Patents

Literature

40results about How to "Fix fading" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Milk protein fiber blended color spinning yarn and its production method

ActiveCN1884650ABright colorImprove performanceYarnLiquid/gas/vapor textile treatmentYarnMilk protein

The invention discloses a milk protein fiber spinning yarn and manufacturing method, which is characterized by the following: making quality percentage in the mixed color spinning yarn at 5-100 percent milk protein fiber; dyeing milk protein fiber and other fibers respectively; adopting active dye for milk fiber through acid dyeing and alkaline color fixing course; reducing fiber destroying; keeping kinds of superior quality of fiber; satisfying personal pursuit for comfortable costume, health and fashion.

Owner:平湖市华孚金瓶纺织有限公司

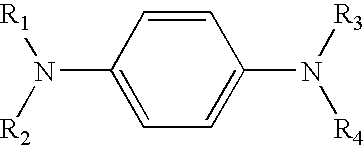

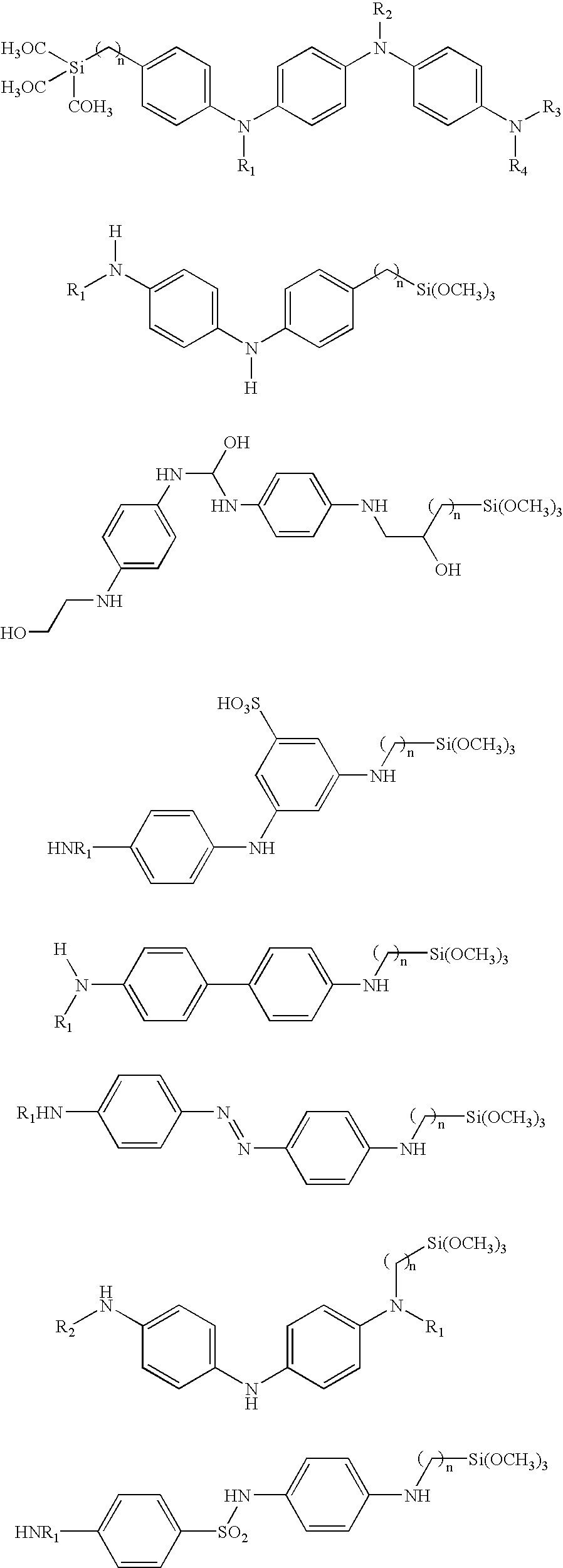

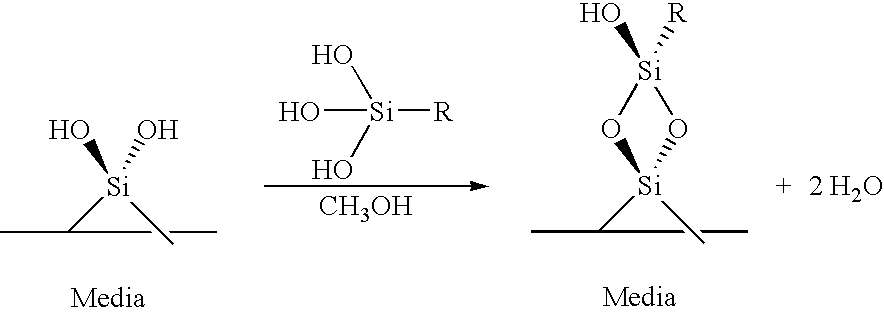

Anti-ozonants covalently attached to silica gel for use in glossy print media

InactiveUS6767640B2Fix fadingPigmenting treatmentOrganic chemistry methodsPrint mediaSilica particle

A method of protecting dyes printed on print media against ozonolysis is provided. The method comprises: (a) providing a first reaction product comprising the reaction of a phenylenediamine or derivative thereof (an anti-ozonant) with a silica or silicate; and (b) reacting the first reaction product in the presence of a water-free solvent with silica groups to form a second reaction product. Also provided is the reaction product resulting from the reaction of (1) the anti-ozonant-silica (or silicate) and (2) silica groups on a substrate. The anti-ozonant-silica (or silicate) is covalently attached to the particles of silica in the media and cannot escape or evaporate away. The use of phenylenediamines as anti-ozonants solves the problem of the fading of dyes on porous media by ozone pollution.

Owner:HEWLETT PACKARD DEV CO LP

Weather-proof mould-proof moisture-proof exterior wall paint

InactiveCN104673015AFix fadingExtended service lifeAntifouling/underwater paintsPaints with biocidesWeather resistanceEmulsion

The invention discloses a weather-proof mould-proof moisture-proof exterior wall paint which consists of the following components in parts by weight: 20-30 parts of ethanol amine, 5-10 parts of XG-95, 200-250 parts of nano kaolin, 250-300 parts of lithopone, 10-20 parts of starch, 500-600 parts of vinyl acetate homopolymer emulsion, 50-80 parts of propylene glycol, 30-50 parts of isopropyl alcohol, 250-300 parts of sericite, 150-200 parts of GR composite titanium dioxide pigment, 20-30 parts of aids and 250-300 parts of purified water. The weather-proof mould-proof moisture-proof exterior wall paint can resist environmental ultraviolet rays, the problems of color fading and gloss loss of the paint are solved, and the service life of the paint is prolonged; and meanwhile, the weather-proof mould-proof moisture-proof exterior wall paint has good stain resistance, rub resistance, powder resistance, weather resistance, mould resistance and moisture resistance.

Owner:胡建辉

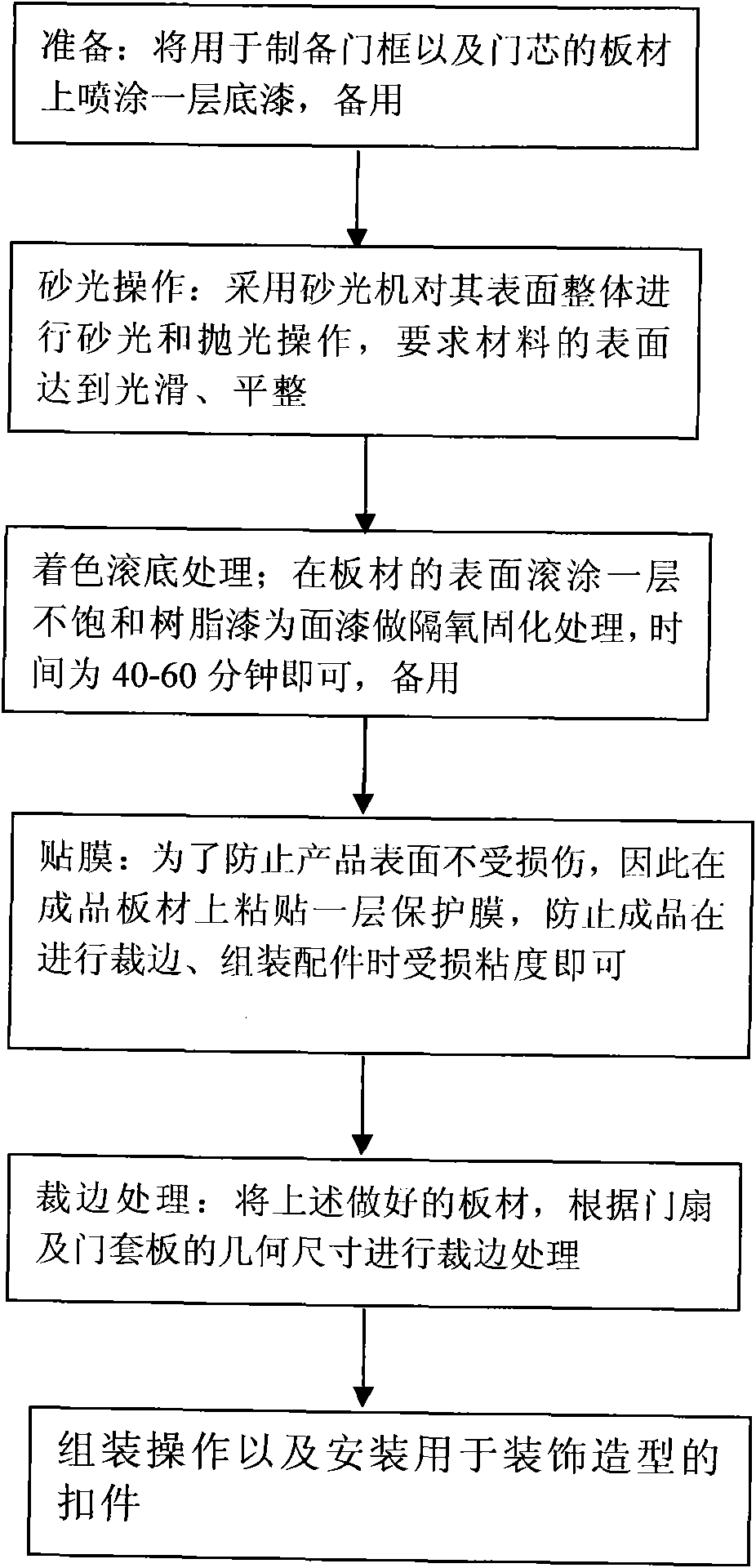

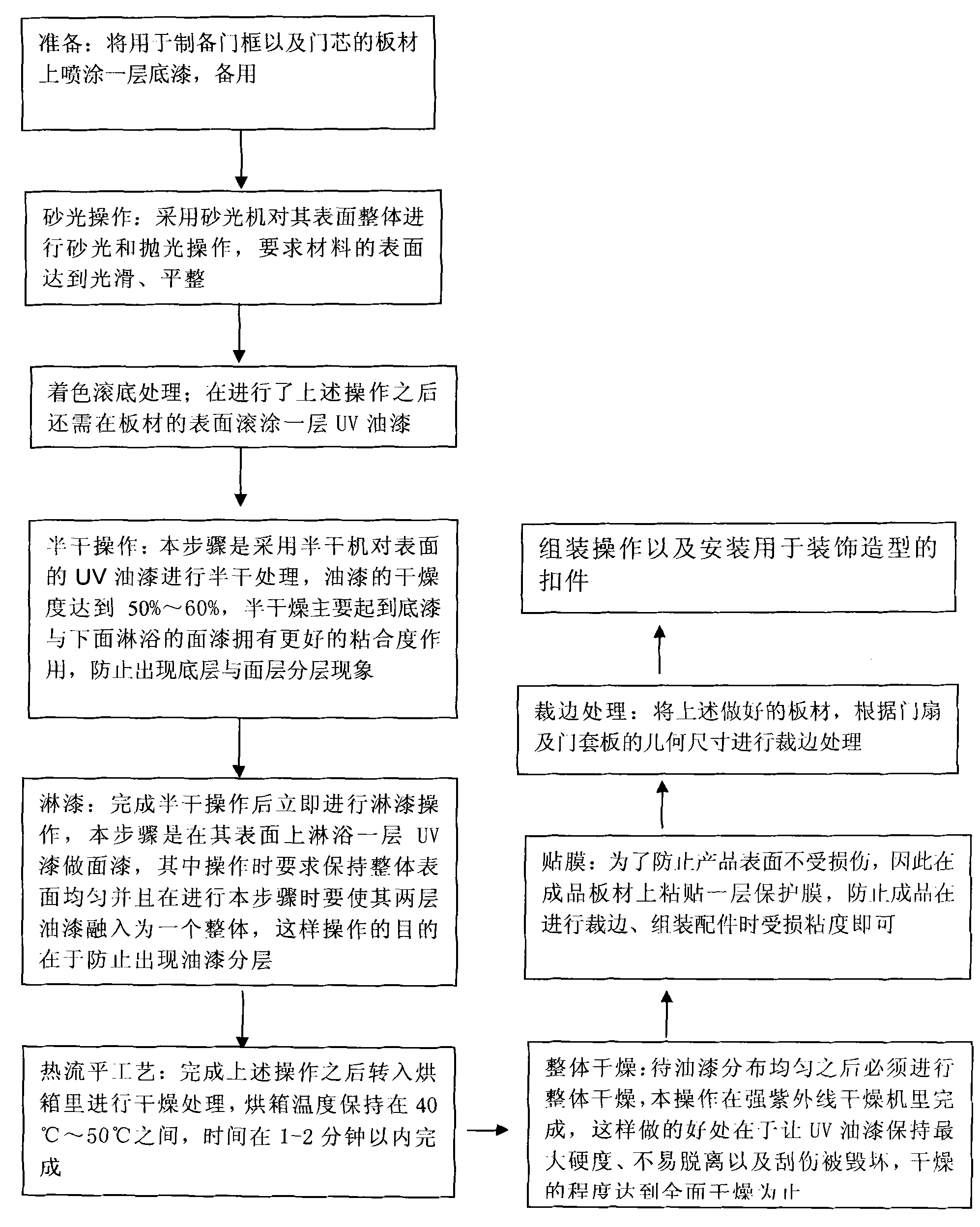

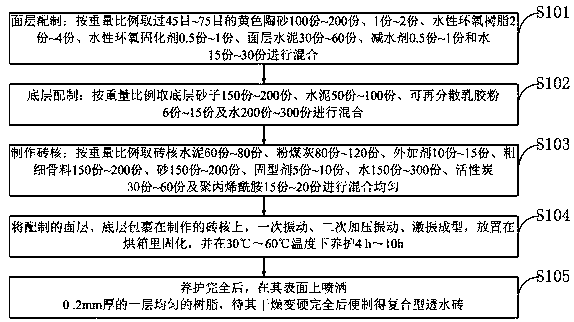

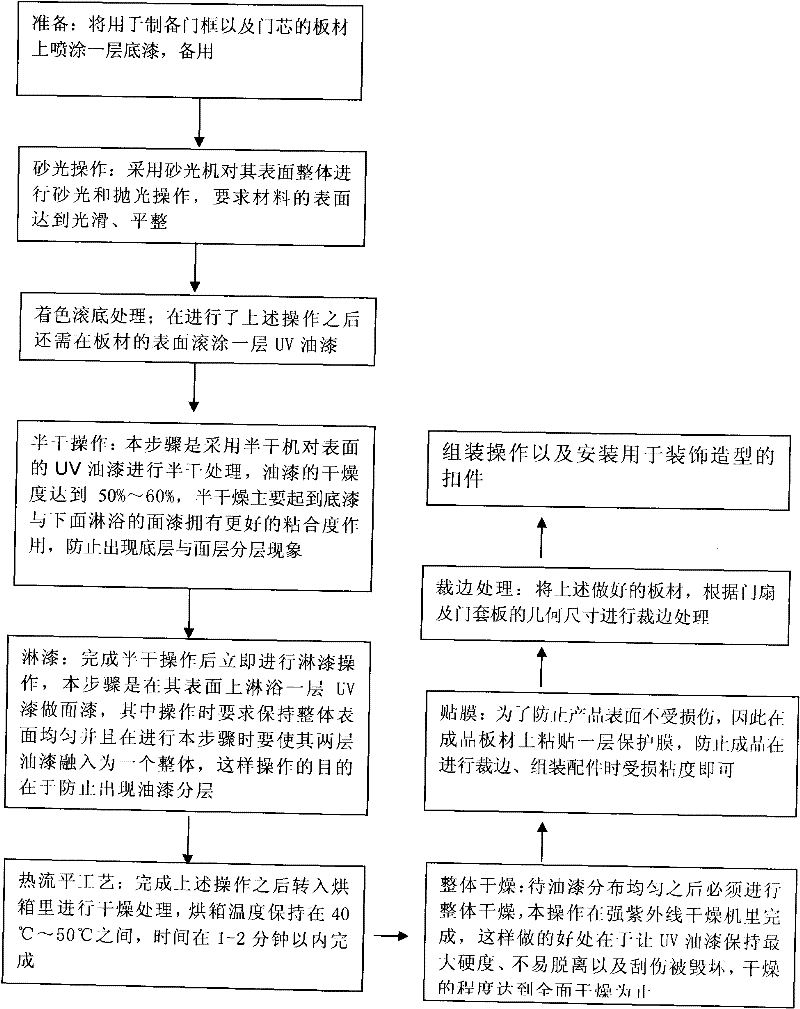

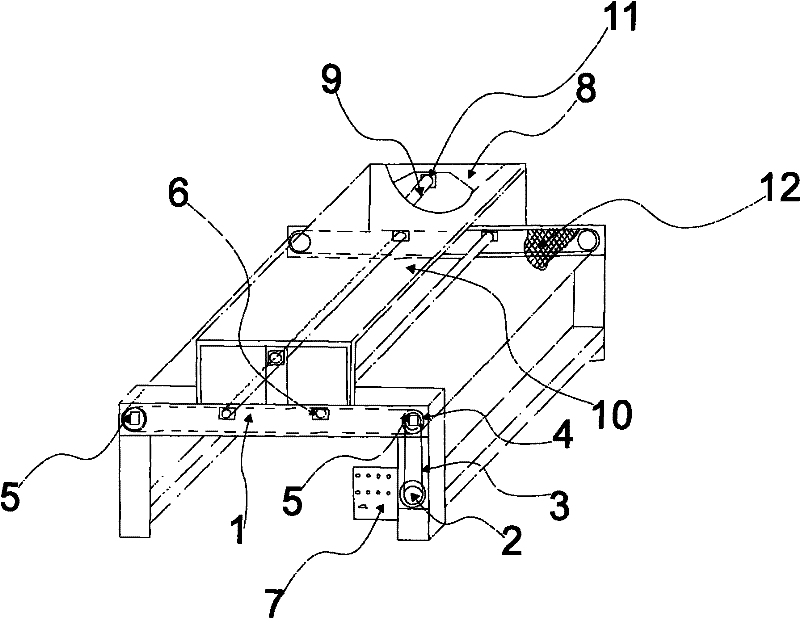

Manufacturing process of wood door and half drying machine

InactiveCN101871307ANot easy to shrinkNot easy to expandPretreated surfacesCoatingsManufacturing engineering

The invention discloses a manufacturing process of a wood door, which is characterized by comprising preparation, sanding operation, colorizing and bottom rolling treatment, lamination, trimming treatment, assembling operation, decorative and shaping fastening piece installation and final entire packaging. The process prevents expansion and contraction in door vertical frame, cross beam and other places. In the invention, the surface oil paint stripping and layering can be prevented by adopting half drying operation, paint spraying, a thermal leveling process and overall drying operation, time is saved and product quality is improved. At the same time, the invention also provides a half drying machine for half drying operation.

Owner:CHENGDU TIANCHENG SHENGMU DOOR

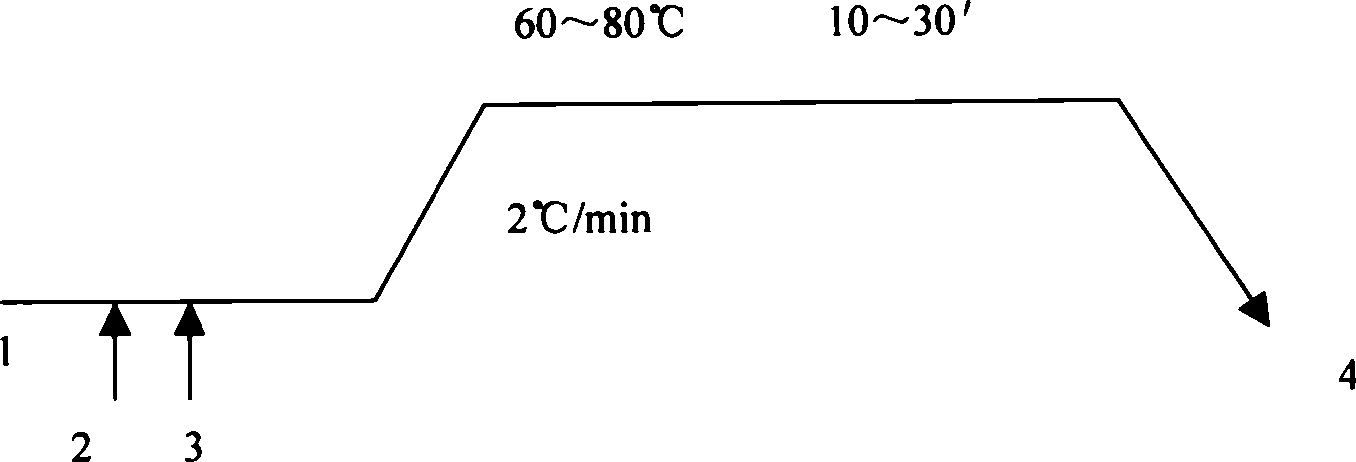

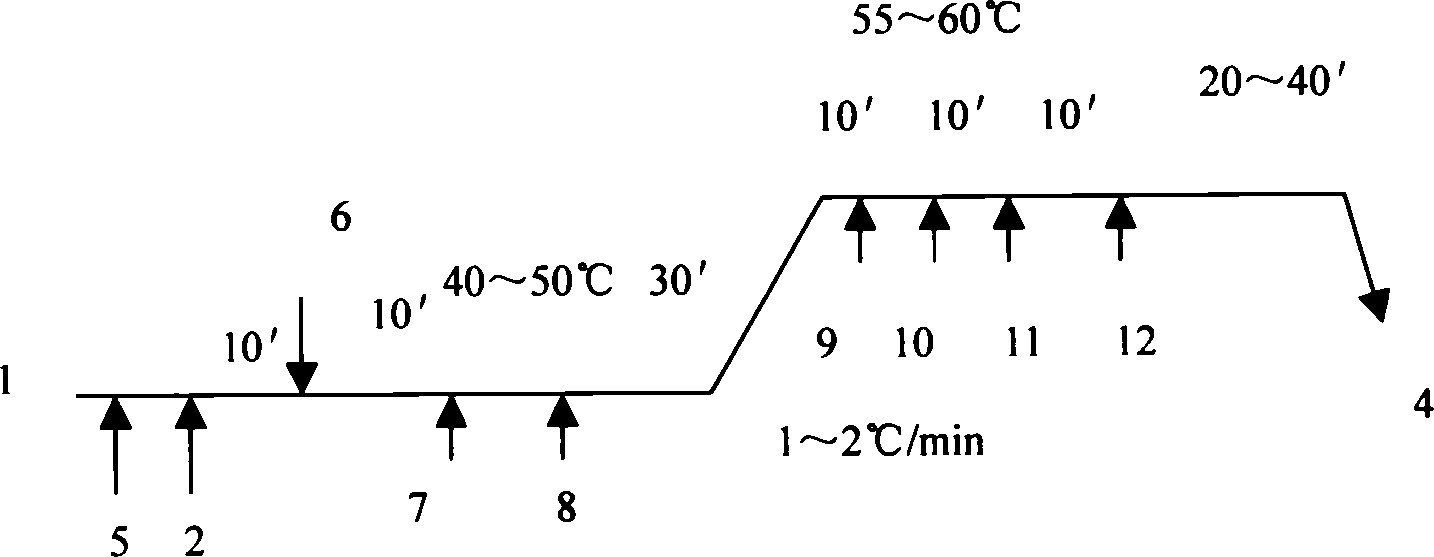

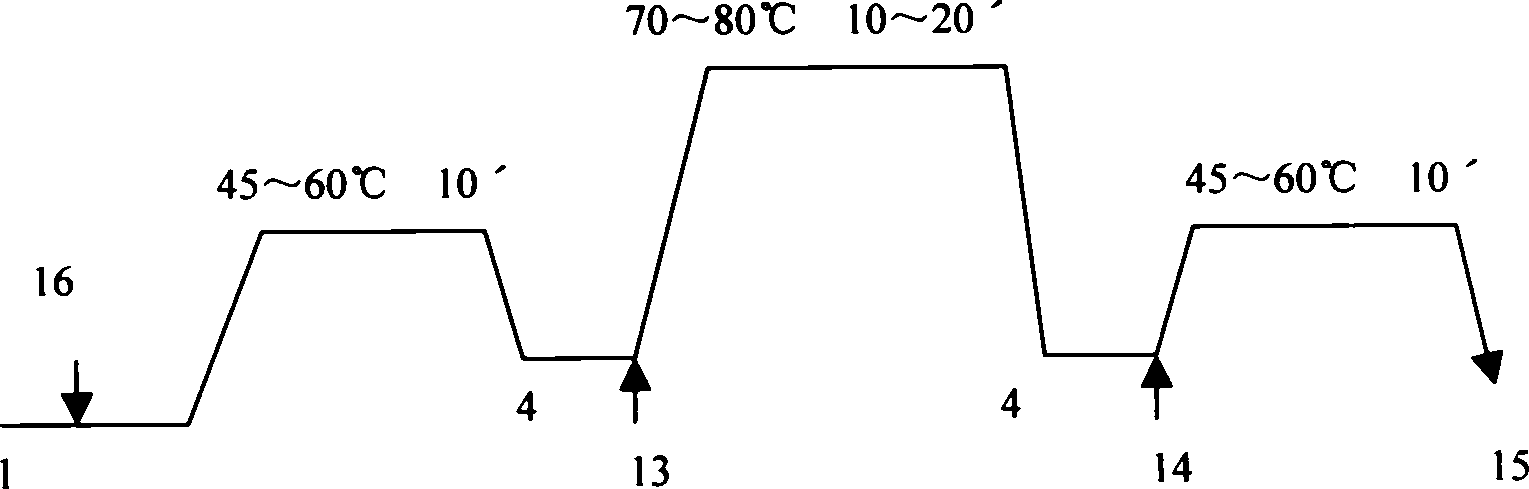

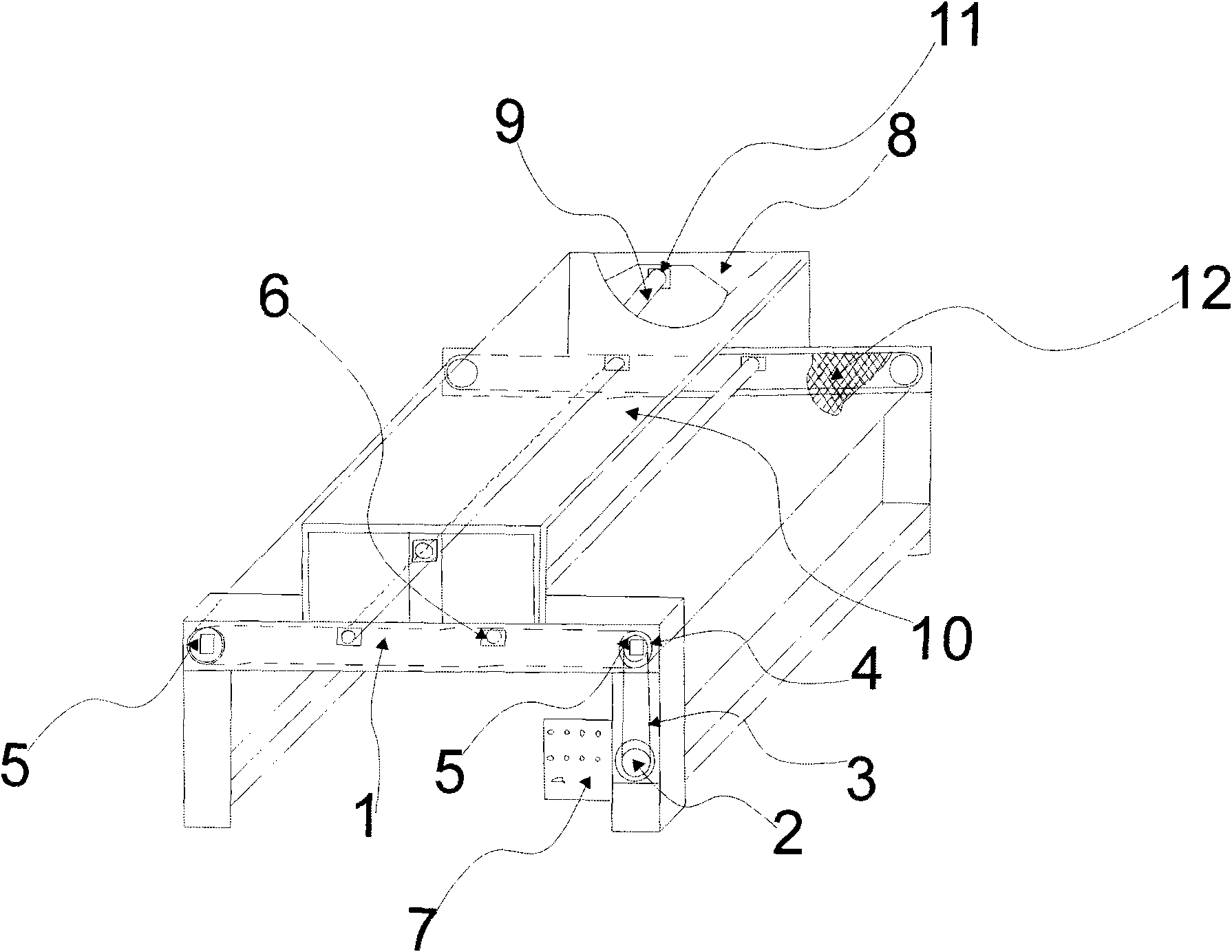

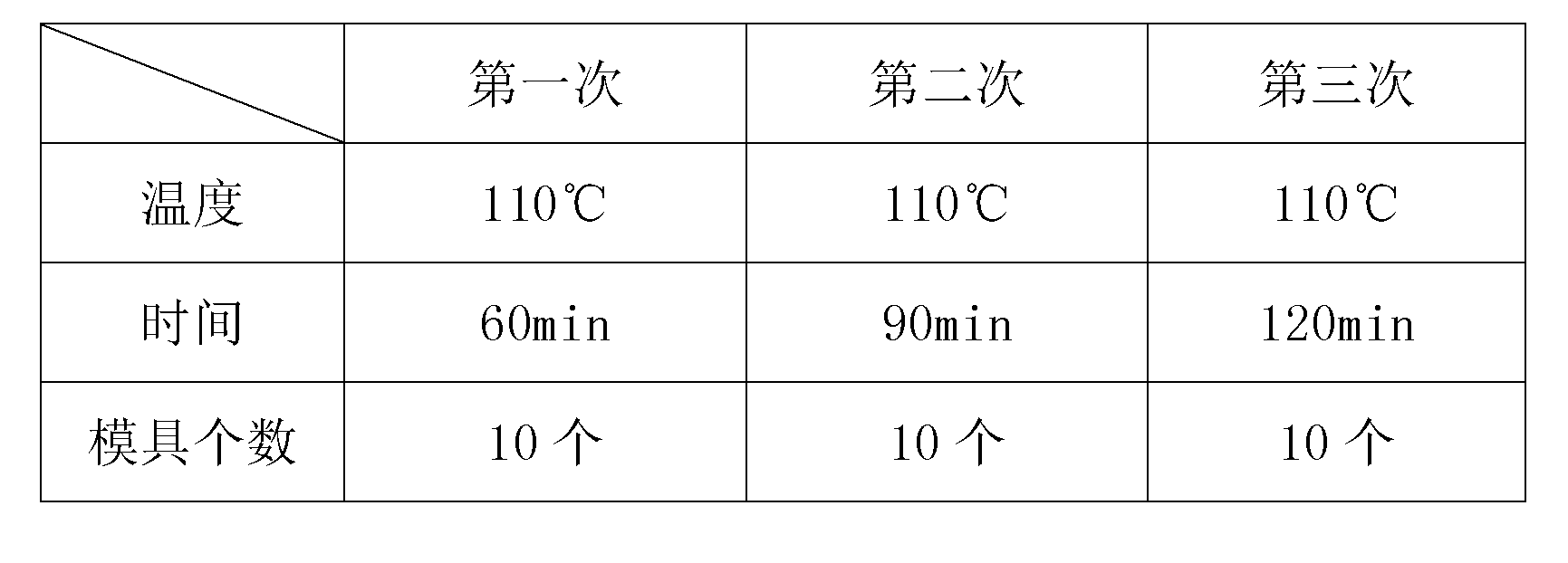

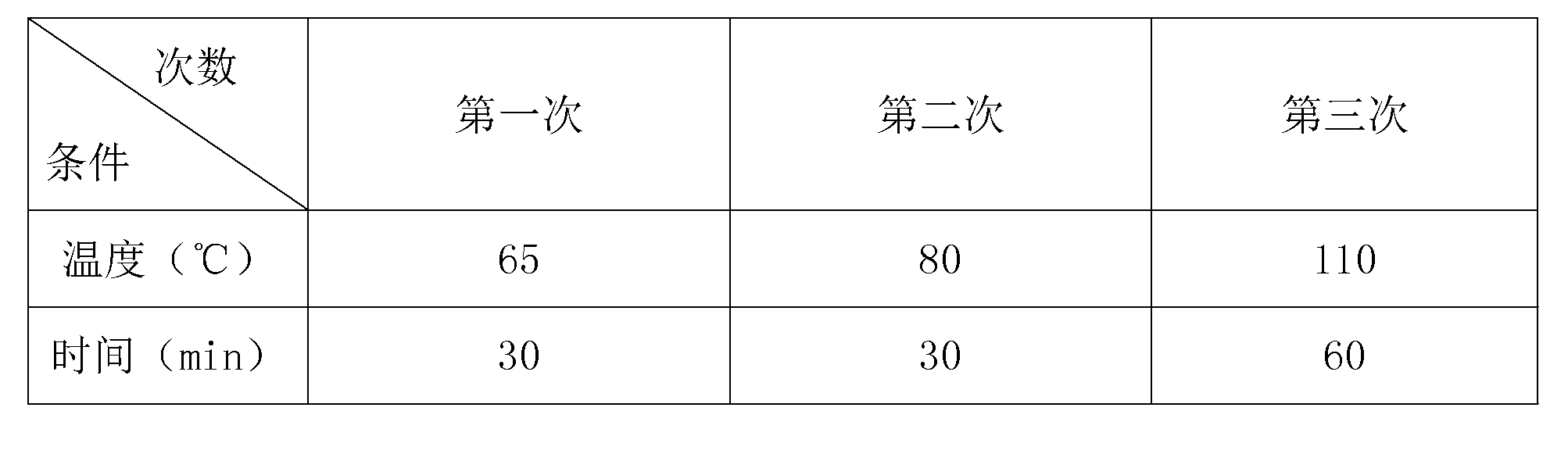

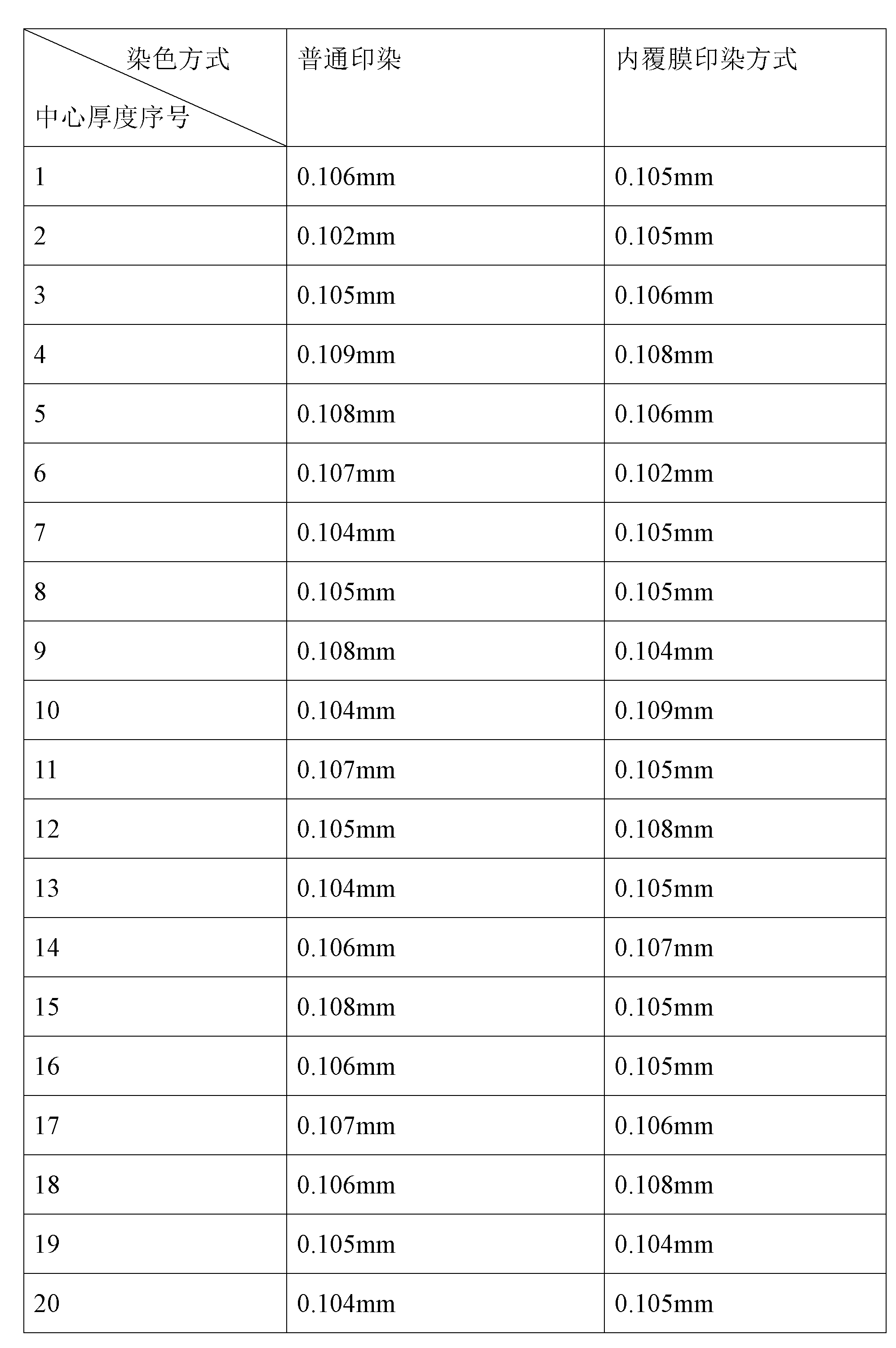

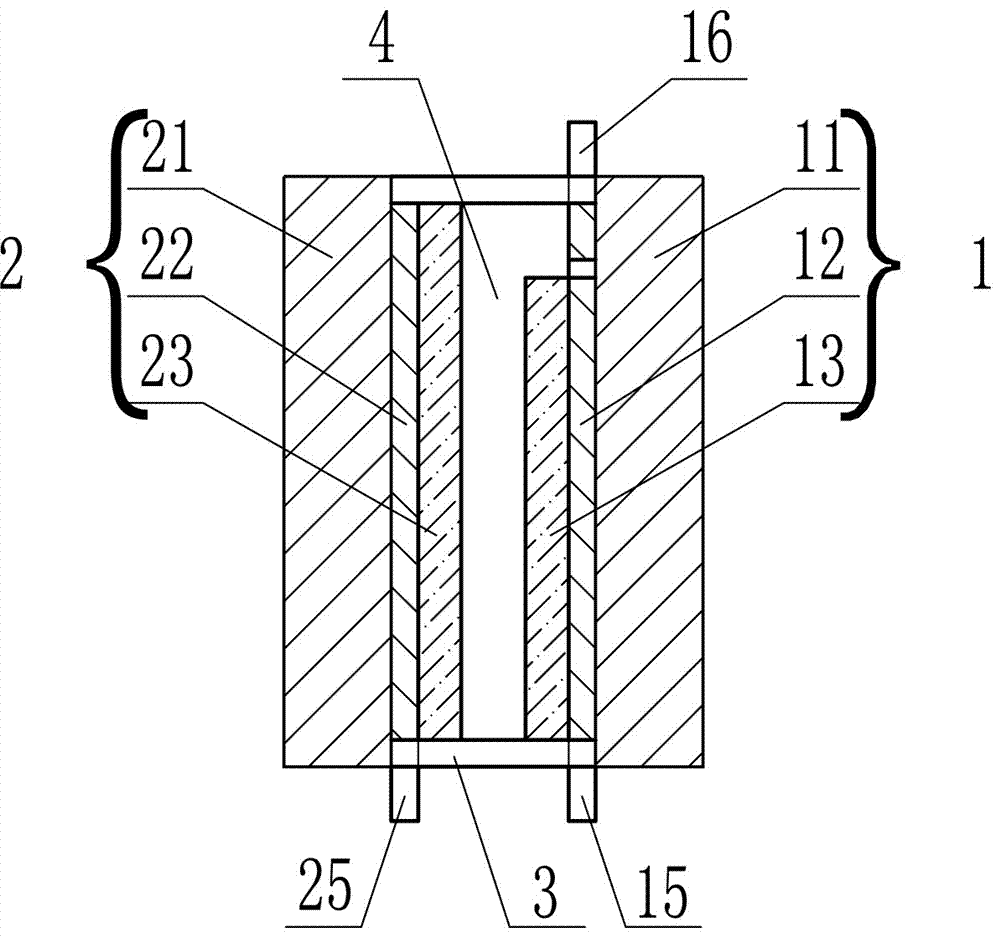

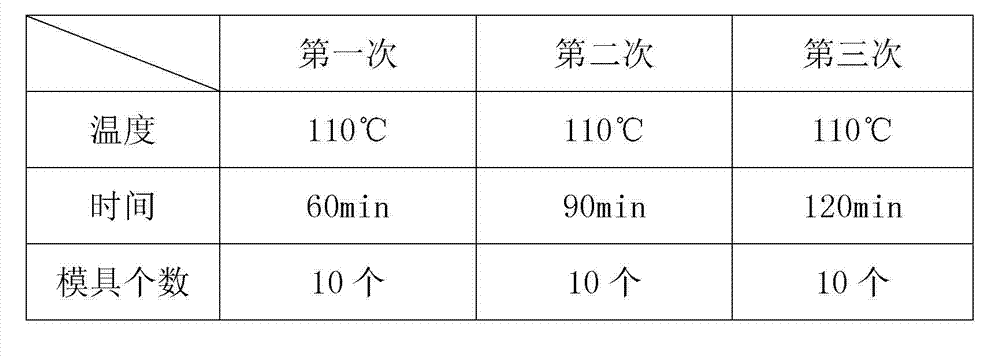

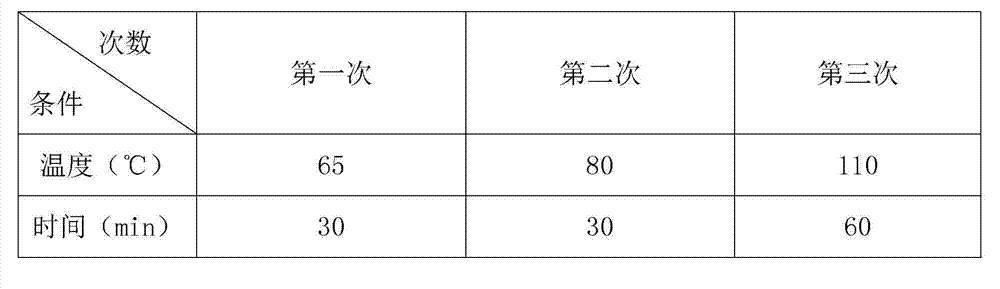

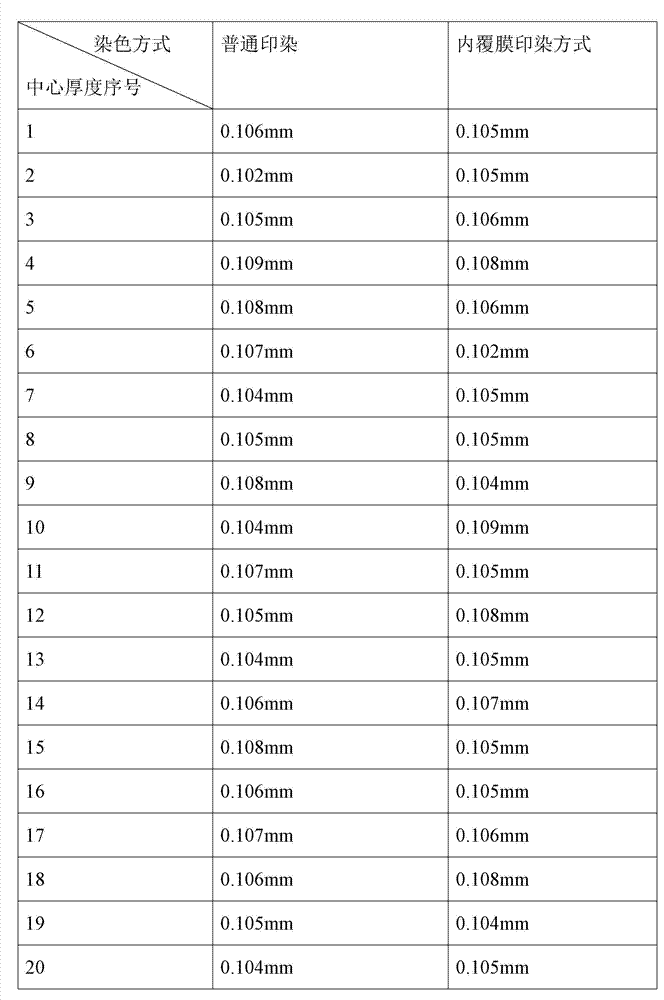

Colored soft hydrophilic contact lens and its making method

The invention relates to a colored soft hydrophilic contact lens and its making method. An organic film and a pigment layer are formed after the heating dye fixation stage through utilizing a film covering, printing and dyeing manner, so the organic film well blocks up the contact of the pigment layer and eyes. A mixture of the organic film, the pigment layer and a lens material monomer is molded, cured and turned to finally obtain the colored soft hydrophilic contact lens, so problems comprising pigment layer fading, weak wearing comfort level and the like are solved.

Owner:JILIN REALCON CONTACT LENS CO LTD

Television shell surface UV (ultraviolet) paint spraying technique

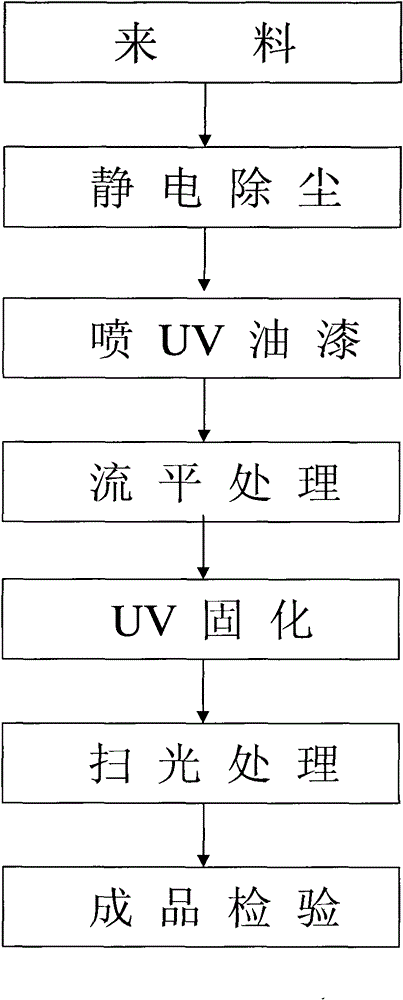

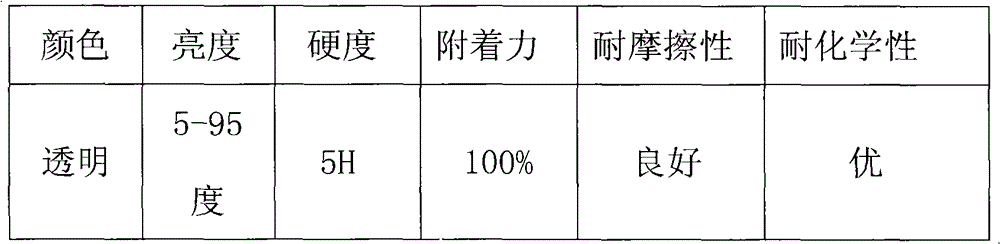

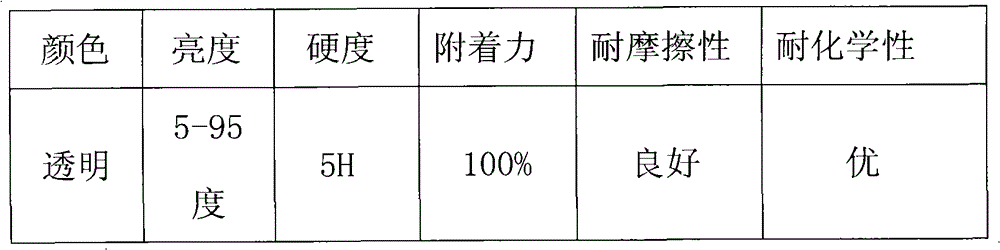

InactiveCN102744192AFix fadingSolve chromatic aberrationPretreated surfacesCoatingsProduct inspectionUltraviolet

The invention relates to a television shell surface UV (ultraviolet) paint spraying technique which comprises the following steps: baiting, electrostatic dust collection, UV oil spraying, UV paint leveling, UV curing, UV photoscanning, and finished product inspection. The concrete operation process comprises the following steps: sanding defective products at a baiting worktable by the operating personnel, and carrying out electrostatic dust collection; sweeping the shell surface, carrying out dust collection again, and sending into a spray chamber; reciprocating scanning in the shell spraying region by a spray gun; after spraying paint on the shell, carrying leveling treatment through a transmission line; after finishing the leveling, carrying out UV irradiation curing by a UV lamp; after finishing UV curing, carrying out electrostatic air blast cooling; and warehousing. The television shell surface UV paint spraying technique can effectively solve the problems of discoloration and color difference in the television shell, enhance the production efficiency, lower the application cost, reduce the environmental pollution and the like.

Owner:FOSHAN NANHAI SZY DIGITAL ELECTRONICS

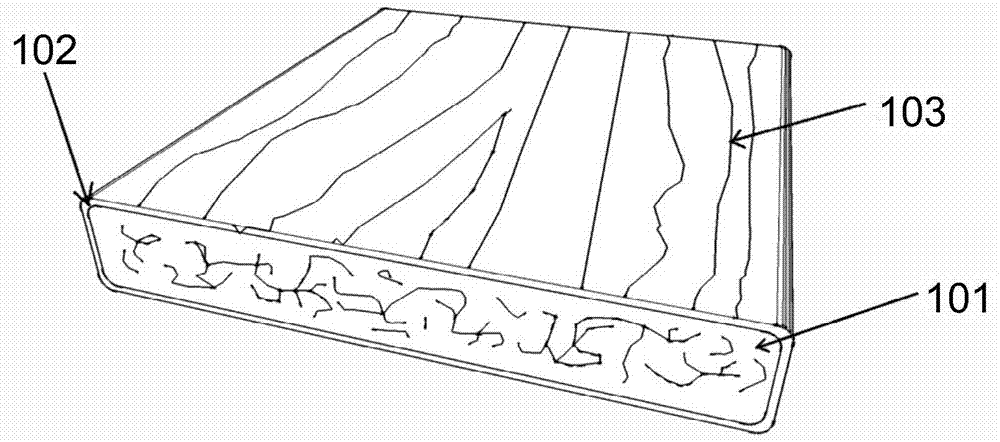

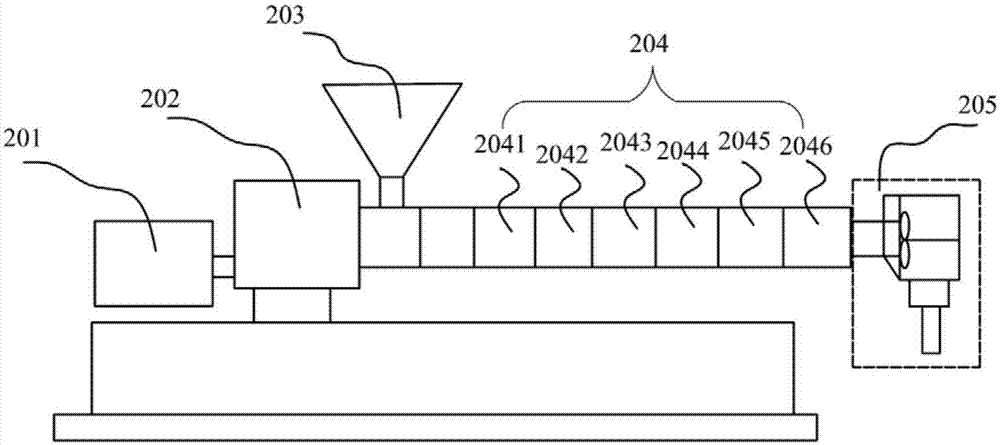

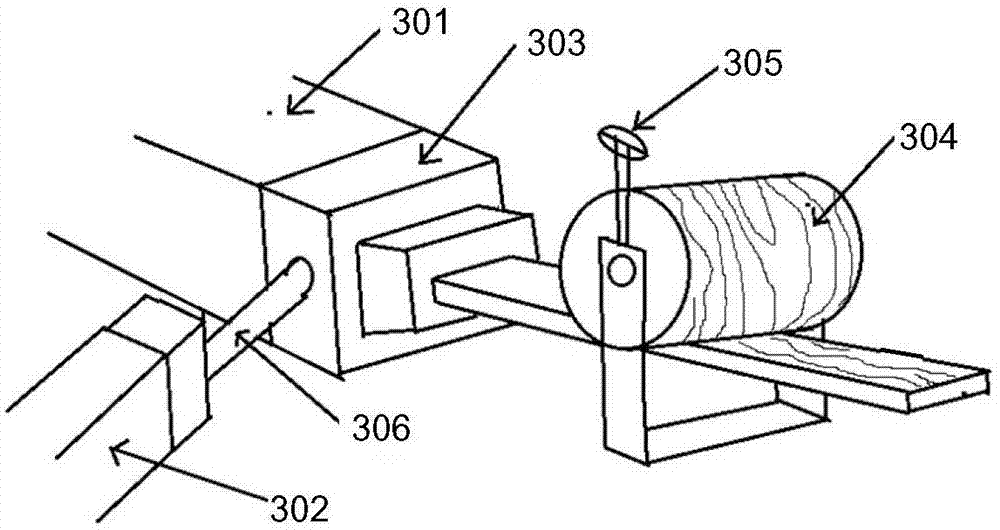

Wood-grain-imitated co-extruded plastic-wood profile and preparation method thereof

ActiveCN104723635AImprove anti-corrosion performanceImprove aging resistanceSynthetic resin layered productsSurface layerAging resistance

The invention provides a wood-grain-imitated co-extruded plastic-wood profile. The wood-grain-imitated co-extruded plastic-wood profile comprises a surface layer and a base material, wherein the adding amounts of plastic and a functional aid in the surface layer are more than the adding amounts of the plastic and the functional aid in the base material, so that the cost is favorable to be reduced; the surface layer is subjected to color adjustment by virtue of a main color and a secondary color (a third color can be increased according to requirements), so that the effects of the color shade and the layer variability of the surface layer can be well achieved. The invention further provides a preparation method of the wood-grain-imitated co-extruded plastic-wood profile. The preparation method comprises the processes of granulation, synchronous extrusion and surface treatment. According to the preparation method, surface layer particles including main color particles and secondary color particles are respectively granulated and are uniformly mixed for co-extruding the surface layer, and the surface layer is subjected to surface treatment in a 'hot plate and cold roller' manner. The co-extruded plastic-wood profile prepared by virtue of the preparation method is low in cost, excellent in water resistance, corrosion resistance and aging resistance and durable, further has the grains, color gradation and texture of imitated and natural wood, so that the user experience is improved.

Owner:湖南格林美资源利用有限公司 +2

Compound modifying preparation for protecting color of cooked meat products

InactiveCN101223984AProtection stabilityFix fadingMeat/fish preservation using chemicalsFood preparationAntioxidantFood coloring

The invention pertains to the food color protection technology field, which relates to a color protection compound modifier for cooked meat products. The modifier is prepared by the following raw materials based on portions by weight: 40-80 portions of emulsifier, 5-20 portions of acidity regulator, 3-20 portions of antioxidant, 5-20 portions of chelating agent and 2-6 portions of anti-caking agent. The invention can remarkably postpone the depigmentation degree of the cooked meat products, facilitating the cooked meat products to keep florid color during sale and circulation processes for a long time, thereby improving the freshness of the cooked meat products.

Owner:中原粮食集团多福多食品有限公司

Production process for cellulose fiber interwoven or cellulose fiber blended fabric

InactiveCN106835441ANot easy to fade and white hairNot easy to get white hairDrafting machinesDyeing processSizingDyeing

The invention provides a production process for cellulose fiber interwoven or cellulose fiber blended fabric. The production process includes the steps of selection of raw materials, spinning, sizing, weaving, dyeing, final treatment and the like; A100-type cellulose fiber is selected as the raw materials, fibrillation is assured not to occur to the cellulose fiber, the obtained fabric is ensured not to fade easily and generate white hairs easily, yarn hairness can be effectively controlled by adopting a Siro spinning yarn mode, the hairness 3mm above the surface of the yarn can be reduced by 80% as compared with a traditional ring spinning method, a sizing agent without PVA (polyvinyl acetate) is used for sizing, possibility that the cellulose fiber interwoven or cellulose fiber blended yarn is split by swelling friction under the damp condition can be reduced, weaving difficulties brought by the cellulose fiber interwoven or cellulose fiber blended yarn and other hairness can be further avoided, friction of the yarn and a machine during dyeing can be reduced by controlling warp and weft-density difference of gray fabric, and fibrillation risk of the cellulose fiber in production is reduced.

Owner:LILANG CHINA

Coloring process of whole body of fiber cement external wall panel

The invention discloses a coloring process of the whole body of a fiber cement external wall panel, comprising the following steps of: (1) doping blended inorganic pigments into the raw material powder for producing the fiber cement external wall panel, enabling the blended inorganic pigments to be absorbed on the surfaces of other granules through high-speed stirring to achieve the purpose of sufficient dispersion, and then stirring by adding water; (2) carrying out kneading and mixing processes on raw materials, and then enabling the raw materials to enter an extruder for extrusion molding;(3) carrying out steam ordinary-pressure curing and autoclave curing on a product in a still kettle to accelerate and enhance the strength of the product; and (4) finally processing the surface of the product, and spraying colorless clearwater paint. The invention enables the whole body of the fiber cement external wall panel to have one color, fresh and lovely luster and elegant appearance and endure high temperature without color fading by adding the inorganic pigments to the fiber cement external wall panel and adopting a customized production and curing process, thereby solving the problems of easy ageing, color fading and stripping of a surface coating of the traditional external wall panel colored by using paint.

Owner:BEIJING NEW BUILDING MATERIALS PLC +1

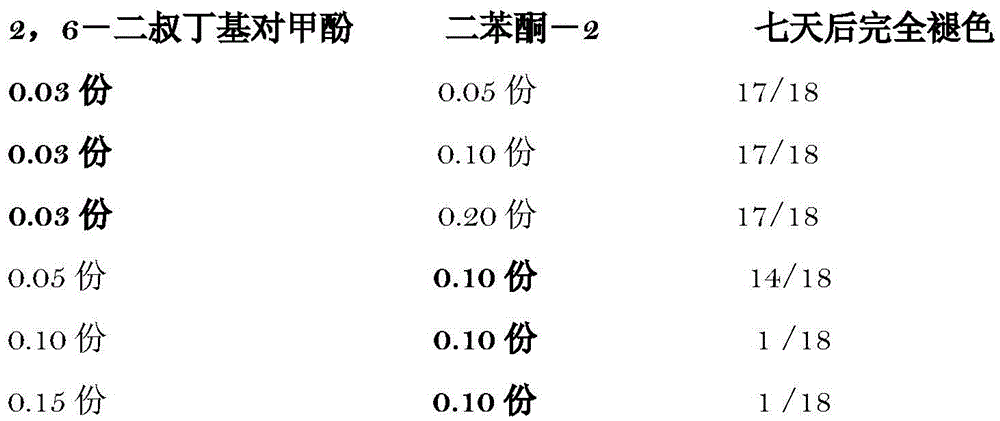

Thermal-aging-resistant color-stable color master batch for nylon and preparation method and application of color master batch

The invention discloses a thermal-aging-resistant color-stable color master batch for nylon and preparation method and application of color master batch in preparation of nylon products through high-temperature injection molding. The color master batch is prepared from the following raw materials in percentage by weight: 60-85% of carrier resin, 10-30% of modified toner, 2-7% of a dispersing agentand 1-3% of an antioxidant, the preparation method of the modified toner comprises the following steps: adding polyvinyl alcohol and a solvent into a reaction container at room temperature, stirringuntil the polyvinyl alcohol and the solvent are completely dissolved, adding an acid-binding agent and a pigment, uniformly stirring and mixing, dropwise adding acyl chloride pretreated by an ice-water bath, carrying out reflux condensation reaction for 2-4 hours, collecting an obtained solid product, washing, and carrying out vacuum drying to obtain the modified toner, wherein the solvent is dichloromethane and / or dimethyl sulfoxide, the acid-binding agent is pyridine and / or triethylamine, and a 254 red pigment is used. The preparation method comprises the following steps: uniformly mixing the carrier resin, the modified toner, the dispersing agent and the antioxidant according to a ratio, banburying, melting, blending, extruding, bracing, cooling with water, air-drying and dicing to obtain the color master batch.

Owner:中广核俊尔(浙江)新材料有限公司 +1

Cotton loose fiber dyeing method

InactiveCN1528975ASmall chromatic aberrationReduce lossDyeing processLiquid/gas/vapor fibres/slivers/rovings treatmentFiberChemistry

The invention discloses a dyeing process method for loose fiber of cotton, sliver, and cotton roll. It includes changes the traditional process of spinning-before-dyeing into the one of dyeing-before-spinning. The method uses azo dyes to dye the loose cotton, the dyed loose cotton is colorful cotton with five colors, the color includes red, yellow, brown and black. It can be produced without special appliances, especially applies to small industry, the color difference of the product is small, the product is soft, pluffy, it solves the problem of color floating, fading, contaminating, cotton joint, bad color firm rate. It reduces yarn back, high speed cone winding process.

Owner:余姚久丰染色厂有限公司

Novel printing method for gold-thread polyester fabric

ActiveCN103821009AReduce stainingGood antifoulingFibre typesDyeing processTextile printerPolymer science

The invention discloses a novel printing method for a gold-thread polyester fabric. The method comprises the processes of pretreatment, printing and aging of the fabric, wherein in the pretreatment, sodium carbonate with the concentration of 2.0 to 2.5 g / L, a refining agent with the concentration of 2.0 to 2.5g / L, a degreaser with the concentration of 0.16 to 0.2g / L and a chelating agent with the concentration of 0.4 to 0.5g / L are added and refining is carried out for 90 minutes at the temperature of 110 DEG C in an air flow dyeing machine; in the printing process, a water-dispersibility polymer polyester composite, a dye, water, resist salt, printing gum and citric acid are selected to be combined to form a gel solution so as to carry out printing on the fabric; the aging is performed at the temperature of 170 DEG C for 5 minutes. The printing method provided by the invention has the advantages as follows: dye yield of the dye is increased, stain resistance and oxidation resistance of gold threads in the polyester printing process are improved and the problem of color fading of the gold threads in the printing process of the polyester fabric is solved.

Owner:浙江嘉欣兴昌印染有限公司

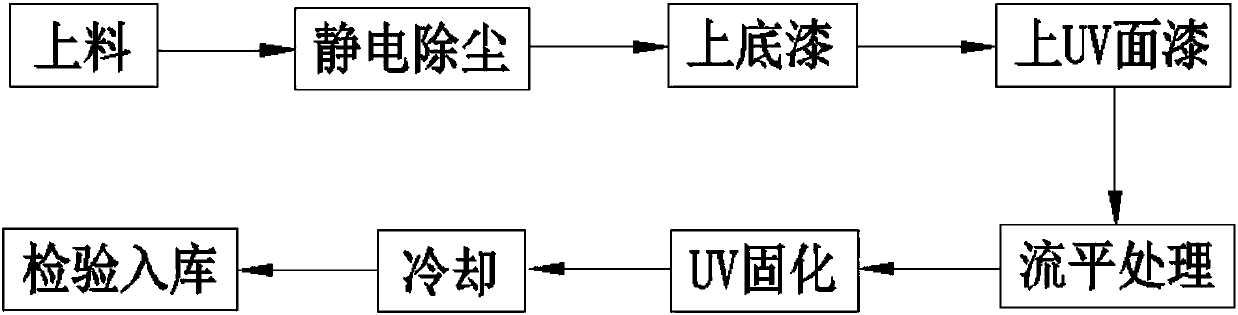

Spraying process for mobile phone shells

InactiveCN107694883AReduce pollutionFix fadingPretreated surfacesSpecial surfacesUV curingUltraviolet radiation

The invention discloses a spraying process for mobile phone shells. The spraying process includes steps of a, loading shells which are subjected to injection molding by the aid of molds, and carryingout polishing treatment on defective products; b, carrying out electrostatic dust removal on the surfaces of products, then blowing and sweeping the surfaces of the products and carrying out electrostatic dust removal again; c, coating primer paint, to be more specific, carrying out primer paint spraying treatment on the products in spraying rooms by the aid of spraying guns, then drying the products and carrying out illumination treatment; d, coating UV (ultraviolet) finish paint, and to be more specific, carrying out UV paint spraying treatment on the products coated with the primer paint bythe aid of the spraying guns; e, carrying out leveling treatment on the products with the sprayed UV paint by the aid of conveyor lines; f, carrying out UV curing, and to be more specific, carrying out ultraviolet radiation on the mobile phone shells by the aid of UV lamps after the leveling treatment is carried out on the mobile phone shells; g, cooling the cured mobile phone shells by means ofelectrostatic air blast; h, carrying out inspection and warehousing. The spraying process has the advantages that the problems of color fading and color difference can be effectively solved by the aidof the mobile phone shells produced by the aid of the spraying process; the production efficiency can be improved, the production cost can be reduced, and environmental pollution can be abated.

Owner:重庆市量劲科技有限公司

Red bayberry pulp drink and processing method thereof

The present invention discloses red bayberry pulp drink comprising the following components by weight: 8-10% of sucrose, 0.08-0.15% ofprotein sugar, 0.10-0.15% of citric acid, 0.03-0.05% of tannic acid, 3-5% of red bayberry juice, 10-15% red bayberry pulp semi-finished product, 0.03-0.05% of iso-ascorbic acid, 0.01-0.05% of red bayberry essence, and balance of water; a processing method of the red bayberry pulp drink comprises the following steps: 1) red bayberry juice preparation, 2) red bayberry pulp semi-finished product preparation; 3) blending, to be more specific, proportionally mixing the water, red bayberry juice, red bayberry pulp, sucrose, protein sugar, tannic acid and xanthan gum, heating to 95 DEG C, keeping for 10-15min, then adding water for fixing to the scale, cooling to 80 DEG C, adding the citric acid, iso-ascorbic acid, mulberry red and red bayberry essence for blending; and 4) filling and sterilization; the red bayberry pulp drink is a completely new drink, and can meet the needs of different people, and the processing method of the red bayberry pulp drink is simple, and can solve the problem of fading.

Owner:苏州苏东庭生物科技有限公司

Sun-proof dye ink ink-jet printing ink

The invention discloses a sun-proof dye ink ink-jet printing ink. The sun-proof dye ink ink-jet printing ink is characterized by comprising the following components by mass percent: 2-5% of water soluble dye, 2-4% of styrene acrylic resin, 0.1-0.4% of an ultraviolet light absorber, 0.1-1.0% of a surfactant, 4-10% of isopropanol, 5-8% of ethylene glycol, 10-20% of a humectant, 0.2-0.5% of a pH stabilizer, 0.1-0.2% of a bactericide and the balance of deionized water. The sun-proof dye ink ink-jet printing ink is strong in stability, effectively improves the light fastness, the weather fastness,the acid resistance and the waterproofness of printed words and images, and solves the problems of fading and shading of the image, the output quality of the image is high, the color rendition is vivid, and an ink head of a printer is effectively protected.

Owner:保定良合新材料科技有限公司

Color protection combination and product containing combination

InactiveCN105616192ASuitable for a wide range of pigmentsWide range of pigmentsCosmetic preparationsToilet preparationsUv absorbanceAnti oxidant

The invention belongs to the field of cosmetics, and relates to a color protection combination, in particular to a color protection combination containing an ultraviolet absorbent and an antioxidant. The cosmetics containing the combination can be insolated outdoors in certain time, and the color cannot completely fade under the condition of receiving light and heat.

Owner:GUANGZHOU KENENG COSMETICS RES CO LTD +2

Preparation process of multi-layer composite automobile leather

ActiveCN111284108AGood flexibilityIncrease elasticityLiquid surface applicatorsOrganic chemistryNonwoven fabricCollagen fiber

The invention discloses a preparation process of multi-layer composite automobile leather. The automobile leather sequentially comprises a sunscreen coating layer, a leather layer, a non-woven fabriclayer, a non-glue cotton layer and a knitted fabric layer from outside to inside. The preparation process of the automobile leather comprises the following steps: step 1, depilating, degreasing, softening and pickling dry leather or salt leather to obtain leather collagen fibers, tanning and dyeing the leather collagen fibers, washing the leather collagen fibers with water, taking the leather collagen fibers out of a drum, and carrying out stacking and drying in vacuum to obtain leather; step 2, uniformly spraying a sun-screening emulsion on the surface of the leather prepared in the step 1 ina spraying manner, and then performing heating and shaping to obtain leather containing a sun-screening coating layer; and step 3, sequentially stacking the leather containing a sunscreen coating layer prepared in the step 2, non-woven fabric, non-glue cotton and knitted fabric, and performing pressing, sewing and trimming to obtain the multi-layer composite automobile leather. The sunscreen emulsion is uniformly sprayed on the surface of the leather in a spraying manner, so that the protective property and the sunscreen property of the leather are improved, and the ageing resistance of the automobile leather is improved.

Owner:YANGZHOU DERWINS PLASTICS TECH

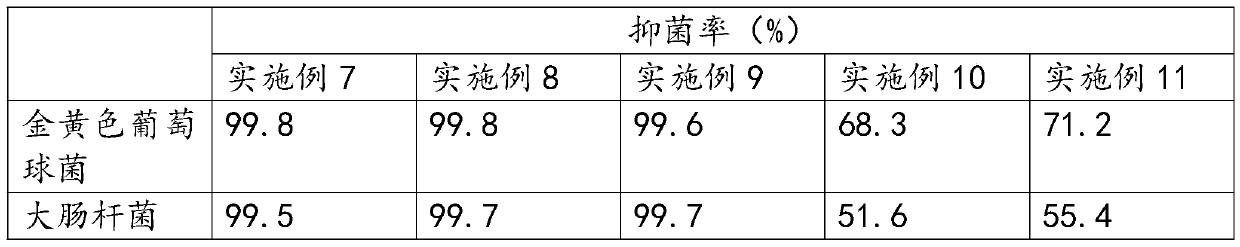

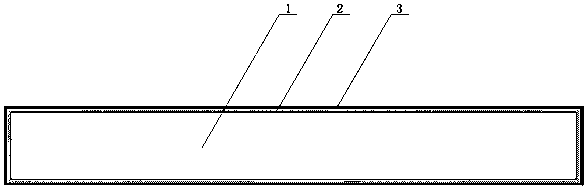

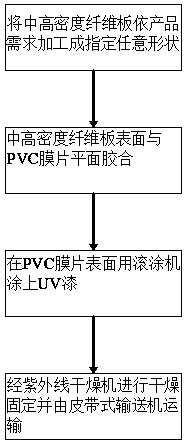

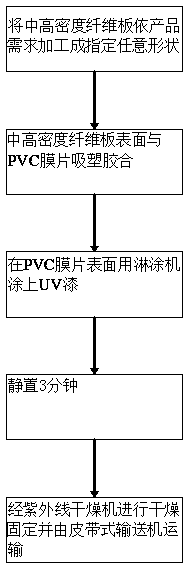

PVC overlaid plywood and manufacturing method thereof

InactiveCN108501133AHigh hardnessImprove wear resistanceOther plywood/veneer working apparatusPretreated surfacesFiberHigh density

The invention discloses PVC overlaid plywood and a manufacturing method thereof and belongs to the technical field of plywood. The PVC overlaid plywood comprises a medium-high density fiber board, a PVC membrane and UV paint, wherein the PVC membrane is arranged on the surface of the medium-high density fiber board; and the UV paint is arranged on the surface of the PVC membrane. The UV paint is sprayed to the PVC membrane and is subjected to UV curing to form a layer of film which is high in hardness, good in abrasion resistance and high in transparency, and the effects of scraping resistance, scraping prevention, heat resistance and durability are achieved. Meanwhile, the curved UV paint is stable in color and luster, the mirror flat effect is better, the paint film is full and free of orange peel phenomenon, and the color and luster uniformity of the surface of the film is effectively increased. The surface of the plywood is wrapped with the PVC membrane easily, conveniently and rapidly, the UV paint coating efficiency is high, the coating cost is low, and coating is environmentally friendly. The problems that wrapping of the plywood wastes time and labor, the poor phenomena like bubbles and delaminating are easily generated, the features of high hardness, scraping prevention, scraping resistance and heat resistance are not achieved, and durability in transportation and useis poor are effectively solved.

Owner:张梦琪

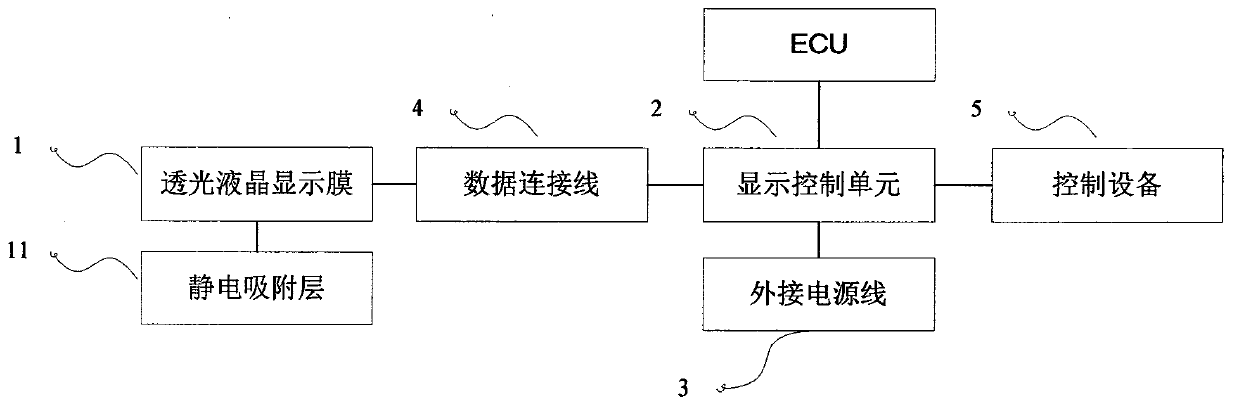

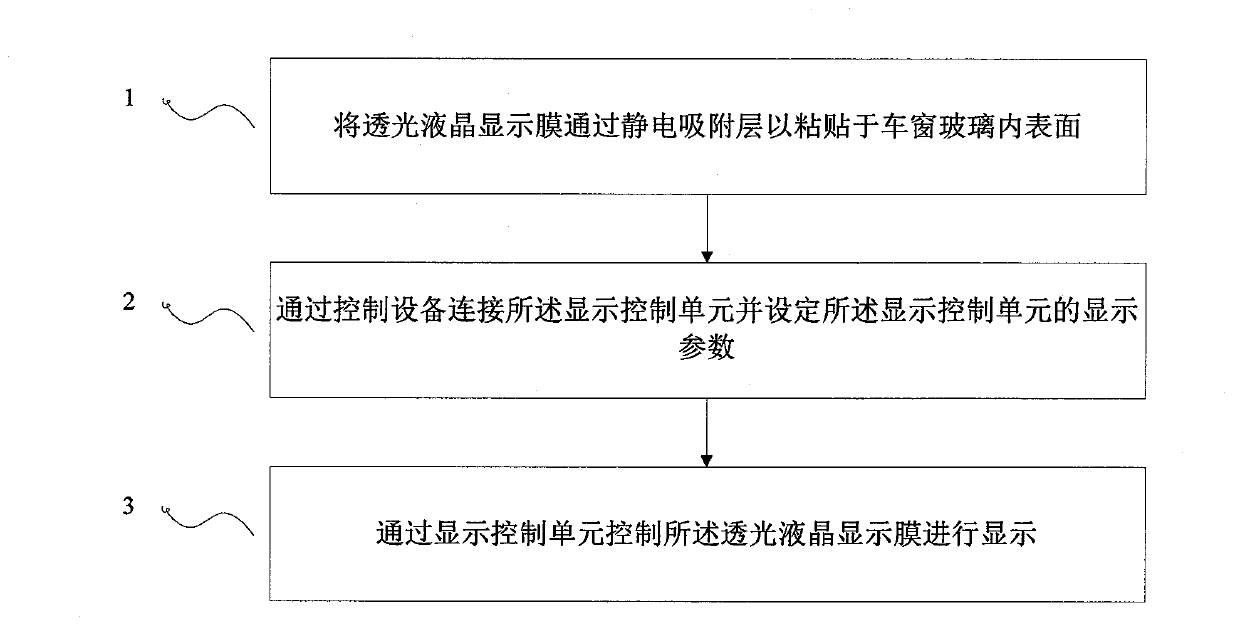

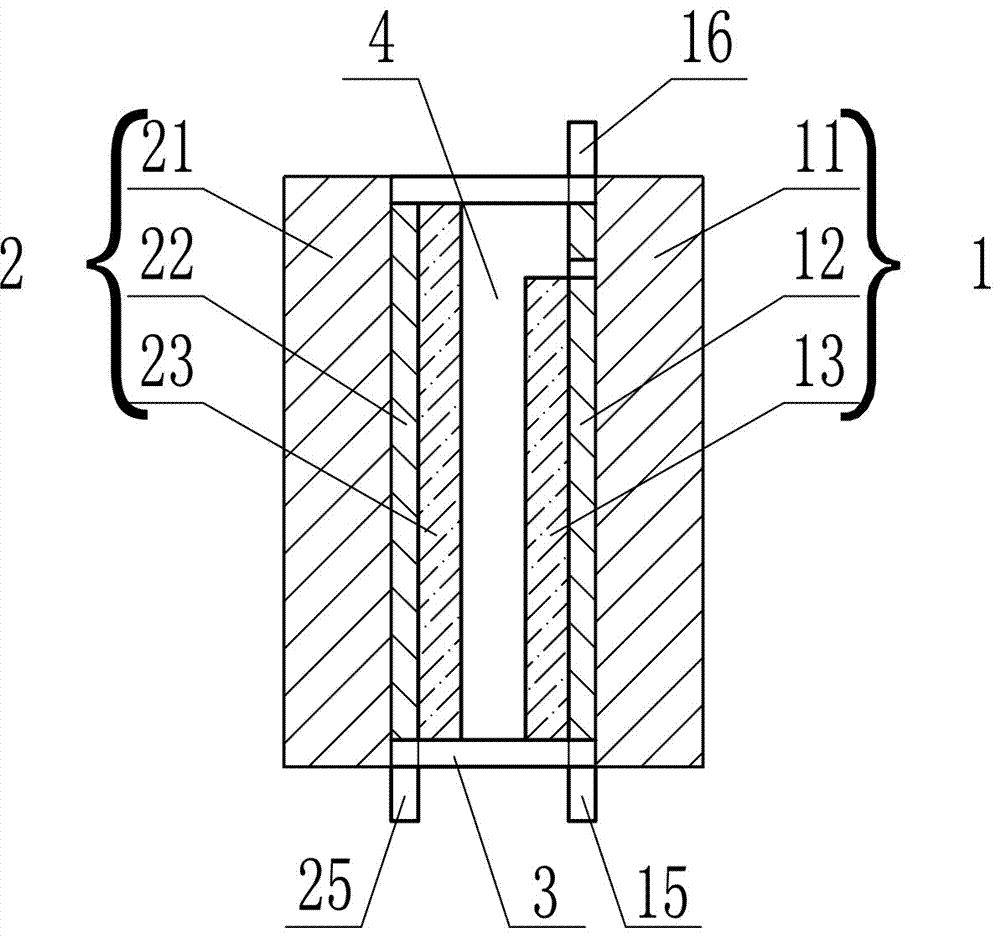

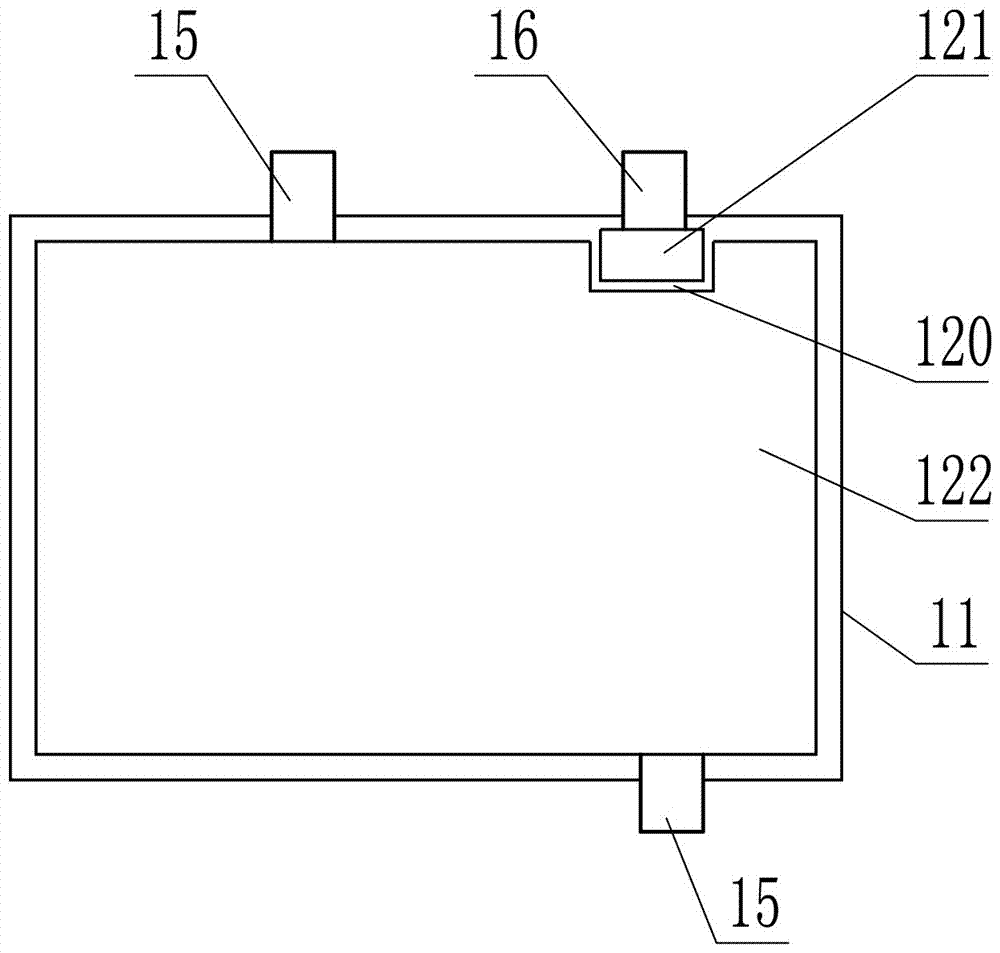

Automobile display screen and display method

InactiveCN103963705AFix fadingSolve the problem of blocking the line of sightOptical viewingElectricityLiquid-crystal display

The invention provides an automobile display screen and a display method. The automobile display screen comprises nonopaque liquid crystal display films and a display control unit, wherein an electrostatic adsorption layer is arranged on one surface of each nonopaque liquid crystal display film, so that the nonopaque liquid crystal display films are stuck to the inner surfaces of the glass for vehicle windows; the display control unit is connected with the nonopaque liquid crystal display films through electric wires so as to supply electricity and transmit data for the nonopaque liquid crystal display films. In the scheme, the nonopaque liquid crystal display films are stuck to the inner surfaces of the glass for the vehicle windows through electrostatic adsorption films for displaying, so that the problem that adhesive labels easily fade or block the line of sight in the prior art can be solved, real words can be replaced at any time, and various problems due to the unreasonable structure of the existing adhesive label are solved.

Owner:王辉

Formula and extraction process of composite natural purple pigment

The invention discloses a formula of a composite natural purple pigment. The composite natural purple pigment is prepared from 250 g of beetroot, 25 g of clitoria ternatea flowers, 25 g of peeled lemons and 1,500 g of water. An extraction process comprises the following steps that the beetroot is washed to completely remove sand, peeling is not needed, the air-dried beetroot and peeled lemons arejuiced and filtered by a 100-mesh fine sieve, then a mixture is put into a pot to be boiled with a big fire and then concentrated with a small fire to the weight required by the formula, and after natural precipitation, an uppermost pure part is taken for use; fresh red-pulp dragon fruits are peeled, diced, juiced and then filtered by the 100-mesh fine sieve, a filter residue is put into the pot to be boiled with a big fire and then concentrated with a small fire to the weight required by the formula, and after natural precipitation, an uppermost pure part is taken for use; water which is 20 times the weight of the clitoria ternatea flowers is added to the clitoria ternatea flowers, after a clitoria ternatea flower liquid is boiled with a big fire, cooking is conducted with a small fire for 10 minutes, sieving is conducted after braising is conducted for 20 minutes, the clitoria ternatea flower liquid continues to be cooked to 1 / 3 of the original volume with a big fire and then is cooked to be in a thick state with a small fire, finally, natural precipitation is conducted for at least 60 minutes, and an upper pure part is taken for use; the extracted beetroot red pigment and clitoria ternatea flower blue pigment (a combination of red-pulp dragon fruit red and clitoria ternatea flower blue) are uniformly mixed and loaded into a sterilized dark essential oil bottle, and the purple natural pigment is formed.

Owner:匠人之心(北京)食品有限公司

Electrochromic device capable of independently controlling electrochromic layers

The invention discloses an electrochromic device capable of independently controlling electrochromic layers. The electrochromic device comprises two electrode plates, an electrolyte layer and a seal edge, wherein the electrolyte layer is arranged between the two electrode plates; the seal edge is used for encapsulating the electrolyte layer; the electrode plates comprise bases, electrode layers arranged on certain sides of the bases and the electrochromic layers arranged on the outer sides of the electrode layers; the electrode layers comprise main electrode areas; the electrode layer on at least one electrode plate is also provided with an auxiliary electrode area mutually isolated from the main electrode areas; each electrode area is provided with an electrode outer leading wire which isconnected with an external power supply; the main electrode areas of the electrode layers are provided with the electrochromic layers; the electrolyte layer is arranged between the two electrode plates, and is encapsulated through a circle of the seal edge between the bases of the two electrode plates. The electrochromic device is used for solving problems that an electrochromic device with two homopolar electrochromic layers cannot be used for discoloring the two electrochromic layers and an electrochromic device with two heteropolar electrochromic layers cannot be used for independently coloring and discoloring the single electrochromic layer.

Owner:姜卫东

Roller-coating and spray-coating mixed production process for log cabinet body of UV paint furniture

InactiveCN112246582ANo volatile substancesColor stablePretreated surfacesSpecial surfacesNumerical controlJapanning

The invention discloses a roller-coating and spray-coating mixed production process for a log cabinet body of UV paint furniture. The process comprises the following steps of fixed-thickness sanding,UV primer roller-coating for sealing wood pores, paint surface sanding for increasing the UV physical adhesive force in the subsequent procedure, secondary UV primer roller-coating for increasing theplumpness of a paint film, primer sanding, numerical control machining, cut edge physical repairing, UV finish paint spray-coating, paint surface physical repairing treatment, color matching and the like. According to the process, UV paint is applied to a log board, and the thickness of the paint film is greatly related to the wood, texture, hardness, splicing width, moisture, adsorption force anddamp-proof stability of the log board; the problems of miniaturization of production equipment and reduction of production cost are solved; and various adverse effects such as paint surface drawing,napping and granulation cannot be caused during UV paint roller-painting of the log board.

Owner:方庆

Colored soft hydrophilic contact lens and making method thereof

The invention relates to a colored soft hydrophilic contact lens and its making method. An organic film and a pigment layer are formed after the heating dye fixation stage through utilizing a film covering, printing and dyeing manner, so the organic film well blocks up the contact of the pigment layer and eyes. A mixture of the organic film, the pigment layer and a lens material monomer is molded, cured and turned to finally obtain the colored soft hydrophilic contact lens, so problems comprising pigment layer fading, weak wearing comfort level and the like are solved.

Owner:JILIN REALCON CONTACT LENS CO LTD

Dimethyldiallylammonium chloride polymer, and preparation method and application thereof

InactiveCN110835386AImprove color fixationImprove wet fastnessDyeing processPolymer scienceCross linker

The invention discloses a dimethyldiallylammonium chloride polymer, and a preparation method and an application thereof. A copolymer is synthesized through a polymerization reaction of dimethyldiallylammonium chloride, diallyl amine and an initiator which are used as raw materials, and a cross-linking agent is added to obtain the novel polycationic perspiration-resistant color fixing agent. The copolymer reacts with an anionic dye used by superfine fiber PU leather to generate color lake, and a formed polymer reticular structure forms a film on the surface of the leather to coat the dye and fiber, so that the perspiration-resistant color fastness of the leather is improved. The color fixing agent prepared in the invention has the advantages of no use of an organic solvent in the productionprocess, greenness, environmental friendliness, no formaldehyde, excellent perspiration resistance and good stability, and the preparation method has the advantages of simplicity, short time, low energy consumption, and provision of an important guarantee for industrial production.

Owner:YANTAI UNIV

Titanium plate painting preparation method based on anodic oxidation

PendingCN113684517ASimple preparation stepsEasy to implementCellsSurface reaction electrolytic coatingTitaniumTitanium plate

The invention discloses a titanium plate painting preparation method based on anodic oxidation. The titanium plate painting preparation method comprises the steps that a titanium plate blank is cut on a pure titanium standard plate according to the design size of a titanium plate painting; the titanium plate blank is subjected to acid pickling; a contour line of the painting is made on the titanium plate blank and dried; and anodic oxidation is conducted on the area in the contour line, and the titanium plate painting is obtained. According to the method, the titanium plate painting can be directly manufactured on the titanium plate by sequentially carrying out the steps of acid pickling, contour line overprinting, drying, anodic oxidation and the like on the titanium plate blank, the titanium plate painting manufacturing steps are simple and convenient to implement, meanwhile, the painting can present different colors by adjusting the current, and the problems that a traditional paper painting is short in storage time, fades and is prone to damage are solved.

Owner:西安秦钛思捷科技有限公司

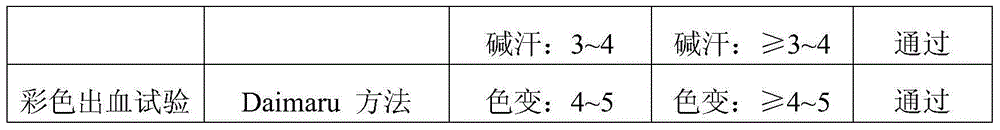

Active and dispersive one-paste printing process of cotton-polyester blended knitted fabric

The invention discloses an active and dispersive one-paste printing process of a cotton-polyester blended knitted fabric. The process comprises the following steps: designing a printing pattern; preparing cotton-polyester knitted plain cloth; preparing a stock thickener, colored paste and alkaline slurry; printing; roasting; overprinting the alkaline slurry; steaming; washing; and drying. The active and dispersive one-paste printing process of the cotton-polyester blended knitted fabric disclosed by the invention lays emphasis on a process flow of coloring a disperse dye and an active dye in different pH value ranges by applying existing equipment of a printing and dyeing mill according to the fixation condition of the disperse dye and the active dye when dispersive / active one-paste printing is carried out on the cotton-polyester blended knitted fabric, so that the technical problem that active and dispersive one-paste printing of the cotton-polyester blended knitted fabric cannot be widely produced in batch is solved.

Owner:ENPING KAM HING TEXTILE & DYEING

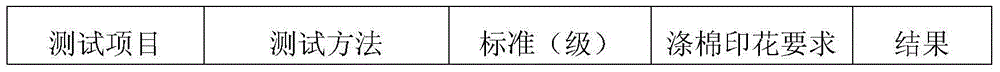

Compound water permeable brick and preparing method thereof

The invention belongs to the field of building materials and discloses a compound water permeable brick and a preparing method thereof, which include a surface course, a brick nuclear and a bottom layer. The surface course material comprises surface course binder, yellow pottery and the like; the bottom layer material comprises sand and the like; and the brick nuclear material comprises gravel, cement, activated carbon, polyacrylamide and water. The preparing method includes preparing surface course, preparing bottom layer, making brick nuclear, encapsulating the prepared surface course and the bottom layer on the made brick nuclear, once vibration, pressure vibration and vibration forming. The compound water permeable brick and the preparing method thereof have the advantages that preparing process is easy, and economical, practical and environment-friendly ecological compound water permeable brick is prepared with cheap raw materials, which has strength performance lacked by common water permeable bricks and provides a sound environment for microorganisms to degrade organic pollutants in the brick body.

Owner:山东霍兹企业管理咨询有限公司

Manufacturing process of wood door

InactiveCN101871307BLong-term aestheticsFix fadingPretreated surfacesCoatingsManufacturing engineering

The invention discloses a manufacturing process of a wood door, which is characterized by comprising preparation, sanding operation, colorizing and bottom rolling treatment, lamination, trimming treatment, assembling operation, decorative and shaping fastening piece installation and final entire packaging. The process prevents expansion and contraction in door vertical frame, cross beam and otherplaces. In the invention, the surface oil paint stripping and layering can be prevented by adopting half drying operation, paint spraying, a thermal leveling process and overall drying operation, time is saved and product quality is improved. At the same time, the invention also provides a half drying machine for half drying operation.

Owner:CHENGDU TIANCHENG SHENGMU DOOR

Layered yoghourt and preparation method thereof

Belonging to the technical field of dairy product processing, the invention discloses a layered yoghourt and a preparation method thereof. The layered yoghurt at least comprises a layer of salted mayonnaise and a layer of yoghurt base material, clear layering exists between the salted mayonnaise and the yoghurt base material, and no smudging phenomenon occurs within the shelf life; the salted mayonnaise raw materials comprise salted duck egg yolk; the preparation method includes the step of OHMIC heating sterilization. According to the invention, salted duck egg yolk is adopted as the raw material, and a specific method is adopted for sauce making, fishy smell is removed, the unique delicate flavor, fragrance and natural bright color of the salted duck egg yolk are reserved, when the salted mayonnaise is used for yoghourt products, the unique and novel taste of the salted mayonnaise can refresh people, and the yoghourt is richer in nutrition. No pigment is added, OHMIC heating sterilization is adopted, the inherent color of the product raw materials can be kept, the color and lustre are natural and healthy, natural pigment is not damaged, and thermal denaturation is avoided; and nocolor migration or layering within the shelf life are ensured after filling of the mayonnaise and yoghourt.

Owner:河北新希望天香乳业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com