Dimethyldiallylammonium chloride polymer, and preparation method and application thereof

A technology of polydimethyl diallyl amine chloride and dimethyl diallyl amine chloride is applied in the field of polymers, which can solve the color change of fabrics, reduce the color fastness to sunlight, harm the human body, etc. problem, to achieve the effect of less harm to human body, excellent color fixing effect and short time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Put dimethyl diallyl ammonium chloride and diallyl amine into the flask according to the mass ratio of 100:13, then add 0.13g of ammonium persulfate initiator, and then add a certain amount of glacial acetic acid to adjust In an acidic environment, after mixing evenly, reflux, heat up to 65°C, stir with magnetic force, and react for 3 hours.

[0038] (2) Add 0.54 g of epichlorohydrin and continue the reaction for 0.5 hour to obtain a crosslinkable polycation.

[0039] (3) Add 25ml of deionized water, and magnetically stir for 10 minutes to obtain the product.

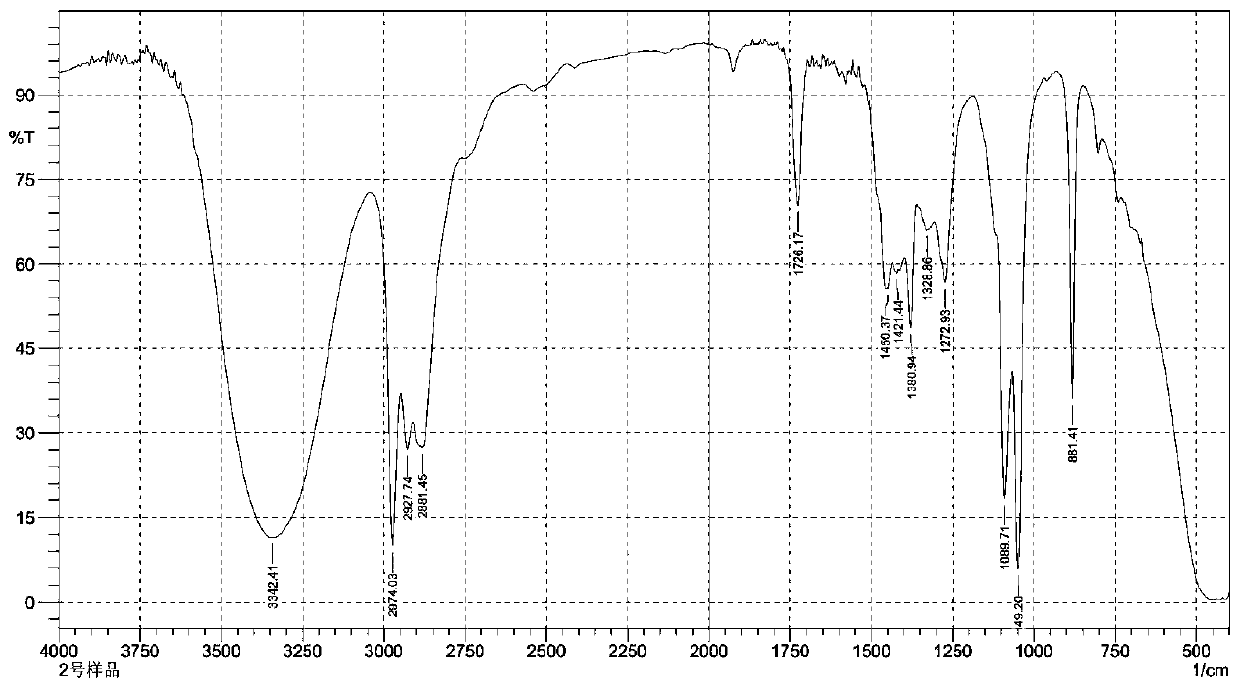

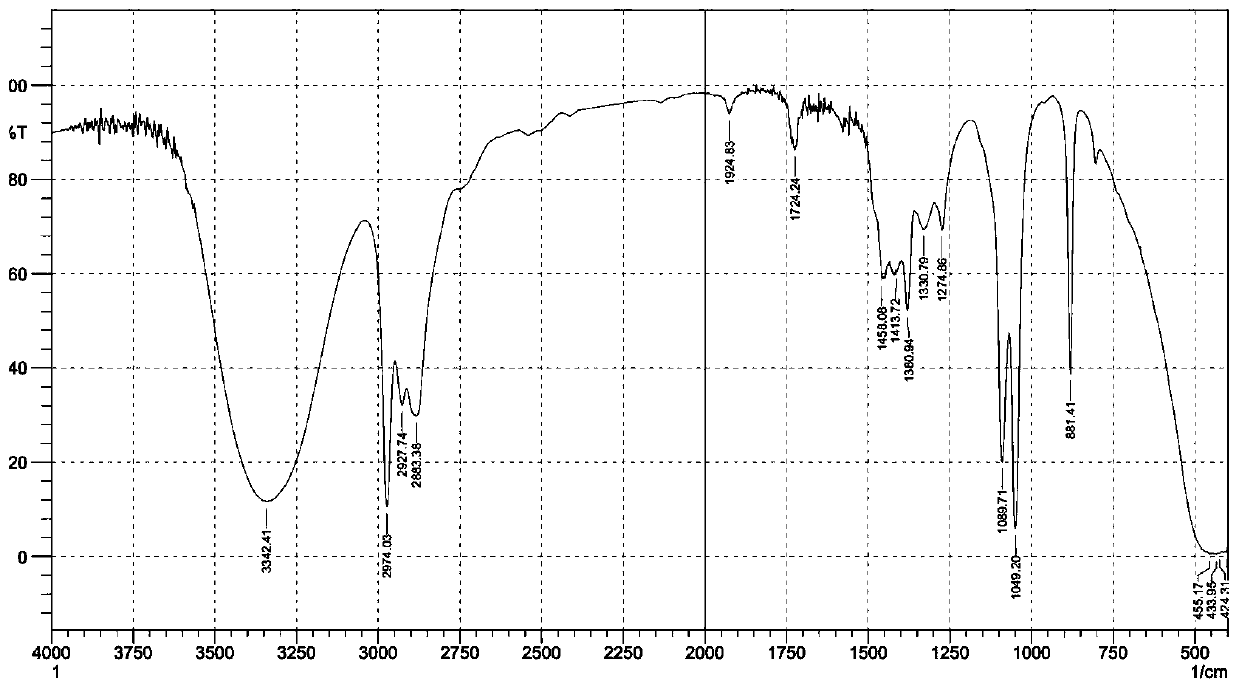

[0040] Such as figure 1 Shown, its infrared spectrogram of the obtained product shows 3342cm -1 The absorption peak is the stretching vibration peak of N-H; 1728cm -1 The absorption peak at shows the residue of diene group; 2972~2881cm -1 DescriptionCH 3 —,—CH 2 ———CH—The presence of the group proves that the polydimethyldiallylamine chloride product is generated.

Embodiment 2

[0042] (1) Put dimethyl diallyl ammonium chloride and diallyl amine into the flask according to the mass ratio of 100:14, then add 0.14g ammonium persulfate initiator, then add a certain amount of glacial acetic acid to adjust In an acidic environment, after mixing evenly, reflux, heat up to 65°C, stir with magnetic force, and react for 3 hours.

[0043](2) Add 0.54 g of epichlorohydrin and continue the reaction for 0.5 hour to obtain a crosslinkable polycation.

[0044] (3) Add 25ml of deionized water, and magnetically stir for 10 minutes to obtain the product.

Embodiment 3

[0046] (1) Put dimethyl diallyl ammonium chloride and diallyl amine into the flask according to the mass ratio of 100:9, then add 0.09g of ammonium persulfate initiator, and then add a certain amount of glacial acetic acid to adjust In an acidic environment, after mixing evenly, reflux, heat up to 65°C, stir with magnetic force, and react for 3 hours.

[0047] (2) Add 0.54 g of epichlorohydrin and continue the reaction for 0.5 hour to obtain a crosslinkable polycation.

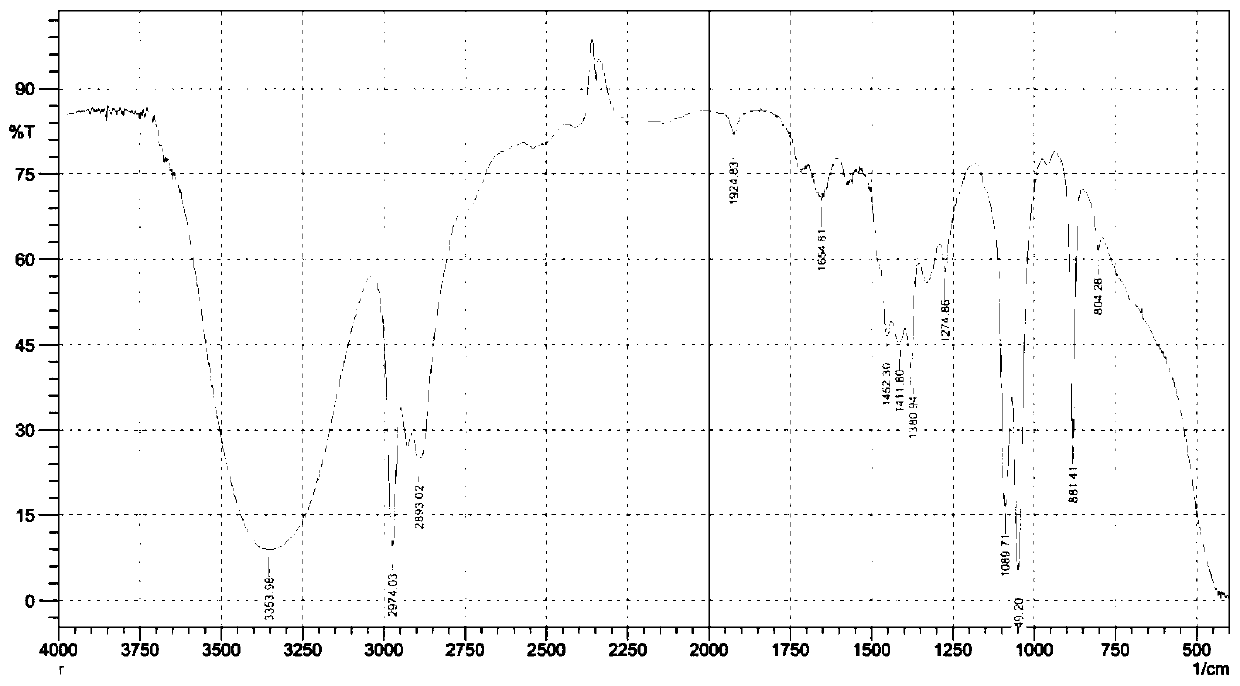

[0048] (3) Add 25ml of deionized water, stir magnetically for 10min, and obtain the product, such as figure 2 As shown, it was proved that polydimethyldiallylamine chloride product was generated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com