Patents

Literature

90 results about "Synthetic copolymer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A synthetic polymer is a type of polymer made by engineers and scientists from artificial components rather than natural ones. Synthetic polymers are commonly found in consumer products such as epoxy, textiles, cookware, tires, plastic bottles and currency. Continue Reading.

Personal Care Compositions Containing Cationic Synthetic Copolymer and a Detersive Surfactant

InactiveUS20080206179A1Good conditionEfficient depositionCosmetic preparationsHair cosmeticsPersonal careSalicylic acid

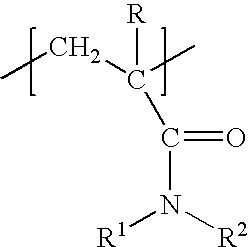

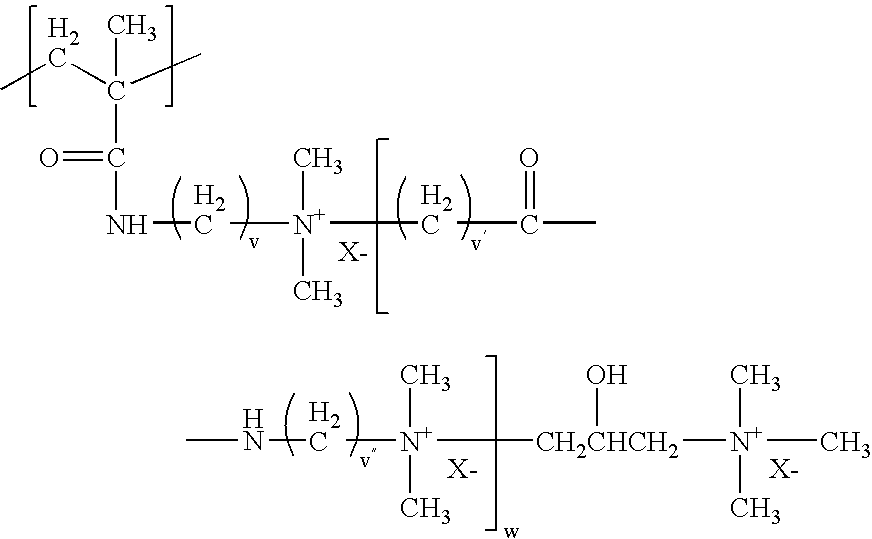

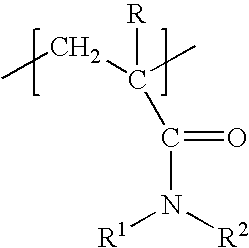

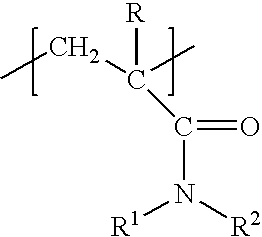

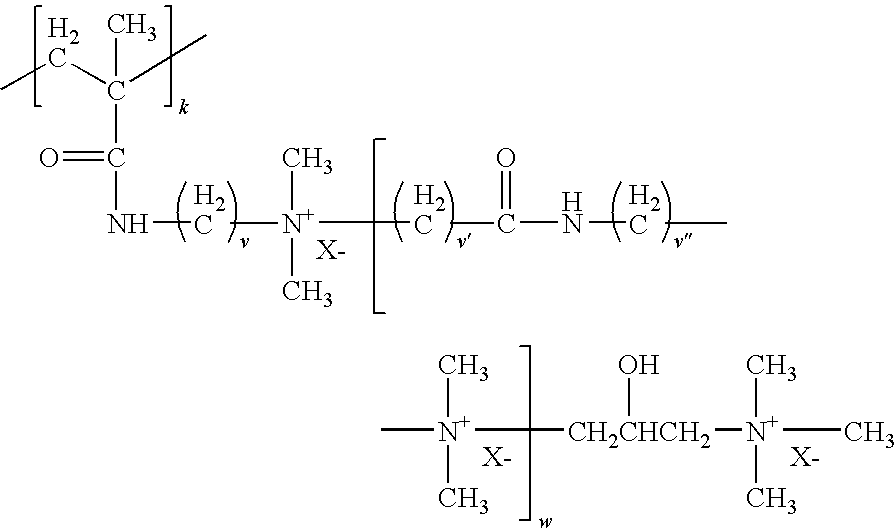

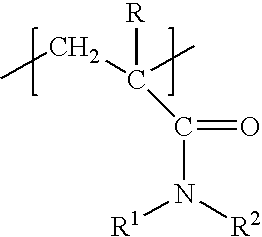

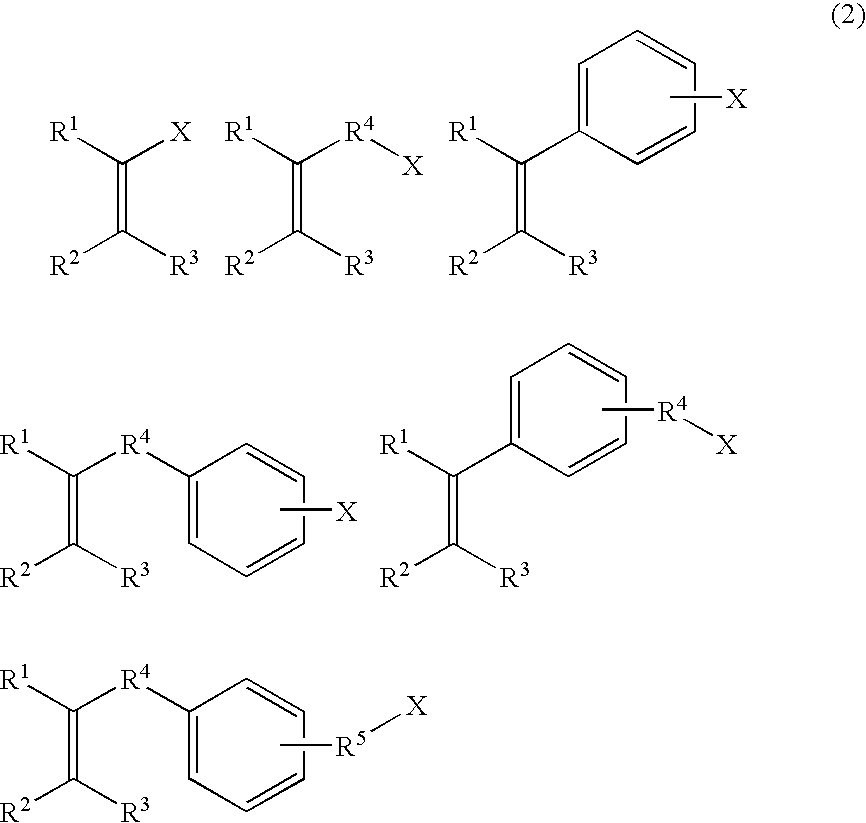

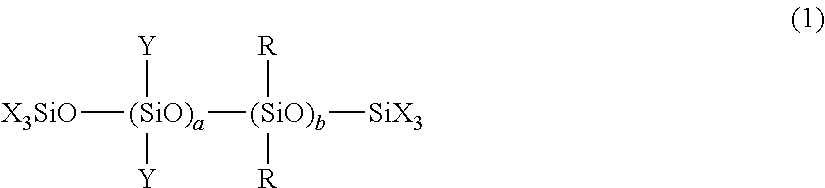

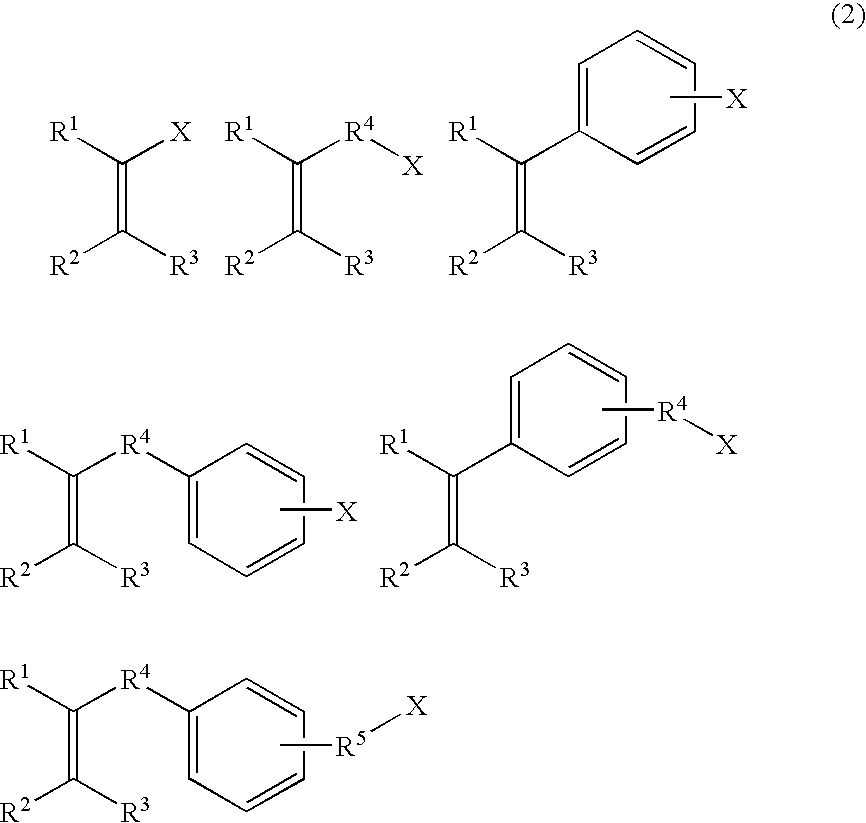

A personal care composition comprising:a) a synthetic random copolymer having a net positive charge comprising;i.) a nonionic monomer unit of the following formula:where R is H or C1-4 alkyl; and R1 and R2 are independently selected from the group consisting of H, C1-4 alkyl, CH2OCH3, CH2OCH2CH(CH3)2, and phenyl, or together are C3-6cycloalkyl; andii.) a cationic monomer unit with 2 or more positive charges of the following formula:where each of v, v′, and v″ is independently an integer of from 1 to 6, w is zero or an integer of from 1 to 10, and X− is an anion.and;b) a detersive surfactant;c) an azole;d) salicylic acid ande) an aqueous carrier.

Owner:THE PROCTER & GAMBLE COMPANY

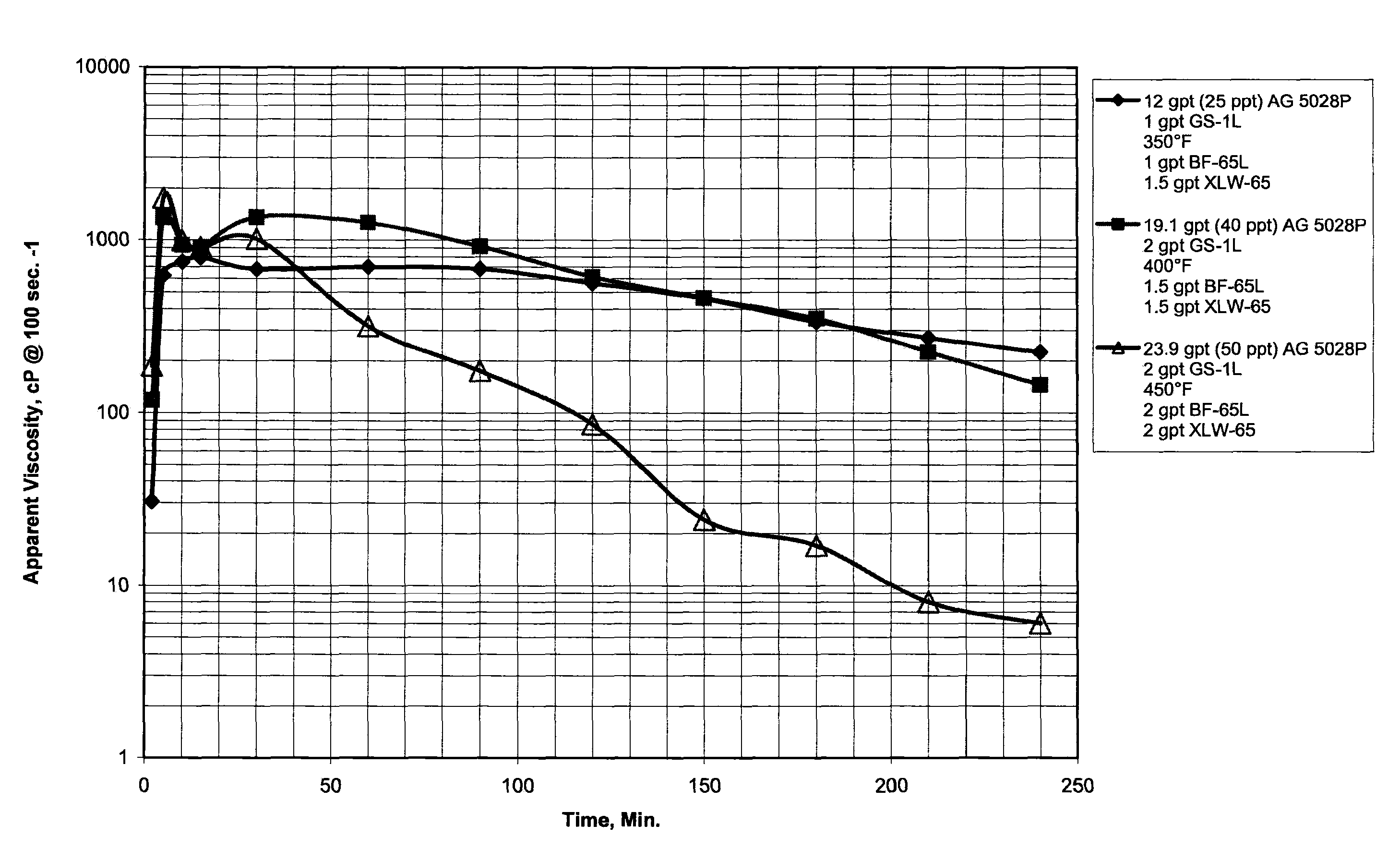

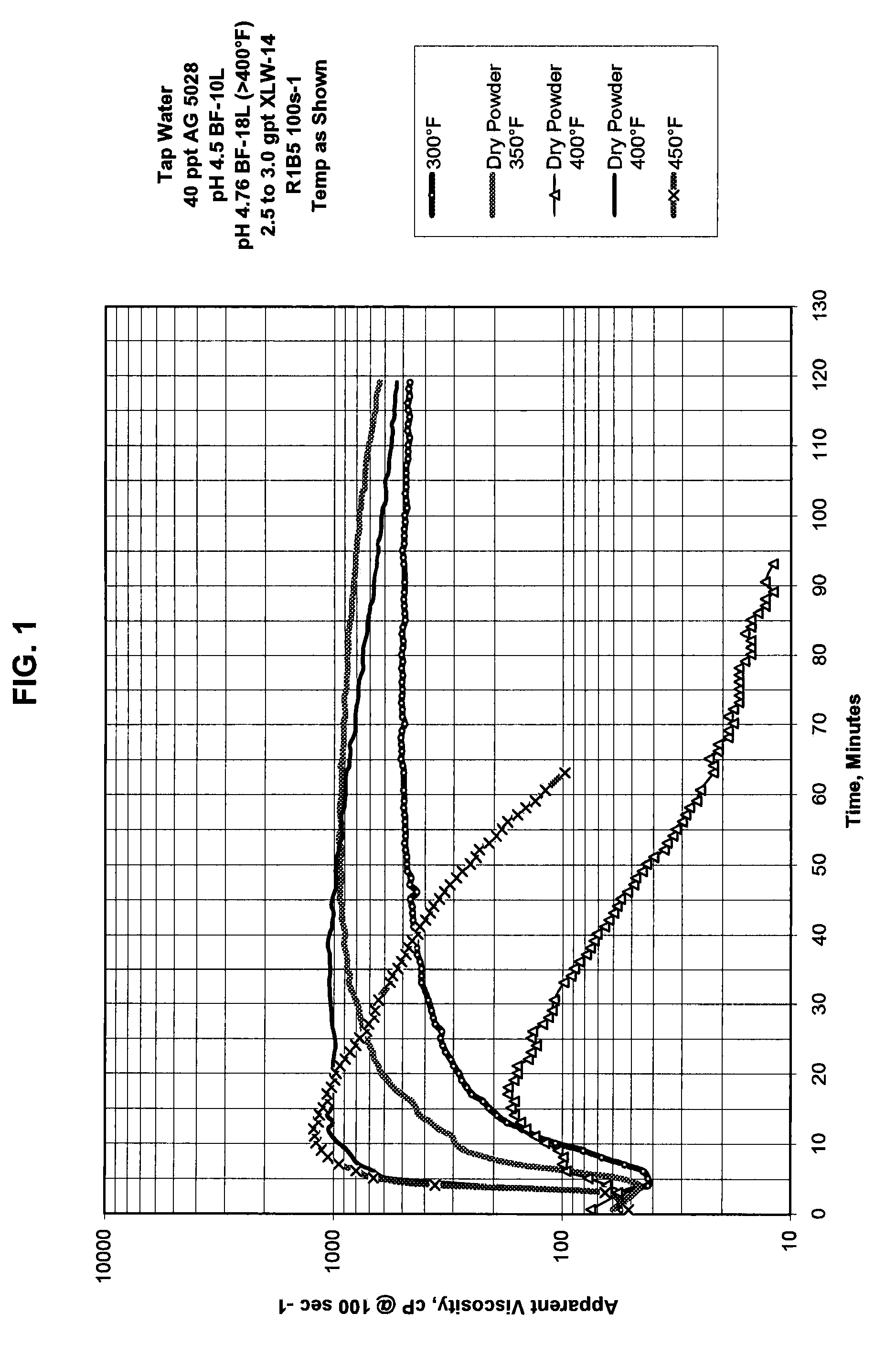

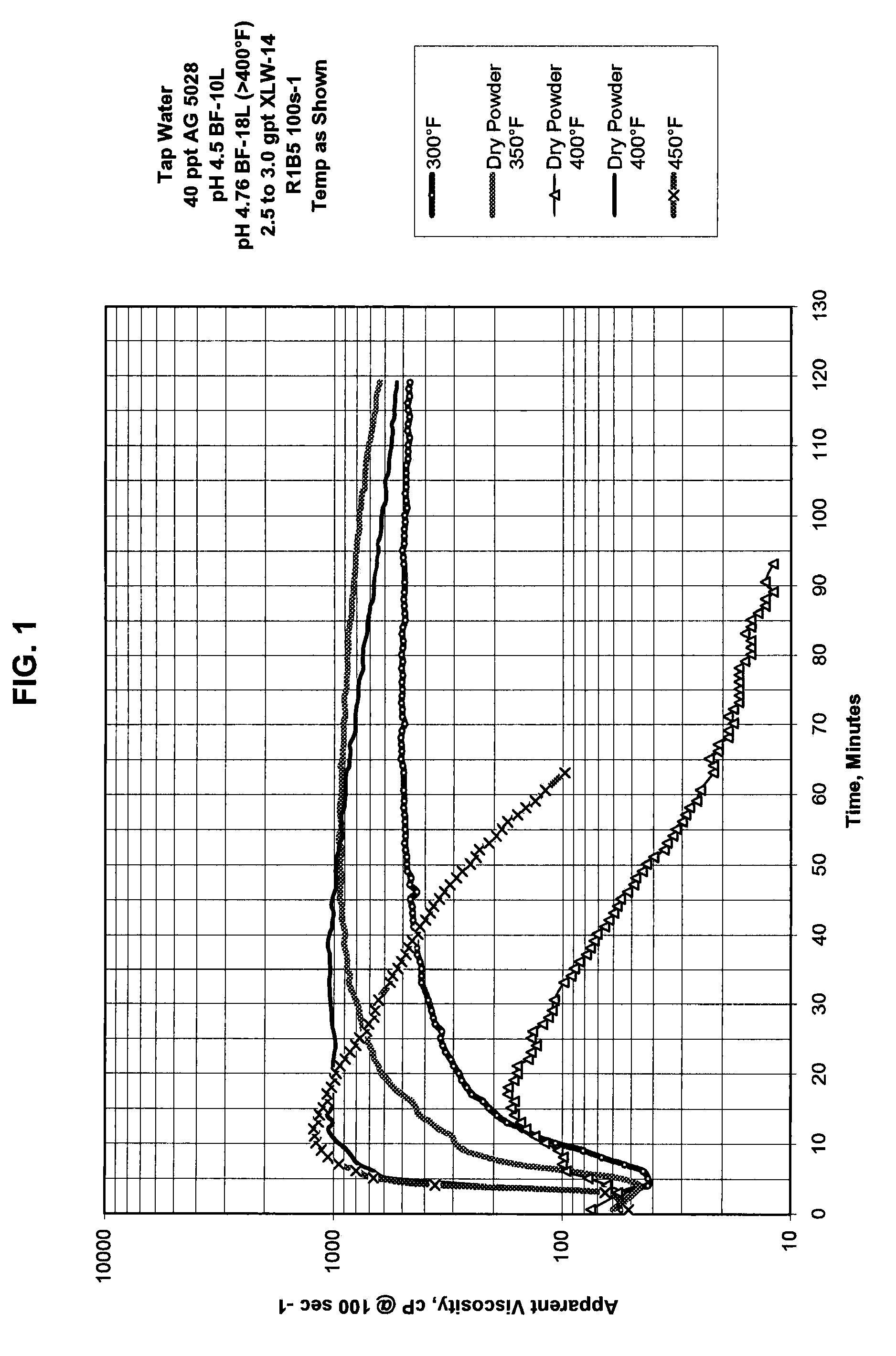

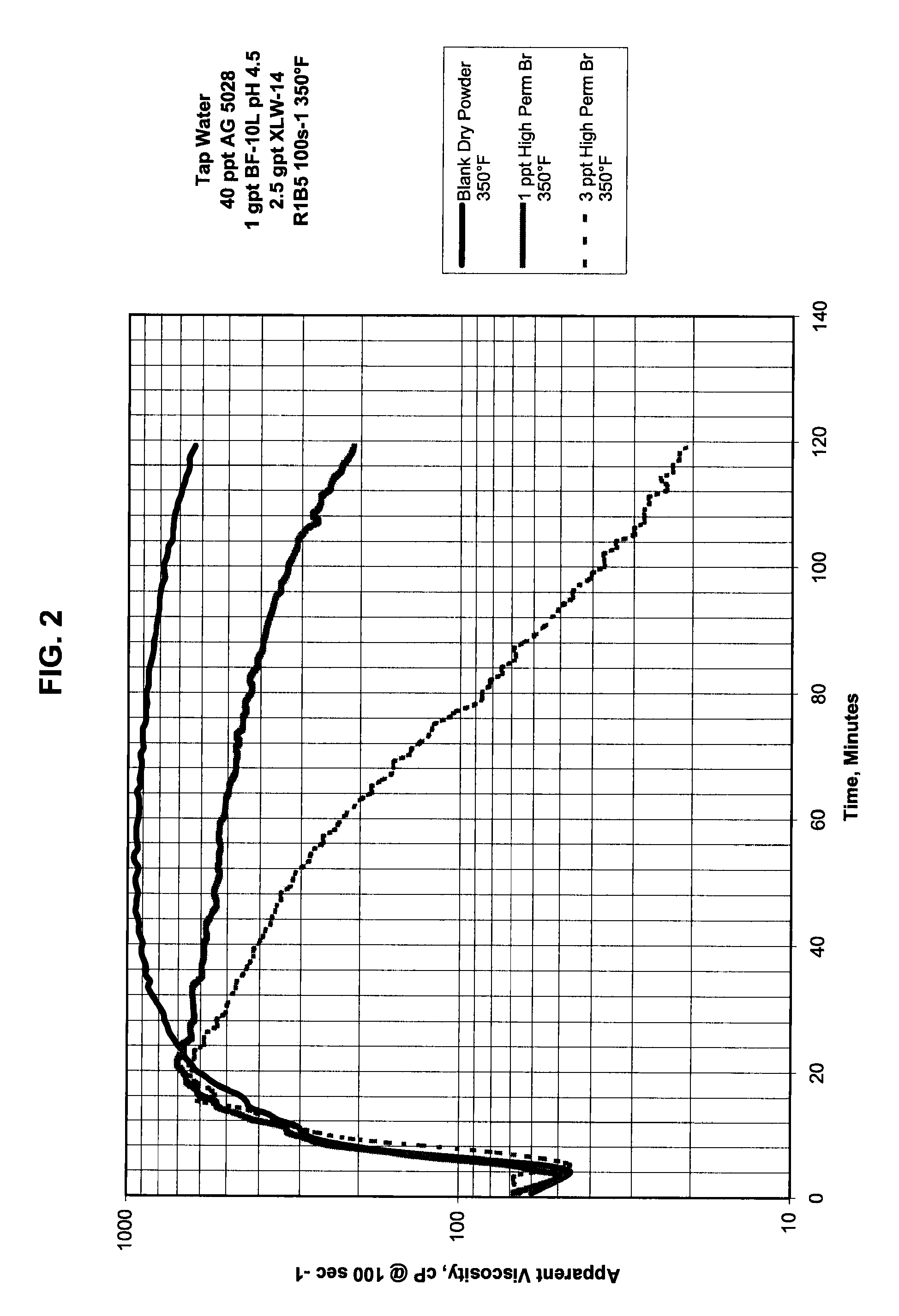

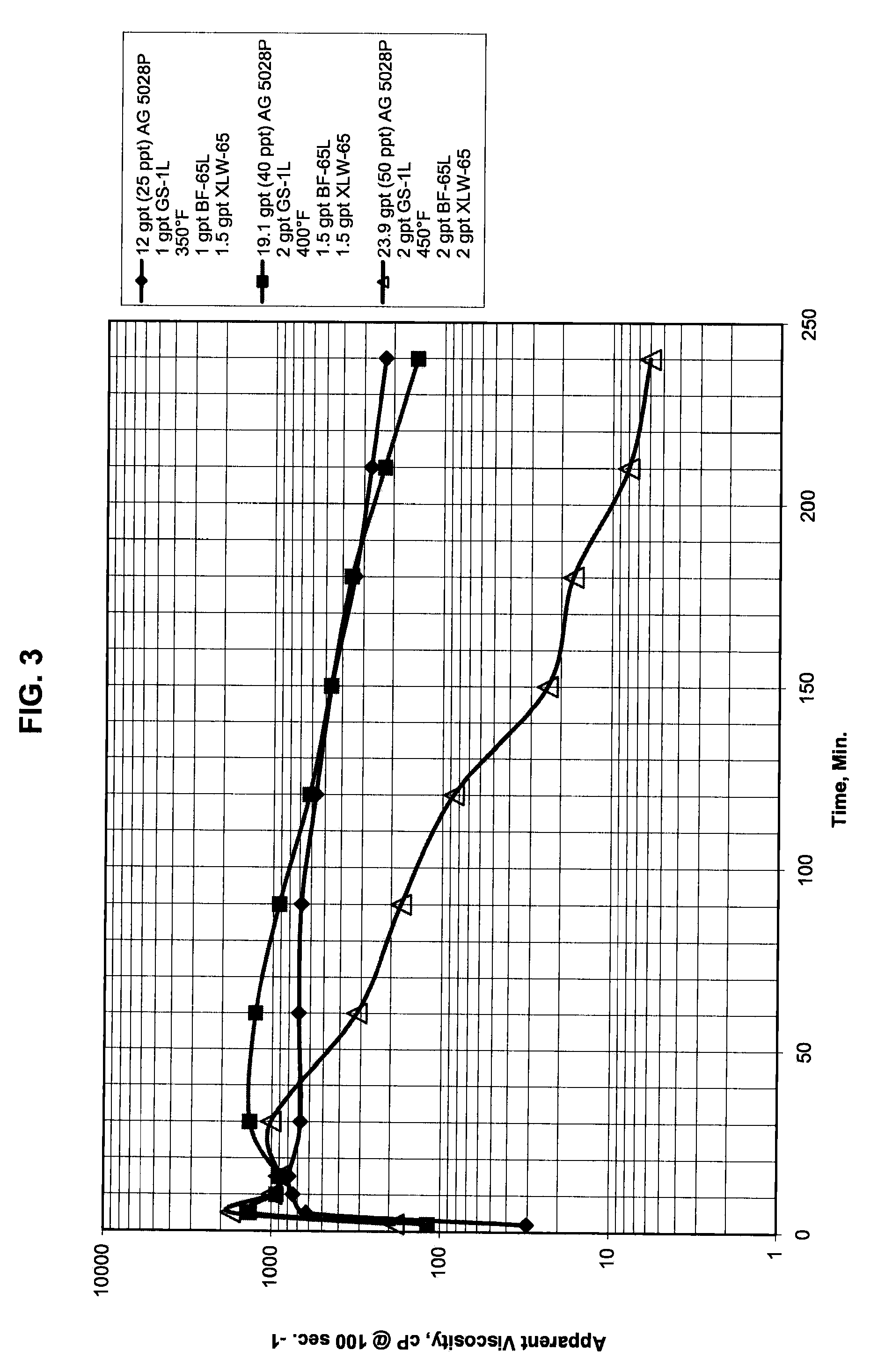

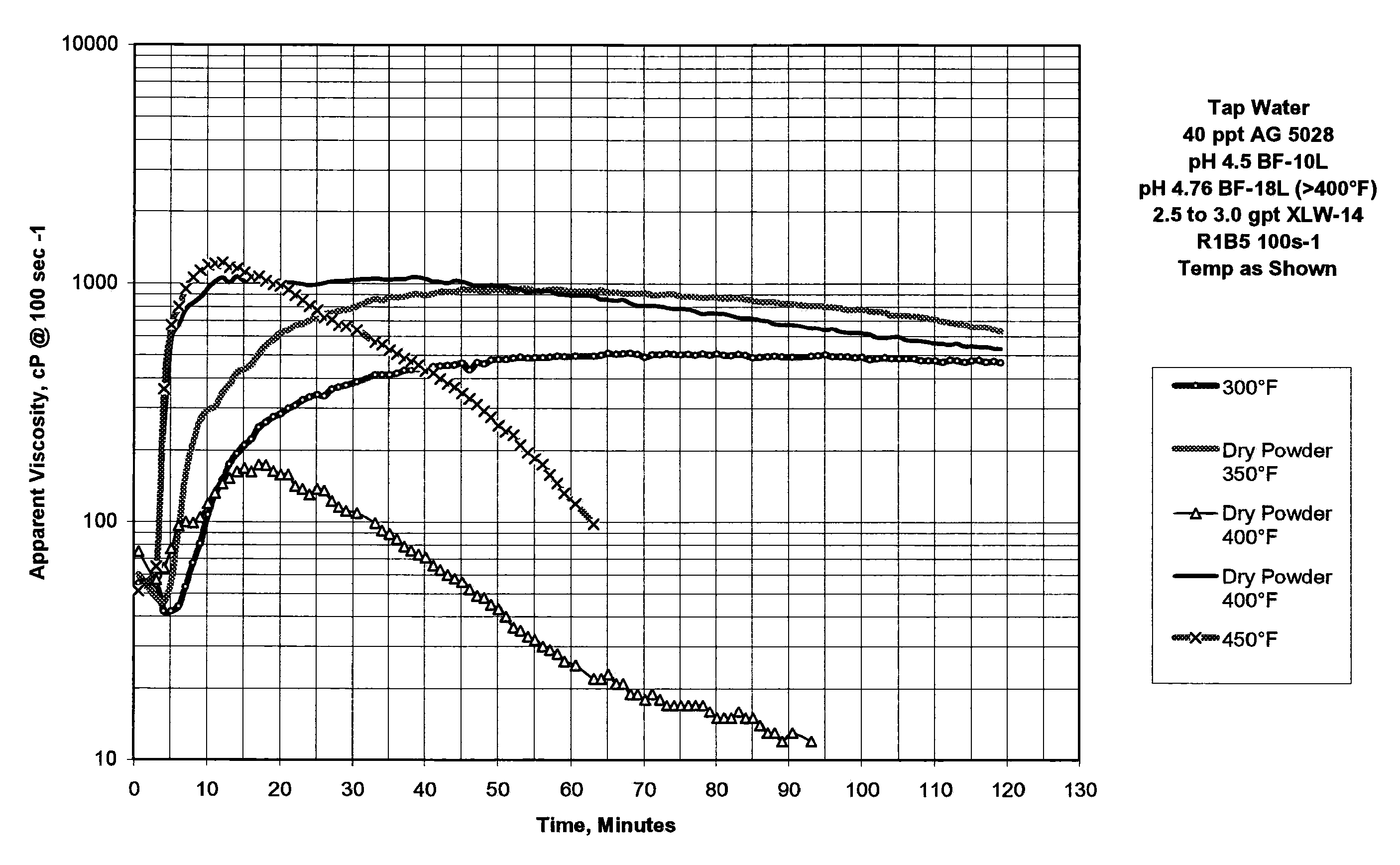

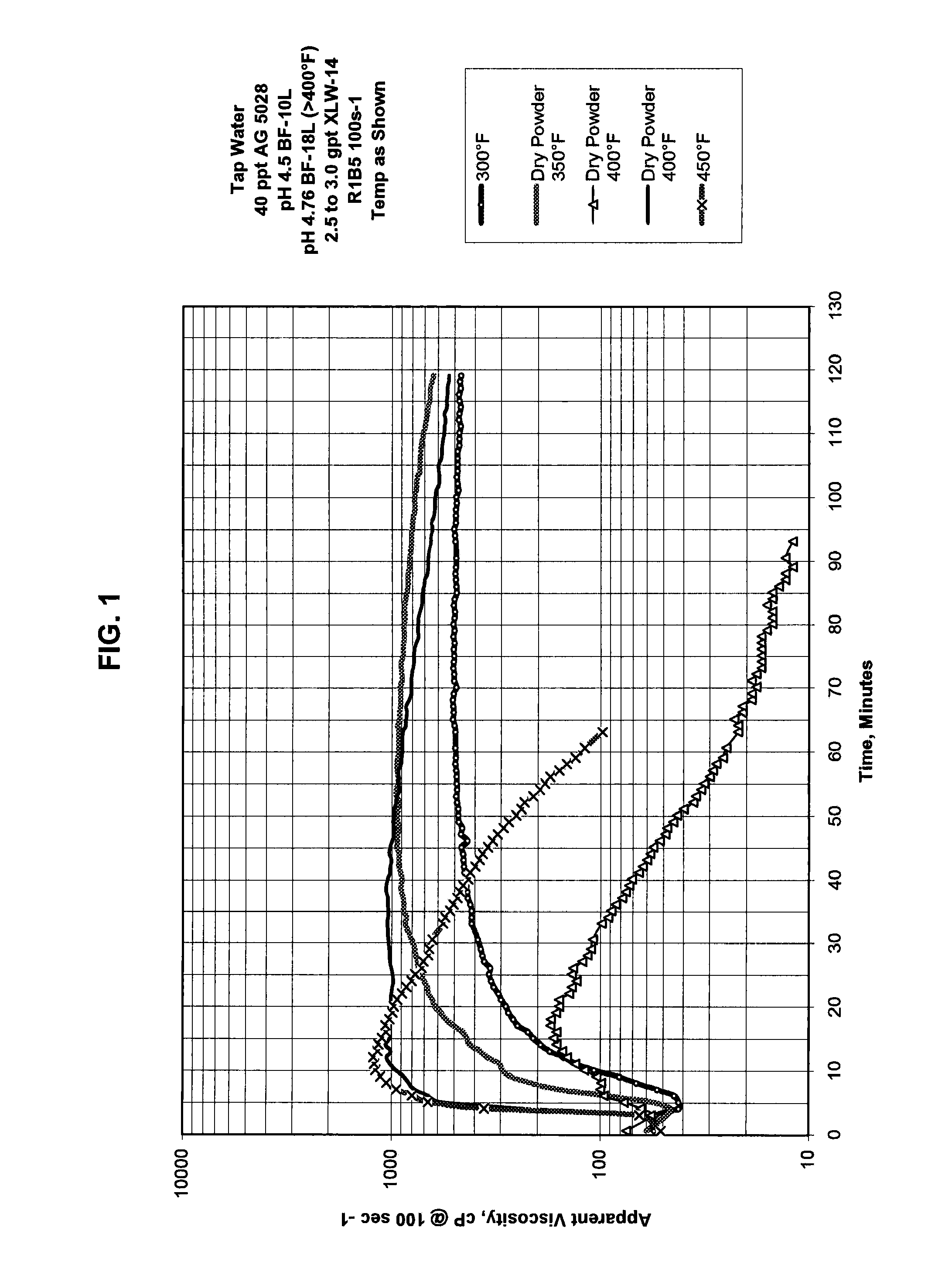

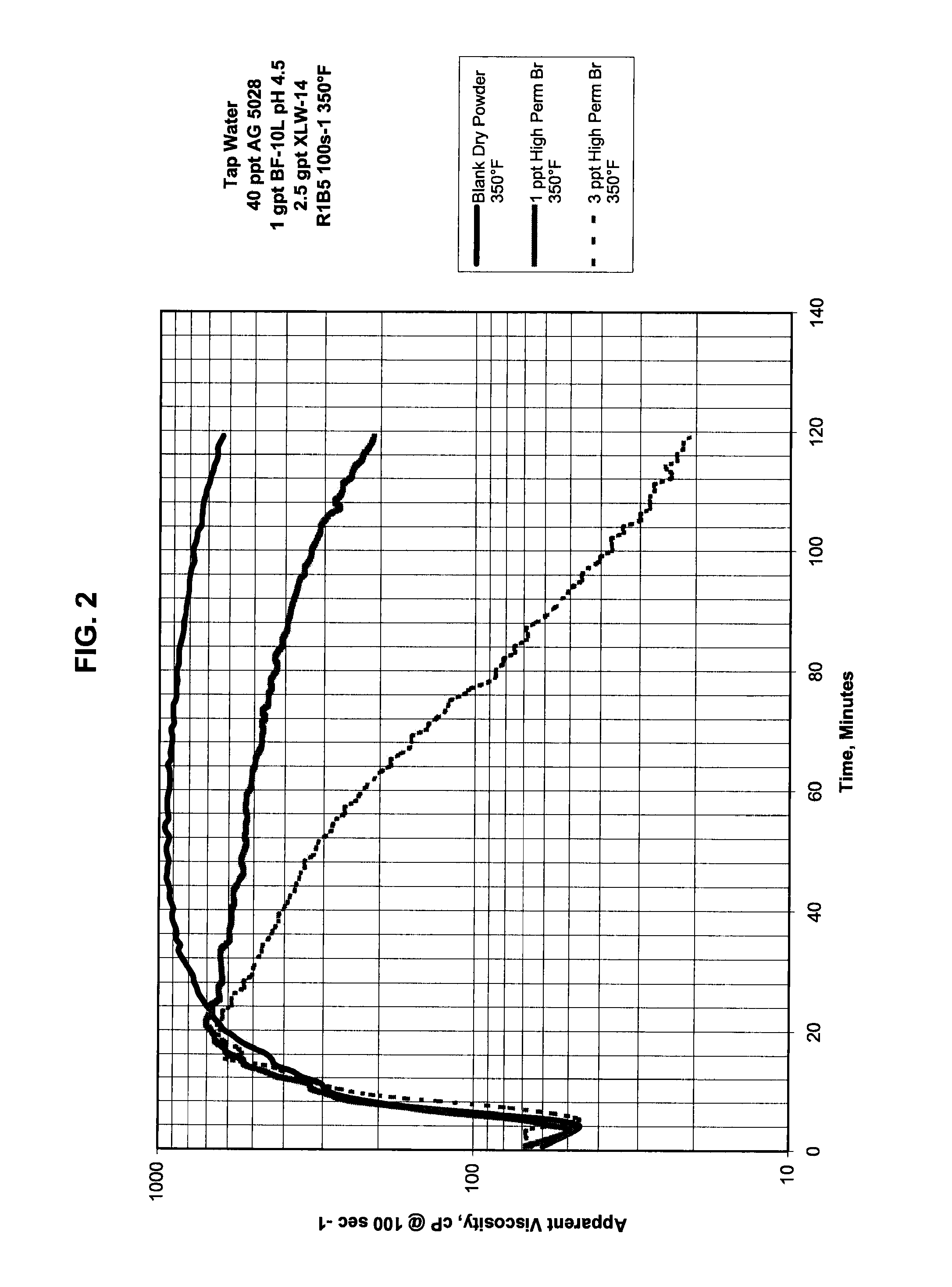

Compositions and Methods of Treating High Temperature Subterranean Formations

Well treatment fluids and methods of treating high temperature subterranean formations of up to about 500° F. (260° C.) are provided. The well treatment fluids and methods utilize a high molecular weight synthetic copolymer and a pH buffer than maintains a pH in a range of about 4.5 to about 5.25 for the fluids. The high molecular weight synthetic copolymer is derived from acrylamide, acrylamidomethylpropanesulfonic acid, and vinyl phosphonates. The well treatment fluids may be energized or foamed.

Owner:BAKER HUGHES INC

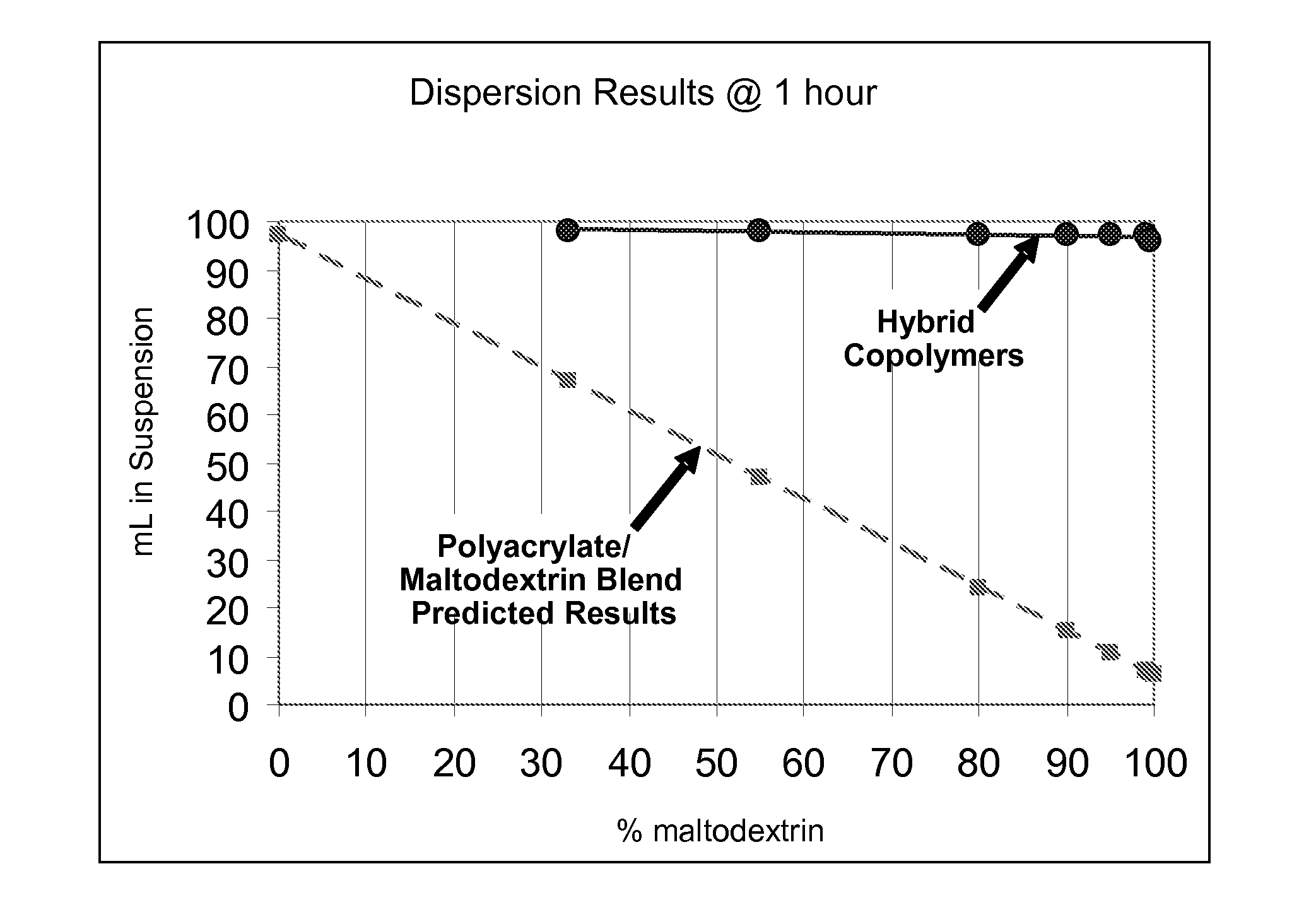

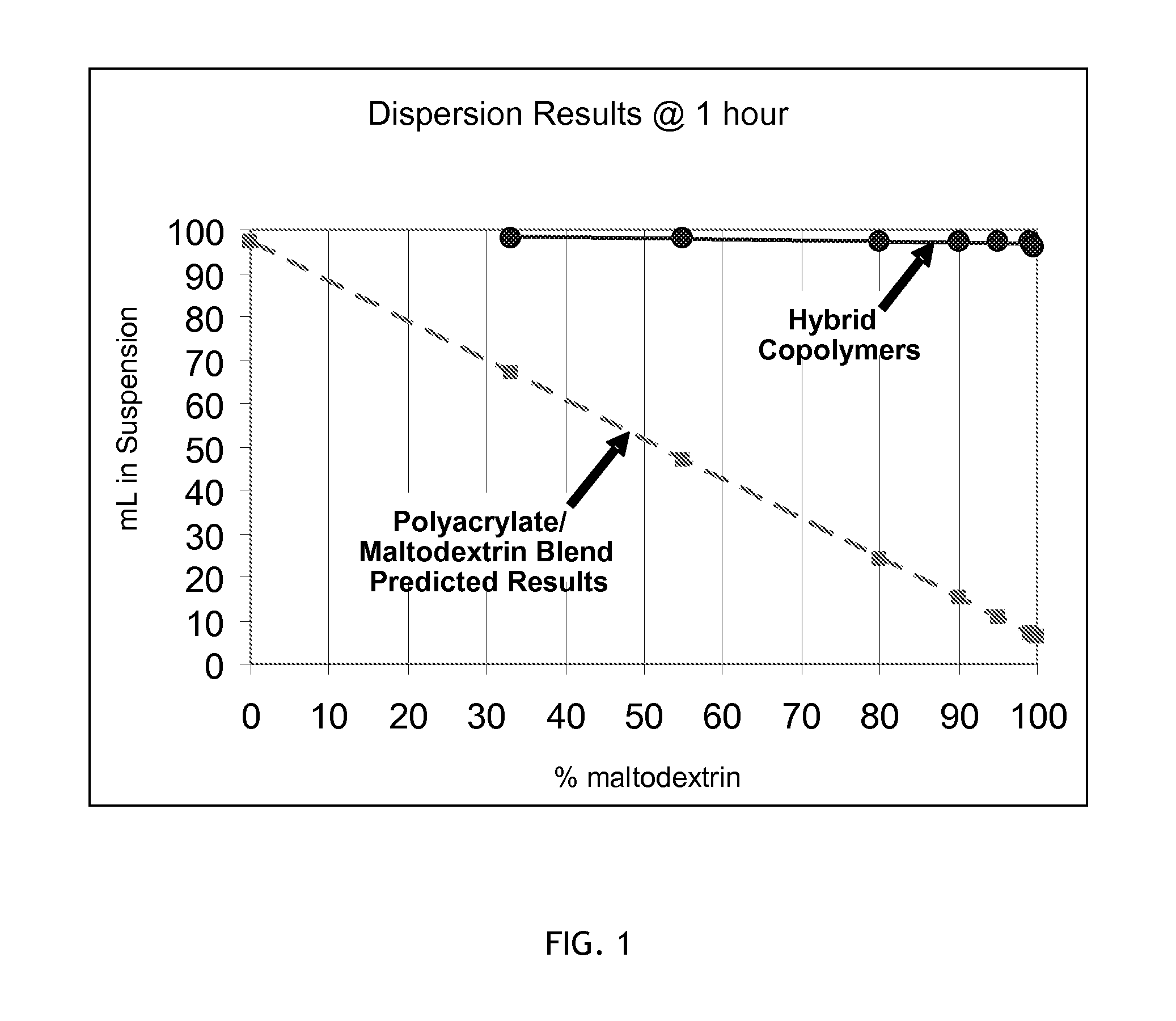

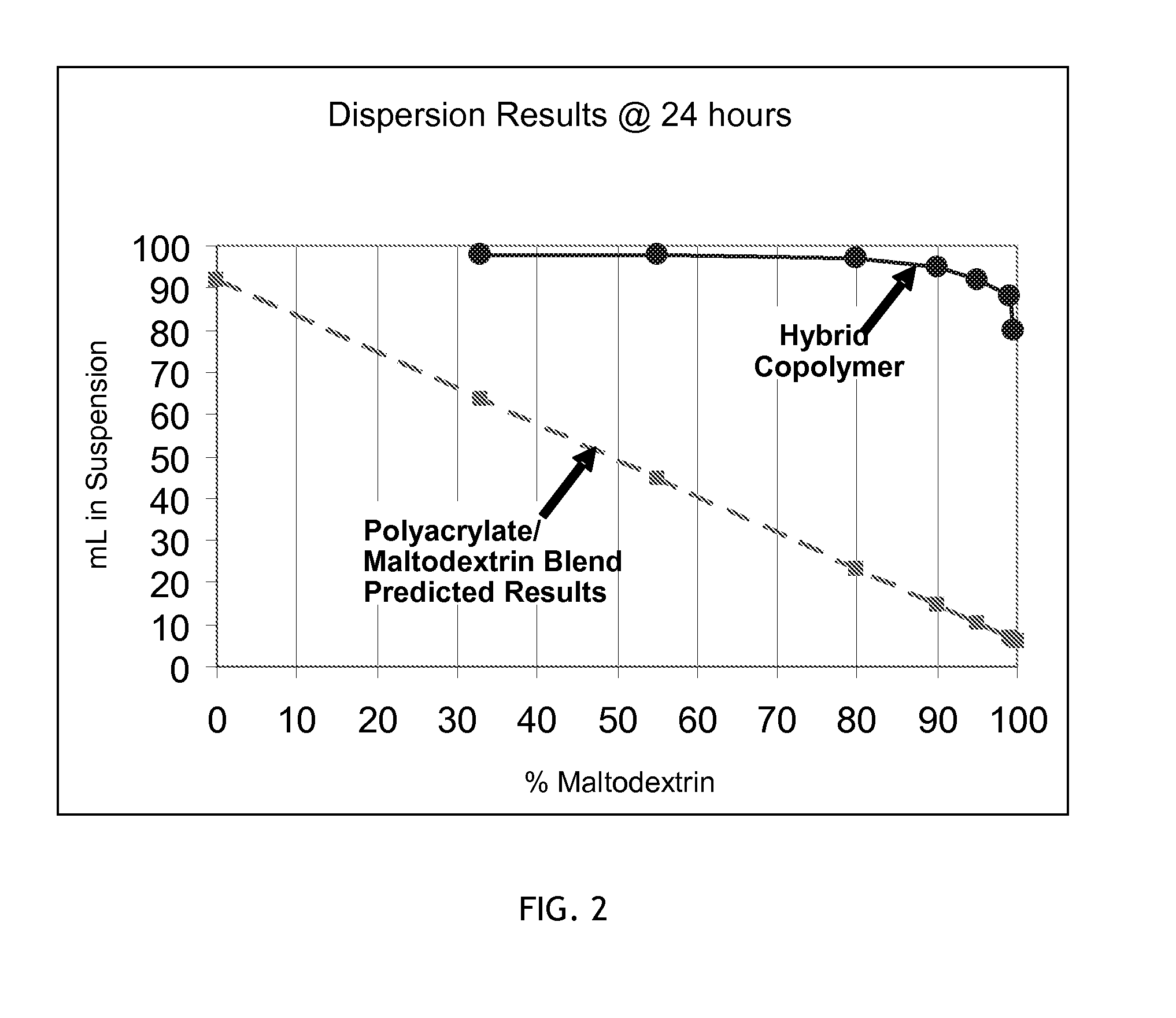

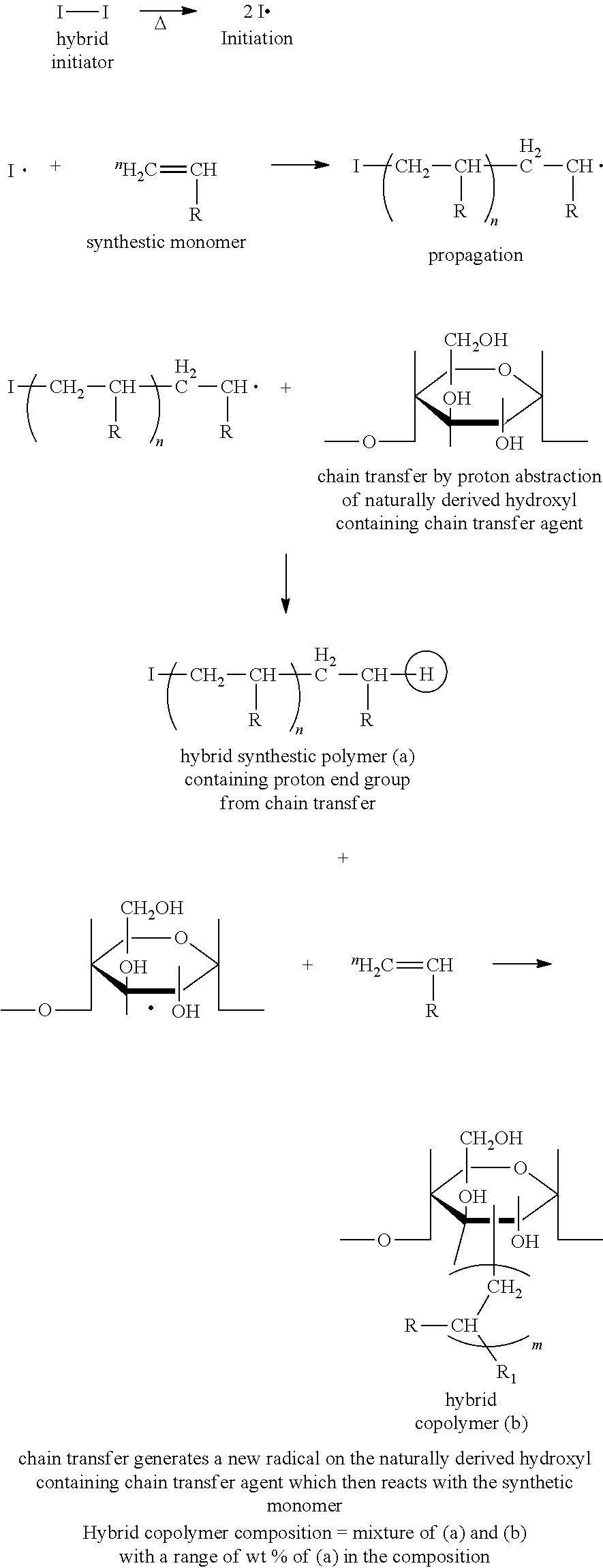

Hybrid copolymer compositions

Hybrid copolymer compositions include a hybrid copolymer including at least one ethylenically unsaturated monomer and a naturally derived hydroxyl containing chain transfer agent as an end group; and a hybrid synthetic copolymer including one or more synthetic polymers derived from the at least one ethylenically unsaturated monomer with at least one initiator fragment as an end group. The hybrid copolymer composition may be prepared as a scale inhibiting composition. Methods of preparing a hybrid copolymer are also included.

Owner:AKZO NOBEL CHEM INT BV

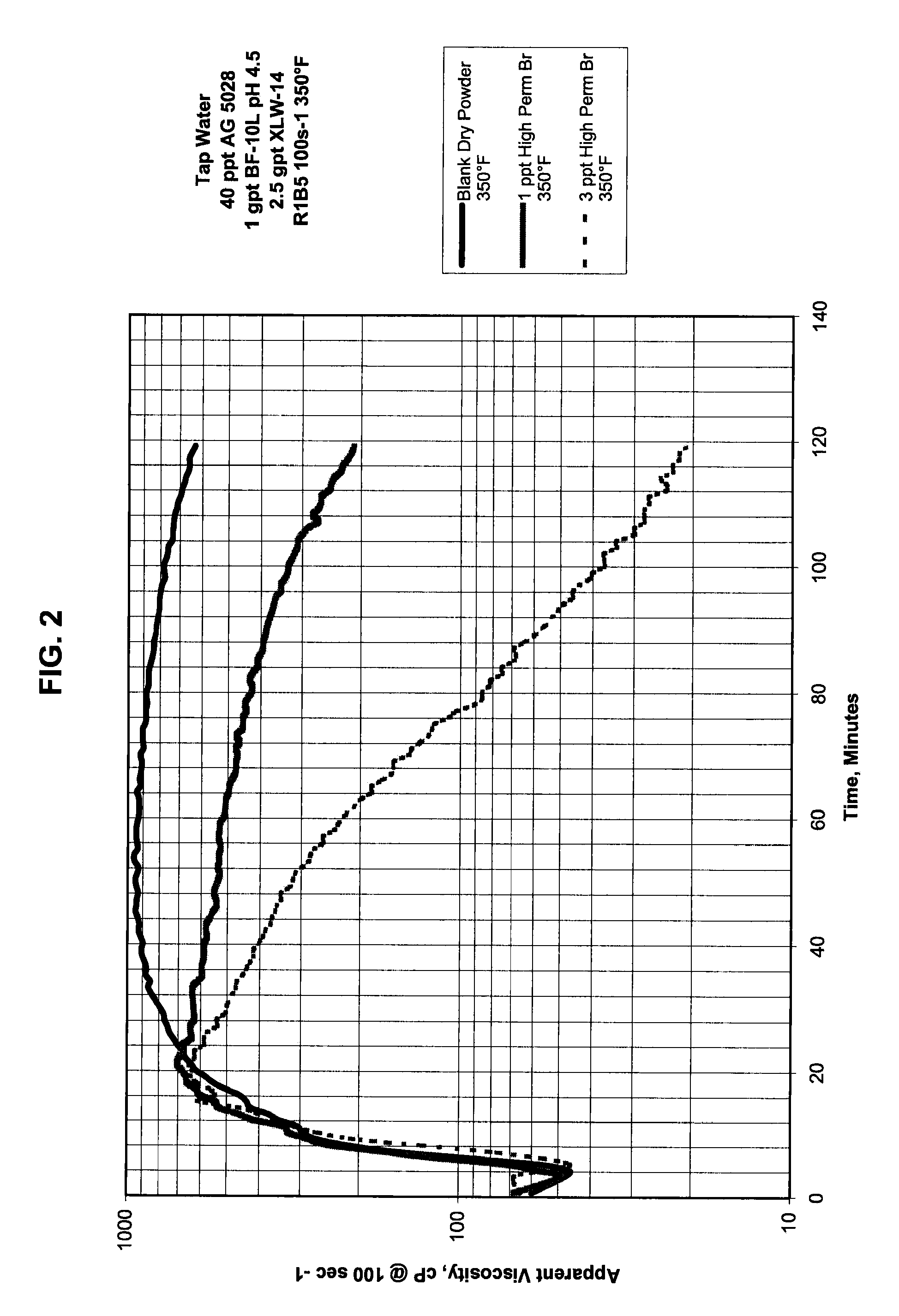

Method of fracturing with phenothiazine stabilizer

Owner:BAKER HUGHES HLDG LLC

Personal care compositions containing cationic synthetic copolymer and a detersive surfactant

A personal care composition comprising:a) a synthetic random copolymer having a net positive charge comprising;i.) a nonionic monomer unit of the following formula:where R is H or C1-4 alkyl; and R1 and R2 are independently selected from the group consisting of H, C1-4 alkyl, CH2OCH3, CH2OCH2CH(CH3)2, and phenyl, or together are C3-6cycloalkyl; andii.) a cationic monomer unit with 2 or more positive charges of the following formula:where k=1, each of v, v′, and v″ is independently an integer of from 1 to 6, w is zero or an integer of from 1 to 10, and X− is an anion.and;b) an effective amount of a pyrithione or a polyvalent metal salt of a pyrithione;c) an effective amount of a zinc-containing layered material;d) a detersive surfactant; ande) an aqueous carrier.

Owner:THE PROCTER & GAMBLE COMPANY

Hybrid copolymer compositions for personal care applications

A personal care composition includes a hybrid copolymer including at least one ethylenically unsaturated monomer and a naturally derived hydroxyl containing chain transfer agent as an end group, a hybrid synthetic copolymer including one or more synthetic polymers derived from the at least one ethylenically unsaturated monomer with at least one initiator fragment as an end group and an effective amount of a cosmetic or personal care additive.

Owner:AKZO NOBEL CHEM INT BV

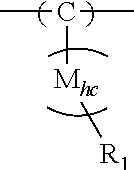

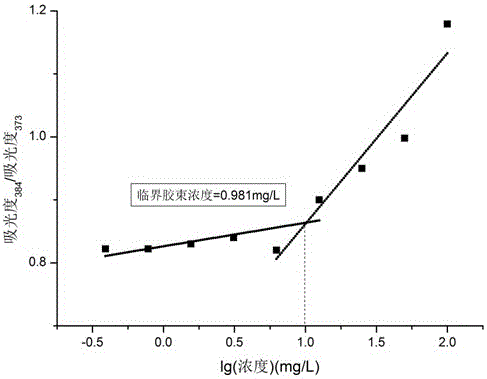

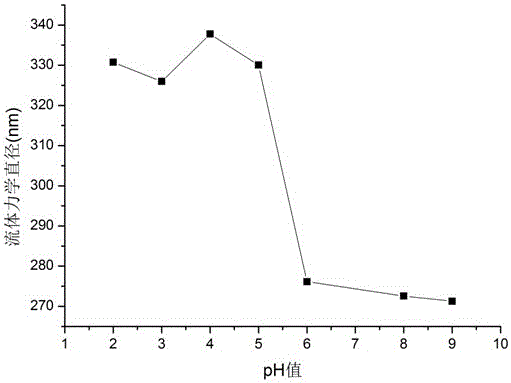

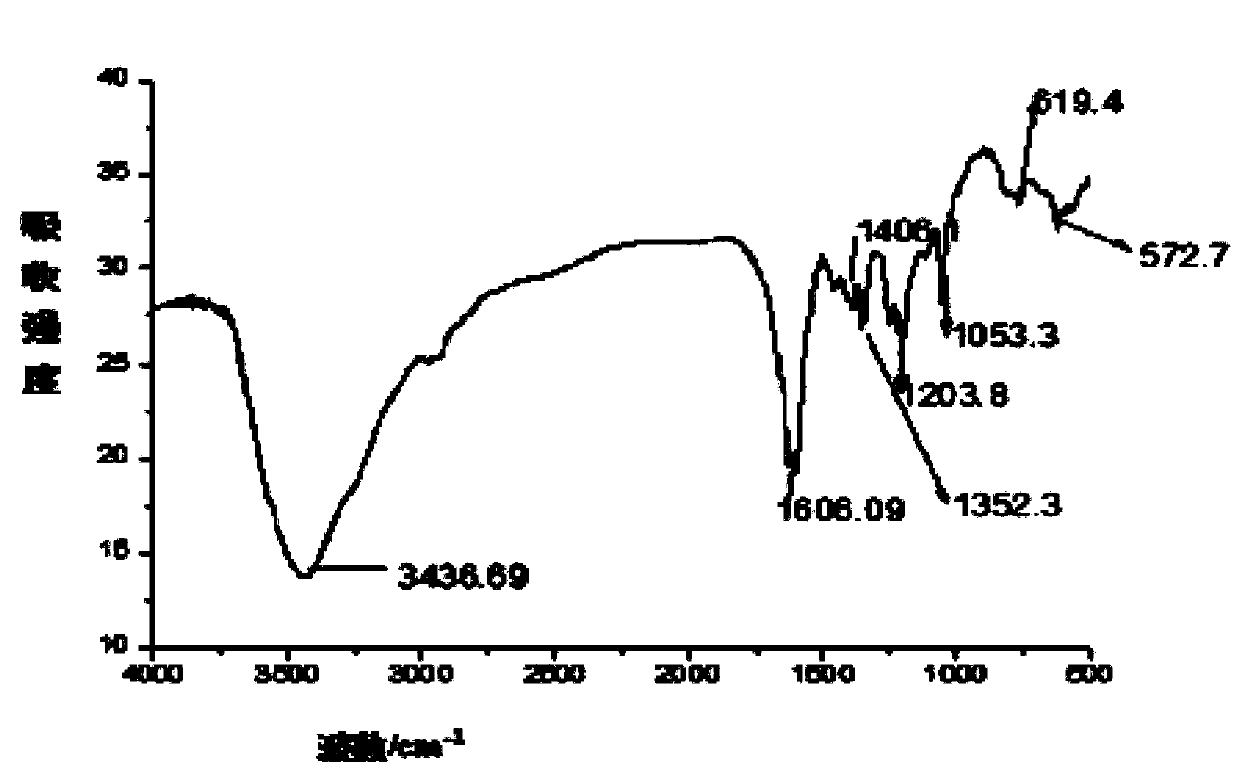

Preparation method of segmented copolymer material with temperature and pH (Potential of Hydrogen) sensitivity

The invention relates to a preparation method of a segmented copolymer material P(MMA-co-DMAEMA)-b-PPEGMA with temperature and pH (Potential of Hydrogen) sensitivity. According to the method, a copolymer poly(methyl methacrylate-co-dimethylaminoethyl methacrylate) is synthesized by adopting a reversible addition-fragmentation chain transfer polymerization method firstly; the synthesized poly(methyl methacrylate-co-dimethylaminoethyl methacrylate) as a macromolecular chain transfer agent is subjected to RAFT (Reversible Additive Fragment Transfer) polymerization with polyethylene glycol methyl ether methacrylate, so as to obtain the segmented copolymer material P(MMA-co-DMAEMA)-b-PPEGMA with the temperature and pH sensitivity. The method provided by the invention has the characteristics of simplicity and convenience, high preparation yield, no pollution to environment and the like; the prepared polymer material has high functionality and narrow molecular weight distribution, can be applied to organic dye adsorption and heavy metal adsorption, and medicine fields including in-vivo transportation of difficultly-soluble anti-cancer medicines and the like.

Owner:南京东焱氢能源科技有限公司

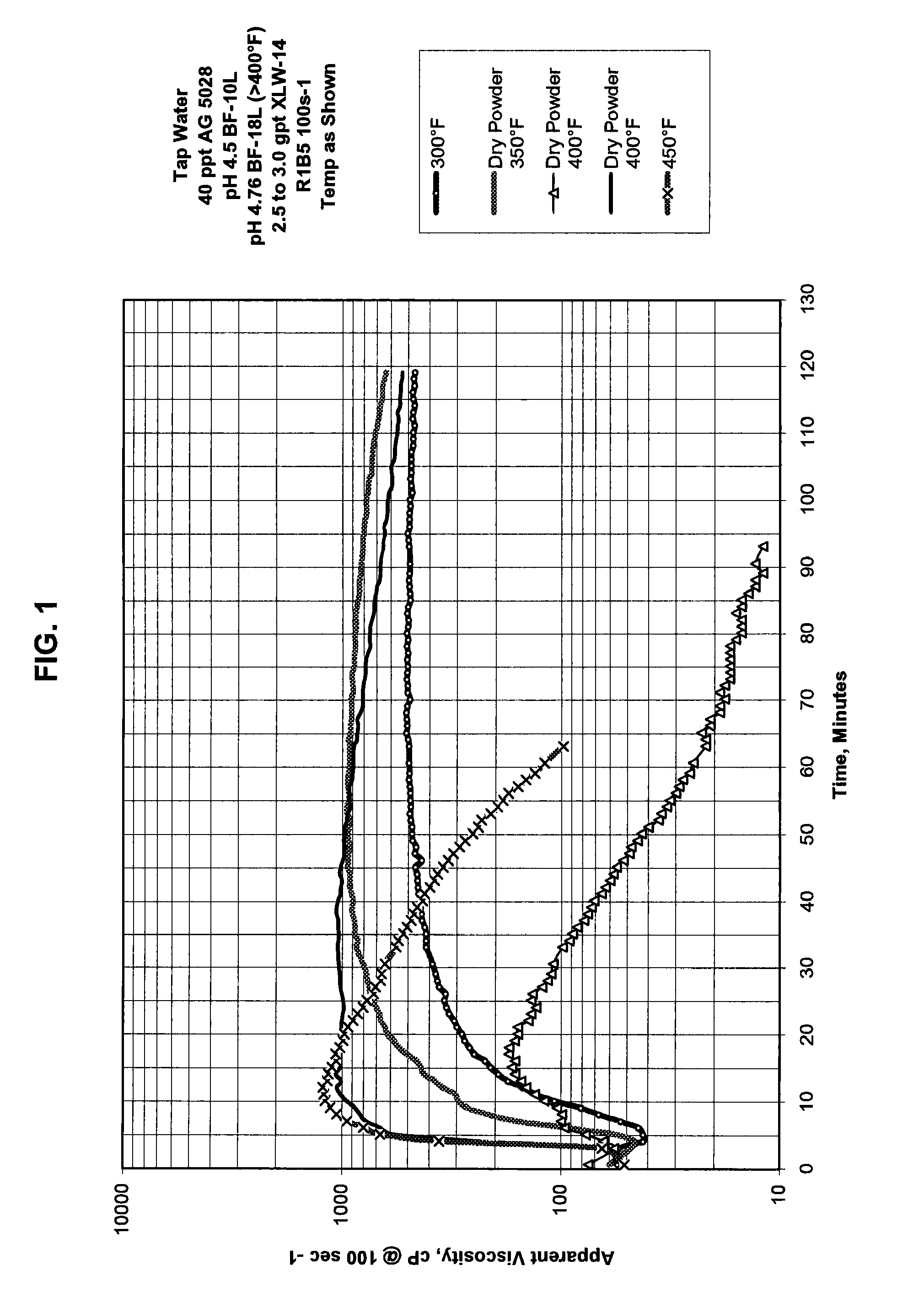

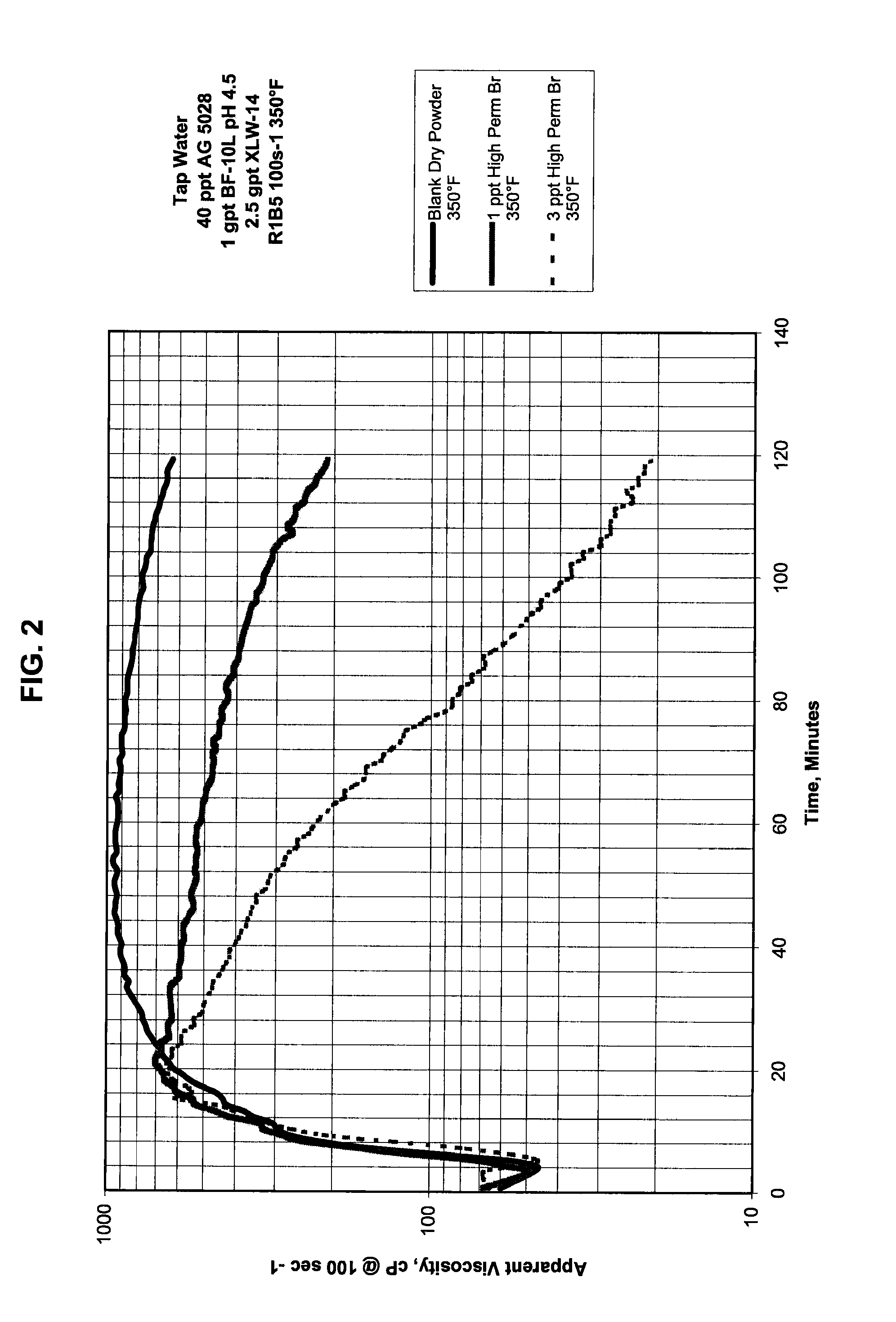

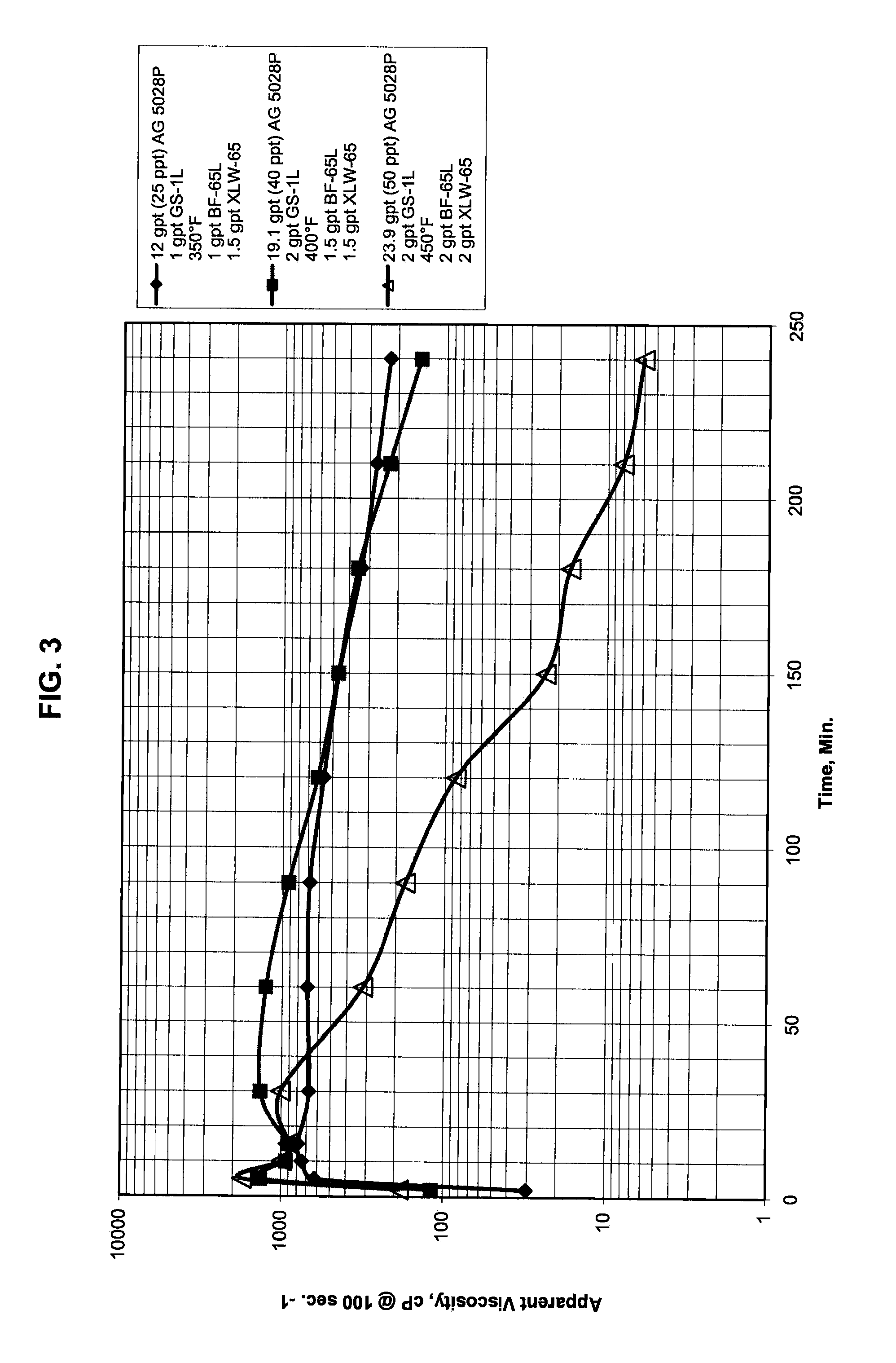

Compositions and methods of treating high temperature subterranean formations

ActiveUS20090192058A1High viscosityPromote hydrationFluid removalFlushingVinylphosphonic acidSynthetic copolymer

Compositions and methods of treating high temperature subterranean formations of up to about 500° F. (260° C.) are provided. The compositions and methods utilize a high molecular weight synthetic copolymer and a pH buffer than maintains a pH in a range of about 4.5 to about 5.25 for the compositions. The high molecular weight synthetic copolymer is derived from acrylamide, acrylamidomethylpropanesulfonic acid, and vinyl phosphonate,

Owner:BAKER HUGHES INC

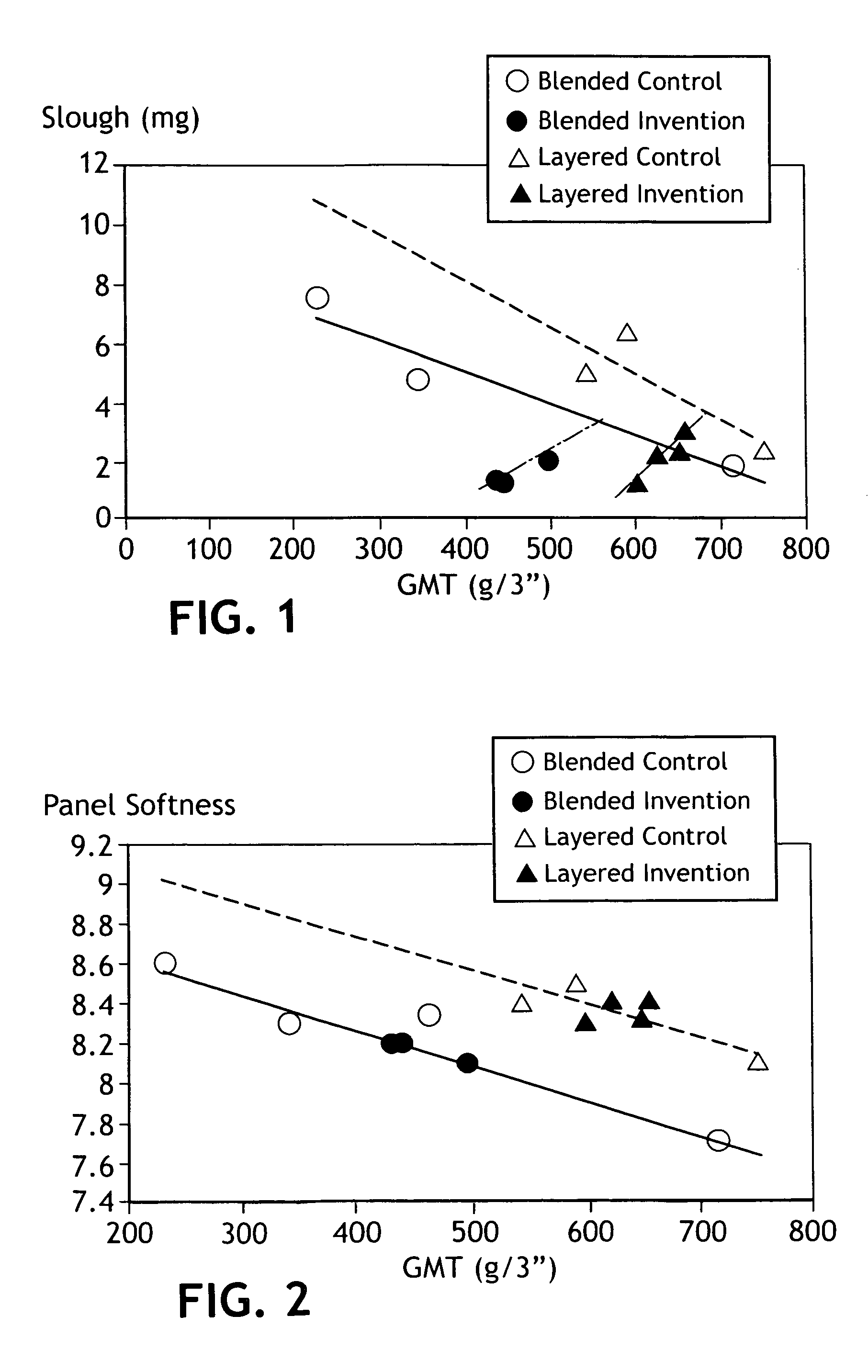

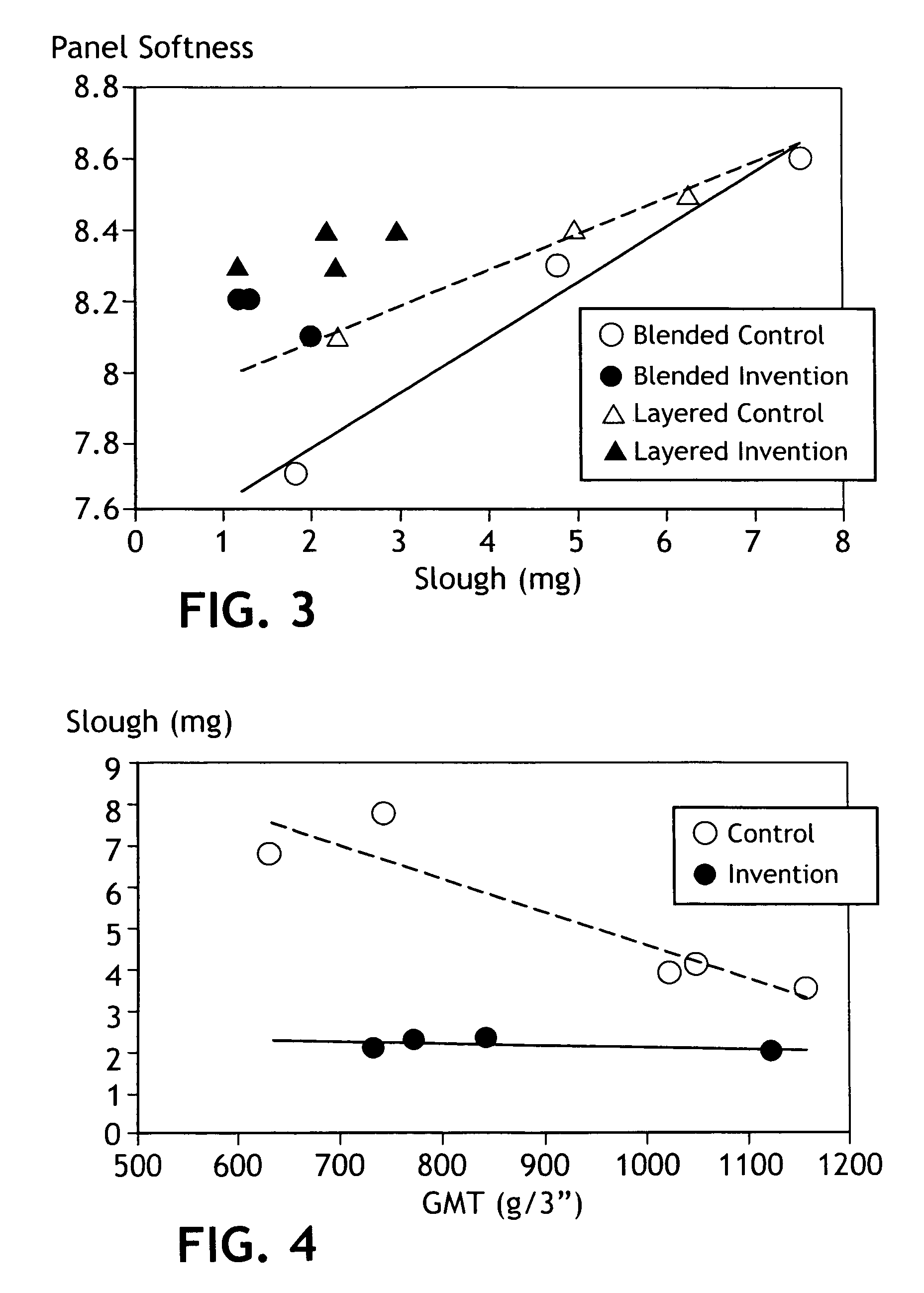

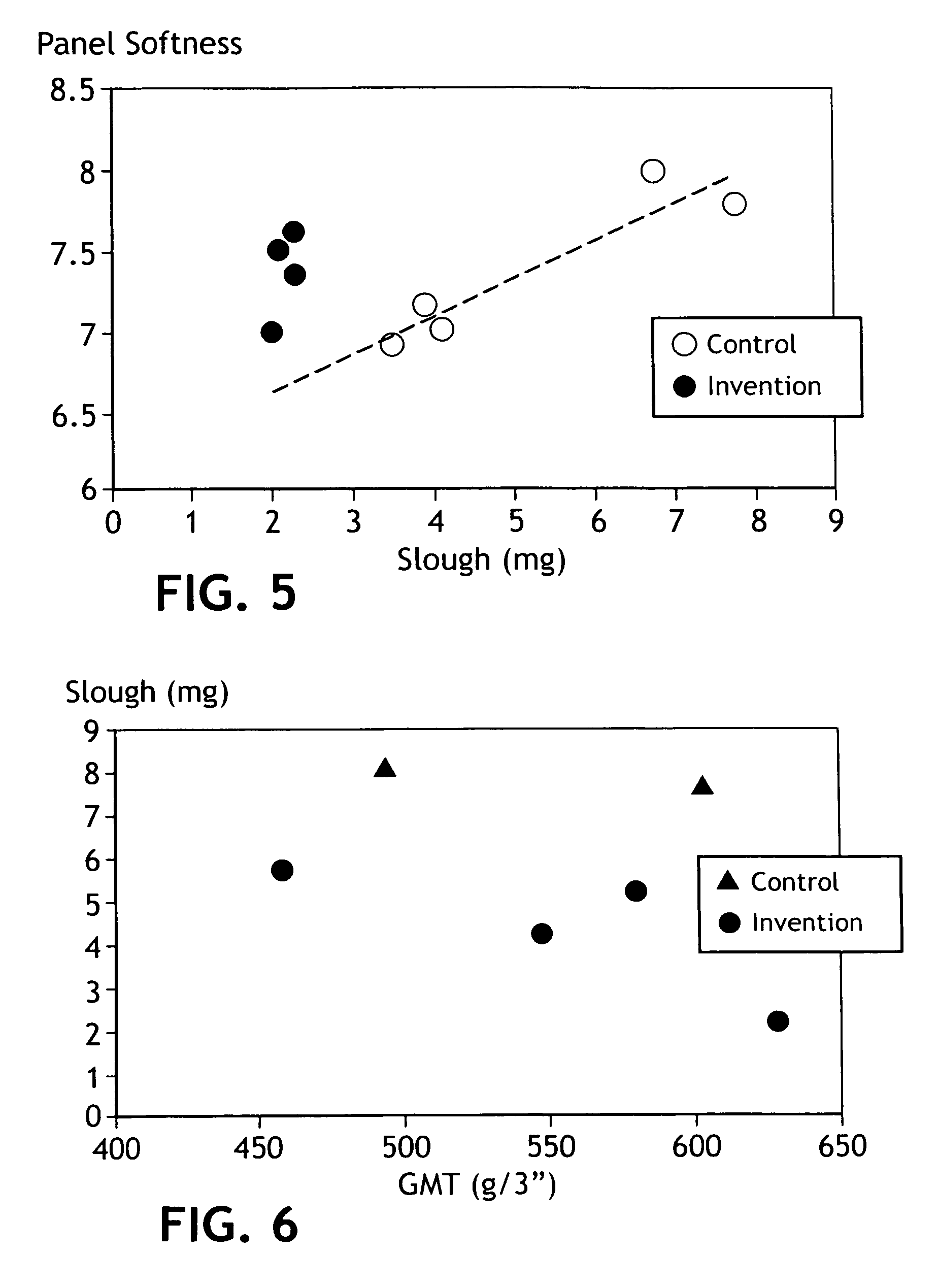

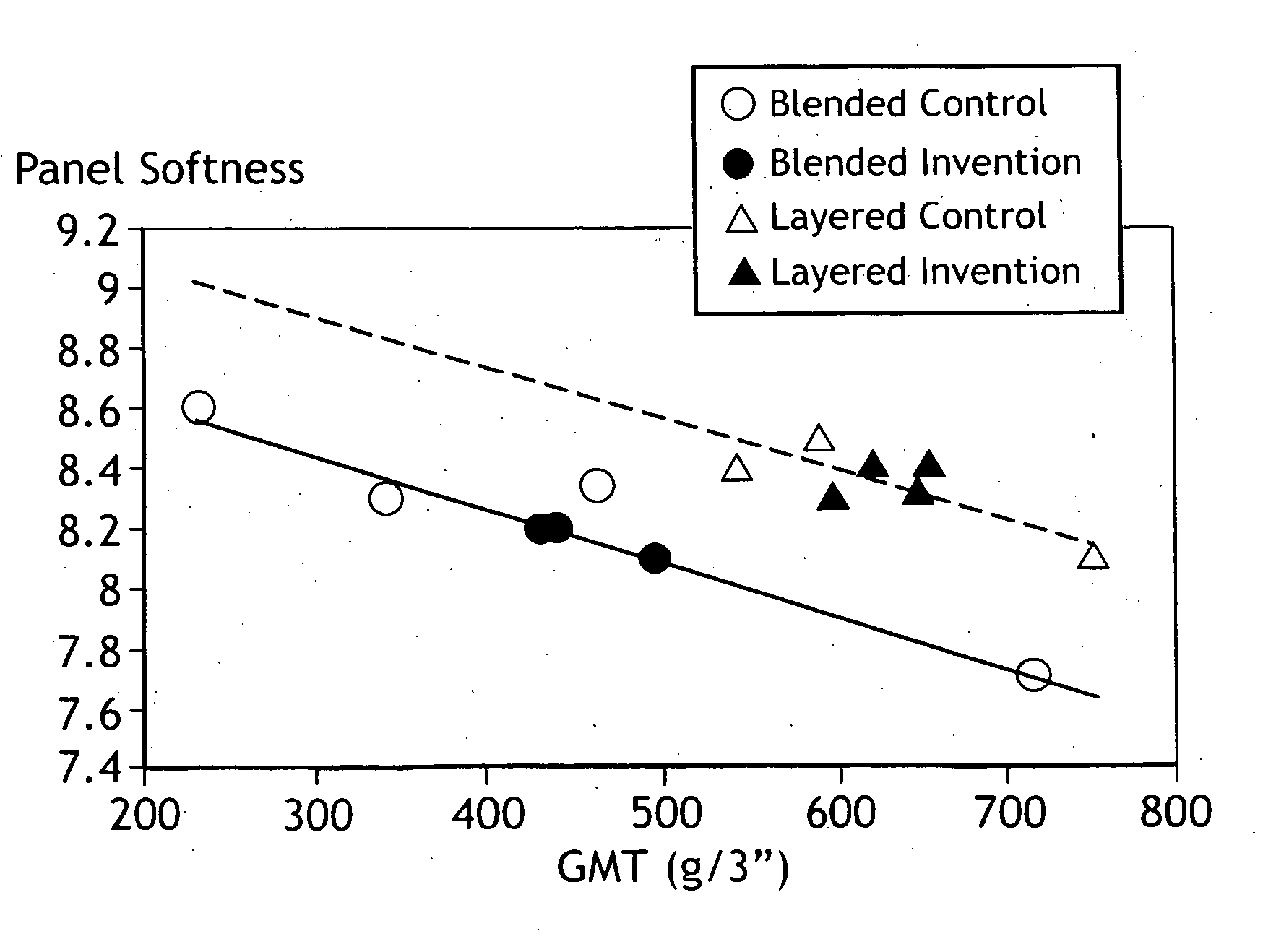

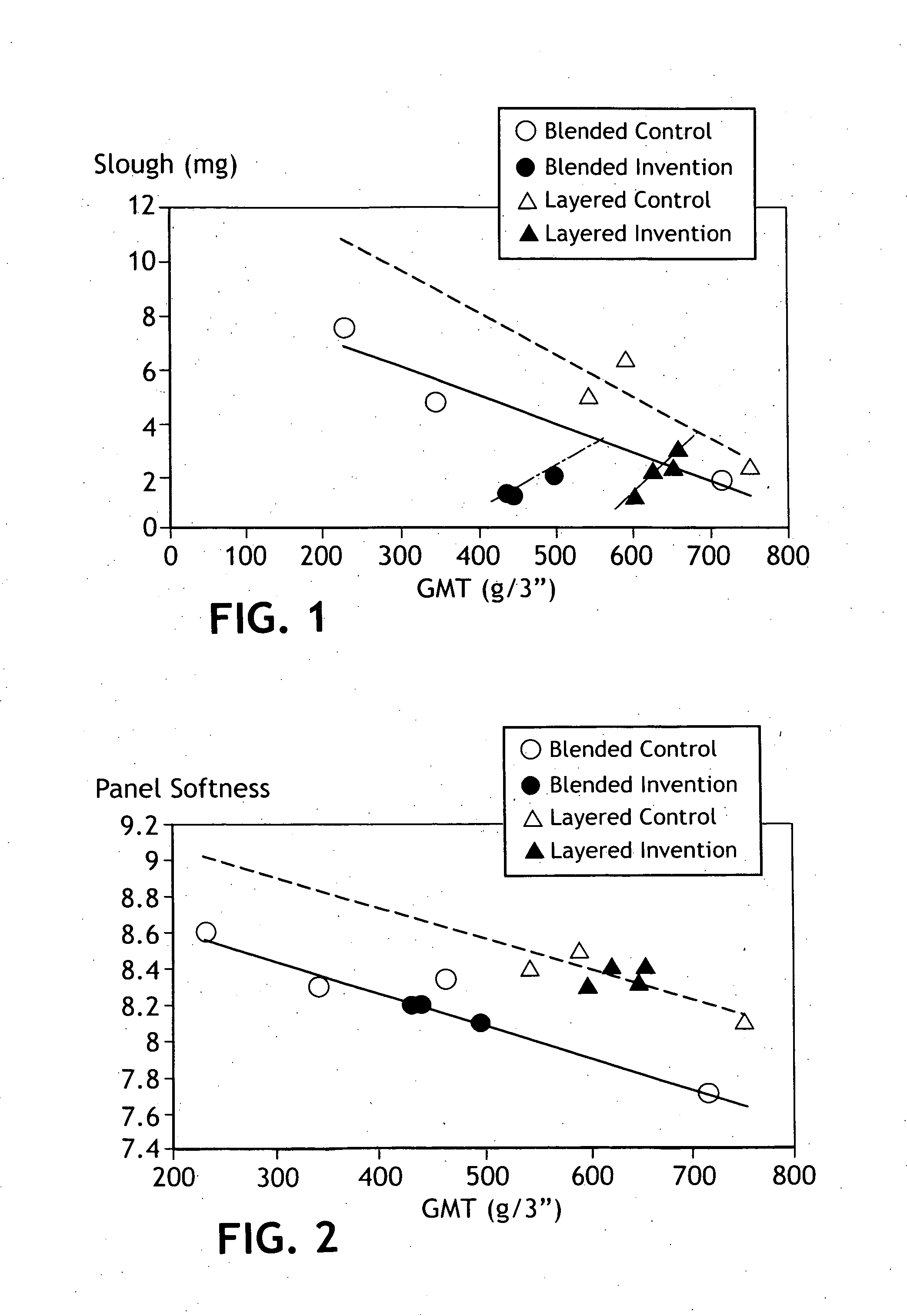

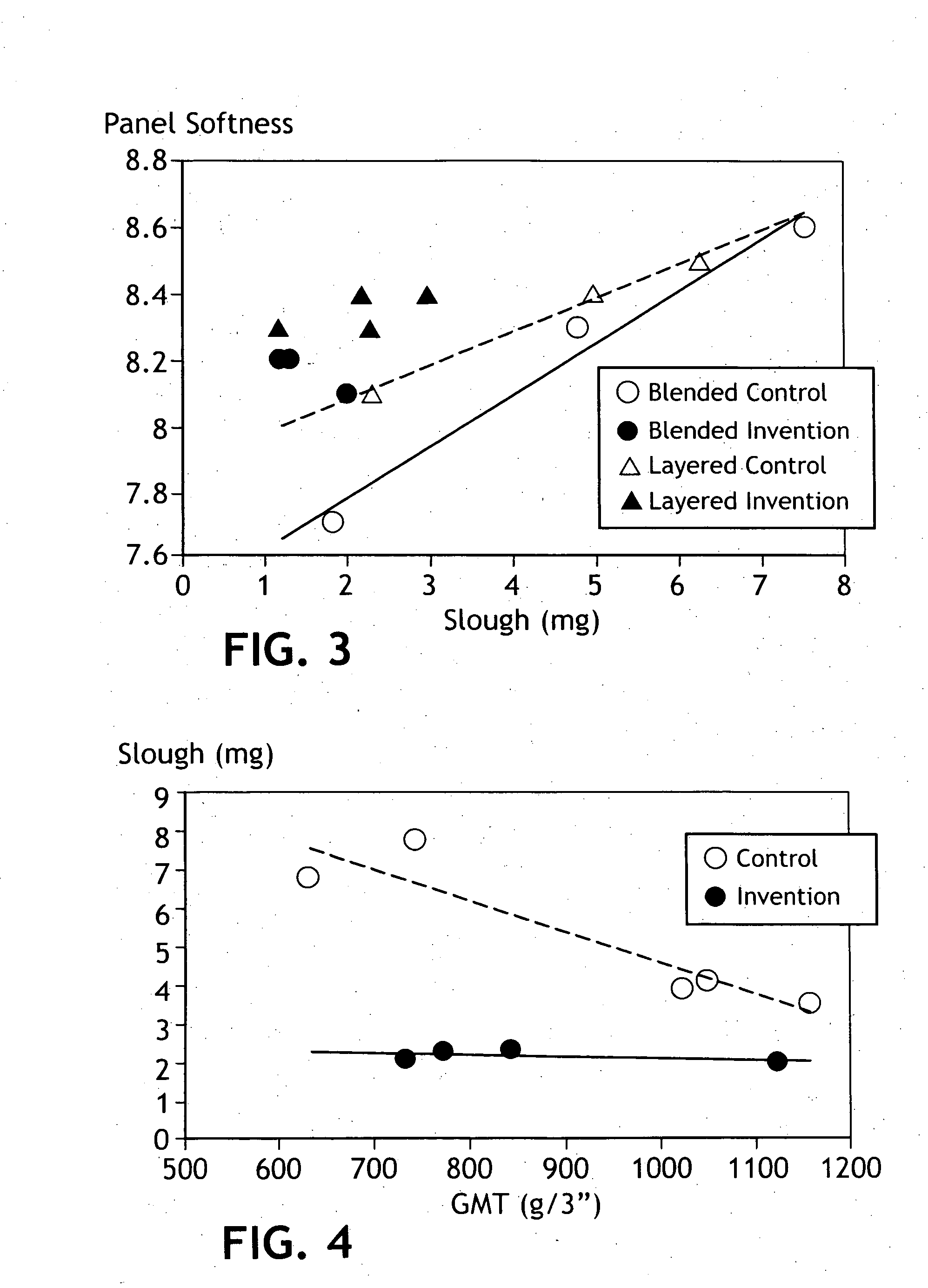

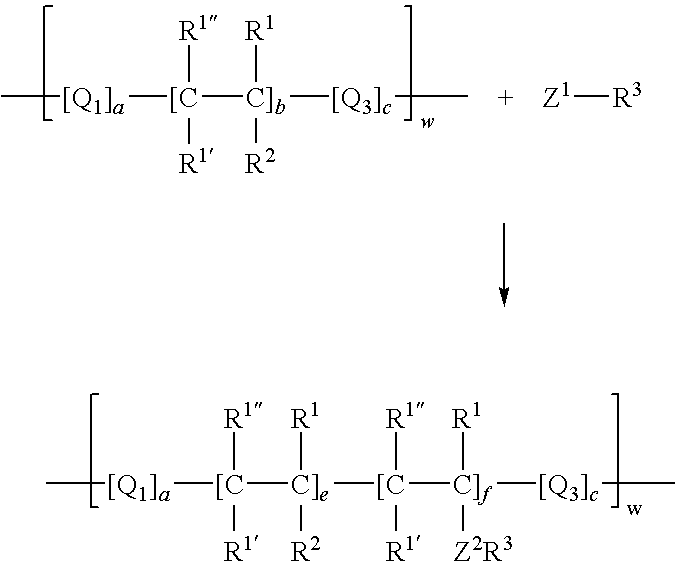

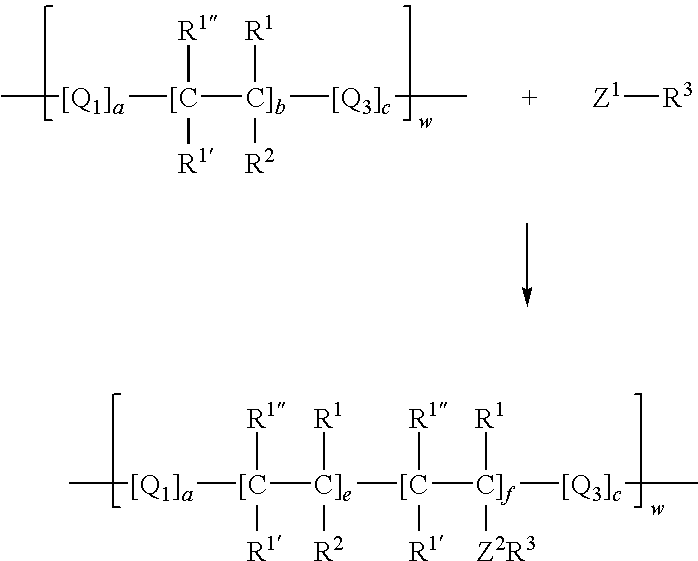

Method of making low slough tissue products

InactiveUS7794565B2Simple structureFine surfaceNatural cellulose pulp/paperSpecial paperFiberPhotochemistry

The present invention is a soft tissue sheet having reduced lint and slough. The tissue sheet comprises papermaking fibers and a synthetic co-copolymer. The synthetic co-polymer has the general structure:wherein R1, R2, R3 are independently selected from a group consisting of: H; C1-4 alkyl radicals; and, mixtures thereof; R4 is selected from a group consisting of C1-C8 alkyl radicals and mixtures thereof; Z1 is a bridging radical attaching the R4 functionality to the polymer backbone; and, Q1 is a functional group containing at least a cationic quaternary ammonium radical. w, x, y≧1 and the mole ratio of x to (x+y) is about 0.5 or greater.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Colorful coating

InactiveCN104119735AHas paint propertiesNo pollution in the processMulticolor effect coatingsWater basedAlcohol

The invention provides a colorful coating. The colorful coating comprises the following components in percentage by mass: 50-55% of film forming matter, 2-6% of water-based color paste, 10-16% of accessory ingredients and 35-40% of deionized water. According to the film forming matter, synthetic copolymer emulsion is used as a film forming matter of the coating. The accessory ingredients comprise the following components in parts by weight: 0.2-0.4 part of dispersing agent, 2-5 parts of film forming additive, 4-6 parts of antifreezing agent, 0.1-0.2 part of antiseptic and antimildew agent, 2-3 parts of thickening agent, 0.1-0.3 part of defoaming agent, 0.2-0.6 part of fragrance enhancer and 0.2-0.6 part of thixotropic agent. The colorful coating is water-based coating; the coating has the paint characteristic and is free of toxicity, non-combustible and slight in fragrance, so that coating is good in safety during storing, transporting and using, free of pollution to the environment during construction and free of fire danger; the dried coating is tough, durable, wearable and anti-scratch; and meanwhile, the coating has resistance to washing with ethyl alcohol, detergent and water.

Owner:丹阳市海信涂料化工厂

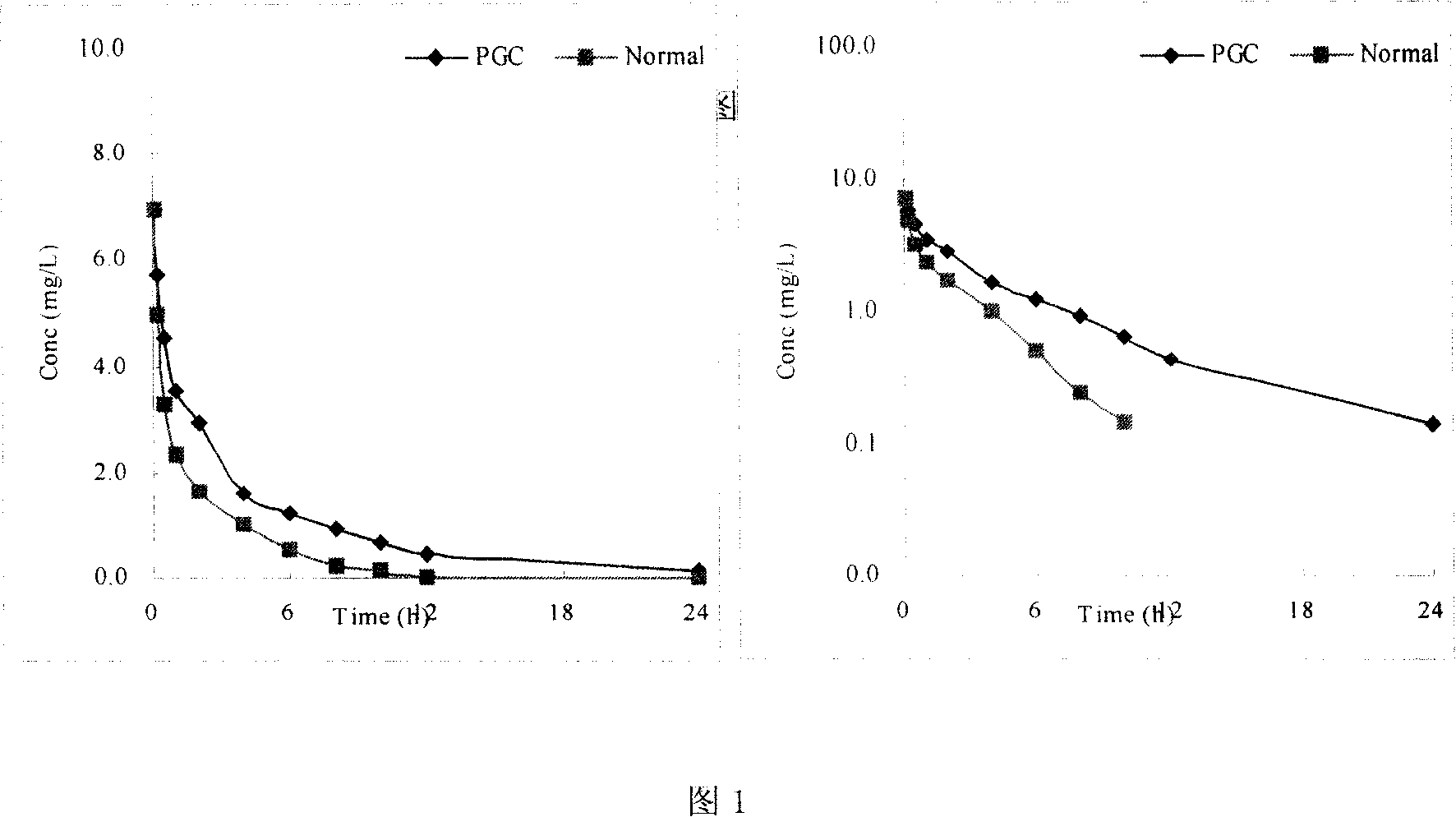

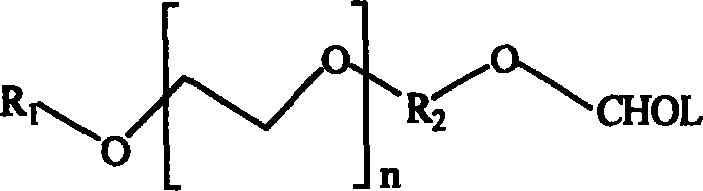

Polyethylene glycol modified sterol copolymer and its uses

The invention discloses a synthesizing method of PGC through grafting PEG on the ChOL at ether bond as surface activator, which can be nanometer emulsion and liposome as well as one of carrier component in the water gel beam and solid liposome nanometer particle or nanometer particle. The invention can be auxiliary material of superior cosmetics, which is injected hypodermally to eliminate wrinkle.

Owner:张文芳

Anticoagulation, antibacterial, anti-adhesion, anti-anti-inflammation and lubricating copolymer coating material for surface of silicon rubber material and preparation method thereof

ActiveCN110204650AHigh densityHigh reactivitySurgeryPharmaceutical containersPhosphatePolymer chemistry

The invention provides an anticoagulation, antibacterial, anti-adhesion, anti-anti-inflammation and lubricating copolymer coating material for the surface of a silicon rubber material and a preparation method thereof. The material is a high molecular copolymer formed by polyelectrolyte and active ester; the polyelectrolyte is a zwitter-ion polyelectrolyte which is generated by polymerizing phosphate ammonium or carboxyl ammonia or sulphur ammonia zwitter-ion monomers. The monomers and active ester monomers of the prepared polyelectrolyte are directly mixed and polymerized, or a homopolymer ofone of the two monomers is prepared at first, the homopolymer is adopted as a chain transfer agent, and the other monomer is adopted as a polymer monomer to obtain the copolymer. The prepared copolymer coating can be bonded on the surface of silicon rubber through the single coating technology to form the stable polymer coating; the number and density of microorganisms and bacteria attached to thesurface of the modified silicon rubber material are remarkably decreased, and the anticoagulation, antibacterial, anti-adhesion and anti-anti-inflammation performance can be remarkably improved; thesurface of the silicon rubber is high in hydrophilicity, the friction coefficient is remarkably lowered, and the lubricating performance can be obviously enhanced.

Owner:NANJING NORMAL UNIVERSITY

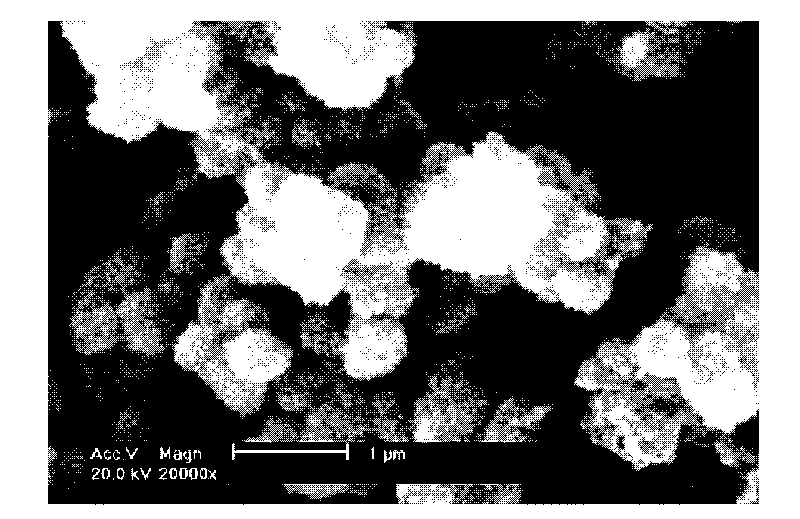

Super absorbent resin with high absorbent velocity and preparation method

Provided are a super absorbent resin with a high absorbent velocity and a preparation method. A polymer and monomer aqueous solution composed of, by weight, 2-10 wt% of PVA, 18-26 wt% of PAAS and 3-9 wt% of AMPS is heated and dissolved. Copolymer gel is synthesized through electron beam radiation crosslinking and grafting. The copolymer gel is then subjected to swelling and immersion cleaning by an immersion cleaning liquid, and then subjected to extraction freezing and freeze-drying to obtain a super absorbent resin. The pH value, normal saline absorbent amount and centrifugal preservation amount of the super absorbent resin have reached international level, and the super absorbent resin is remarkably superior to famous super absorbent resin products (P is less than 0.01) at home and abroad especially in the absorbent amount and the absorbent velocity of triple-distilled water and is in international advanced level. The super absorbent resin has advantages of simple technology, good biocompatibility and safe usage. The super absorbent resin can be widely used in a plurality of fields of medical and health supplies such as uracratia mattresses, infant diapers, woman sanitary napkins and the like, water retention and moisture preservation of agriculture and forestry and the like. The super absorbent resin has great application and development values.

Owner:SUZHOU UNIV

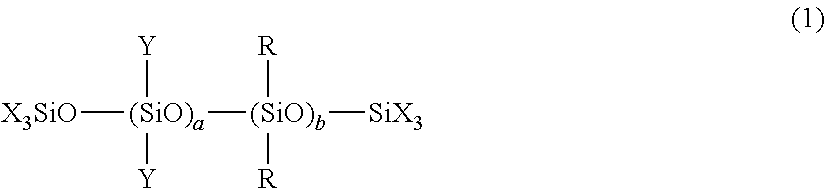

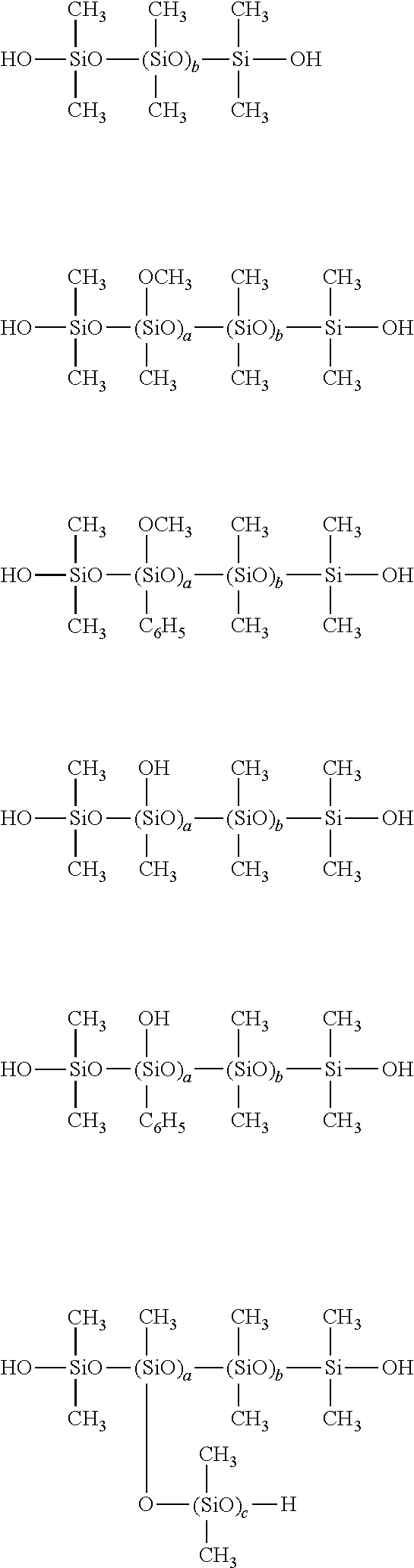

Silicone-based copolymer resin powder, making method, and cosmetics

A silicone-based copolymer resin powder is prepared by reacting a siloxane oligomer obtained from ring-opening of (a1) a cyclic organosiloxane in the presence of (a3) an acid catalyst and (a4) an anionic surfactant with (a2) a silane coupling agent having an alkoxy group and a polymerizable double bond to obtain (A) a linear or branched organopolysiloxane containing at least 2 silicon-bonded hydroxyl groups per molecule,copolymerizing (A) the linear or branched organopolysiloxane with (B) an ethylenically unsaturated monomer to form a copolymer as a core, andfurther polymerizing to the copolymer another ethylenically unsaturated monomer as a shell,the powder containing up to 0.3% by weight of the cyclic organosiloxane and up to 1% by weight of the anionic surfactant.

Owner:NISSHIN CHEM IND CO LTD

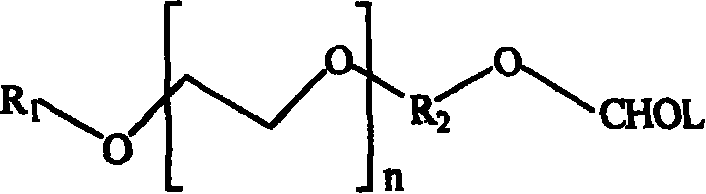

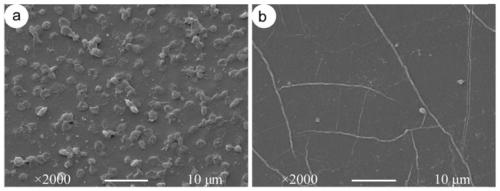

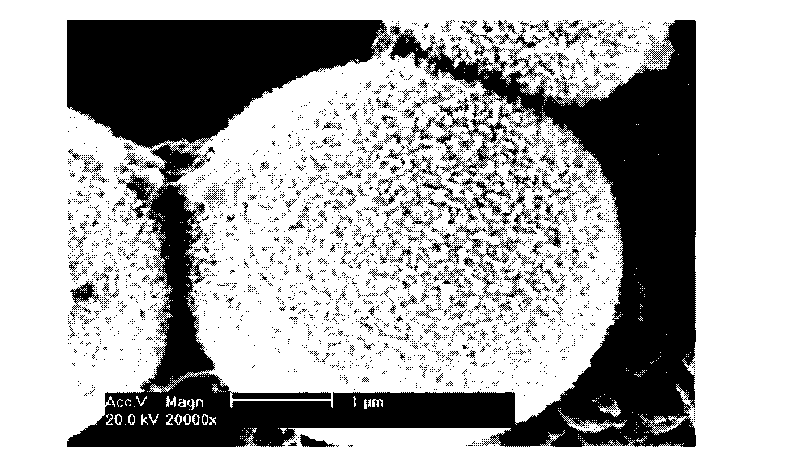

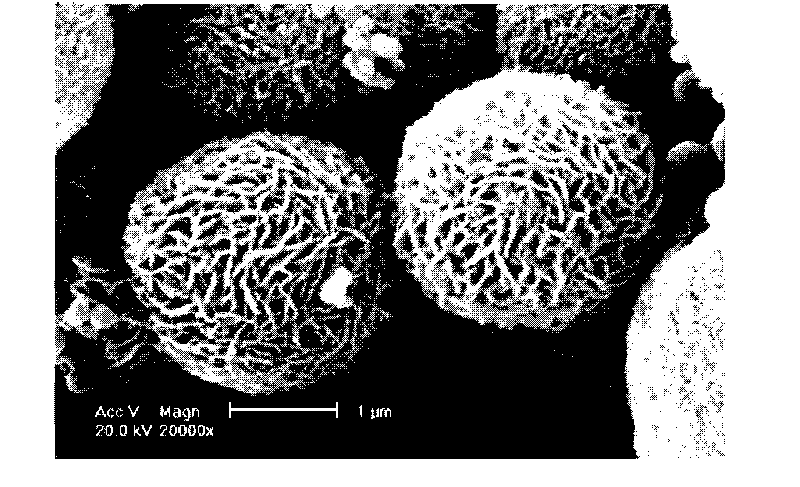

Method for preparing nano-structure aniline-co-pyrrole copolymer microsphere

InactiveCN101690880AUniform sizeGood shape controllabilityMicroballoon preparationMicrocapsule preparationMicrosphereConductive polymer

The invention provides a method for preparing nano-structure aniline-co-pyrrole copolymer microsphere, belongs to the technical field of high polymer materials, and solves the problems of impure obtained polymer, complicated post-processing process, environmental pollution of the used solvent, difficult industrial production and the like in the prior polymerizing method for preparing the nano-structure conductive polymer microsphere produces due to the adding of an extra template or massive additives. The copolymer is prepared by changing medium types of polymerization, selecting aniline or N-ethyl aniline and pyrrole as monomers and implementing a static chemical oxidation polymerization method. The method can prepare copolymer microspheres of between 400 nanometers and 4.4 microns. The method has the characteristics of simple operation, high yield and low cost. The prepared copolymer microspheres have excellent characteristics of nano materials. Furthermore, as an aqueous system, the method, which avoids organic solvent, is a green method for synthesizing the copolymer microspheres. The invention provides a new approach for preparation of the nano-structure polymer microspheres.

Owner:FUZHOU UNIV

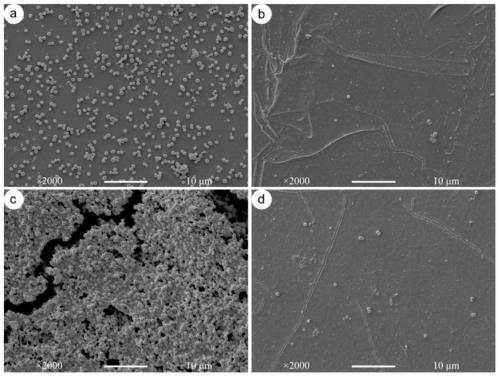

Nanofiber membrane, preparation method and application

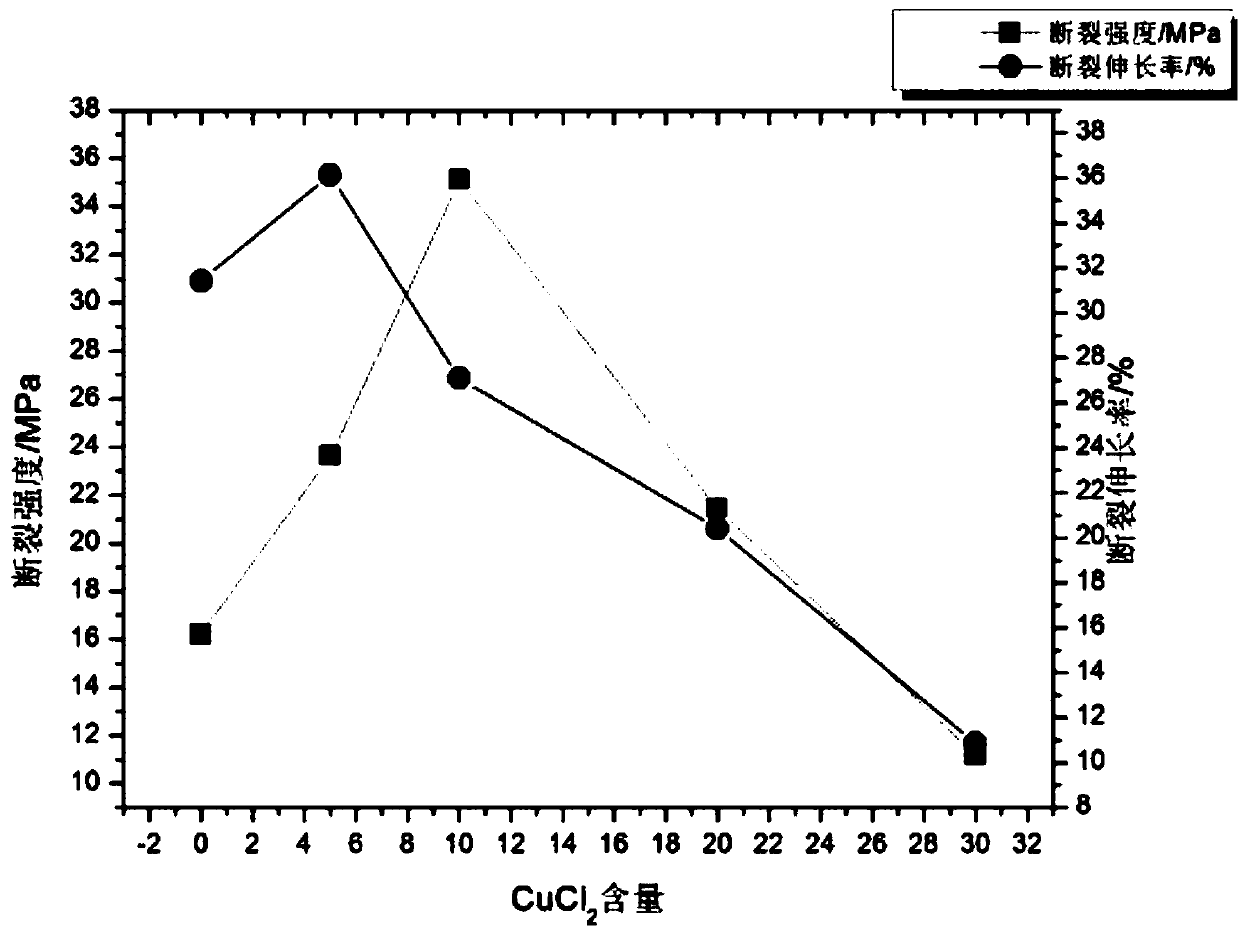

ActiveCN107780053AAvoid reunionHigh breaking strengthFilament/thread formingMonocomponent synthetic polymer artificial filamentSolventMechanical property

The invention discloses an electrostatic spinning nanofiber membrane. Acrylic ester, acrylic acid and polyethylene glycol methacrylate are polymerized into a copolymer. Then, a metal salt solvent is added to the copolymer to prepare a spinning solution, and the spinning solution is injected into an electrostatic spinning device to carry out electrostatic spinning. According to the nanofiber membrane, a preparation method and application, under the precondition of not obviously influencing nanofiber surface morphology, the breaking tenacity of the nanofiber membrane is effectively increased byone to two times; when the amount of an added copper chloride substance is 10% of that of an acrylic acid substance in the copolymer, the mechanical property of the nanofiber membrane is the best, thebreaking tenacity of the nanofiber membrane is 35.12 MPa, and the breaking elongation rate is 26.91%.

Owner:东隆家纺股份有限公司

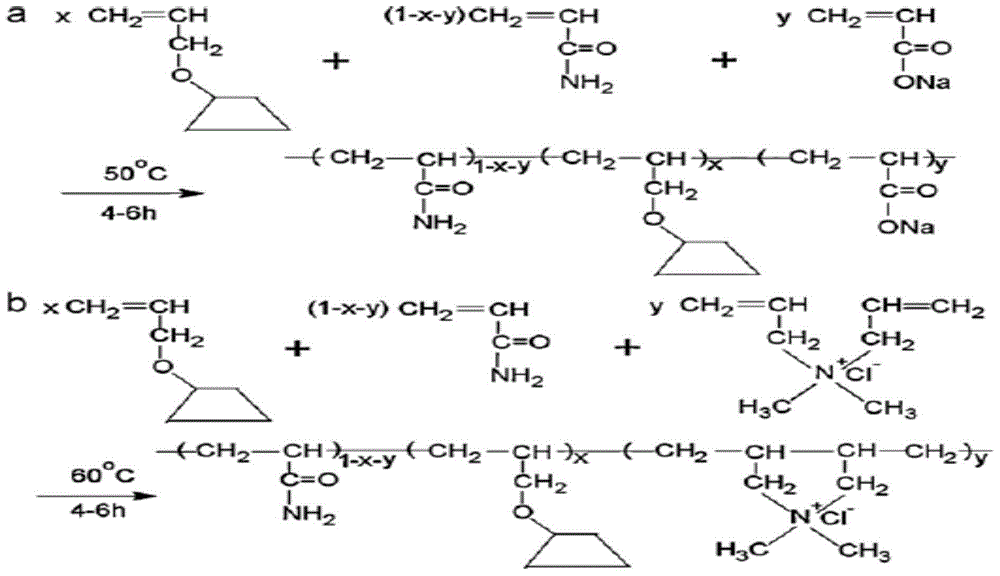

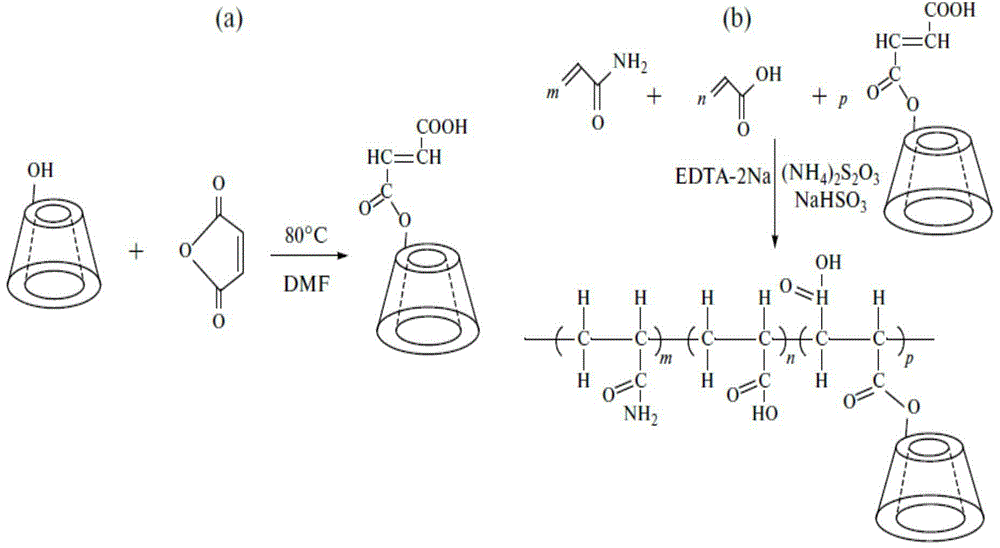

Method for preparing AA/AM/MAH-beta-CD ternary oil-displacing agent

The invention discloses a method for preparing an AA / AM / MAH-beta-CD ternary oil-displacing agent. Although a method for synthesizing a polymer through the cyclodextrin is utilized, but the method for synthesizing a copolymer through the maleic anhydride is not reported; because the cyclodextrin has special characteristics of external hydrophilic and internal lyophobic, the cyclodextrin is grafted to a polymer chain so that the viscosity of the polymer water solution is increased and the supramolecular chemistry is introduced into the petroleum industry. The method has the advantages that the method for synthesizing the unsaturated cyclodextrin monomer is simple, the temperature-resistant and the salt-resistant effect are obvious, the yield is high and the cost is low. The unsaturated cyclodextrin monomer is grafted to the copolymer chain through a simple method, the temperature-resistant and the salt-resistant research (the salt used in the experiment includes sodium chloride and calcium chloride) are processed, and the experiment result shows that the temperature-resistant and the salt-resistant property of the ternary copolymer are increased due to the introduction of the cyclodextrin.

Owner:SOUTHWEST PETROLEUM UNIV

Polyethersulfone hollow fiber intelligent membrane with pH sensitivity as well as preparation method and application thereof

The invention relates to a polyether sulphone hollow intelligent fibrous membrane with pH sensitivity, a method for preparing the same and application of the fibrous membrane. The method is characterized in that 8 to 24 weight portions of acrylonitrile, 5 to 18 weight portions of crylic acid, 70 to 85 weight portions of a solvent and 0.1 to 0.5 weight portion of an evocating agent are added into a reaction kettle with a stirrer, a thermometer and a condenser; under stirring, the mixture reacts for 8 to 24 hours at a temperature of between 55 and 70 DEG C to obtain an acrylonitrile-crylic acid copolymer solution; and 10 to 28 weight portions of polyether sulphone, 70 to 85 weight portions of a solvent and 1.5 to 6 weight portions of an additive are put into a vessel and dissolved for 2 to 24 hours at a temperature of between 75 and 95 DEG C under stirring to prepare a polyether sulphone solution, and 0.2 to 0.6 weight portion of the synthetic copolymer polyether sulphone solution is added into the prepared polyether sulphone solution; and the mixed solution is mixed for 2 to 24 hours at a temperature of between 55 and 65 DEG C under stirring. The mixed solution is subjected to filtering and defoaming and is positioned for curing to prepare a polyether sulphone spinning solution. The polyether sulphone spinning solution is spun to prepare the intelligent type hollow fibrous membrane with pH sensitivity by dry spraying-wet spinning technology; and the membrane has different screening coefficient and flux on acidic amino acid and basic amino acid, thereby being applied to separation of amino acid.

Owner:SICHUAN UNIV

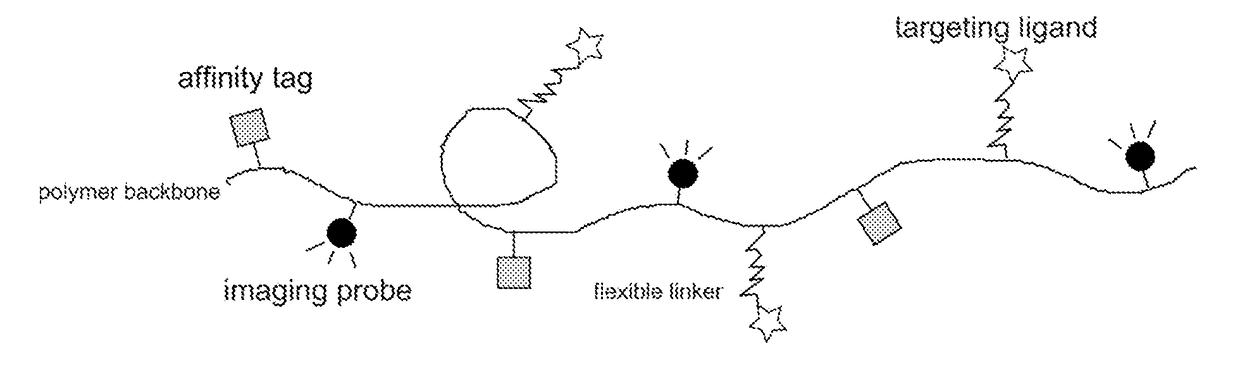

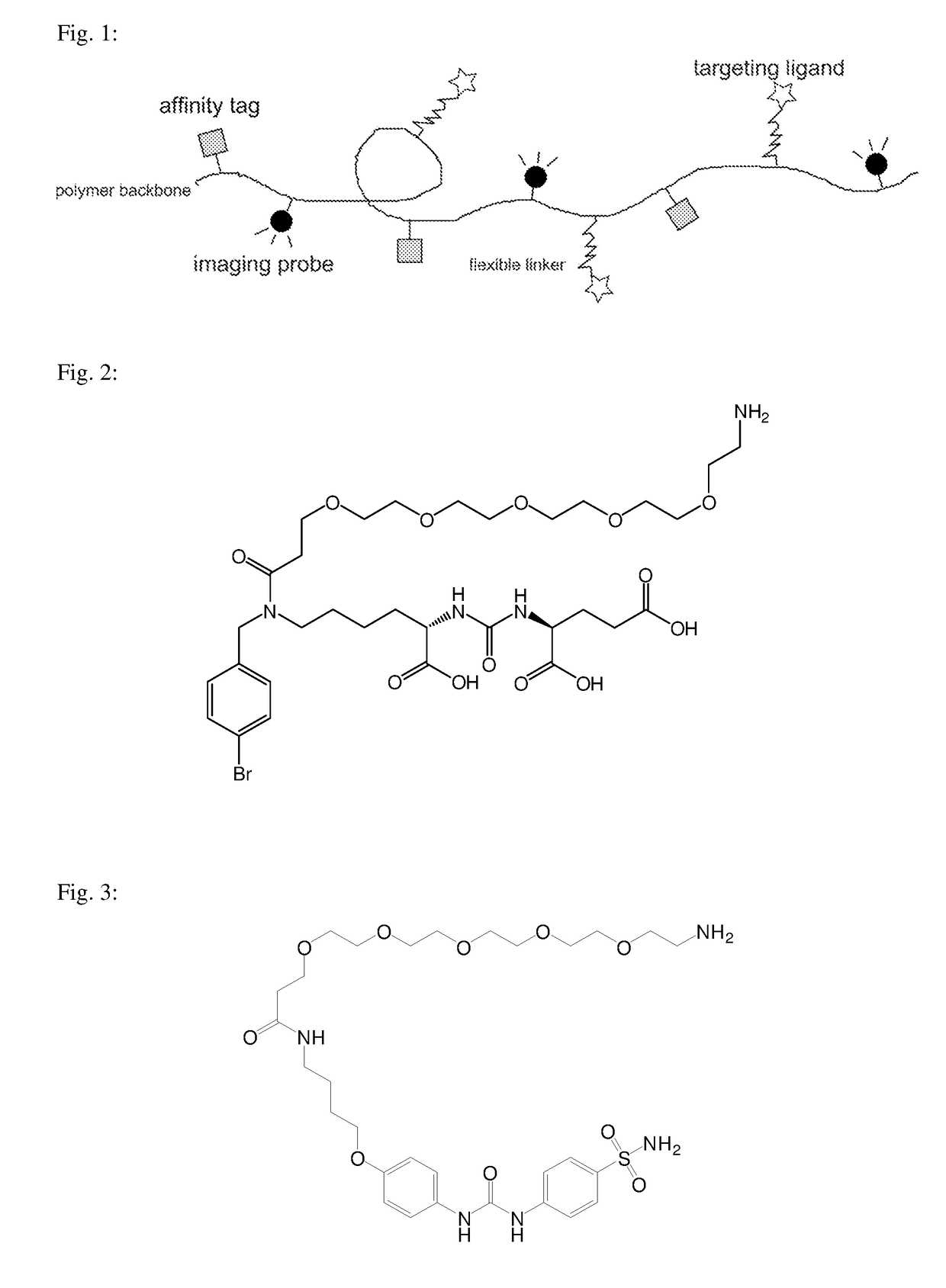

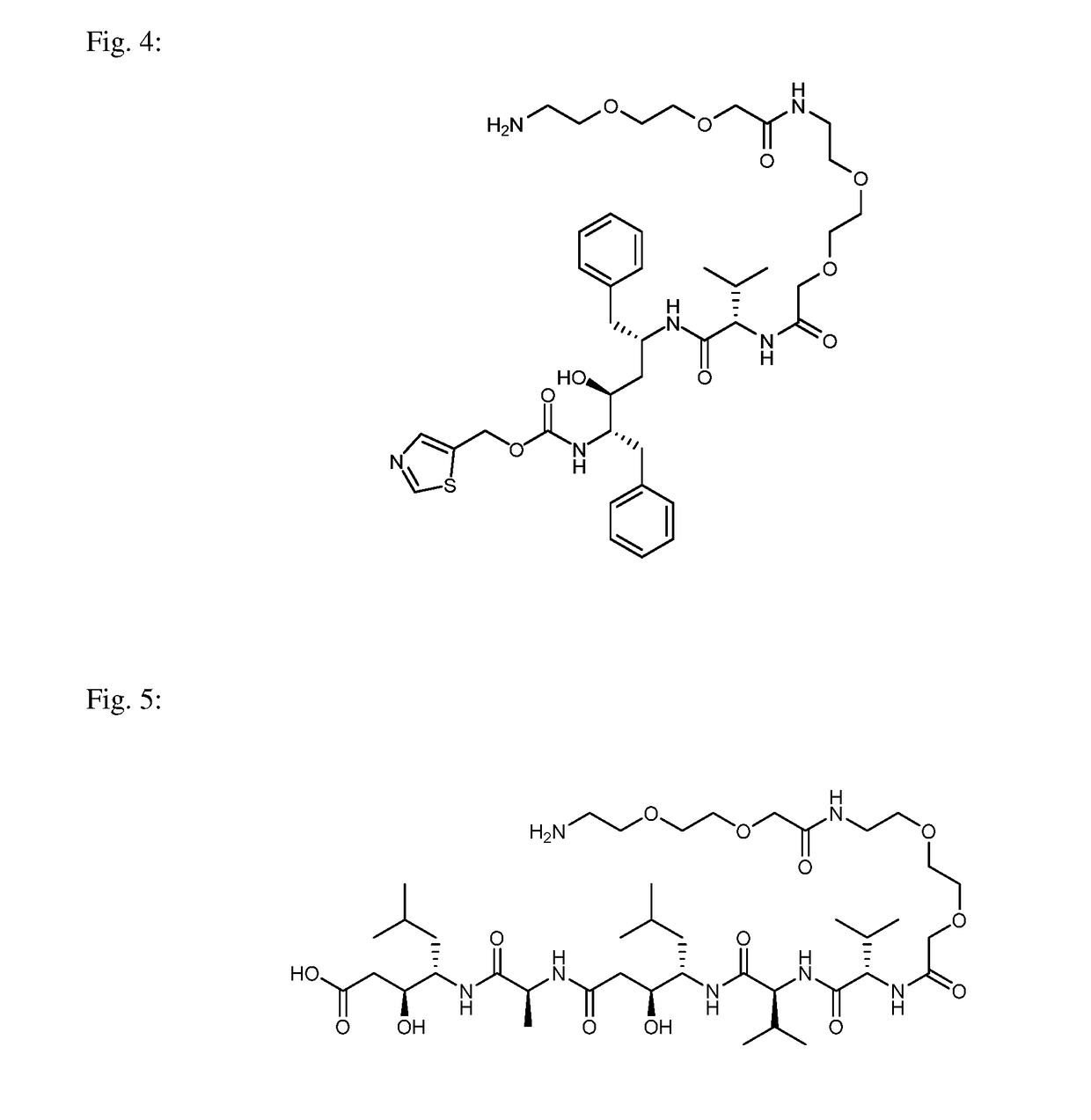

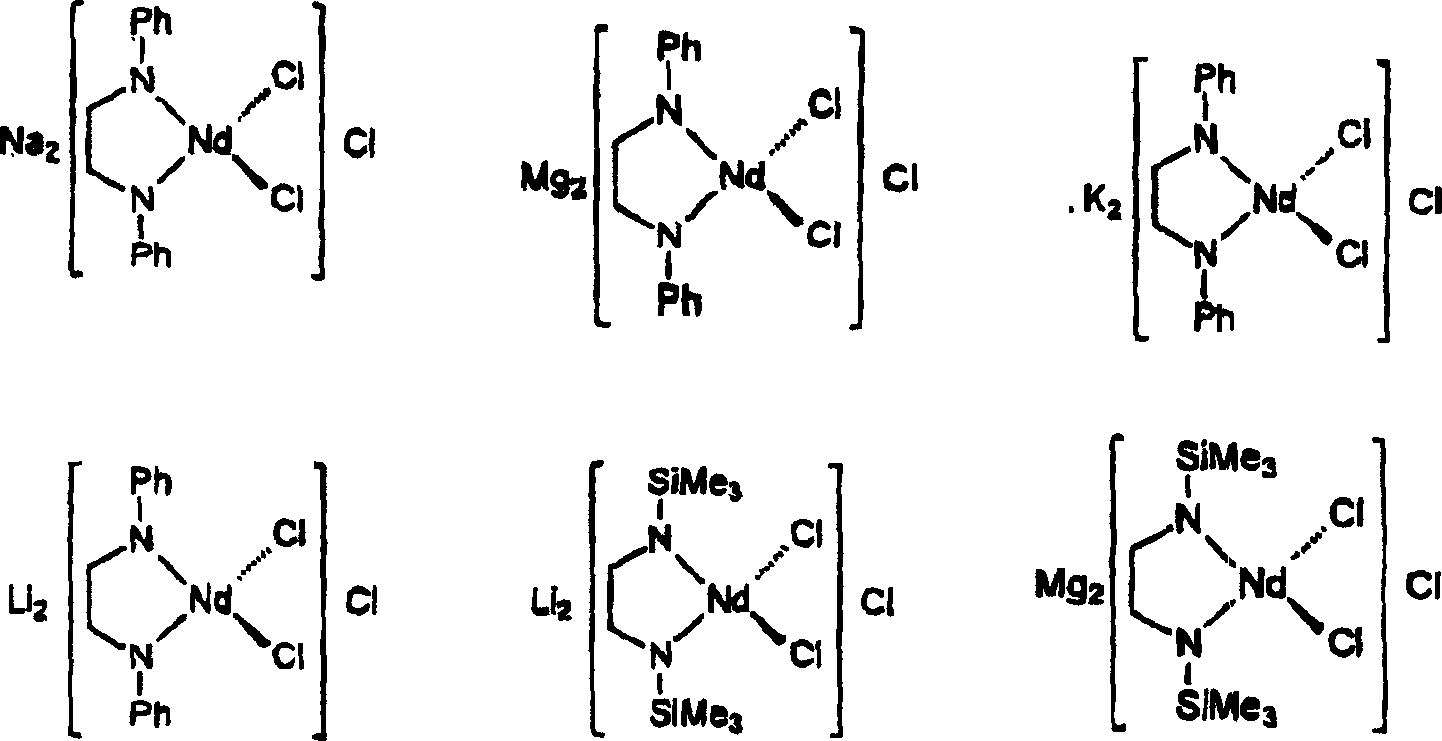

Macromolecular conjugates for visualization and separation of proteins and cells

InactiveUS20180052152A1Avoid steric hindranceEasy to preparePharmaceutical non-active ingredientsCarrier-bound/immobilised peptidesWater solubleCombinatorial chemistry

Macromolecular water-soluble conjugates based on synthetic copolymers to which at least one affinity tag, at least one imaging probe, and at least one targeting ligand are bound via covalent bonds. The macromolecular conjugate may be used in identification, visualization, quantification or isolation of proteins and / or cells. The targeting ligand may be attached to the synthetic copolymer via a flexible linker.

Owner:INST OF ORGANIC CHEM & BIOCHEMISTRY OF THE ACAD OF SCI OF THE CZECH REPUBLIC +2

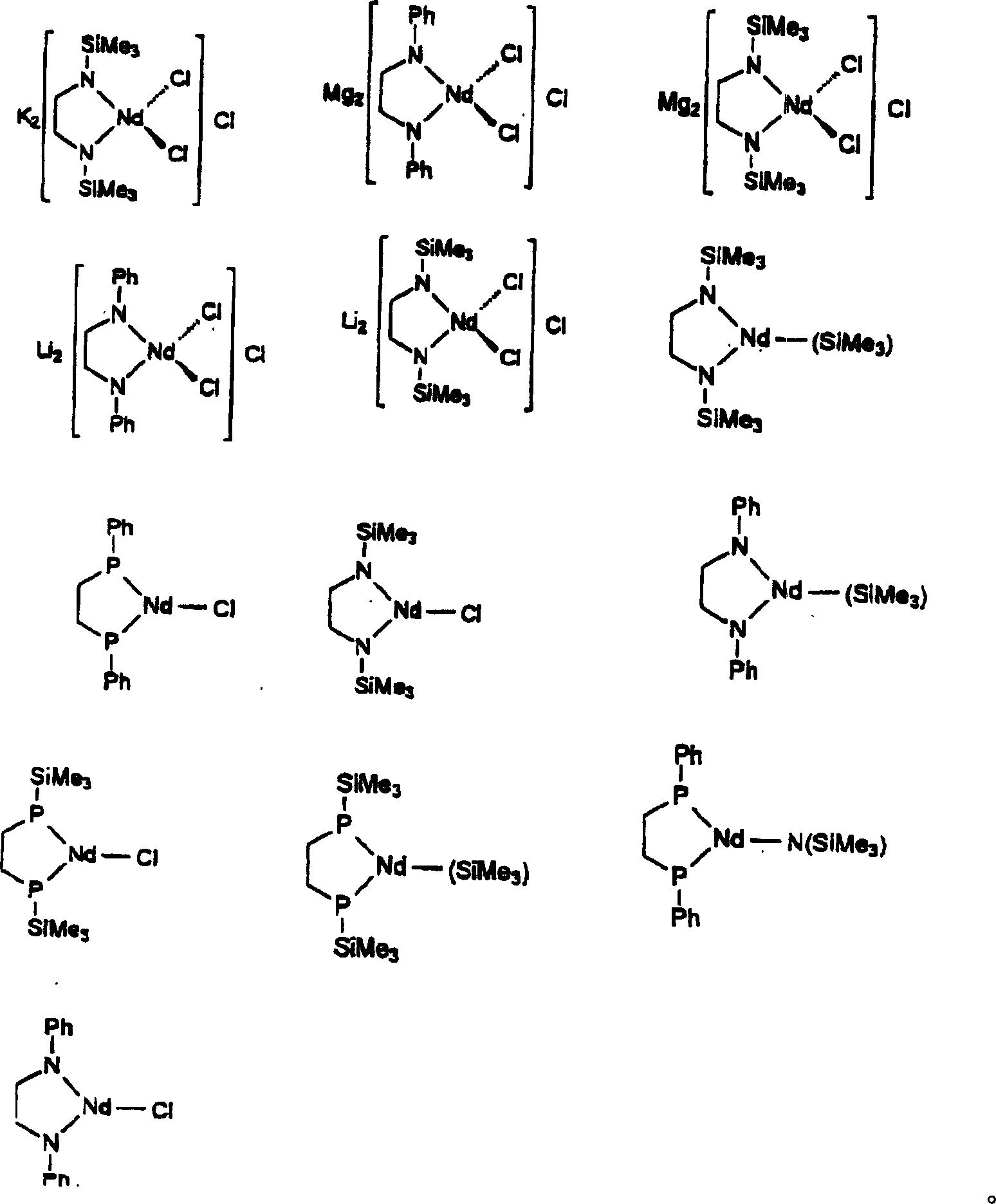

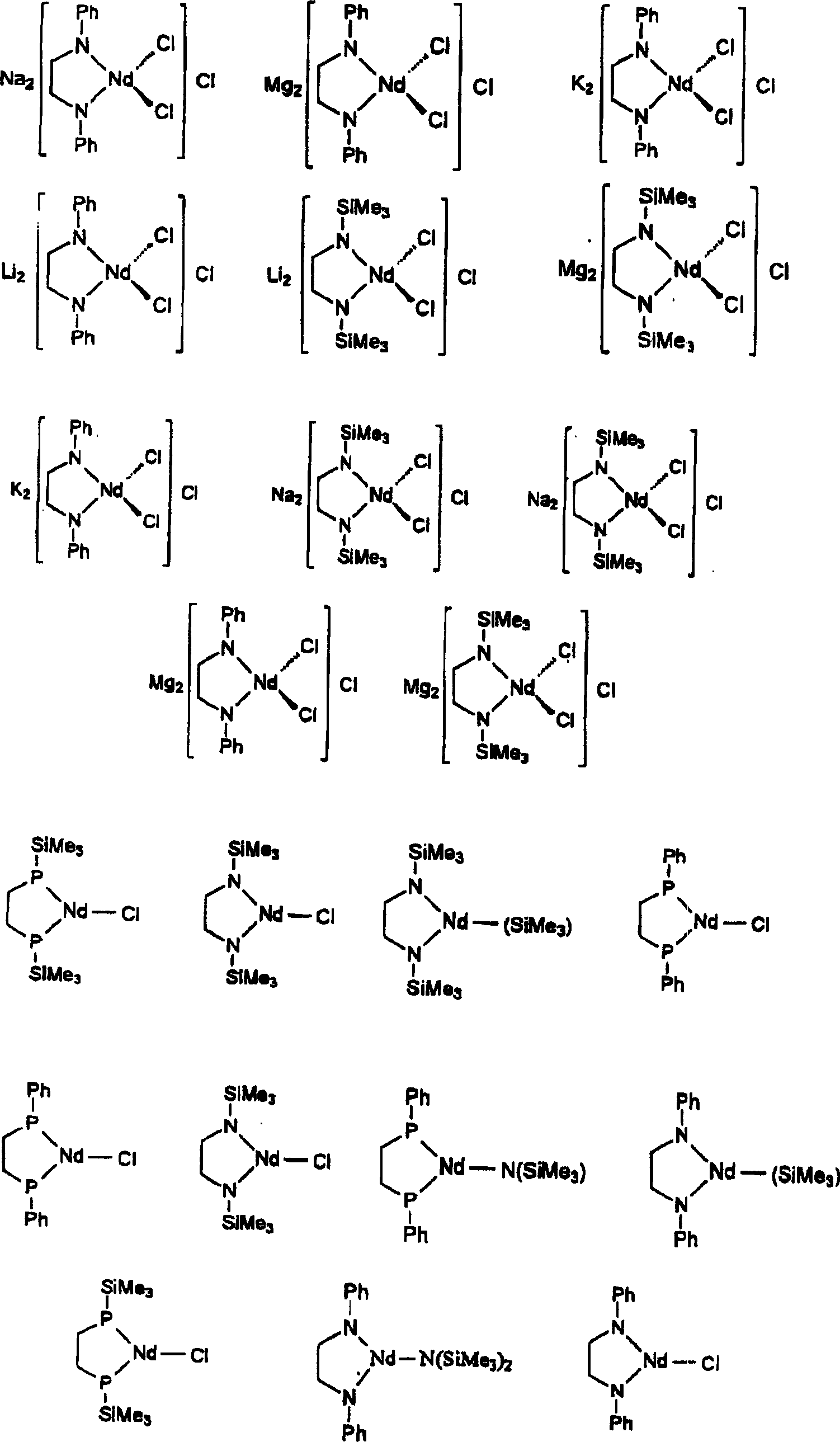

Random or block co-or terpolymers produced by using of metal complex catalysts

Random or block co- or terpolymers produced by using metal complex catalysts in a reaction of one conjugated diene monomer with one aromatic Random or block co- or terpolymers produced by using metomers with one aromatic alpha-olefin or terpolymers of one conjugated diene monomer with one aromatic alpha-olefin and one aliphatic alpha-olefin by using metal complexes comprising metals of group 3 to 10 of the Periodic System of the Elements in combination with activators and optionally a support material. More particularly the metal complexes used for the synthesis of co- or terpolymer are lanthanide metals. Even more particularly diene monomer(s) and aromatic alpha-olefin monomer(s) such as, but not limited to, butadiene and styrene or isoprene and styrene are copolymerized giving random or block copolymers or butadiene, styrene and isoprene are terpolymerized giving random or block terpolymers using metal complexes comprising lanthanide metals in combination with activators and optionally a support material. Preferably random co- or terpolymers are formed.

Owner:DOW GLOBAL TECH LLC

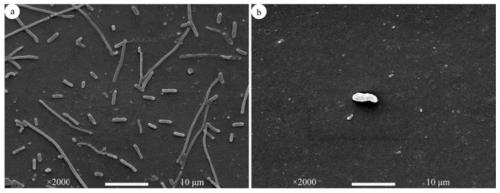

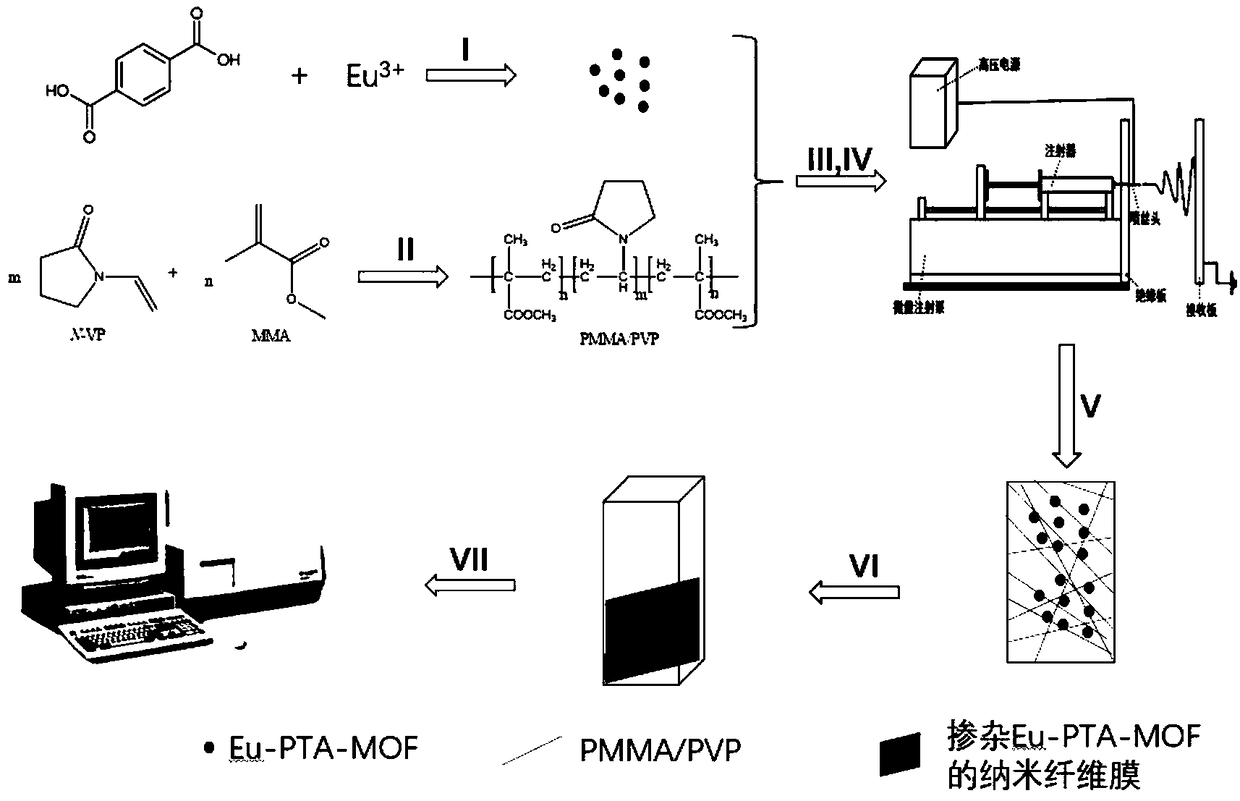

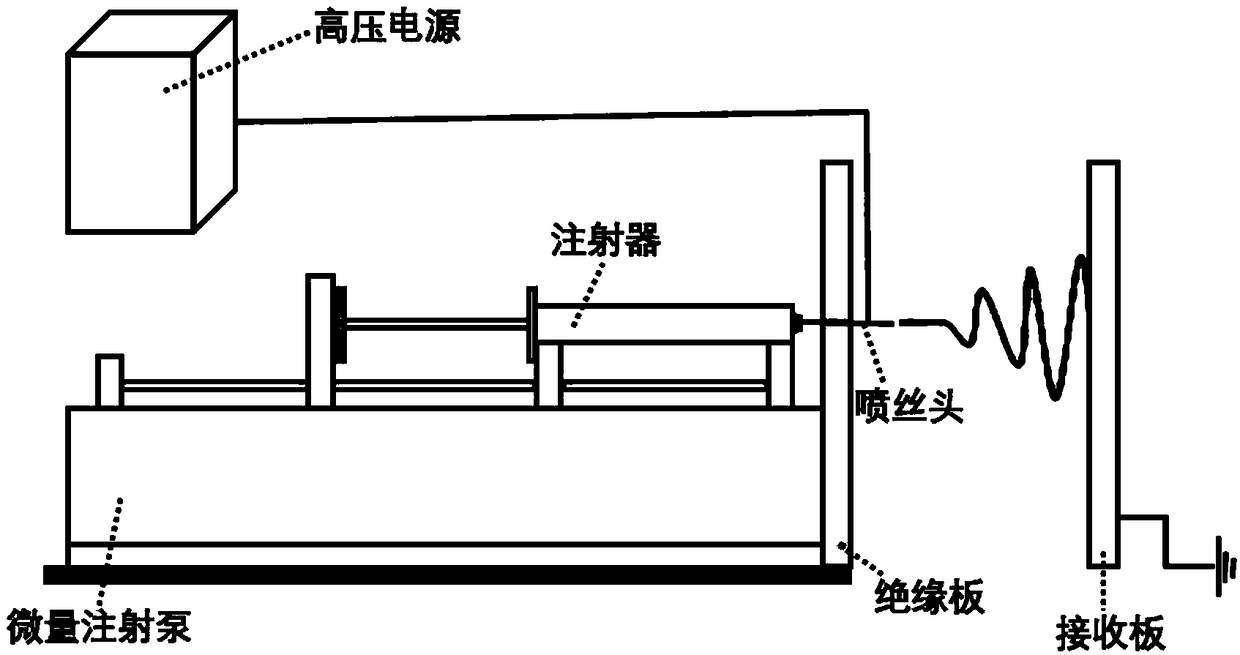

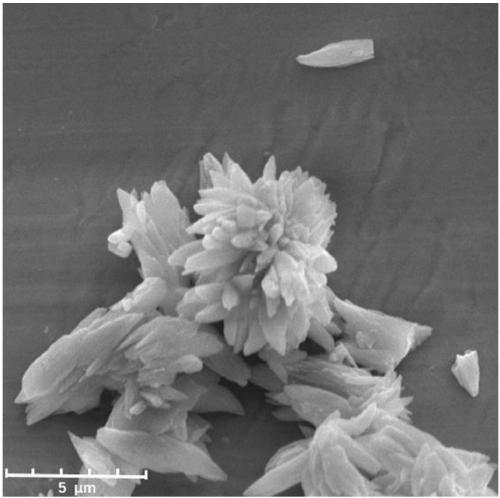

Lanthanide-MOF (Metal Organic Framework) doping-based electrostatic spinning fiber membrane serving as fluorescent sensor for selectively detecting uric acid and preparation method thereof

ActiveCN109283164ASimple dilutionWide pH detection rangeMonocomponent synthetic polymer artificial filamentFluorescence/phosphorescenceFiberMetal-organic framework

The invention discloses a lanthanide-MOF (Metal Organic Framework) doping-based electrostatic spinning fiber membrane serving as a fluorescent sensor and a preparation method thereof. The sensor is applied to the quantitative detection of uric acid in human urine. The detection process comprises the following steps of: (I) synthesizing Eu-PTA-MOF powder; (II) synthesizing a copolymer PMMA / PVP; (III) preparing an electrostatic spinning solution; (IV) preparing a nanofiber membrane; (V) cutting the nanofiber membrane; (VI) inserting the cut membrane into a cuvette; and (VII) recording fluorescence spectrum data. The prepared electrostatic spinning fiber membrane shows various kinds of characteristic blue fluorescence of Eu<3+> and good hydrophilicity and shows good fluorescence detection stability at the pH value of 4.5-8.0 in 30 minutes; the quenching efficiency of the uric acid on the electrostatic spinning fiber membrane fluorescence shows good concentration dependence and anti-interference performance; the detection range of the uric acid is 3-100 [mu]M and the detection limit is 1.3 [mu]M; in addition, the electrostatic spinning fiber membrane can be used repeatedly. The invention provides a simple and efficient method for the quantitative detection of the uric acid in biological fluids.

Owner:WUHAN DGENSEE CO LTD

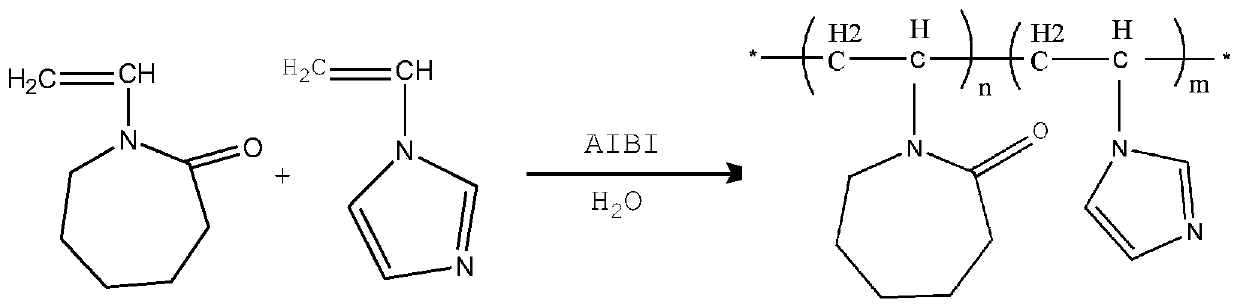

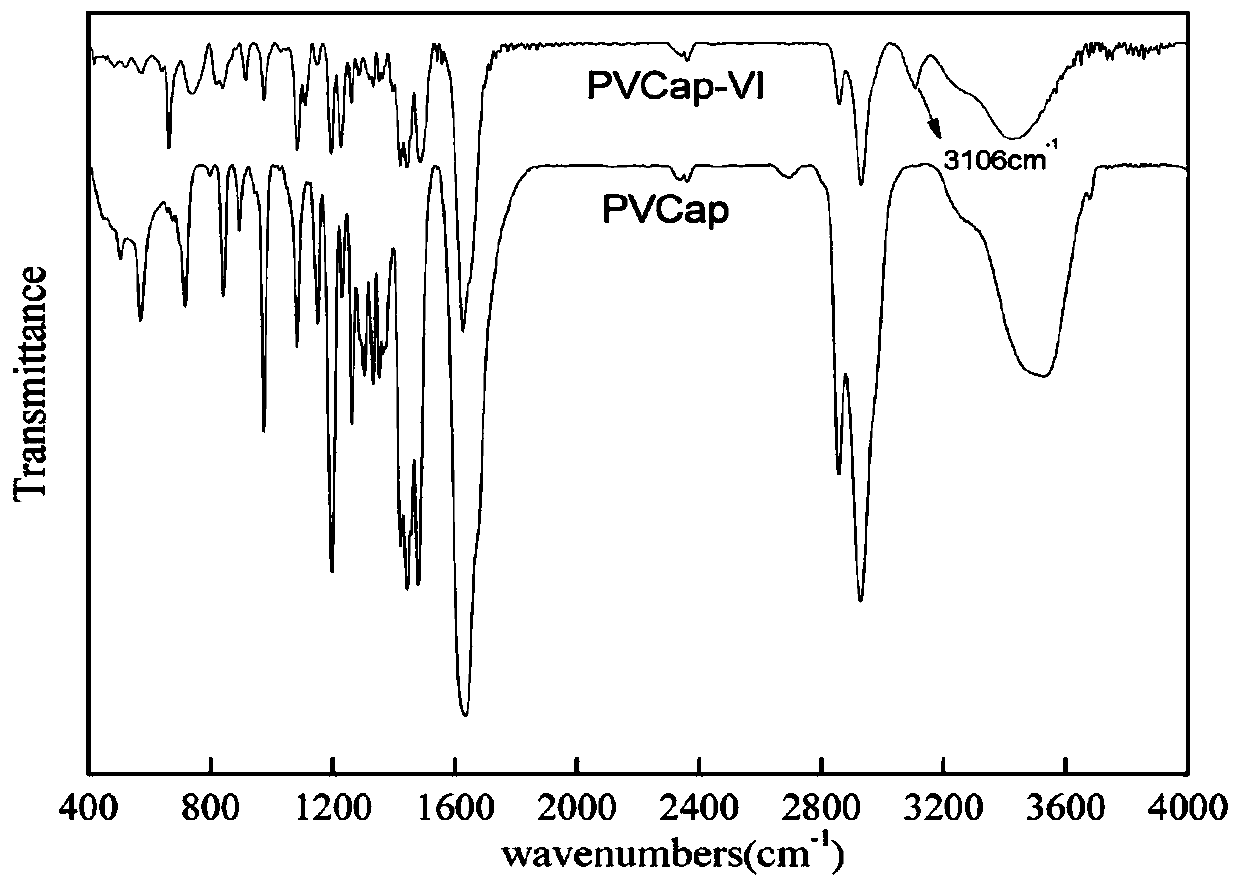

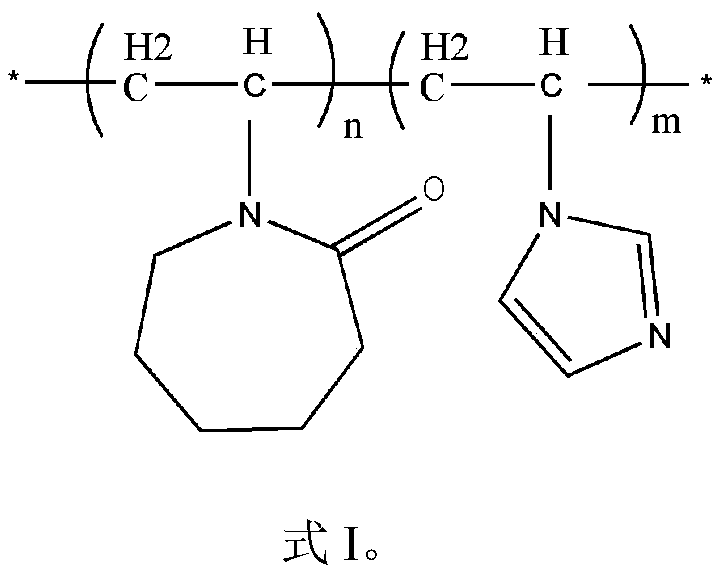

Composite hydrate kinetic inhibitor based on vinyl imidazole copolymer and application thereof

ActiveCN109764241AGood water solubilityPromote environmental protectionPipeline systemsDiethylene glycol monobutyl etherSolubility

The invention provides a composite hydrate kinetic inhibitor based on a vinyl imidazole copolymer and an application thereof. The composite hydrate kinetic inhibitor is prepared from a vinyl imidazolecopolymer and an assisting agent, wherein the assisting agent is N-butyl-N-methylpyrrolidinium tetrafluoroborate and diethylene glycol monobutyl ether, the structure of the vinyl imidazole copolymeris as shown in a formula I (described in the specification), wherein n is equal to 10-600, m is equal to 2-900, and the molecular weight distribution coefficient of the vinyl imidazole copolymer is between 1.2 and 1.8. By introducing 1-Vinylimidazole in the process of copolymer synthesizing, through the strong hydrophilicity and biodegradability of imidazole five-membered ring, compared with a single homopolymer PVCap, the water solubility and environmental friendliness of the copolymer inhibitor are improved.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Method of fracturing with phenothiazine stabilizer

Well treatment fluids and methods of treating high temperature subterranean formations of up to about 500° F. (260° C.) are provided. The well treatment fluids and methods utilize a high molecular weight synthetic copolymer and a pH buffer than maintains a pH in a range of about 4.5 to about 5.25 for the fluids. The high molecular weight synthetic copolymer is derived from acrylamide, acrylamidomethylpropanesulfonic acid, and vinyl phosphonates. The well treatment fluids may be energized or foamed.

Owner:BAKER HUGHES HLDG LLC

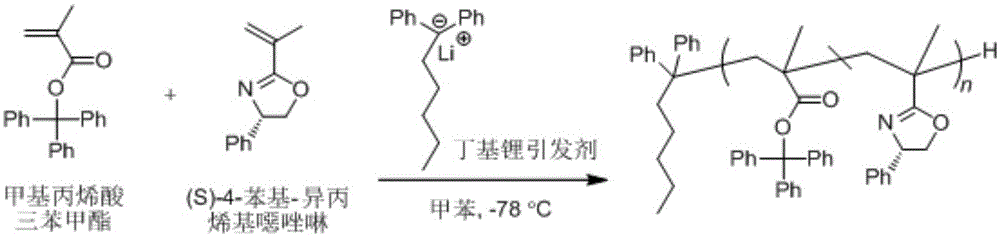

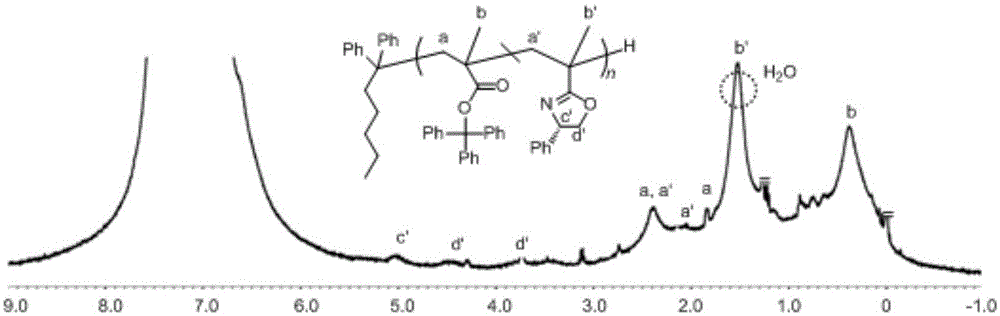

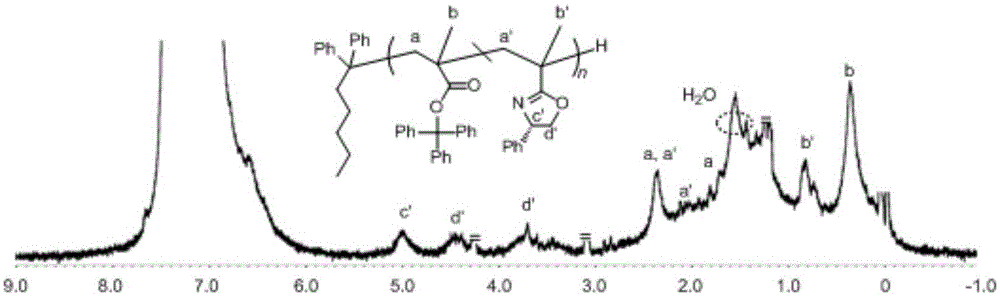

Asymmetric anionic copolymerization method of methacrylate chiral polymer

The invention provides an asymmetric anionic copolymerization method of a methacrylate chiral polymer. The method comprises the following steps: reacting methacrylic acid with trityl chloride to generate a large-volume triphenylmethyl acrylate monomer, carrying out an asymmetric anionic copolymerization reaction on the large-volume triphenylmethyl acrylate monomer and a self-made chiral function monomer under specific anion conditions to obtain a large-volume methacrylate chiral polymer; and purifying the polymer to finally obtain a target product. The structural characterization and analysis of the obtained polymer are carried out by using nuclear magnetic resonance hydrogen spectrum (<1>H-NMR) and an element analysis technology to determine that the molecular structure of the polymer and proportions of all components of the polymer accord with design requirements. Performances of the synthesized copolymer are deeply analyzed through using a gel permeation chromatograph and a polarimeter to obtain the molecular weight of the novel chiral copolymer and the distribution thereof, and the optical active characteristics of the copolymer. The method has the advantages of clear and feasible synthesis route, manure process, simple operation, easy realization, and large-scale batch production.

Owner:HARBIN ENG UNIV

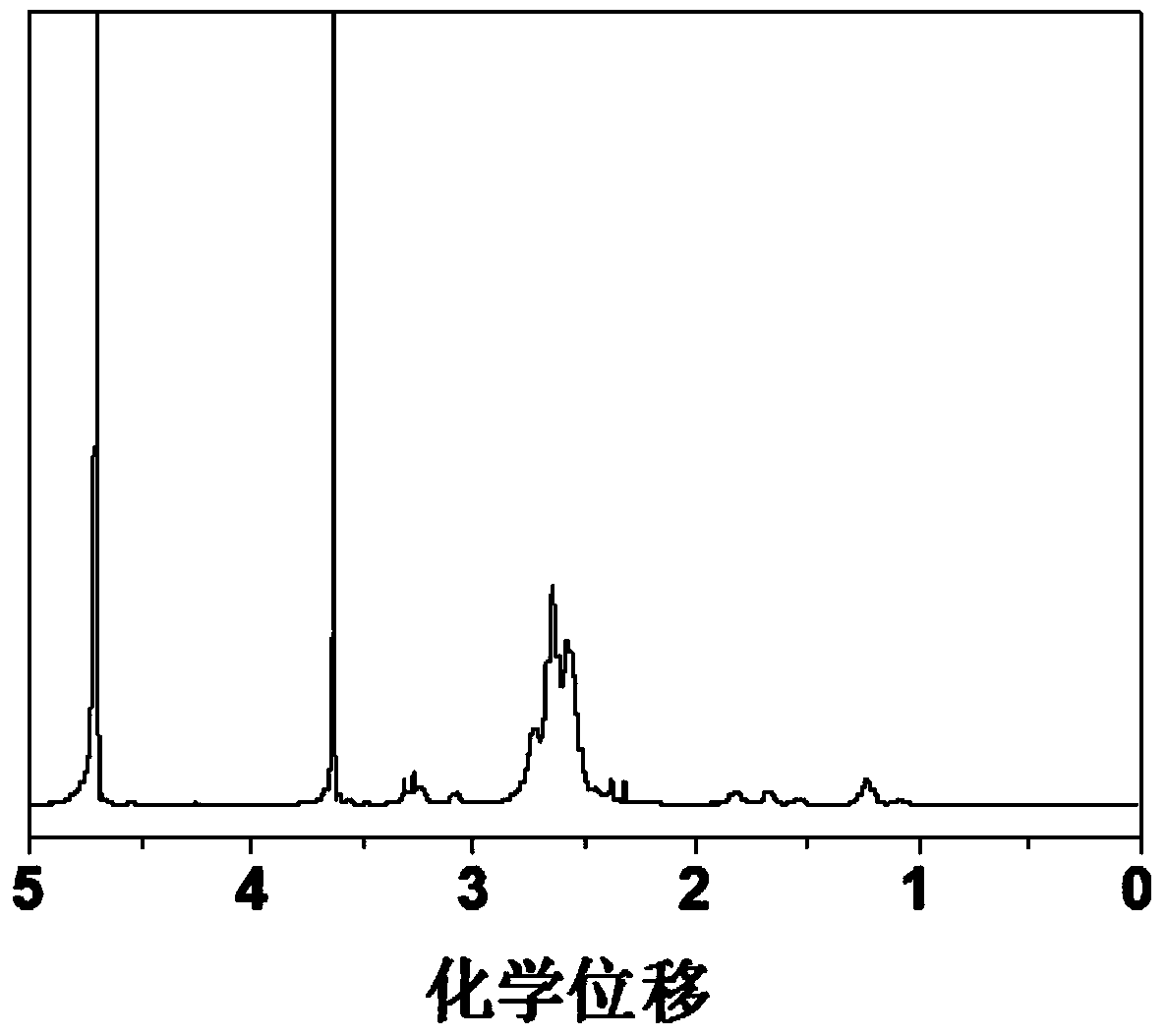

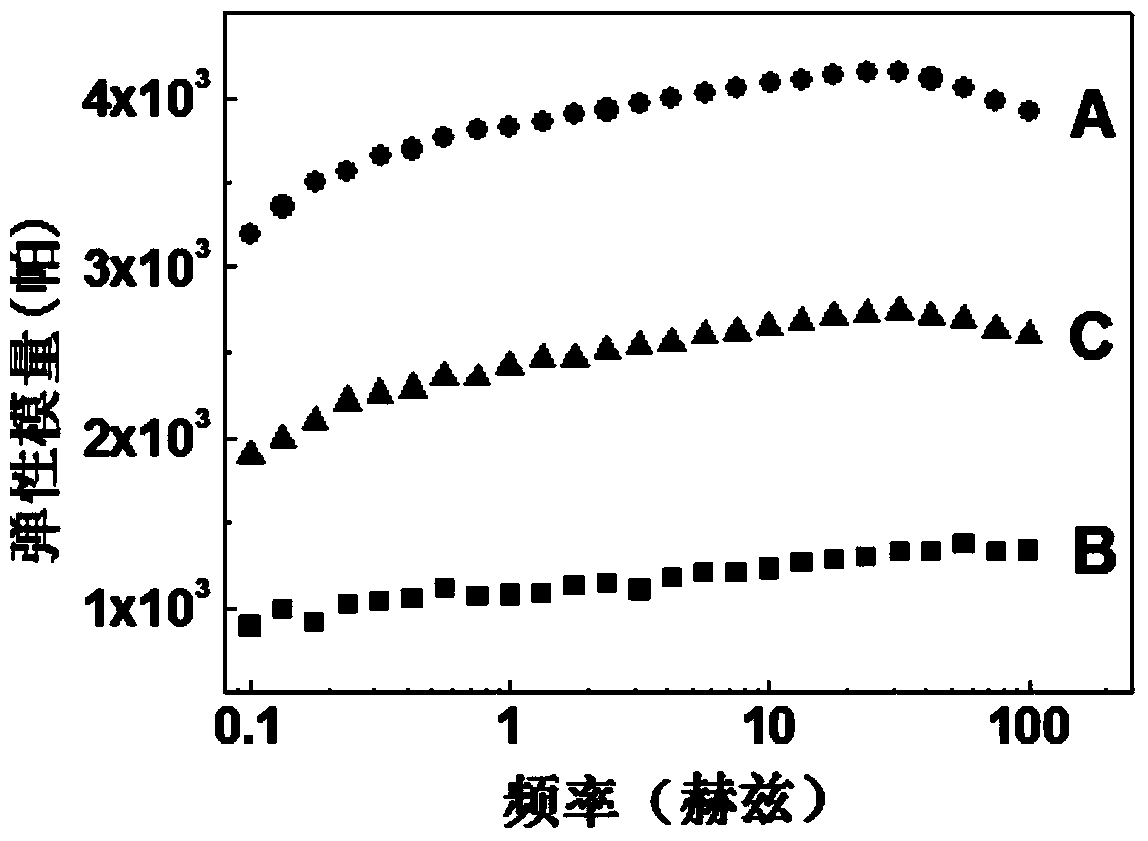

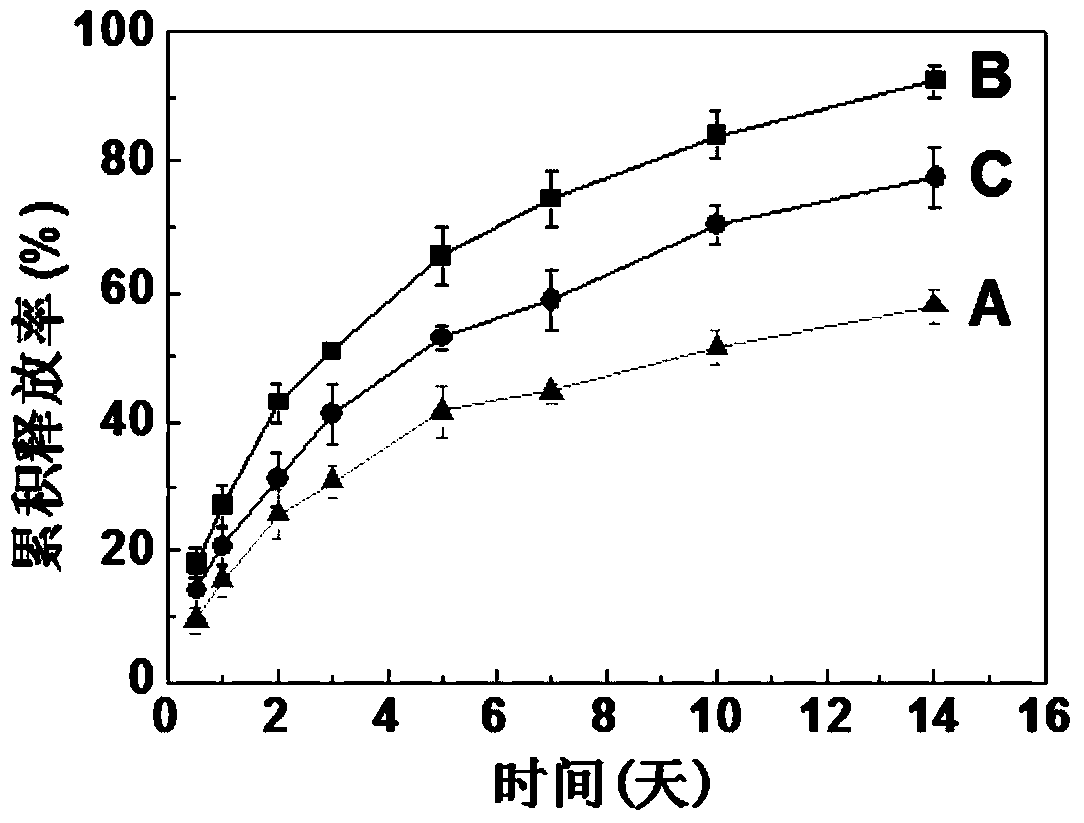

High-strength supramolecular hydrogel, as well as preparation method and application thereof

InactiveCN104069507ASimple and fast manufacturing methodGuaranteed biocompatibilityGenetic material ingredientsPharmaceutical non-active ingredientsGene deliveryPolymer science

The invention relates to a method for preparing high-strength supramolecular hydrogel. The method comprises the following steps: (1) synthesizing polyethylene glycol-polycaprolactone-polycationic copolymer; (2) preparing a copolymer / nucleic acid composite liquid; and (3) mixing the copolymer / nucleic acid composite liquid obtained in the step (2) and an alpha-cyclodextrin liquid to prepare the high-strength supramolecular hydrogel. The invention also relates to the high-strength supramolecular hydrogel prepared by the method and an application of the hydrogel. The hydrogel forming process does not have chemical crosslinking reactions, the influence of chemical crosslinking reaction by-products on the activity of nucleic acid can be effectively avoided, the hydrogel has an effective gene transfer effect, the preparation method is convenient and quick, the hydrogel can be formed at room temperature, and the bioactivity of an embedded gene and the biocompatibility of a material can be kept. According to the hydrogel, the defect of quick degradation of current similar gel materials can be overcome, the nucleic acid can be released for more than 2 weeks, and the aim of long-time durable transfection can be achieved.

Owner:广州新犇富科技有限公司

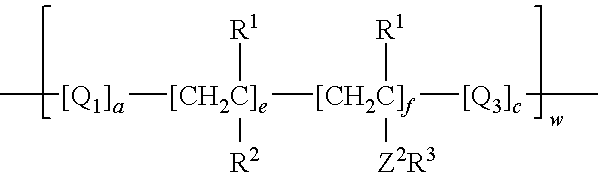

Method of making low slough tissue products

InactiveUS20080185114A1Low viscosityQuick applicationNatural cellulose pulp/paperSpecial paperFiberPhotochemistry

The present invention is a soft tissue sheet having reduced lint and slough. The tissue sheet comprises papermaking fibers and a synthetic co-copolymer. The synthetic co-polymer has the general structure:wherein R1, R2, R3 are independently selected from a group consisting of: H; C1-4 alkyl radicals; and, mixtures thereof; R4 is selected from a group consisting of C1-C8 alkyl radicals and mixtures thereof; Z1 is a bridging radical attaching the R4 functionality to the polymer backbone; and, Q1 is a functional group containing at least a cationic quaternary ammonium radical. w, x, y≧1 and the mole ratio of x to (x+y) is about 0.5 or greater.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Direct ch arylation method using palladium-based catalyst

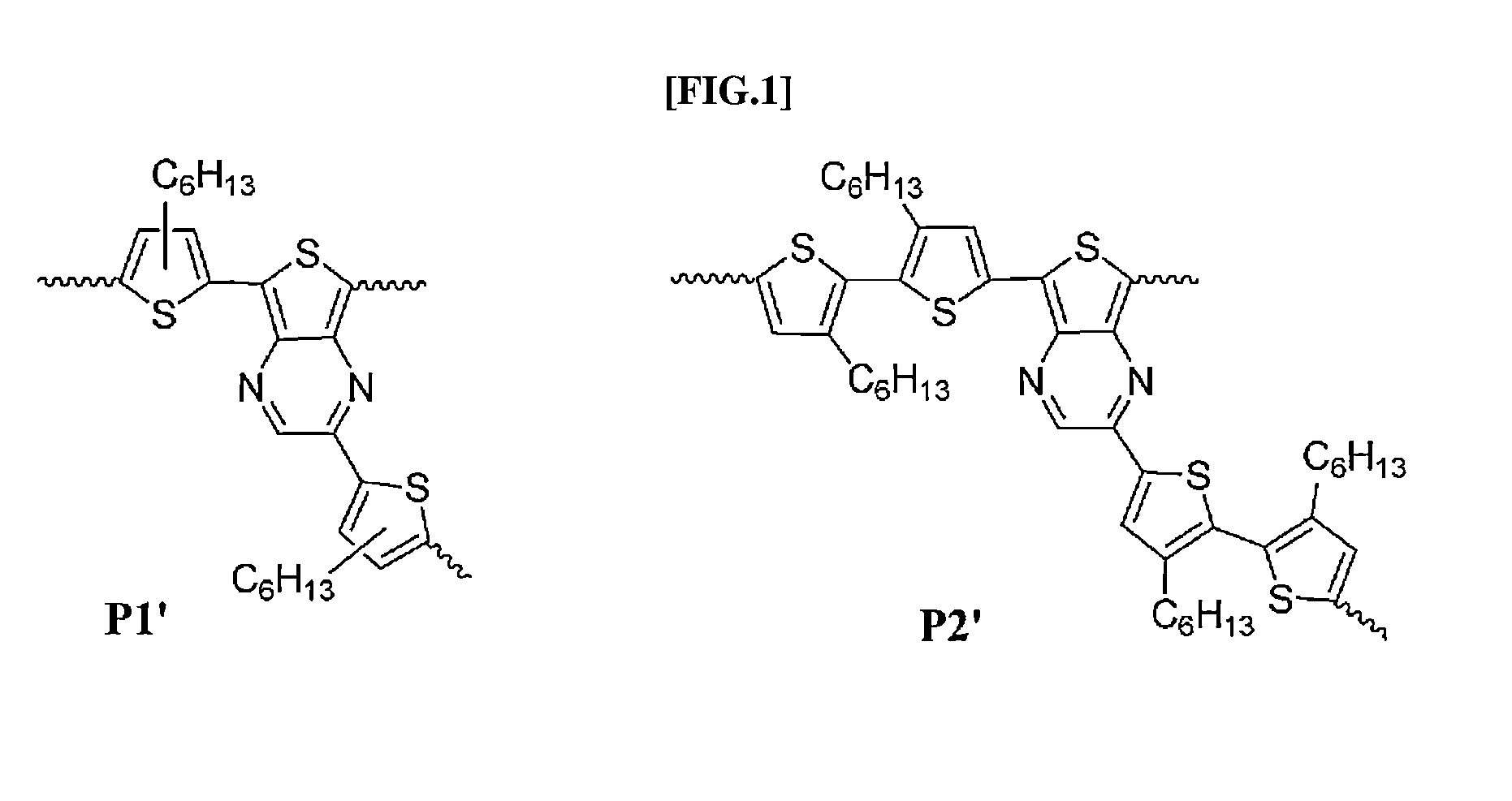

InactiveUS20140142263A1Lower bandgapLow costFinal product manufactureOrganic-compounds/hydrides/coordination-complexes catalystsArylTerthiophene

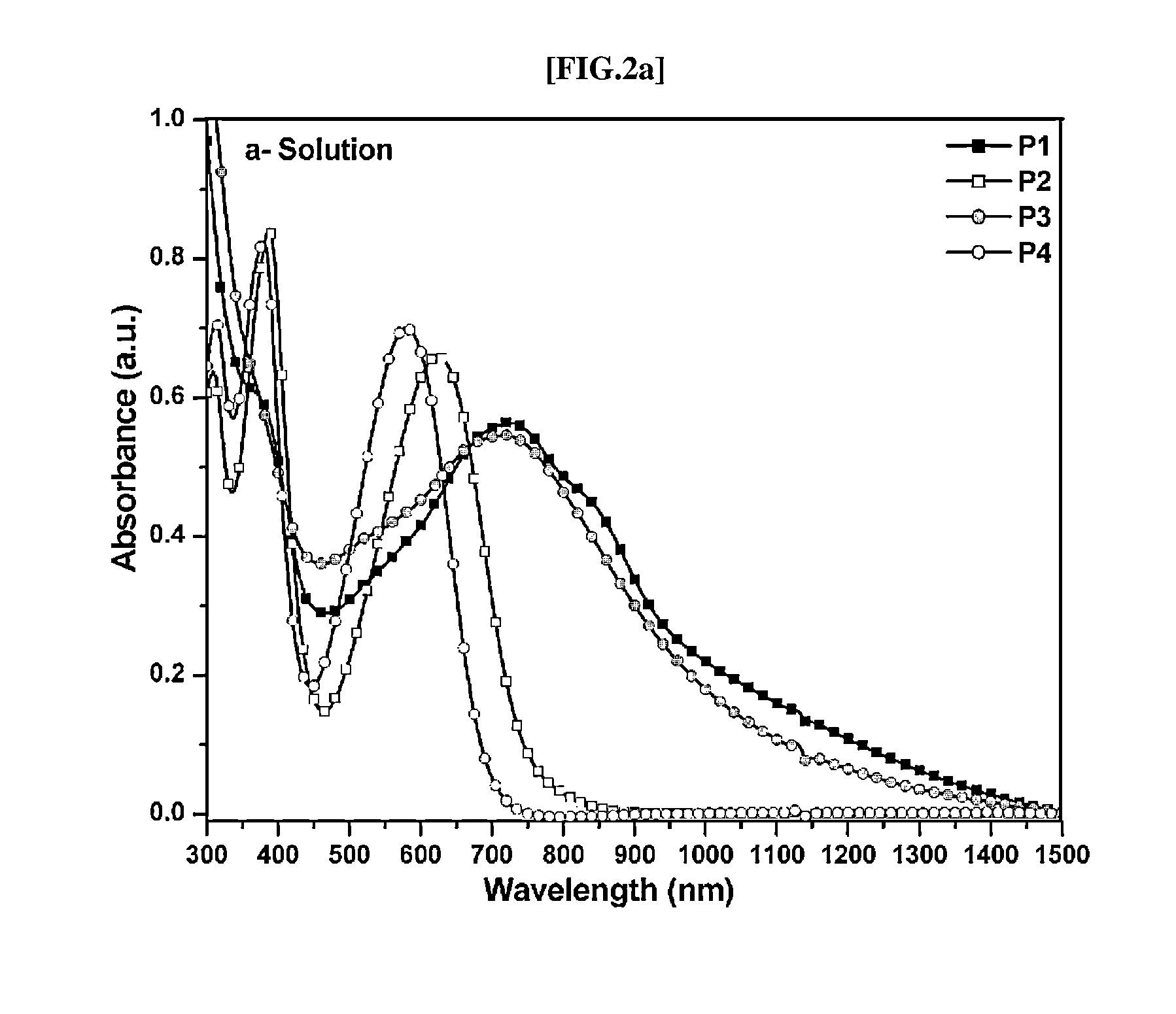

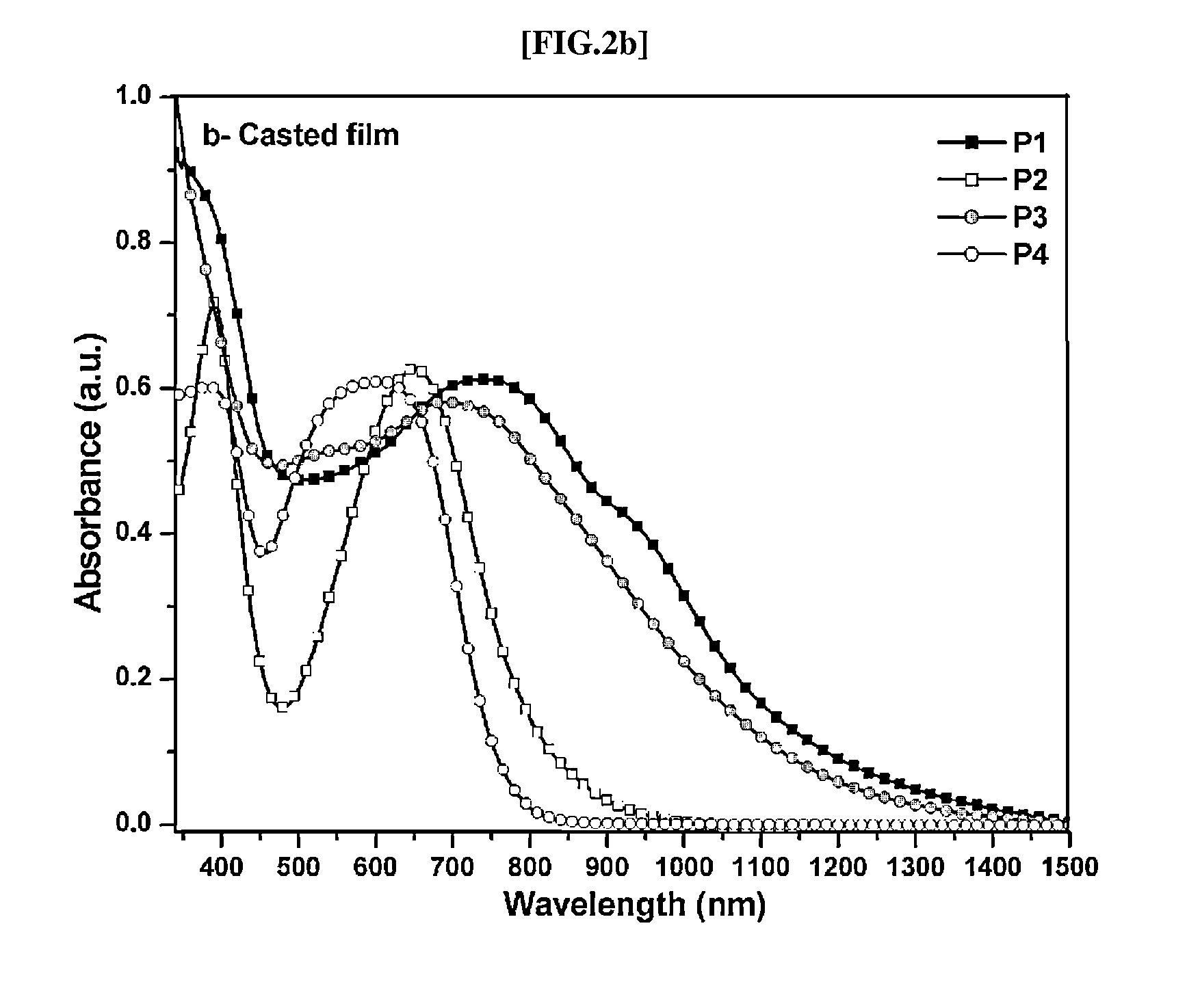

Disclosed herein is a first example of effective direct position specific C—H arylation of thieno[3,4-b]pyrazine derivative and several hetero aryl bromide under the ‘Heck-type’ experiment condition using Pd(OAc)2 / n-Bu4NBr as a catalyst system, thienopyrazine in which aryl is replaced to increase various values. The current synthesis methodology is a simpler method than a facial method and is used to prepare π-conjugated oligomer and / or polymer material based on interesting hexylthiophen and thienopyrazine portion for electronic industries which construct a new synthetic organic material using potential application programs. The arylation generates more position selectivity in a C—H bond than in a pyrazine C—H bond. The optical and electrical characteristics of the synthesis copolymer are survey.

Owner:GWANGJU INST OF SCI & TECH

Process for incorporating poorly substantive paper modifying agents into a paper sheet via wet end addition

InactiveUS7678232B2Imparting softnessReduced strengthNon-fibrous pulp additionNatural cellulose pulp/paperHydrogenCellulose fiber

Synthetic co-polymers having moieties capable of forming hydrogen bonds, ionic bonds, or covalent bonds with cellulose fibers and paper modifying moieties capable of modifying a paper sheet are disclosed. These synthetic co-polymers are derived from the reaction of an aldehyde functional polymer and an aldehyde reactive paper modifying agent containing a non-hydroxyl aldehyde reactive functional group.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com