Stain resisting and odor removing paint and preparation method thereof

A deodorant and antifouling technology, applied in biocide-containing paints, antifouling/underwater coatings, coatings, etc., can solve problems such as high cost and no special consideration of VOC content, and achieve solutions to fading and excellent UV resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

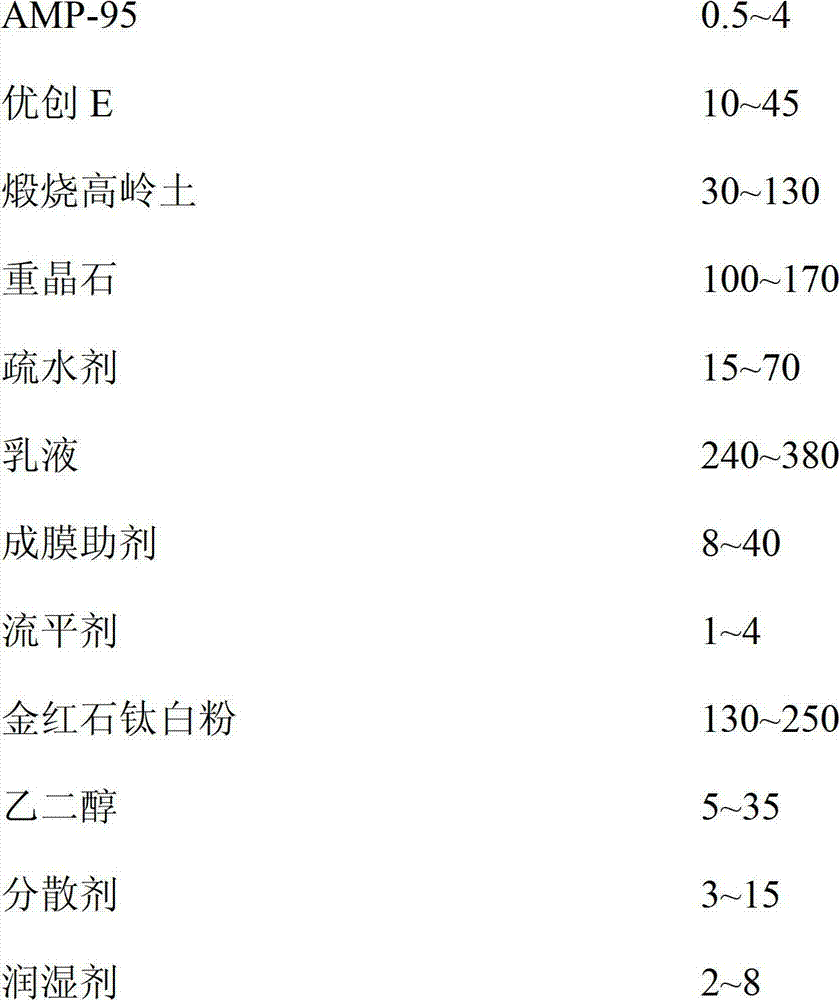

[0068] A stain-resistant and odor-repellent paint comprising the following components in parts by weight:

[0069] AMP-95 (Nanjing Gutian Chemical Co., Ltd.) 5, Youchuang E (Dow Chemical) 45, calcined kaolin (Fengye Kaolin Co., Ltd.) 130, barite (Baixin Quartz Sand Processing Plant, Lingshou County, Hebei) 100, Lotus leaf hydrophobic agent AS-CW30677, styrene-acrylate copolymer emulsion 380, film-forming aid 8, leveling agent 4, rutile titanium dioxide 130, ethylene glycol 35, dispersant 19, wetting agent 7, preservative 0.5, antifungal agent 10, defoamer 4, thickener 7, deionized water 200.

[0070] The preparation method of described anti-pollution and deodorant paint, comprises the steps:

[0071] (1) Weigh 165 parts by weight of deionized water and put it into the reactor, then start the high-speed disperser and control the speed at 300r / min;

[0072] (2) Weigh the formulated amount of AMP-95, dispersant, wetting agent, 5 parts by weight of thickener and 1 / 2 of the formu...

Embodiment 2

[0078] A stain-resistant and odor-repellent paint comprising the following components in parts by weight:

[0079] AMP-95 (Nanjing Gutian Chemical Co., Ltd.) 0.5, Youchuang E (Dow Chemical) 45, calcined kaolin (Fengye Kaolin Co., Ltd.) 30, barite (Baixin Quartz Sand Processing Plant, Lingshou County, Hebei Province, barium sulfate content ≥ 97wt%) 170, lotus leaf hydrophobic agent AS-CW30615, styrene-acrylate copolymer emulsion (BASF ECO559) 240, 2,2,4-trimethyl-1,3-pentanediol monoisobutyl Ester 40, GSK-588 series leveling agent 1, rutile titanium dioxide 250, ethylene glycol 5, dispersant 3, wetting agent 8, Kathon preservative KF-883, Nordes EPW paint film antifungal agent 2, 4200 defoamer (BASF) 8, ASE-60 thickener 20, deionized water 160.

[0080] The preparation method of described anti-pollution and deodorant paint, comprises the steps:

[0081] (1) Weigh 150 parts by weight of deionized water and put it into the reactor, then start the high-speed disperser and control ...

Embodiment 3

[0088] A stain-resistant and odor-repellent paint comprising the following components in parts by weight:

[0089] AMP-95 (Nanjing Gutian Chemical Co., Ltd.) 4. Youchuang E (Dow Chemical) 25. Calcined kaolin (Fengye Kaolin Co., Ltd.) 94. Barite (Baixin Quartz Sand Processing Plant, Lingshou County, Hebei Province, barium sulfate content ≥ 93wt%) 146, lotus leaf hydrophobic agent AS-CP40535, odor-cleaning resin 3710277, dipropylene glycol methyl ether 20, 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate 16 , leveling agent 3, rutile titanium dioxide 175, ethylene glycol 21, SN-5040 dispersant (Taiwan Zhongya Chemical) 15, AES 1, AEO-71, benzoic acid 0.5, antifungal agent OBPA (Shandong Aipu Chemical Co., Ltd. Company) 10, 4200 defoamer (BASF) 6, hydroxyethyl cellulose 13, deionized water 180.

[0090] The preparation method of described anti-pollution and deodorant paint, comprises the steps:

[0091] (1) Weigh 155 parts by weight of deionized water and put it into the reactor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com