Method for preparing nano-structure aniline-co-pyrrole copolymer microsphere

A pyrrole copolymer and nanostructure technology, which is applied in the preparation of microspheres, microcapsule preparations, etc., can solve the problems of complex post-processing procedures, impure polymers, difficult industrial production, etc. Processing difficulties, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0013] The concrete steps of preparation method are:

[0014] (1) Preparation of monomer solution: Add monomer aniline or N-ethylaniline and comonomer pyrrole into the reaction medium solution, stir to fully dissolve it to form a monomer solution, and then put it in a reaction water bath to keep the temperature until the reaction temperature, the reaction temperature is from 0 to 50°C;

[0015] (2) Preparation of oxidant solution: add oxidant to the same reaction medium solution as in step (1), stir to make it fully dissolve to form oxidant solution, and then put it in a reaction water bath to keep the temperature to the reaction temperature, and the reaction temperature is 0 to 50°C ;

[0016] (3) mixed solution, polymerization reaction: adding the oxidant solution of the step (2) dropwise into the monomer solution of the step (1) to initiate the polymerization reaction;

[0017] (4) Continue the reaction: after the oxidant is added dropwise, continue the reaction under sta...

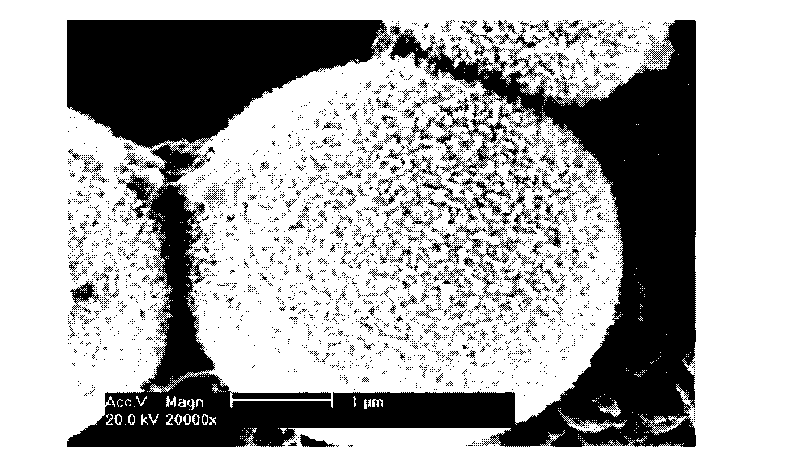

Embodiment 1

[0032] Measure 4.5mmol aniline and 0.5mmol pyrrole, put them in a dry and clean beaker, add 0.1mol L -1 Aqueous NaOH solution (initial pH 13.01) was stirred in an ice-water bath at 0°C for 0.5 h to obtain a monomer mixture. Another weighed 5mmol ammonium persulfate was dissolved in 0.1mol L -1 NaOH aqueous solution was stirred in an ice-water bath at 0°C for 0.5 h until it was completely dissolved, and a colorless transparent solution was obtained. Add the ammonium persulfate aqueous solution dropwise to the monomer mixture above at a rate of 1 drop per second under static conditions. After the dropwise addition, the reaction was continued until 24h. After the reaction was completed, 2 mL of the reaction solution was taken for centrifugal washing, and the sample was used for polymer morphology testing. The remaining reaction solution was filtered, and the filter cake was dried at 60° C. for 7 days to obtain copolymer powder with a polymerization yield of 74% and an electr...

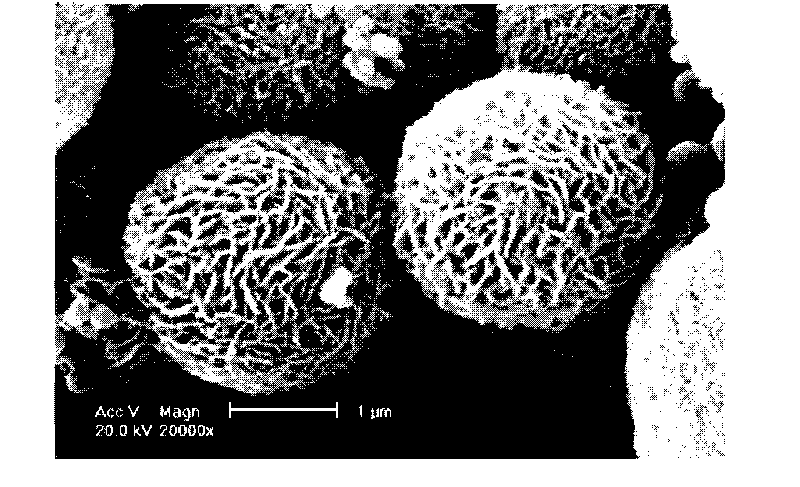

Embodiment 2

[0035] Measure 4.5mmol aniline and 0.5mmol pyrrole, put them in a dry and clean beaker, add 0.2mol L -1 Ammonia solution (initial pH value 11.08) was stirred in an ice-water bath at 0°C for 0.5 h to obtain a monomer mixture. Another weighed 5mmol ammonium persulfate was dissolved in 0.1mol L -1 Ammonia solution was stirred in an ice-water bath at 0°C for 0.5 h until it was completely dissolved, and a colorless transparent solution was obtained. Add the ammonium persulfate aqueous solution dropwise to the monomer mixture above at a rate of 1 drop per second under static conditions. After the dropwise addition, the reaction was continued to 72h. After the reaction was completed, 2 mL of the reaction solution was taken for centrifugal washing, and the sample was used for polymer morphology testing. Filter the remaining reaction solution, and dry the filter cake at 60°C for 7 days to obtain a copolymer powder with a polymerization yield of 65% and an electrical conductivity of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com