Patents

Literature

351 results about "Alkyl phenols" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Alkyl Phenols. Alkyl phenol ethoxylates are non-ionic surfactant components of industrial and domestic detergents, paints, cosmetics and pesticide formulations.

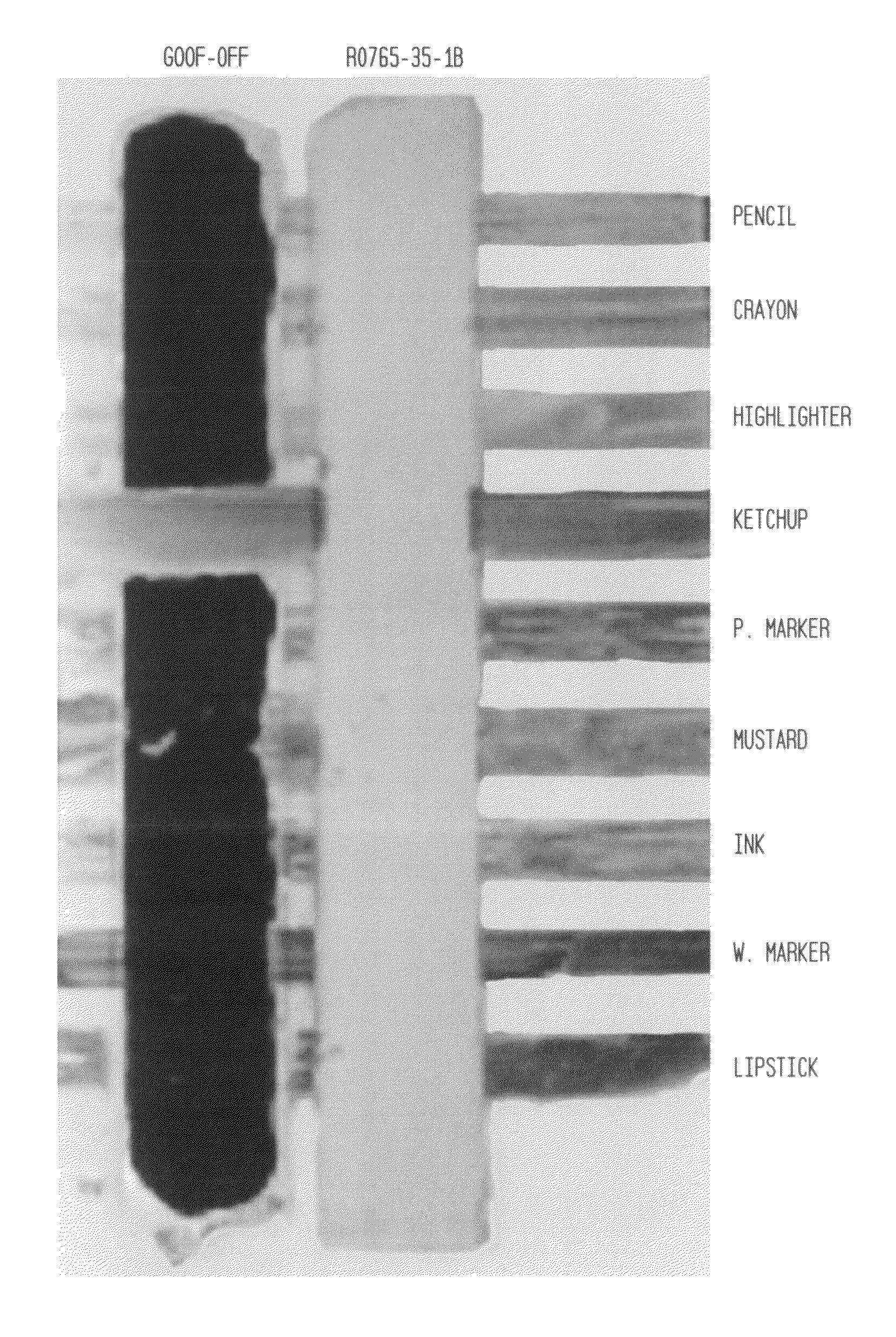

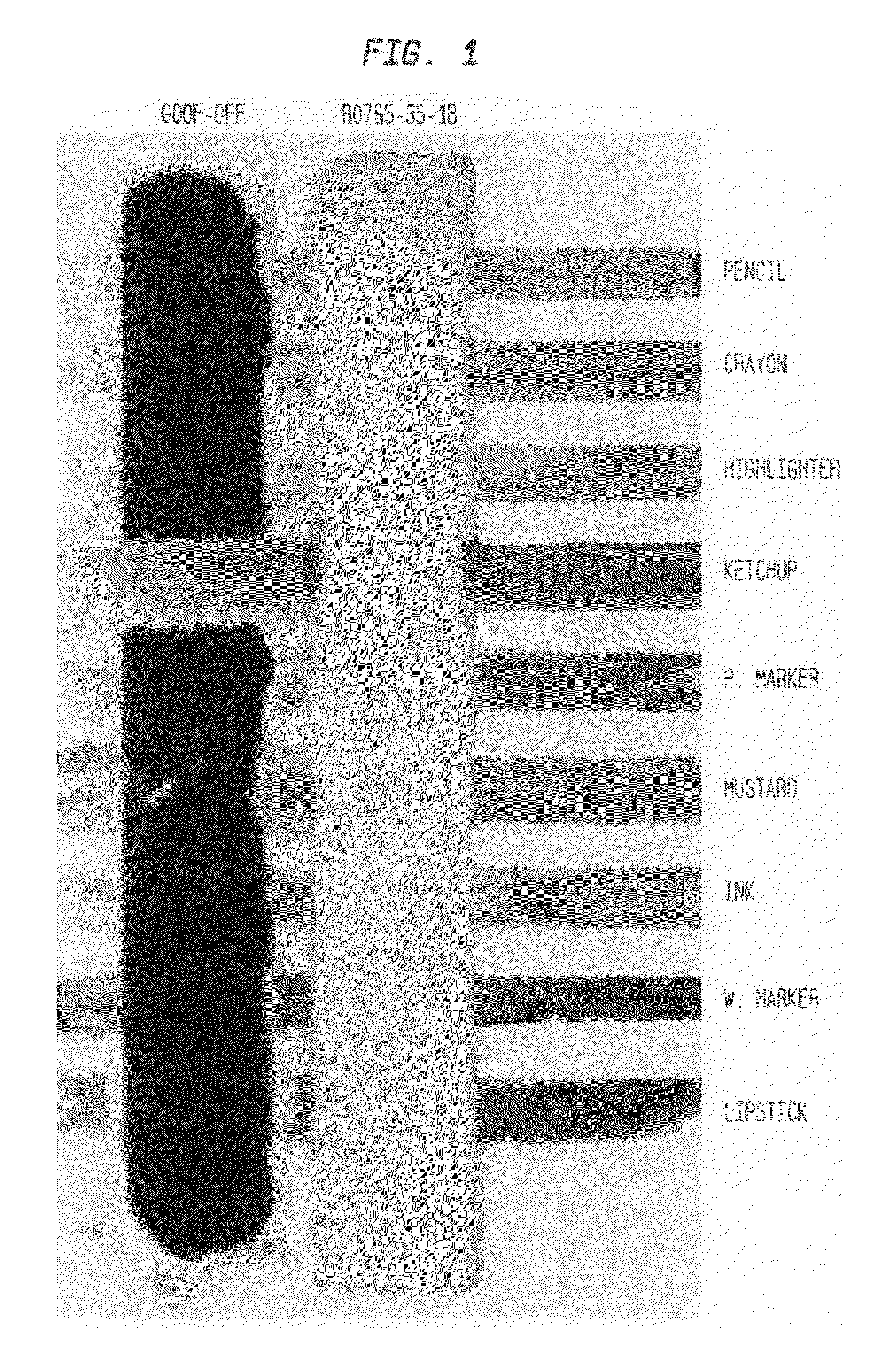

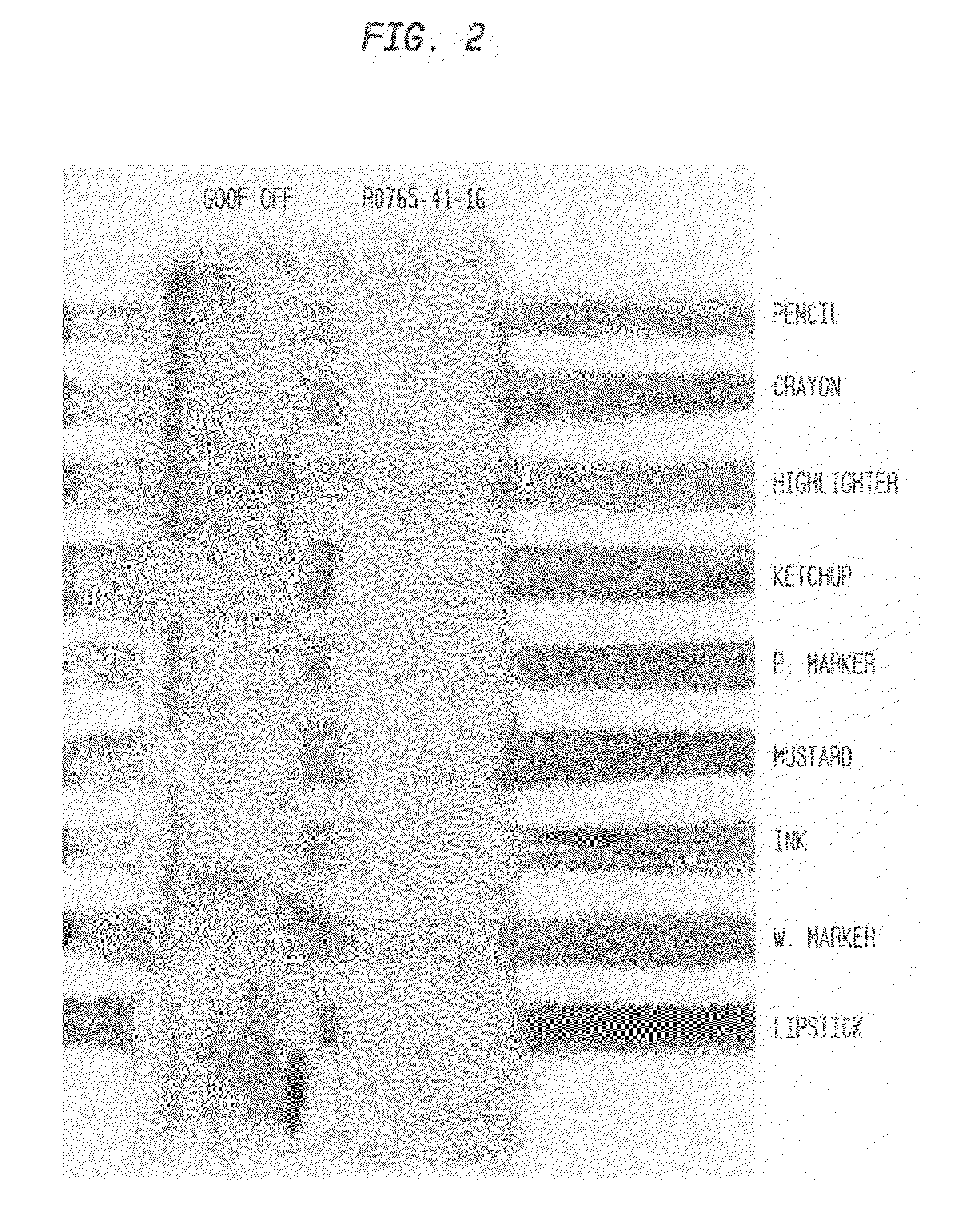

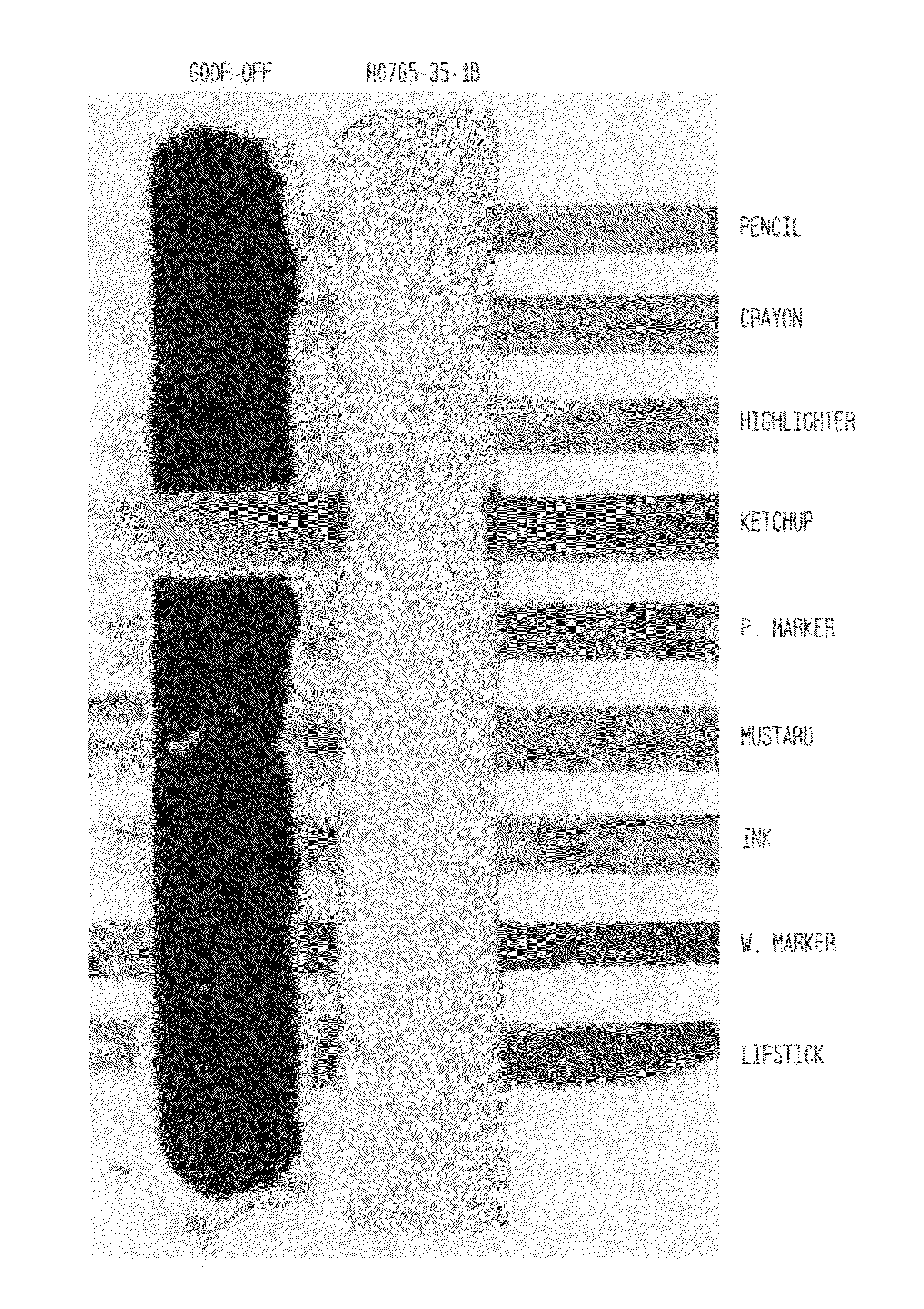

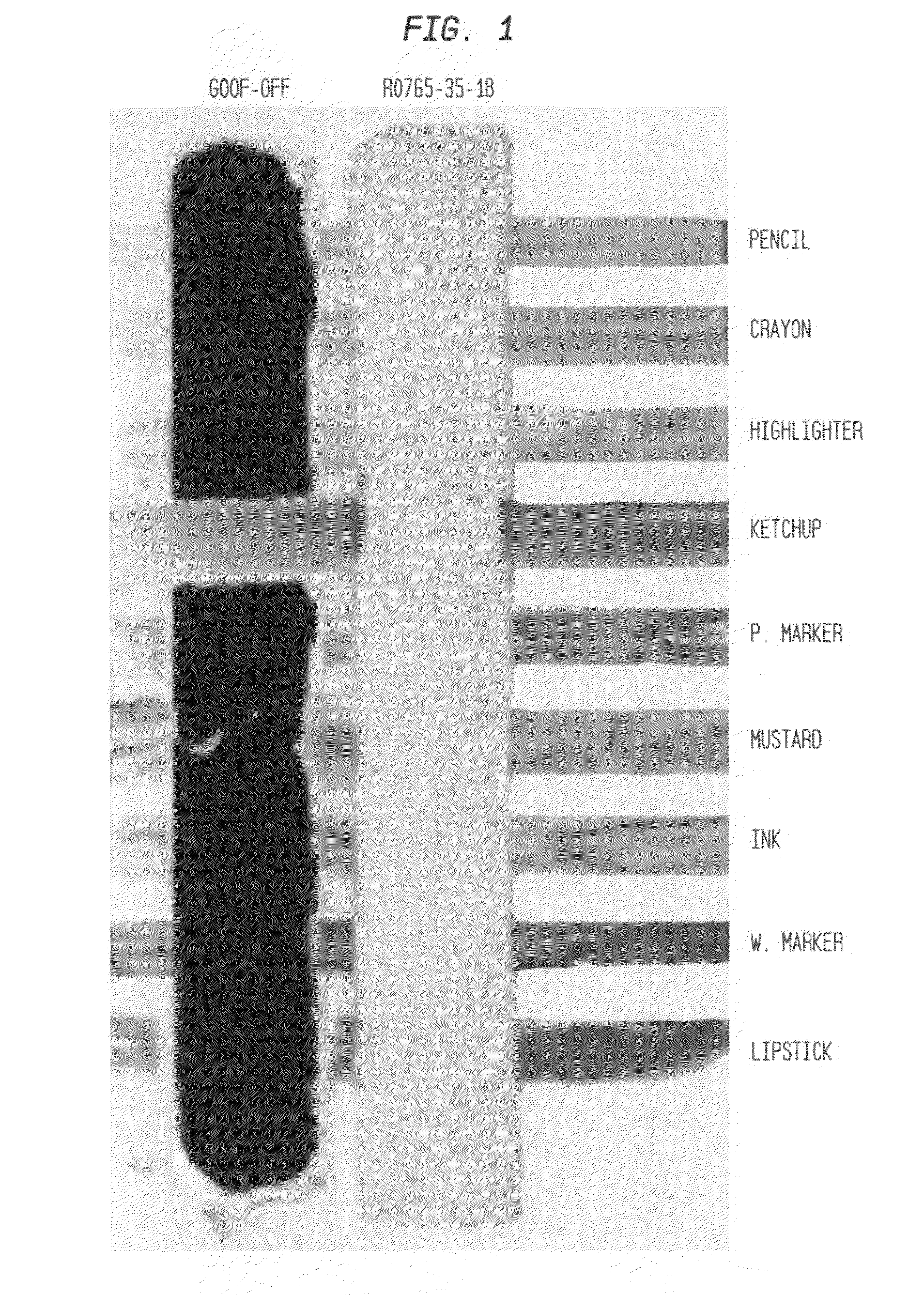

Cleaning compositions incorporating green solvents and methods for use

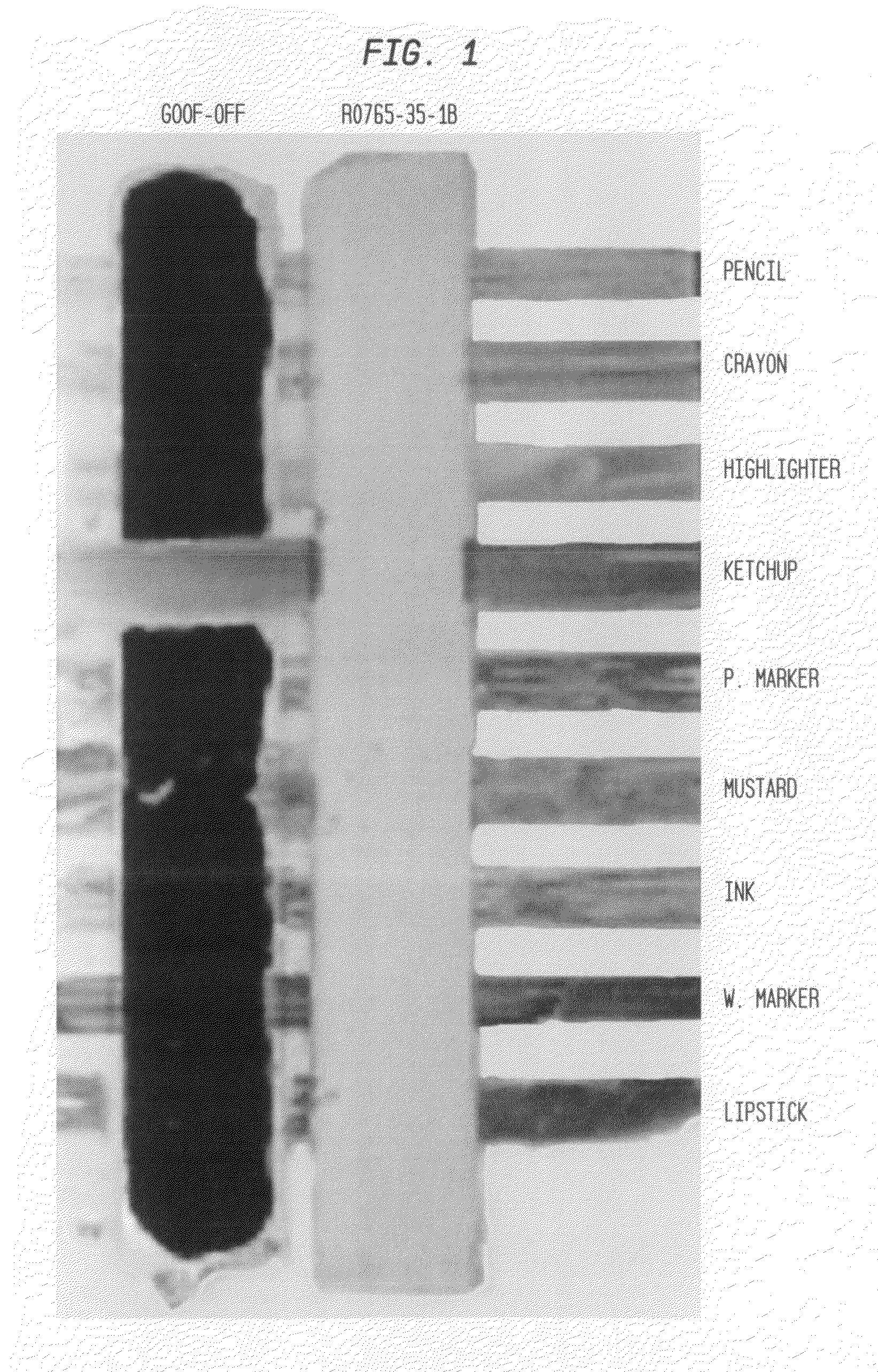

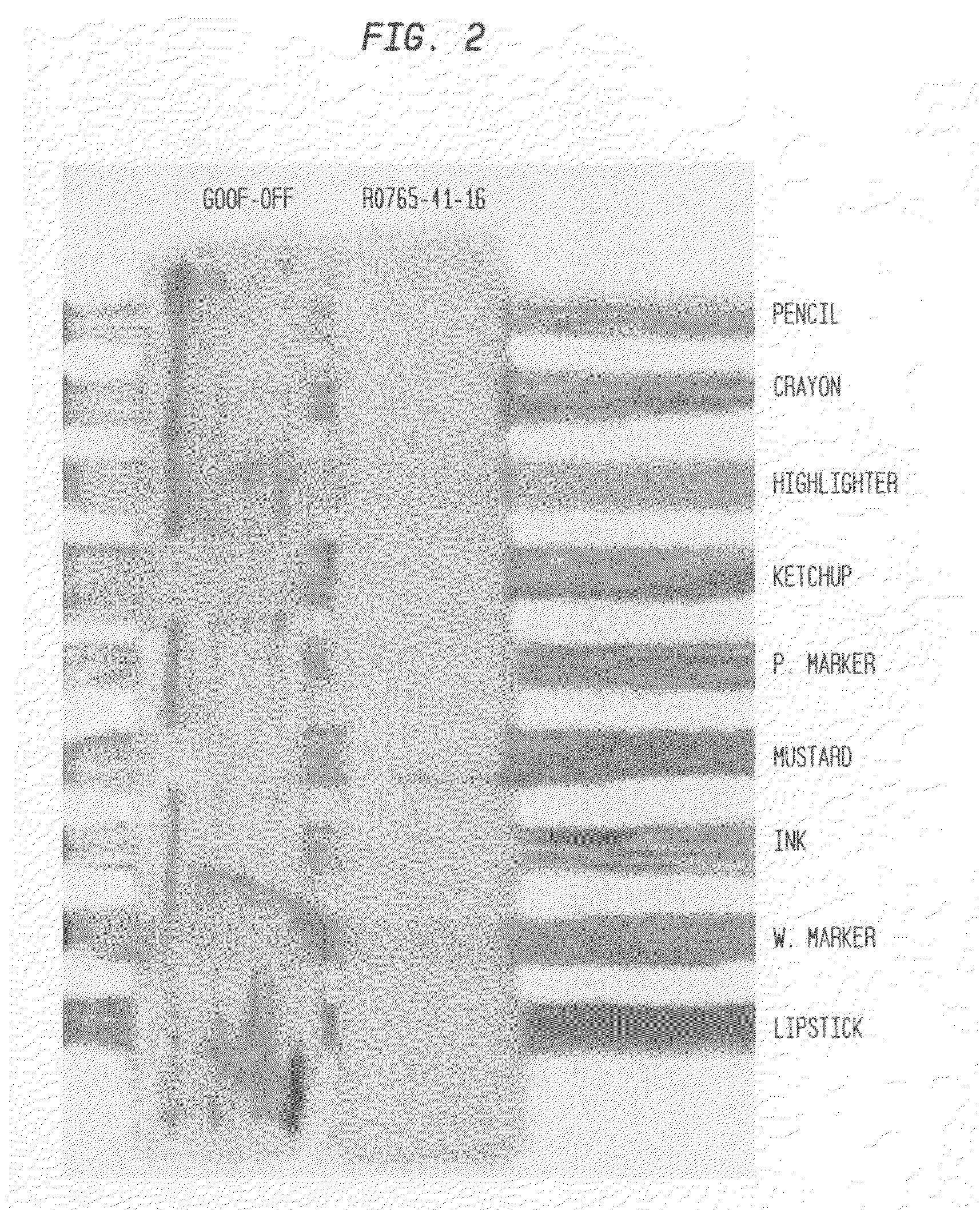

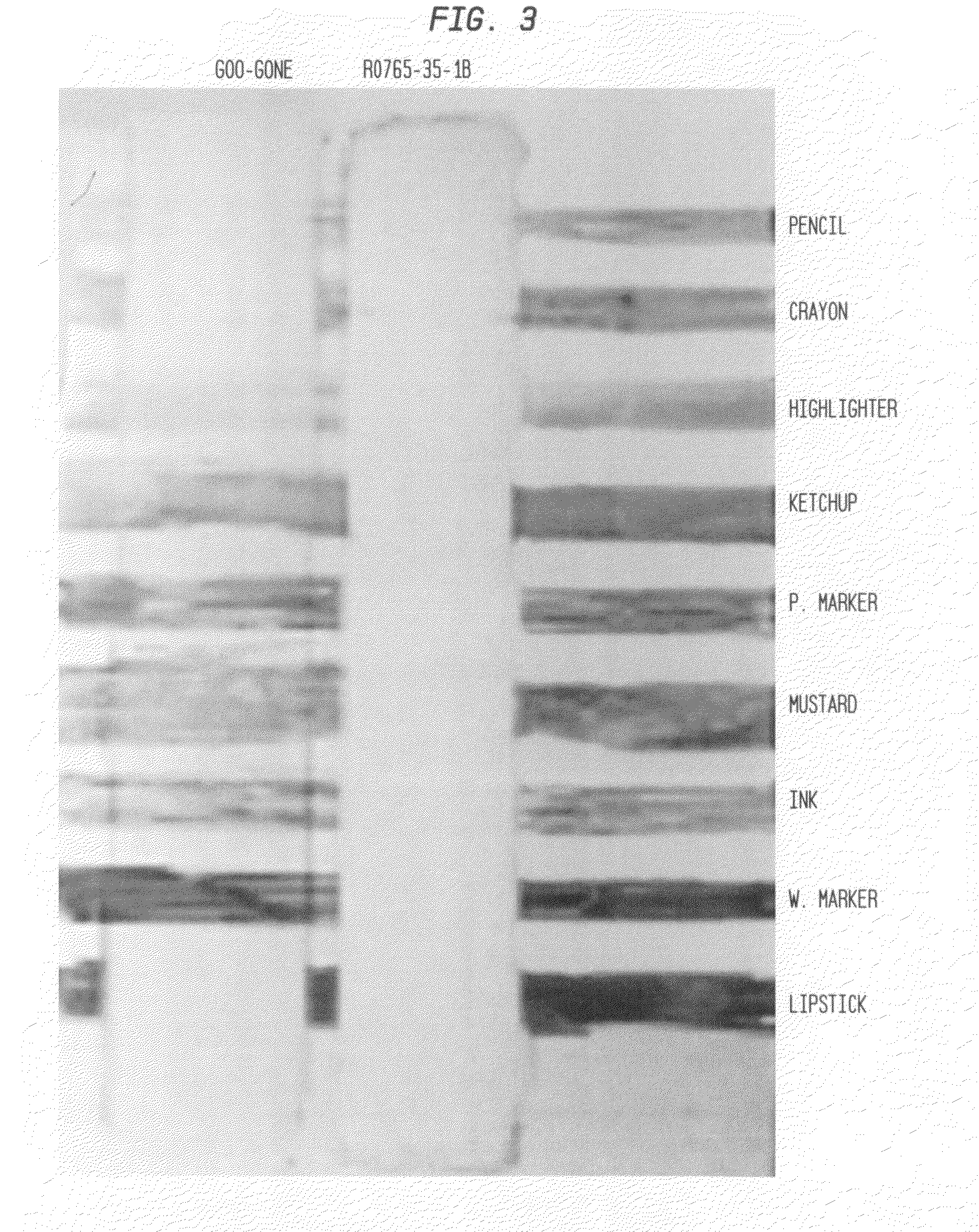

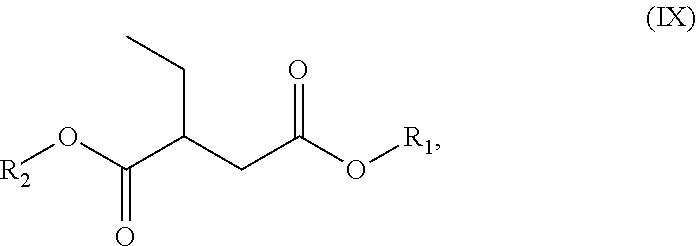

ActiveUS20090281012A1High flash pointLow vapor pressureOrganic detergent compounding agentsDetergent mixture composition preparationGlutaric acidActive agent

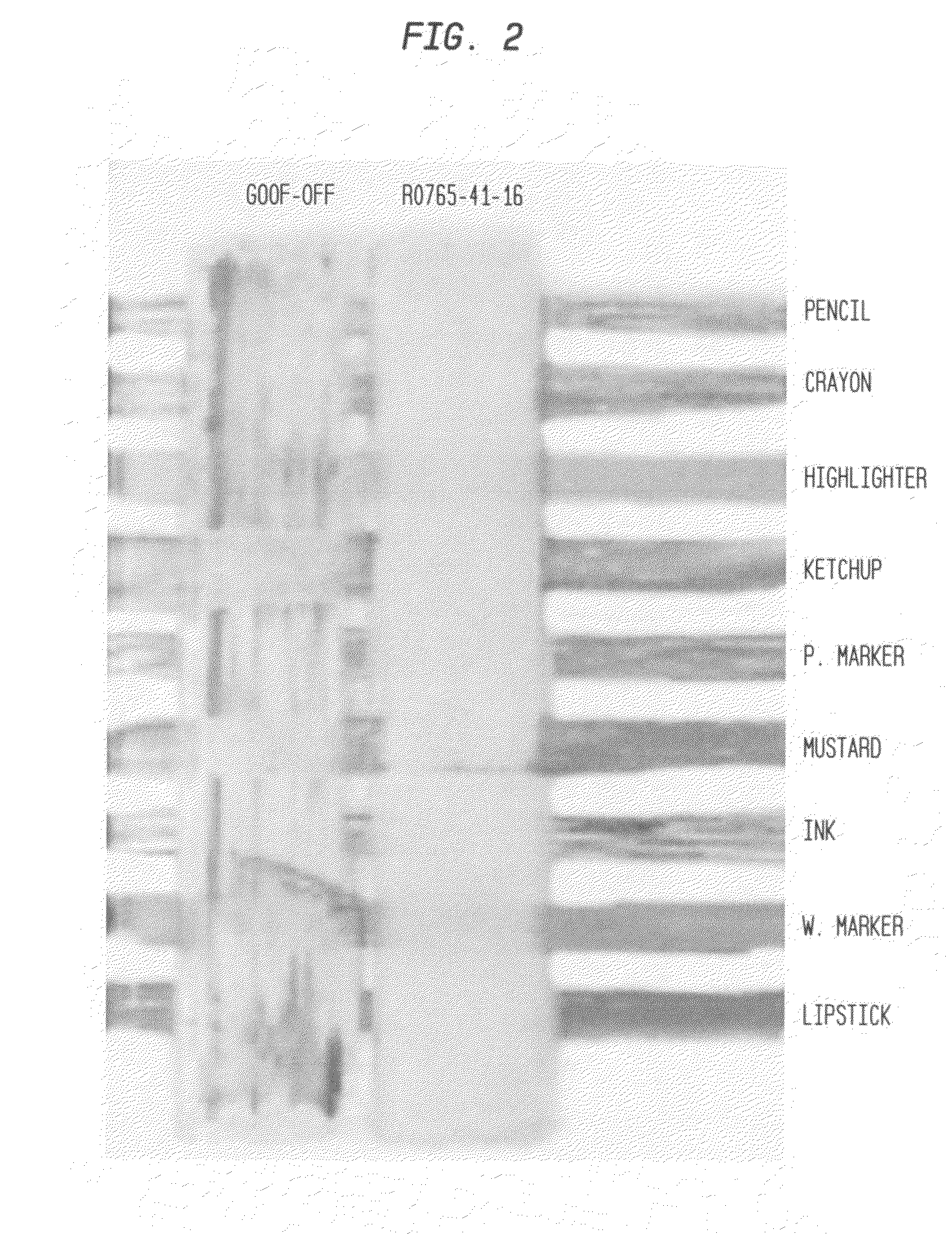

An environmentally-friendly cleaning composition for industrial and consumer applications comprising (a) a blend of dibasic esters, (b) one or more surfactants (c) and, optionally, (d) water or a solvent. The dibasic esters are be derived from a blend of adipic, glutaric, and succinic diacids, and, in one particular embodiment, the blend comprises dialkyl adipate, dialkyl methylglutarate and dialkyl ethylsuccinate, wherein the alkyl groups individually comprise a C1-C12 hydrocarbon group. The one or more surfactants are typically chosen from alcohol alkoxylate, an alkyl phenol ethoxylate, a terpene, a terpene alkoxylate or any derivates thereof. Optionally, additional components or additives including delaminates such as pinene and d-limonene, fragrances, whiteners, stabilizers, thickeners and the like can be added to the composition. The industrial or consumer application selected from the group consisting of a graffiti cleaner, a painted-substrate cleaner, an ink cleaner, a metal substrate cleaner, a plastic substrate cleaner, an environmentally friendly cleaner, a stain-spot cleaner, an industrial hand cleaner, a resin cleaner, a tar resin cleaner, a textile cleaner, a paint stripper and any combination thereof.

Owner:RHODIA OPERATIONS SAS

Use of eco-friendly microemulsions in oil cleaning applications

InactiveUS20130146545A1Easily biodegradablePoint becomes highSurface-active detergent compositionsTransportation and packagingDibasic esterPhenol

An environmentally-friendly cleaning composition for oil cleaning comprising (a) a blend of dibasic esters, (b) one or more surfactants (c) and, optionally, (d) water or a solvent. The dibasic esters are be derived from a blend of adipic, glutaric, and succinic diacids, and, in one particular embodiment, the blend comprises dialkyl adipate, dialkyl methylglutarate and dialkyl ethylsuccinate, wherein the alkyl groups individually comprise a C1-C12 hydrocarbon group. The one or more surfactants are typically chosen from alcohol alkoxylate, an alkyl phenol ethoxylate, a terpene, a terpene alkoxylate or any derivates thereof. Optionally, additional components or additives including delaminates such as pinene and d-limonene, fragrances, whiteners, stabilizers, thickeners and the like can be added to the composition.

Owner:RHODIA OPERATIONS SAS

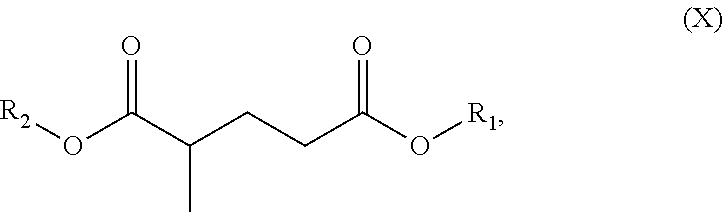

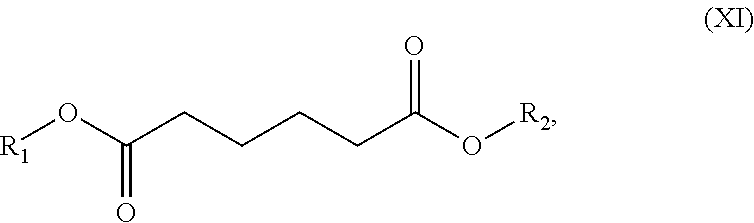

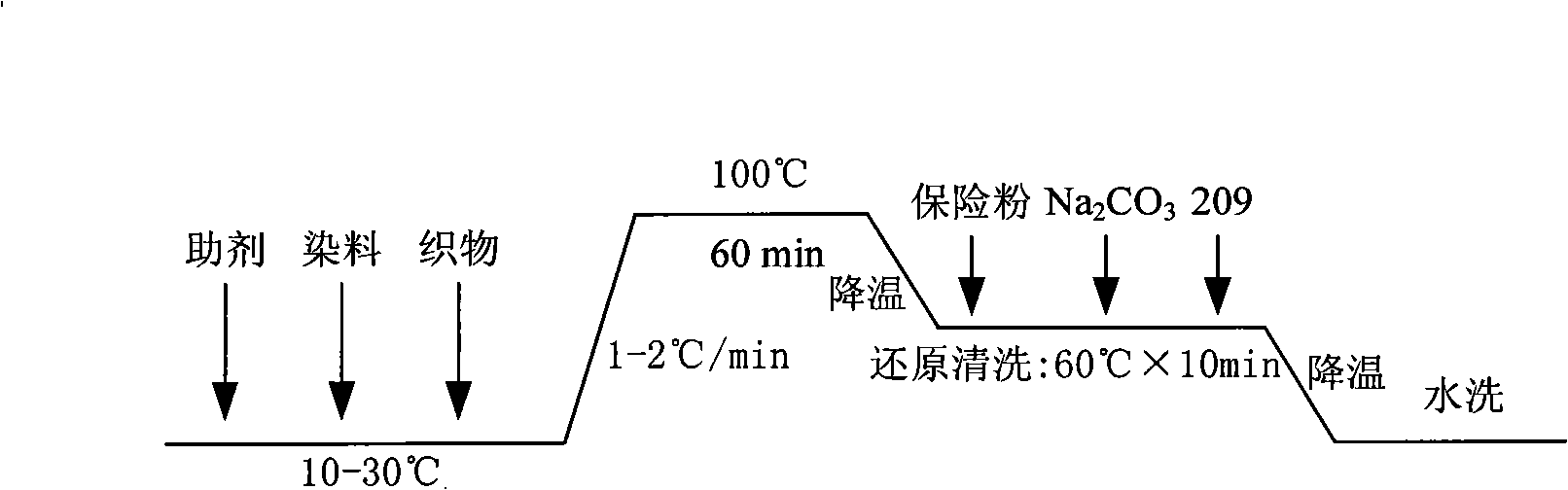

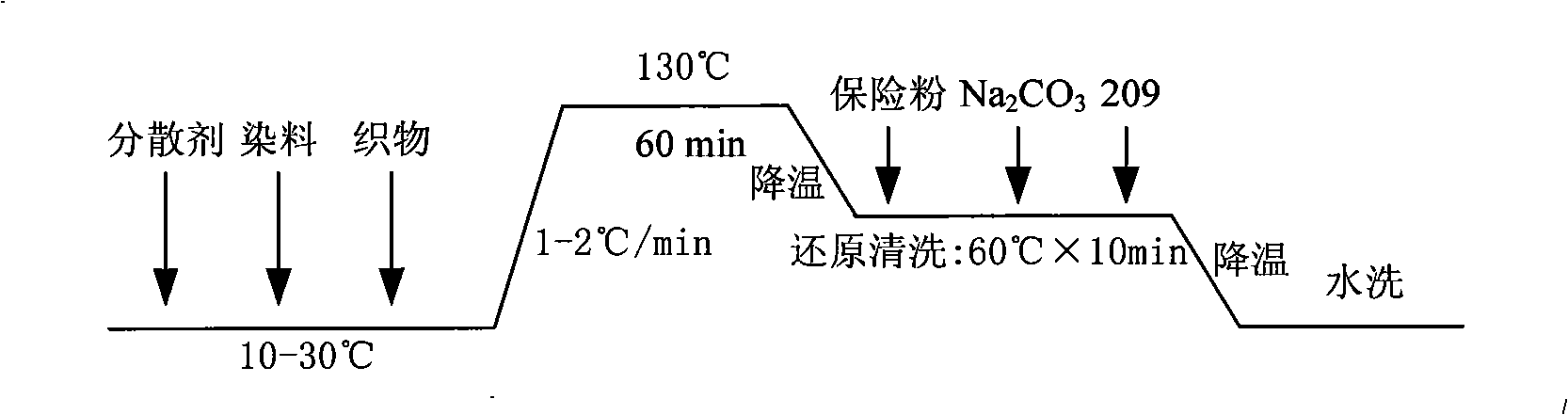

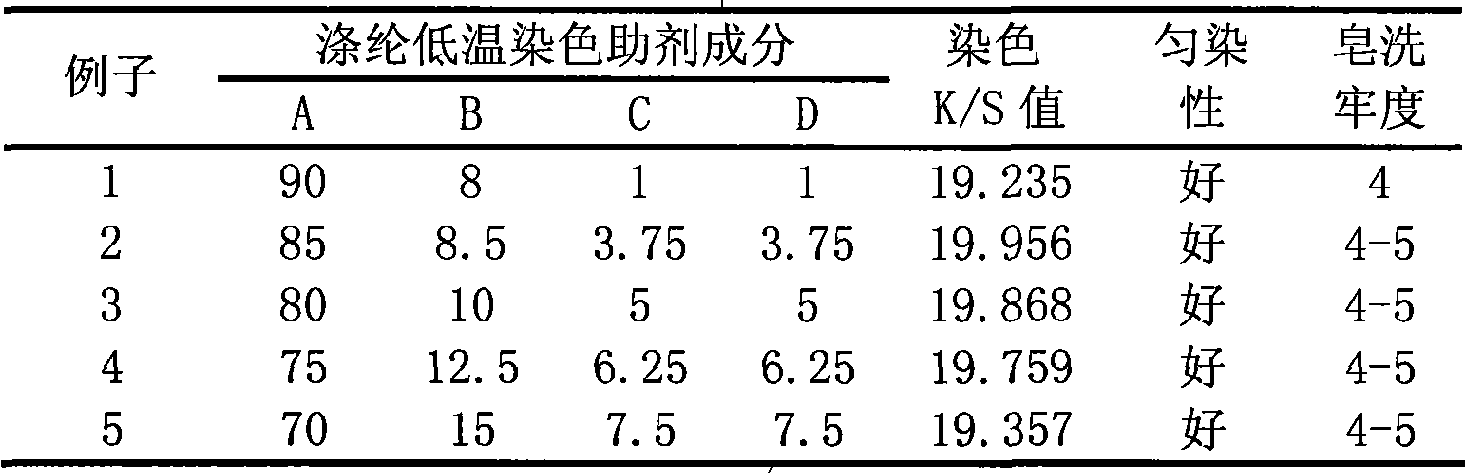

Environment-friendly type terylene low temperature dyeing assistant with alkyl phthalic imide as vector and preparation thereof

The invention discloses an environment-friendly terylen low-temperature dyeing auxiliary agent taking alkyl phthalimide as a carrier and a preparation method thereof. The compositions in percentage by weight of the dyeing auxiliary agent are: 70 to 90 percent of alkyl phthalimide compound, 8 to 15 percent of concentrated emulsion 8206, 1 to 7.5 percent of castor oil polyoxyethylene ether sulphonated matter and 1 to 7.5 percent of alkyl phenol polyoxyethylene ether, wherein the alkyl phthalimide is takes as the carrier; and the concentrated emulsion 8206, the castor oil polyoxyethylene ether sulphonated matter and the alkyl phenol polyoxyethylene ether are takes as an emulsifying agent. The environment-friendly terylen low-temperature dyeing auxiliary agent is used in low-temperature dyeing of terylen and terylen-containing textile fabrics; moreover, the dyeing auxiliary agent not only has the characteristics of nontoxicity, tastelessness, environmental protection and low cost, etc., but also has the advantages of high dye uptake, excellent level dyeing property, high dyeing fastness and wide application range, etc., thereby meeting the requirements of low-temperature dyeing production of terylen-containing textile fabrics.

Owner:ZHEJIANG SCI-TECH UNIV +1

Emulsions for lignocellulosic products, methods of their manufacture, improved lignocellulosic products and methods for their manufacuture

Emulsions are provided which are useful in imparting water-resistance to lignocellulosic products. In one embodiment, the emulsions contain a nonsaponifiable wax, a saponified wax, an alkyl phenol component, a dispersant / surfactant such as a salt of polynaphthalenesulfonic acid, and a carboxymethylcellulose. Such emulsions may be added to hot, even boiling, water without the emulsion separating or curdling. Various embodiments are stable for extended periods of time when stored at room temperature, do not require the addition of a preservative biocide to avoid contributing to biodegradation in a lignocellulosic product. The emulsions are pourable liquids at room temperature. Optionally, the emulsions may be added to lignocellulosic products with a preservative to inhibit the preservative from leaching out.

Owner:HEXION INC

Wax emulsions for gypsum products

Emulsions, useful for imparting water resistance to gypsum products are disclosed. The emulsions of the invention include at least one wax, an alkyl phenol and a hydrophyllic metallic salt, preferably magnesium sulfate. The emulsions of the invention do not require the addition of a starch compound and therefore exhibit enhanced stability even at higher solids content then compared to prior art emulsions.

Owner:MOMENTIVE SPECIALTY CHEMICALS

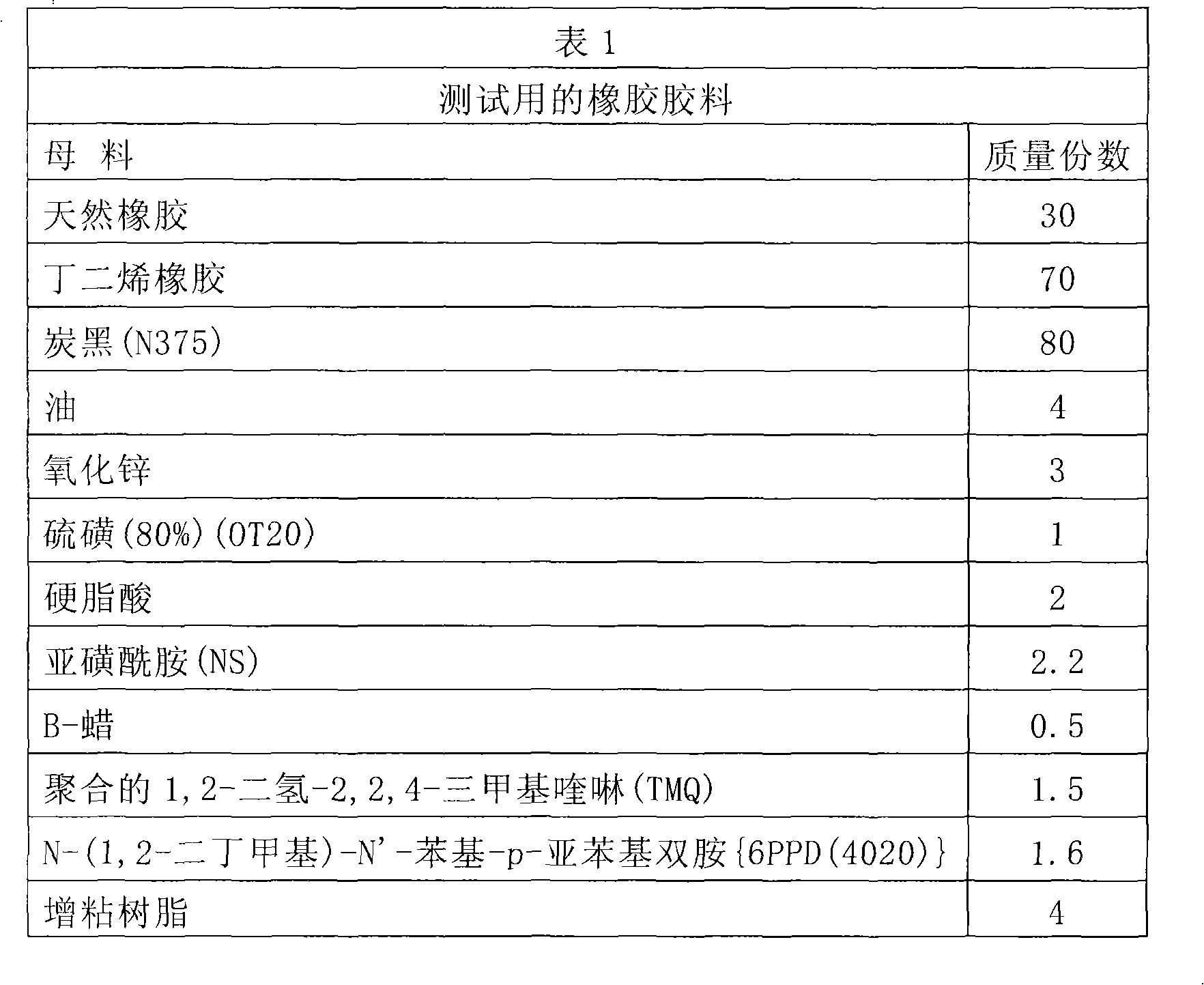

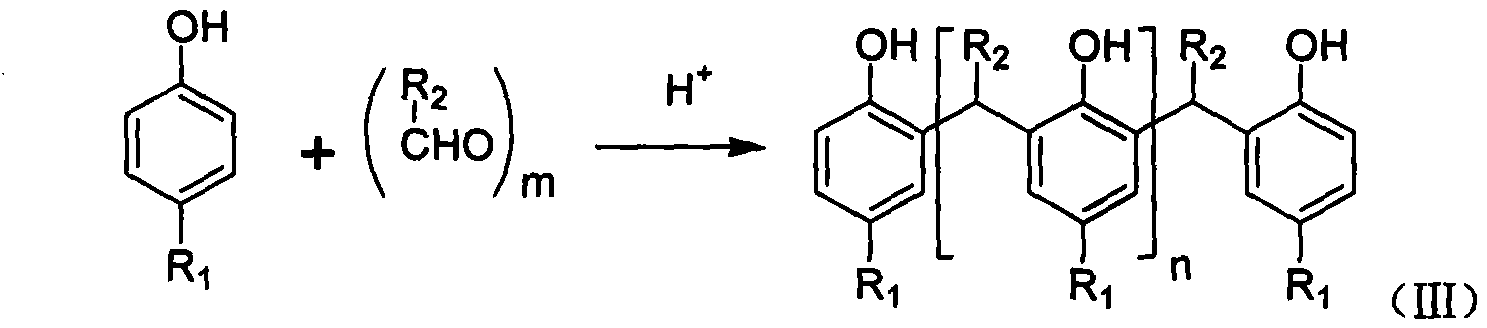

Improved process for producing alkylphenols thermoplastic resin

ActiveCN101338013AImprove the production processImproved economical production processSpecial tyresAlkylphenolReaction speed

The invention relates to an improved process for alkyl phenol-formaldehyde thermoplastic tackifying resin. Liquid formaldehyde and solid formaldehyde are added, while water generated by a condensation reaction is continuously distilled out. The reaction speed of the condensation reaction of alkyl phenol and the formaldehyde is reduced due to water in the system, so the production efficiency as well as the production output is improved.

Owner:SINO LEGEND CHINA CHEM

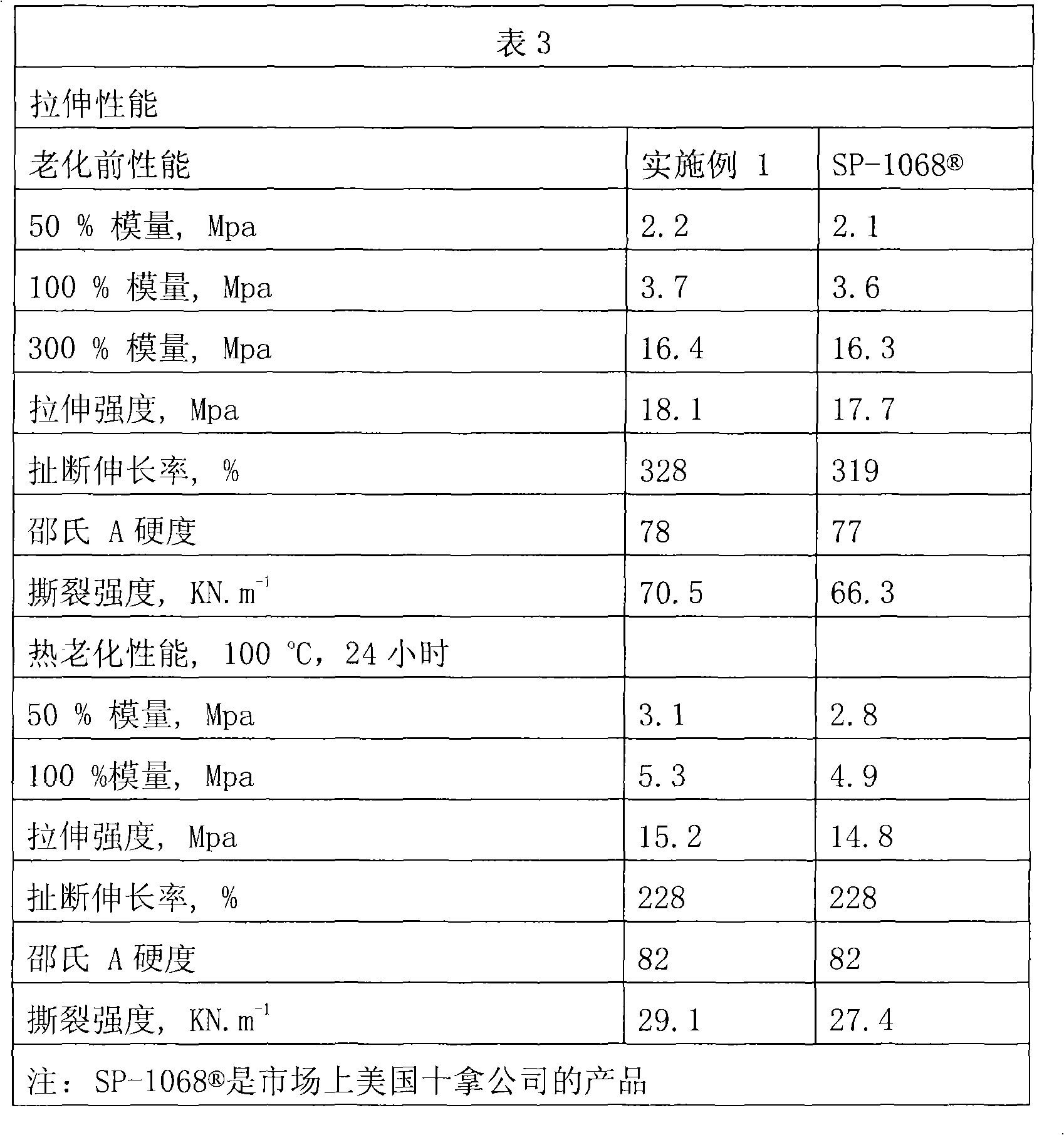

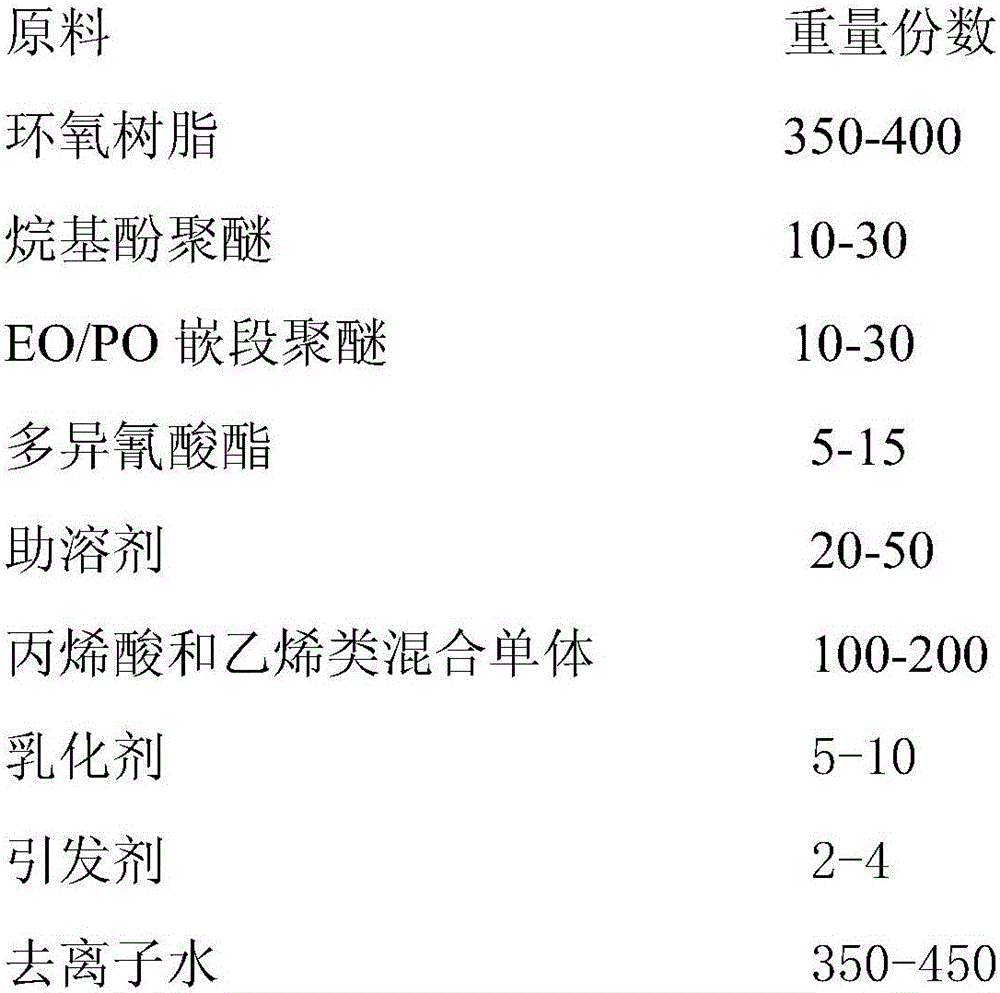

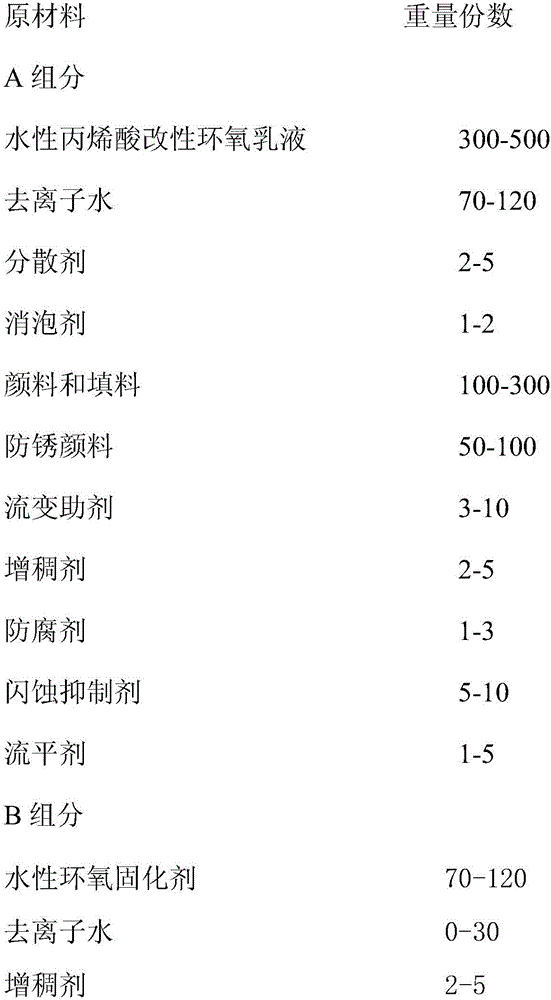

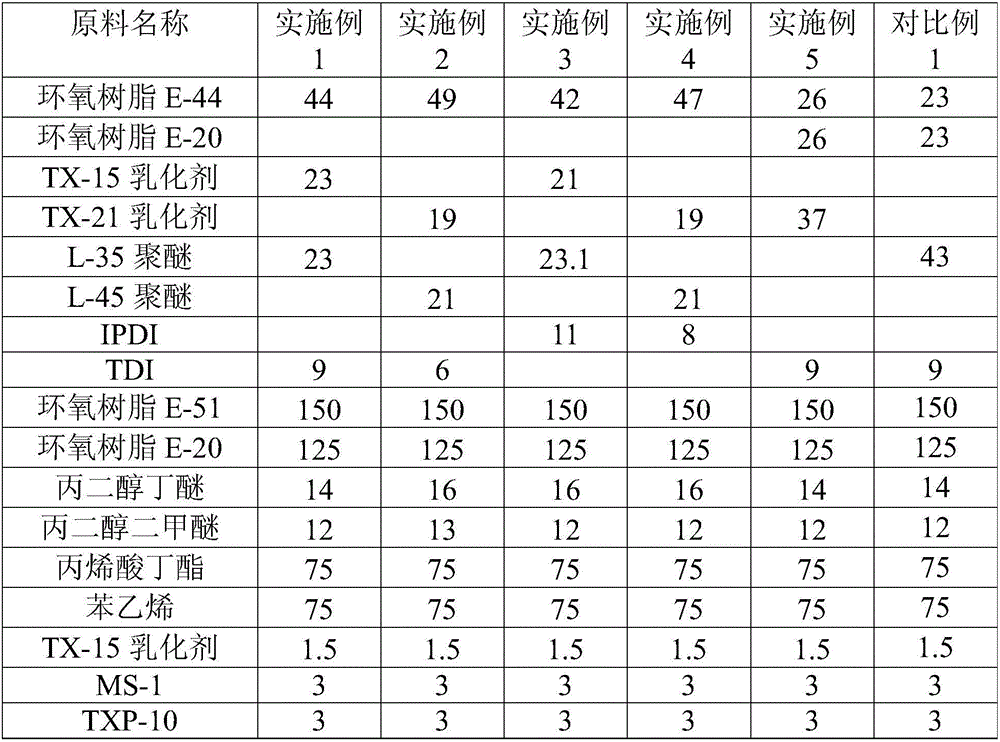

Waterborne acrylic acid modified epoxy emulsion and high-performance waterborne epoxy anticorrosive coating

The invention discloses a waterborne acrylic acid modified epoxy emulsion. Firstly, epoxy resin, polyisocyanates and alkyl phenol polyether react to prepare an epoxy polyether addition product, then the addition product is used as an emulsifying agent to be mixed with epoxy resin and a cosolvent, stirring and emulsification are performed to prepare an epoxy resin emulsion, an acrylic monomer pre-emulsifying solution prepared from an acrylic acid and vinyl mixed monomer, the emulsifying agent, initiator and deionized water is dropwise added into the emulsion, and acrylic acid-epoxy resin grafting hybridization emulsion polymerization is performed to obtain the waterborne acrylic acid modified epoxy emulsion. The invention further discloses a double-component waterborne epoxy anticorrosive coating obtained by using the emulsion as a main component and adding a pigment, a filler, various additives and the like. The VOC content is low and is reduced by 80% compared with the VOC content of solvent paint, the coating application property is good, a paint film is quick to dry, coating interval time is short, the mechanical properties and anticorrosive performance of the paint film can reach the level of solvent type epoxy anticorrosive paint, and the coating is suitable for anticorrosive coating of ships, container, railway vehicles and steel components of auto spare parts.

Owner:MARINE CHEM RES INST

Agent for cleaning, lustering and protecting surface easy to eliminate and method for producing the same

ActiveCN101220245AWill not burn and explodeNo smellPolishing compositionsParaffin waxSurface cleaning

The invention relates to an easy-erased glazing and protective agent and a preparation method. The invention takes silicon oil, insect wax, paraffine, carnauba wax, stearic acid, trolamine, alkyl phenol polyoxyethylene ether (4), 1.2-benzisothiazdin-3- ketone, essence and de-ionized water as raw materials. In production process, the insect wax, paraffine, carnauba wax and the stearic acid are added to knives barrier emulsified kettle and are heated until reaching from 85 to 88 DEG C; after being hot melted, the raw materials are stirred and then are added with triethanolamine, silicon oil, alkyl phenol polyoxyethylene ether (4) and essence sequentially and stirred evenly. In the process of continuous stirring, the de-ionized water which has a temperature of 85 to 90 DEG C and accounts for from one fifth to two-fifths of the total amount of water is dropped into the emulsified kettle slowly in 30 to 40 minutes, and normal-temperature water is added after phase inversion process of materiels is finished; another 10 minutes is needed for shearing and stirring until all the water are added into the emulsified kettle; the 1.2-benzisothiazdin-3- ketone is added and stirred evenly. At last a nylon screen with 200 meshes is used for filtering, thereby obtaining the easy-erased glazing and protective agent.

Owner:北京绿伞科技股份有限公司

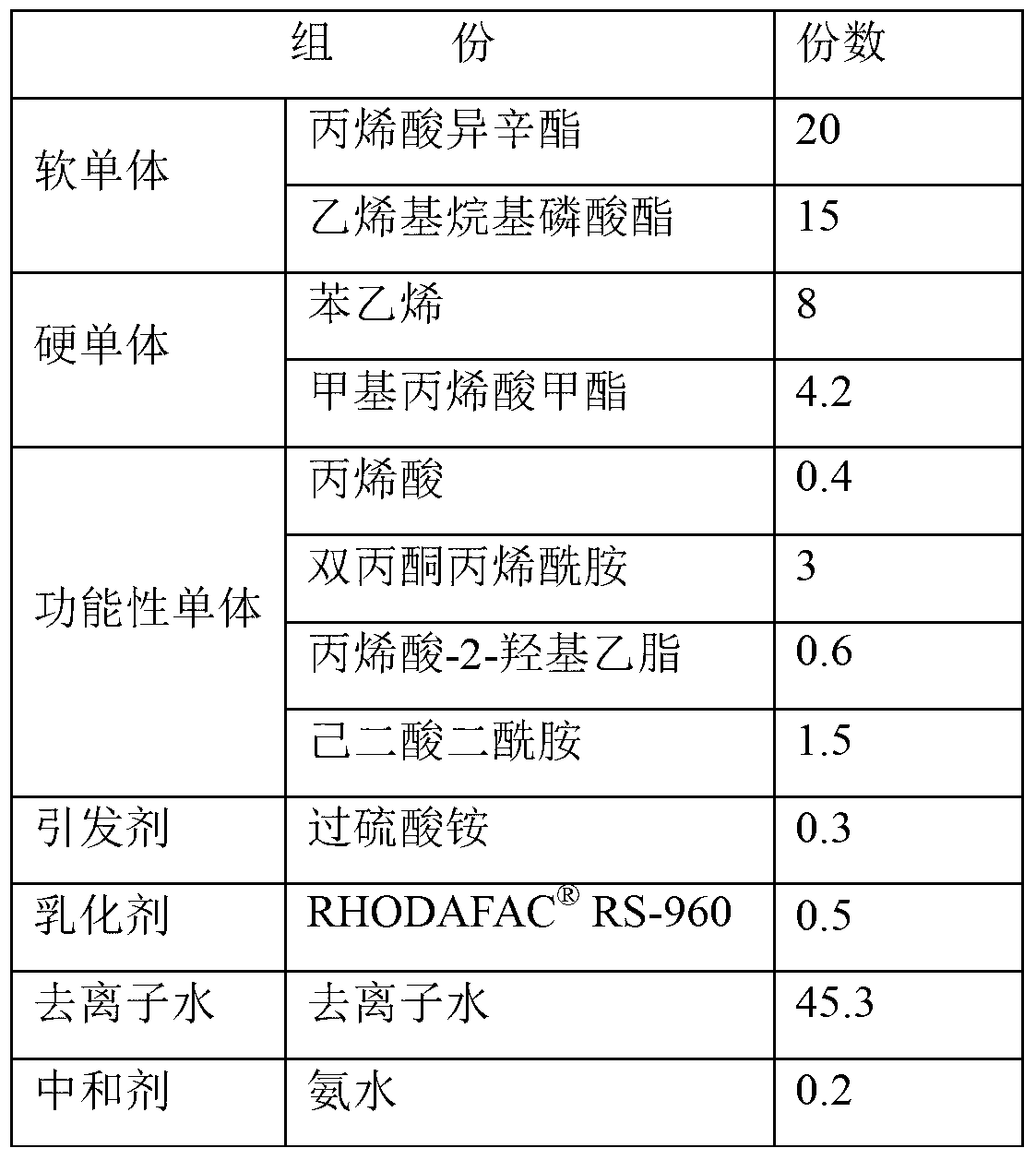

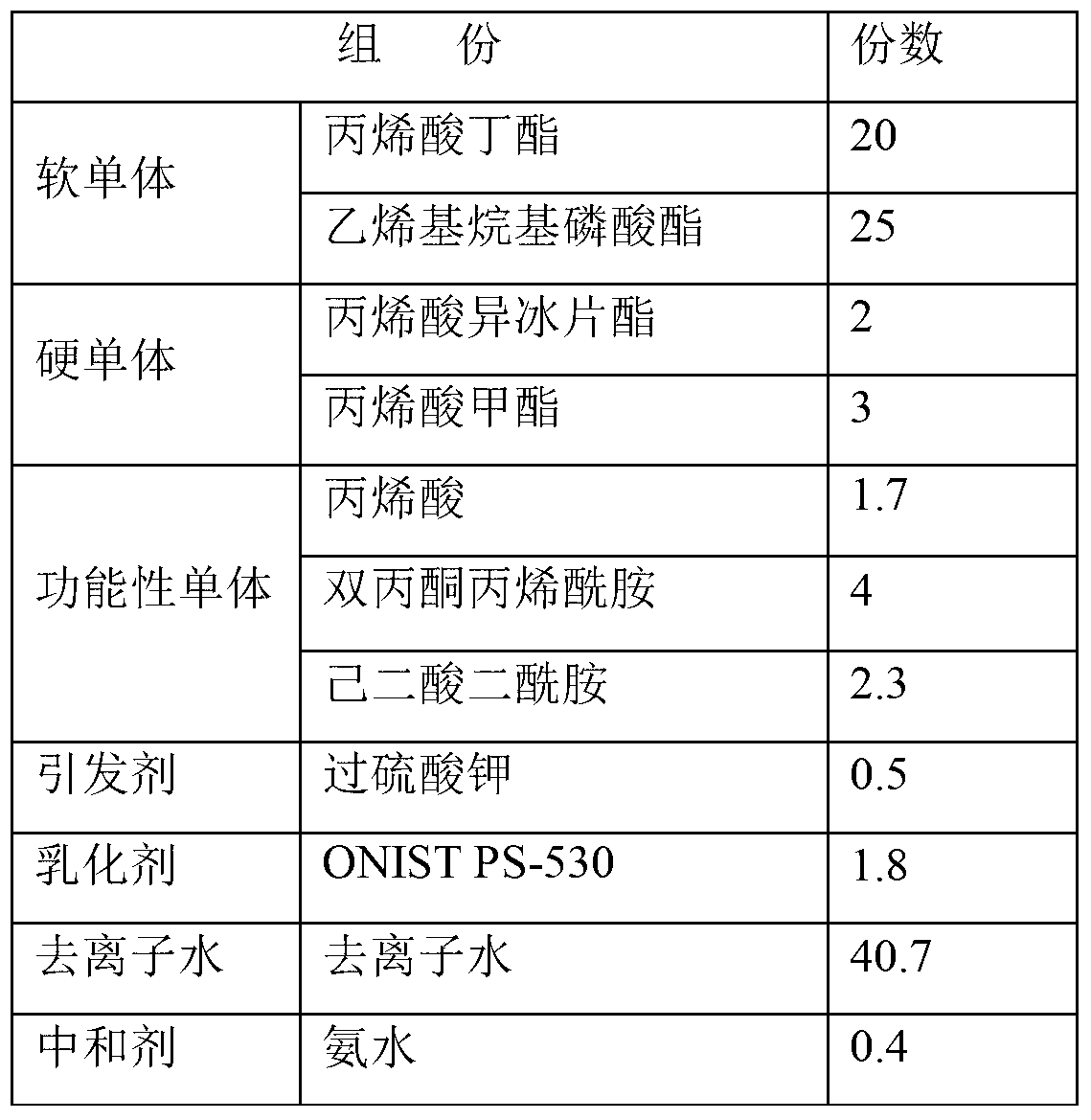

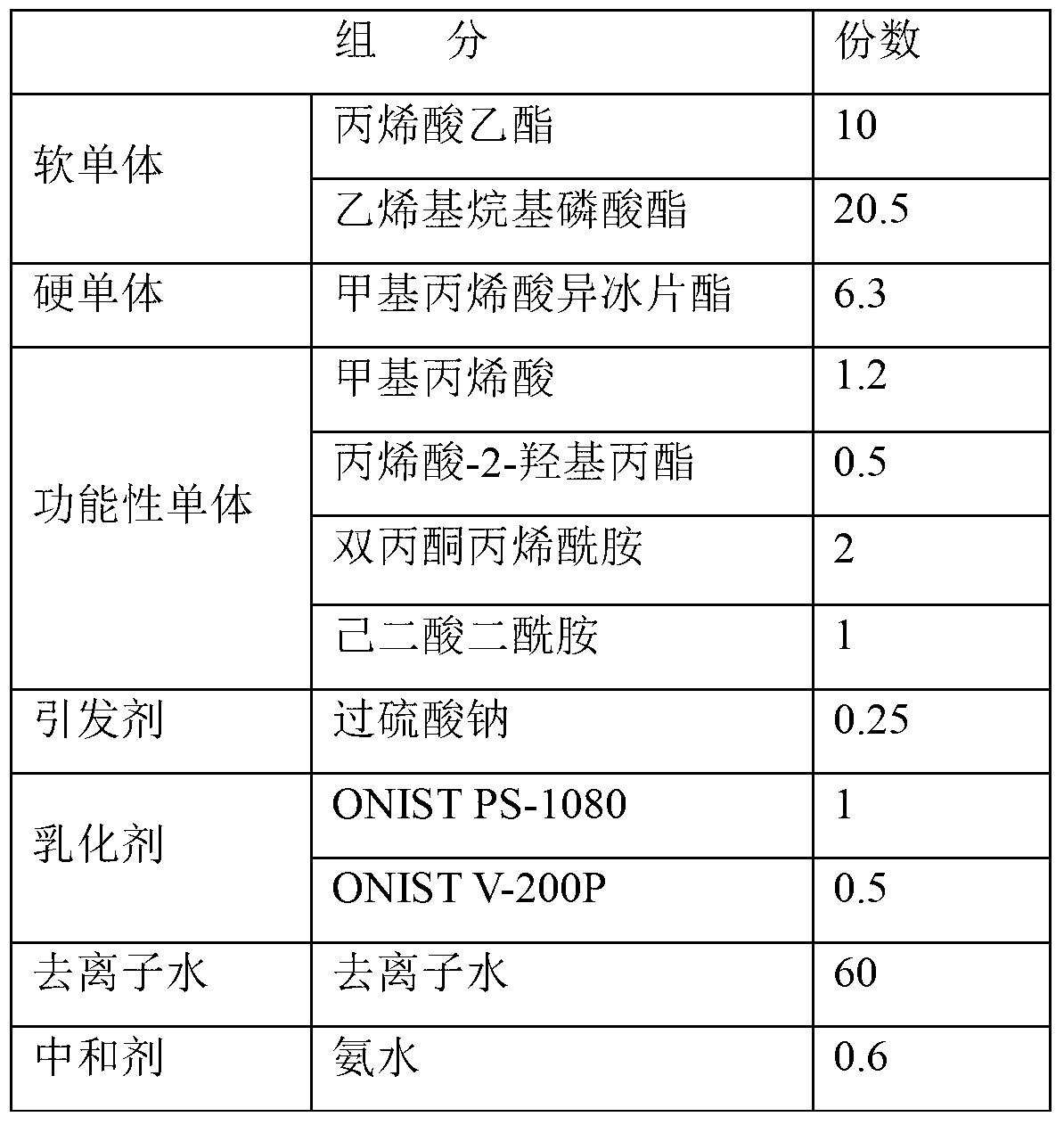

Environmental protection fire retardation type textile printing coating material and preparation method thereof

ActiveCN103225215AImprove flame retardant performanceFeel goodDyeing processTextile printerEngineering

The present invention discloses an environmental protection fire retardation type textile printing coating material and a preparation method thereof. According to the present invention, a fire retardation type acrylate is adopted as a main base material to prepare a fire retardation type coating material for textile printing, wherein the prepared fire retardation type coating material self-extinguishes within 5 seconds after leaving fire, and has characteristics of good fire retardation effect, good elasticity, low cost, excellent washing fastness resistance, and excellent color fastness; during a production process and a use process of the product, no formaldehyde is released, an environmental protection characteristic is provided, and the product does not contain heavy metals and alkyl phenol substances, and is an environmentally friendly and green product; and the preparation method has characteristics of easy production process control, high production efficiency and stable system, and is suitable for industrial scale production.

Owner:连云港百利合新材料发展有限公司

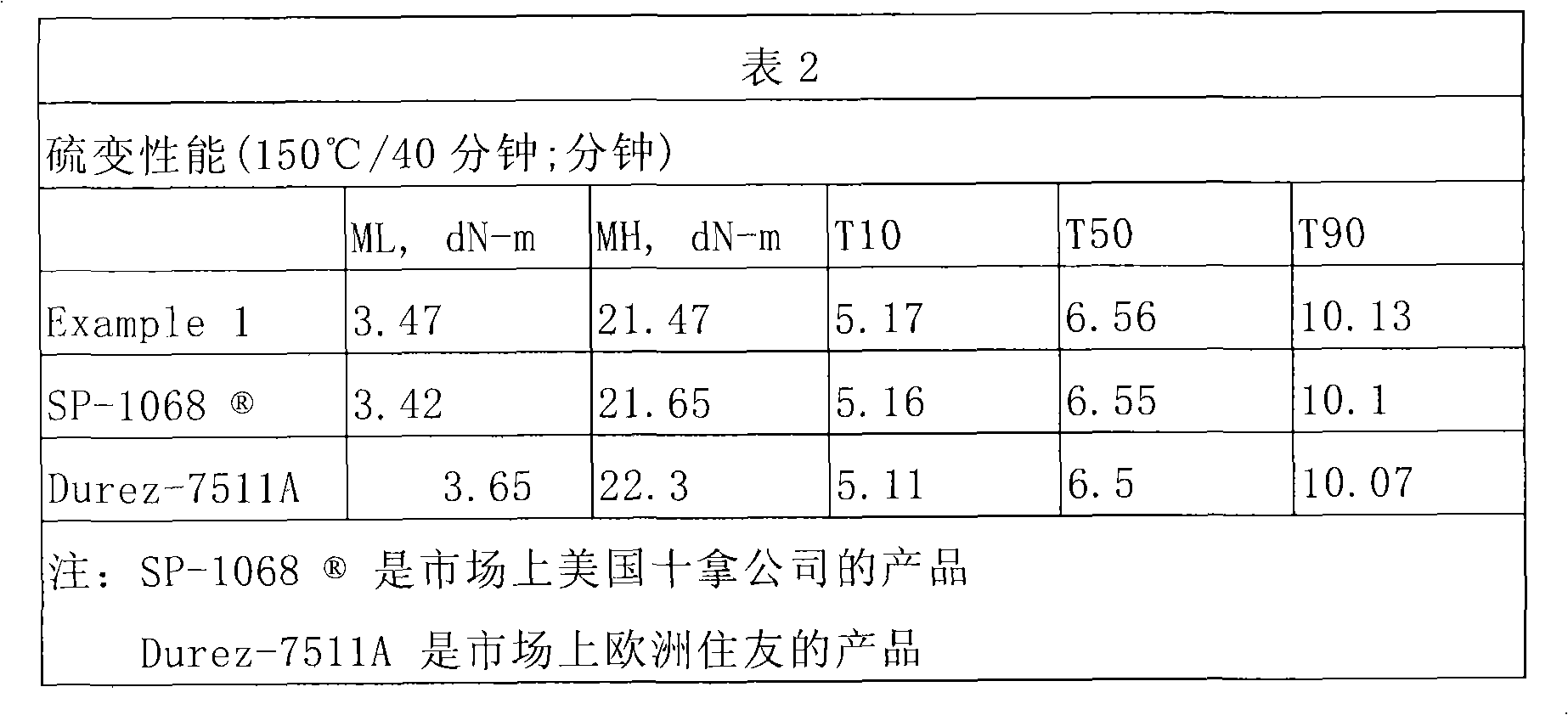

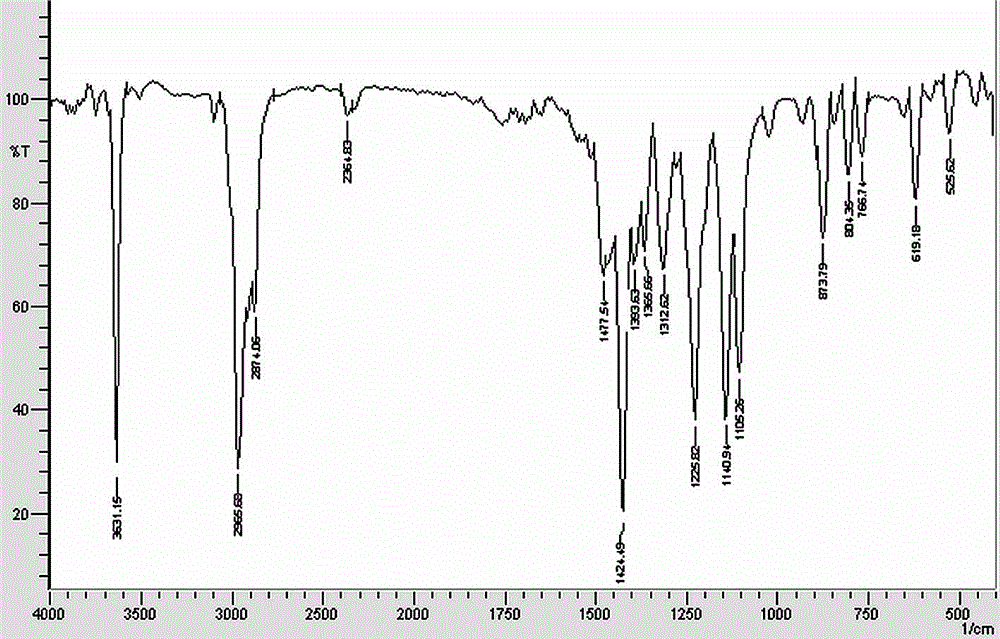

Alkyl Phenolic Resin and Method of Preparation Thereof

Described herein are alkyl phenolic resins and methods of producing them. The content of residual phenol in the alkyl phenolic resin may be less than about 2% w / w, the softening point of the alkyl phenolic resin may be about 85° C. to about 105° C., the tackiness of the alkyl phenolic resin may be about 8 N to about 25 N, the alkyl group of the alkyl phenol may have 6-12 carbon atoms, and the content of 4-(1,1,3,3-tetramethylbutyl) phenol in the alkyl phenol may be from about 0% to about 85% w / w. The invention also relates to a use of the alkyl phenolic resin as rubber tackifier.

Owner:SINO LEGEND CHINA CHEM +1

Wax emulsions for gypsum products

Emulsions, useful for imparting water resistance to gypsum products are disclosed. The emulsions of the invention include at least one wax, an alkyl phenol and a hydrophyllic metallic salt, preferably magnesium sulfate. The emulsions of the invention do not require the addition of a starch compound and therefore exhibit enhanced stability even at higher solids content then compared to prior art emulsions.

Owner:MOMENTIVE SPECIALTY CHEMICALS

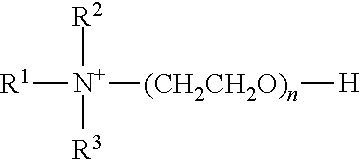

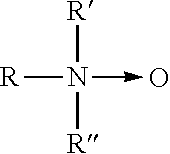

Cyclosporin Compositions

A composition is disclosed herein comprising from about 0.001% to about 0.4% cyclosporin A, castor oil, and a surfactant selected from the group consisting of alcohol ethoxylates, alcohols, alkyl glycosides, alkyl polyglycosides, alkylphenol ethoxylates, amine oxides, block polymers, carboxylated alcohol or alkylphenol ethoxylates, carboxylic acids / fatty acids, cellulose derivatives, ethoxylated alcohols, ethoxylated alkylphenols, ethoxylated aryl phenols, ethoxylated fatty acids, ethoxylated fatty acids, ethoxylated fatty esters and oils, fatty alcohols, fatty esters, glycol esters, lanolin-based derivatives, lecithin and lecithin derivatives, lignin and lignin derivatives, methyl esters, monoglycerides and derivatives, phosphalipids, polyacrylic acids, polyethylene glycols, polyethylene oxide-polypropylene oxide copolymers, polyethylene oxides, polymeric surfactants, polypropylene oxides, propoxylated alcohols, propoxylated alkyl phenols, propoxylated fatty acids, protein-based surfactants, sarcosine derivatives, silicone-based surfactants, sorbitan derivatives, stearates, sucrose and glucose esters and derivatives, and combinations thereof.

Owner:SAINT REGIS MOHAWK TRIBE

Aluminum and aluminum alloy cleaning agent and using method thereof

ActiveCN101012411AImprove cleaning rateImprove cleaning efficiencyInorganic/elemental detergent compounding agentsSurface-active detergent compositionsCleansing AgentsPhenol

The invention discloses an aluminium and aluminium alloy abluent, which comprises the following parts: 5-25W% alkyl phenol polyoxyethylene ether, 5-25W% aliphatic alcohol polyoxyethylene ether, 1-10W% cationic modified alkyl phenol polyoxyethylene ether, 2-10W% propanediol butyl ether, 2-8W% glucose, 1-8W% sodium bisilicate and 40-80W% water. The product displays light yellow transparent liquid with density at 1.05+-0.02 g / cm3, which simplifies normal disposal technique.

Owner:DALIAN SANDAAOKE CHEM

Special underwear laundry detergent and preparation method for same

InactiveCN102382728AEffectiveImprove the bactericidal effectAmpholytes/electroneutral surface-active compoundsDetergent compounding agentsBetaineFatty acid

The invention discloses special underwear laundry detergent and a preparation method for the same, which belong to the field of daily chemical engineering. According to the ratio of parts by weight, raw materials include 5-25% of sodium dodecyl benzene sulfonate, 5-10% of coconut oil fatty acid diethanol amide, 2-5% of alkyl phenol polyoxyethylene (OP-10), 2-4% of dodecyl dimethyl betaine (BS-12), 0.1-1% of carboxymethylcellulose, 0.05-1.20% of ethylene diamine tetraacetic acid, 0.1-5.45% of polyhexamethyl biguanide, 0.3-10% of dodecyl dimethyl benzyl ammonium chloride, 1-3% of salt, 0.1-0.3% of essence and 50-80% of deionized water. The preparation method includes that the deionized water and the raw materials are added into a material dissolving kettle for dissolving the materials, and then the special underwear laundry detergent is obtained. The special underwear laundry detergent and the preparation method have the advantages that biguanides and bis-quaternary ammonium are adopted for sub-composition and can effectively act on germs under the effect of special penetration enhancers, germicidal power is improved, and the special underwear laundry detergent can be stored stably and is less in consumption and high in cost performance.

Owner:周强

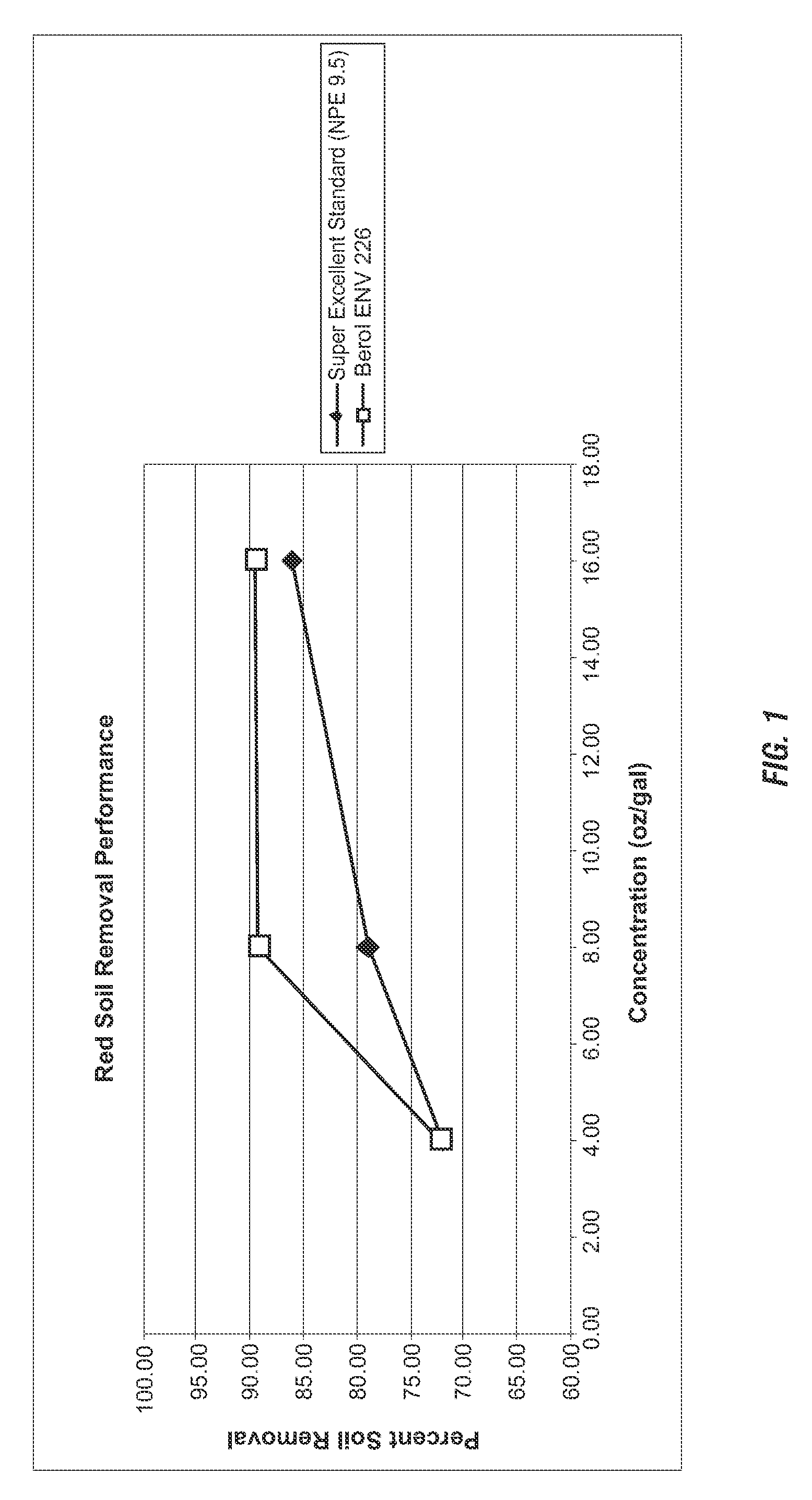

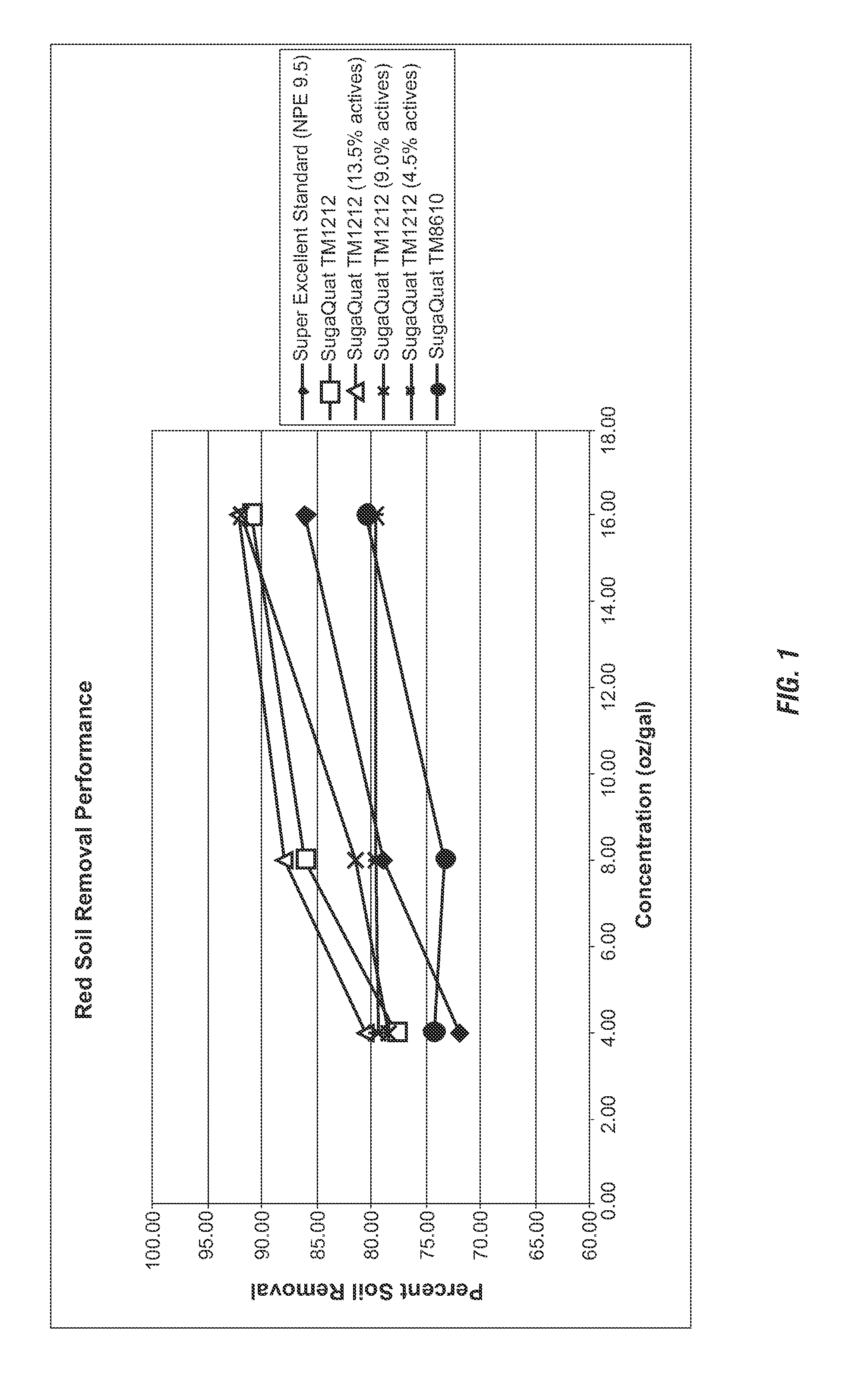

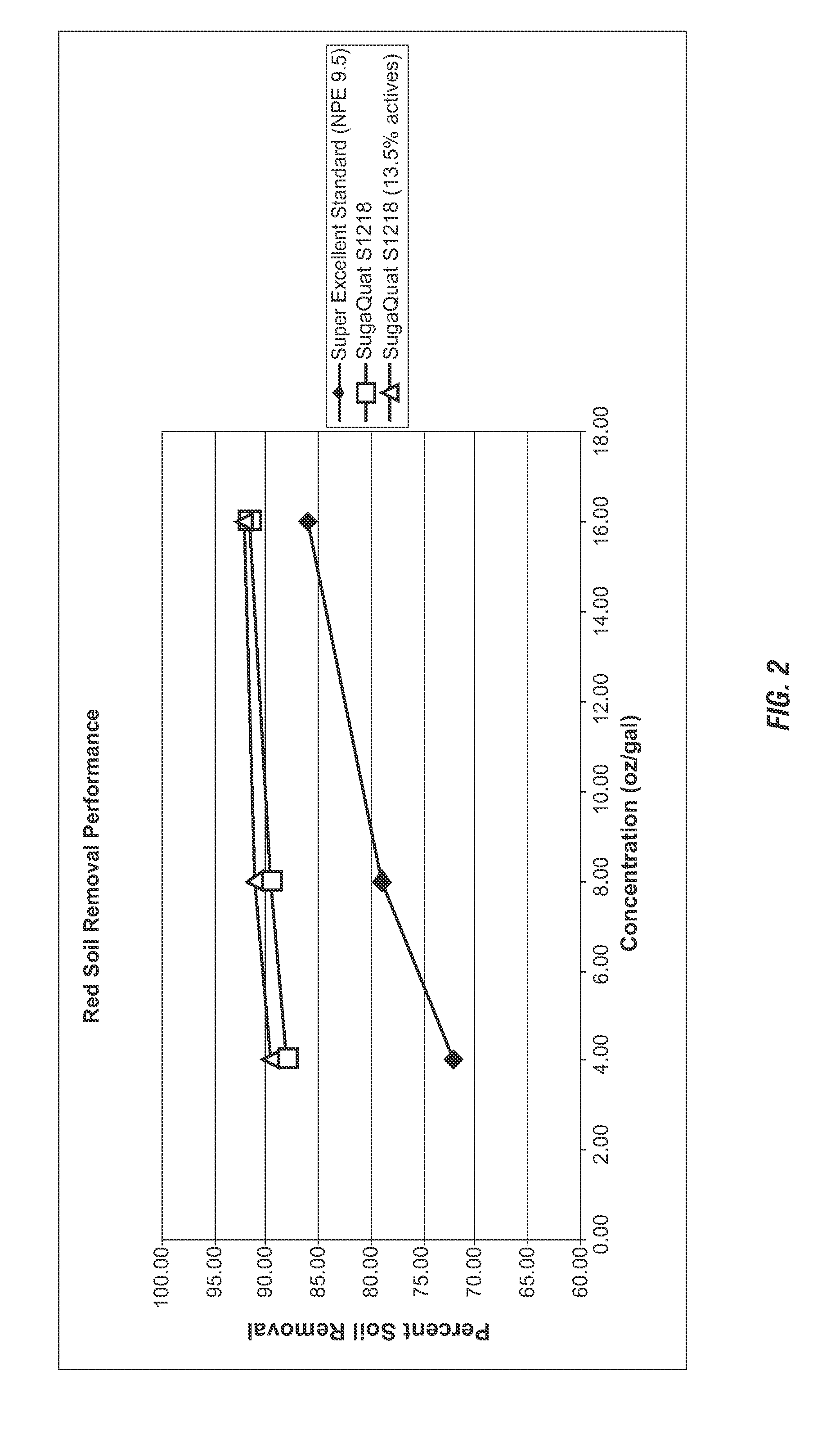

Ethoxylated alcohol and monoethoxylated quaternary amines for enhanced food soil removal

ActiveUS20120046216A1Cationic surface-active compoundsOrganic detergent compounding agentsAlcoholNonylphenol ethoxylate

A cleaning composition including an ethoxylated alcohol and monoethoxylated quaternary amine blend, a water conditioning agent, an acid source, a solvent, and water. In one embodiment, the cleaning composition is substantially free of alkyl phenol ethoxylates. The cleaning composition is capable of removing soils including up to 20% proteins. The cleaning compositions include a biodegradable, volatile organic compound free, environmentally friendly alternative to nonyl phenol ethoxylates with substantially similar cleaning of food soils.

Owner:ECOLAB USA INC

Emulsions for composite materials

Emulsions are provided which are useful in imparting water-resistance to lignocellulosic composite products. In one embodiment, the emulsions comprise at least one wax, an alkyl phenol, a salt of polynaphthalenesulfonic acid, and a complexed starch. Emulsions of this embodiment may be added to hot, even boiling, water without the emulsion separating or curdling. The emulsions of the present invention are stable for extended periods of time when stored at room temperature, do not require the addition of a bactericide, and are pourable liquids at room temperature.

Owner:HEXION INC

Elastic paint for exterior wall decoration and its manufacturing method

The invention relates to an elastic paint for exterior wall decoration and its manufacturing method, which is prepared from acrylic acid self-crosslinking copolymerized emulsion, 5-chloro-2-methyl-4-isothiazoline-3-one, n-octylisothiazolin-one, ammonium polycarboxylate, alkyl phenol polyoxyethylene ether, hydroxyethyl cellulose, 3-n-butylphosphoric ester, propylene glycol, 2,2,4-trimethyl-1,titanium dioxide, calcium, talcum powder, porcelain clay, 2-amido-2-methyl-1-propanol and polyurethane modified polyether through agitating and grinding.

Owner:TIANJIN BO XING ENG SCI & TECH LIMITED COMPANY OF CNPC

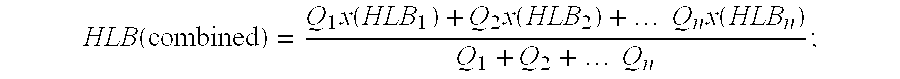

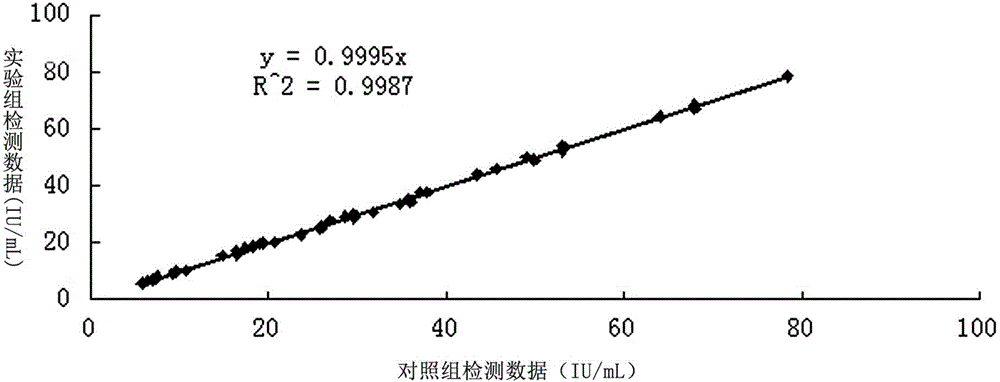

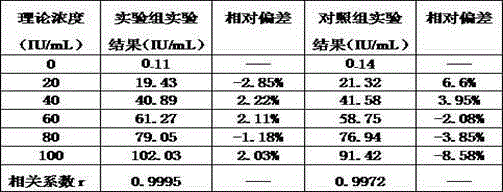

Rheumatoid factor detection reagent

The present invention discloses a rheumatoid factor detection reagent, which comprises a reagent R1 and a reagent R2, wherein the reagent R1 comprises a phosphate buffer solution, lauryl imidazolinium betaine, dioctadecyl dimethyl ammonium chloride, dodecyl trimethyl ammonium chloride, alkyl phenol ethoxylates (APEO), 1-hydroxyethylidene-1,1-diphosphonic acid, sodium azide and a stabilizer SHE-50, and the reagent R2 comprises a phosphate buffer solution, thermal polymerization I human IgG, latex microspheres, Kathon-CG, alkyl phenol ethoxylates (APEO) and sodium azide. According to the present invention, a variety of the reagents in the detection reagent of the present invention provide the synergy effect, and the detection reagent has characteristics of good accuracy, good stability, wide linear range, cheap price and easy use, and can completely meet the clinical needs.

Owner:郁东

Cleaning compositions incorporating green solvents and methods for use

ActiveUS8222194B2Point becomes highLow vapor pressureSoap detergents with organic compounding agentsOrganic detergent compounding agentsGlutaric acidActive agent

An environmentally-friendly cleaning composition for industrial and consumer applications comprising (a) a blend of dibasic esters, (b) one or more surfactants (c) and, optionally, (d) water or a solvent. The dibasic esters are be derived from a blend of adipic, glutaric, and succinic diacids, and, in one particular embodiment, the blend comprises dialkyl adipate, dialkyl methylglutarate and dialkyl ethylsuccinate, wherein the alkyl groups individually comprise a C1-C12 hydrocarbon group. The one or more surfactants are typically chosen from alcohol alkoxylate, an alkyl phenol ethoxylate, a terpene, a terpene alkoxylate or any derivates thereof. Optionally, additional components or additives including delaminates such as pinene and d-limonene, fragrances, whiteners, stabilizers, thickeners and the like can be added to the composition. The industrial or consumer application selected from the group consisting of a graffiti cleaner, a painted-substrate cleaner, an ink cleaner, a metal substrate cleaner, a plastic substrate cleaner, an environmentally friendly cleaner, a stain-spot cleaner, an industrial hand cleaner, a resin cleaner, a tar resin cleaner, a textile cleaner, a paint stripper and any combination thereof.

Owner:SPECIALTY OPERATIONS FRANCE

Water based anticorrosive penetrant inspection agent, and preparation method

A penetration coloring liquid and penetration color developing liquid both being used in crack detection is featured as preparing said coloring liquid from 5-30 of peretrating agent, 3-9 of dyestuff, 0.5-10 of fatty acid trolamide, 0.01-1 of benzene triazole and 0.1-2 of polyoxyethylene alky-phenolic ether; preparing said color developing liquid from 5-10 of binder, 3-7 of absorbent, 0.5-2 of fatty acid trolamide and 0.1-2 of polyoxyethylene alky-phenolic ether. The method for preparing said liquid is also disclosed.

Owner:CHINA ERZHONG GRP DEYANG HEAVY IND

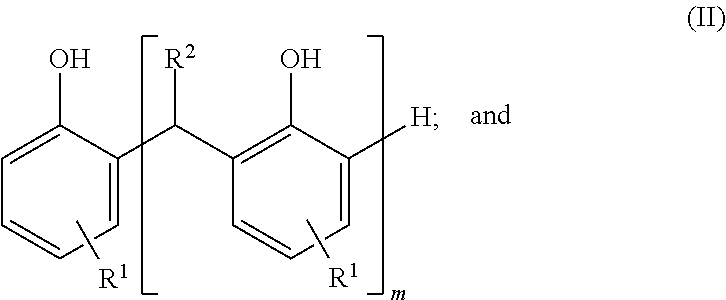

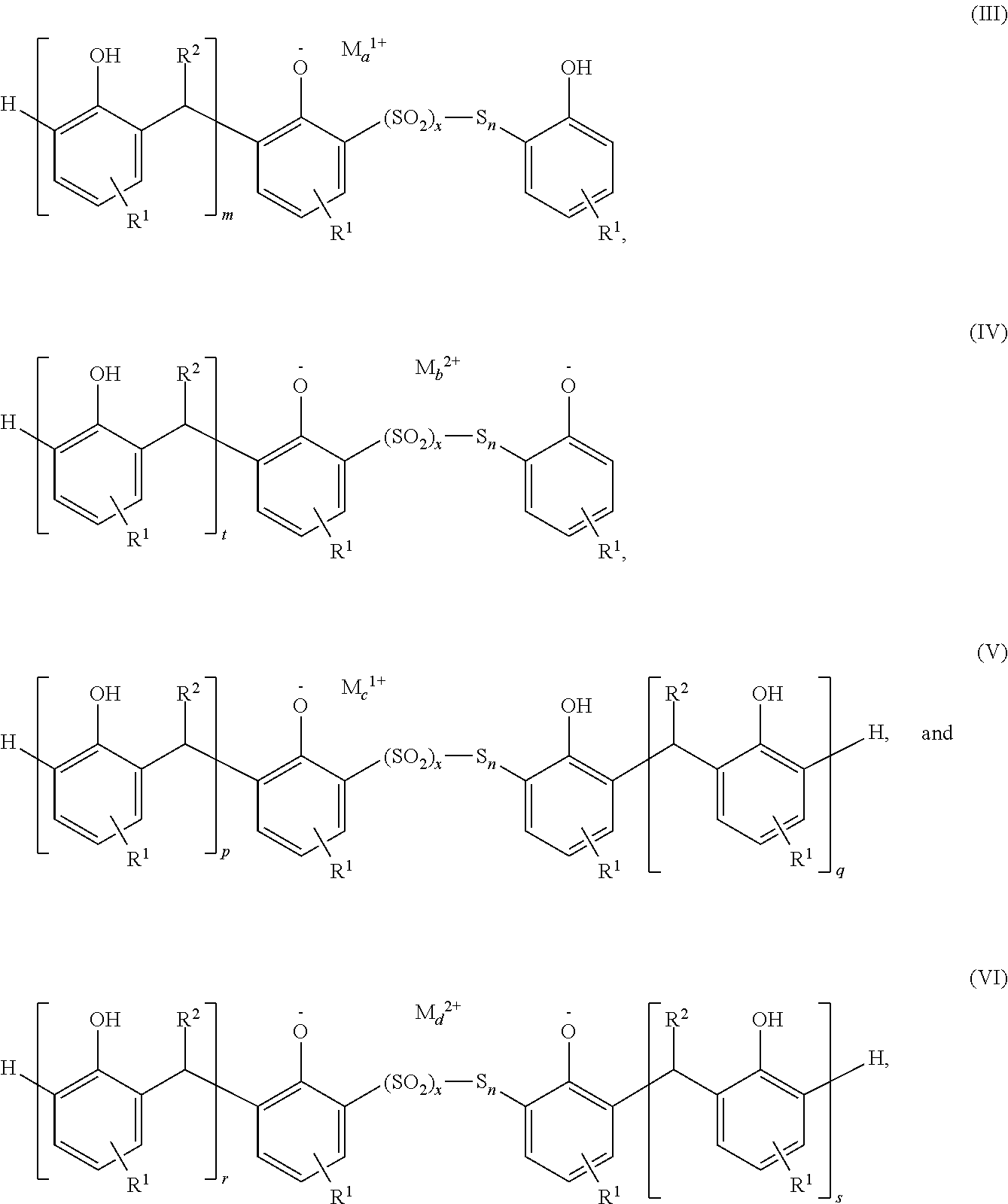

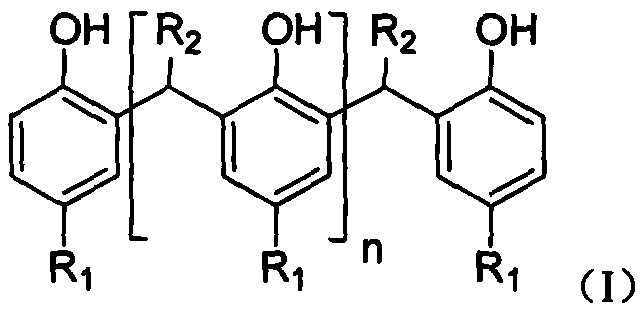

Sulfurized metal alkyl phenate compositions having a low alkyl phenol content

Provided herein are sulfurized metal alkyl phenate compositions having a low alkyl phenol content. The sulfurized metal alkyl phenate compositions can be prepared by reacting a phenol compound of Formula (I) disclosed herein with an aldehyde to form a phenolic resin of Formula (II) disclosed herein and then by reacting the phenolic resin simultaneously with a metal base and a first sulfurizing agent. The sulfurized metal alkyl phenate compositions and the overbased sulfurized metal alkyl phenate compositions disclosed herein may be used as detergents for formulating lubricating oil compositions. The lubricating oil compositions disclosed herein have a reduced amount of the free phenol compound and a salt thereof.

Owner:CHEVRON ORONITE CO LLC

Biphenol compound preparation method

ActiveCN103553881AIncrease productivityEase of serializationOrganic chemistryOrganic compound preparationAlkaline earth metalCatalytic oxidation

The invention provides a biphenol compound preparation method. The biphenol compound preparation method is characterized in that 2, 6-dialkyl phenol is used as a raw material and is subjected to oxygen or air catalytic oxidation so as to prepare a 2, 2', 6, 6'-tetraalkyl-4, 4'- biphenol product. The reaction is carried out in the following two steps under the condition of the inexistence of a solvent: firstly smelting the 2, 6-dialkyl phenol in an inert gas environment, then mixing with hydroxide of alkali metals or alkaline-earth metals or organic salt, heating to 110-190 DEG C, and carrying oxidative coupling reaction under the condition of introducing oxygen or air; and then carrying out reduction reaction at 150-250 DEG C in an inert gas environment so as to obtain 2, 2', 6, 6'-tetraalkyl-4, 4'- biphenol product. The biphenol compound preparation method has the advantages that the yield is high, the conversion rate of the 2, 6-dialkyl phenol can reach 85-90%, and the content of the 2, 2', 6, 6'-tetraalkyl-4, 4'- biphenol product is higher than 98.5%; no solvents are used in the whole preparation process, the continuity of the production process can be realized, and the 2, 6-dialkyl phenol which is unreacted and separated out from a reaction system has good quality and can directly serve as the raw material to be recycled, so that the productivity is further increased.

Owner:四川宝利丰科技有限公司

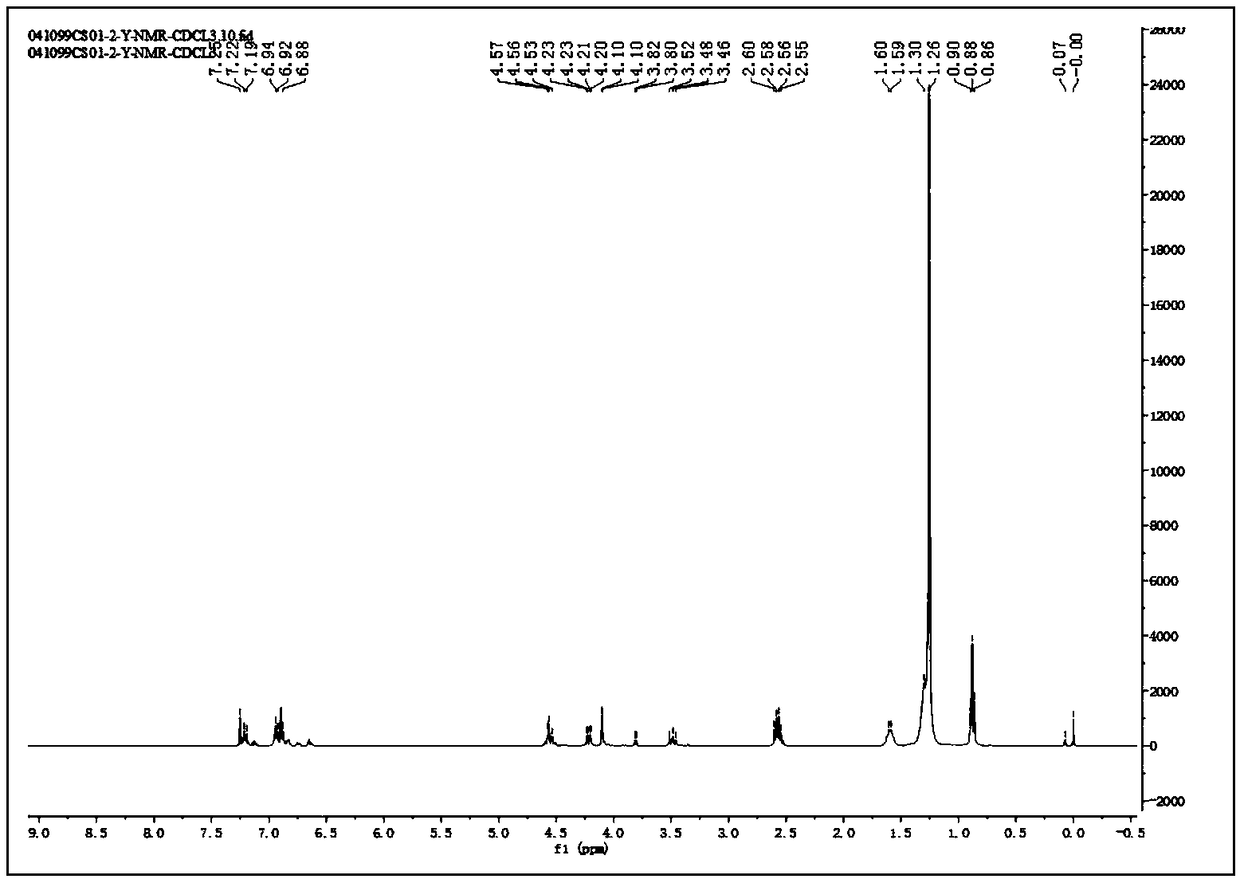

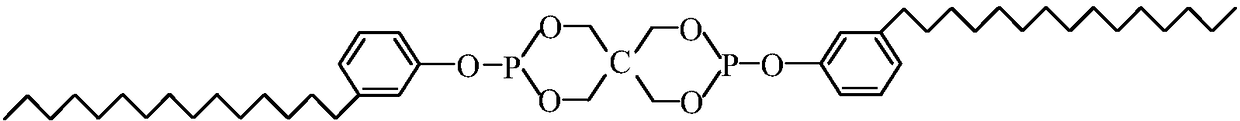

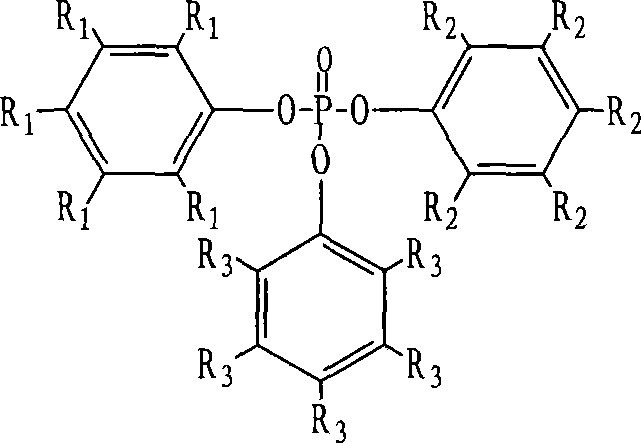

Novel efficient biology-based phosphite ester antioxidant and preparation methods thereof

ActiveCN108530485ADoes not consume energy resourcesHigh molecular weightGroup 5/15 element organic compoundsAntioxidantStructural formula

The invention discloses a novel efficient biology-based phosphite ester antioxidant and two preparation methods thereof. The structural formula of the antioxidant is as shown in the specification. Thepreparation methods are characterized in that cardanol is subjected to hydrogenation to obtain 3-pentadecyl-phenol, and the 3-pentadecyl-phenol, phosphorus trichloride and quaternary pentane are allowed to have esterification reaction under certain reaction conditions to obtain the biology-based phosphite ester antioxidant. The novel efficient biology-based phosphite ester antioxidant has the advantages that the antioxidant does not contain nonyl phenol and is large in molecular weight, green, environmentally friendly and safe; due to the fact that the antioxidant contains two trivalent phosphorus, each trivalent phosphorus contains three P-O bonds, and P is positively trivalent, the antioxidant can combine with instable components in polymer to generate oxide, and the antioxidant is goodin effect.

Owner:SHANDONG LINYI SUNNY WEALTH CHEM CO LTD +1

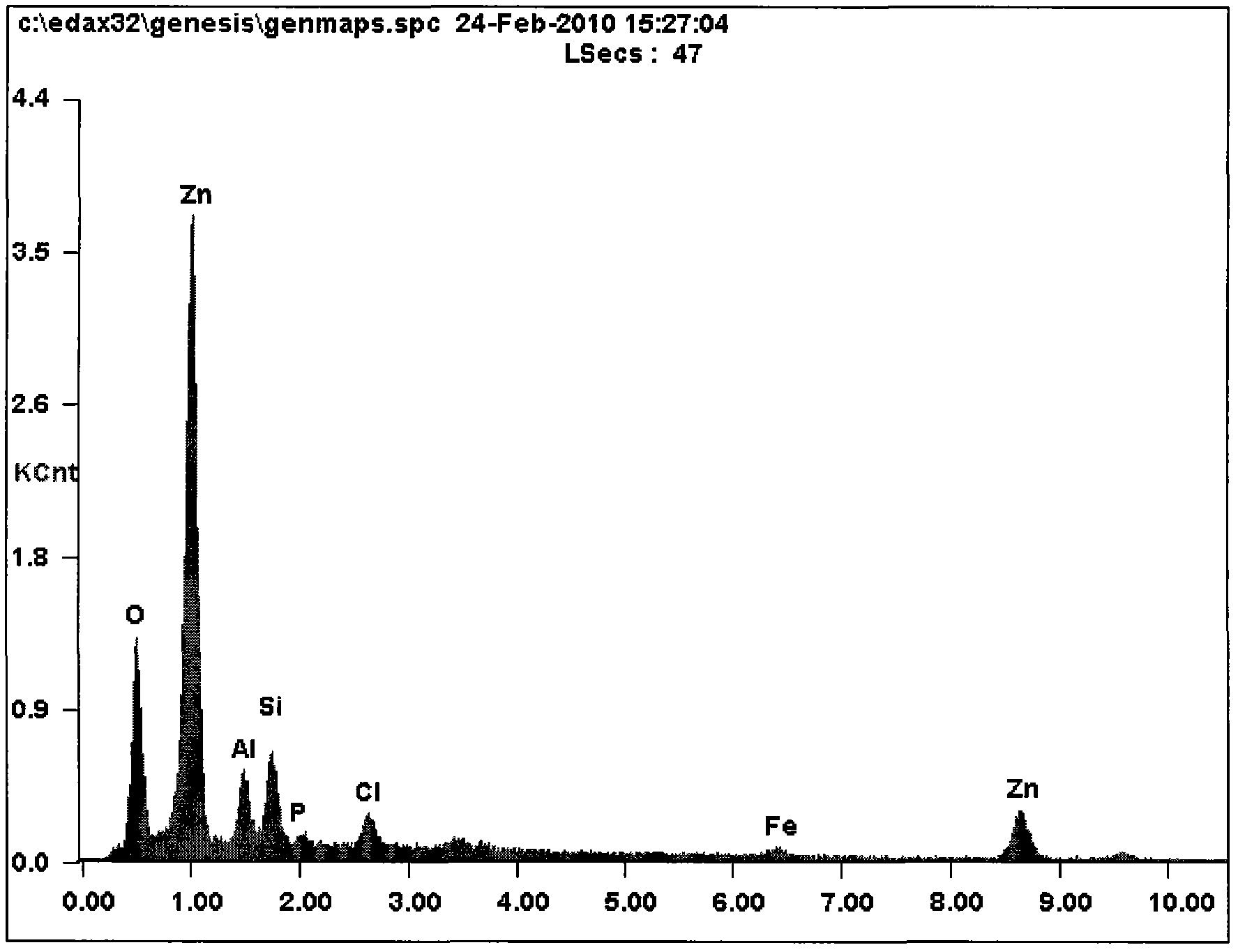

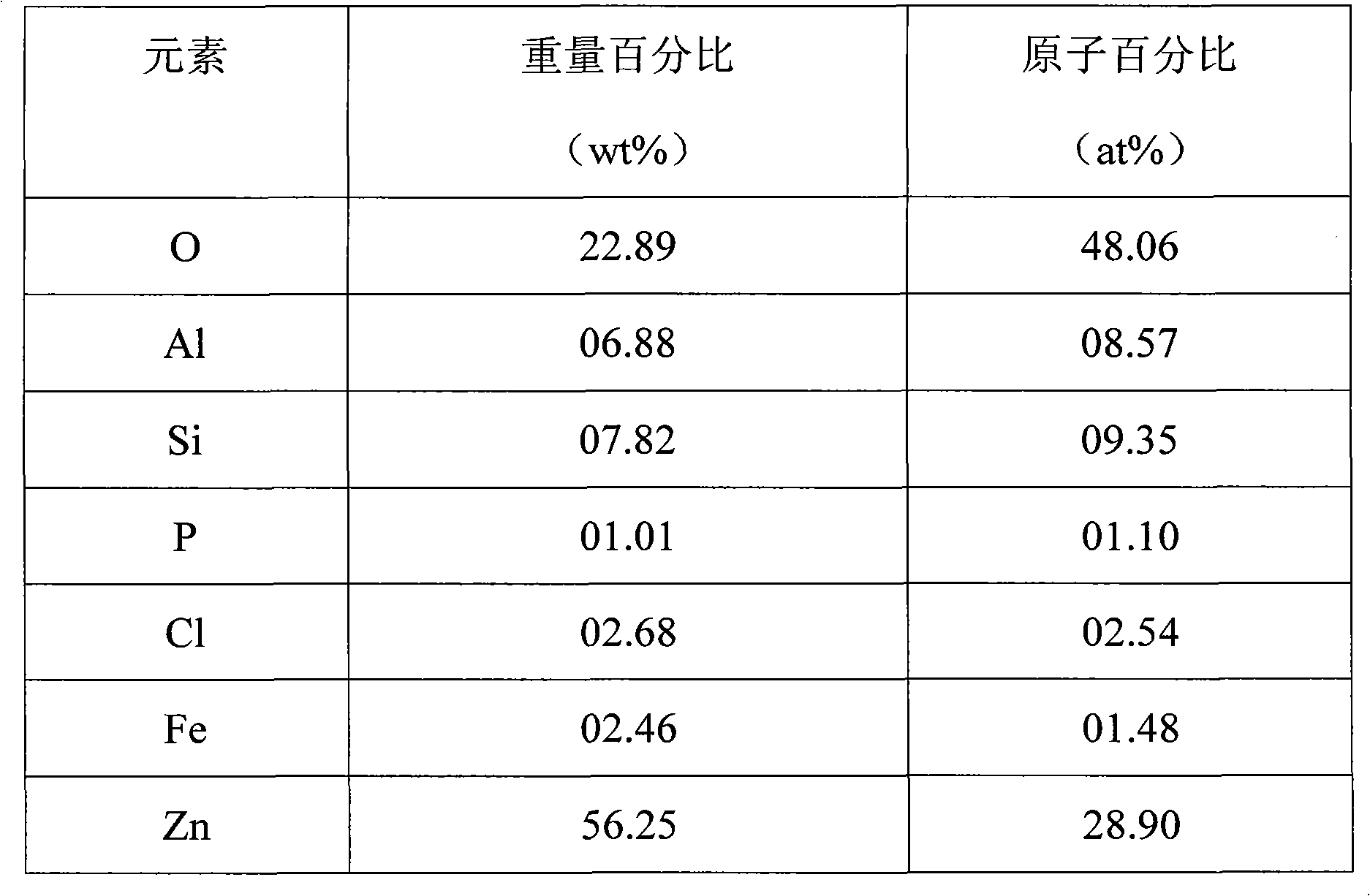

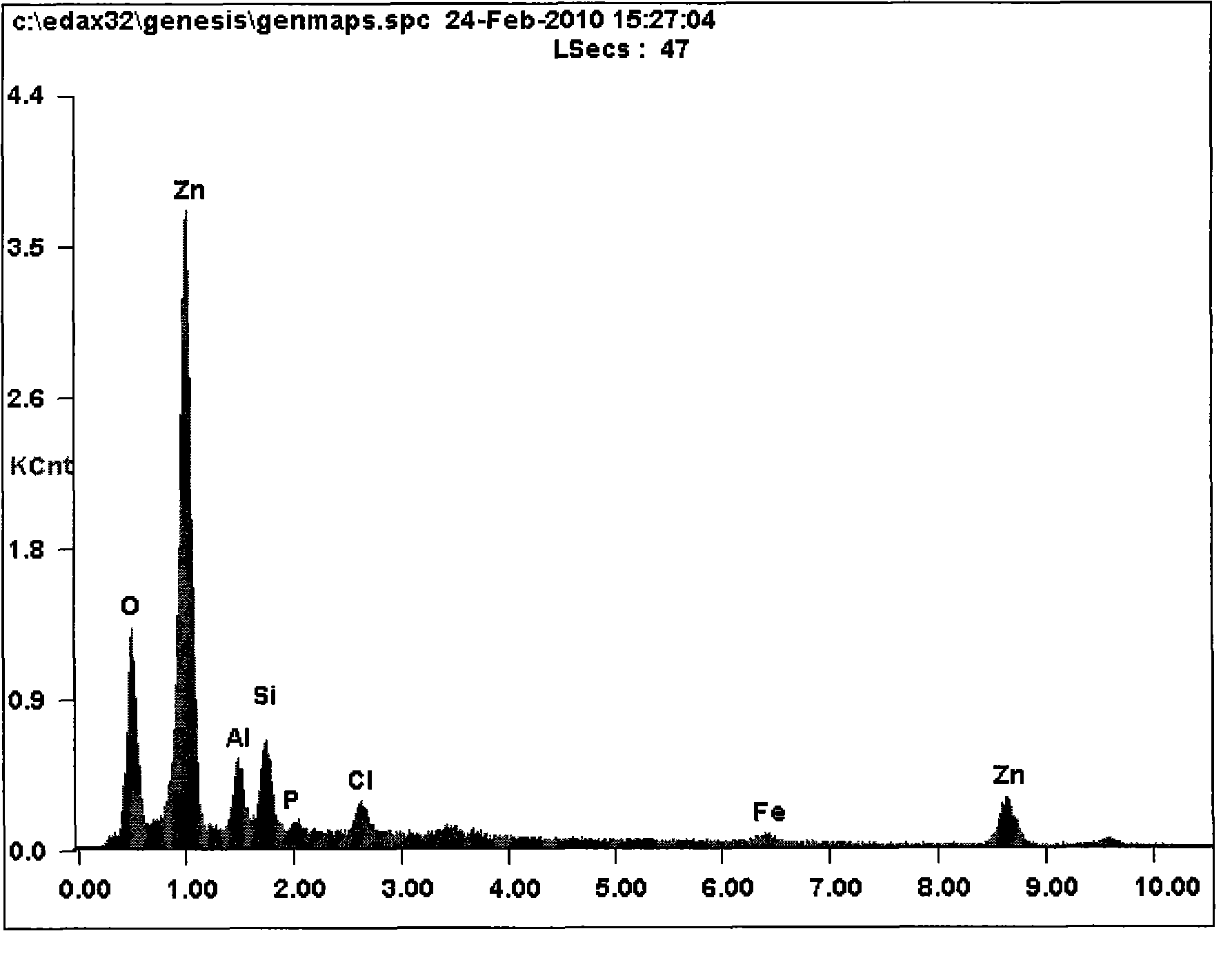

Surface treatment method for chromium and zinc-free coating of neodymium-iron-boron permanent magnet material

ActiveCN102464909AHigh energy consumptionImprove anti-corrosion performanceAnti-corrosive paintsPaints with free metalsEpoxyTin dioxide

Owner:BEIJING ZHONG KE SAN HUAN HI TECH +1

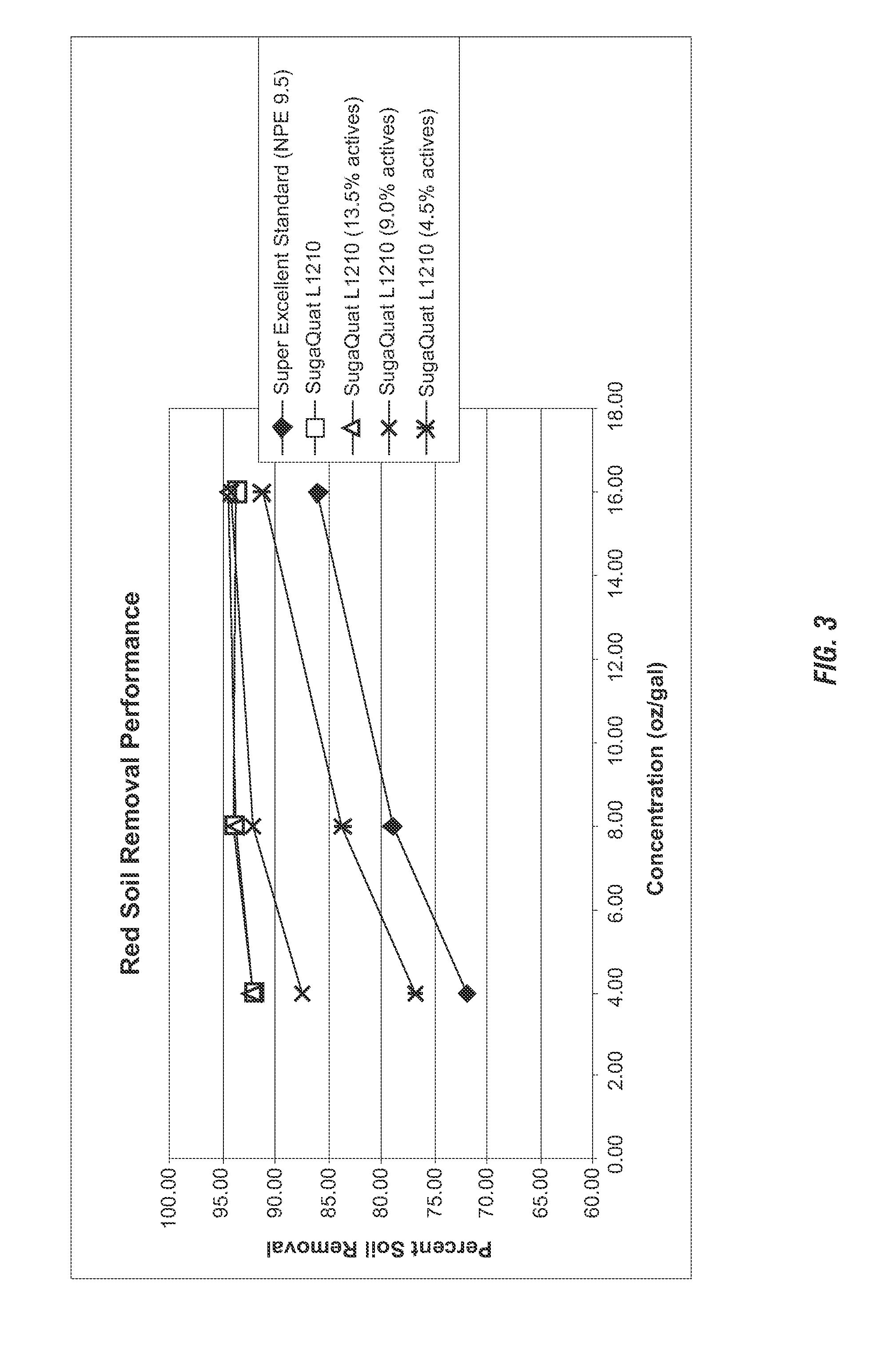

Quaternary functionalized alkyl polyglucosides for enhanced food soil removal

ActiveUS20120071385A1Inorganic/elemental detergent compounding agentsCationic surface-active compoundsNonylphenol ethoxylateAlkyl polyglycoside

A cleaning composition including a primarily C12 quaternary functionalized alkyl polyglucoside, a water conditioning agent, an acid source, a solvent, and water. In one embodiment, the cleaning composition is substantially free of alkyl phenol ethoxylates. The cleaning composition is capable of removing soils including up to 20% proteins. The cleaning compositions include a biorenewable, environmentally friendly alternative to nonyl phenol ethoxylates and exhibit superior cleaning of food soils.

Owner:ECOLAB USA INC

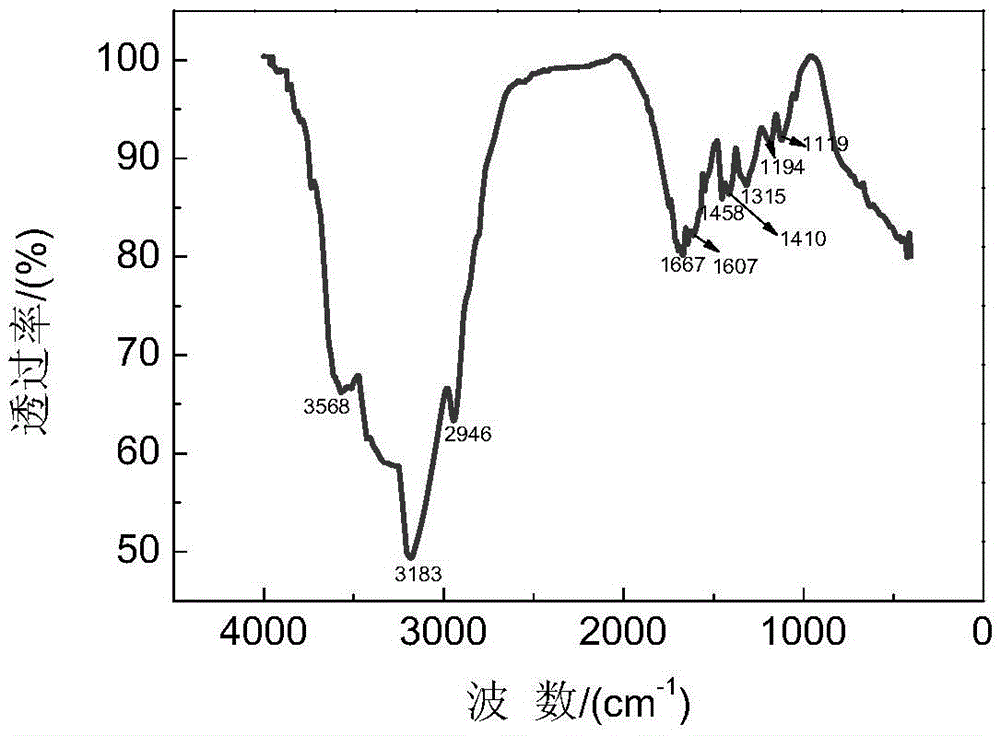

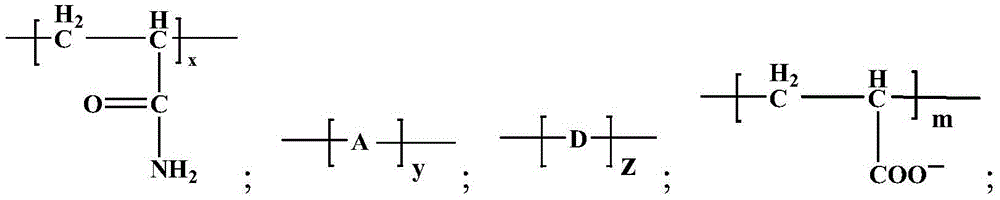

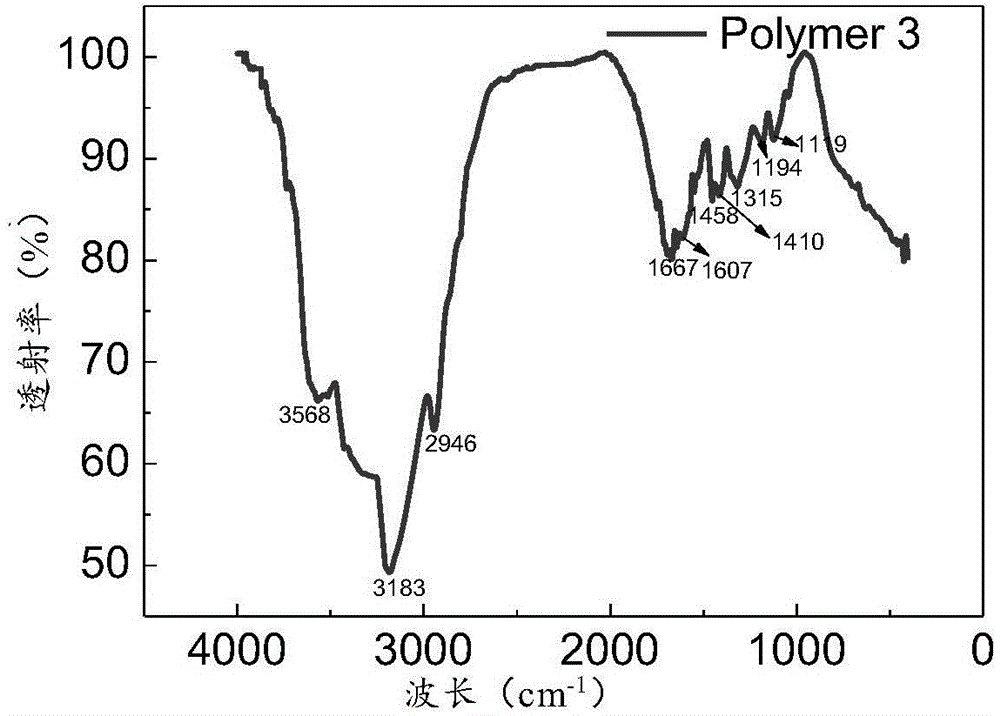

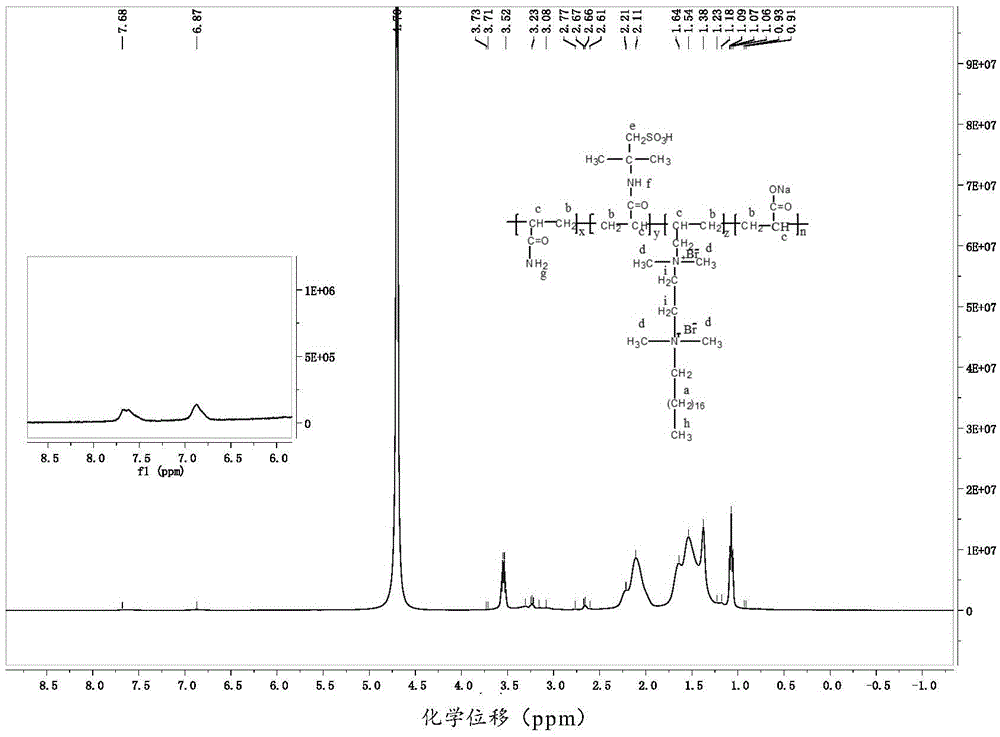

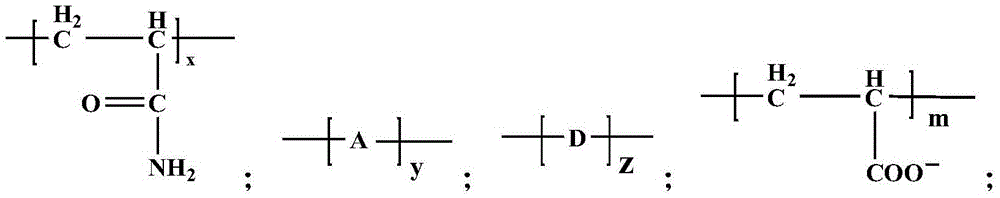

Hydrophobic associated polymer and preparation method thereof

The invention provides a hydrophobic associated polymer, which comprises the following four repetitive units represented in the description. In the formula, y=0.001 to 0.02, z=0.01 to 0.12, m=0.08-0.3, and x+y+z+m=1; the A represents a monomer unit of hydrophobic monomer, which can be one or more of allyl alkyl quaternary ammonium salt, acrylamide alkyl sulfonic acid, acrylamide alkyl sulfonate, alkyl phenol polyoxyethylene acrylate, and polyoxyethylene alkyl acrylate; the D represents a monomer unit of functional monomer, and the viscosity average molecular weight of the hydrophobic associated polymer is in a range of 30 million to 45 million. Compared with the prior art, the provided acrylamide monomer unit of the hydrophobic associated polymer can provide hydrophilic groups; the monomer unit of hydrophobic monomer can provide hydrophobic side groups, the provided polymer can construct spatial network in water and provides viscosity for the solution; monomer unit of acrylic acid ions can improve the solubility of polymer; and the introduction of monomer unit of functional monomer can improve the temperature resistant and salt resistant performance of the polymer.

Owner:SICHUAN GUANGYA POLYMER CHEM

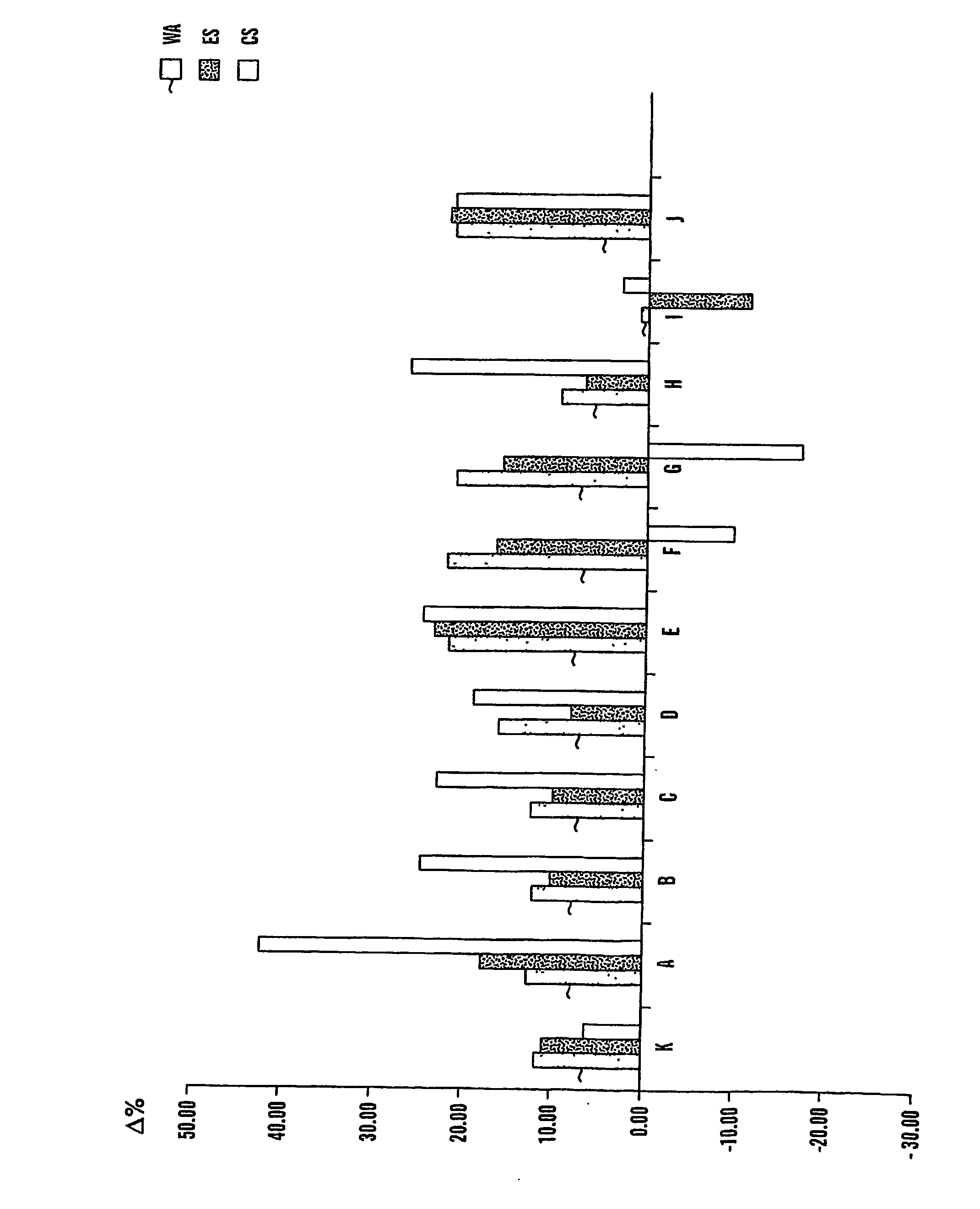

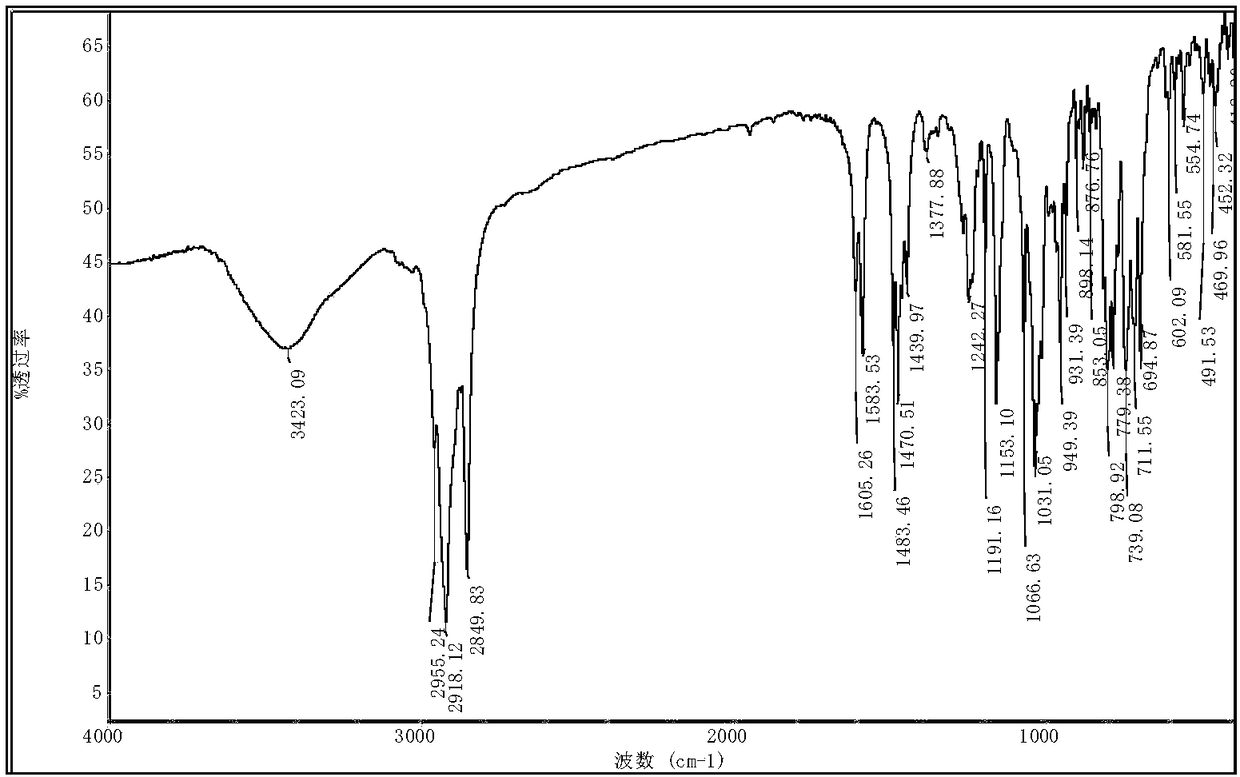

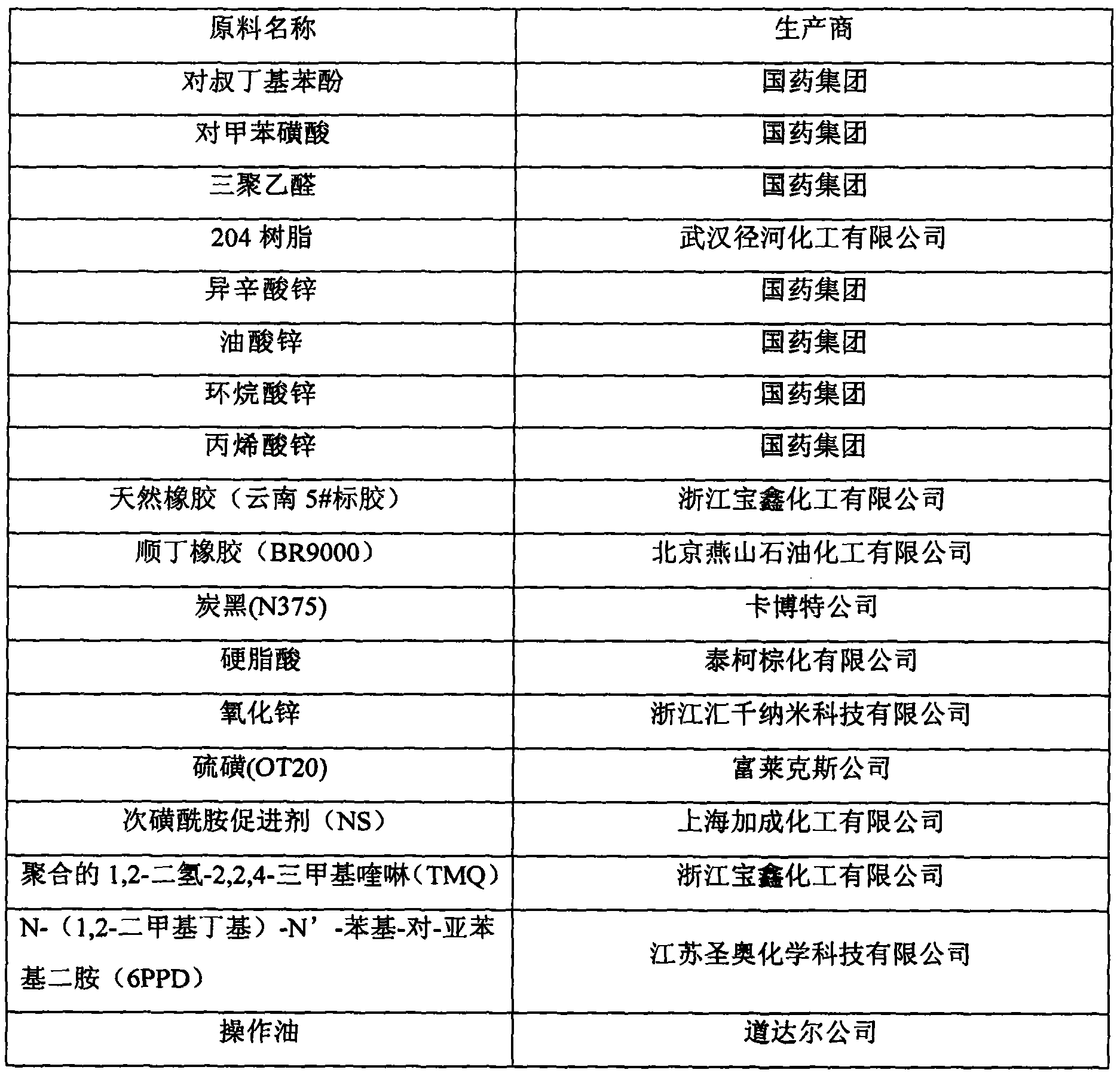

Preparation method for modified alkyl phenolic resin and application thereof

The invention relates to a modified alkyl phenolic resin, which is prepared by compounding alkyl phenolic resin and an organic zinc salt modifying agent. The preparation method for the modified alkyl phenolic resin is simple and the dynamic performance of a rubber composition adopting the alkyl phenolic resin can be improved effectively.

Owner:BEIJING RED AVENUE INNOVA

Ink cleaning composition and methods for use

ActiveUS8440598B2Point becomes highLow vapor pressureSoap detergents with organic compounding agentsDetergent mixture composition preparationDibasic esterAdipate

Owner:SPECIALTY OPERATIONS FRANCE

Hydrophobic associated polymer and preparing method thereof

The invention provides a hydrophobic associated polymer. The hydrophobic associated polymer comprises four repetitive units (please see the specification), wherein y=0.001-0.2, z=0.005-0.3, m=0.03-0.2 and x+y+z+m=1; A is a monomeric unit of a hydrophobic monomer, and the hydrophobic monomer is selected from one or more of allyl alkyl quaternary ammonium salt, acrylamide alkyl sulfonic acid, acrylamide alkyl sulfonic acid salt, alkyl phenol polyoxyethylene acrylic ester and acrylic acid polyoxyethylene alkyl ester; D is a monomeric unit of a functional monomer; the viscosity average molecular weight of the hydrophobic associated polymer ranges from 500 thousands to 15 millions. Compared with the prior art, hydrophilic base groups can be provided through the monomeric unit of acrylamide in the hydrophobic associated polymer; hydrophobic lateral groups can be provided through the monomeric unit of the hydrophobic monomer, and the necessary viscoelasticity of a solution is provided; the solubleness of the hydrophobic associated polymer can be improved through a sodium acrylate unit; the temperature resistance and the salt tolerance of the hydrophobic associated polymer can be improved through the monomeric unit of the functional monomer.

Owner:SICHUAN GUANGYA POLYMER CHEM

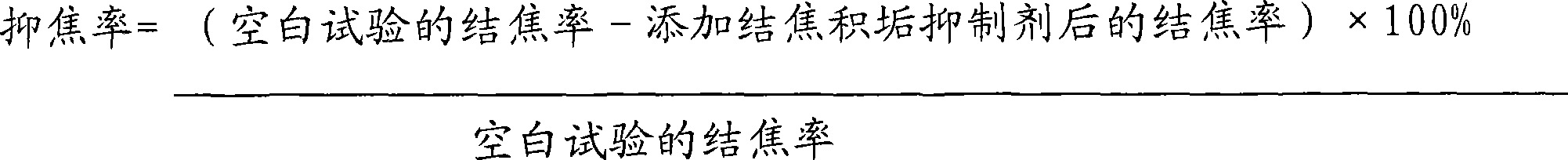

Coking and fouling inhibitor and use method thereof in heavy oil precessing system

ActiveCN101469280AStrong focus suppression effectReduce the amount addedThermal non-catalytic crackingCatalytic crackingOil processingNitrogenous heterocyclic compound

The invention provides a coking scale deposit inhibitor used in a heavy oil processing system, which comprises (A) triphenyl phosphate compound and (B) nitrogenous heterocyclic compound, the weight ratio of the (A) to the (B) is 10:1-1:10, and the inhibitor also comprises one or two of (C) succimide type compound and (D) alkyl phenol compound, and the total content of (C) to the (D) is not more than 50 weight percent of that of the coking scale deposit inhibitor. The invention also provides an application method for the coking scale deposit inhibitor. Compared with the prior art, the coking scale deposit inhibitor can reduce the coking scale deposit of a heavy oil processing system, and has the advantages of stronger inhibition effect, small addition, simple preparation method and lower cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com