Compound water permeable brick and preparing method thereof

A permeable brick and cement technology, applied in the field of building materials, can solve the problems of sand loss, poor strength performance, high price fading, etc., and achieve the effect of simple preparation process, avoiding severe wear and smooth appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

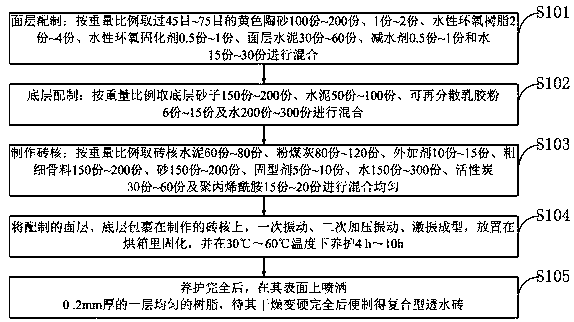

[0043] like figure 1 As shown, the preparation method of the composite permeable brick provided by the implementation of the present invention may further comprise the steps:

[0044] S101: Preparation of the surface layer: 100-200 parts, 1-2 parts, 2-4 parts of water-based epoxy resin, 0.5-1 parts of water-based epoxy curing agent, 100-200 parts, 1-2 parts, 45-mesh-75-mesh yellow pottery sand according to the weight ratio 30-60 parts of surface cement, 0.5-1 part of superplasticizer and 15-30 parts of water.

[0045] S102: Bottom layer preparation: Mix 150-200 parts of bottom-layer sand, 50-100 parts of cement, 6-15 parts of redispersible latex powder and 200-300 parts of water in proportion by weight.

[0046] S103: Make brick core: Take 60-80 parts of brick core cement, 80-120 parts of fly ash, 10-15 parts of admixture, 150-200 parts of coarse and fine aggregate, and 150-200 parts of sand according to weight ratio 5-10 parts of solid agent, 150-300 parts of water, 30-60 p...

Embodiment 1

[0061] In the composite permeable brick provided by the implementation of the present invention, each component of the composite permeable brick consists of 25 parts by weight of the surface layer, 150 parts of the brick core and 150 parts of the bottom layer;

[0062] Each component of the surface layer consists of 1-2 parts of binder, 100-200 parts of yellow pottery sand, 2-4 parts of water-based epoxy resin, 0.5-1 part of water-based epoxy curing agent, Consists of 30-60 parts of surface cement, 0.5-1 part of water reducing agent and 15-30 parts of water;

[0063] The components of the brick core are composed of 60-80 parts of brick core cement, 80-120 parts of fly ash, 10-15 parts of admixture, 150-200 parts of coarse and fine aggregate, and 150 parts of sand in parts by weight. 200 parts, 5-10 parts of solid agent, 150-300 parts of water, 30-60 parts of activated carbon and 15-20 parts of polyacrylamide;

[0064] The component of described fly ash is by weight ratio by 6...

Embodiment 2

[0067] In the composite permeable brick provided by the implementation of the present invention, each component of the composite permeable brick consists of 50 parts by weight of the surface layer, 300 parts of the brick core and 300 parts of the bottom layer;

[0068] Each component of the surface layer consists of 1-2 parts of binder, 100-200 parts of yellow pottery sand, 2-4 parts of water-based epoxy resin, 0.5-1 part of water-based epoxy curing agent, Consists of 30-60 parts of surface cement, 0.5-1 part of water reducing agent and 15-30 parts of water;

[0069] The components of the brick core are composed of 60-80 parts of brick core cement, 80-120 parts of fly ash, 10-15 parts of admixture, 150-200 parts of coarse and fine aggregate, and 150 parts of sand in parts by weight. 200 parts, 5-10 parts of solid agent, 150-300 parts of water, 30-60 parts of activated carbon and 15-20 parts of polyacrylamide;

[0070] The component of described fly ash is by weight ratio by 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com