Patents

Literature

206 results about "2-methyl-1-propanol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for removing carbon dioxide from combustion exhaust gas

InactiveUS6036931AHigh absorption rateImprove absorption rateDispersed particle separationHydrogen sulfides2-methylaminoethanolMorpholine

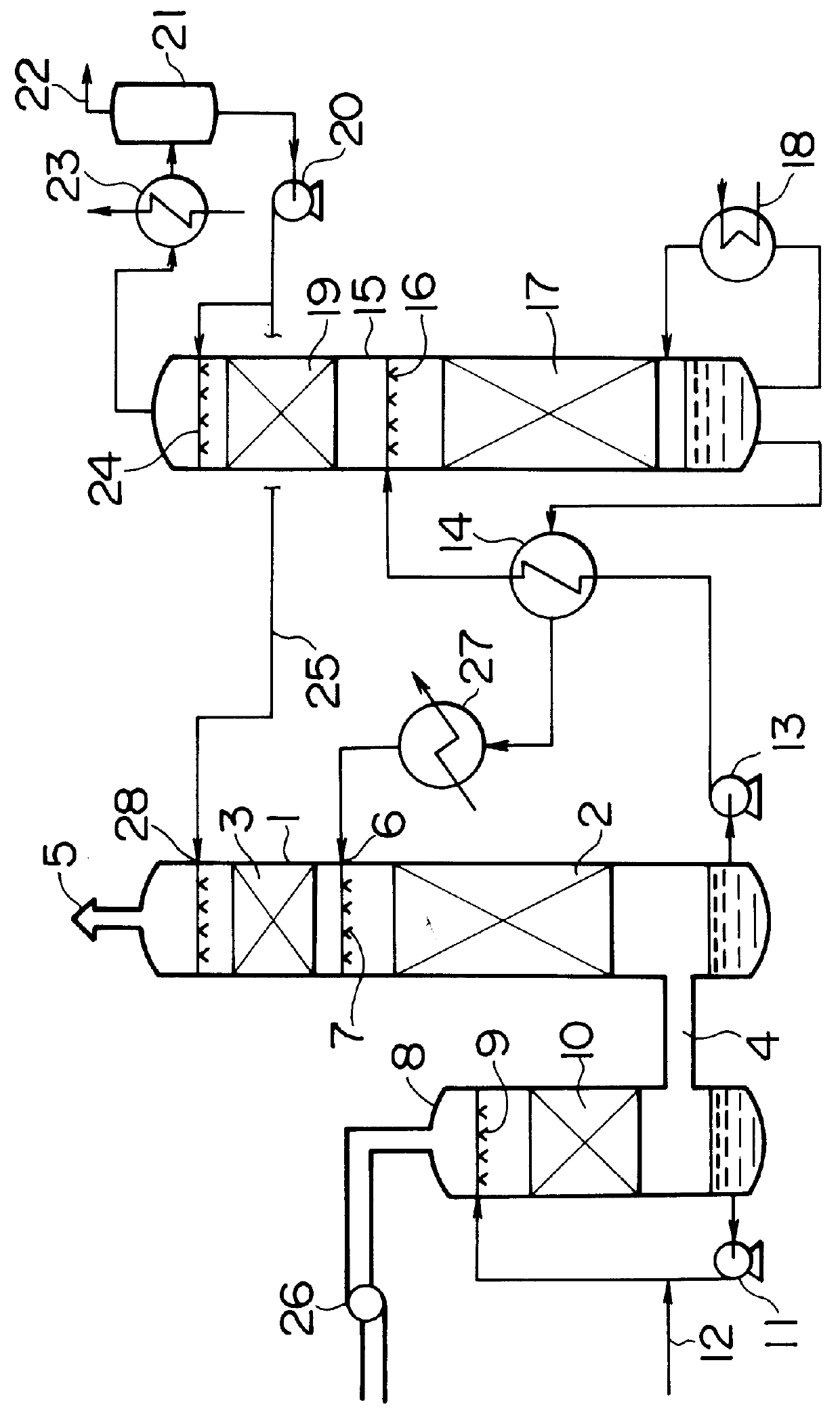

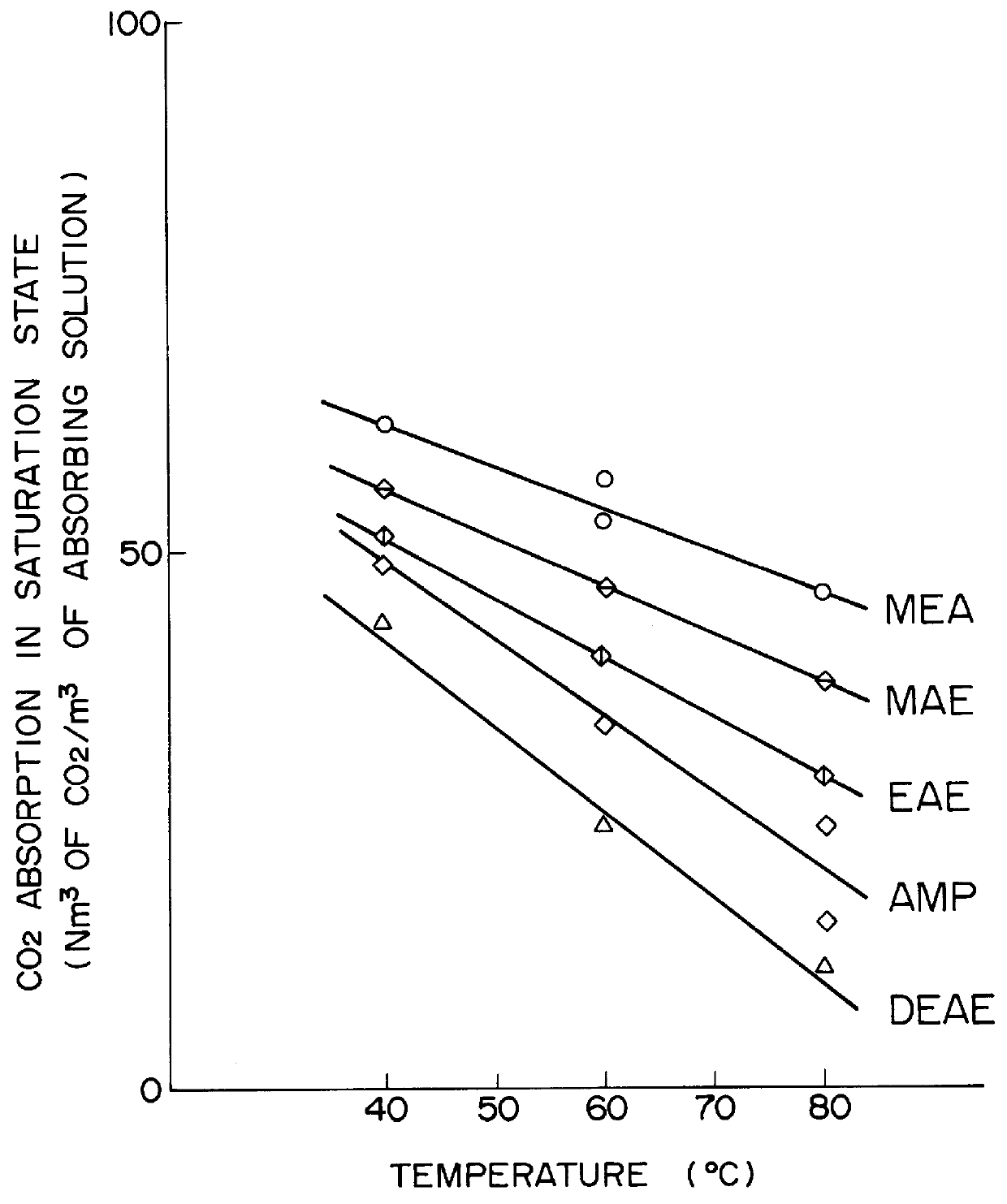

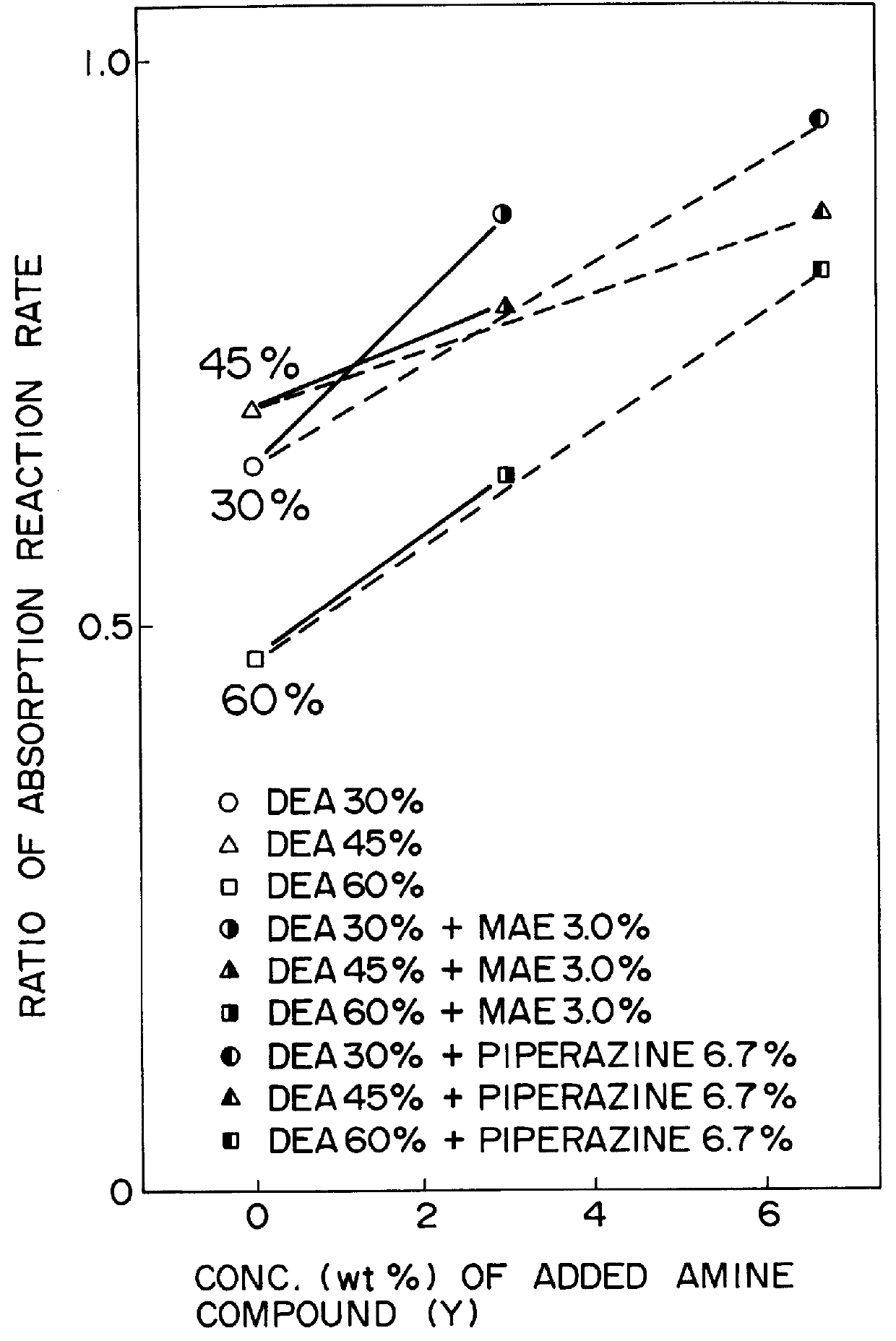

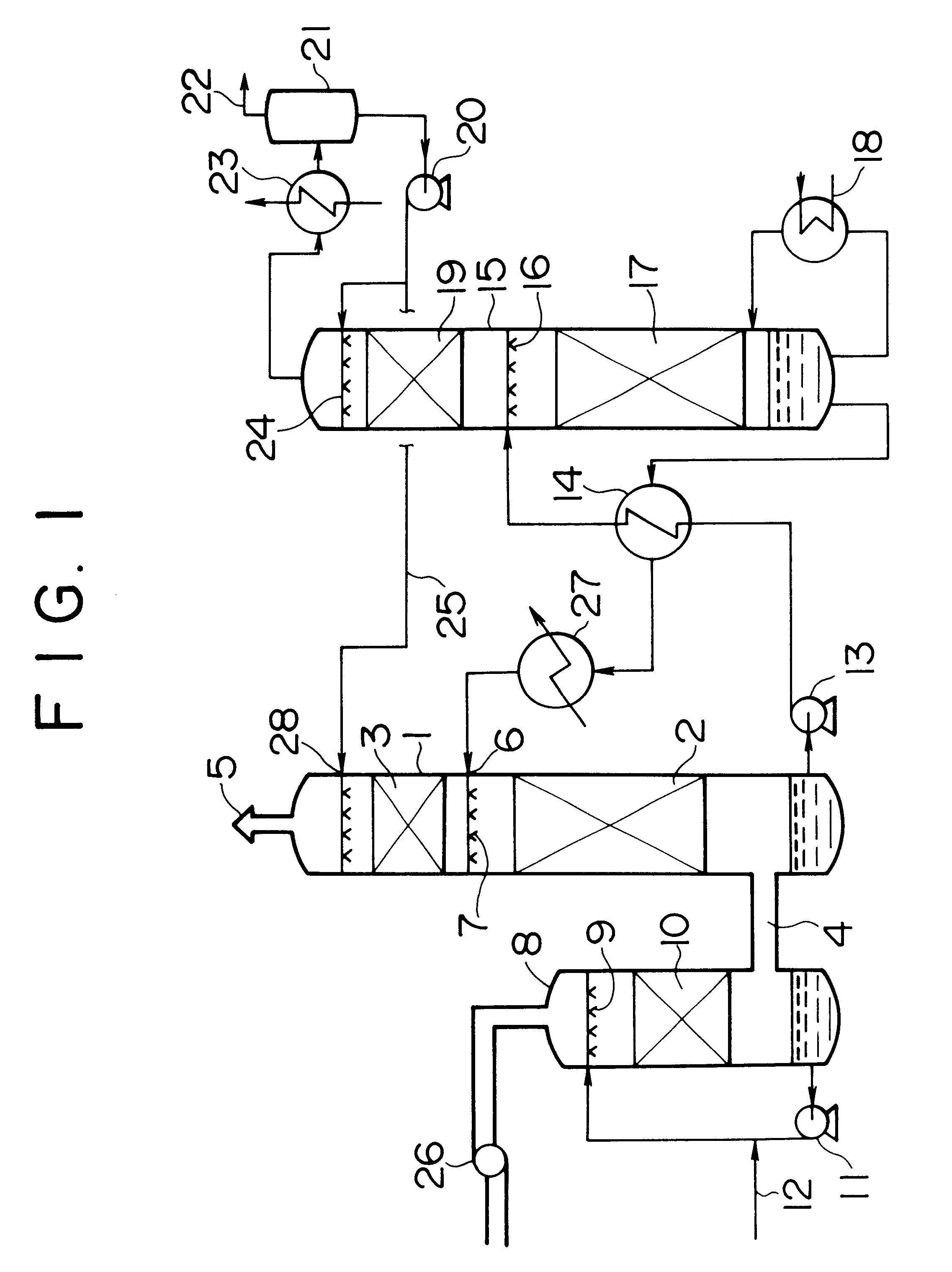

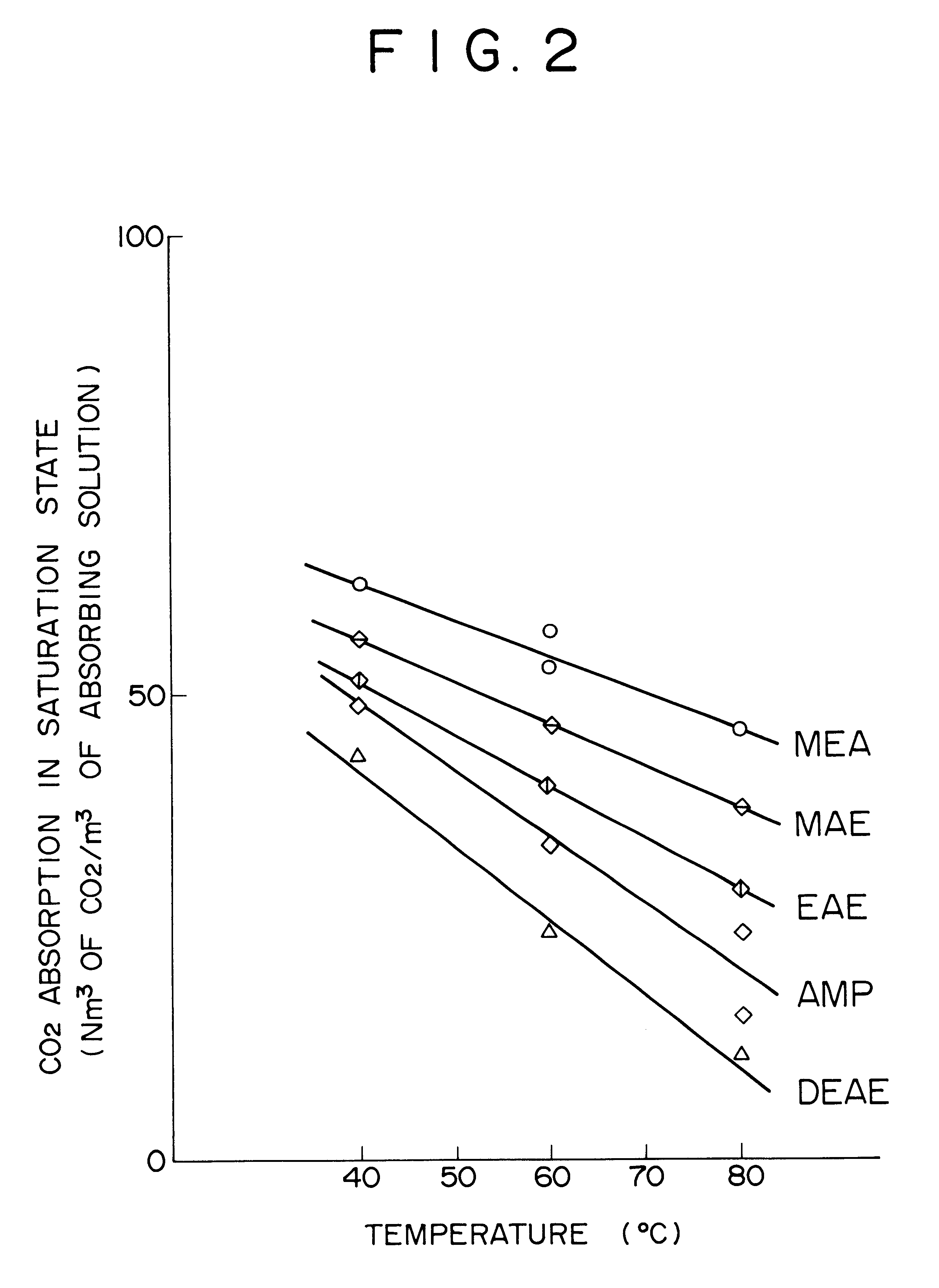

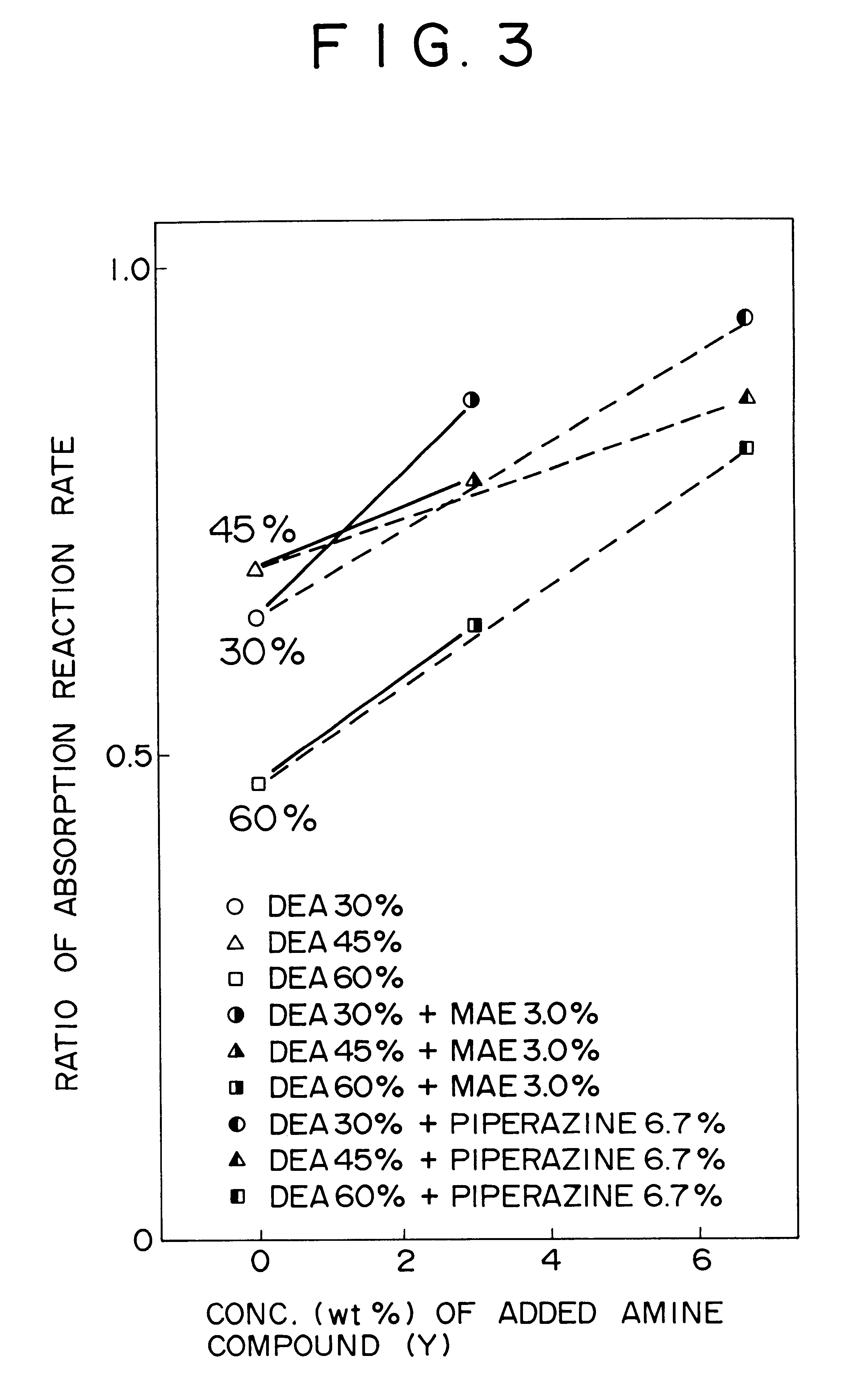

There are disclosed a method for removing CO2 from a combustion exhaust gas which comprises the step of bringing the combustion exhaust gas under atmospheric pressure into contact with an aqueous solution of a hindered amine selected from the group consisting of 2-amino-2-methyl-1-propanol, 2-methylaminoethanol, 2-ethylaminoethanol and 2-piperidineethanol; and another method for removing carbon dioxide from a combustion exhaust gas which comprises the step of bringing the combustion exhaust gas under atmospheric pressure into contact with a mixed aqueous solution of 100 parts by weight of an amine compound (X) selected from the group consisting of 2-amino-2-methyl-1,3-propanediol, 2-amino-2-methyl-1-propanol, 2-amino-2-ethyl-1,3-propanediol, t-butyldiethanolamine and 2-amino-2-hydroxymethyl-1,3-propanediol; and 1-25 parts by weight of an amine compound (Y) selected from the group consisting of piperazine, piperidine, morpholine, glycine, 2-methylaminoethanol, 2-piperidineethanol and 2-ethylaminoethanol.

Owner:THE KANSAI ELECTRIC POWER CO +1

Method for removing carbon dioxide from combustion exhaust gas

InactiveUS6500397B1Improve absorption rateHigh absorption rateHydrogen sulfidesDispersed particle separation2-methylaminoethanolMorpholine

There are disclosed a method for removing CO2 from a combustion exhaust gas which comprises the step of bringing the combustion exhaust gas under atmospheric pressure into contact with an aqueous solution of a hindered amine selected from the group consisting of 2-amino-2-methyl-1-propanol, 2-methylaminoethanol, 2-ethylamino-ethanol and 2-piperidineethanol; and another method for removing carbon dioxide from a combustion exhaust gas which comprises the step of bringing the combustion exhaust gas under atmospheric pressure into contact with a mixed aqueous solution of 100 parts by weight of an amine compound (X) selected from the group consisting of 2-amino-2-methyl-1, 3-propanediol, 2-amino-2-methyl-1-propanol, 2-amino-2-ethyl-1, 3-propanediol, t-butyldiethanolamine and 2-amino-2-hydroxymethyl-1,3-propanediol; and 1-25 parts by weight of an amine compound (Y) selected from the group consisting of piperazine, piperidine, morpholine, glycine, 2-methylamino-ethanol, 2-piperidineethanol and 2-ethylaminoethanol.

Owner:THE KANSAI ELECTRIC POWER CO +1

Hard Surface Cleaners Comprising Low VOC, Low Odor Alkanolamines

InactiveUS20130196893A1Organic detergent compounding agentsDetergent solventsSurface cleaningOctanol

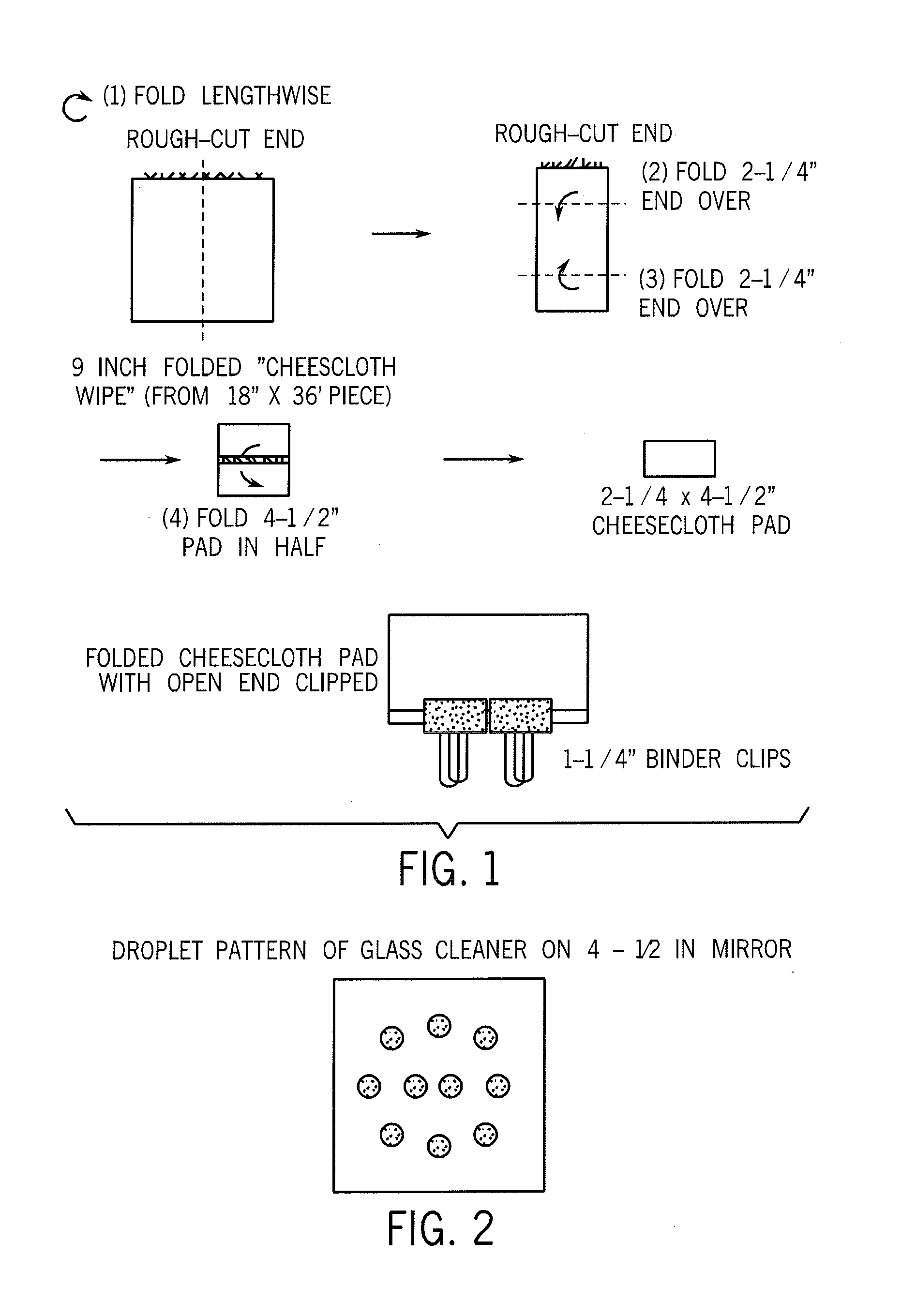

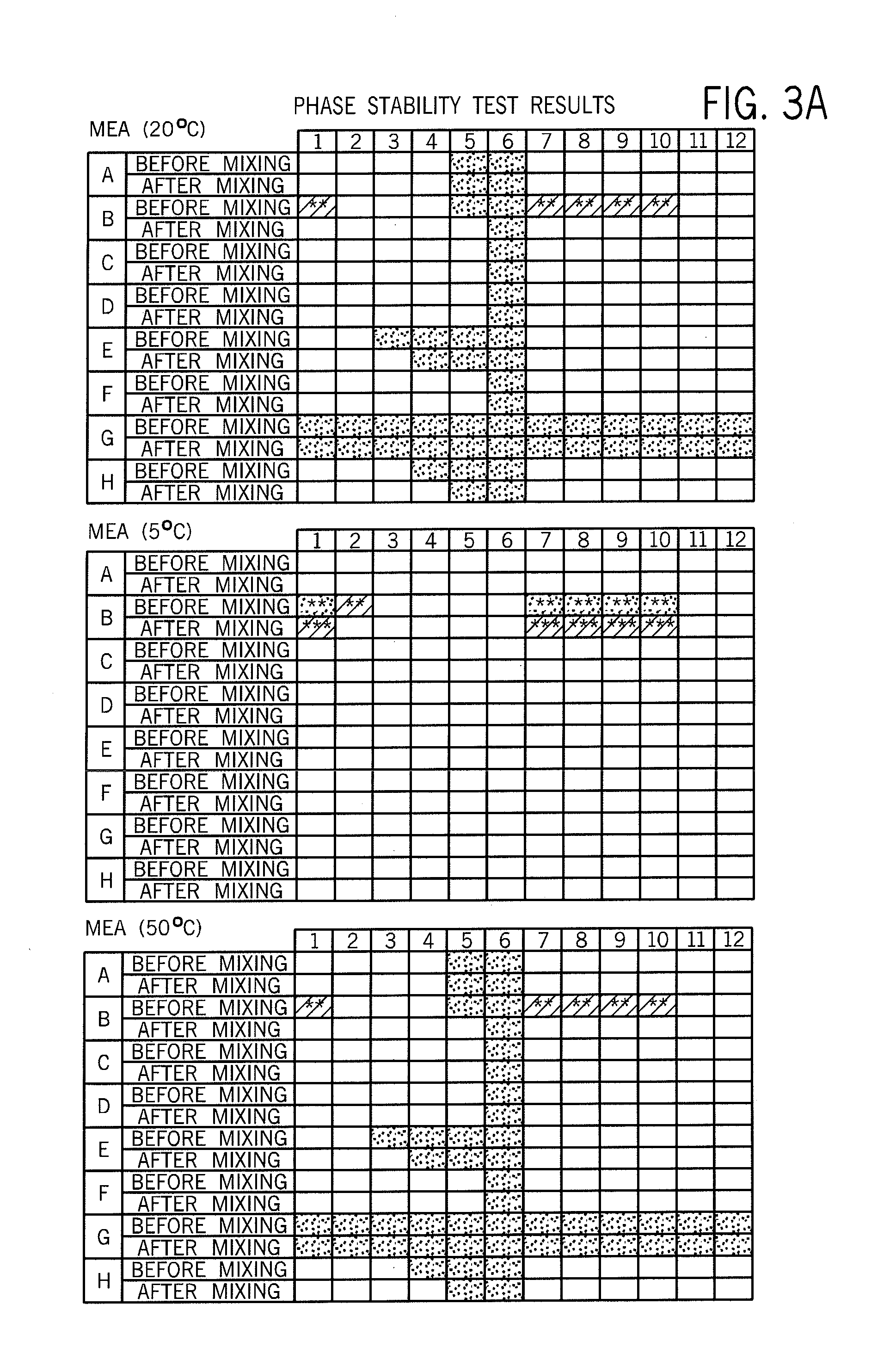

Hard surface cleaning compositions comprise: A. Surfactant, e.g., a nonionic ethoxylated alcohol; B. Solvent, e.g., propyleneglycol n-butyl ether; C. Low VOC, low odor, alkanolamine selected from the group consisting of tris(hydroxymethyl)amino methane; 2-amino-2-methyl-1,3-propanediol; 2-amino-2-ethyl-1,3-propanediol; 2-amino-2-methyl-1-propanol; N,N-dimethylamino-2-methyl-1-propanol; and 3-amino-4-octanol; D. Water, and E. Optionally, one or more of an alkaline agent, builder, fragrance, preservative, biocide, colorant, dye and rheology modifier.

Owner:BUSBY MOLLY I +1

Organic amine compound absorbent for removal of carbon dioxide in fire coal flue gas

ActiveCN103394277AImprove protectionSolving Corrosion ProblemsDispersed particle separationBy chemical separationSulfolaneAbsorption capacity

The invention discloses an organic amine compound absorbent for removal of carbon dioxide in fire coal flue gas; the organic amine compound absorbent comprises the following components: by mass, 10%-45% of a main absorbent component, 0-10% of an assistant absorbent component, 0.01%-6% of a corrosion inhibitor, 0.01-3% of an antioxidant, 0-5% of a defoaming agent and the balance of water; wherein the main absorbent component comprises the following components: account for the total mass percentage of the organic amine composite absorbent, 3%-20% of monoethanolamine MEA, 0-12% of 2-amino-2-methyl-1-propanol AMP, 1%-15% of sun of piperazine PZ and N-aminoethyl piperazine AEP and 1%-12% of sum of aminoethyl ethanolamine AEEA and N-methyl monoethanolamine MMEA; and the assistant absorbent comprises one or a plurality of component selected from the group comprising diethanol amine DEA, diethylenetriamine DETA, triethylene tetramine TETA, N-methyldiethanolamine MDEA, sulfolane and tertbutylaminoethoxyethanol TBEE. The organic amine compound absorbent has the advantages of good stability, large absorption capacity, high purification degree, low regeneration energy consumption, good desorption effect, great reduction of degradation loss of the compound absorbent in the process of using, and the like.

Owner:STATE GRID CORP OF CHINA +1

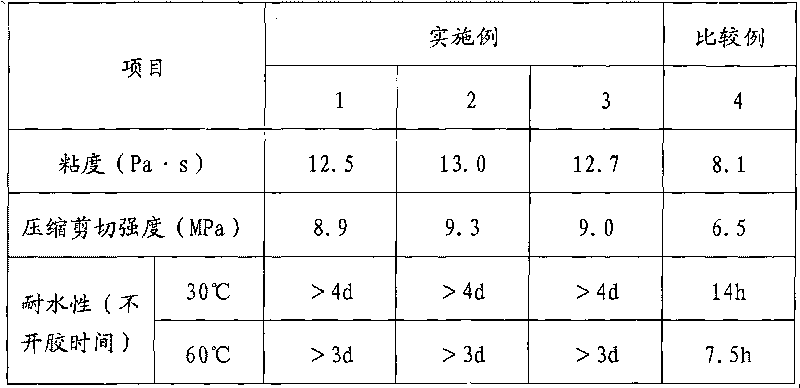

Water-resistant white latex

ActiveCN101705065AImprove water resistanceIncrease crosslink densityMonocarboxylic acid ester polymer adhesivesMacromolecular adhesive additivesAdhesive1-Propanol

The invention discloses water-resistant white latex, which comprises the following main components: vinyl acetate, butyl acrylate, diacetone acrylamide, N-hydroxymethyl acrylamide, polyvinyl formal water agent, dibutyl phthalate, deionized water, initiator, defoamer, glycol alcohol, emulsifier, 2-amino-2-methyl-1-propanol. The white latex has the following advantages that: 1, polyvinyl formal is used as protective colloid to improve the water resistance of adhesive; 2, the diacetone acrylamide and the N-hydroxymethyl acrylamide are added as modification-polymerization monomer so as to increase crosslinking density and improve bonding strength; and 3, the butyl acrylate is added as the modification-polymerization monomer, and the copolymerization of the butyl acrylate and the vinyl acetate can reduce the glass transition temperature and minimum film-forming temperature of the white latex, improve the low-temperature film-forming performance of emulsion and play a role in internal plasticization so as to increase the flexibility of the white latex.

Owner:GUANGDONG SANVO CHEM IND TECH

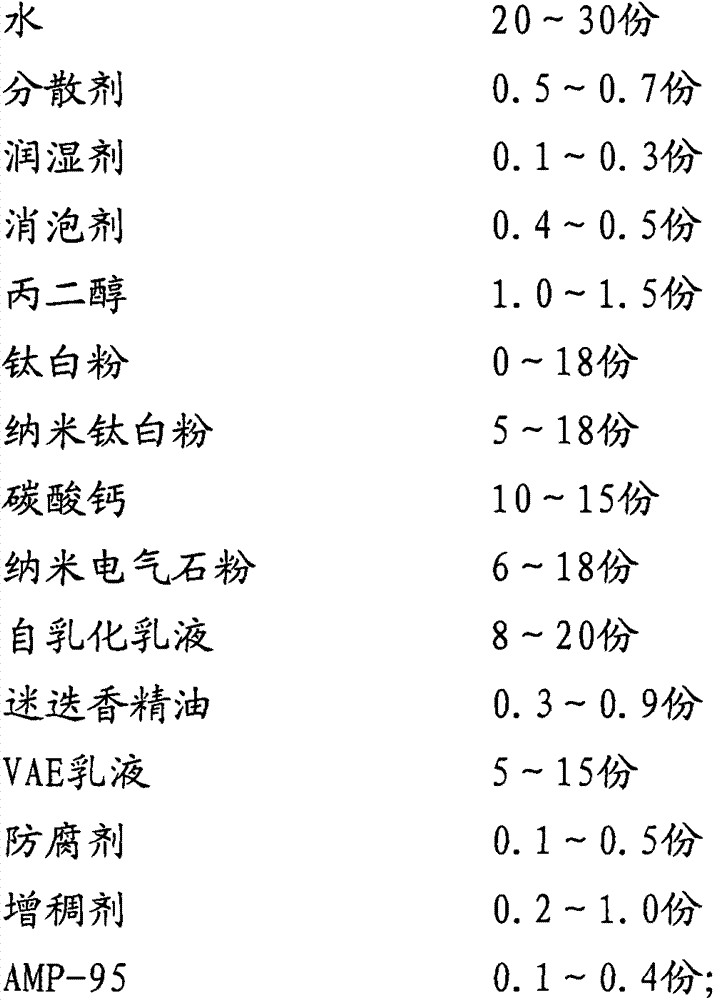

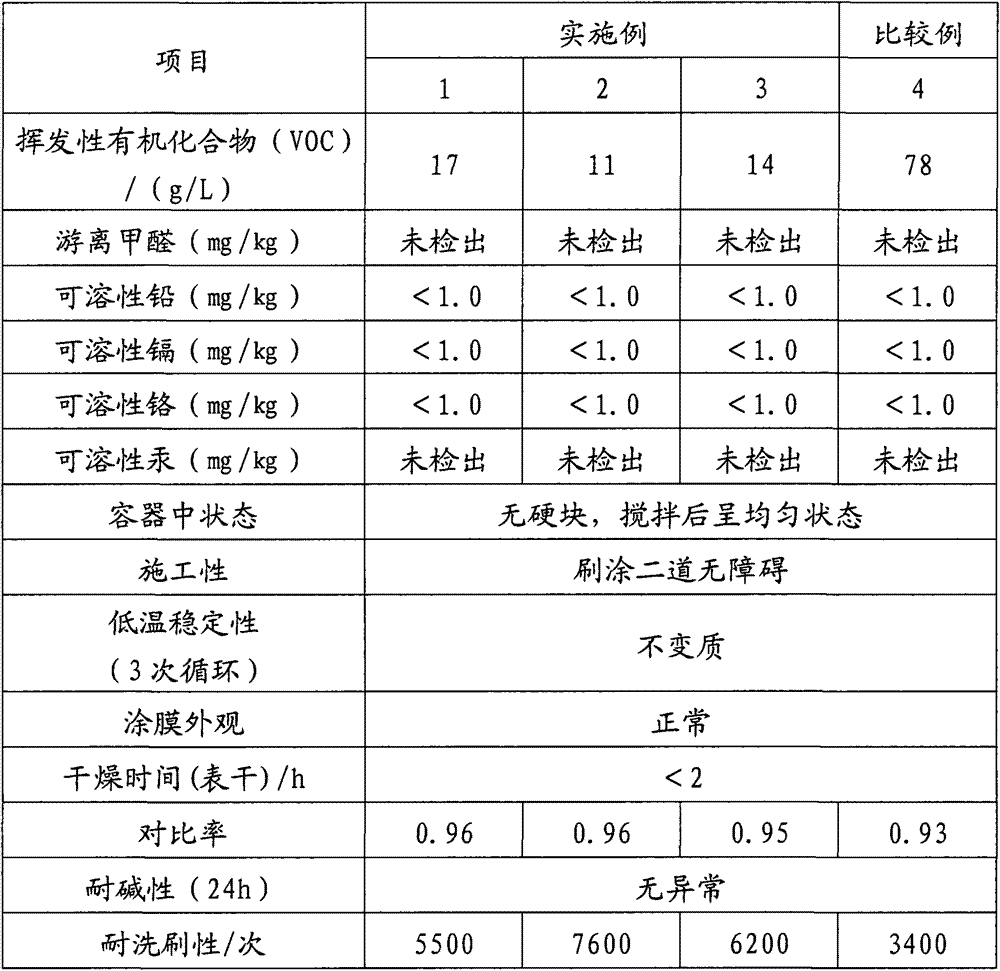

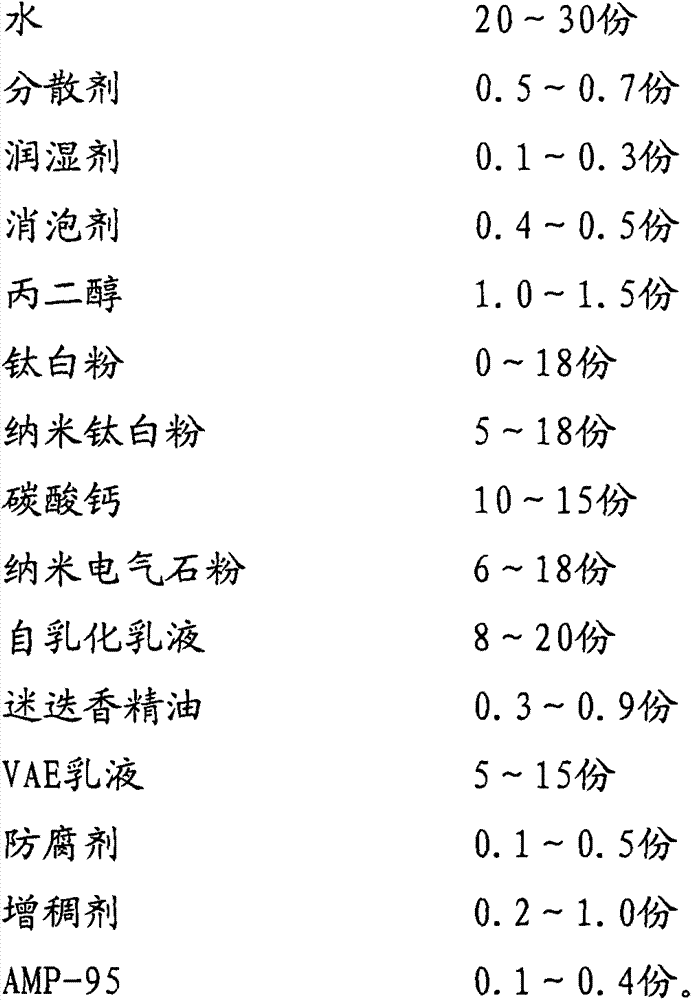

Environment-friendly emulsion paint and preparation

InactiveCN103756520AVAE reductionEnvironmental protection is goodAntifouling/underwater paintsPaints with biocidesPliability2-methyl-1-propanol

The invention discloses environment-friendly emulsion paint and preparation. The emulsion paint consists of water, a dispersant, a wetting agent, a defoamer, propylene glycol, titanium dioxide, nano titanium dioxide, calcium carbonate, nano tourmaline powder, a self-emulsified emulsion, rosemary essential oil, a VAE (Vinyl Acetate-ethylene Emulsion) emulsion, a preservative, a thickener and AMP-95 (2-amino-2-methyl-1-propanol). The paint has the advantages of being good in environmental performance, and effectively reducing VOC (Volatile Organic Compounds), having a health-care function, fragrance for keeping a cool head and functions of strengthening, sweating, invigorating stomach, soothing the nerves and treating headache, and expanding blood capillaries, promoting blood circulation, improving the immunity of human body and accelerating absorption of essential oil by human body by released far infrared heat effect, having an antibacterial function and high weather resistance of a film, improving the fullness and the flexibility of the film, and also improving the durability, chemical resistance and adhesive force of the film.

Owner:GUANGDONG SANVO CHEM IND TECH

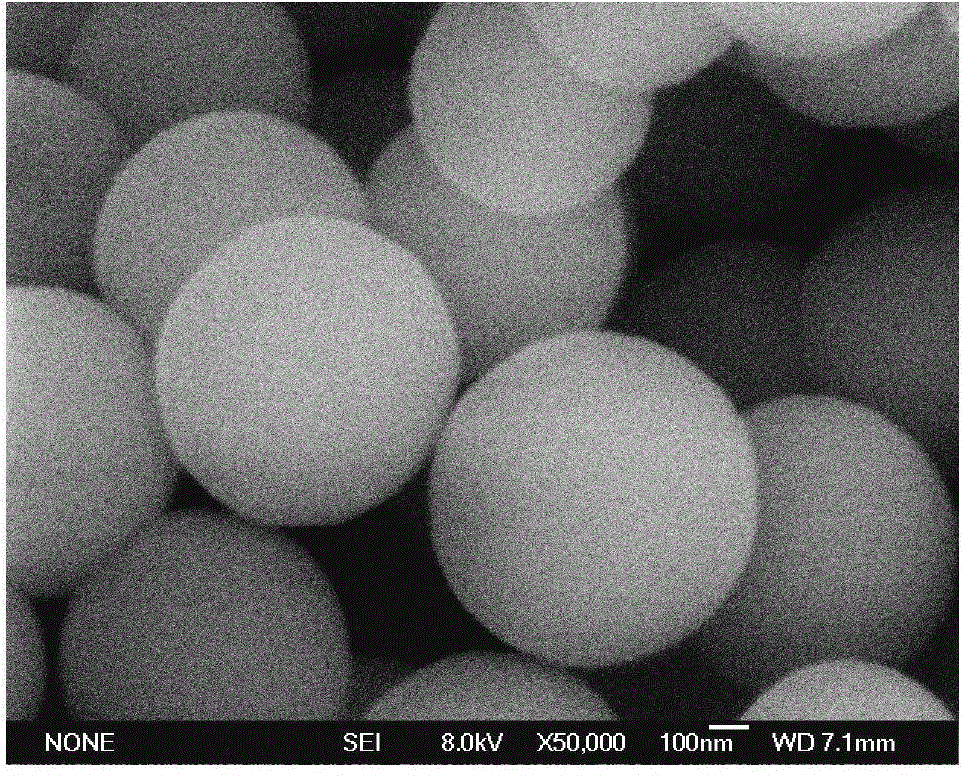

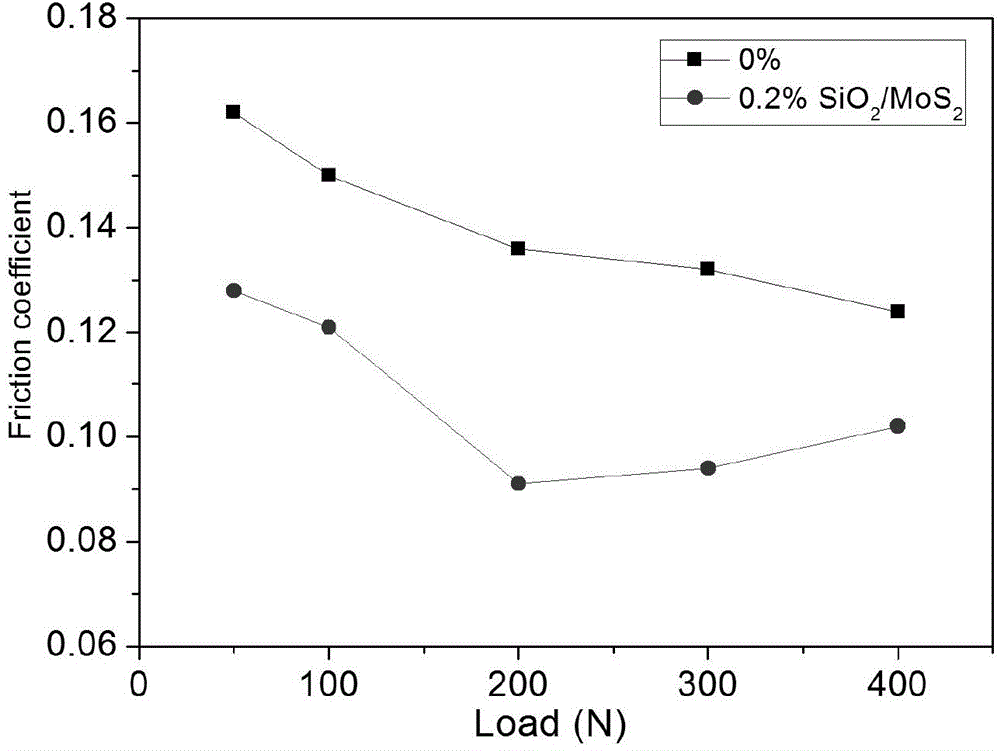

SiO2/MoS2 core-shell-structure microspheres and preparation method thereof

ActiveCN104694208AImprove the coordination effectImprove stabilityAdditivesDispersityEthylenediamine

The invention discloses SiO2 / MoS2 core-shell-structure microspheres and a preparation method thereof. The method comprises the following steps: dissolving tetraethoxyl silicion and triethanolamine (or diethanolamine or ethylenediamine or 2-amino-2-methyl-1-propanol) in anhydrous ethanol, dropwisely adding distilled water, and carrying out hydrolysis reaction under certain conditions to prepare SiO2 microspheres; and dispersing the obtained SiO2 microspheres in a water solution containing ammonium molybdate, polyvinylpyrrolidone (K30) and sodium diethyldithiocarbamate, and carrying out hydrothermal reaction in a high-pressure autoclave to obtain the SiO2 / MoS2 core-shell microspheres. The SiO2 microspheres prepared by the method have uniform size; and the composite SiO2 / MoS2 core-shell microspheres have the advantages of uniform shape and size and favorable dispersity, and can be used for a lubricating oil additive to improve the lubricating conditions.

Owner:峰特(浙江)新材料有限公司

Elastic paint for exterior wall decoration and its manufacturing method

The invention relates to an elastic paint for exterior wall decoration and its manufacturing method, which is prepared from acrylic acid self-crosslinking copolymerized emulsion, 5-chloro-2-methyl-4-isothiazoline-3-one, n-octylisothiazolin-one, ammonium polycarboxylate, alkyl phenol polyoxyethylene ether, hydroxyethyl cellulose, 3-n-butylphosphoric ester, propylene glycol, 2,2,4-trimethyl-1,titanium dioxide, calcium, talcum powder, porcelain clay, 2-amido-2-methyl-1-propanol and polyurethane modified polyether through agitating and grinding.

Owner:TIANJIN BO XING ENG SCI & TECH LIMITED COMPANY OF CNPC

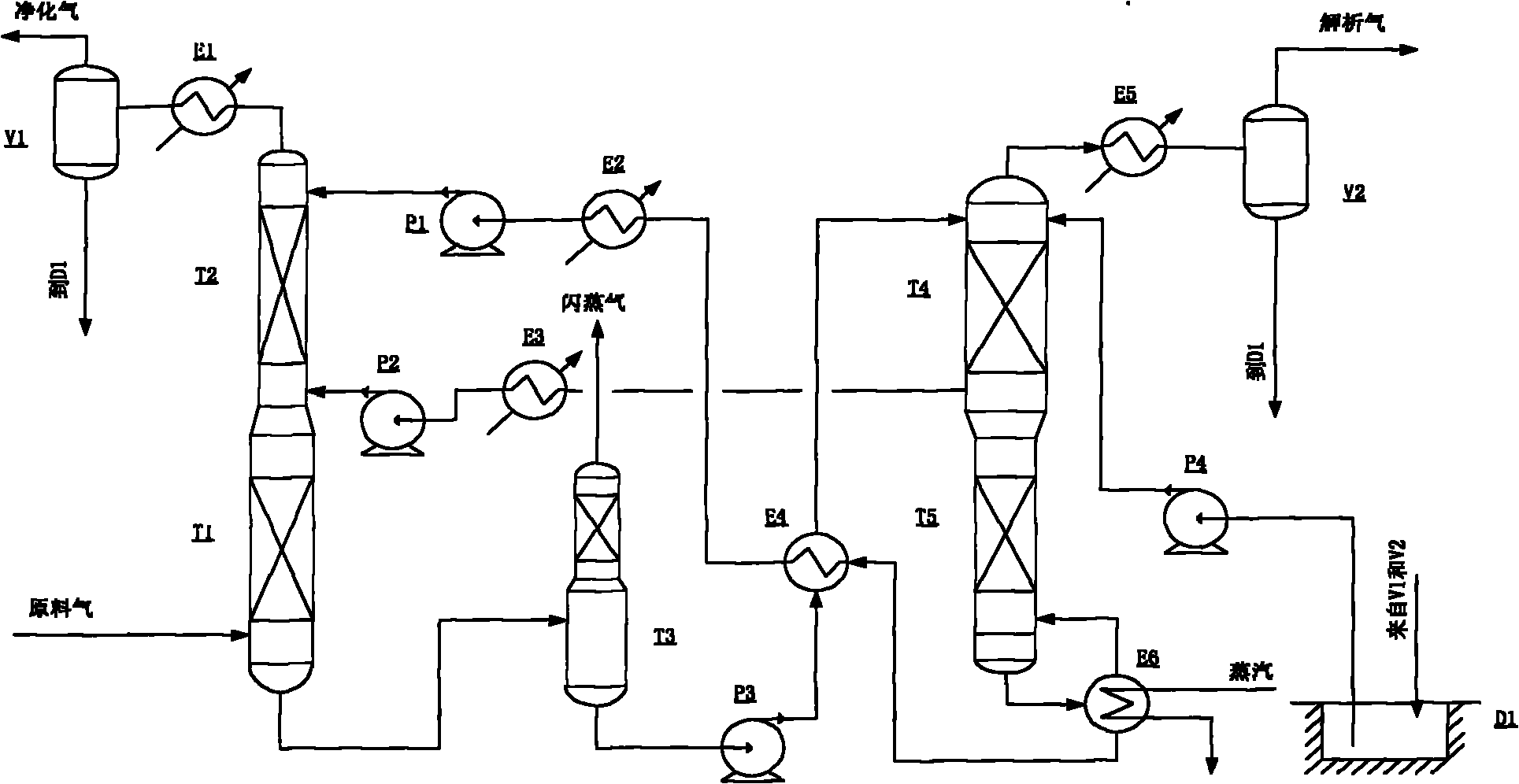

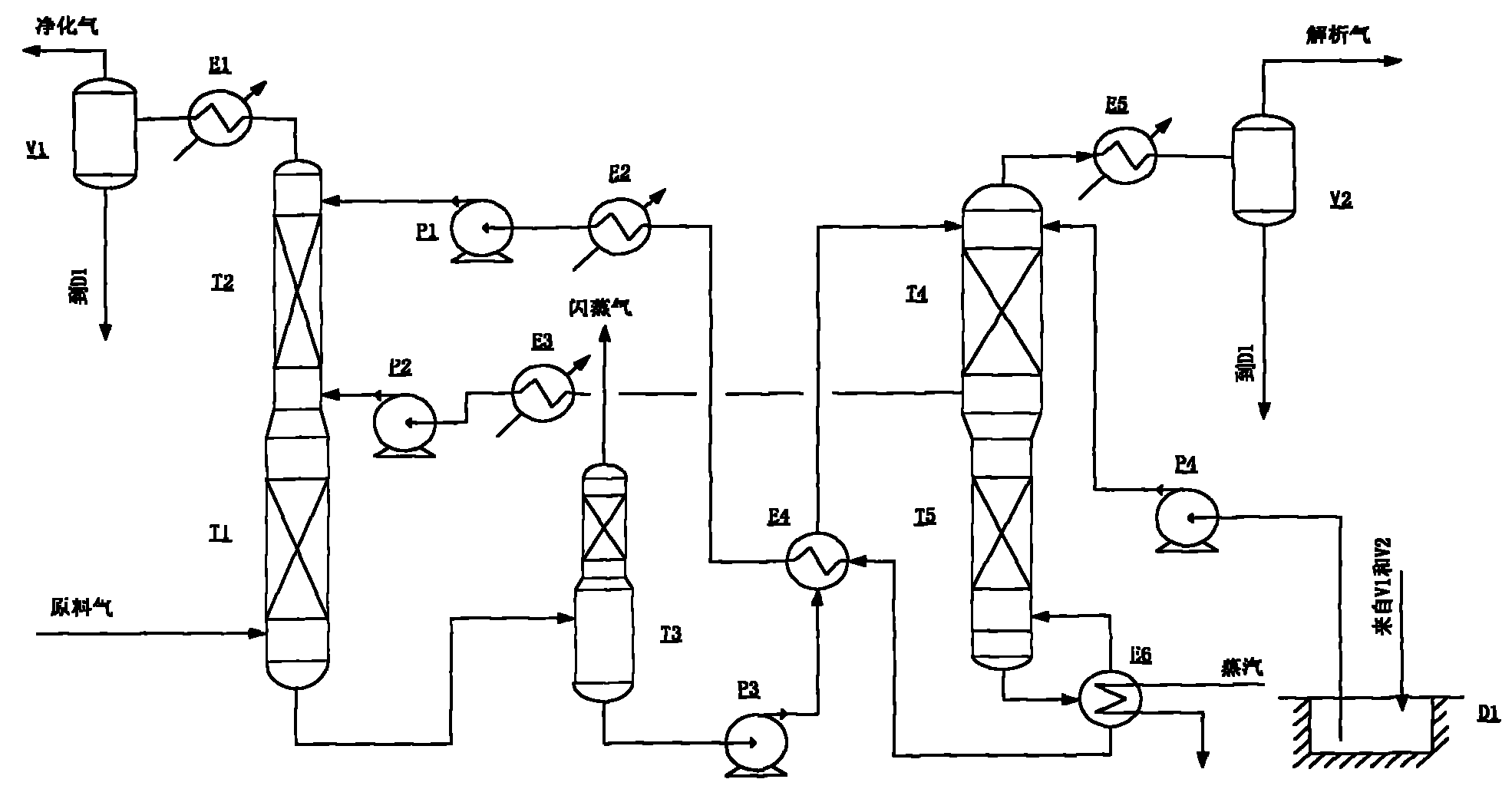

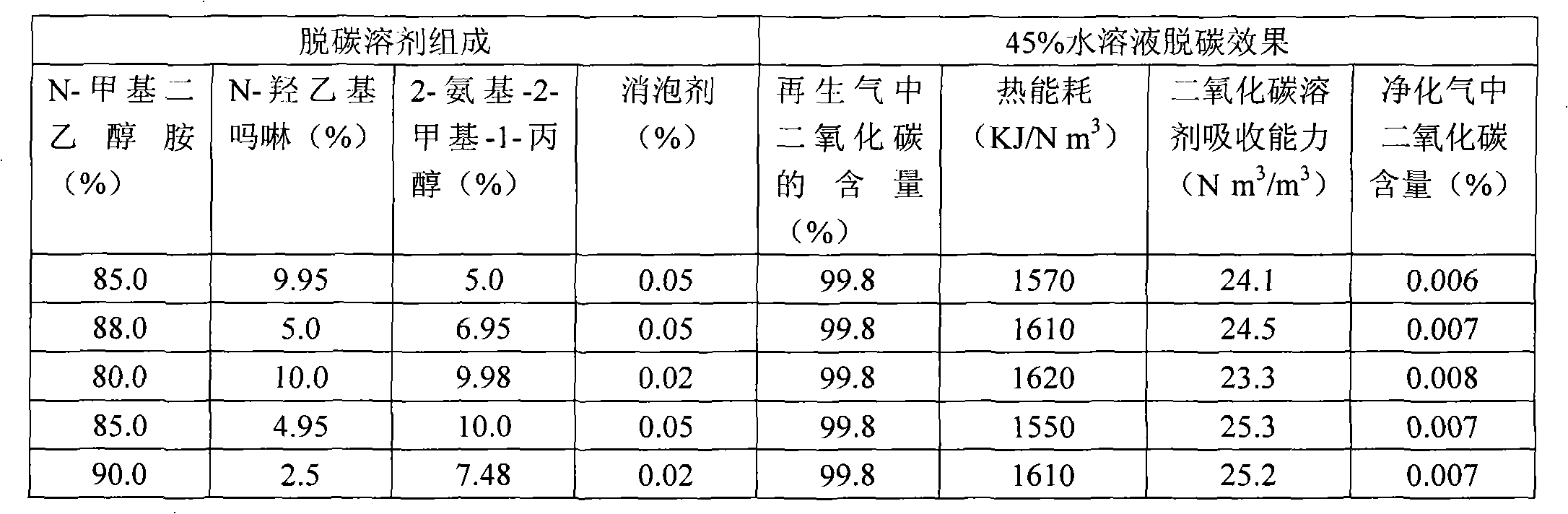

Novel high-efficient compound decarbonization solvent

ActiveCN101816878AHigh boiling pointReduce volatilityProductsCarbon compoundsAbsorption capacityCo2 absorption

The invention discloses a novel high-efficient compound decarbonization solvent which comprises N-methyldiethanolamine and an active agent. The active agent is a mixture which consists of at least two of N-hydroxyethyl morpholine, 2-amino-2-methyl-1-propanol and piperazine, wherein the weight ratio of the N-hydroxyethyl morpholine is 80 to 90 percent; the weight ratio of the active agent is 10 to 20 percent and a defoaming agent is also added into the compound decarbonization solvent. The novel high-efficient compound decarbonization solvent has the advantages of high carbon dioxide absorption capacity, high purification degree, low regeneration energy consumption, and no foams after long-term use of the decarbonization solvent.

Owner:四川精事达科技有限公司

Environmental protection type high performance emulsion paint

An environmental protection type high-performance emulsion paint contains water, alcohol-type filming agent, 2-amino-2-methyl-1-propanol, anionic polycarboxylic acid, isobutyrate-type filming assistant, rutile-type titanium white powder, anatase-type titanium white powder, superfine talc powder, phenylpropane emulsion, chelated titanate as coupling agent, polyurethane a vheologic modifier, and antibacterial antiaseptic. Its advantages are low VOC, low poison and high mechanical performance.

Owner:刘文录

Method for preparing waterborne plastic toy paint

The invention provides a method for preparing a waterborne plastic toy paint. The paint comprises the following components in percentage by weight: 50 to 70 percent of copolymer emulsion A of butyl acrylate, styrene and acrylonitrile, 10 to 15 percent of copolymer emulsion B of methyl methacrylate, styrene and N-methylol acrylamide, 2 to 5 percent of propylene glycol butyl ether film forming auxiliary agent, 5 to 7 percent of mono-isobutyric acid trimethyl pentanediol ester film forming auxiliary agent, 0.1 to 0.4 percent of polysiloxane and polyester copolymer leveling agent, 0.1 to 0.4 percent of polysiloxane mixture defoaming agent, 0.1 to 0.4 percent of associative type polyurethane thickener, 0.1 to 0.4 percent of 2-amino-2-methyl-1-propanol organic amine neutralizer, 2 to 6 percent of hard polyethylene wax emulsion, 0 to 15 percent of deionized water and 0 to 25 percent of color paste; and the preparation method comprises the following steps of: adding all the acrylic acid emulsion, deionized water, organic amine neutralizer, leveling agent, defoaming agent, film forming auxiliary agents and wax emulsion to a paint mixing kettle with stirring at a rotary speed of 60 to 120rpm, stirring the mixture at a rotary speed of 200 to 300rpm for 10 to 20min, adding the color paste to the mixture at a rotary speed of 60 to 120rpm, stirring the mixture at a rotary speed of 200 to 300rpm for 10 to 20min, adding the thickener until the viscosity of the mixture meets the index of 70 to 110s(paint-1 cup) and the adhesive force of the spraying plate paint film reaches the first grade(by the cut test on an ABS plate), and filtering and packaging.

Owner:SHANGHAI HUAYI FINE CHEM CO LTD

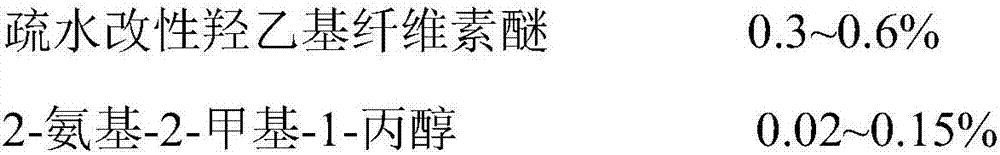

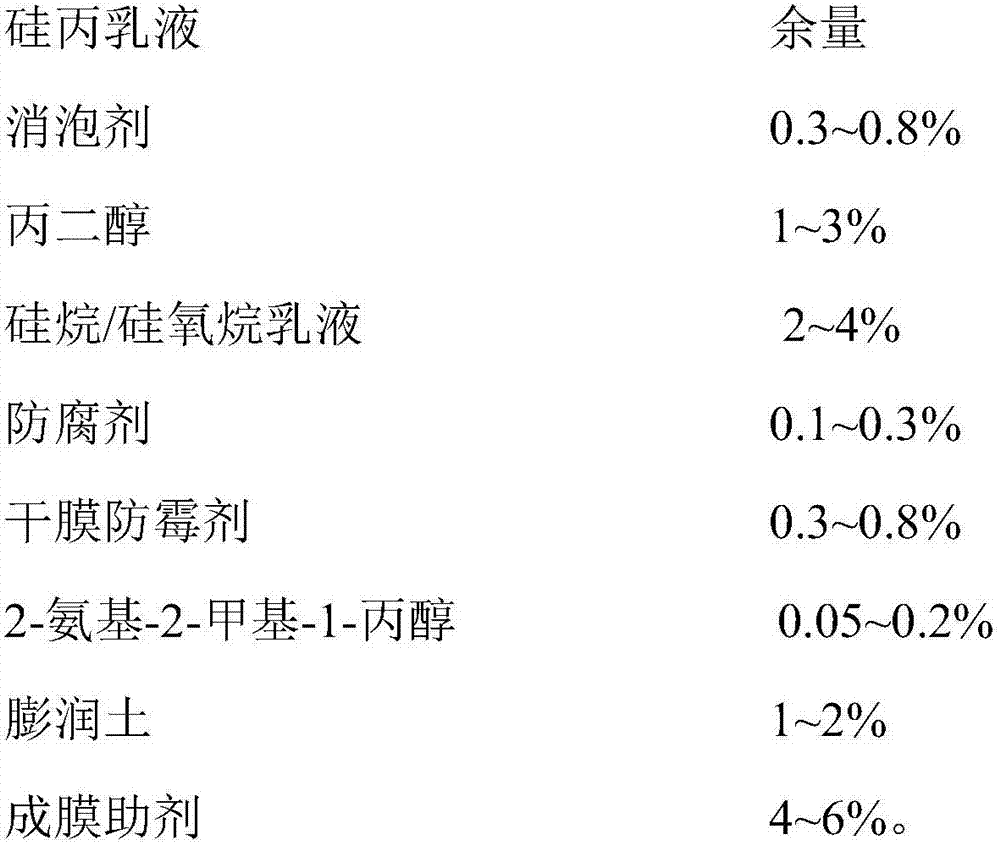

Waterproof heat-insulated granite-speckle-imitated multi-color paint and preparation method thereof

InactiveCN107129735AMeet the progress requirements of energy conservation and environmental protectionGood weather resistanceAntifouling/underwater paintsPaints with biocidesSodium BentoniteSilanes

The invention discloses a waterproof heat-insulated granite-speckle-imitated multi-color paint and a preparation method thereof. The waterproof heat-insulated granite-speckle-imitated multi-color paint comprises a base paint and a continuous phase, wherein the base paint mainly comprises hydrophobic modified hydroxyethyl cellulose ether, 2-amino-2-methyl-1-propanol, propylene glycol, a silicone acrylic emulsion, a silane / siloxane emulsion, a heat reflection high-molecular polymer, a protective colloid solution, hollow glass beads, quartz sand and water; the continuous phase mainly comprises a silicone acrylic emulsion, propylene glycol, a silane / siloxane emulsion, 2-amino-2-methyl-1-propanol and bentonite; the protective colloid solution consists of synthetic flake silicate, a preservative and deionized water; and the protective colloid solution and a colored paint are made into sand in water colored grains, and the colored grains and components of the continuous phase are made into an end paint. The waterproof heat-insulated granite-speckle-imitated multi-color paint is high in weatherability, water resistance and cost performance, is heat-insulated and has high simulation ability, and construction procedures are saved.

Owner:广东东艺宝建材有限公司

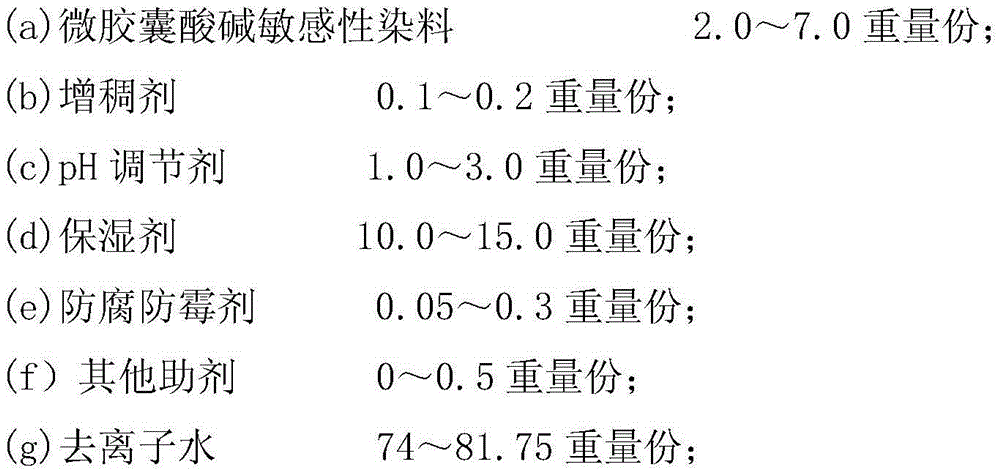

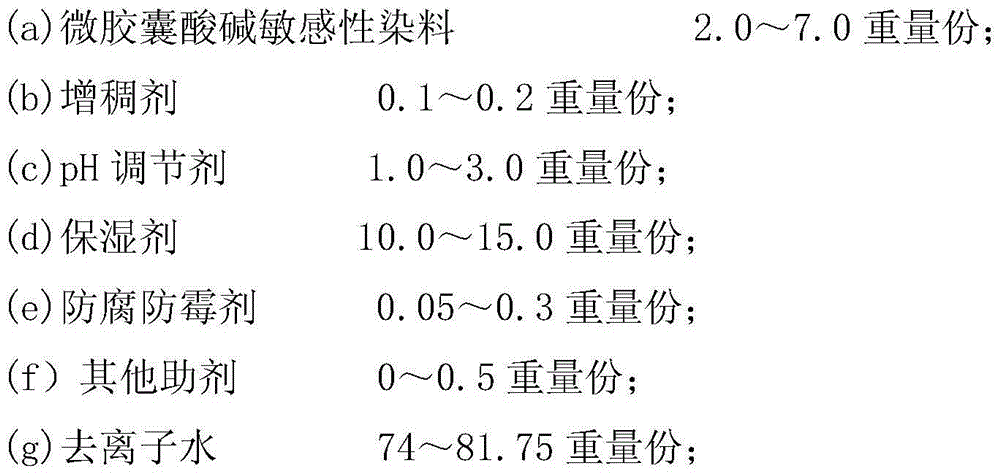

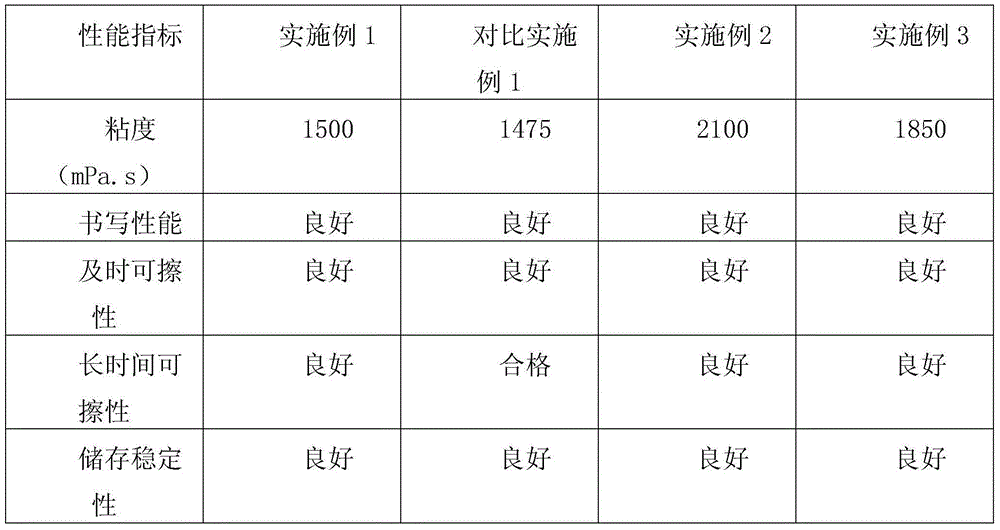

Erasable neutral ink and preparation method thereof

The invention provides an erasable neutral ink composition comprising a neutral ink component (A) and an erasable liquid component (B), wherein the component (A) comprises the following components in parts by weight: 2.0-7.0 parts of a microcapsule acid-alkali sensitive dye (a), 0.1-0.2 part of a thickening agent (b), 1.0-3.0 parts of a pH regulator (c), 10.0-15.0 parts of a humectant (d), 0.05-0.3 part of an antiseptic and anti-mildew agent (e), 0-0.5 part of other auxiliary agents (f) and 74-81.75 parts of deionized water (g), wherein the total weight of the components (a)-(g) accounts for 95-100% of the total weight of the composition, the viscosity of the neutral ink component is 1500-3000mPa.s, and the thixotropic value is more than or equal to 2.5; and the component (B) is an alkaline solution comprising an aqueous solution of one or more of sodium hydroxide, 2-amino-2-methyl-1-propanol, N-methylethanolamine, dimethylethanolamine, monoethanolamine, diethanolamine, triethanolamine, butyl ethanolamine, butyl diethanolamine, 2-amino-2-ethyl-1,3-propylene glycol and N-aminopropyl-methylethanolamine.

Owner:LOTUS STATIONERY

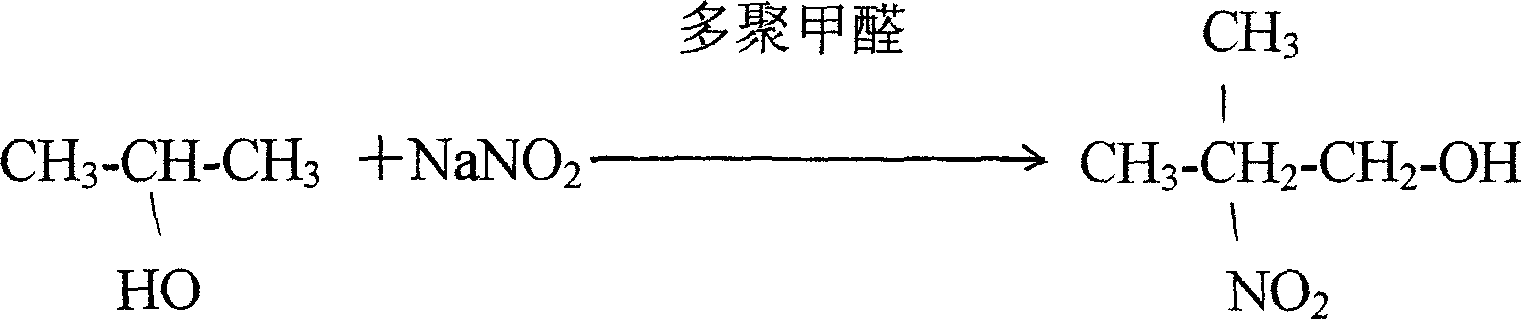

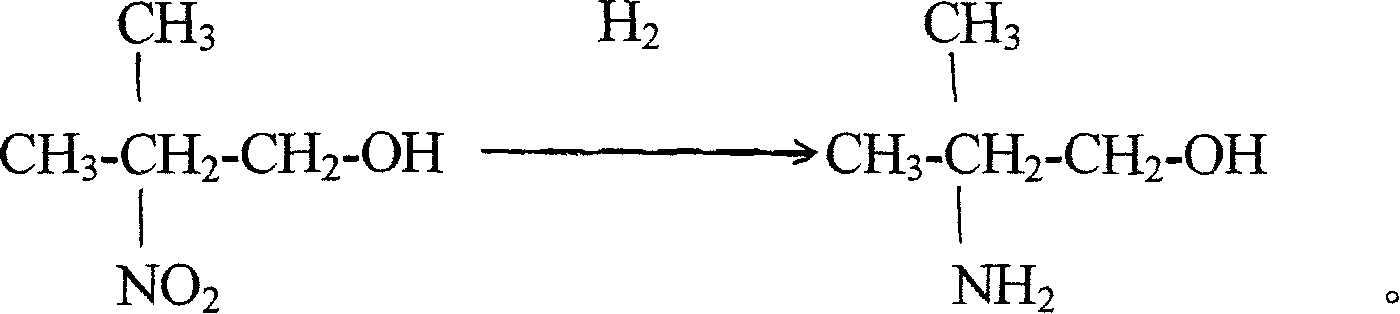

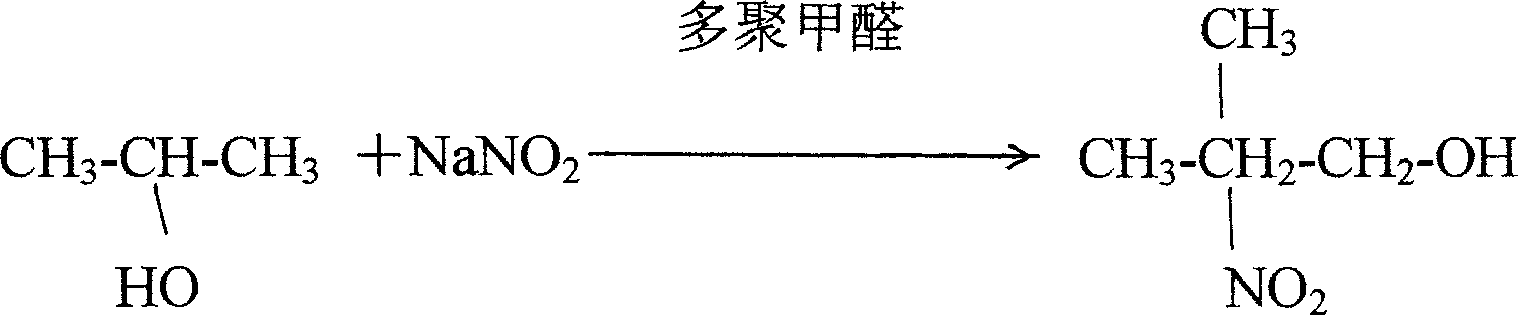

Production process of 2-amino-methyl-1-propanol

InactiveCN1810767ASimple processEasy to operateOrganic compound preparationAmino-hyroxy compound preparationPropanol1-Propanol

The present invention discloses one kind of production process of 2-amino-2-methyl-1-propanol. The production process includes the steps of: the reaction of sodium nitrite, isopropanol and polyformaldehyde to obtain 2-nitro-2-methyl-propanol crystal; and reaction of 2-nitro-2-methyl-propanol crystal and H2 to produce 2-amino-2-methyl-1-propanol. The production process is simple, easy in operation, and high in product purity, higher than 98 %.

Owner:符爱清

Aqueous light color nanometer static-conductive coating for inner wall and its production method

The invention relates to a water-based nano paint for internal walls as well as the preparing process, wherein the paint comprises (by weight ratio) polyacrylic ester emulsion 35-40, polyurethane thickening agent 0.4-0.8, polyacrylic ammonia salt dispersing agent 0.6-3, propylene glycol 3-10, chloromethyl or methoylisothiazolinone or their mixture 0.15-0.25, organosilicon defoaming agent 0.05-0.3, non-ionic surface active agent 0.2-0.4, 2-amido-2-methyl-1-propanol 0.2-0.4, nano stannic anhydride6-16, titanium dioxide powder 9-12, and balancing water.

Owner:SHANGHAI RES INST OF BUILDING SCI CO LTD

Alkyd resin coating for industrial outer wall and preparation method thereof

InactiveCN105038543AImprove adhesion performanceImprove adhesionAnti-corrosive paintsPolyester coatingsResin coatingDimethyl siloxane

The invention discloses an alkyd resin coating for an industrial outer wall. The alkyd resin coating comprises, by weight parts, 60-68 parts of drying oil alkyd resin, 20-50 parts of epoxy modified alkyd resin, 15-30 parts of acyclic acid modified alkyd resin, 2-4 parts of propylene glycol monomethyl ether acetic ester, 5-10 parts of propylene glycol, 5-10 parts of alcohol etherification melamine resin, 2-8 parts of urea resin, 1-3 parts of 2-amino-2-methyl-1-propanol, 20-25 parts of carboxymethyl cellulose, 1-3 parts of silane coupling agent, 1-4 parts of sodium dodecylbenzene sulfonate, 1-3 parts of polyoxyethylene polyoxypropylene ether, 1-2 parts of wetting agent, 1-3 parts of solydimethyl siloxane, 0.5-1.5 parts of preservative, 1-2 parts of hydroxypropyl guar gum, 40-60 parts of water, 5-20 parts of amyl acetate, 5-10 parts of super fine calcium carbonate, 2-8 parts of magnesium silicate, 6-10 parts of kaolin and 2-8 parts of china clay. The invention further discloses a method for preparing the alkyd resin coating for the industrial outer wall. The alkyd resin coating for the industrial outer wall is good in adhesive force and excellent in corrosion resistance.

Owner:ANHUI KAILIN ADVANCED MATERIAL CO LTD

Down washing agent and preparation method thereof

InactiveCN103451954AEfficient removalGood conditionFibre treatmentAmpholytes/electroneutral surface-active compoundsSodium bicarbonateSodium laurate

The invention provides a down washing agent which is characterized by being prepared from the following raw materials in parts by weight: 1-2 parts of polyoxyethylene octadecanol ether, 3-4 parts of rosin-polythylene oxide ester, 3-4 parts of betaine, 1-2 parts of sodium laurate, 2-3 parts of dimer acid, 1-2 parts of sodium bicarbonate, 2-3 parts of polyisobutylene, 4-5 parts of 2-amino-2-methyl-1-propanol, 3-4 parts of softening agent and 150 parts of water. The down washing agent is capable of effectively removing dirt on down, recovering the original elasticity and bulkiness of the down and keeping the original warmth retention property, better in conditioning and nursing effects for the down, strong in detersive power, good in stability, suitable for both hot water and cold water and free of hand injury because of being neutral.

Owner:安徽华强羽绒有限公司

Preparation method of 2-amino-2-methyl-1-propanol

InactiveCN1911899AReduce volumeEconomical savings on investment costsOrganic compound preparationAmino-hyroxy compound preparationCyanideAcetonitrile

The preparation process of 2-amino-2-methyl-1-propanol includes the following steps: combination reaction of isobutene, chlorine and methyl cyanide in the weight ratio of 1 to 0.5-5 to 1-100 to obtain N-[1-(chloromethyl)propyl] acetyl chloroamine; and subsequent adding water for the first hydrolysis reaction of N-[1-(chloromethyl)propyl] acetyl chloroamine to obtain N-[1-(chloromethyl)propyl] acetamide and the second hydrolysis reaction of N-[1-(chloromethyl)propyl] acetamide to obtain the 2-amino-2-methyl-1-propanol. The preparation process of 2-amino-2-methyl-1-propanol has the beneficial effects of cheap facile material, less steps, low cost, high product purity and being suitable for industrial production.

Owner:YIFAN XINFU PHARMA CO LTD

Water-based anticorrosive paint

ActiveCN104277652AImprove water resistanceAccelerated corrosionAnti-corrosive paintsWater basedMethyl group

The invention discloses a water-based anticorrosive paint which is prepared from the following raw materials in parts by weight: 100 parts of organic fluorosilicon modified acrylate emulsion, 10-20 parts of composite ferrotitanium powder, 5-13 parts of mica, 20-45 parts of modified zinc phosphate, 3-10 parts of zinc oxide, 10-25 parts of talcum powder, 5-7 parts of kaolin, 3-15 parts of nano titanium dioxide, 0.1-0.5 part of 2-amino-2-methyl-1-propanol, 0.2-2.5 parts of defoaming agent, 10-18 parts of film formation assistant, 5-8 parts of thickener and 80-120 parts of water. The water-based anticorrosive paint has the advantages of favorable water resistance, favorable corrosion resistance and long service life, and is used in outdoor and corrosive environments.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Corrosion-resistance fluorocarbon resin coating

InactiveCN105400314AImprove adhesionImprove corrosion resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyResin coating

The invention discloses corrosion-resistance fluorocarbon resin coating. The coating is prepared from the following raw materials in parts by weight: 30-50 parts of FEVE fluorocarbon resin, 20-45 parts of aliphatic epoxy resin, 20-40 parts of acrylated alkyd resin, 5-15 parts of bentonite, 5-12 parts of magnesium silicate, 10-20 parts of modified kaolin, 2-8 parts of hollow glass microspheres, 2-8 parts of graphene, 10-18 parts of melamine resin, 2-7 parts of 2-amino-2-methyl-1-propanol, 5-10 parts of methylcellulose, 1-3 parts of anionic polyacrylamide, 2-7 parts of IPDI isocyanate curing agent, 1-1.8 parts of polydimethylsiloxane, 2-8 parts of butyl acetate, 1-10 parts of propylene glycol, 2-8 parts of dimethyl valerate, 1-4 parts of a wetting agent, 1-3 parts of preservative and 30-60 parts of water. The corrosion-resistance fluorocarbon resin coating has good adhesion and excellent corrosion resistance.

Owner:合肥市易远新材料有限公司

Environment-friendly quick-drying water-based ink

The invention provides an environment-friendly quick-drying water-based ink. According to the invention, composite resin formed by an acrylate emulsion or a vinyl acetate-ethylene copolymer emulsion and alkali-soluble resin is used as a connecting material; a cosolvent is composed of dimethylaminoethanol or 2-amino-2-methyl-1-propanol and one selected from a group consisting of ethanol, ethylene glycol, propylene glycol, isopropanol and methyl acetate; a triethanolamine buffering agent or a dimethylacetamide buffering agent is added into an ink system as a pH value stabilizing agent; and a wetting agent, a drier and pigments are added, so the environment-friendly quick-drying water-based ink is obtained. Since the composite resin is used as the connecting material, the tinting strength and ink color stability of the water-based ink are improved, and the obtained water-based ink system is small in viscosity and short in drying time; and due to addition of the pH stabilizing agent, changes in pH value and system viscosity during usage of the ink are reduced, and more stable printing effect is obtained.

Owner:四川省蓝扬科技有限公司

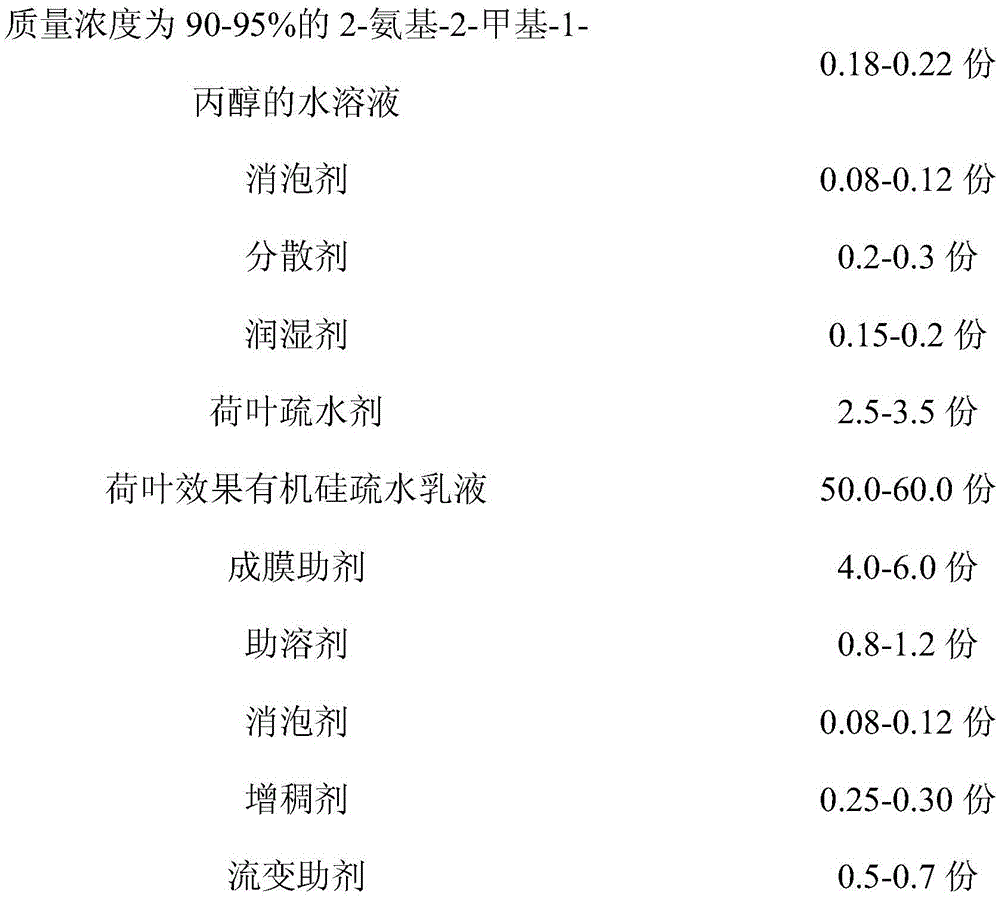

Finish-coat paint for real stone paint and preparation method of finish-coat paint

InactiveCN105462411AImprove stain resistanceExtended service lifeAntifouling/underwater paintsPaints with biocidesEmulsionPreservative

The invention relates to finish-coat paint for real stone paint, wherein the finish-coat paint is prepared from the following components in parts by weight: water, a germicidal and anti-corrosion agent, bentonite, an aqueous solution of 2-amino-2-methyl-1-propanol with mass concentration of 90-95%, a defoamer, a dispersant, a wetting agent, a lotus leaf hydrophobing agent, lotus-leaf-effect organosilicone hydrophobic emulsion, a coalescing agent, a cosolvent, the defoamer, a thickening agent and a rheological auxiliary. The finish-coat paint for the real stone paint overcomes the defects that the existing finish-coat paint for the real stone paint is poor in stain resisting effect and is free from self-cleaning ability, and has the advantages that excellent hydrophobicity, excellent stain resistance and a photocatalystic self-cleaning function are achieved, and the service life of the real stone paint can be prolonged.

Owner:SKSHU PAINT

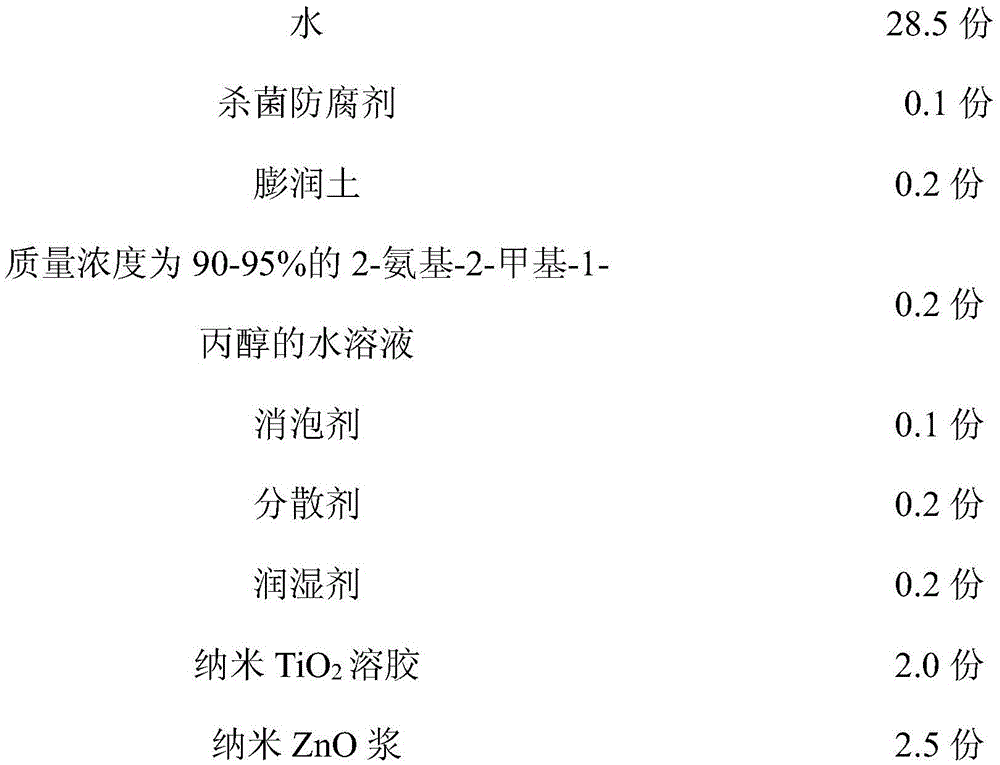

Stain resisting and odor removing paint and preparation method thereof

InactiveCN102876142AFix fadingSolve the loss of colorAntifouling/underwater paintsPaints with biocidesRutileDefoaming Agents

The invention discloses stain resisting and odor removing paint and a preparation method thereof. The stain resisting and odor removing paint comprises the following components of 2-amino-2-methyl-1-propanol-95 (AMP-95), unihub E, calcined kaolin, barite, a water repellent agent, emulsion, a film forming aid, a flatting agent, rutile titanium dioxide, glycol, a dispersing agent, a wetting agent, a preservative, an antimildew agent, a defoaming agent, a thickening agent and deionized water, wherein 10 to 45 weight parts of unihub E, 30 to 130 weight parts of calcined kaolin and 100 to 170 weight parts of barite are involved. The stain resisting and odor removing paint is relatively low in cost and volatile organic compound (VOC) and special for interior decoration.

Owner:WUHU SHUANGBAO BUILDING MATERIAL

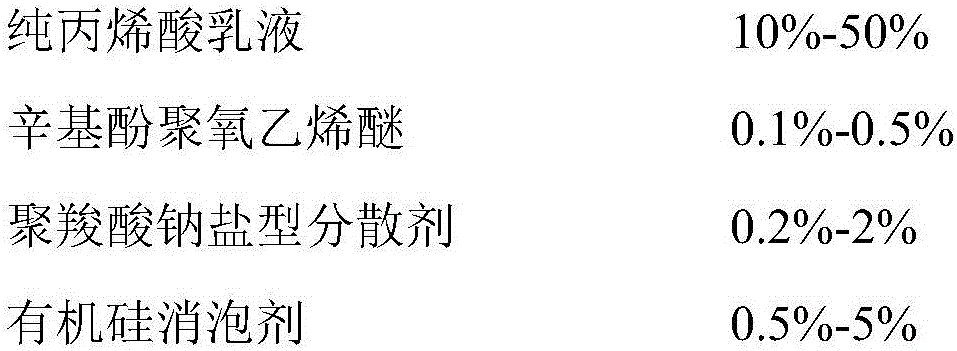

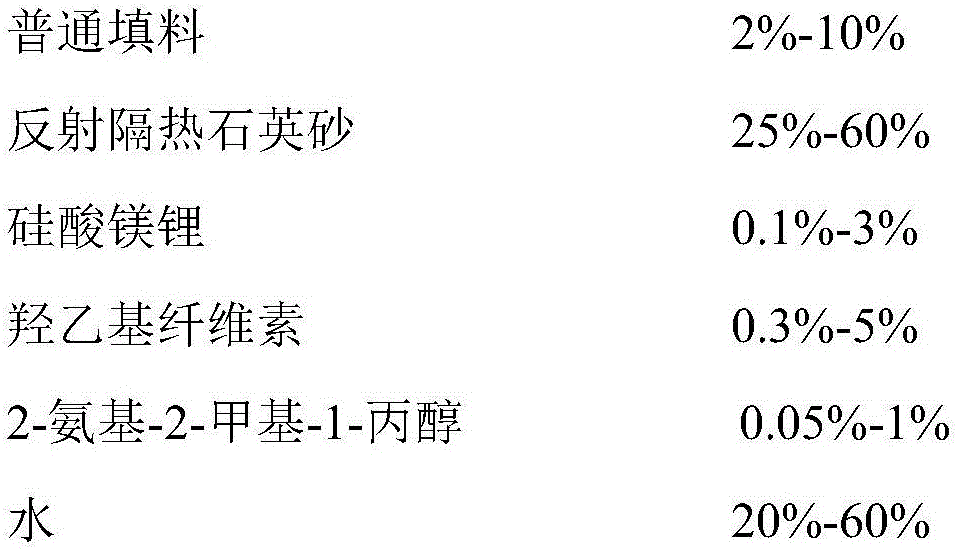

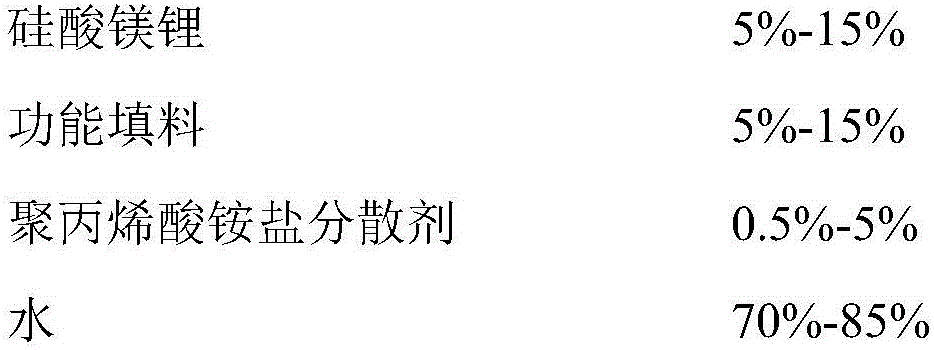

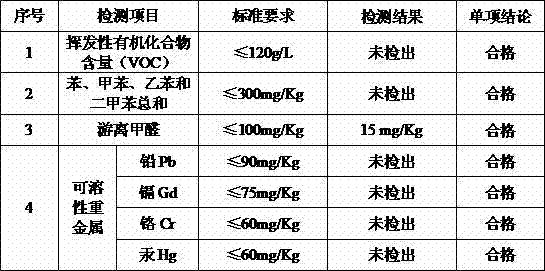

Reflective-insulation quality-sense colorful coating and a preparing method thereof

ActiveCN106497284AImprove functionalityReduce the temperatureReflecting/signal paintsMulticolor effect coatingsHydroxyethyl cellulose2-methyl-1-propanol

Reflective-insulation quality-sense colorful coating is disclosed. The coating comprises a base quality-sense component A, a functionalization component B and a light-covered oil-coated component C. The base quality-sense component A comprises a pure acrylic acid emulsion, octylphenol polyoxyethylene ether, a sodium polycarboxylate type dispersant, a silicone defoamer, a common filler, reflective-insulation quartz sand, magnesium lithium silicate, hydroxyethyl cellulose, 2-amino-2-methyl-1-propanol and water. The functionalization component B comprises magnesium lithium silicate, a functional filler, an ammonium polyacrylate dispersant and water. The light-covered oil-coated component C comprises a coating emulsion, Texanol ester alcohol, water and a thickening agent. A preparing method of the coating is disclosed. The coating can imitate marble decorative effects with high quality, has a coarse rock sense better than that of common colorful coating, has a certain reflective insulation property and is more energy saving and environment friendly.

Owner:宁波新安涂料有限公司 +1

Anticorrosive and environmentally-friendly water-based coating and preparation method thereof

InactiveCN109021788AAvoid pollutionAvoid wastingFireproof paintsAntifouling/underwater paintsWater basedEpoxy

The invention discloses an anticorrosive and environmentally-friendly water-based coating. The coating is mainly prepared from, by weight, 40-50 parts of waterborne epoxy resin, 30-50 parts of a basematerial, 5-10 parts of a filler, 4-6 parts of modified graphene oxide, 1-2 parts of a photocatalyst, 1-3 parts of an emulsifier, 2-3 parts of a silicone acrylate leveling agent, 3-5 parts of sodium diisooctyl sulfosuccinate, 2-5 parts of an NXZ defoamer, 2-3 parts of hydroxyethyl cellulose, 20-30 parts of deionized water and 0.5-1 part of 2-amino-2-methyl-1-propanol. The invention also disclosesa preparation method of the coating. The preparation method comprises the following steps: emulsification of the waterborne epoxy resin, preparation of a filler mixture, preparation of a base materialmixture, and uniform grinding and stirring. Potassium silicate, sodium silicate and silica sol are compounded as a base material, the waterborne epoxy resin is used as an emulsion, and water as a dispersion medium, so environmental pollution and resource waste caused by using of an organic solvent are avoided, and the coating has no pollution in the production or use process, and has excellent environmental protection performance and mechanical performances.

Owner:SHENZHEN NANSHUO MINGTAI TECH CO LTD

Diatomite coating with formaldehyde adsorbing and decomposing effects

The invention provides a diatomite coating with formaldehyde adsorbing and decomposing effects. The diatomite coating is formed by compounding raw materials comprising a diatomite dispersion liquid loaded with a material capable of decomposing formaldehyde, a 5040 dispersant, 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate, a Kh-550 type silane coupling agent, a polyacrylate thickener, 2-amino-2-methyl-1-propanol, kaolin, mica powder, titanium dioxide powder, octyl phenol polyoxyethylene ether, ethylene glycol, a 705 EVA emulsion, an AGITAN-208 defoaming agent, isothiazolinone, water and the like, wherein the diatomite dispersion liquid loaded with the material capable of decomposing formaldehyde is formed by compounding a Cu / Al2O3 catalyst, anatase-type nanometer titanium dioxide, nanometer tungsten trioxide, diatomite, a 5040-type dispersant, a 405 wetting agent, an AGITAN-208 type defoaming agent, a 400 polyethylene glycol, 2-amino-2-methyl-1-propanol, a Kh-570 type silane coupling agent, a TT-935 thickener and water. The prepared product has formaldehyde adsorbing and decomposing effects.

Owner:中健生命科技(深圳)有限公司

High-water-resistance antibacterial waterborne woodware coating

InactiveCN104629574AHigh strengthImprove wear resistanceAntifouling/underwater paintsPaints with biocidesBENZYL ALCOHOL/WATERAntibacterial property

The invention discloses a high-water-resistance antibacterial waterborne woodware coating. The high-water-resistance antibacterial waterborne woodware coating comprises the following raw materials: a waterborne silica sol / acrylic polyurethane composite emulsion, nanometer silicon nitride, nanometer zinc oxide, bamboo charcoal powder, kaolin, doped nanometer titanium dioxide, benzyl alcohol, ethylene glycol butyl ether, 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate, dipropylene glycol, diglycol, 2-amino-2-methyl-1-propanol, a silane coupling agent, hydroxypropyl methyl cellulose, chitosan, a defoaming agent, a dispersant, a flatting agent and water. The high-water-resistance antibacterial waterborne woodware coating has the advantages of high strength, good abrasion resistance and scratch resistance, excellent water resistance and antibacterial property, good comprehensive property and long service life as the woodware coating.

Owner:安徽嘉年华漆业有限公司

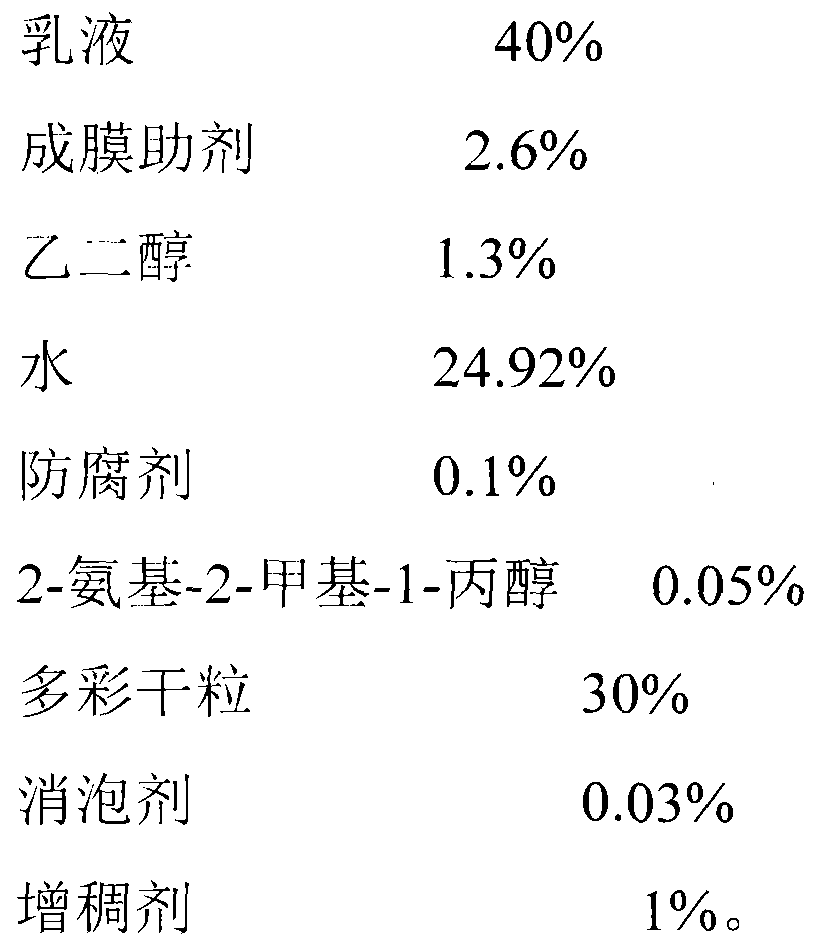

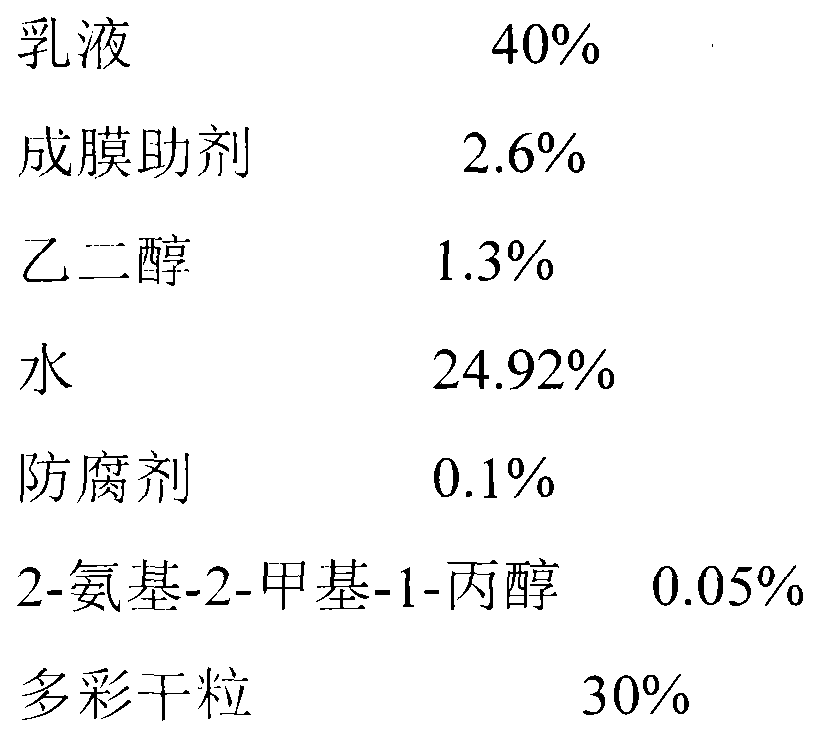

Waterborne colorful granite coating and preparation method thereof

InactiveCN105566975AFull display of irregular shapesEasy to operateMulticolor effect coatingsProduct systemEmulsion

The invention discloses a waterborne colorful granite coating and a preparation method thereof. The waterborne colorful granite coating is composed of the following raw materials by weight percent: 40% of an emulsion, 2.6% of a coalescing agent, 1.3% of ethylene glycol, 24.92% of water, 0.1% of a preservative, 0.05% of 2-amino-2-methyl-1-propanol, 30% of dry colorfulgranules, 0.03% of a defoamer and 1% of a thickener. The waterborne colorful granite coating and the preparation method thereof are convenient to adjust color, simple in production process, stable in product system, low in construction difficulty, and low in requirement.

Owner:艾美力斯(北京)环保材料有限公司

Ionic liquid activated post-combustion carbon dioxide capture solvent

InactiveCN105561757ALow regeneration energy consumptionFast absorption rateDispersed particle separationAir quality improvementStructural formulaSolvent

Belonging to the technical field of capture of carbon dioxide in gas, the invention relates to a capture solvent for capturing carbon dioxide in a post-combustion carbon dioxide gas source and application. The capture solvent includes alcohol amine, an ionic liquid activator and deionized water, wherein the alcohol amine is one or more of 2-amino-2-methyl-1-propanol, 2-(methylamino)-ethanol, 2-(ethylamino)-ethanol, 2-(diethylamino)-ethanol, 2-(2-hydroxyethyl)-piperidine, diglycolamine, dimethylamino-2-propanol, and triethanolamine. The negative ion of the ionic liquid activator has an amino acid structure, the structural formula of amino acid is H2N-R-COOH (R=CnH2n, n=1-5), and the positive ion is one or more of organic amine salt positive ion and organic alcohol amine positive ion. The capture solvent provided by the invention has the advantages of low regeneration energy consumption, fast absorption rate and the like, also consumes little ionic liquid, has strong stability, and is not easy to degrade. Therefore, the capture solvent has very good prospect in the field of carbon dioxide capture after large-scale combustion.

Owner:CHINA PETROLEUM & CHEM CORP +1

Modified acrylate emulsion for eliminating formaldehyde in air and preparation method of modified acrylate emulsion

InactiveCN107868166AUniform particle sizeExcellent formaldehyde purification efficiencyCross-linkFunctional monomer

The invention discloses a modified acrylate emulsion for eliminating formaldehyde in air and a preparation method of the modified acrylate emulsion. The modified acrylate emulsion is prepared from thefollowing components in parts by weight: 20-50 parts of alkyl acrylate, 0-80 parts of alkyl methacrylate, 0-30 parts of benzene series, 0-30 parts of alkyl alkenoate, 0.1-5 parts of alkyl carboxylicacid, 1-10 parts of a cross-linking functional monomer, 1-5 parts of an emulsifier, 0.5-2.5 parts of an initiator, 0.1-0.5 parts of a buffer agent, 0.01-0.05 parts of a chelating agent, 100 parts of deionized water, 0-0.5 parts of a PH regulator, 1-10 parts of acetoacetamide and 1-10 parts of 2-amino-2-methyl-1-propanol. According to the modified acrylate emulsion, acetoacetamide as a formaldehyderemoval functional monomer can be effectively linked to an acrylate polymer chain, the functional group absorbing formaldehyde is retained without influence on basic performance of original emulsion;the modified acrylate emulsion is universal, unaffected by placing time and cannot be subjected to yellowing.

Owner:佛山市顺德区巴德富实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com