Environment-friendly water-based chloroprene universal rubber and preparation method thereof

An all-purpose adhesive, water-based technology, used in chloroprene adhesives, adhesives, adhesive types, etc., can solve the problems of uncontrollable emissions, affecting people's living environment and physical health, and achieve low cost, solid high content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

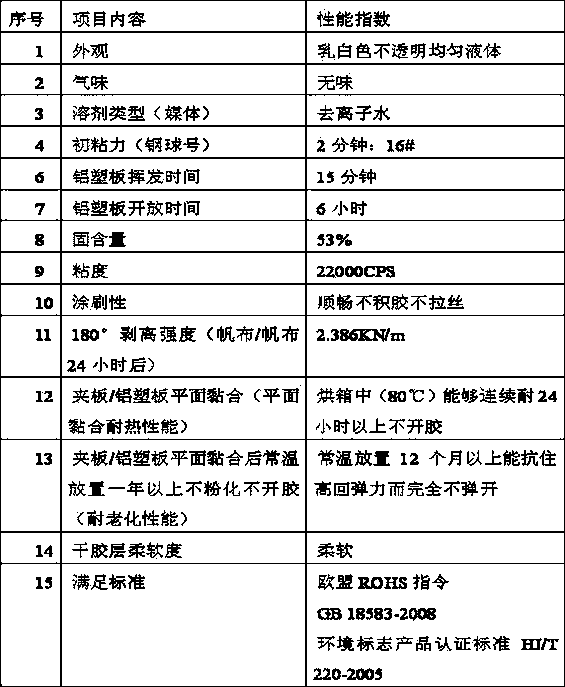

example A

[0049] 1. Preparation formula:

[0050] Raw material name Weight ratio (%)

[0051]Aqueous Rosin Glyceride Emulsion 6

[0052] Aqueous rosin pentaerythritol ester emulsion 5.4

[0053] Water-based petroleum resin emulsion 4

[0054] Aqueous Alkylphenolic Emulsion 10

[0055] Water-based acrylic emulsion (rigid) 13

[0056] Water-based EVA emulsion 9

[0057] Water-based anionic neoprene latex 36

[0058] Deionized water 6

[0059] Nano calcium carbonate concentrate 8

[0060] Water-based defoamer 0.2

[0061] Wetting and dispersing agent 0.3

[0062] Fumed silica 1.5

[0063] Water-based antiseptic and antifungal agent 0.3

[0064] Alkali-swellable thickener 0.3

[0065] Add up to 100 .

[0066] 2 . Preparation Process:

[0067] a. Put the measured water-based rosin glyceride emulsion, water-based rosin pentaerythritol ester emulsion, water-based petroleum resin emulsion, water-based alkylphenolic emulsion, water-based acrylic emulsion, and water-based EVA emuls...

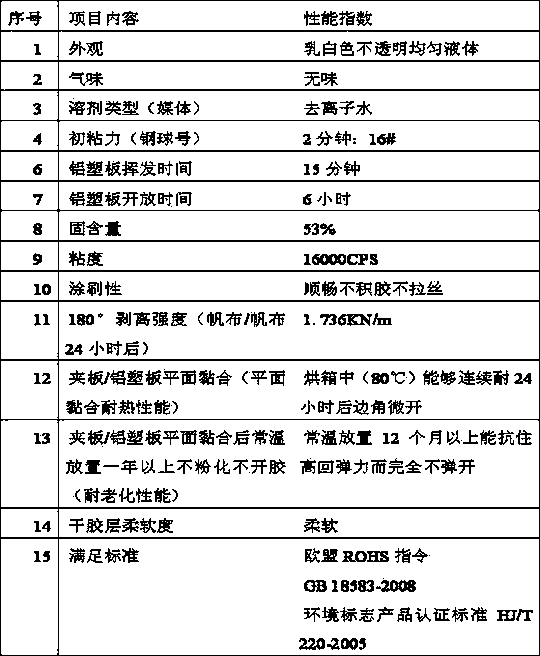

example B

[0086] 1. Preparation formula:

[0087] Raw material name Weight ratio (%)

[0088] Aqueous Rosin Glyceride Emulsion 5

[0089] Aqueous rosin pentaerythritol ester emulsion 5.4

[0090] Water-based petroleum resin emulsion 4

[0091] Aqueous Alkylphenolic Emulsion 8

[0092] Water-based acrylic emulsion (rigid) 11

[0093] Water-based EVA emulsion 8

[0094] Water-based anionic neoprene latex 42

[0095] Deionized water 6

[0096] Nano calcium carbonate concentrate 8

[0097] Water-based defoamer 0.3

[0098] Wetting and dispersing agent 0.2

[0099] Fumed silica 1.5

[0100] Water-based antiseptic and antifungal agent 0.2

[0101] Alkali-swellable thickener 0.4

[0102] Add up to 100 .

[0103] 2 . Preparation Process:

[0104] a. Put the measured water-based rosin glyceride emulsion, water-based rosin pentaerythritol ester emulsion, water-based petroleum resin emulsion, water-based alkylphenolic emulsion, water-based acrylic emulsion, and water-based EVA emuls...

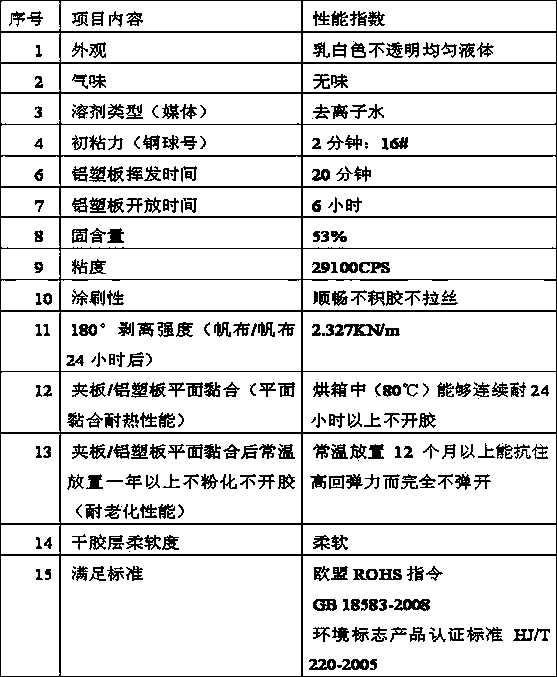

example C

[0123] 1. Preparation formula:

[0124] Raw material name Weight ratio (%)

[0125] Aqueous Rosin Glyceride Emulsion 5

[0126] Aqueous rosin pentaerythritol ester emulsion 4

[0127] Water-based petroleum resin emulsion 4

[0128] Aqueous Alkylphenolic Emulsion 7

[0129] Water-based acrylic emulsion (rigid) 10

[0130] Water-based EVA emulsion 7

[0131] Water-based anionic neoprene latex 47

[0132] Deionized water 6

[0133] Nano calcium carbonate concentrate 8

[0134] Water-based defoamer 0.3

[0135] Wetting and dispersing agent 0.1

[0136] Fumed silica 1

[0137] Water-based antiseptic and antifungal agent 0.1

[0138] Alkali-swellable thickener 0.5

[0139] Add up to 100 .

[0140] 2 . Preparation Process:

[0141] a. Put the measured water-based rosin glyceride emulsion, water-based rosin pentaerythritol ester emulsion, water-based petroleum resin emulsion, water-based alkylphenolic emulsion, water-based acrylic emulsion, and water-based EVA emulsion in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com