Graphene/mesoporous titanium dioxide visible light catalyst and preparation method

A mesoporous titanium dioxide and titanium dioxide technology, which is applied in the fields of nanocomposite materials and photocatalysis, can solve the problems of irregular morphology, single titanium dioxide structure, poor visible light catalytic effect, etc., and achieves uniform size, excellent photocatalytic activity, and simple preparation process. safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Add 20 mg of graphene oxide to 80 mL of glacial acetic acid, ultrasonicate for 2 hours to obtain a graphene oxide dispersion, then add 1 mL of n-butyl titanate dropwise to the above graphene oxide dispersion, and place on a magnetic stirrer Continue to stir for 30 minutes, then transfer the above mixed solution to a 100 ml hydrothermal reaction kettle, and react at 160°C for 30 hours. After the hydrothermal reaction product is separated by high-speed centrifugation, it is washed with absolute ethanol and repeated centrifugal washing several times. Placed in a vacuum oven and dried at 60°C for 24 hours, the resulting sample was further heat-treated in an argon-protected tube furnace at 350°C for 2h to obtain a graphene / mesoporous titania nanocomposite photocatalyst.

Embodiment 2

[0027] Add 20 mg of graphene oxide to 80 mL of glacial acetic acid, ultrasonicate for 3 hours to obtain a graphene oxide dispersion, then add 2 mL of n-butyl titanate dropwise to the above graphene oxide dispersion, and place on a magnetic stirrer Continue to stir for 30 minutes, then transfer the above mixed solution to a 100 ml hydrothermal reaction kettle, and react at 200 ° C for 24 hours. After the hydrothermal reaction product is separated by high-speed centrifugation, it is washed with absolute ethanol and repeated centrifugal washing several times. Placed in a vacuum oven and dried at 60°C for 24 hours, the resulting sample was further heat-treated at 400°C for 30 minutes in an argon-protected tube furnace to obtain a graphene / mesoporous titania nanocomposite photocatalyst.

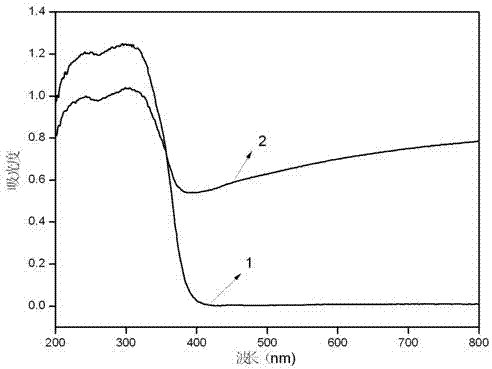

[0028] figure 1 The graphene / mesoporous titania nanocomposite material prepared for this embodiment and the ultraviolet-visible absorption spectrogram of titania, from figure 1 We can see that af...

Embodiment 3

[0036] Add 20 mg of graphene oxide to 80 mL of glacial acetic acid, ultrasonicate for 2 hours to obtain a graphene oxide dispersion, then add 3 mL of n-butyl titanate dropwise to the above graphene oxide dispersion, and place on a magnetic stirrer Continue stirring for 30 minutes. Then the above mixed solution was transferred to a 100 ml hydrothermal reaction kettle, and reacted at 220°C for 18 hours; the product after the hydrothermal reaction was centrifuged at high speed, washed with absolute ethanol and repeated centrifugal washing several times, and then placed in a vacuum oven. After drying at 60°C for 24 hours, the resulting sample was further heat-treated at 500°C for 30 minutes in an argon-protected tube furnace to obtain a graphene / mesoporous titania nanocomposite photocatalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com