Reflective-insulation quality-sense colorful coating and a preparing method thereof

A multi-color paint, texture technology, applied in the direction of reflection/signal paint, multi-color effect paint, coating, etc., can solve the problems of reducing the effect of hollow microbeads, the hollow microbeads are easily broken, lose reflection and heat insulation, etc., to increase the function The effect of reducing the temperature, reducing the energy consumption of buildings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] 1. Prepare the raw materials of each component according to the following formula; wherein:

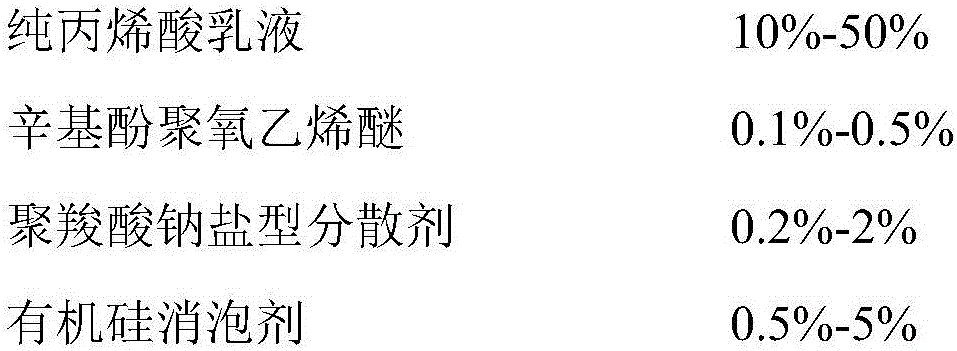

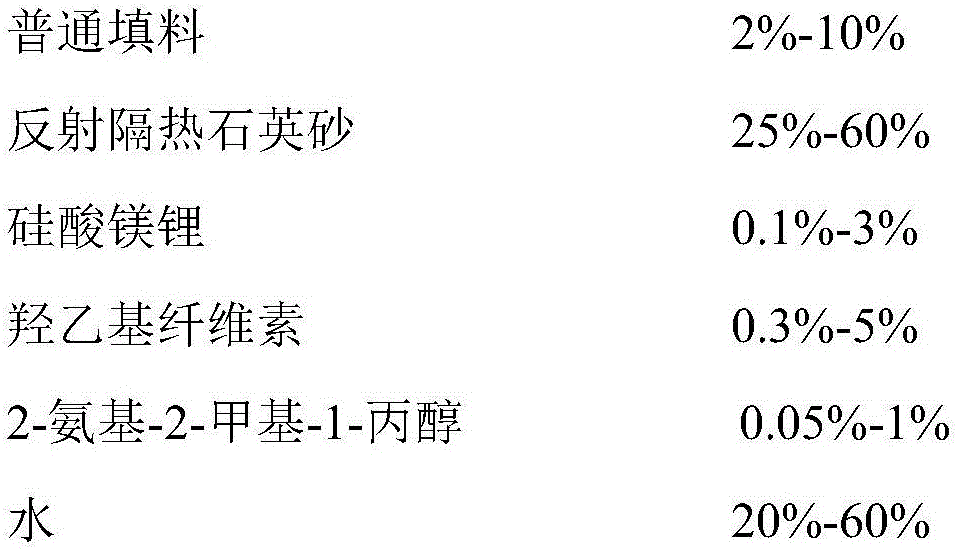

[0050] Basic texture component A formula (percentage by weight):

[0051]

[0052] Functionalized component B formula (percentage by weight):

[0053]

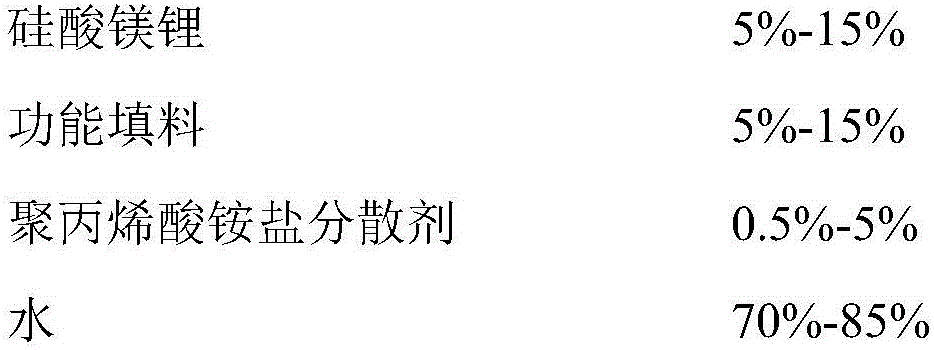

[0054]Light coating oil component C formula (percentage by weight):

[0055]

[0056] The formulation of each component of the finished coating (percentage by weight):

[0057] Basic Texture Component A 60%

[0058] Functionalized Component B 20%

[0059] Light coating oil component C 20%

[0060] 2. Preparation of basic texture component A: Pour 29.9% of water into the dispersion kettle, add 1% hydroxyethyl cellulose at the speed of the disperser at 1000r / min, disperse for 15 minutes, and then add 0.1% of 2-amino -2-Methyl-1-propanol continued to disperse for 30 minutes, then added 0.5% octylphenol polyoxyethylene ether, 1% polycarboxylate sodium salt dispersant and 2% silicone defoamer, and dispersed for 15 minu...

Embodiment 2

[0066] 1. Prepare the raw materials of each component according to the following formula; wherein:

[0067] Basic texture component A formula (percentage by weight):

[0068]

[0069] Functionalized component B formula (percentage by weight):

[0070]

[0071] Light coating oil component C formula (percentage by weight):

[0072]

[0073] The formulation of each component of the finished coating (percentage by weight):

[0074] Basic Texture Component A 50%

[0075] Functionalized Component B 15%

[0076] Light coating oil component C 35%

[0077] 2. Preparation of basic texture component A: Pour 24% of water into the dispersion kettle, add 2% hydroxyethyl cellulose at the speed of the disperser at 1500r / min, disperse for 20min, and then add 0.2% of 2-amino -2-Methyl-1-propanol continued to disperse for 45 minutes, then added 0.3% octylphenol polyoxyethylene ether, 0.8% polycarboxylate sodium salt dispersant and 2% silicone defoamer, and dispersed for 30 minutes....

Embodiment 3

[0083] 1. Prepare the raw materials of each component according to the following formula; wherein:

[0084] Basic texture component A formula (percentage by weight):

[0085]

[0086]

[0087] Functionalized component B formula (percentage by weight):

[0088]

[0089] Light coating oil component C formula (percentage by weight):

[0090]

[0091] The formulation of each component of the finished coating (percentage by weight):

[0092] Basic Texture Component A 45%

[0093] Functionalized Component B 30%

[0094] Light coating oil component C 25%

[0095] 2. Preparation of basic texture component A: Pour 10% of water into the dispersing kettle, add 1.5% hydroxyethyl cellulose at the speed of the dispersing machine at 1500r / min, disperse for 30 minutes, and then add 0.5% of 2-amino -2-Methyl-1-propanol continued to disperse for 55 minutes, then added 0.5% octylphenol polyoxyethylene ether, 1.5% polycarboxylate sodium salt type dispersant and 3% silicone defoam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com