Environment-friendly solvent universal glue and preparation method thereof

An environmentally friendly solvent and universal adhesive technology, applied in the direction of adhesive types, adhesives, rosin adhesives, etc., to achieve the effects of low cost, improved environmental protection index, and glue-saving construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

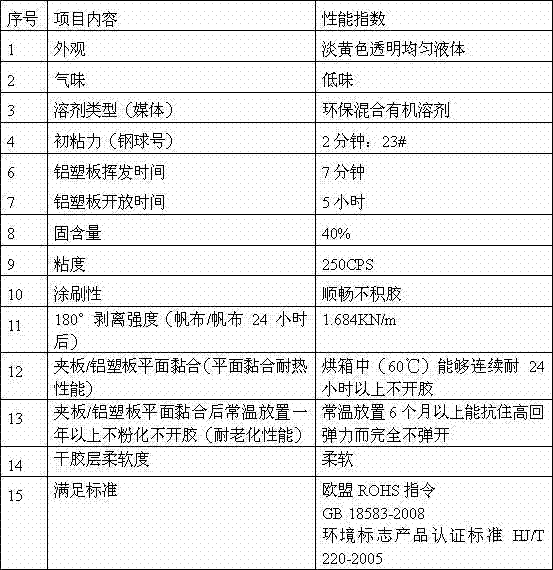

Embodiment A

[0043] 1. Preparation formula:

[0044] Raw material name Proportion

[0045] Star SBS thermoplastic styrene butadiene rubber 8.5

[0046] Linear SBS thermoplastic styrene butadiene rubber 2.5

[0047] Rosin 6.8

[0048] Hydrogenated rosin 9

[0049] C9 petroleum resin 4

[0050]Tackifying resin 6

[0051] 6# extraction solvent oil 15

[0052] Methylal 30

[0053] Methyl acetate 15

[0054] Wetting agent 0.2

[0055] Antioxidant 1.0

[0056] Antioxidant 0.5

[0057] Softener 1.5

[0058] Add up to 100 .

[0059] 2 . Preparation Process:

[0060] a. Put the measured 6# solvent oil, methylal, and methyl acetate into a container with a stirring device, start the stirring device, and disperse and stir for 10 minutes to become a uniform mixed solution;

[0061] b. On the premise of keeping stirring, measure and input SBS thermoplastic styrene-butadiene rubber (including star type and linear type), and disperse and stir the materials for 30 minutes;

[0062] c. Stir ...

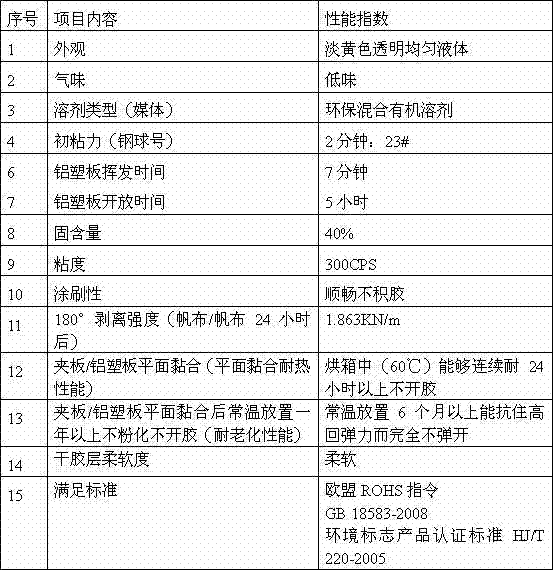

Embodiment B

[0078] 1. Preparation formula:

[0079] Raw material name Proportion

[0080] Star SBS thermoplastic styrene butadiene rubber 9

[0081] Linear SBS thermoplastic styrene butadiene rubber 2

[0082] Rosin 7

[0083] Hydrogenated rosin 9.5

[0084] C9 petroleum resin 4

[0085] Tackifying resin 6

[0086] 6# extraction solvent oil 15

[0087] Methylal 30

[0088] Methyl acetate 15

[0089] Wetting agent 0.2

[0090] Antiaging agent 0.8

[0091] Antioxidant 0.5

[0092] Softener 1.0

[0093] Add up to 100 .

[0094] 2 . Preparation Process:

[0095] a. Put the measured 6# solvent oil, methylal, and methyl acetate into a container with a stirring device, start the stirring device, and disperse and stir for 10 minutes to become a uniform mixed solution;

[0096] b. On the premise of keeping stirring, measure and input SBS thermoplastic styrene-butadiene rubber (including star type and linear type), and disperse and stir the materials for 30 minutes;

[0097] c. Stir...

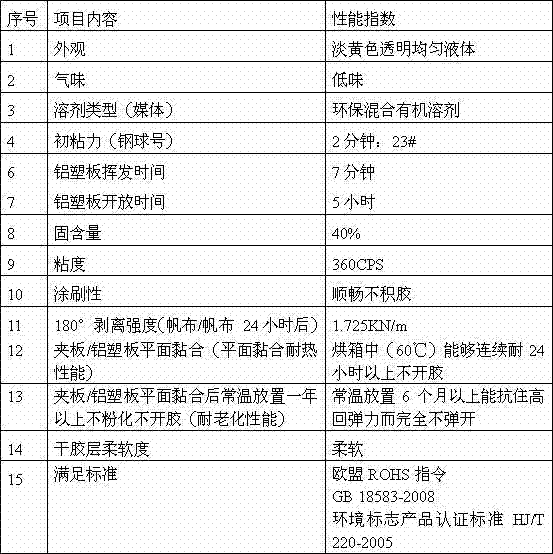

Embodiment C

[0113] 1. Preparation formula:

[0114] Raw material name Proportion

[0115] Star SBS thermoplastic styrene butadiene rubber 10

[0116] Linear SBS thermoplastic styrene butadiene rubber 1

[0117] Rosin 7.2

[0118] Hydrogenated rosin 10

[0119] C9 petroleum resin 4

[0120] Tackifying resin 6

[0121] 6# extraction solvent oil 15

[0122] Methylal 30

[0123] Methyl acetate 15

[0124] Wetting agent 0.2

[0125] Antiaging agent 0.6

[0126] Antioxidant 0.4

[0127] Softener 0.6

[0128] Add up to 100 .

[0129] 2. Preparation Process:

[0130] a. Put the measured 6# solvent oil, methylal, and methyl acetate into a container with a stirring device, start the stirring device, and disperse and stir for 10 minutes to become a uniform mixed solution;

[0131] b. On the premise of keeping stirring, measure and input SBS thermoplastic styrene-butadiene rubber (including star type and linear type), and disperse and stir the materials for 30 minutes;

[0132] c. Stir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com