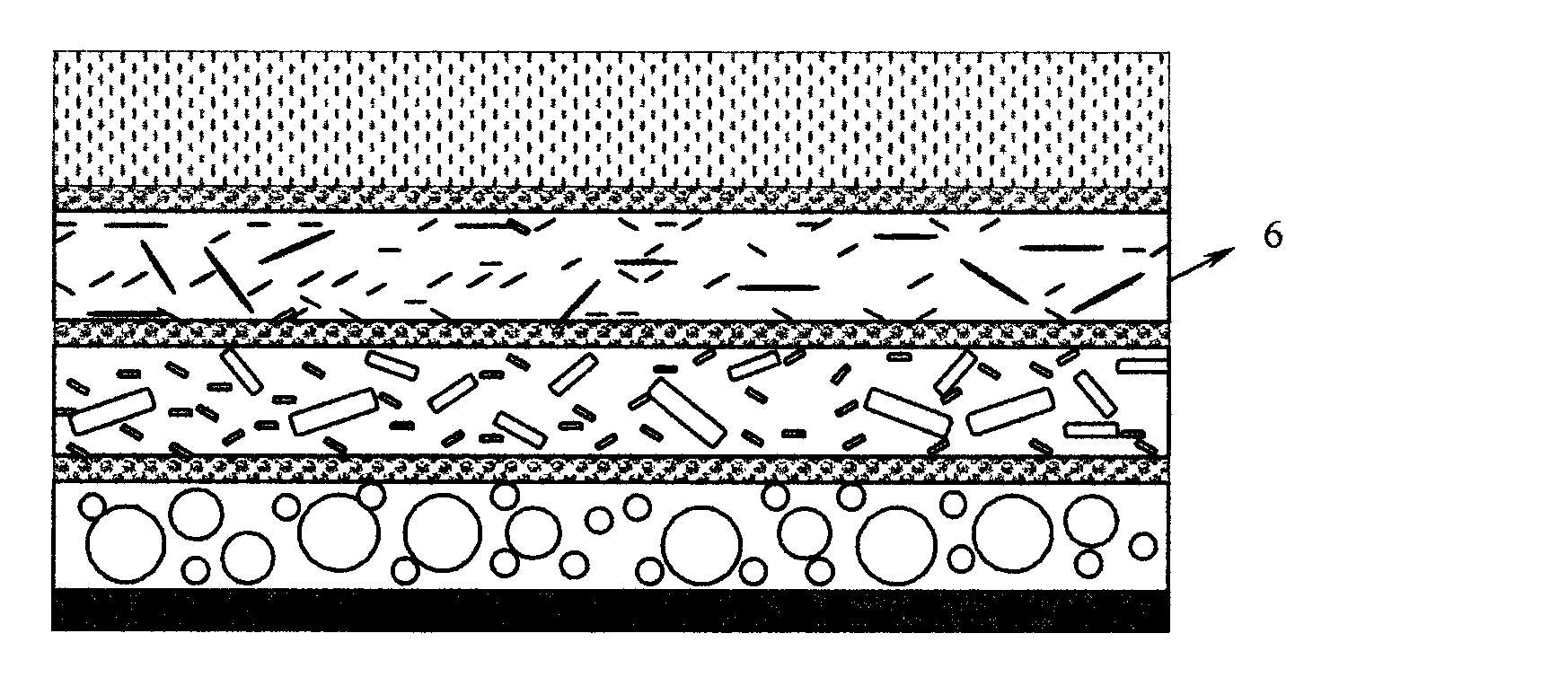

InactiveCN103903608AImprove heat and aging resistanceExcellent ozone resistanceSynthetic resin layered productsSound producing devicesInsulation layerFoaming agent

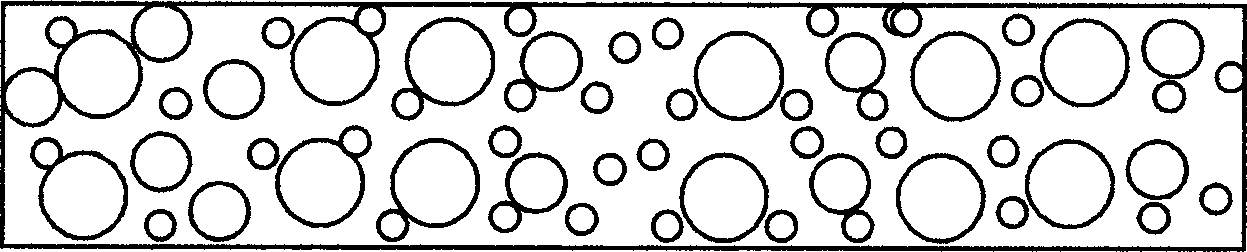

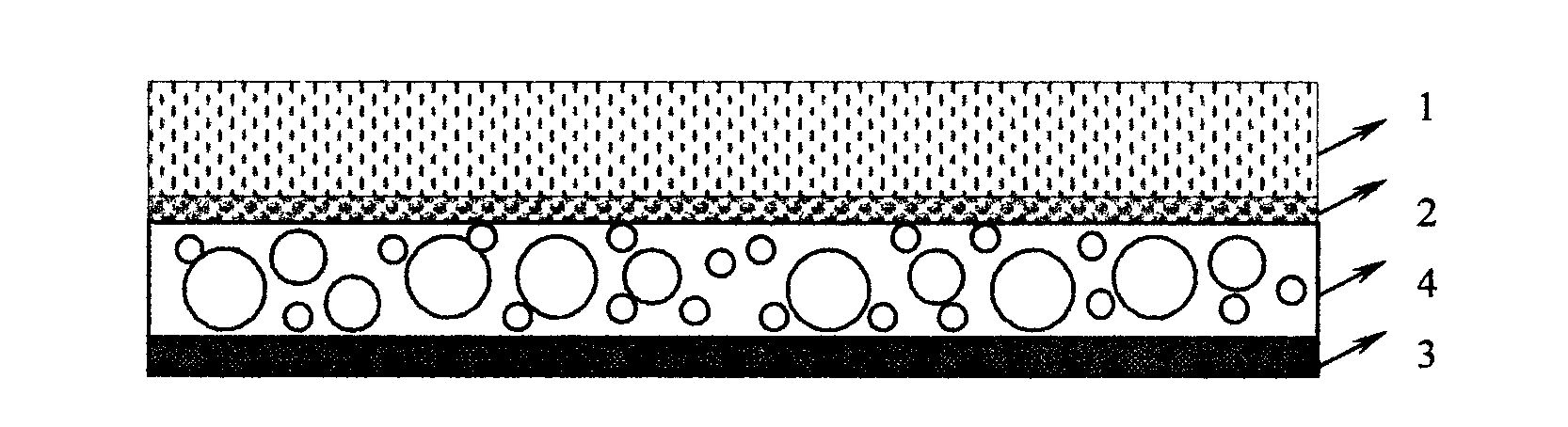

The invention relates to the field of products of sound insulation material, solves the problems in the prior art that the sound insulation material is poor in sound insulation effect, is incomprehensive in high and low frequency sound insulation, causes pollution and is easy to age, and provides an efficient sound insulation material and a manufacturing method thereof. The efficient sound insulation material includes a sound insulation layer, a sound absorption layer, and a bubble layer, wherein the bubble layer is located between the sound insulation layer and the sound absorption layer. The sound absorption layer is made of a sound insulation compound, and the sound insulation compound is prepared by raw materials of the following substances: a thermoplastic resin, inorganic fillers, and a foaming agent, wherein the inorganic fillers account for 15-80wt%, the foaming agent accounts for 5-15wt%, and the rest is the thermoplastic resin. In the efficient sound insulation material, the fillers with different particle diameters correspond to sound waves of different wave bands or frequencies, and thus consumption of sound energy of different frequencies is relatively comprehensive, and the sound insulation effect is good, so the sound insulation material is suitable for popularization and application.

Owner:浙江艾迪雅汽车部件新材料有限公司

Epoxy conductive resin applicable to binding of LED (light-emitting diode) chips, and preparation method thereof

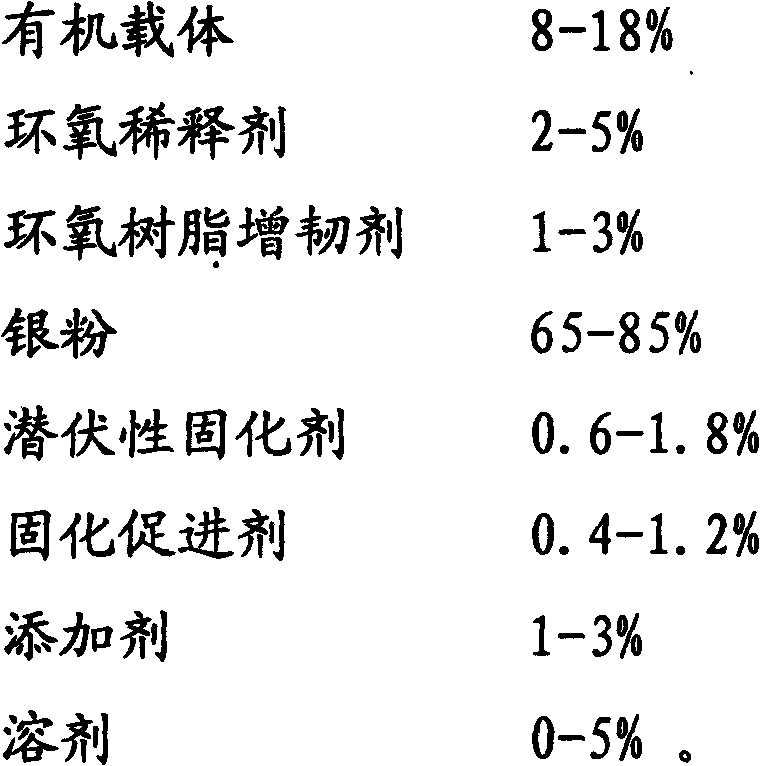

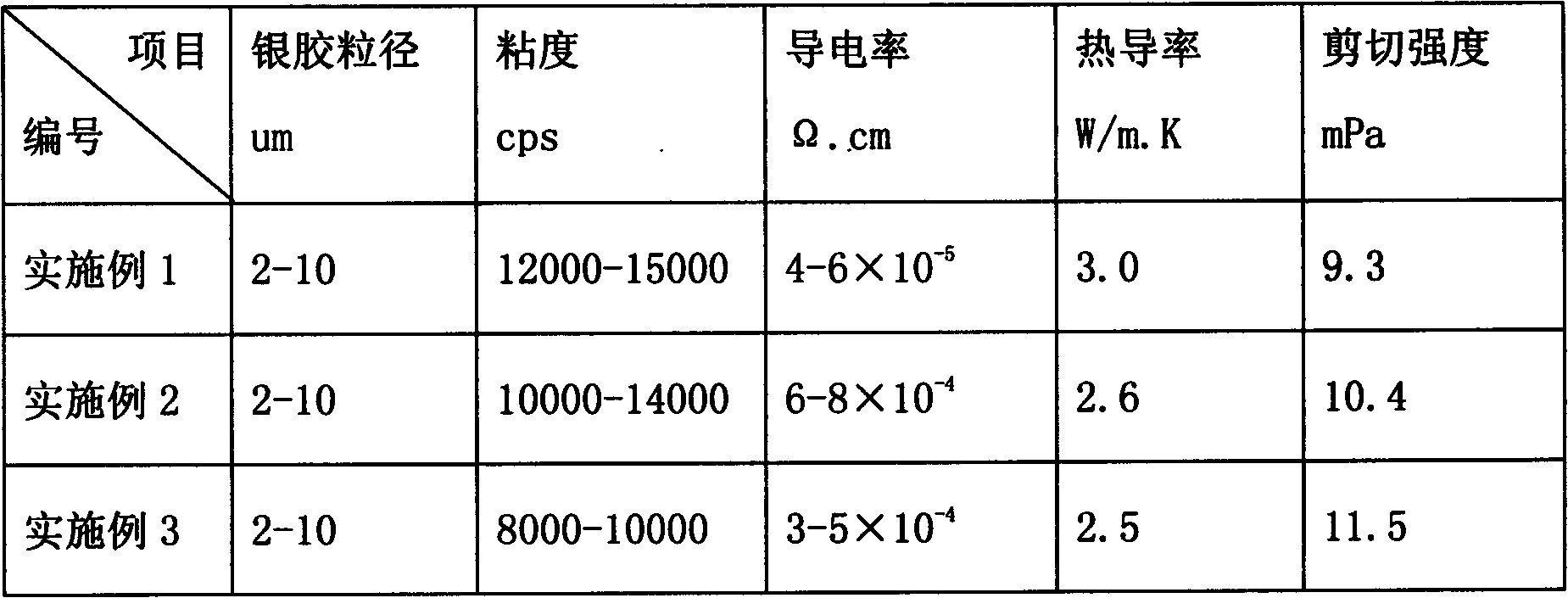

ActiveCN102634313ALow resistivityStrong impact resistanceEpoxy resin adhesivesElectrically-conducting adhesivesEpoxyUltimate tensile strength

The invention discloses epoxy conductive resin applicable to binding of LED (light-emitting diode) chips. A preparation method comprises the steps of: adding 8-18% of an organic carrier and 2-5% of epoxy diluent, evenly stirring, conducting vacuum defoamation for 15-20 minutes, adding and evenly mixing 0.6%-1.8% of a latent curing agent, 0.4-1.2% of a curing accelerator, 1-3% of epoxy resin flexibilizer, and 1-3% of an additive into a reaction kettle, conducting vacuumizing for 30-60 minutes with the vacuum degree of minus 0.1MPa; and finally adding 65-85% of silver powder into a three-dimensional stirred tank, and fully stirring evenly and grinding in a three-roll machine for one to three times, thus obtaining the epoxy conductive resin. The epoxy conductive resin has low resistivity, strong impact resistance, high heat conducting coefficient, strong mechanical strength, and good heat-resistant and aging-resistant performances, and can meet the active technology demand of LED packaging industry.

Owner:GUANGZHOU BAIYUN CHEM IND

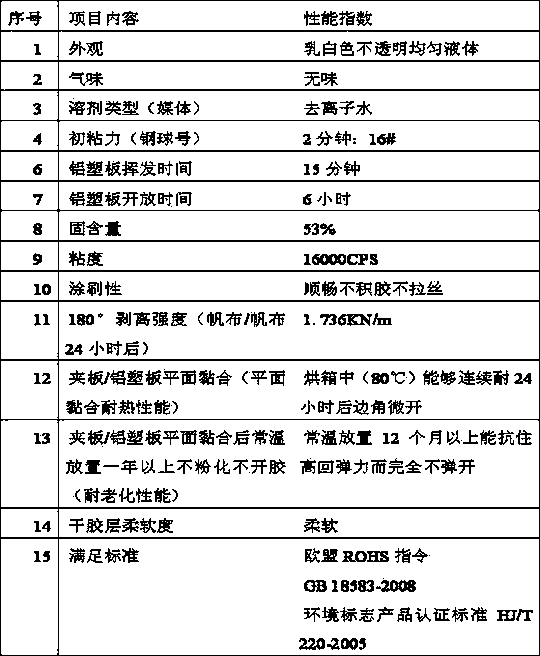

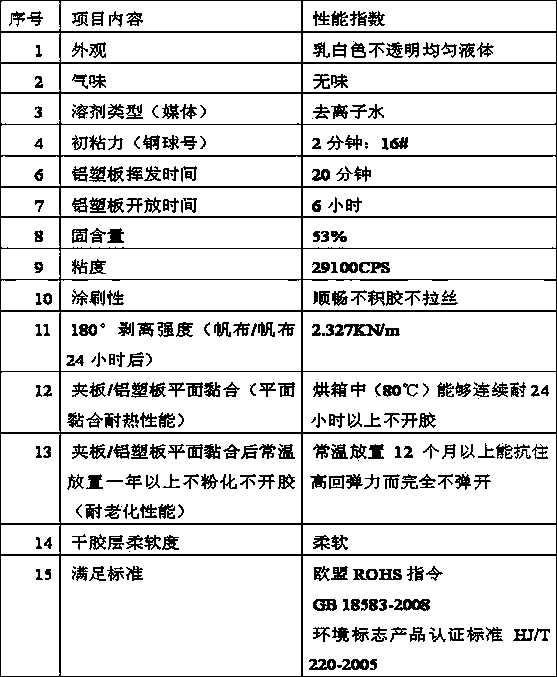

Aqueousneoprene type environment-friendly glue and preparation method thereof

ActiveCN101560367ATransportation safetyHigh bonding strengthAcid polymer adhesivesAldehyde/ketone condensation polymer adhesivesAcrylic resinFireproofing

The invention discloses an aqueous neoprene type environment-friendly glue which comprises aqueous rosin emulsion with low grain diameter and high stability, aqueous acrylic resin emulsion, ethane-vinyl acetate emulsion, anion type neoprene latex, aqueous foam suppressor, wetting dispersant, preservative, tackifier, nanometer calcium carbonate concentrated slurry, aerosol, and the like. The invention also discloses a preparation method of the aqueous neoprene type environment-friendly glue; the aqueous neoprene type environment-friendly glue takes water as a dispersed media, is uniform milky liquid, has the comprehensive advantages of no organic solvent, no heavy metal, insipidity, good initial adhesive force, excellent bond strength, excellent hold tack, excellent heat resistance and aging resistance, short drying time, long opening time, large spray area of unit weight, glue saving, excellent oily leather resistance, fireproofing, safe transportation, and the like, has the advantages of reducing environment pollution, improving operation and construction environment, saving large amounts of organic fuel, insipidity, and the like, is widely applied to industries of soft furniture of cases and bags, sofas, swivel chairs, mattresses, pillows, folding screens, and the like, and is especially suitable for application of green high-grade export products of occident.

Owner:黄楚填

High-temperature-resistant rubber sealing ring for automobiles

The invention discloses a high-temperature-resistant rubber sealing ring for automobiles. The high-temperature-resistant rubber sealing ring comprises the following raw materials in parts by weight: 70-90 parts of ethylene-propylene-diene-terpolymer rubber, 10-30 parts of chloroprene rubber, 1-4 parts of an anti-aging agent, 0.8-1.5 parts of active zinc oxide, 0.2-0.4 part of magnesium oxide, 0.5-1.0 part of calcium oxide, 0.6-1.5 parts of butyltin mercaptide, 30-40 parts of modified kaolin, 10-15 parts of magnesium methacrylate, 1-3 parts of a promoter, 6-10 parts of soybean oil, 1-2 parts of ethyl methacrylate, 40-80 parts of paraffin oil, 0.2-0.5 part of triallyl phosphate, 1.0-1.5 parts of a crosslinking agent BIBP, 0.5-1.2 parts of an assistant crosslinking agent TAIC, 0.3-0.5 part of microcrystalline wax, 2-3 parts of a vulcanizing agent and 0.5-1 part of phthalic anhydride. The sealing ring disclosed by the invention has strong weather resistance, corrosion resistance and ozone resistance, and can be suitable for being used as the high-temperature-resistant rubber sealing ring for the automobiles.

Owner:TONGLING SANSHENG ELECTRONICS

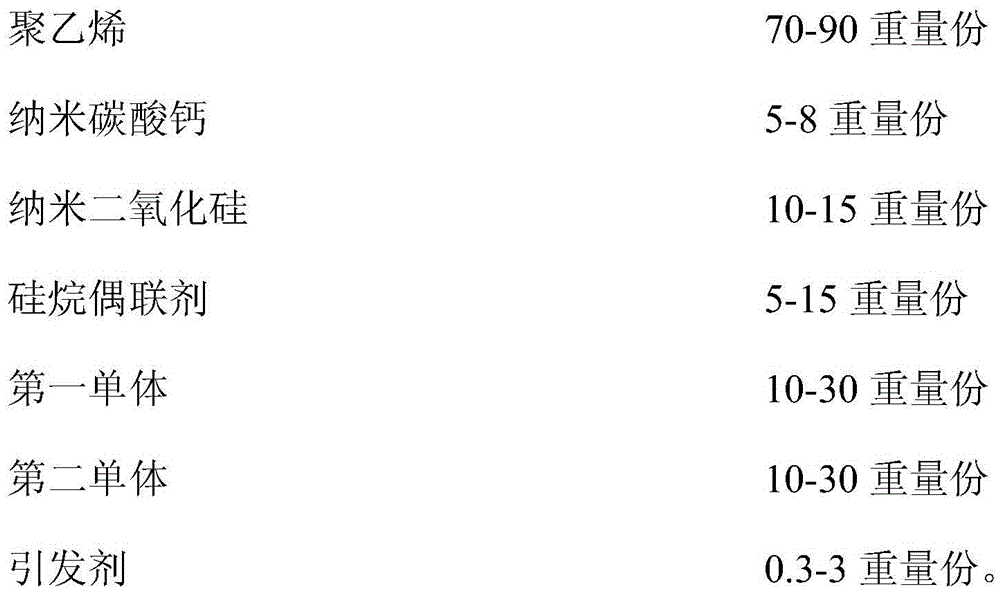

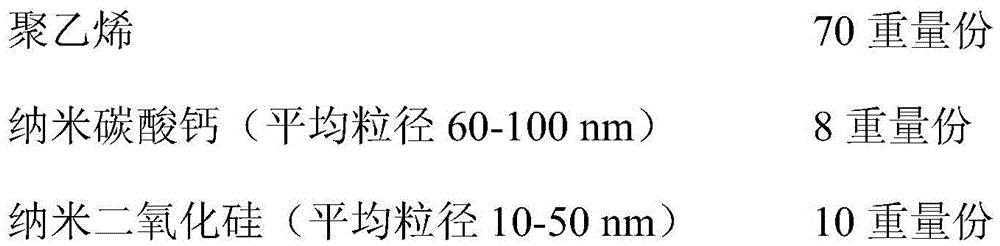

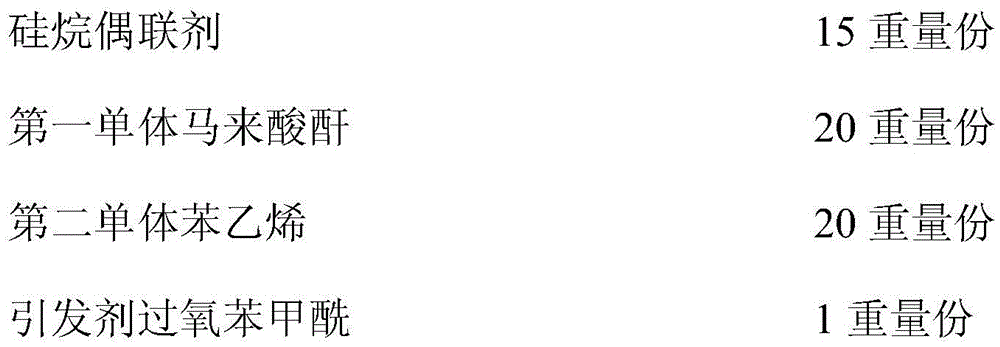

Polyethylene nano-modified composite and preparing method and application thereof

The invention provides a polyethylene nano-modified composite and a preparing method and application thereof. According to the polyethylene nano-modified composite, polyethylene, nano calcium carbonate, nano silica, a silane coupling agent, a first monomer, a second monomer and an initiator are adopted for preparing and obtaining a nano-modified master batch; due to the fact that nano calcium carbonate and nano silica are dispersed in the nano-modified master batch, the nano-modified master batch has good mechanical performance; in addition, the compatibility of nano calcium carbonate and nano silica with the polyethylene material can be enhanced through the silane coupling agent, and thus nano calcium carbonate and nano silica can have a better dispersing effect. The polyethylene nano-modified composite with an intercalation structure is obtained through an in-situ grafting and intercalation technology, nano composite of polyethylene and inorganic matter is achieved, and thus the mechanical property, the heat resistance, the aging resistance and the like of polyethylene plastic are effectively improved.

Owner:广州枫叶管业有限公司

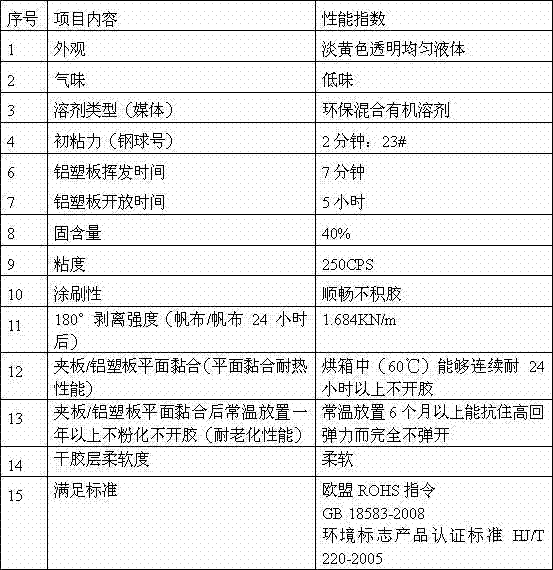

Environment-friendly solvent universal glue and preparation method thereof

InactiveCN102775938AGet rid of severe constraintsLow costMineral oil hydrocarbon copolymer adhesivesRosin adhesivesThermoplasticPolymer science

The invention discloses an environment-friendly solvent universal glue and a preparation method thereof. The best weight ratio of the universal glue is 9% of starburst SBS thermoplastic styrene-butadiene rubber, 2% of linear SBS thermoplastic styrene-butadiene rubber, 7% of rosin, 9.5% of hydrogenated rosin, 4% of C9 petroleum resin, 6% of a tackifying resin, 15% of No. 6 extraction solvent oil, 30% of methylal, 15% of methyl acetate, 0.2% of a wetting agent, 0.8% of an anti-aging agent, 0.5% of an antioxidant and 1.0% of a softening agent. The environment-friendly solvent universal glue has the comprehensive superiorities of low VOC, high solid content, no heavy metals, low smell, excellent initial adhesion, excellent cohesive strength, excellent permanent adhesion, excellent heat-resistant and ageing-resistant performance, short drying time, long opening time, large spraying area per weight (glue economization), and the like, has the advantages of reducing environment pollution, improving operation and construction environment, being low cost and low smell, and the like, is widely used in plate decoration industries of aluminum-plastic plates, clamping plates, density plates, paint-free plates, polymer plates, metal sheets, and the like, and is particularly suitable for applications in green high-grade decoration industries.

Owner:深圳市顾康力化工有限公司

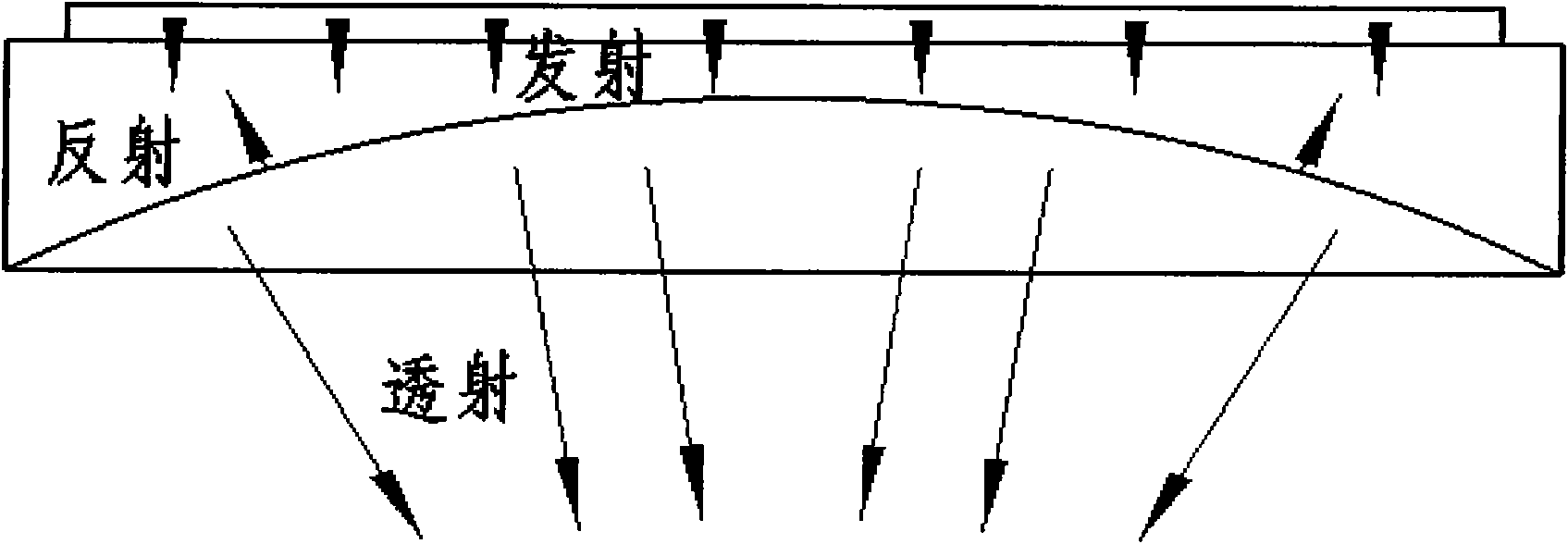

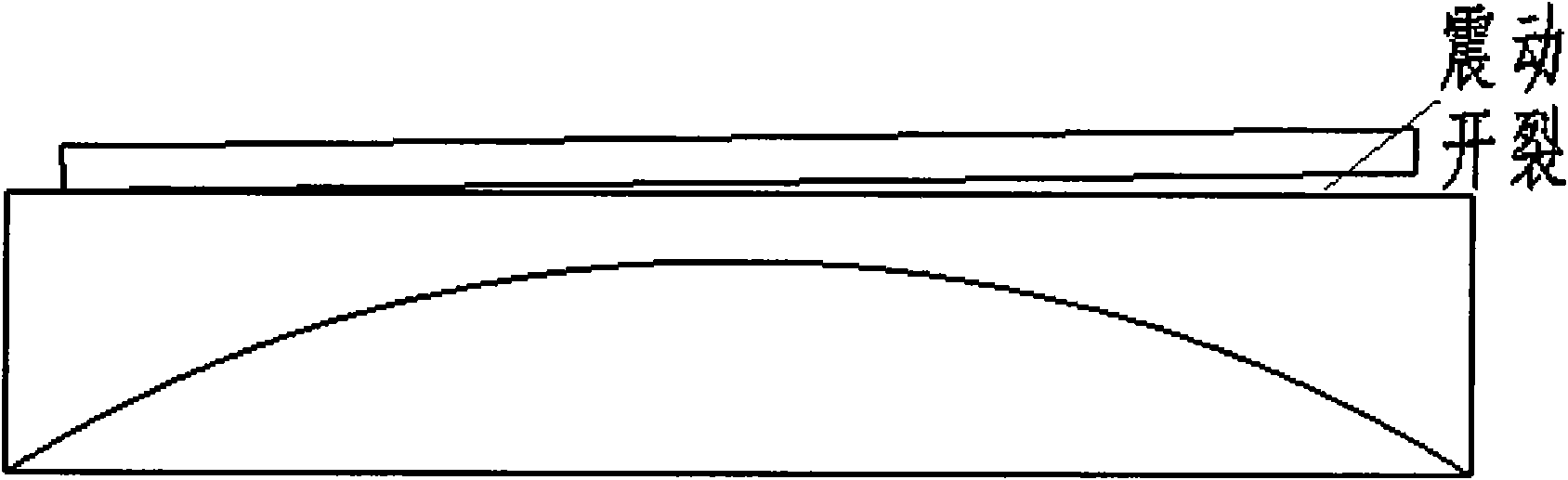

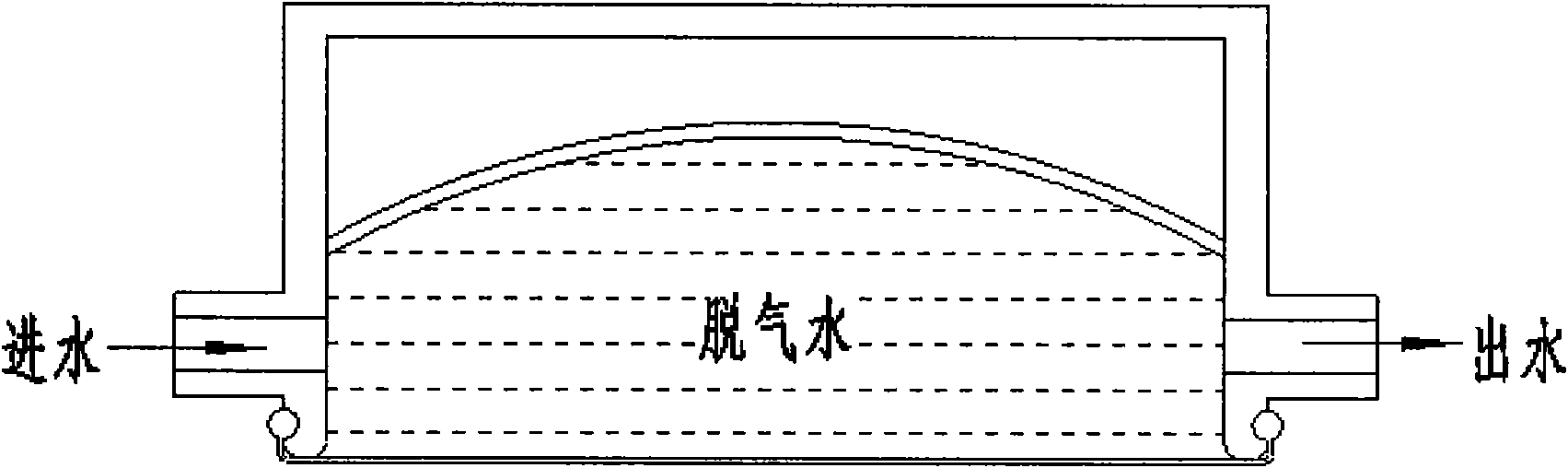

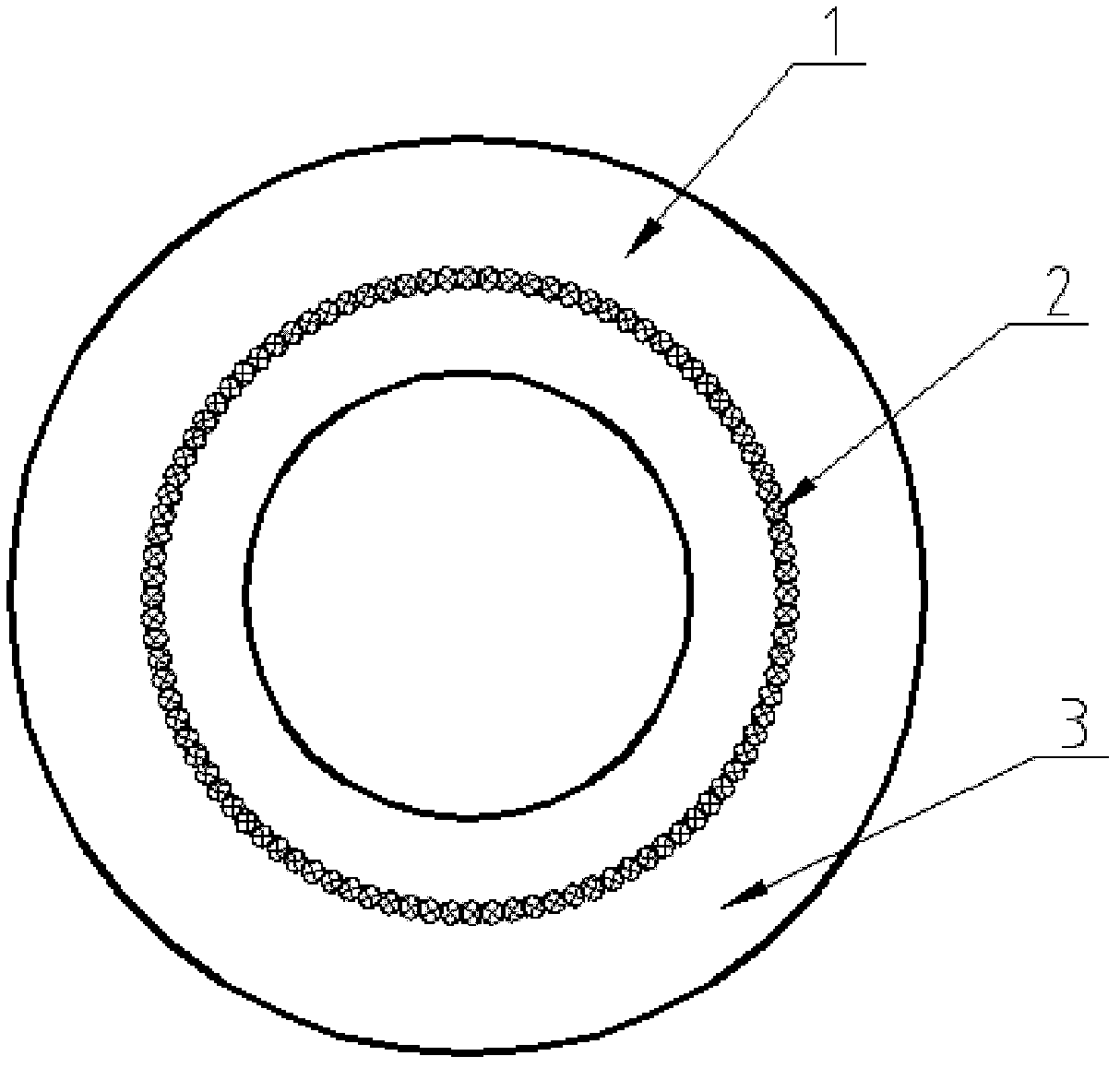

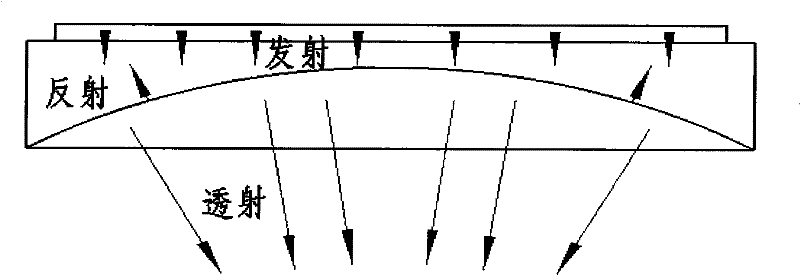

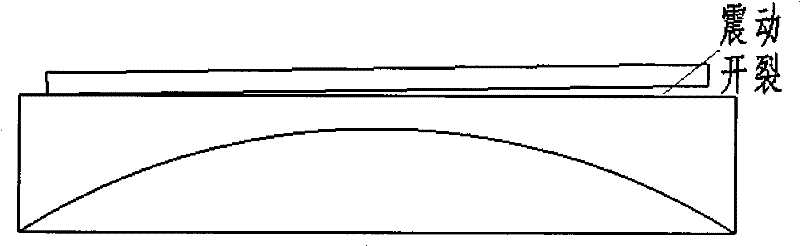

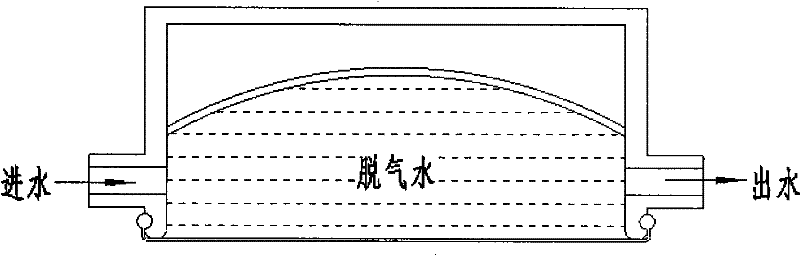

Focusing ultrasonic energy converter for weight loosing

ActiveCN101766869AImprove efficiencyUtilize the effective emission areaUltrasound therapyEpoxyElectricity

The invention relates to a focusing ultrasonic energy converter for weight loosing. A self-focusing ceramic sheet of the ultrasonic energy converter presents the shape of a spherical ring with a hole in the middle, an outer ring is fixed by epoxy resin in an embedding manner through mould pressing, and an inner ring is fixed by a hollow copper stud and an epoxy resin nut in a screwing manner. A shunting tee joint, a hollow stud and a shunting pipe form a specific circulating water system. The piezoelectric ceramic sheet, an electrode slice and a rear cover are compacted and fixed by the nut and the hollow stud so as to form a crimping power supply mode. Compared with a planar ceramic energy converter using an acoustic lens, the focusing ultrasonic energy converter that adopts the self-focusing method of the ring-shaped spherical surface has the characteristics of small focusing field and high energy. The application of the installing method of the hollow stud ensures the degassing water circulation when the energy converter is in working. Moreover, the structure of the energy converter is simple, and the installing and using are convenient.

Owner:BEIJING ANHEJIALIER TECH CO LTD

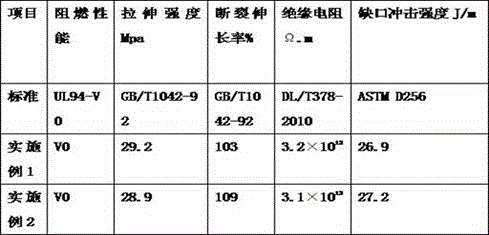

Flame-retardant heat-resisting ageing-resistant cable sheath material

InactiveCN104098900AHigh mechanical strengthImprove fatigue resistanceInsulated cablesInsulated conductorsFiberMelamine phosphate

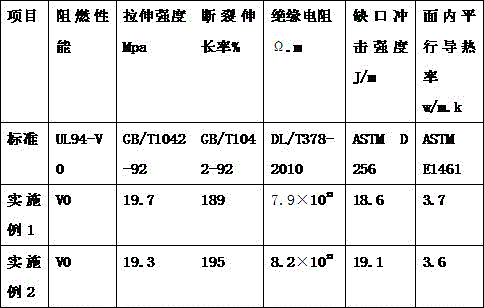

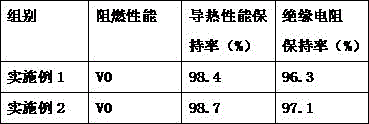

The invention discloses a flame-retardant heat-resisting ageing-resistant cable sheath material. The cable sheath material comprises the following raw materials in parts by weight: 5-8 parts of polybutylene terephthalate (PBT), 20-25 parts of polyphenylene sulfone (PPSU) resin, 15-20 parts of polyethylene (PE), 10-14 parts of chopped glass fiber, 3-5 parts of asbestos fiber, 1-1.5 parts of alumina whiskers, 7-9 parts of montmorillonite, 10-12 parts of diatomite, 15-17 parts of plaster, 10-11 parts of magnesium hydroxide, 3-5 parts of melamine phosphate, 1-3 parts of zinc stearate, 0.7-1.3 parts of glycerol monostearate, 1.5-1.9 parts of epoxy soybean oil, and 2-3 parts of a silane coupling agent. The cable sheath material disclosed by the invention has the advantages of excellent heat resistance, excellent ageing resistance, high tensile strength, high shock strength and excellent flame-retardant property.

Owner:安徽宁国市高新管业有限公司

Anti-flaming aging-resistant rubber material

The invention discloses an anti-flaming aging-resistant rubber material which comprises the following constituents in parts by weight: 40 parts to 45 parts of butadiene styrene rubber, 30 parts to 36 parts of polyurethane elastomer, 10 parts to 15 parts of chlorinated butyl rubber, 2 parts to 3 parts of vulcanizing agent BPO, 1.2 parts to 1.8 parts of sulphur, 2 parts to 4 parts of divinyl carboxylic acid sodium, 20 parts to 30 parts of calcite powder, 9 parts to 11 parts of kieselguhr, 5 parts to 7 parts of aluminum silicate, 14 parts to 15 parts of carbon black N660, 14 parts to 15 parts of carbon black N330, 10 parts to 12 parts of magnesium hydroxide, 3 parts to 5 parts of quartz powder, 5 parts to 7 parts of zinc oxide, 2 parts to 4 parts of calcium stearate, 5 parts to 8 parts of barium stearate, 5 parts to 7 parts of diphenyl phosphate ester, 2 parts to 4 parts of melamine, and 1.5 parts to 2.5 parts of silane coupling agent KH450. The anti-flaming aging-resistant rubber material has an excellent anti-flaming aging-resistant performance, so that smog is effectively prevented from generating during a combustion process; besides, the ozone resistance and the weather resistance of the anti-flaming aging-resistant rubber material are excellent; moreover, the anti-flaming aging-resistant rubber material further has the advantages of high elasticity, high hardness and high strength.

Owner:南通鹏达体育用品有限公司

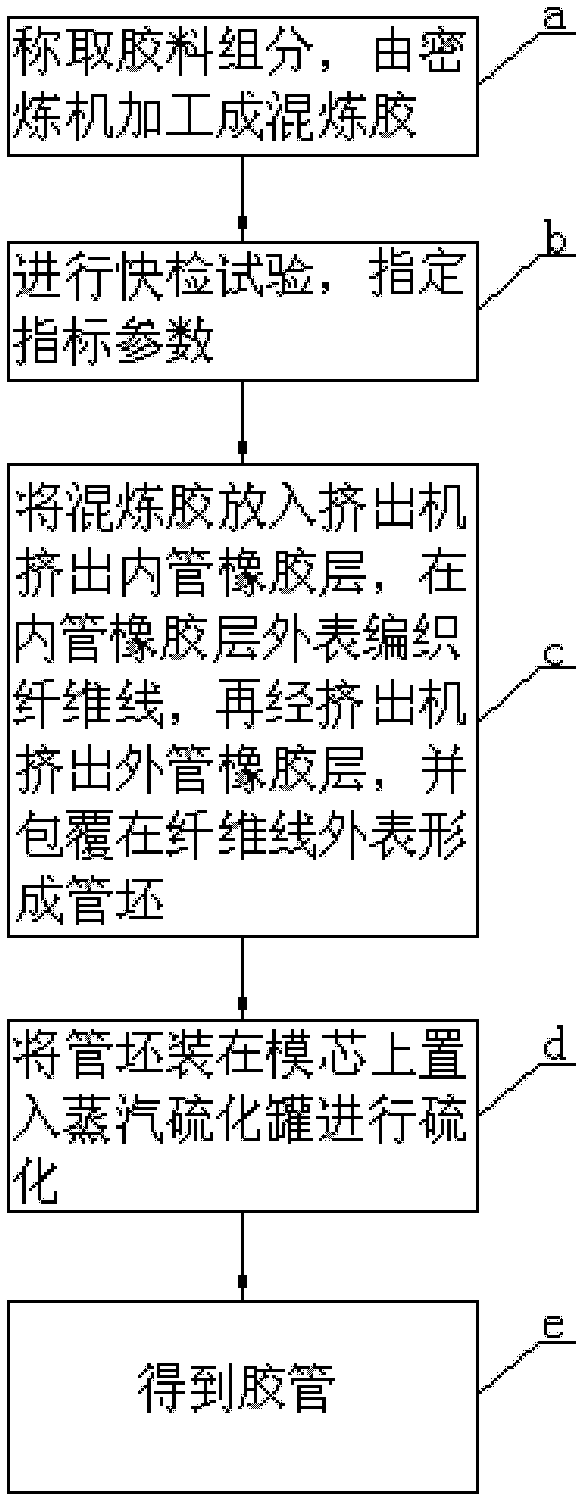

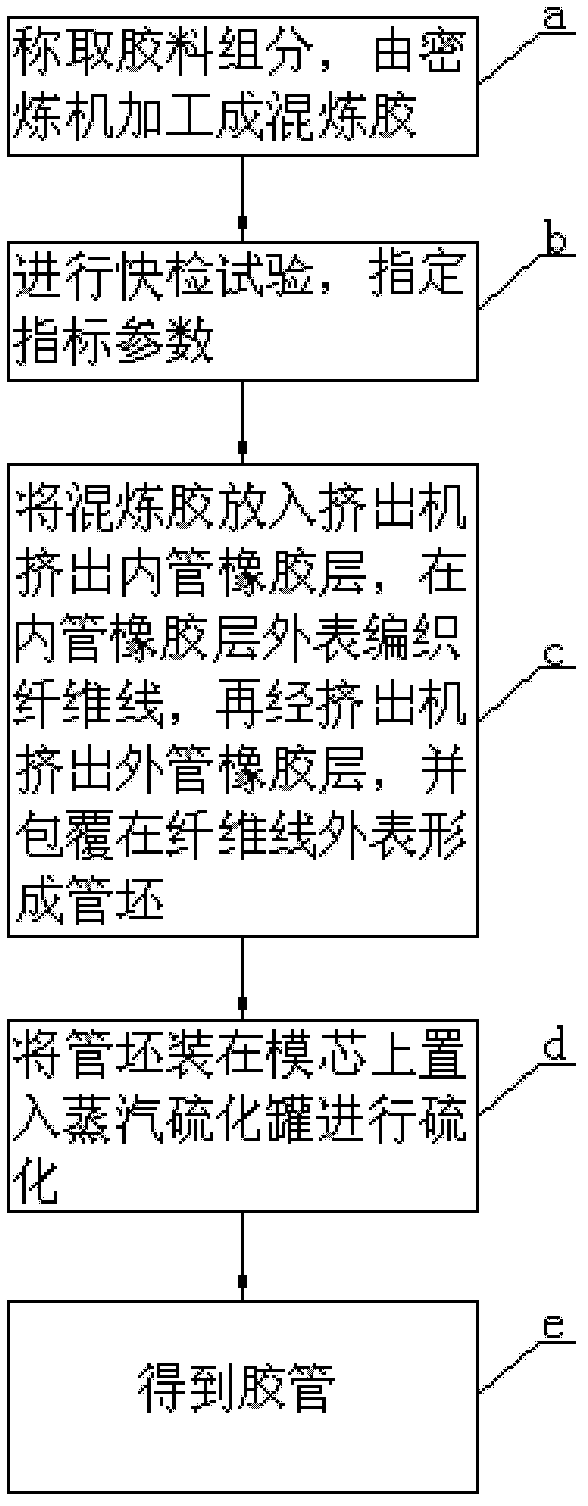

High-pressure power steering gear rubber tube and manufacturing process thereof

ActiveCN102628531AGood oil resistanceExcellent heat and aging resistanceFlexible pipesTubular articlesFiberVulcanization

The invention relates to the technical filed of automotive part manufacture, in particular to a high-pressure power steering gear rubber tube and a manufacturing process of the high-pressure power steering gear rubber tube. The high-pressure power steering gear rubber tube is formed by sequentially compositing an inner pipe rubber layer, a fiber wire enhancement layer and an outer pipe rubber layer from inside to outside. The main sizing material is chlorosulfonated polyethylene rubber (CSM). Each layer of rubber enables a banburying machine to be manufactured into rubber compounds to be compounded and extruded, two copies of fiber wires are weaved on the outer surface of the inner pipe rubber layer, then a pipe blank is formed by extruding the outer pipe rubber layer and wrapping on the surface of the fiber wire, the pipe blank is sleeved on a pipe die core to be arranged in a steam vulcanization tank for vulcanization, and the rubber pipe is obtained after depoling and level pressure of the pipe blank. The high-pressure power steering gear rubber tube has the advantages of being heat-resisting, oil-resisting, voltage-resisting, age-resisting, good in pulse performance, low in manufacture cost and high in percent of pass, and greatly meeting development requirements of modern automotives.

Owner:ZHEJIANG JUNHE RUBBER TECH

Ultra-strong MPP (modified polypropylene) power communication pipe and preparation method for same

The invention relates to an ultra-strong MPP (modified polypropylene) power communication pipe and a preparation method for the same. The ultra-strong MPP power communication pipe comprises PP (polypropylene), PE (polyethylene), an EPDM (ethylene propylene diene monomer), an inorganic filler, a silane coupling agent, an antioxidant and an auxiliary antioxidant. The preparation method comprises the following steps: feeding the inorganic filler into a high-speed mixer for stirring; feeding EPDM powder into the high-speed mixer for stirring; spraying the silane coupling into the high-speed mixer by virtue of a metering pump; feeding the PP and the PE into the high-speed mixer for stirring; feeding the antioxidant and the auxiliary antioxidant into the high-speed mixer for stirring; preparing a toughened raw material; extruding the mixed toughened raw material by virtue of an extruder. The ultra-strong MPP power communication pipe and the preparation method for the same have the beneficial effects that the components in the formula cooperate to strengthen the tensile strength of the pipe by 60 percent, improve the ring stiffness by 10 percent, improve the surface hardness by 50 and achieve high compression resilience, small deformation, high heat and aging resistance and high electric insulativity.

Owner:杭州联通管业有限公司

Oil-resistant and high-temperature-resistant rubber material for automobiles

The invention discloses an oil-resistant and high-temperature-resistant rubber material for automobiles. The oil-resistant and high-temperature-resistant rubber material comprises the following raw materials in parts by weight: 45-55 parts of butadiene rubber, 20-25 parts of acrylate rubber, 20-35 parts of silicon rubber, 15-20 parts of white carbon black, 10-15 parts of modified nano talcum powder, 2-5 parts of sulfur, 0.5-1.2 parts of zinc oxide, 1-3 parts of tricresyl phosphate, 0.5-2 parts of oxidized polyethylene, 3.5-4.5 parts of a promoter TMDT, 2-5 parts of an anti-aging agent, 0.2-0.5 part of epoxy flaxseed oil, 0.2-0.5 part of triethyl o-acetylcitrate and 1.0-1.5 parts of microcrystalline wax. The rubber material disclosed by the invention is good in wear resistance, heat resistance and oil resistance, and can be applied to automobile fuel tanks.

Owner:安徽宁国尚鼎橡塑制品有限公司

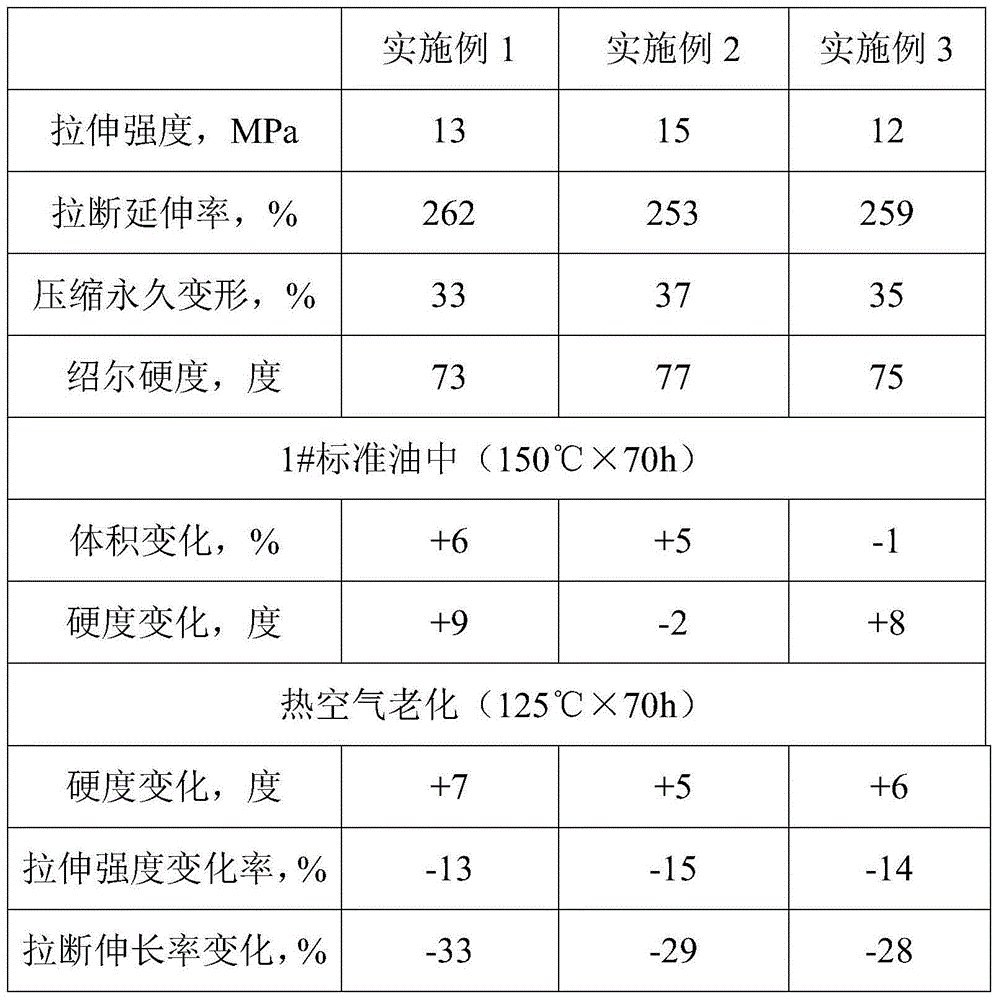

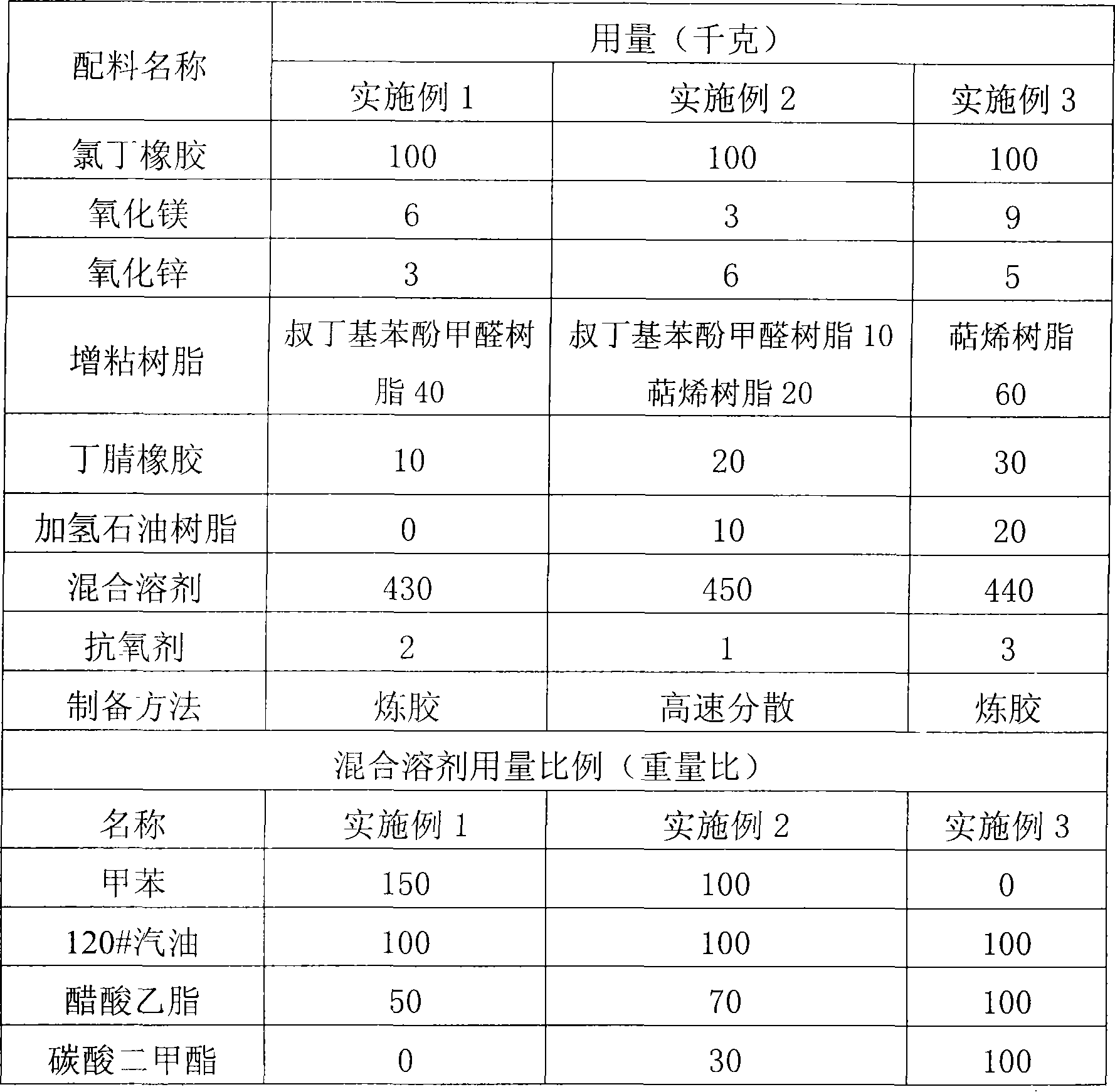

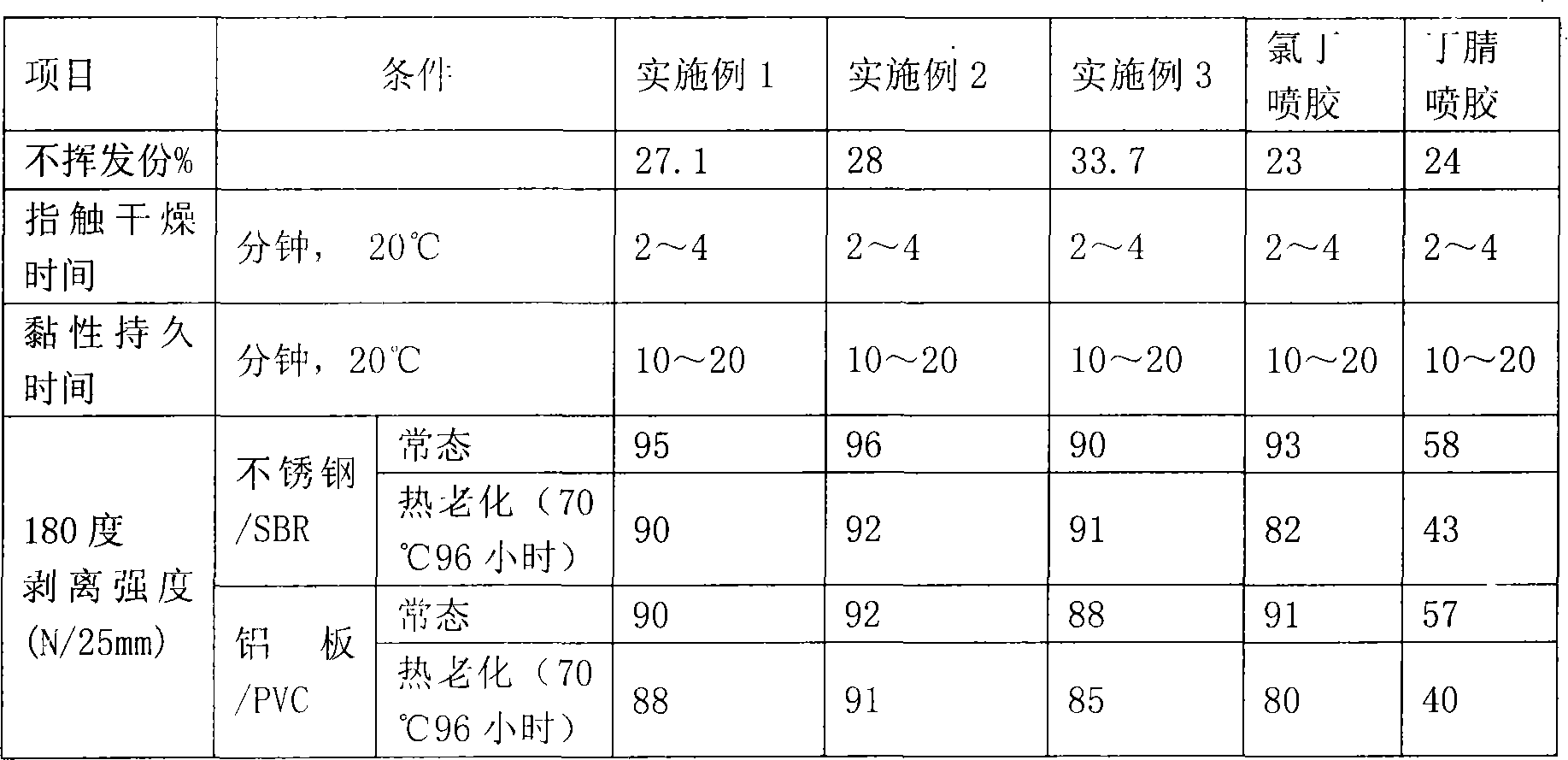

Chlorobutyl-butyronitrile glue-spraying adhesive for inside decorative material for vehicle and preparation method thereof

InactiveCN101624504AEasy to useFast dryingAldehyde/ketone condensation polymer adhesivesConjugated diene hydrocarbon adhesivesPolymer scienceAdhesive

The invention relates to chlorobutyl-butyronitrile glue-spraying adhesive for an inside decorative material for a vehicle and a preparation method thereof. The preparation method comprises the following steps: blending neoprene rubber of which Mooney Viscosity is 17 to 50, liquid butyronitrile rubber and viscosity increasing resin in a weight ratio of 100:10-30:20-60, adding magnesium oxide, zinc oxide and antioxidant into the mixture, and reacting the mixture in a mixed solvent at the temperature of between 20 and 60 DEG C to form the adhesive, wherein the neoprene rubber of which Mooney Viscosity is 17 to 50 is obtained through rubber mixing or high-speed dispersion. The adhesive can be dried and cured after 10 to 15 minutes at normal temperature, has the advantages of good adhesive film toughness, high adhesive strength, water resistance, good heat ageing resistance and strong universality, and is suitable for adhering the inside decorative materials for vehicles such as trains, automobiles, ships and the like.

Owner:刘水平

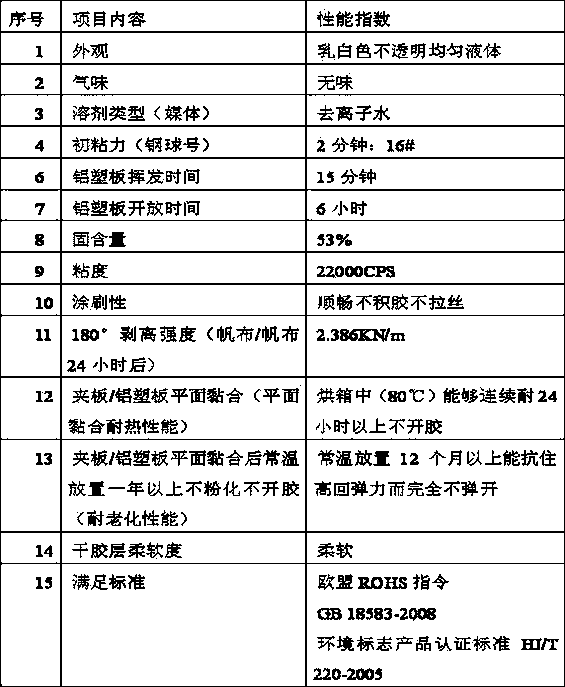

Environment-friendly water-based chloroprene universal rubber and preparation method thereof

InactiveCN103805097AGet rid of severe constraintsLow costMineral oil hydrocarbon copolymer adhesivesAldehyde/ketone condensation polymer adhesivesGlycerolMaterials science

The invention discloses environment-friendly water-based chloroprene universal rubber and a preparation method thereof. The universal rubber comprises the following main components in percentage by weight: 5% of a water-based rosin glycerol ester emulsion, 5.4% of a water-based pentalyn emulsion, 4% of a water-based petroleum resin emulsion, 8% of a water-based alkyl phenol emulsion, 11% of a water-based acrylic emulsion, 8% of a water-based EVA (Ethylene Vinyl-Acetate) emulsion, 42% of water-based anionic chloroprene latex and 6% of deionized water. The universal rubber disclosed by the invention has the comprehensive advantages of zero VOC (Volatile Organic Compounds), high solid content, no organic solvents, no heavy metals, no taste, excellent binding performance, heat-resistance and aging-resistance, shorter drying time, long open time, excellent leather grease resistance, rubber saving and the like, has the advantages of avoiding environmental pollution, improving the operation and construction environments, being low in cost, tasteless, fireproof and safe and the like, and can be widely applied to panel decorative industries such as aluminum-plastic panels, clamp boards, density boards, paint-free boards, macromolecular panels, screens and metal sheets. The environment-friendly water-based chloroprene universal rubber is especially suitable for being applied to green and environment-friendly top-grade decorative industries.

Owner:深圳市顾康力化工有限公司

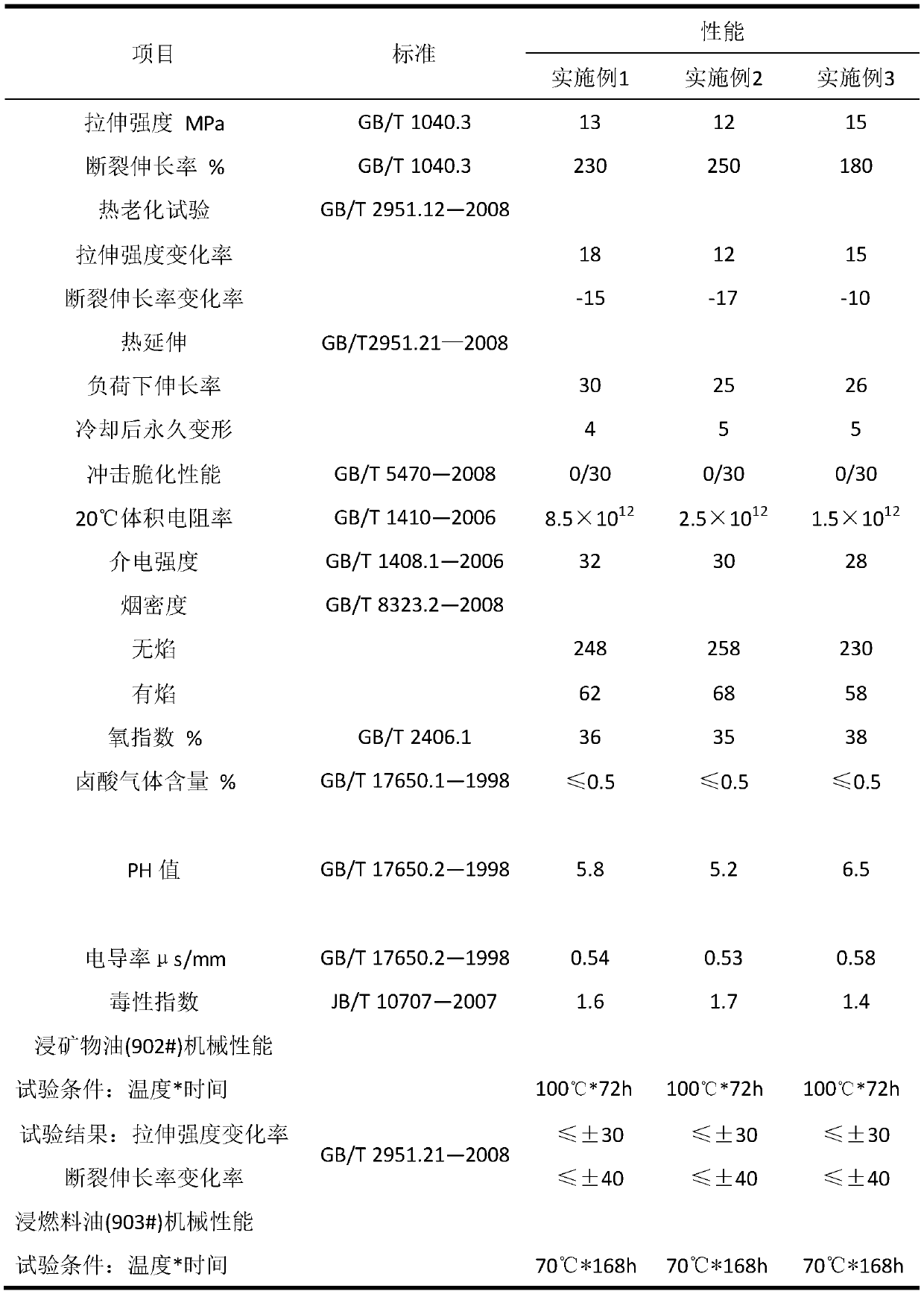

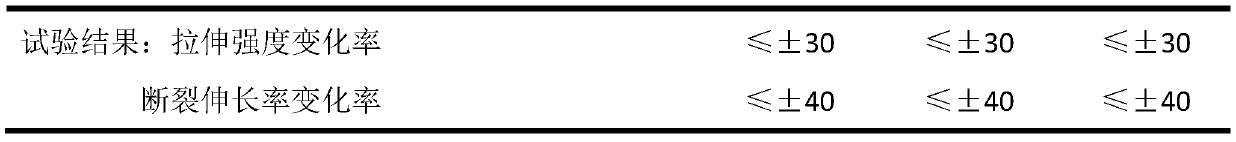

Preparation method of irradiation cross-linking polyolefin insulating material for locomotives

InactiveCN110684270AHigh elongation at breakImprove flame retardant performancePlastic/resin/waxes insulatorsLow-density polyethyleneLinear low-density polyethylene

The invention belongs to the technical field of insulating materials for locomotives, and particularly relates to a preparation method of an irradiation cross-linking polyolefin insulating material for locomotives, wherein the polyolefin insulating material comprises: 40-50 parts of an ethylene-vinyl acetate copolymer, 20-40 parts of metallocene linear low density polyethylene, 15-25 parts of an ethylene-octene copolymer, 10-20 parts of a maleic anhydride grafted ethylene-octene copolymer, 80-150 parts of modified aluminum hydroxide, 50-80 parts of modified magnesium hydroxide, 50-100 parts ofa triazine flame retardant, 1-2 parts of a coupling agent, 3-8 parts of a lubricant, 0.5-2 parts of a high-temperature-resistant antioxidant, 1-3 parts of a light stabilizer, 2-5 parts of a char-forming smoke suppressant, 8-15 parts of modified bentonite, 10-15 parts of active kaolin powder and 2-5 parts of a cross-linking agent. According to the invention, the prepared polyolefin insulating material has characteristics of excellent heat resistance, excellent aging resistance, high mechanical strength, environmental protection and no toxicity.

Owner:BAOSHENG SCI & TECH INNOVATION

Nanocomposite material as well as preparation method and application thereof

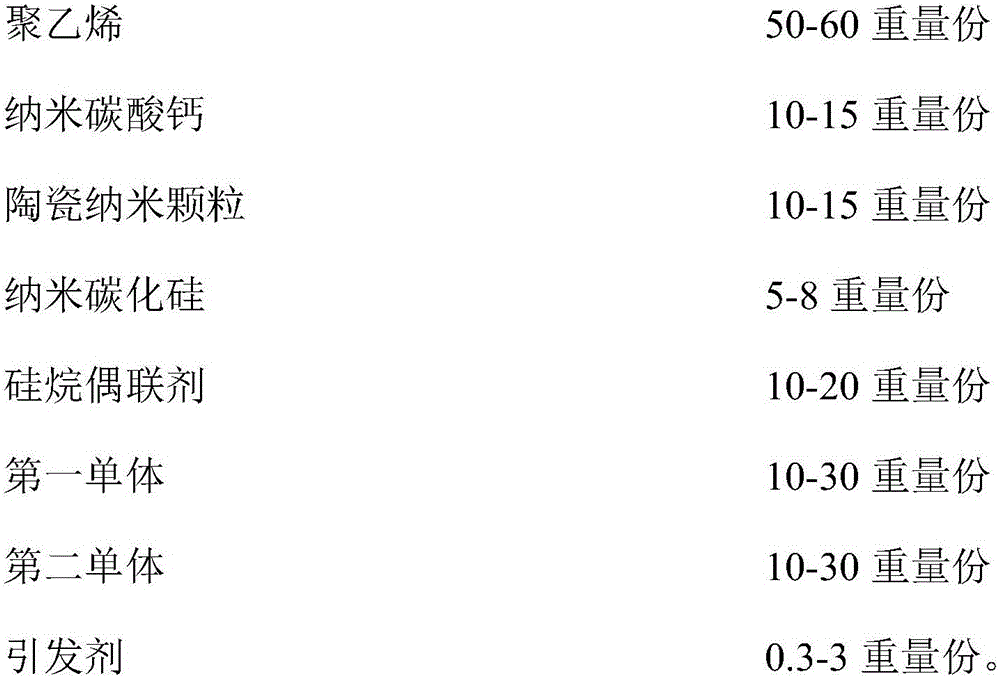

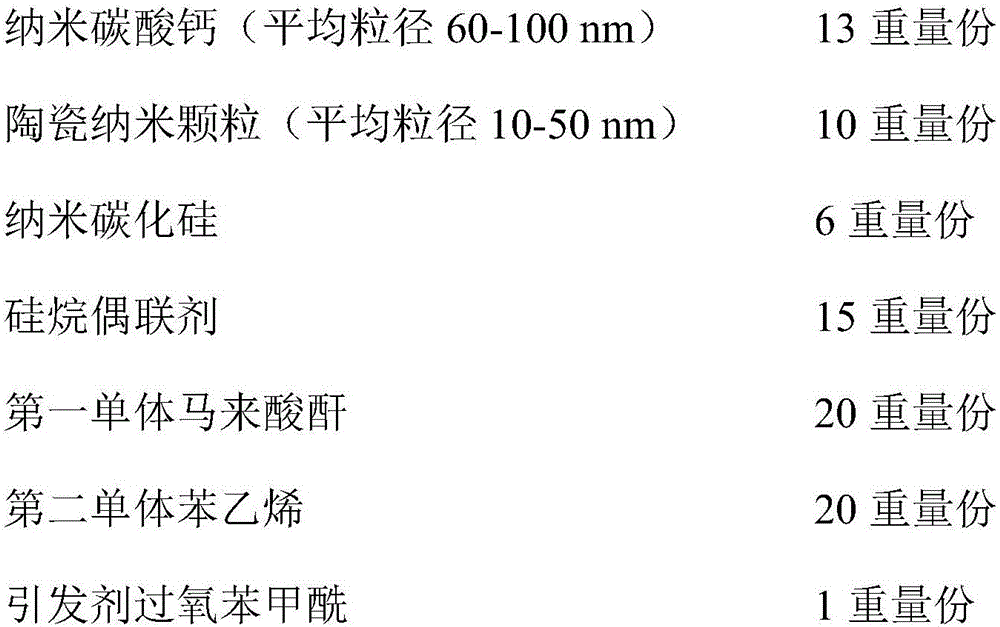

The invention provides a nanocomposite material as well as a preparation method and application thereof. According to the nanocomposite material, a nano modified masterbatch is prepared by adopting polyethylene, nano calcium carbonate, ceramics nanoparticles, nano silicon carbide, a silane coupling agent, a first monomer, a second monomer and an initiator; the nano calcium carbonate and the ceramics nanoparticles are dispersed in the nano modified masterbatch, so that the nano modified masterbatch has good mechanical property; besides, the silane coupling agent can enhance compatibility between the nano calcium carbonate as well as the ceramics nanoparticles and a polyethylene material, so that a better dispersing effect is achieved; an in-situ grafting intercalation technology is utilized to obtain the nanocomposite material with an intercalation structure, and nano-compositing of the polyethylene and inorganic substances is realized, thus effectively improving the mechanical property, heat resistance, ageing resistance and the like of polyethylene plastic.

Owner:WUXI MINGSHENG TEXTILE MACHINERY

Nano-composite material, preparation method and application thereof

InactiveCN106750894AGood compatibilityImprove mechanical propertiesNano compositesMechanical property

The invention provides a nano-composite material, a preparation method and application thereof. According to the nano-composite material provided by the invention, polyethylene, nano calcium carbonate, ceramic nano-particles, nano silicon carbide, a silane coupling agent, a first monomer, a second monomer and an initiator are prepared into a nano-modified masterbatch, because of the nano calcium carbonate and ceramic nano-particles, the nano-modified masterbatch has good mechanical properties. In addition, the silane coupling agent can improve the compatibility between the nano calcium carbonate, ceramic nano-particles and a polyethylene material so as to reach better dispersion effect. In-situ graft intercalation technology is utilized to obtain the nano-composite material with an intercalation structure so realize nano-compounding of polyethylene and inorganic substances, thereby effectively improving the mechanical properties, heat resistance, aging resistance and the like of polyethylene plastics.

Owner:WUXI MINGSHENG TEXTILE MACHINERY

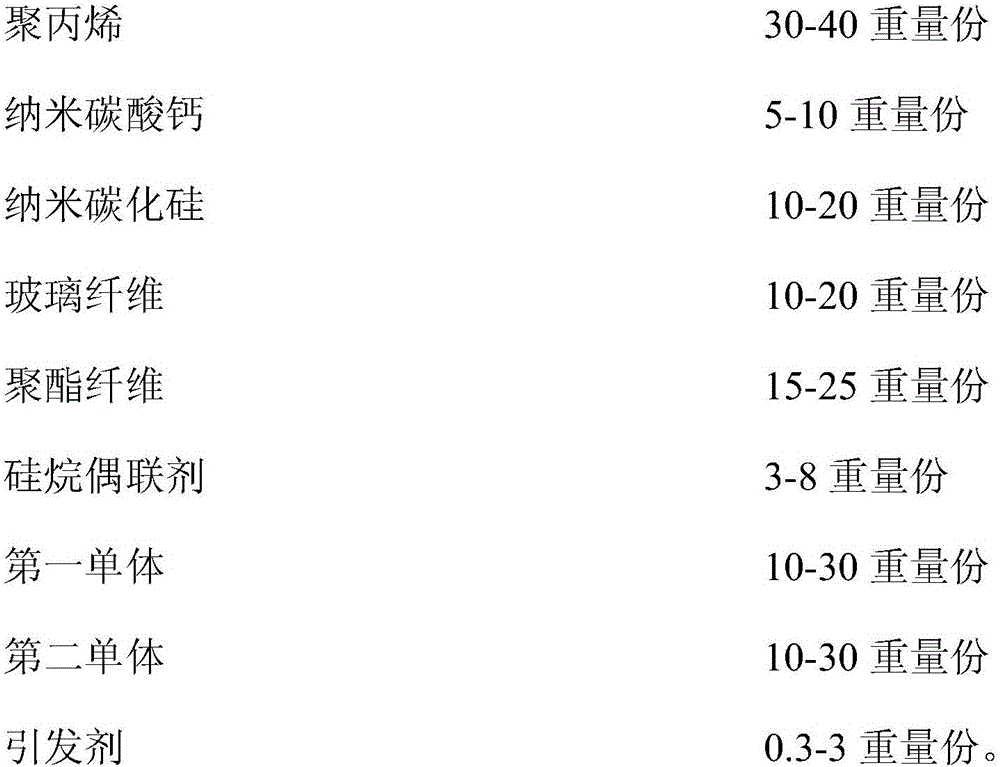

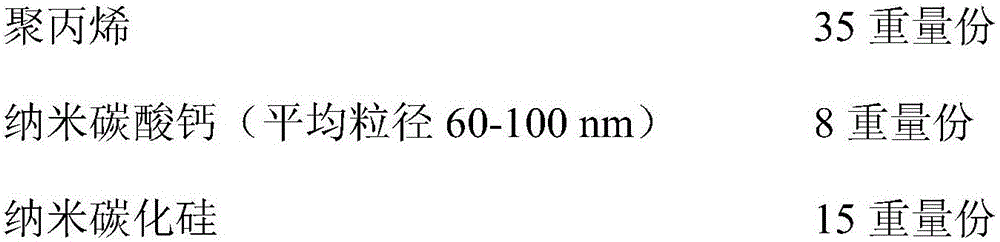

Nano-composite material as well as preparation method and application thereof

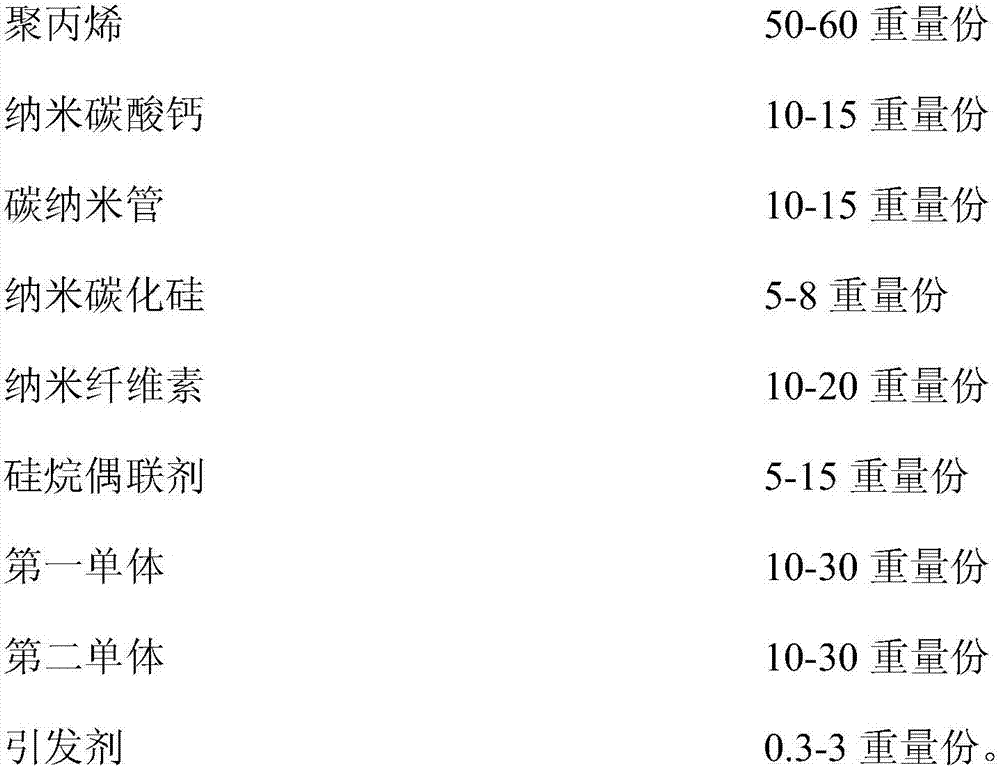

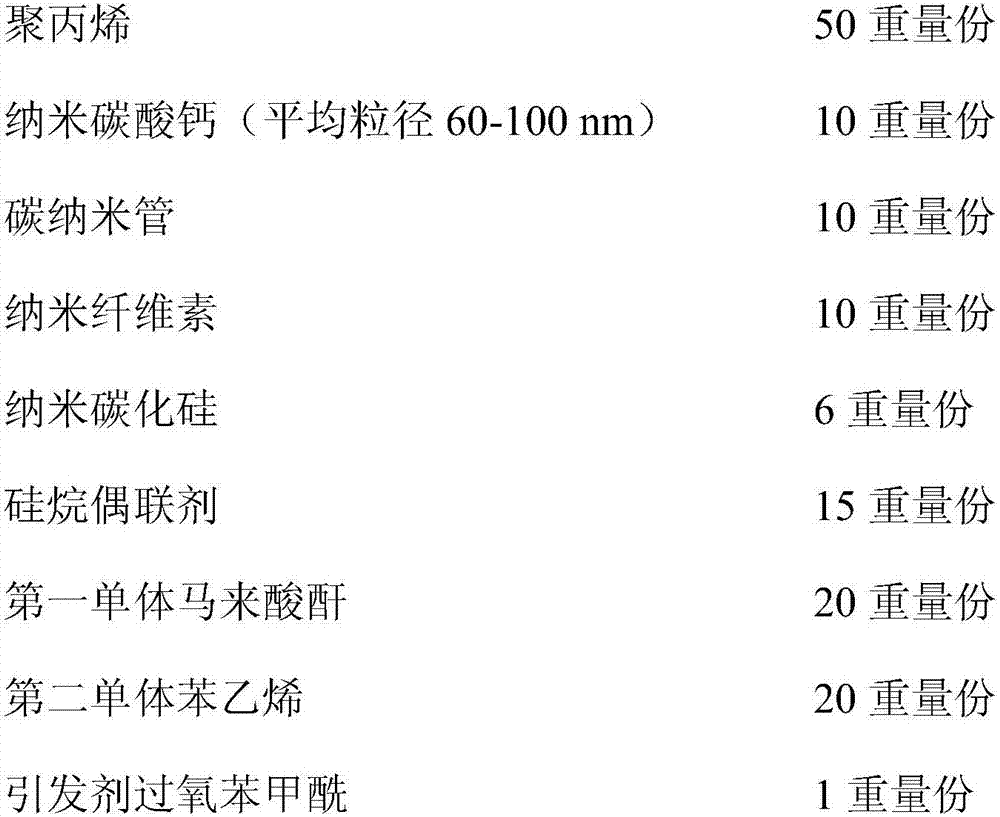

The invention provides a nano-composite material as well as a preparation method and application thereof. The nano-composite material provided by the invention is a nano-modified master batch prepared from polypropylene, nano calcium carbonate, carbon nanotubes, nano-silicon carbide, nano-cellulose, a silane coupling agent, a first monomer, a second monomer and an initiator; the nano calcium carbonate, the nano-silicon carbide, the carbon nanotubes and the nano-cellulose are dispersed in the nano-modified master batch, so that the nano-modified master batch has good mechanical properties; furthermore, the silane coupling agent can enhance the compatibility between the nano calcium carbonate and the ceramic nanoparticles as well as a polypropylene material, so that the nano-modified master batch has a better dispersion effect; the nano-composite material having an intercalated structure is obtained by using an in-situ grafting intercalation technique, so that the nano-compounding between the polypropylene and inorganic matters can be realized, and the mechanical properties, heat resistance, aging resistance and the like of polypropylene plastics are effectively improved.

Owner:俞惠英

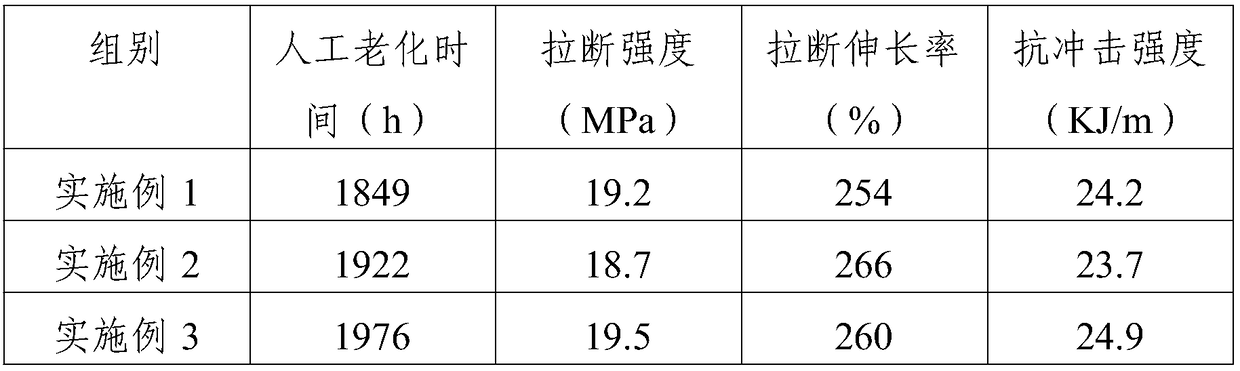

Processing technology of insulating thermosetting plastic material

The invention belongs to the technical field of thermosetting plastic processing and discloses a processing technology of an insulating thermosetting plastic material. The processing technology comprises the following steps: 1, crushing and grinding raw materials; 2, preparing modified resin; 3, preparing modified graphite; 4, conducting banburying; 5, preparing the thermosetting plastic material. The processing technology is simple in process, great in operability and suitable for industrialized production.

Owner:FUYANG SIBO IND DESIGN

Resin adhesive for bonding bulletproof plate and application thereof

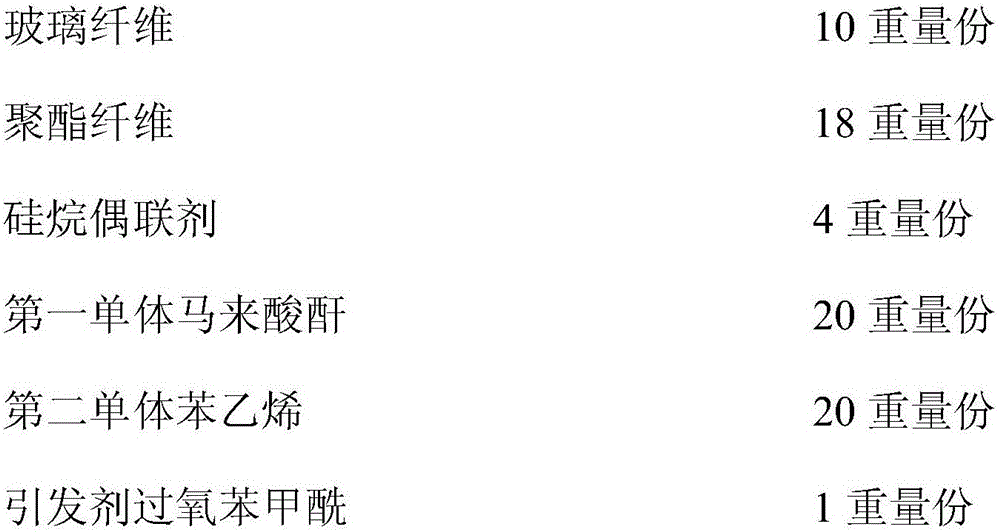

PendingCN114574127ADetermine viscosityDetermine the adhesionNon-macromolecular adhesive additivesMacromolecular adhesive additivesThermoplasticFiber

The invention discloses a resin adhesive for bonding bulletproof plates and application of the resin adhesive, the adhesive is prepared from the following raw material components in percentage by mass: 6 # extraction solvent oil, cyclohexane, star-shaped thermoplastic styrene-butadiene rubber, linear thermoplastic styrene-butadiene rubber, terpene resin, 2402 phenolic resin, an antioxidant, a surfactant and a softening agent, and the adhesive belongs to environment-friendly resin. The adhesive is nontoxic and harmless, does not harm a human body, has better properties such as initial adhesion, permanent adhesion, heat resistance, aging resistance, softness and the like, and can improve the adhesion performance of ceramic and a high-strength fiber hard composite material PE plate in the bulletproof plate, so that the ceramic and the PE plate are not layered when the compounded ceramic bulletproof plate is impacted in a high-low temperature environment, and the ceramic bulletproof plate is not damaged. And meanwhile, the same ceramic around the bullet-proof position cannot fall off and loosen, and the defensive performance and the multi-shot performance of the ceramic bullet-proof plate are effectively improved.

Owner:JIANGSU LINRY NEW MSTAR TECH

Improved heat-resistant conveyer belt

The invention discloses an improved heat-resistant conveyer belt, which is prepared from the following raw materials in parts by weight: 22-42 parts of ethylene propylene terpolymer, 11-16 parts of calcium carbonate, 7-9 parts of terpene resin, 2-8 parts of sulphur, 3-9 parts of peroxide, 7-14 parts of coumarone, 11-16 parts of heavy oil, 5-8 parts of magnesium oxide, 6-10 parts of pine tar, 22-32 parts of carbon black, 5-10 parts of solid chlorinated paraffin, 7-13 parts of aluminium hydroxide, 6-10 parts of dioctyl phthalate, 2-4 parts of stearic acid, 9-14 parts of asbestos fiber, 25-35 parts of natural rubber, 15-20 parts of chlorinated polyethylene, 4-8 parts of zinc oxide, 5-10 parts of aromatic oil, 5-8 parts of an accelerant NOBS and 3-7 parts of magnesium oxide. The improved heat-resistant conveyer belt disclosed by the invention is low in material cost, long in service life, excellent in heat resistance and ageing resistance, and high in tensile strength.

Owner:QINGDAO HI TECH PATENT TECH TRANSFER PLATFORM

Preparation method for rubber for piston sealing ring with good anti-aging effect

InactiveCN109438782AExcellent heat and aging resistanceImprove stabilityBulk chemical productionTemperature resistancePhthalimides

The invention provides a preparation method for rubber for a piston sealing ring with a good anti-aging effect, and relates to the technical field of the rubber processing. The rubber for the piston sealing ring is prepared by the following raw materials in parts by weight: 60-80 parts of natural rubber, 40-50 parts of isoprene rubber, 20-30 parts of polyacrylate rubber, 14-20 parts of polyvinylidene chloride, 2-5 parts of p-trifluoromethyl benzonitrile, 10-12 parts of glass fibers, 3-5 parts of titanium dioxide, 4-6 parts of nano zinc oxide, 2-3 parts of paraffin, 1-3 parts of sulfur, 4-6 parts of phthalimide, 1-3 parts of a coupling agent, 6-8 parts of a lubricant, and 4-5 parts of an inhibitor. The preparation method thereof mainly comprises steps of supercritical carbon dioxide treatment, open mixing, high-temperature vulcanizing and the like. The preparation method is capable of overcoming deficiency of the prior art, improving an anti-aging property and corrosion resistance of traditional rubber, and through adding multiple chemical substances, enabling the obtained rubber to have the advantages of tear resistance, high-temperature resistance, wear resistance and the like.

Owner:宁国华祥汽车零部件股份有限公司

Antiskid permeable pavement

ActiveCN112195711AExtended service lifeImprove structural regularityIn situ pavingsPaving gutters/kerbsAdipic acidMaterials science

The invention discloses an antiskid permeable pavement which comprises a pavement base layer and an adhesive stone surface layer paved on the surface of the pavement base layer, the adhesive stone surface layer is prepared from the following raw materials in parts by weight: 2-5 parts of a component A, 3-7 parts of a component B and 95-105 parts of aggregate; the component A is prepared from the following raw materials: polyester of aliphatic dicarboxylic acids, polyether polyol, dipropylene glycol, neopentyl glycol, linoleic acid, castor oil, 2,2,3,3,4, 4,5,5-octafluoro-1-amyl alcohol, epoxyresin E-44, epoxy resin E-14, diphenyl-methane-diisocyanate, hexamethylene diisocyanate, nano silicon dioxide, nano calcium carbonate, boron carbide and modified lignin; the component B is prepared from the following raw materials: 1,8-diazacyclo[5,4,0]undecene-7 and triethanolamine. The anti-skid permeable pavement provided by the invention has the advantages of good skid resistance and water permeability, excellent aging resistance, short curing time and long service life.

Owner:江苏固迈新材料技术有限公司

Aqueousneoprene type environment-friendly glue and preparation method thereof

ActiveCN101560367BTransportation safetyHigh bonding strengthAldehyde/ketone condensation polymer adhesivesAcid polymer adhesivesAcrylic resinFireproofing

Owner:黄楚填

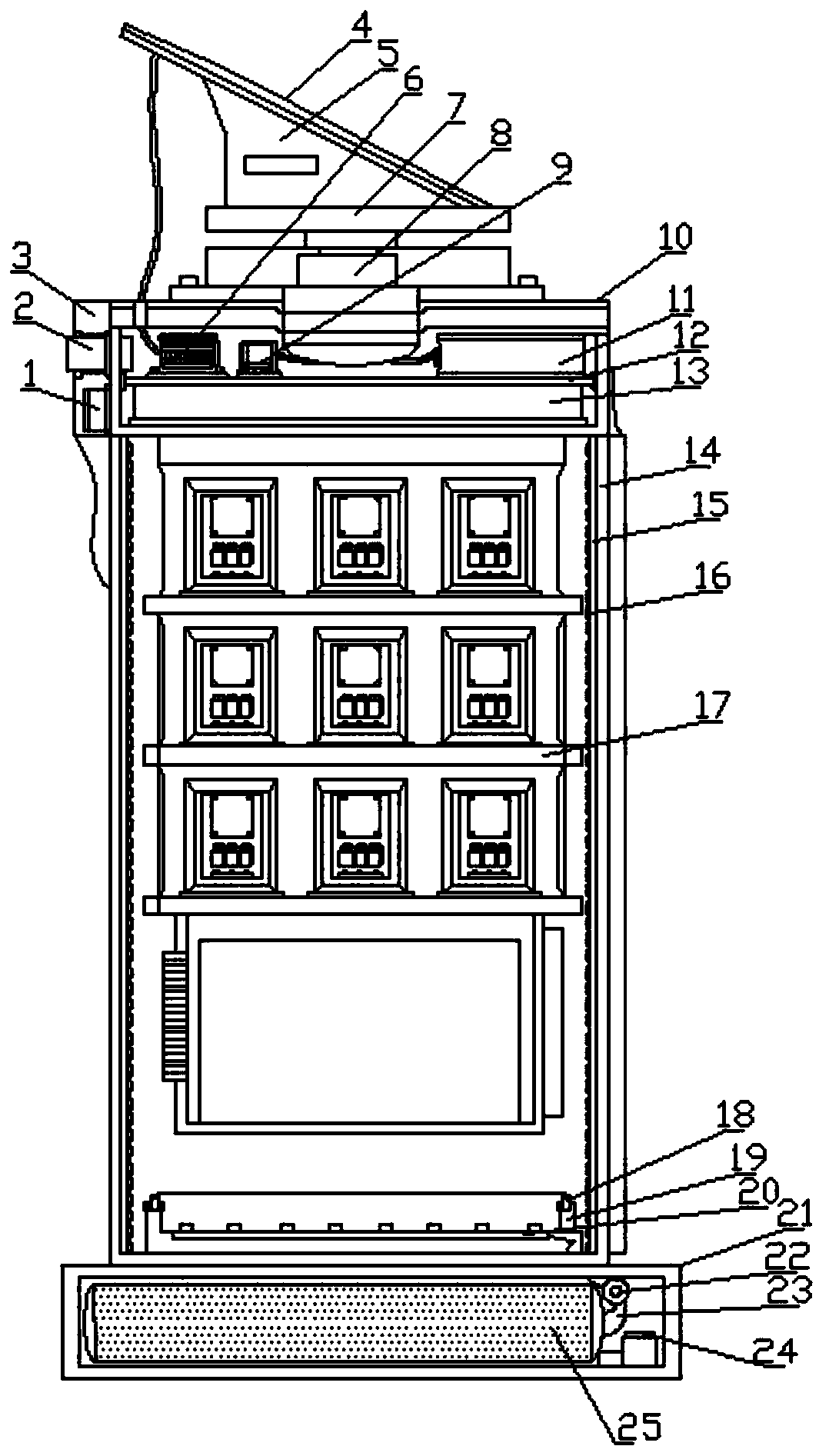

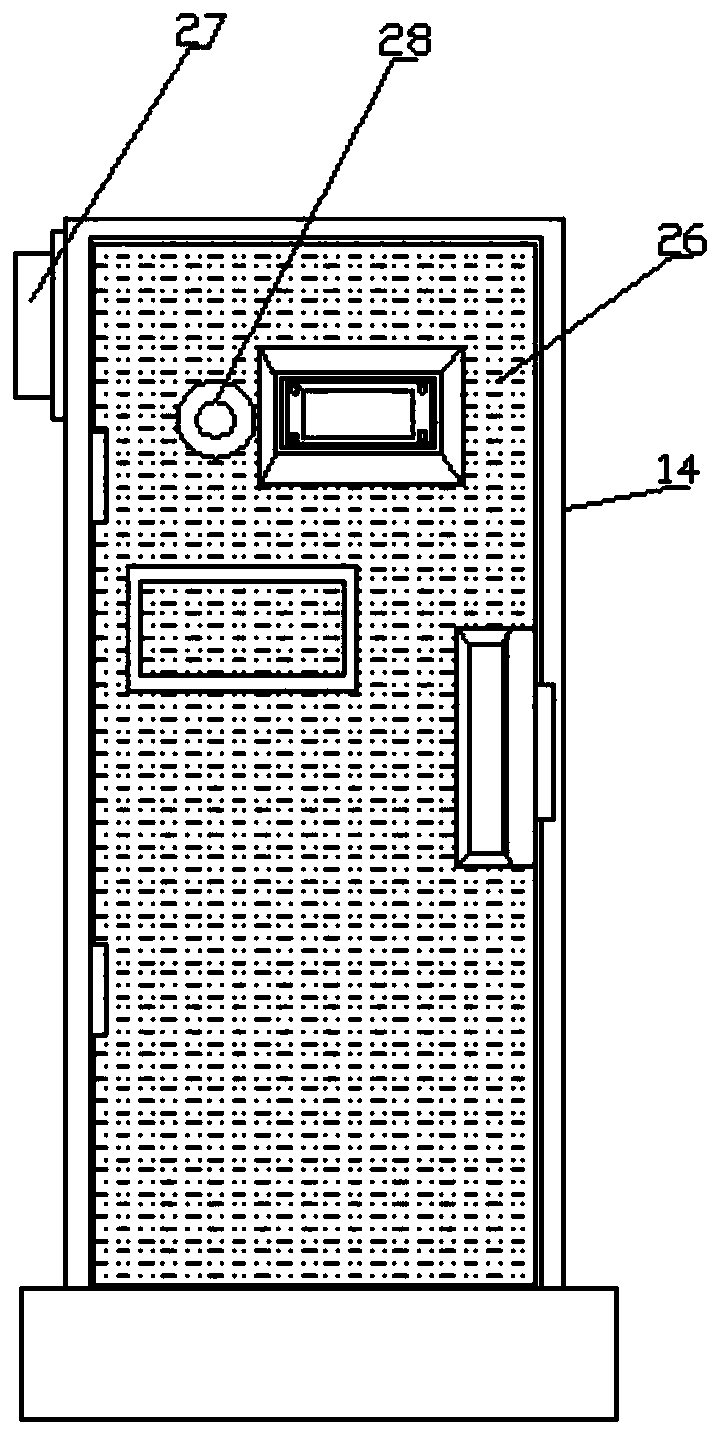

High-/low-voltage cabinet device of combined transformer for photovoltaic power generation

InactiveCN110556716AReduce the temperatureAvoid high temperature aging too fastBatteries circuit arrangementsSubstation/switching arrangement cooling/ventilationSurface layerLow voltage

The invention discloses a high- / low-voltage cabinet device of a combined transformer for photovoltaic power generation. The high- / low-voltage cabinet device comprises an electromagnetic valve, a base,a cabinet body and a side door. A pressure tank is mounted in the base through a mounting seat. A single-chip microcomputer controller is mounted at one end of the pressure tank through a limiting block. The cabinet body is mounted at the top of the base through bolts. A curing layer is arranged on the inner surface layer of the cabinet body, and a TPO perforated hemispheroid is adhered to the inner side of the curing layer through environment-friendly adhesive. Smoke sensors are mounted at the two ends of the bottom in the cabinet body through limiting seats. A servo motor controller is arranged at one end of the top of the cabinet body through a mounting plate. A mounting chamber is mounted at the top of the cabinet body through bolts. A sponge block is mounted at the bottom in the mounting chamber through screws. The novel high-low voltage cabinet device of the combined transformer for photovoltaic power generation is diversified in function, simple to operate and convenient to produce, meets various requirements in use, and is suitable for wide popularization and application.

Owner:淮安市伟杰配电控制设备有限公司

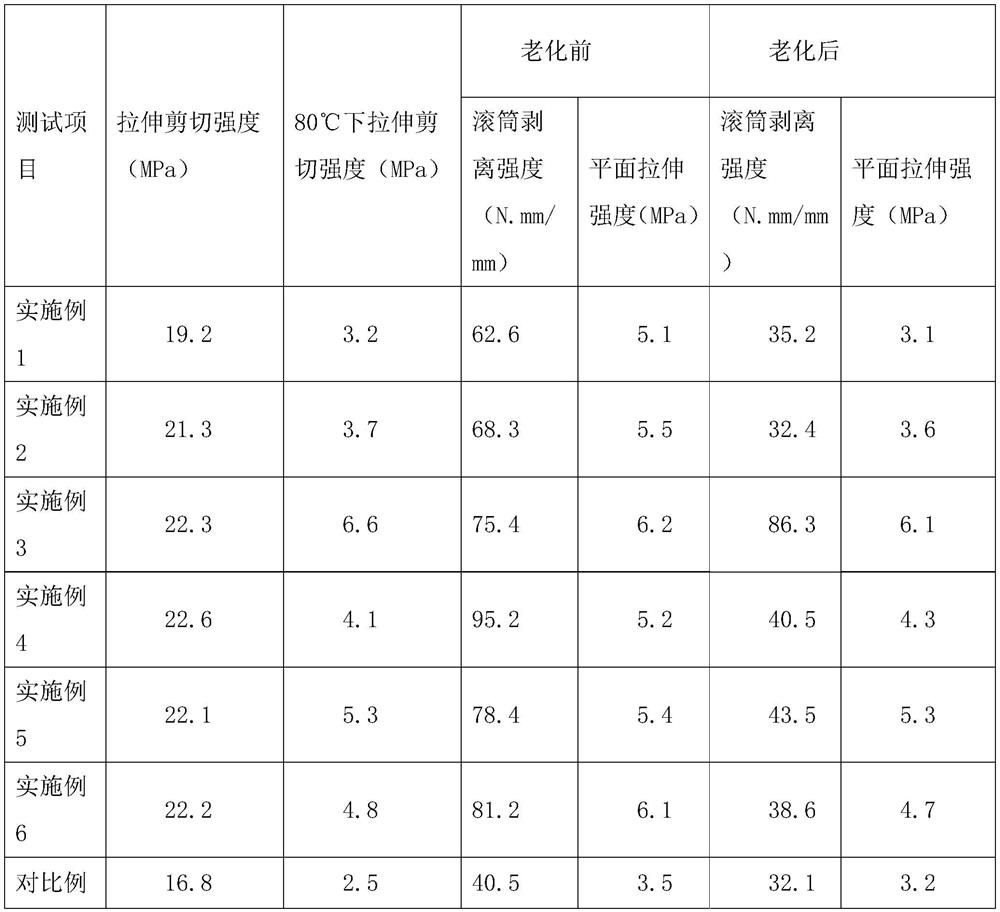

Room-temperature-cured bi-component epoxy adhesive with high heat resistance and high peel strength

InactiveCN112300740AGood value for moneyLow costNon-macromolecular adhesive additivesModified epoxy resin adhesivesPolymer sciencePolyamide

The invention discloses a room-temperature-cured bi-component epoxy adhesive with high heat resistance and high peel strength. The room-temperature-cured bi-component epoxy adhesive comprises a component A and a component B, wherein the component A is bisphenol A epoxy resin, self-made acrylic acid modified epoxy resin, core-shell toughening particles, a reactive diluent and a silane coupling agent, the component B is prepared from polyamide, an accelerator and a filler. The room-temperature cured double-component epoxy adhesive with high heat resistance and high peel strength is operated for40-50 minutes at the temperature of 25 DEG C, has better bonding force on the surfaces of various metal substrates after being cured, and is generally used for various sandwich structure plates, the roller peel strength is higher than 60N. mm / mm, and the plane tensile strength is higher than 5MPa. In addition, the epoxy adhesive has good heat resistance and aging resistance, still has good performance under the condition of 80 DEG C, and after a specific aging test, the strength attenuation is still within a required range. Meanwhile, compared with similar products, the epoxy adhesive is relatively low in overall cost, has very high cost performance and has relatively strong competitiveness in the market of sandwich structure plates.

Owner:上海汉司实业有限公司

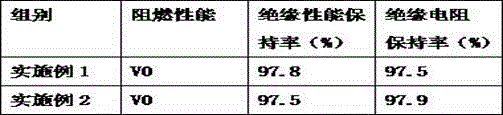

Electric power engineering construction tool box and preparation method thereof

The invention belongs to the field of electric equipment and discloses an electric power engineering construction tool box.The box comprises a box body.The box is characterized by being prepared through the method comprising the steps of 1, ball milling; 2, smashing and grinding; 3, resin modification; 4, calcination and mixing; 5, stirring, fusion and injection molding.The tool box is prepared from high-performance plastic materials, and has the better insulation and flame retardant performance, the excellent mechanical performance, corrosion resistance and high temperature resistance.

Owner:JUNAN POWER SUPPLY CO OF STATE GRID SHANDONG ELECTRIC POWER CO +1

Production method of anti-aging PVC board

PendingCN112226010AImprove heat and aging resistanceReduce the effects of agingPolymer scienceFoaming agent

The invention discloses a production method of an anti-aging PVC board. The production method is characterized by comprising the following steps: (1) raw material adding; (2) high-speed hot mixing; (3) low-speed cold mixing; (4) twin-screw extrusion; (5) cooling and shaping; (6) traction; (7) cutting; and (8) inspecting and packaging. According to the invention, a main material PVC resin, a reclaimed material and an auxiliary material heat stabilizer, a processing modifier, a foaming regulator, a foaming agent, an impact modifier, a filler, a lubricant, a plasticizer, a hindered amine light stabilizer and an ultraviolet light absorber are used as production raw materials of the PVC board according to specific mass percentages, wherein the hindered amine light stabilizer simultaneously improves the heat resistance and aging resistance of the PVC board in the production and use processes, the ultraviolet absorber improves the ultraviolet resistance of the PVC board, and the aging effectof ultraviolet rays on the PVC board is slowed down.

Owner:HAINING OUPAI IND & TRADE CO LTD

Focusing ultrasonic energy converter for weight loosing

ActiveCN101766869BImprove efficiencyUtilize the effective emission areaUltrasound therapyEpoxyElectricity

The invention relates to a focusing ultrasonic energy converter for weight loosing. A self-focusing ceramic sheet of the ultrasonic energy converter presents the shape of a spherical ring with a hole in the middle, an outer ring is fixed by epoxy resin in an embedding manner through mould pressing, and an inner ring is fixed by a hollow copper stud and an epoxy resin nut in a screwing manner. A shunting tee joint, a hollow stud and a shunting pipe form a specific circulating water system. The piezoelectric ceramic sheet, an electrode slice and a rear cover are compacted and fixed by the nut and the hollow stud so as to form a crimping power supply mode. Compared with a planar ceramic energy converter using an acoustic lens, the focusing ultrasonic energy converter that adopts the self-focusing method of the ring-shaped spherical surface has the characteristics of small focusing field and high energy. The application of the installing method of the hollow stud ensures the degassing water circulation when the energy converter is in working. Moreover, the structure of the energy converter is simple, and the installing and using are convenient.

Owner:BEIJING ANHEJIALIER TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com