Nano-composite material as well as preparation method and application thereof

A nano-composite material and nano-modification technology, applied in the field of nano-composite materials and their preparation, can solve the problems of general heat resistance and aging resistance, poor mechanical properties, etc., achieve excellent performance, improve mechanical properties, and good dispersion effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

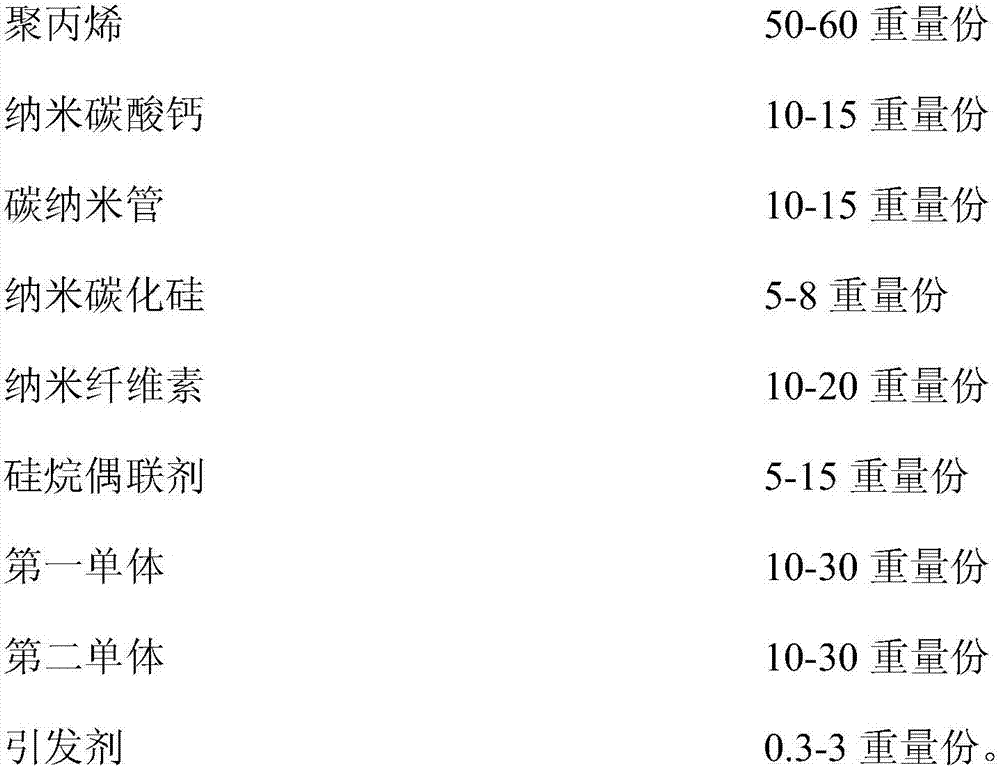

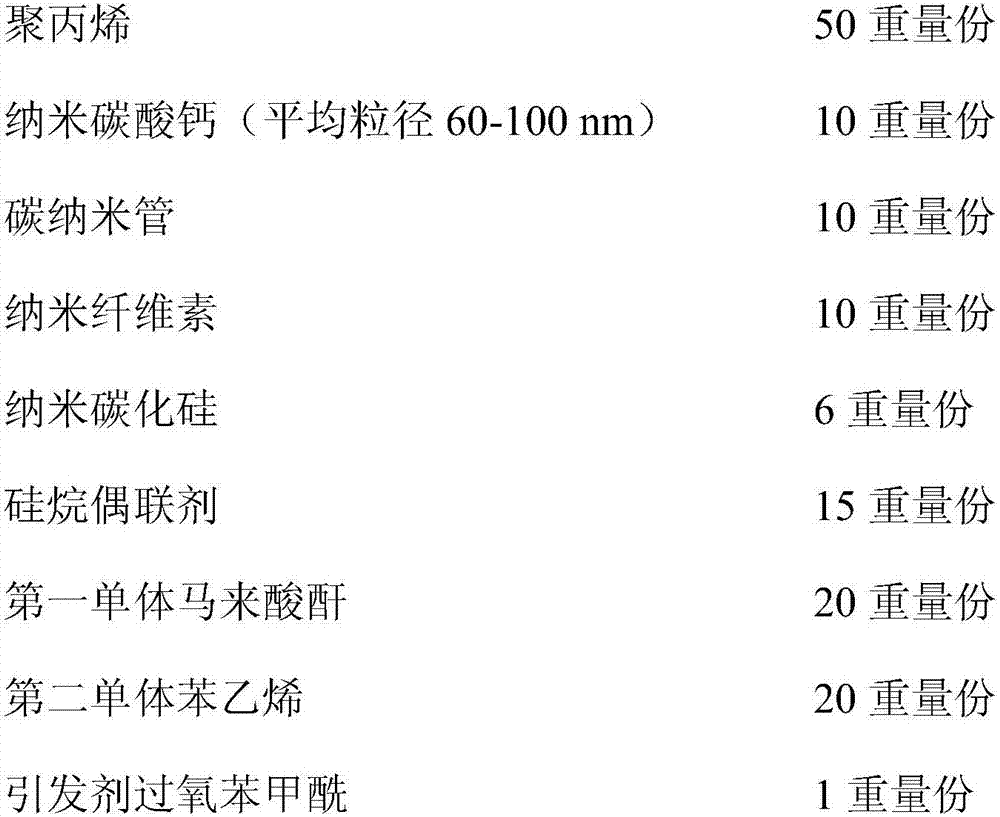

[0040] In this embodiment, the nanocomposite is prepared from nano-modified masterbatch and polypropylene, the mass ratio of nano-modified masterbatch to polypropylene is 4:9, and the nano-modified masterbatch is prepared from The following components by weight were prepared:

[0041]

[0042] The preparation method is as follows:

[0043] (1) Under the protection of nitrogen, polypropylene, nano-calcium carbonate, nano-cellulose, nano-silicon carbide, silane coupling agent, first monomer, second monomer and initiator were swollen at 25°C for 10min, and then at 100 Stir and react at ℃ for 0.5 hours, and dry the product to obtain a nano-modified masterbatch;

[0044] (2) Mix the nano-modified masterbatch and polypropylene evenly, and knead in a twin-screw extruder. The preheating temperature in the screw region of the twin-screw extruder is 300° C., and the screw speed is 400r / min, to obtain The nanocomposite.

Embodiment 2

[0046] In this embodiment, the nanocomposite material is prepared from nano-modified masterbatch and polypropylene, the mass ratio of nano-modified masterbatch to polypropylene is 4.8:10, and the nano-modified masterbatch is made of The following components by weight were prepared:

[0047]

[0048]

[0049] The preparation method is as follows:

[0050] (1) Under the protection of nitrogen, polypropylene, nano-calcium carbonate, nano-cellulose, nano-silicon carbide, silane coupling agent, first monomer, second monomer and initiator were swollen at 20°C for 15min, and then at 80 Stir and react at ℃ for 5 hours, and dry the product to obtain a nano-modified masterbatch;

[0051] (2) Mix the nano-modified masterbatch and polypropylene evenly, and knead in a twin-screw extruder, the preheating temperature of the screw area of the twin-screw extruder is 200°C, and the screw speed is 300r / min, to obtain The nanocomposite.

Embodiment 3

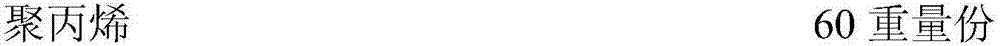

[0053] In this embodiment, the nanocomposite is prepared from nano-modified masterbatch and polypropylene, the mass ratio of nano-modified masterbatch to polypropylene is 5:9, and the nano-modified masterbatch is prepared from The following components by weight were prepared:

[0054]

[0055]

[0056] The preparation method is as follows:

[0057] (1) Under the protection of nitrogen, polypropylene, nano-calcium carbonate, nano-cellulose, nano-silicon carbide, silane coupling agent, first monomer, second monomer and initiator were swelled at 10°C for 20min, and then at 90 Stir and react at ℃ for 3 hours, and dry the product to obtain a nano-modified masterbatch;

[0058] (2) Mix the nano-modified masterbatch and polypropylene evenly, and knead in a twin-screw extruder. The preheating temperature in the screw region of the twin-screw extruder is 250° C., and the screw speed is 250r / min, to obtain The nanocomposite.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Heat distortion temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com