Patents

Literature

109results about How to "The preparation process is simple and safe" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-performance polycarboxylate water reducing agent and preparation method thereof

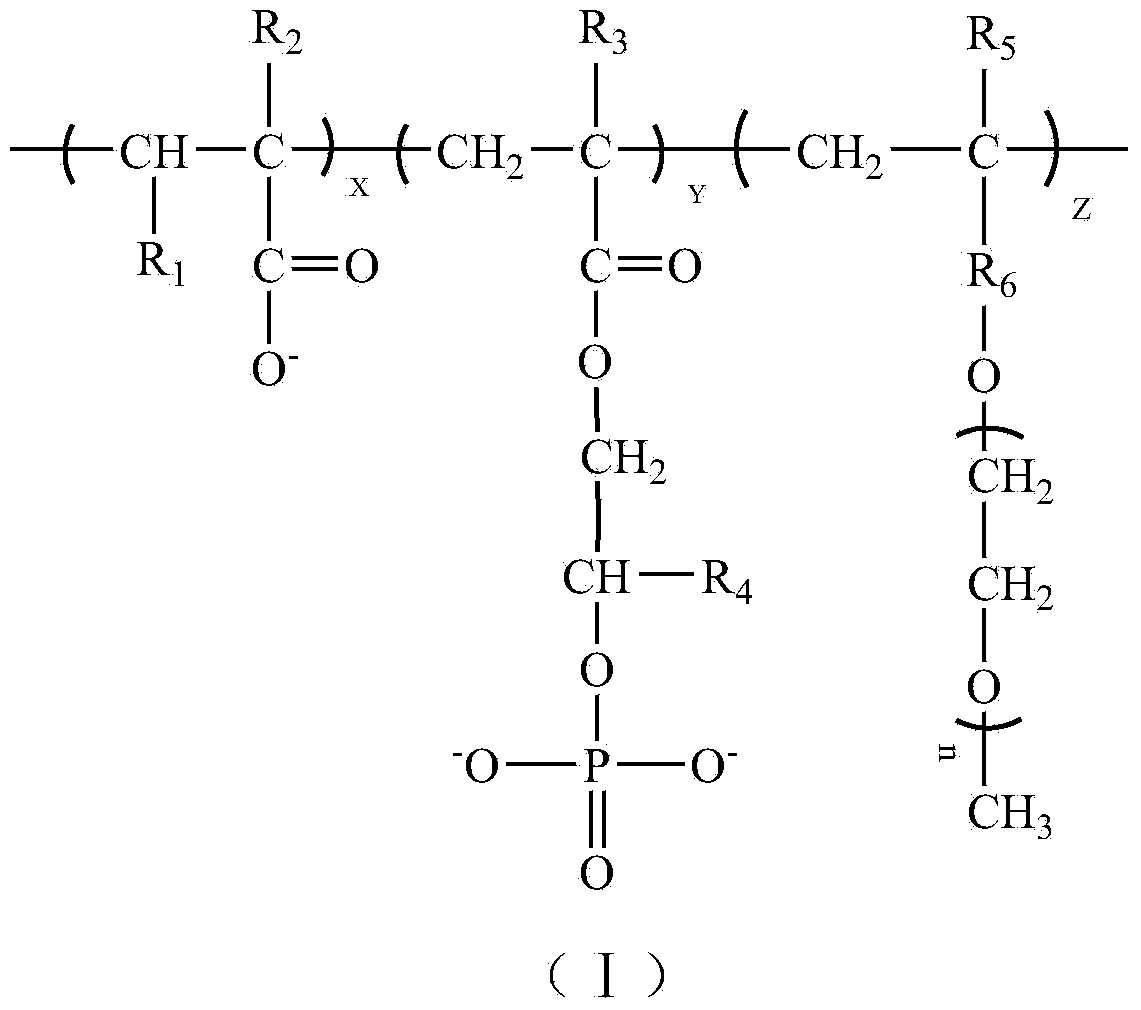

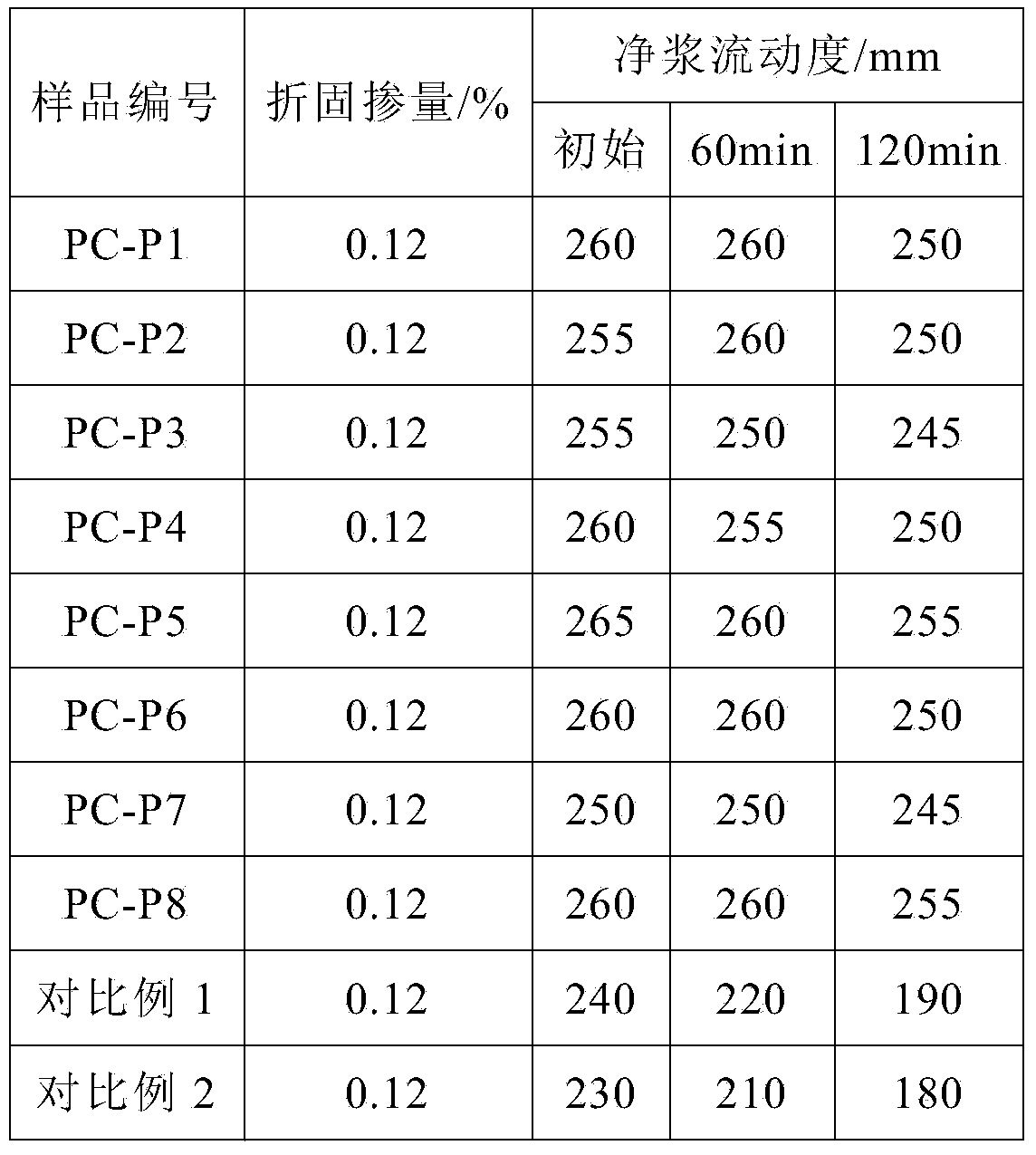

The invention discloses a high-performance polycarboxylate water reducing agent. The polycarboxylate water reducing agent has a structural general formula shown as a structural formula (I). The invention further provides a preparation method of the high-performance polycarboxylate water reducing agent. Apart from a polyether macromonomer and an unsaturated carboxylic acid monomer, an unsaturated phosphate monomer is added to obtain a product, namely, the high-performance polycarboxylate water reducing agent having a phosphate structure. The polycarboxylate water reducing agent disclosed by the invention is safe and simple in preparation process, environmentally friendly, low in energy consumption, low in cost, and suitable for industrial large-scale production. In the structural formula (I), R1 is -H, -COO- or -CH2COO-; R2 is -H or -CH3; R3 is -H or -CH3; R4 is -H or -CH3; R5 is -H or -CH3; R6 is -CH2- or -CH2CH2-; X, Y, Z and n are integers; X=1-100; Y=1-100; Z=1-100; and n=22-53.

Owner:CCCC SHEC WUHAN PORT NEW MATERIALS

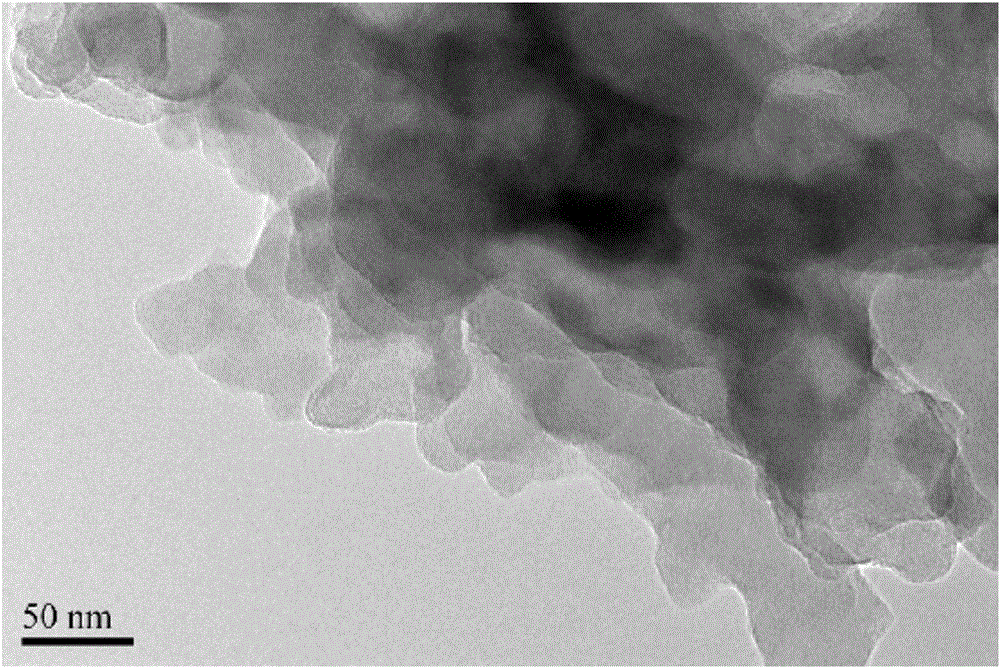

Graphene/mesoporous titanium dioxide visible light catalyst and preparation method

InactiveCN102350334AUniform particle sizeUniform sizePhysical/chemical process catalystsWater/sewage treatment by irradiationDispersityAcetic acid

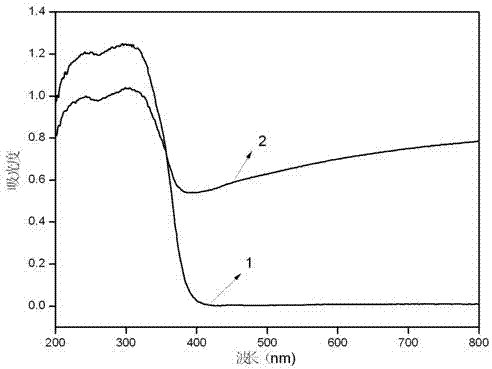

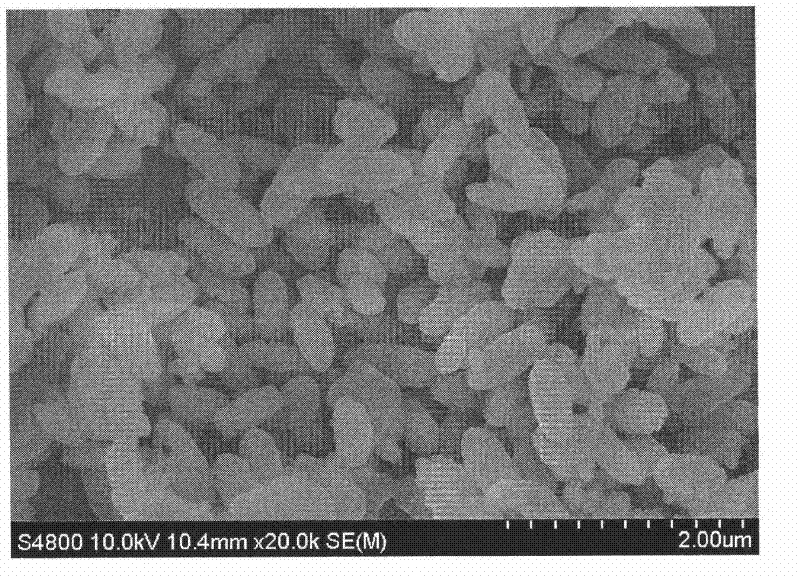

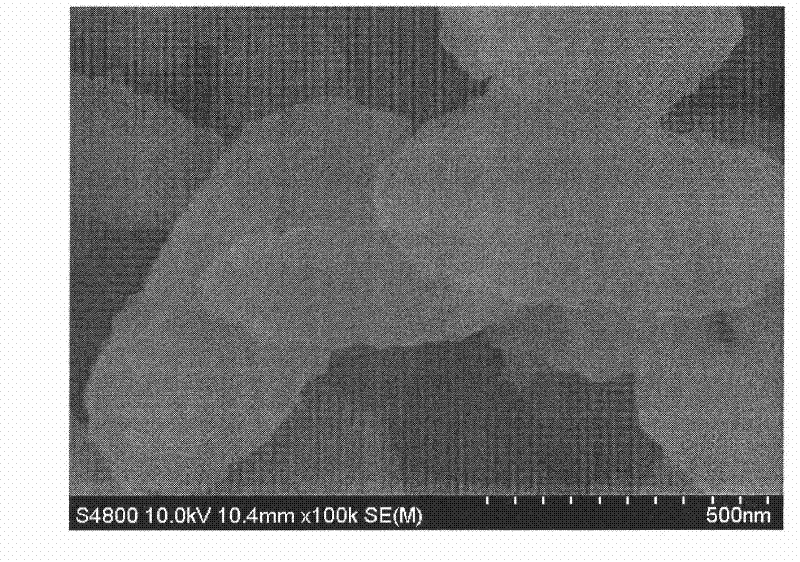

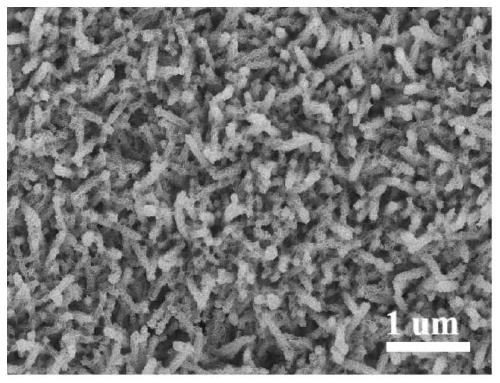

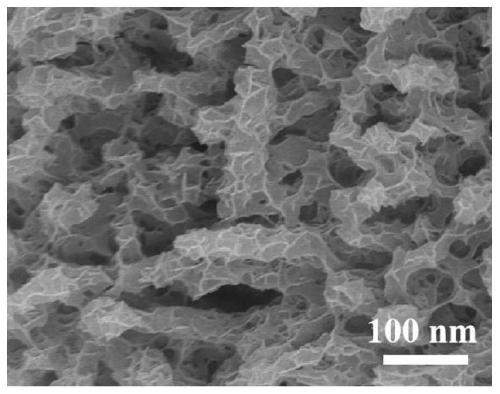

The invention relates to a graphene / mesoporous titanium dioxide visible light catalyst and a preparation method, and belongs to the technical fields of nanometer composite materials and photocatalysis. The method comprises the following steps of: adding a graphene oxide into glacial acetic acid, and performing ultrasonic dispersion to obtain dispersion liquid of the graphene oxide; and adding a titanium source into the dispersion liquid of the graphene oxide, and preparing the graphene / mesoporous titanium dioxide nanometer composite visible light catalyst in a one-step in-situ form by a hydrothermal method. The graphene / mesoporous titanium dioxide visible light catalyst has the advantages of readily available raw materials and low cost, the preparation process is simple and convenient, and titanium dioxide in the obtained nanometer composite material has a nanometer poroid structure, a regular size and a special appearance; and titanium dioxide nanometer granules can be distributed onthe surface of graphene and are high in dispersity. Photocatalytic degradation experiments indicate that the graphene / mesoporous titanium dioxide nanometer composite light catalyst has a good photocatalytic degradation effect on rhodamine B under the irradiation of visible light, and is an ideal nanometer composite visible light catalyst.

Owner:JIANGSU UNIV

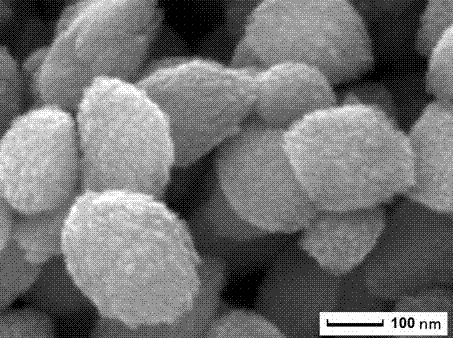

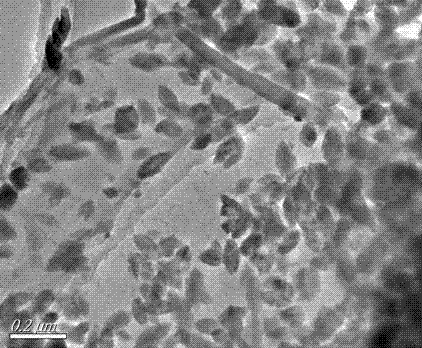

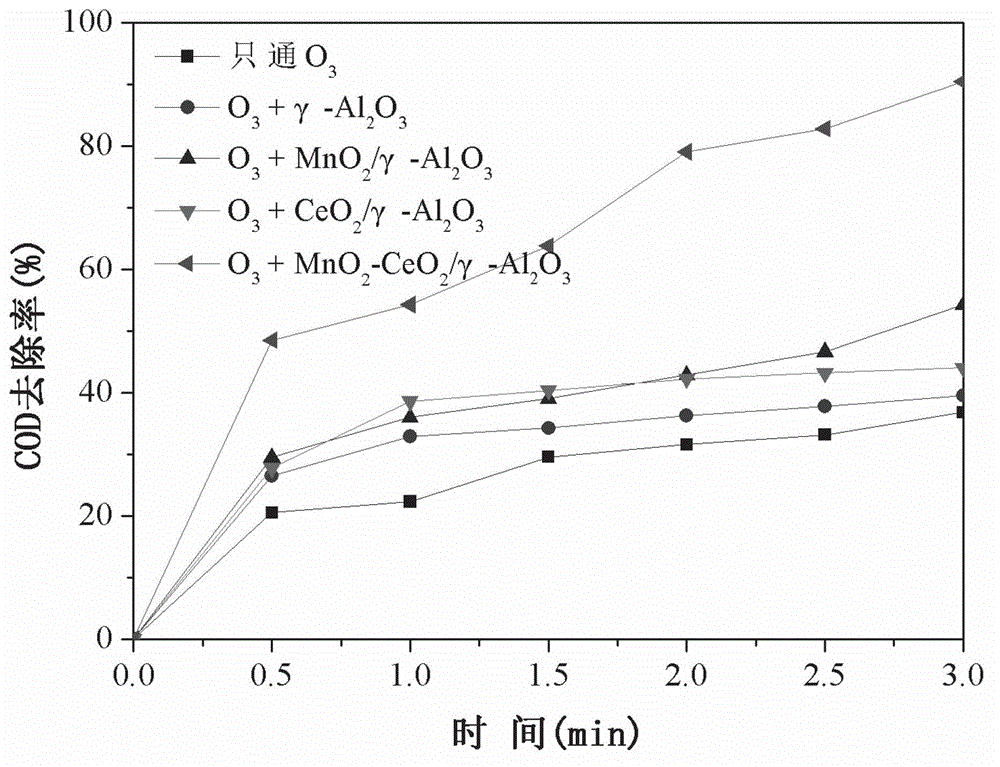

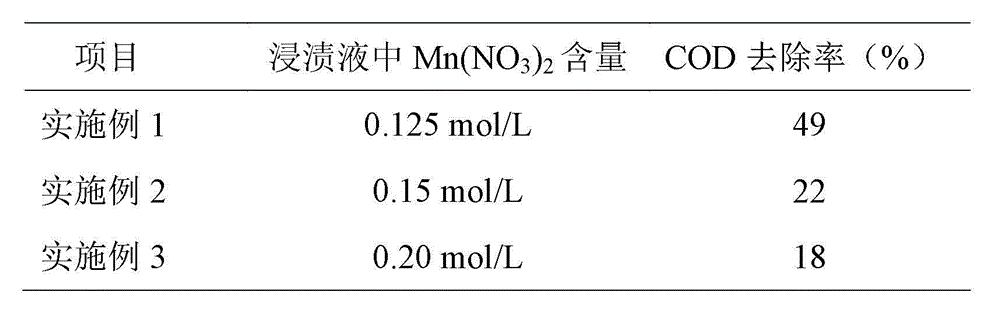

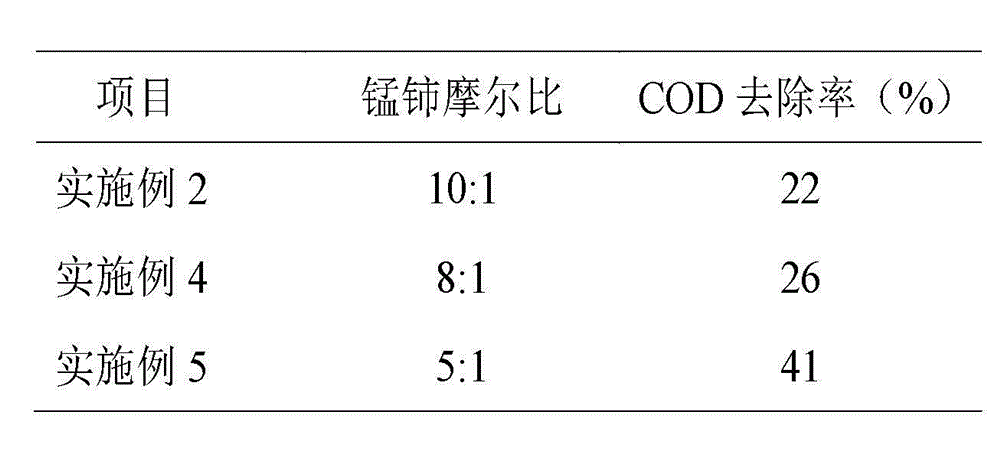

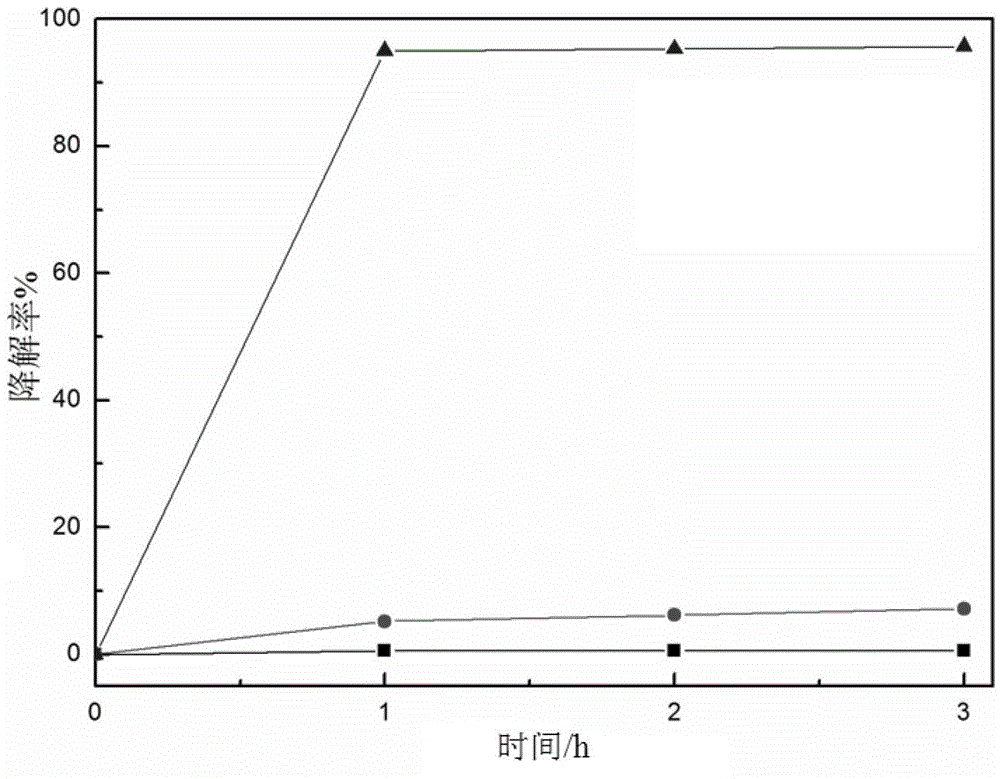

Method for preparing double-component metallic oxide catalytic ozonation catalyst

InactiveCN102941084AThe preparation process is simple and safeReduce manufacturing costMetal/metal-oxides/metal-hydroxide catalystsWater/sewage treatment by oxidationOxideCatalytic ozonation

The invention relates to a method for preparing a double-component metallic oxide catalytic ozonation catalyst. The method is characterized in that, after being activated, gamma-Al2O3 microballoon is soaked in mixed liquor of manganous nitrate and cerous nitrate, and then after drying and roasting, the loading type manganese and cerium double-component composite catalyst is prepared. The catalyst has high catalytic activity, is applied in organic pollutant degradation through catalytic ozonation, remarkably fastened in degradation rate compared with degradation using ozone singly or using unloaded gamma-Al2O3 microballoon, greatly improved compared with loading catalyst using single component of manganese or cerium and capable of reducing input amount of ozone, and according saves operation cost. Simultaneously, the catalyst has the advantages of being simple in preparing method, low in cost, stable in catalytic performance, capable of being repeatedly used and the like and is favorable for popularization and application of the catalytic ozonation technology.

Owner:DALIAN UNIV OF TECH

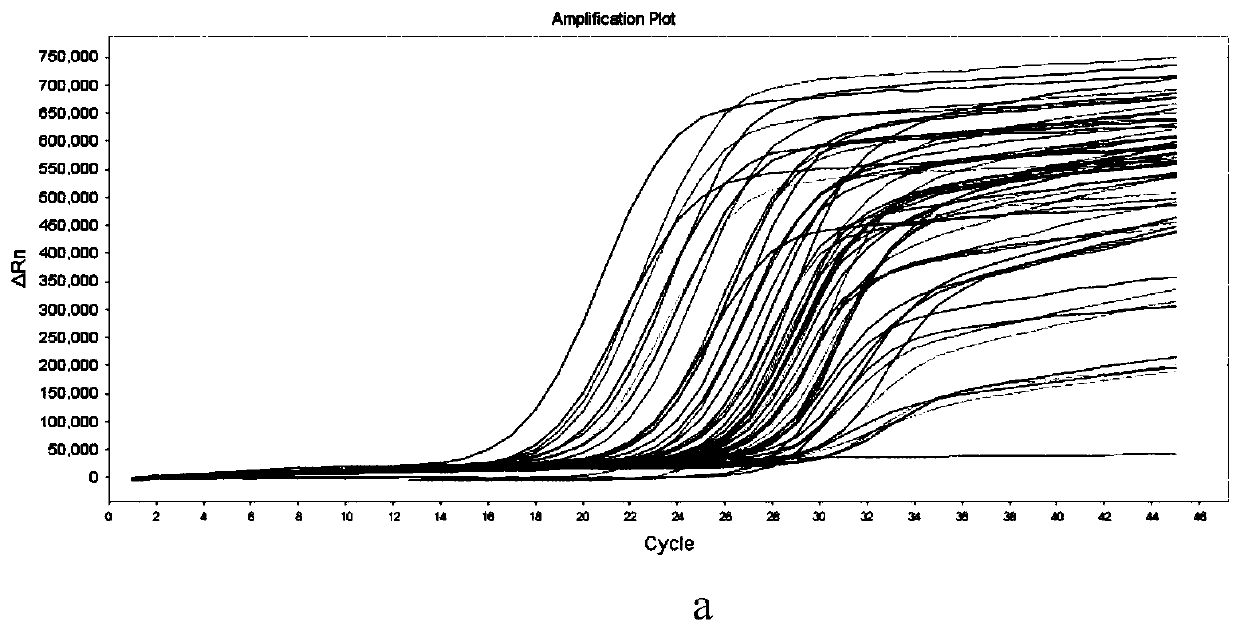

Novel coronavirus detection kit

PendingCN111187858AAccurate detectionPut an end to the possibilityMicrobiological testing/measurementMicroorganism based processesVirologyBioinformatics

The invention discloses a novel coronavirus detection kit. The kit comprises a qRT-PCR reaction liquid, a qRT-PCR enzyme liquid, an internal standard, a negative quality control substance and a positive quality control substance, wherein the internal standard is an RNA pseudovirus containing an internal reference detection gene fragment; the positive quality control substance is an RNA pseudoviruscontaining a target detection gene fragment; and the qRT-PCR reaction liquid comprises four groups of upstream and downstream primers with sequences of SEQ ID NO:1-8 and four probes with sequences ofSEQ ID NO:9-12. The kit can be used to simultaneously detect three sections of target gene fragments, so that missed detection can be effectively avoided. In addition, pseudoviruses are used in boththe internal standard and the positive quality control substance of the kit, so that safety of the kit is effectively improved, and detection accuracy of the kit is further ensured. The kit is high sensitivity and good in stability.

Owner:SICHUAN MACCURA BIOTECH CO LTD

SCR denitration catalyst as well as preparation method and application thereof

ActiveCN102658172AHigh activityGood choicePhysical/chemical process catalystsDispersed particle separationAlkaline earth metalRare earth

The invention discloses an SCR (Selective Catalytic Reduction) denitration catalyst as well as a preparation method and the application of the catalyst, wherein, sulfated zirconia is taken as a carrier, the surface of the carrier is loaded with rare-earth metal oxides that are taken as active ingredients and is loaded with transition metal oxides that are taken as a cocatalyst. The preparation method of the catalyst comprises the steps as follows: (1), zirconia is soaked in sulfuric acid solution, and the sulfated zirconia carrier is obtained after drying and burning are carried out; and (2), the zirconia carrier is in contact with ionic or complexing metal to be loaded proportionally in any sequence, adsorption is performed, and then the SCR denitration catalyst is obtained after drying and burning are carried out. The SCR denitration catalyst achieves excellent alkali metal and alkaline earth metal poisoning resistance when being used for the flue gas denitration, and is especially suitable for the flue gas denitration when the content of alkali metal or alkaline earth metal in flue gas is higher; the denitration efficiency of the SCR denitration catalyst stabilizes at more than 95 percent under a certain condition; and the denitration efficiency can still stabilize at more than 90 percent after being soaked in alkali metal solution or alkaline earth metal solution.

Owner:ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH

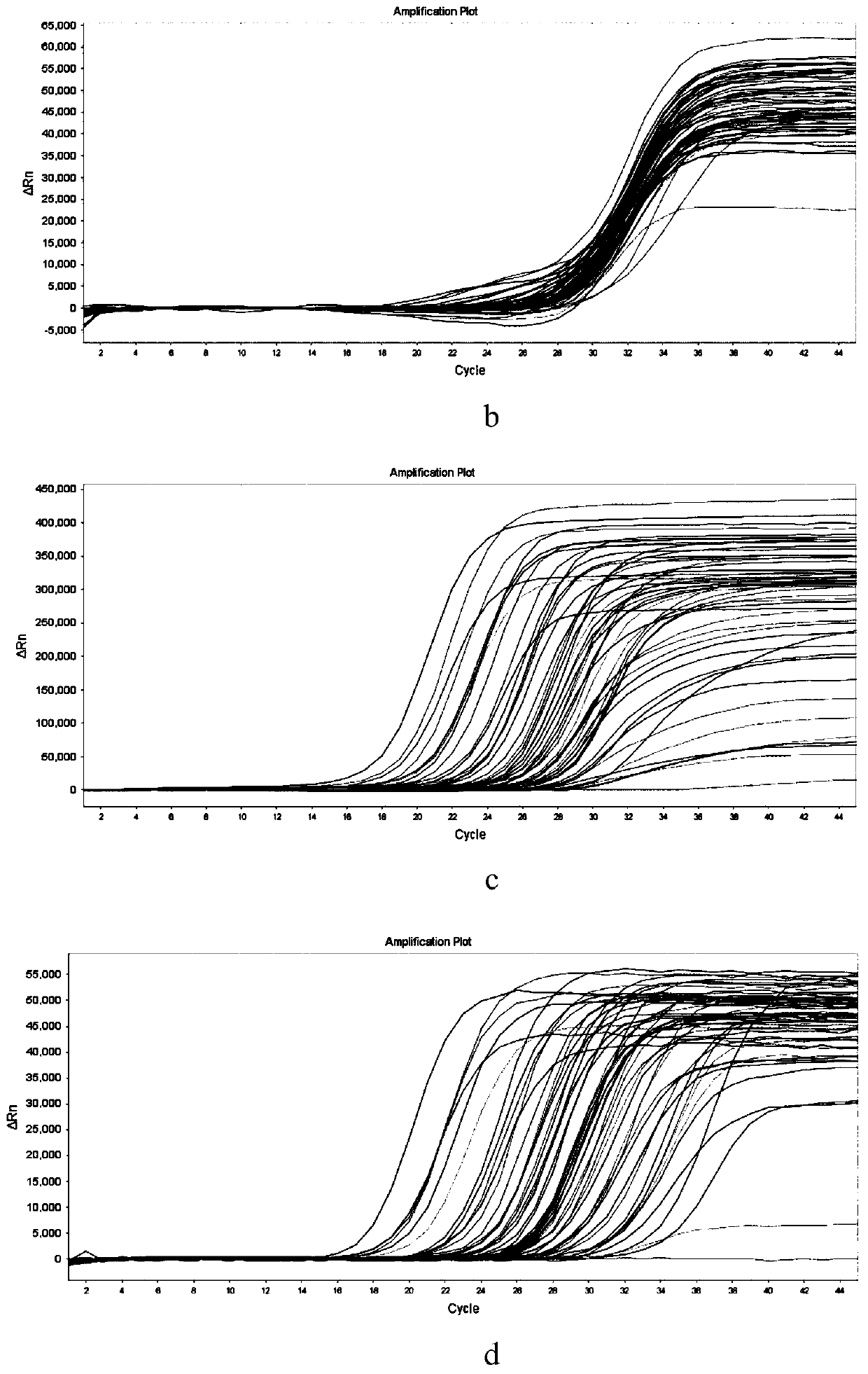

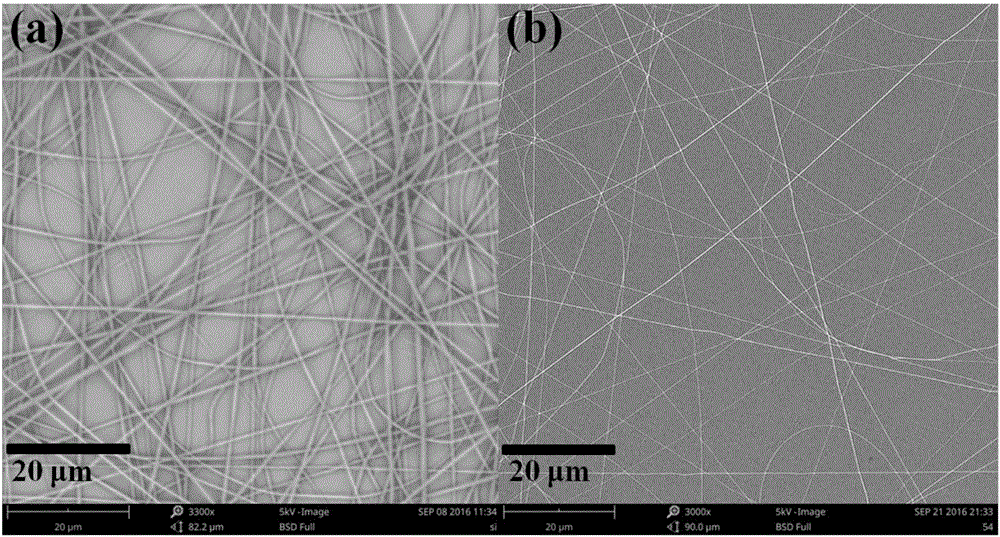

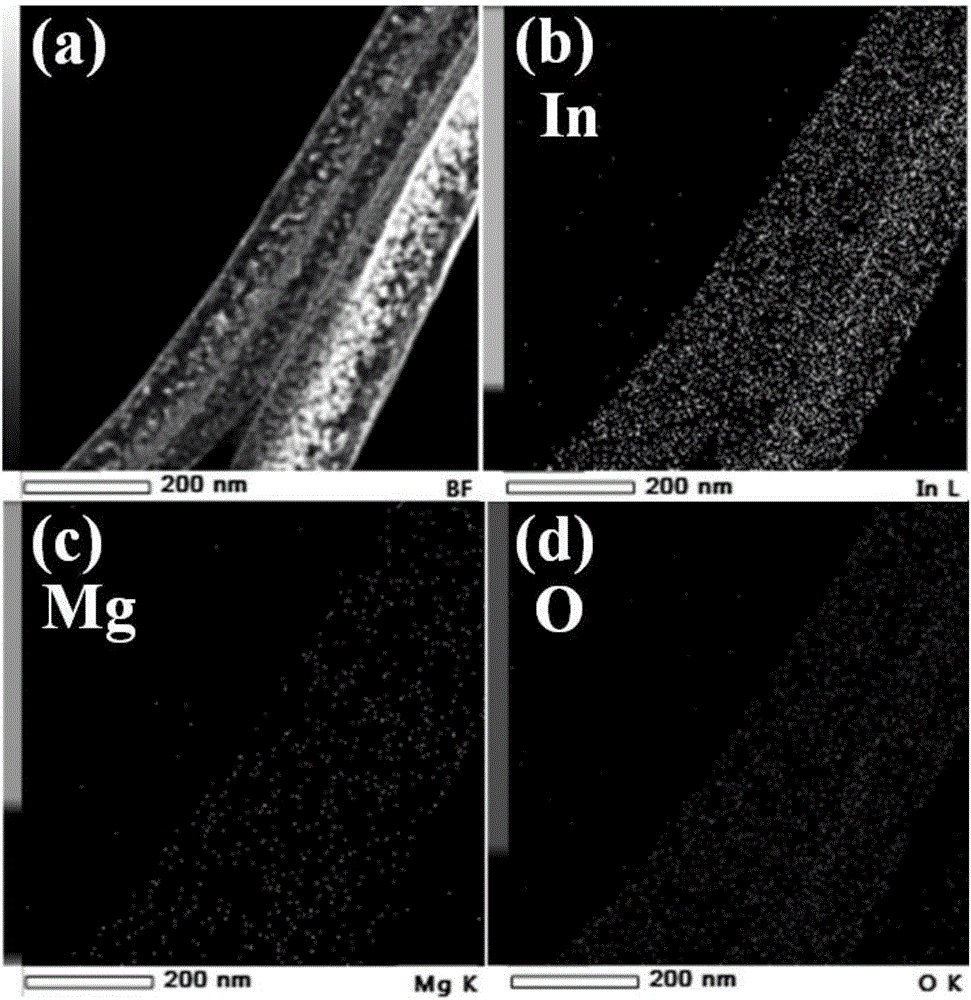

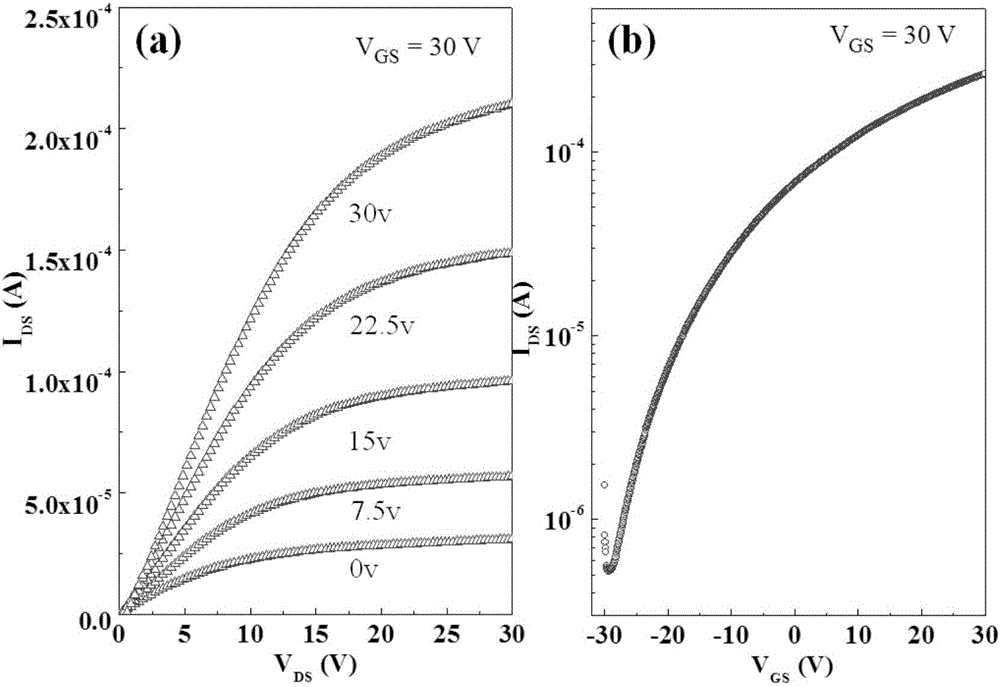

Regulation and control method for electrical property of indium oxide nanofiber field effect transistor

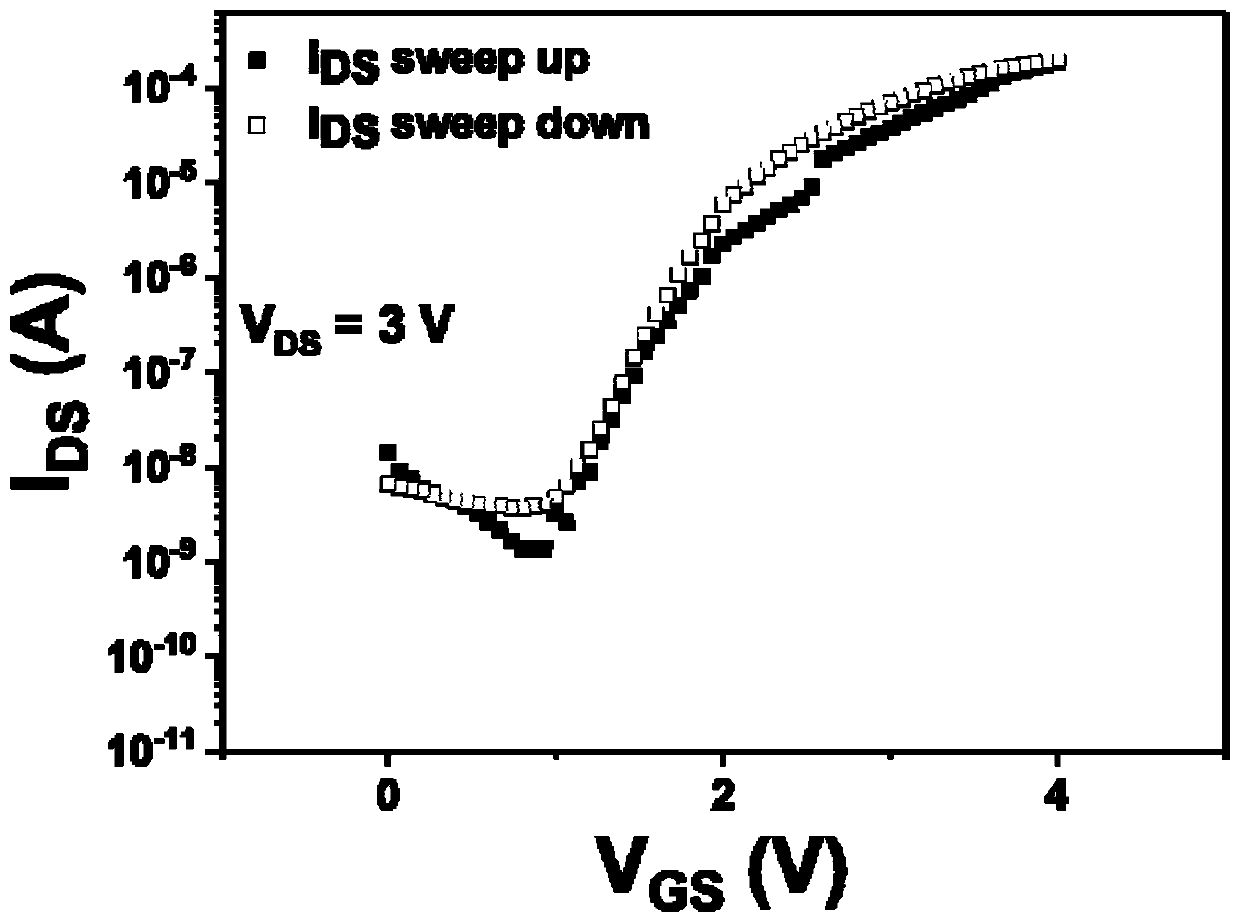

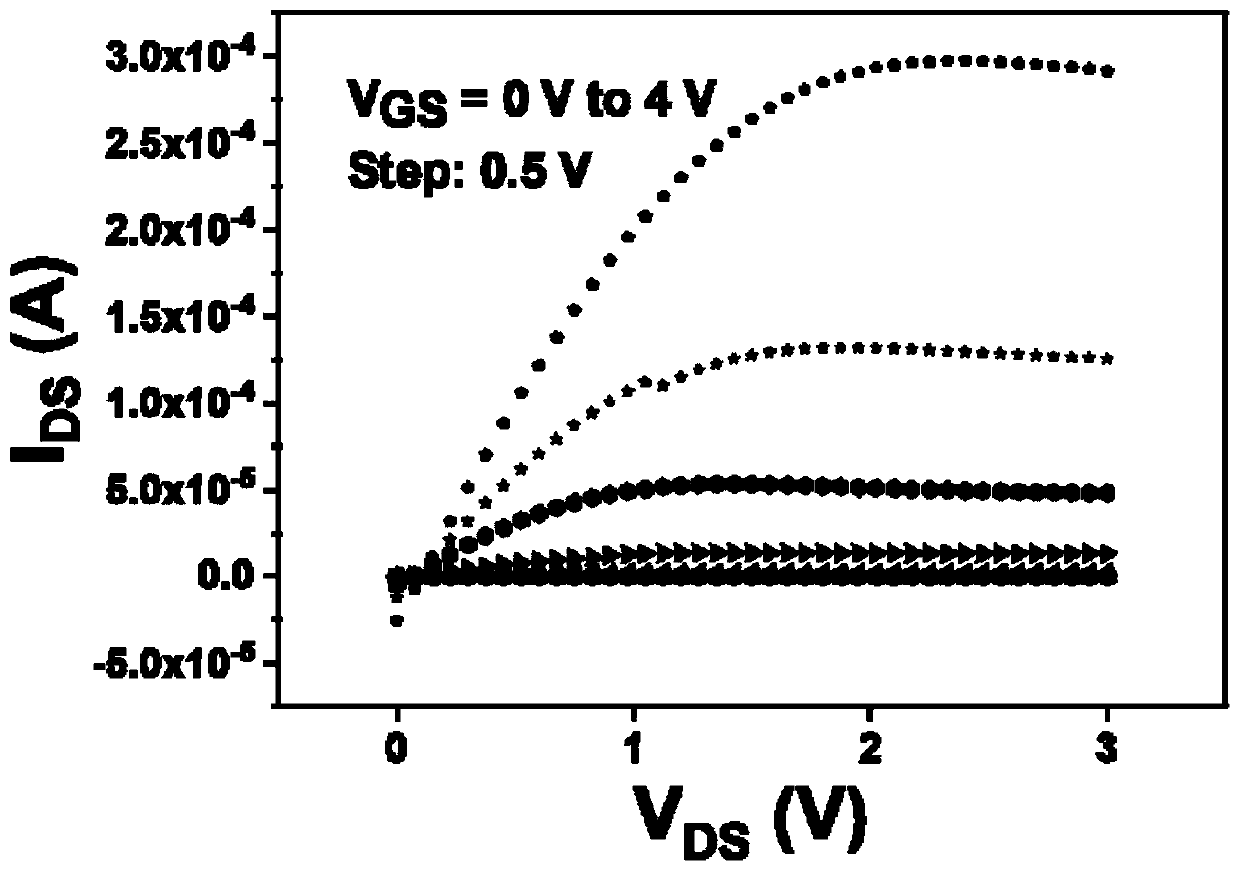

InactiveCN106486541ARegulation transmissionReduce concentrationInorganic material artificial filamentsNanoinformaticsIndiumElectrospinning

The invention belongs to the regulation and control technical field of electrical property of a transistor, and relates to a regulation and control method for electrical property of an indium oxide nanofiber field effect transistor. In<2>O<3> nanofibers are prepared through a simple, convenient and low-cost electrospinning technology; the electrical property of the In<2>O<3> nanofiber field effect transistor is regulated and controlled through simple and feasible metal doping so as to regulate and control the electrical property, such as a threshold voltage, an off-state current, a switching ratio and the like, of the In<2>O<3> nanofiber field effect transistor in a simple and convenient, efficient and low-cost manner, in order to obtain the excellent-performance and metal-doped In<2>O<3> nanofiber field effect transistor; the preparation process is simple, convenient, and safe, and the principle is reliable, and the production cost is low; and the prepared In<2>O<3> nanofibers and the metal-doped In<2>O<3> nanofibers have wide application prospect in the fields of an electronic switching device, a display, biological and chemical sensors and the like, and large-scale industrial production can be performed easily.

Owner:QINGDAO UNIV

Preparation method for bismuth oxyiodide/graphene oxide compound visible light catalytic material

InactiveCN102941105ALow costThe preparation process is simple and safePhysical/chemical process catalystsIodideBismuth

A preparation method for a bismuth oxyiodide / graphene oxide compound visible light catalytic material relates to a preparation method of the visible light catalytic material. The preparation method aims at solving the problems in the compound light catalytic material prepared through the existing method of being complex in operation, long in periodicity, high in requirement for devices and not suitable for large-scale production. The bismuth oxyiodide / graphene oxide compound visible light catalytic material is prepared through iodide, Bi(NO3)3-5H2O and the graphene oxide dispersion liquid. The method includes: 1 preparing graphene oxide dispersion liquid; 2 mixing and stirring iodide, Bi(NO3)3-5H2O and the graphene oxide dispersion liquid to obtain turbid liquid; and 3 conducting ultrasonic processing, then filtering, washing and drying sequentially to obtain the bismuth oxyiodide / graphene oxide compound visible light catalytic material. The preparation method is mainly used for preparing the bismuth oxyiodide / graphene oxide compound visible light catalytic material.

Owner:HARBIN NORMAL UNIVERSITY

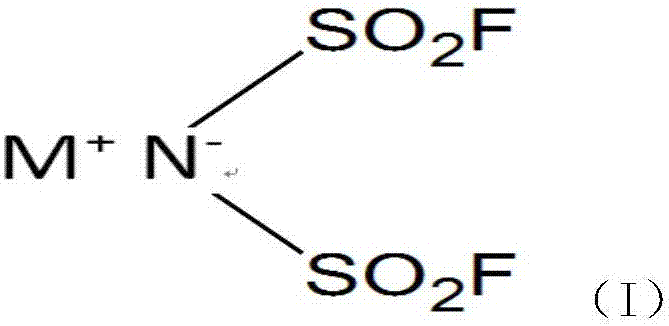

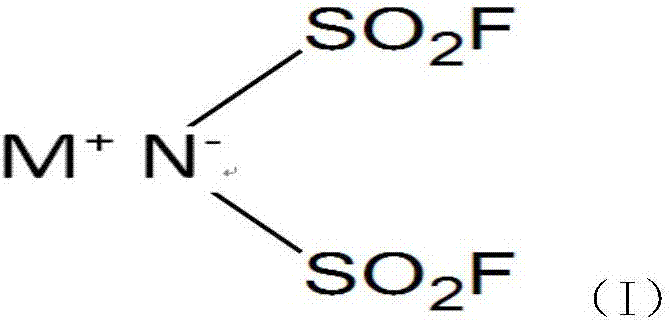

Preparation method of bis(fluorosulfonyl)imide salt

ActiveCN107226461AThe preparation process is simple and safeSuitable for industrial applicationsNitrosyl chlorideImideHigh activity

The invention discloses a method for preparing bis(fluorosulfonyl)imide salt. The method comprises the following steps: reacting bis(chlorosulfonyl)imide and a fluorination reagent to obtain bis(fluorosulfonyl)imide; and reacting the bis(fluorosulfonyl)imide and an alkali metal salt chelator to obtain the corresponding bis(fluorosulfonyl)imide salt. The method provided by the invention does not need the use HF and other high-activity compounds, and is simple and safe in preparation process, thereby being suitable for industrialization application.

Owner:ZHEJIANG RES INST OF CHEM IND CO LTD +2

Method for preparing graphite phase carbon nitride nanosheet through airtight oxidation

ActiveCN106517115APrevent escapeAvoid lostMaterial nanotechnologyNitrogen and non-metal compoundsBiological imagingPolytetrafluoroethylene

The invention discloses a method for preparing a graphite phase carbon nitride nanosheet through airtight oxidation. The method comprises the following steps: with a layered graphite phase carbonitride material as a raw material, putting the layered graphite phase carbonitride material, potassium permanganate and concentrated sulfuric acid in an enclosed reaction vessel with a polytetrafluoroethylene lining for a pressurized oxidation reaction so as to obtain oxidized graphite phase carbon nitride; removing unreacted potassium permanganate with hydrogen peroxide; carrying out washing with hydrochloric acid and distilled water; and then carrying out drying so as to obtain the graphite phase carbon nitride nanosheet. Compared with conventional methods, the method provided by the invention has the advantages of less operation steps, low temperature requirement and short reaction time. The prepared graphite phase carbon nitride nanosheet has high purity and few structural defects and has extensive application prospects in fields like heterogeneous catalysis, photocatalysis and biological imaging.

Owner:OCEAN UNIV OF CHINA

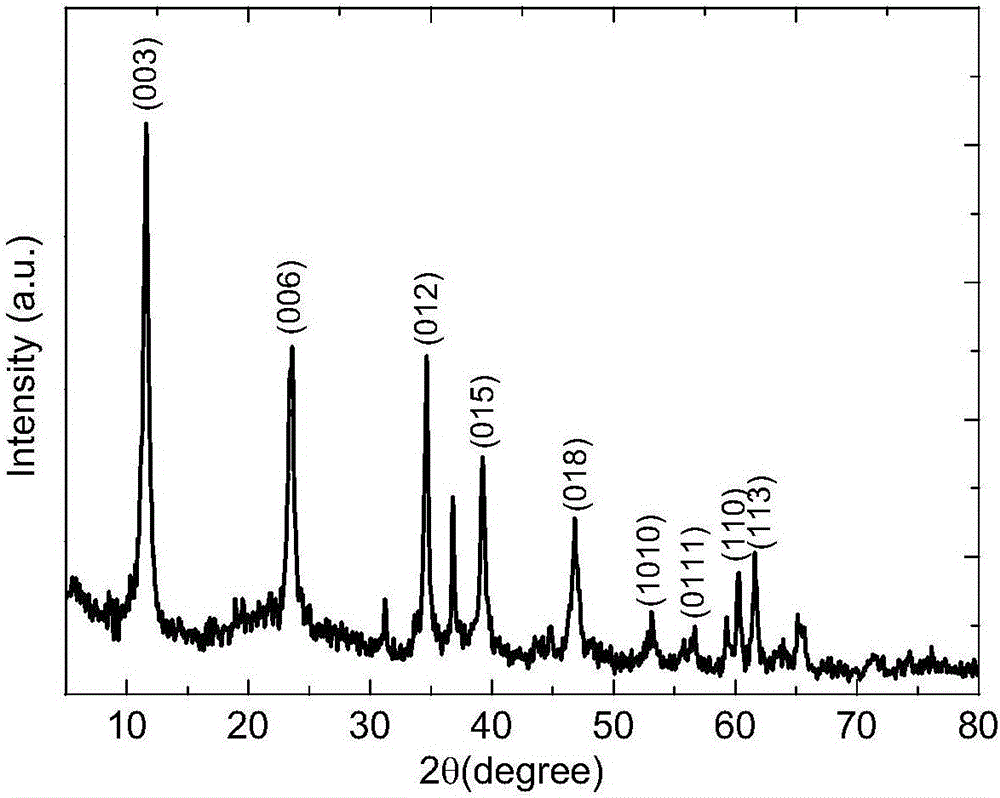

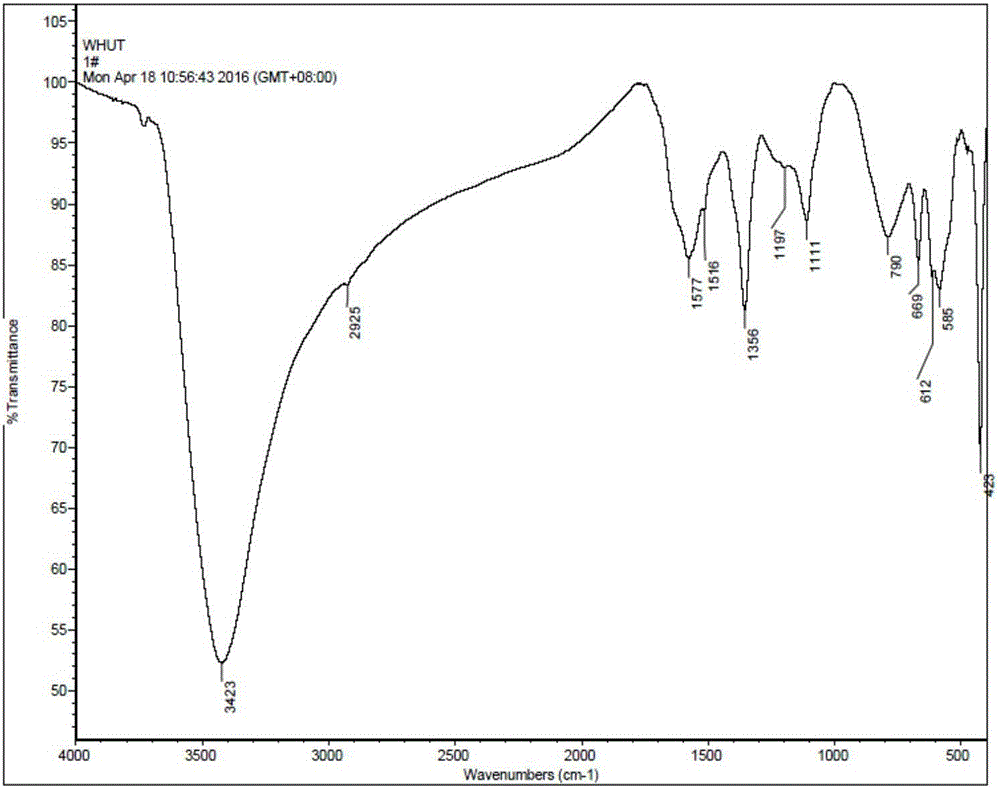

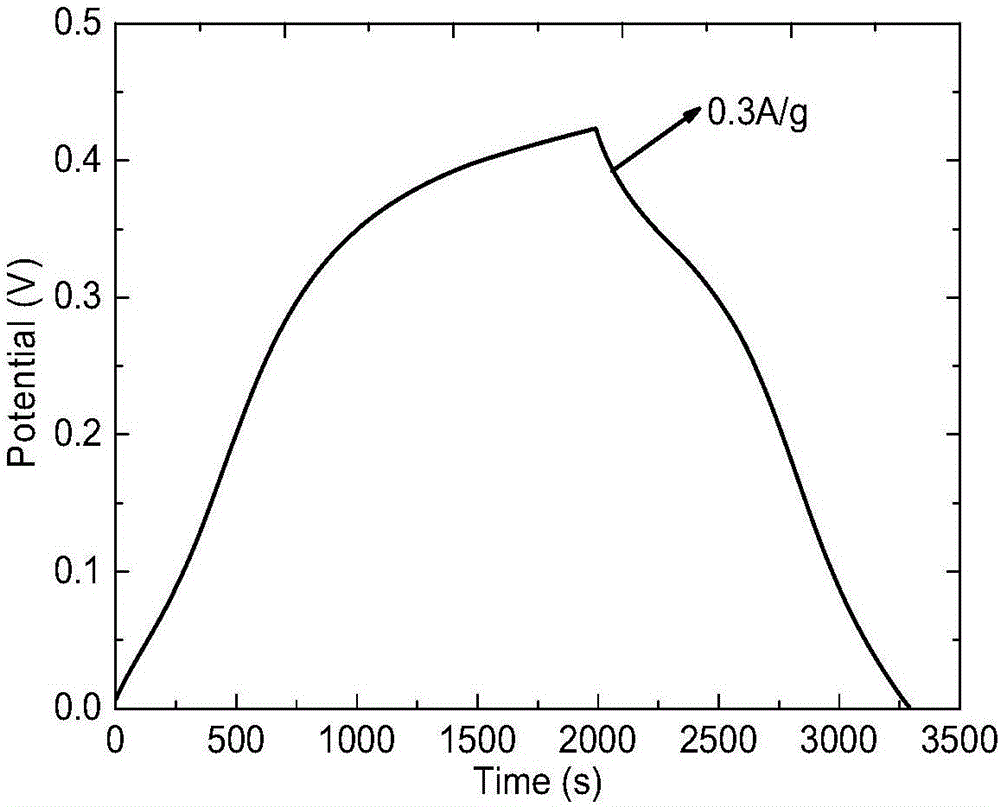

Cobalt aluminum hydrotalcite/fluorinated graphene composite material, and preparation method thereof

ActiveCN106206056AImprove electrochemical performanceImprove stabilityHybrid capacitor electrodesCobalt compoundsHigh pressureCrusher

This invention relates to a cobalt aluminum hydrotalcite / fluorinated graphene composite material, and a preparation method thereof. The composite material is prepared by the steps of: 1) preparing graphite oxide powder by a Hummers method; 2) dispersing the graphite oxide powder in deionized water; stripping by an ultrasonic cell crusher; centrifuging by a centrifuge; obtaining supernatant liquor; adding hydrofluoric acid solution in the supernatant liquor to stir and react; putting the solution into a high-pressure reactor to perform constant-temperature fluoridation; cooling to room temperature; filtering and washing till the solution is neutral, so as to obtain the fluorinated graphene; 3) dispersing the fluorinated graphene in ethanol solution; stripping by the ultrasonic cell crusher to obtain fluorinated graphene suspension; 4) adding cobalt sulfate heptahydrate, aluminum chloride hexahydrate and urea into the fluorinated graphene suspension to stir and react; putting the solution into the high-pressure reactor to perform hydrothermal reaction; then cooling to the room temperature; and obtaining the cobalt aluminum hydrotalcite / fluorinated graphene composite material after post-processing.

Owner:WUHAN UNIV OF TECH

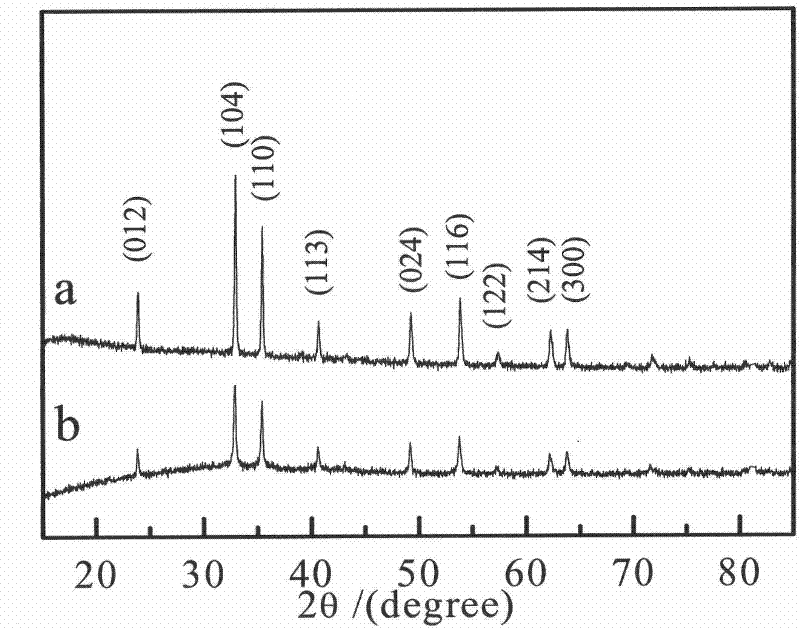

A kind of preparation method and application of rice granular α-ferric oxide

InactiveCN102259933AHigh structural purityImprove electrochemical performanceCell electrodesNanotechnologyIron saltsFreeze-drying

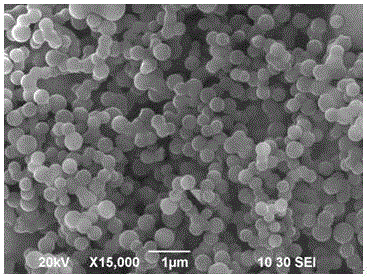

The invention discloses a preparation method and application of rice-like alpha-iron trioxide. The preparation process adopts a hydrothermal reaction method, and the specific steps are as follows: first, mechanical stirring is used to uniformly disperse the iron salt and the surfactant in deionized water to obtain a mixed solution; the mixed solution is placed in a reactor for hydrothermal reaction; finally, the obtained The product is washed and freeze-dried to obtain a precursor; then the precursor is calcined at 200-900° C. for 1-40 hours, cooled to room temperature and ground to obtain red rice-like ferric oxide powder material. The invention has the advantages of wide source of raw materials, simple preparation method, convenient operation, green and pollution-free, and the obtained material has high structural purity, regular morphology and uniform particle size distribution. It can reach more than 1000mAh / g, and has better cycle life.

Owner:CHINA UNIV OF MINING & TECH

Preparation method and application of corn starch porous carbon packaged core-shell structure silicon/carbon material

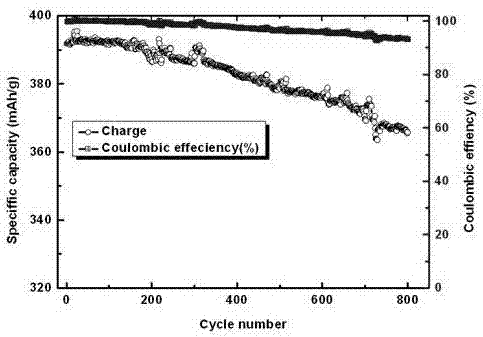

InactiveCN107528063AThe preparation process is simple and safeImprove cycle lifeMaterial nanotechnologyCell electrodesWater bathsPorous carbon

The invention discloses a preparation method and application of a corn starch porous carbon packaged core-shell structure silicon / carbon material. The preparation method comprises the following steps: firstly, preparing a buffering solution; adding the buffering solution and amylase into corn starch; carrying out enzymolysis in a water bath under a magnetic force; carrying out washing and drying treatment on the corn starch; then, carrying out pre-oxidization and putting a pre-oxidized material into a muffle furnace; carrying out calcination in a protective atmosphere to obtain a target product; taking nano silicon powder and glucose and carrying out magnetic stirring and ultrasonic dispersion; transferring suspension liquid into a high-pressure reaction kettle and carrying out hydrothermal reaction; after cooling the material to room temperature, carrying out water washing and drying; transferring the material into a tubular furnace and carrying out the calcination in the protective atmosphere; cooling and grinding to obtain a target product; weighing corn starch porous carbon and a core-shell structure silicon / carbon material and stirring and dispersing; then carrying out vacuumizing, water washing and drying to obtain a target product. When the material prepared by the preparation method is used as a negative electrode material of a lithium-ion battery, the material has relatively good cycle life and rate performance.

Owner:河南新太行电源股份有限公司

Environment-friendly water-based automobile shellac cleaning agent and preparation method thereof

InactiveCN102559401ANon-volatileReduce washing costsInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsWater basedShellac

The invention discloses an environment-friendly water-based automobile shellac cleaning agent. The environment-friendly water-based automobile shellac cleaning agent consists of the following components: fatty alcohol-polyoxyethylene ether phosphate, limonene, fatty acid diethanol amide, sodium carbonate and deionized water. The cleaning agent is prepared by compounding various non-toxic surfactants with excellent biodegradability and aids, has obvious synergistic effect among the components, can effectively remove shellac dirt form the surface of the automobile and has a good anti-rust effect on metal. The production method is simple to operate and low in production cost, and has good environmental and economic value.

Owner:任航

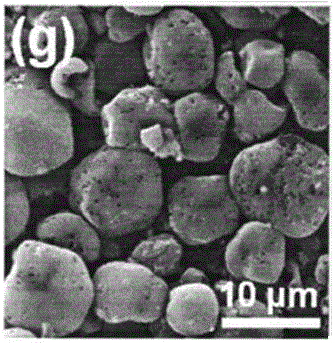

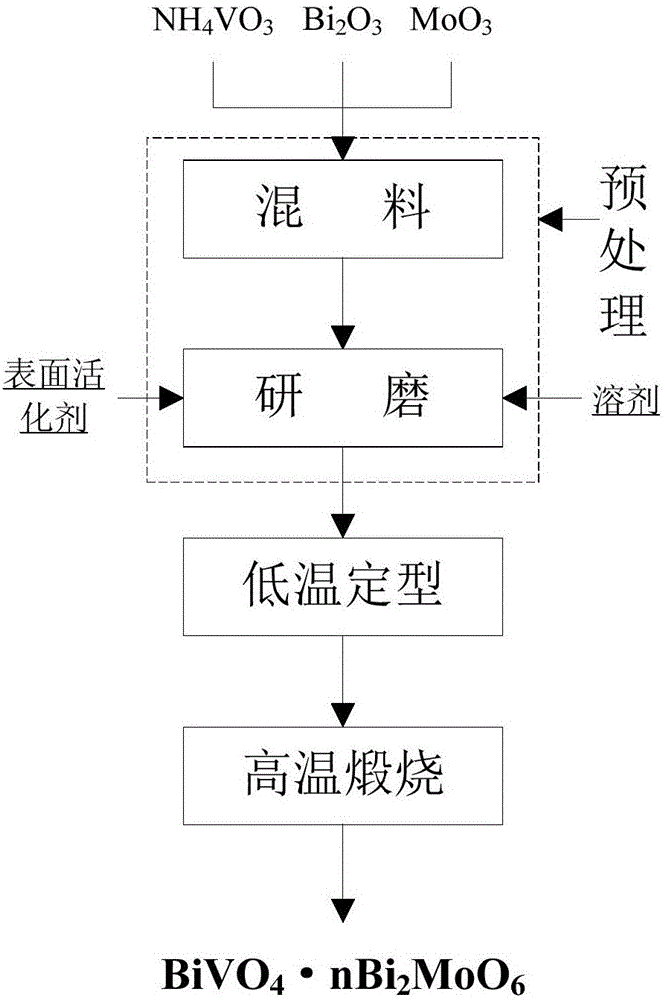

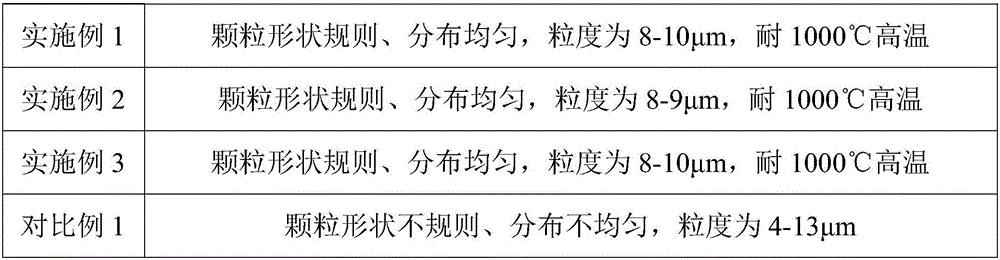

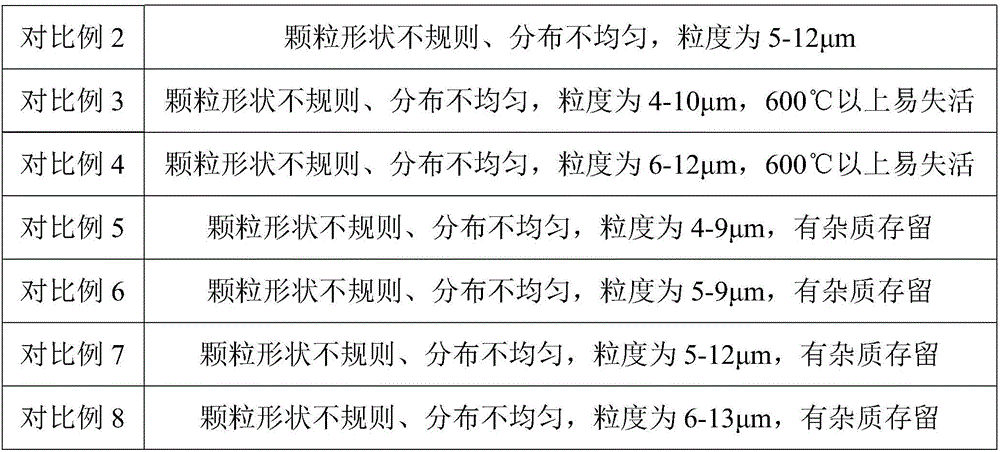

Preparation method of bismuth vanadate molybdate pigment

The invention provides a preparation method of a bismuth vanadate molybdate pigment, comprising the following steps: pretreatment of raw materials; primary calcination of the pretreated raw materials to obtain a precursor; and secondary calcination of the precursor to obtain the bismuth vanadate molybdate pigment. Calcination is performed twice in four steps, and after the raw materials are subjected to low temperature calcination for setting, high temperature calcination and curing, the bismuth vanadate molybdate pigment with good quality and high temperature resistance is obtained. The method provided by the invention avoids the problem of consumption of large amounts of acid and alkali in a liquid phase settling-calcination method, and is favorable for reducing the production cost; and the preparation process is simple, safe and easy to be industrialized.

Owner:HEBEI IRON AND STEEL

Preparation method and application of corn starch porous carbon@graphite

InactiveCN107359345AThe preparation process is simple and safeImprove cycle lifeMaterial nanotechnologyNegative electrodesWater bathsPorous carbon

The invention discloses a preparation method and application of corn starch porous carbon@graphite. The preparation method comprises the steps of firstly, weighing disodium hydrogen phosphate and citric acid to prepare a buffer solution, slowly adding the buffer solution and amylase to corn starch, performing water bath, performing enzymolysis under magnetic stirring, and cleaning and drying the solution; secondly, performing pre-oxidation; and finally, placing the pre-oxidized material in a muffle furnace for calcination, wherein the selected corn starch porous carbon is of a spherical structure, macropore structures and mesoporous structures are formed in a spherical surface by simple enzymolysis, pre-oxidization and carbonization technologies, the corn starch porous carbon prepared in the previous steps and a graphite material are accurately weighed and are placed in an agate ball milling tank according to a certain proportion, ball-milling and mixing are performed by an XQM planetary ball-milling machine, and drying and grinding are performed to obtain a target product. The preparation method has the advantages that the preparation process is simple and safe, and the prepared battery negative electrode has relatively long cycle lifetime and rate performance.

Owner:河南新太行电源股份有限公司

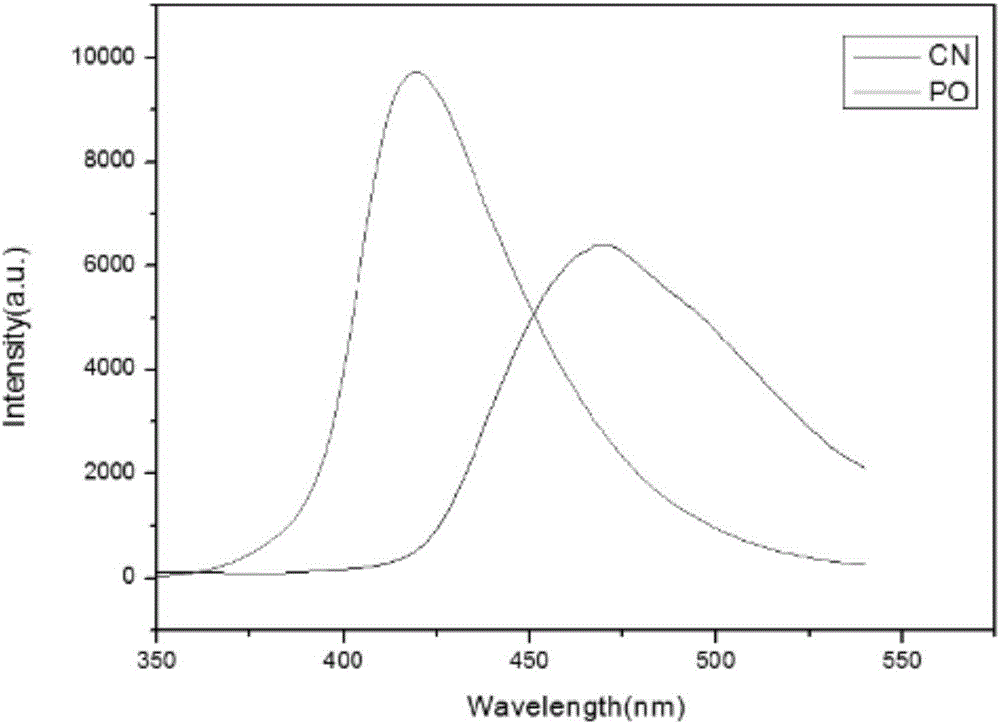

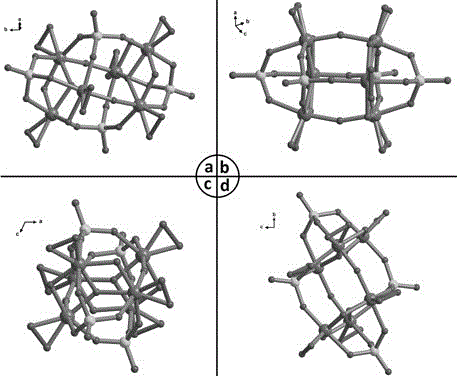

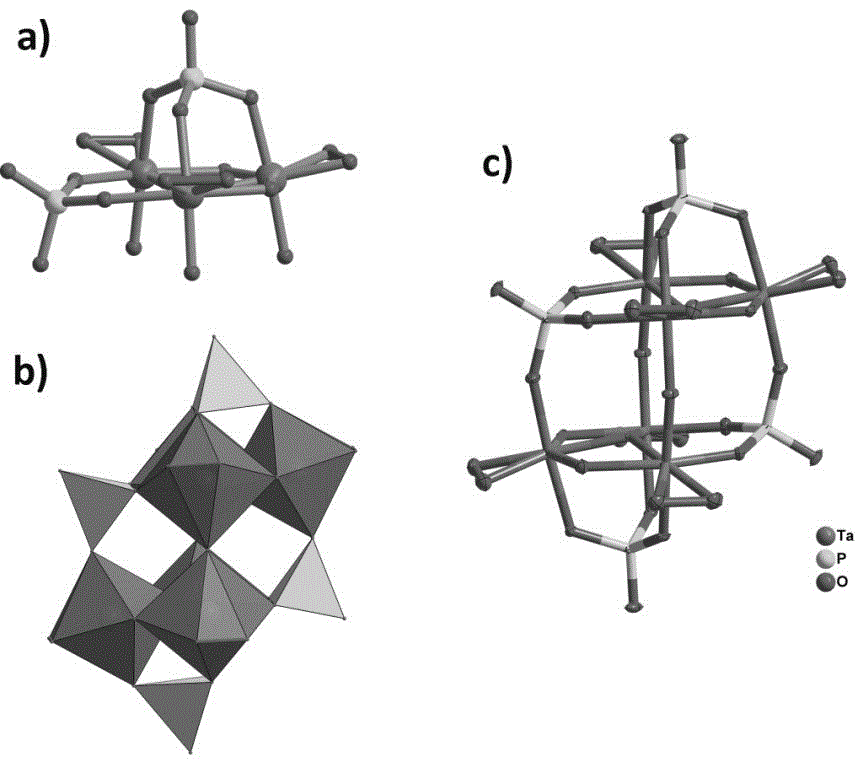

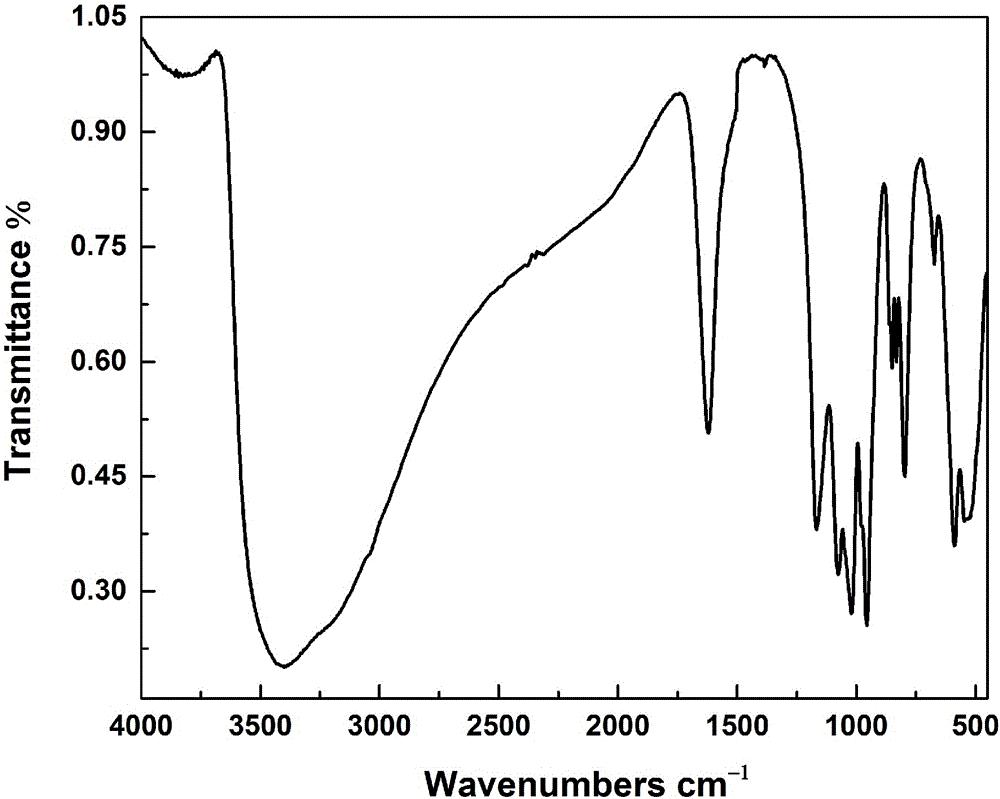

Novel heterotantalate and preparation method and application thereof

ActiveCN106732775AClear structureImprove stabilityWater/sewage treatment by irradiationOrganic-compounds/hydrides/coordination-complexes catalystsFluorescenceMethyl blue

The invention discloses novel heterotantalate. A chemical formula of the novel heterotantalate is K3[H3P4(TaO2)6(OH)4O20].12H2O, the crystal belongs to the monoclinic system, the space group is P2(1 / C), the lattice parameter is a=12.6862(10)angstrom, b=9.9322(8)angstrom, c=16.8359(13)angstrom, and beta=105.3940(10)angstrom. The novel heterotantalate is prepared by enabling potassium hexatantalate to react with phosphoric acid under a conventional hydrogen peroxide solution condition. The material has high stability, and has the performances of photocatalytically degrading Rhodamine B, azophloxine and methyl blue; furthermore, the novel heterotantalate is simple in preparation process, easy to operate, low in cost, high in yield, and has a potential application prospect.

Owner:HENAN UNIVERSITY

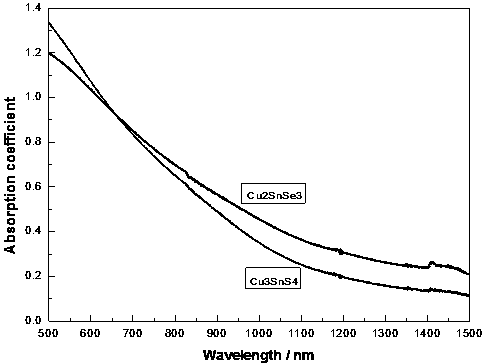

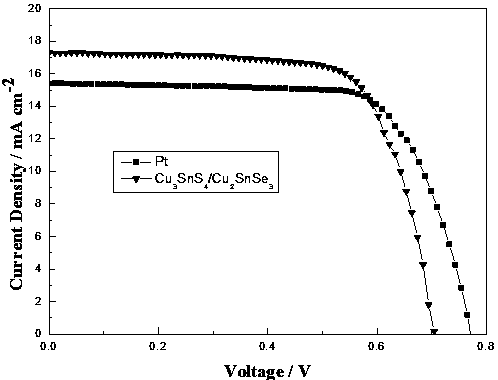

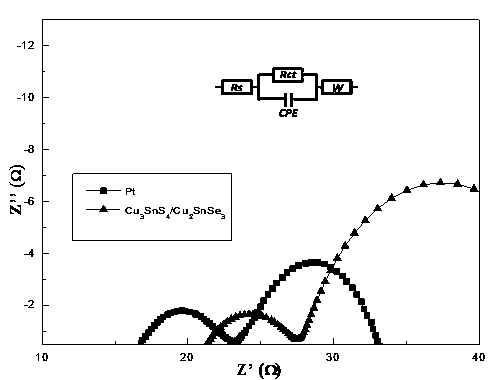

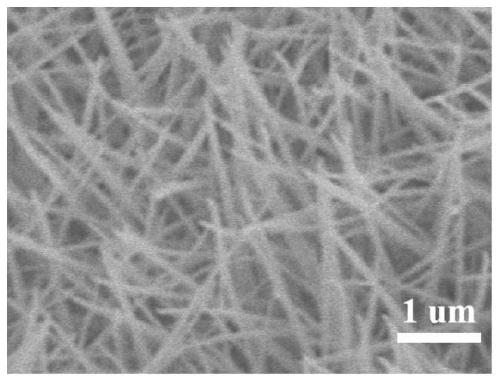

Cu3SnS4/Cu2SnSe3 composite photocathode for photoelectrochemical solar cell and preparation method thereof

InactiveCN103714973AThe photoelectric conversion efficiency is quiteThe preparation process is simple and safeLight-sensitive devicesIonCorrosion

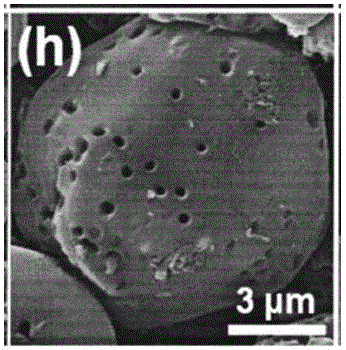

The invention relates to a Cu3SnS4 / Cu2SnSe3 composite photocathode for a photoelectrochemical solar cell and a preparation method of the Cu3SnS4 / Cu2SnSe3 composite photocathode. The preparation method includes the steps that firstly, Cu3SnS4 nano-particles with the diameter ranging from 200 nanometers to 300 nanometers and Cu2SnSe3 nano-particles with the diameter ranging from 250 nanometers to 350 nanometers are synthesized through the solvothermal method; secondly, mechanical agitation and ultrasonic treatment are carried out on the Cu3SnS4 nano-particles and the Cu2SnSe3 nano-particles respectively, and the Cu3SnS4 nano-particles and the Cu2SnSe3 nano-particles are dissolved in deionized water to form 'ink' through ultrasonic treatment; thirdly, the black 'ink' is applied to a conducting substrate, and then annealing is carried out for 0.5-1h under the temperature of 450DEG C-550DEG C to obtain the mesoporous Cu3SnS4 / Cu2SnSe3 composite photocathode. According to the method, the mesoporous Cu3SnS4 / Cu2SnSe3 composite photocathode adopted as the photocathode of the photoelectrochemical solar cell is good in corrosion resistance, large in specific area, good in catalytic performance and conductivity and low in production cost; the photoelectric conversion efficiency of the cell prepared through the method is as high as that of a traditional Pt counter electrode, and therefore the method is suitable for industrialized production of photoelectrochemical solar cells.

Owner:CHINA UNIV OF MINING & TECH

Preparation method and applications of core-shell zinc oxide@zinc oxide@molybdenum trioxide nano array composite film

ActiveCN111039574AUniform colorImprove stabilityHybrid capacitor electrodesCoatingsElectrolytic agentNanowire

The invention discloses a preparation method and applications of a core-shell type zinc oxide@zinc oxide@molybdenum trioxide nano array composite film, and relates to a preparation method and applications of a core-shell type zinc oxide@zinc oxide@molybdenum trioxide nano array composite film. In the prior art, the existing MoO3 and ZnO serving as electrode materials are low in conductivity, the surface energy can be increased due to material nanocrystallization, nano materials are extremely easy to disorderly accumulate and agglomerate, and the nano materials are also easy to generate side reaction with electrolyte to cause structural degradation, so that the electrochemical stability becomes poor. A purpose of the invention is to solve the problems in the prior art. According to the invention, a ZnO@ZnO core-shell structure nano array and nanosheet / transparent conductive base low composite film is prepared by using zinc nitrate, sodium hydroxide, ammonia water and a molybdenum targetmaterial as raw materials, and then a ZnO@ZnO@MoO3 core-shell nanowire and nanosheet array / transparent conductive base low composite film is obtained by using a molybdenum target material as a raw material.

Owner:HARBIN UNIV OF COMMERCE

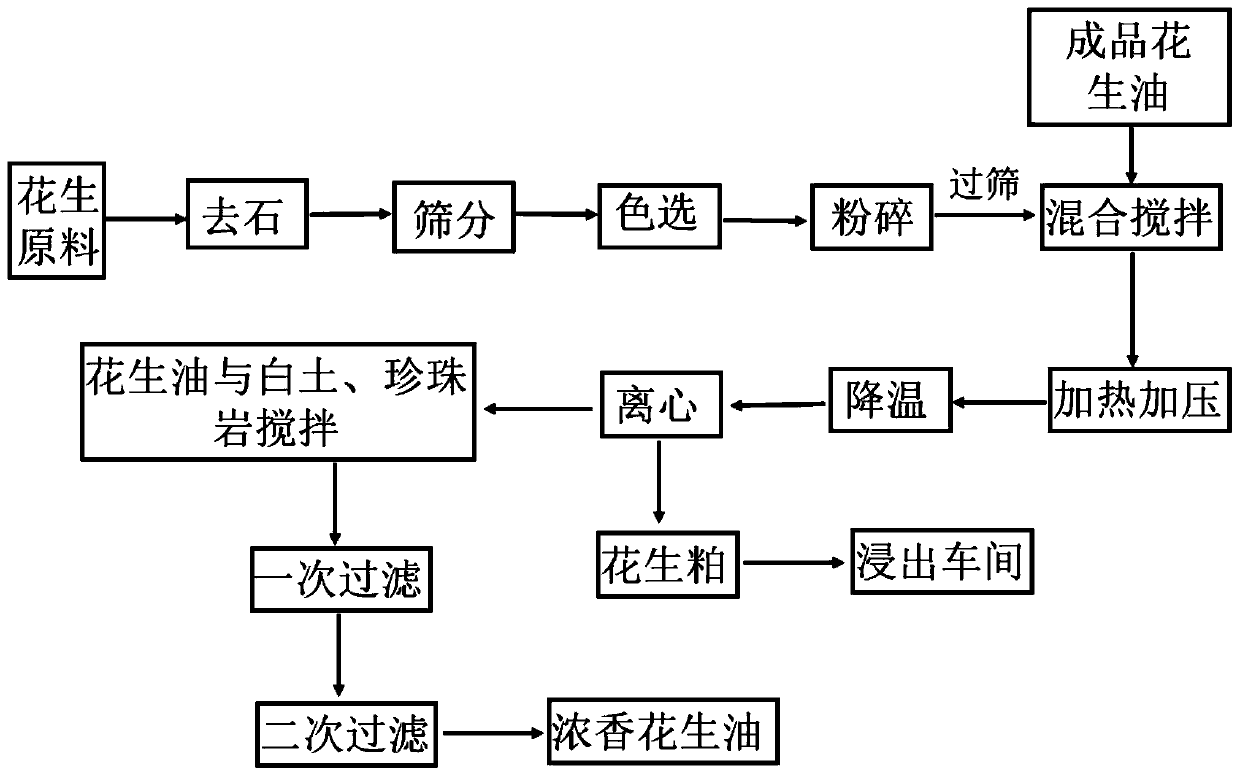

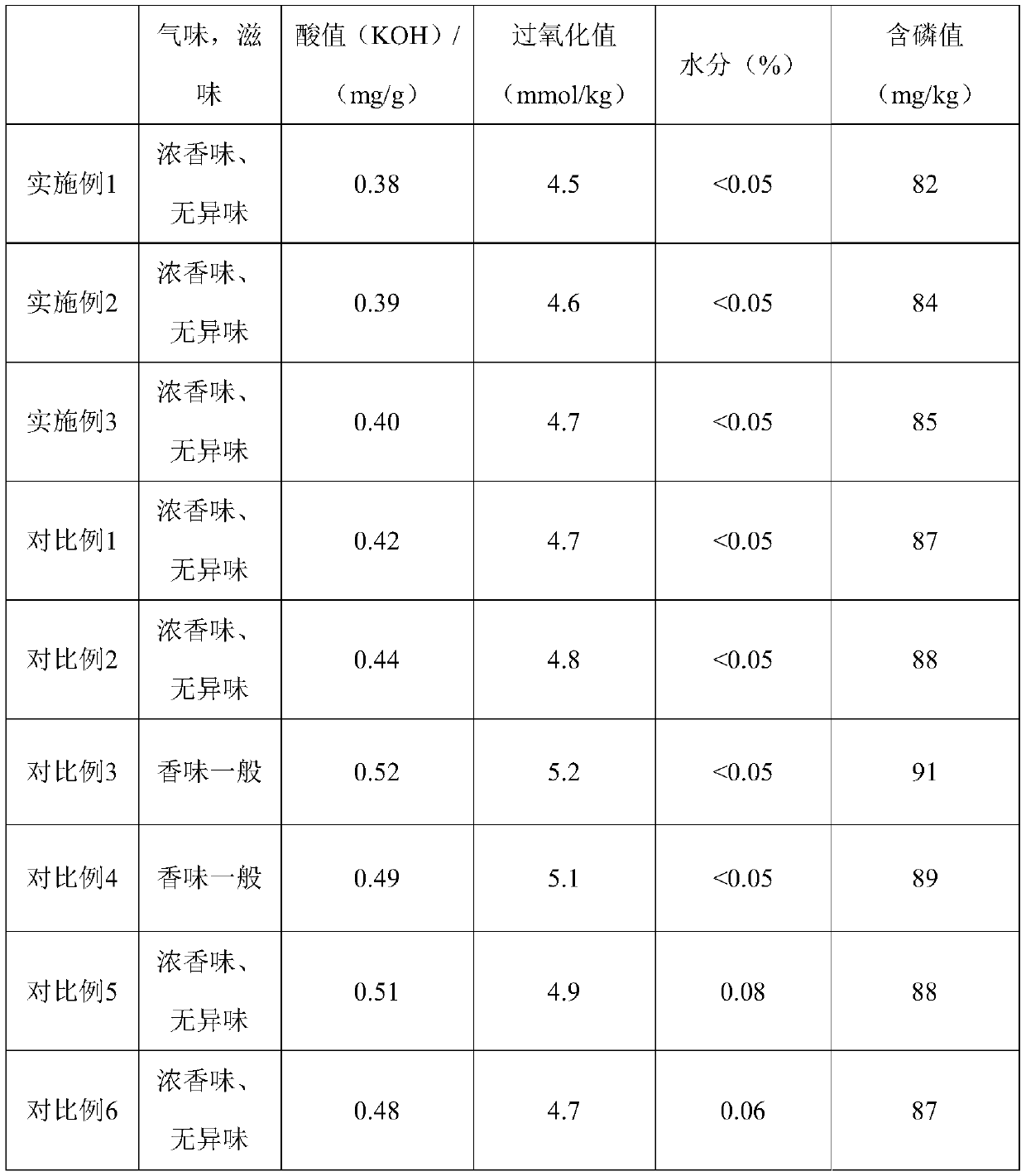

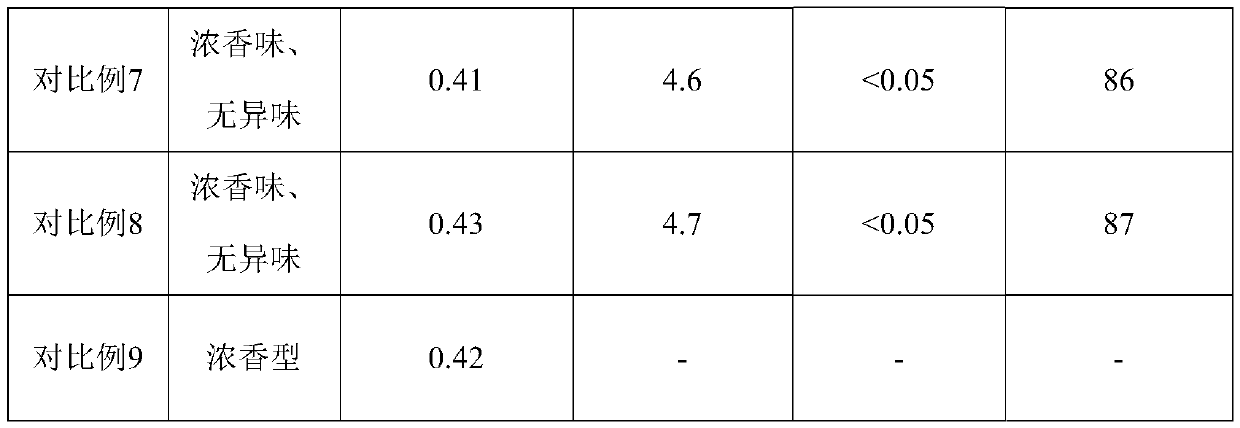

Production process of fragrant peanut oil

ActiveCN111440657AThe preparation process is safe and simpleEasy to operateFatty-oils/fats refiningFatty-oils/fats productionProcess engineeringEdible oil

The invention discloses a production process of fragrant peanut oil, and belongs to the field of edible oil processing. The production process mainly comprises the following steps: firstly, removing stones from peanut raw materials, screening and carrying out color sorting; removing impurities, removing peanut coat, crushing peanut kernels, sieving to obtain crushed peanut kernels, adding the crushed peanut kernels into finished peanut oil, mixing, stirring, heating, pressurizing, cooling to room temperature, centrifuging to obtain peanut oil, adding carclazyte and perlite, stirring, and finally filtering to obtain the fragrant peanut oil. The technological process is simple, safe, convenient to operate and low in energy consumption, and special protection requirements are not needed. Theobtained fragrant peanut oil meets the national and industrial standards and has a very strong oil flavor and is a new peanut oil product.

Owner:广东漠阳花粮油有限公司

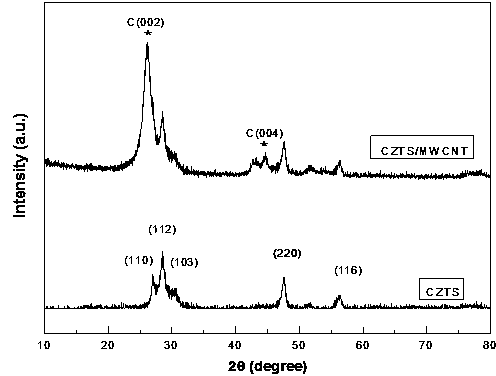

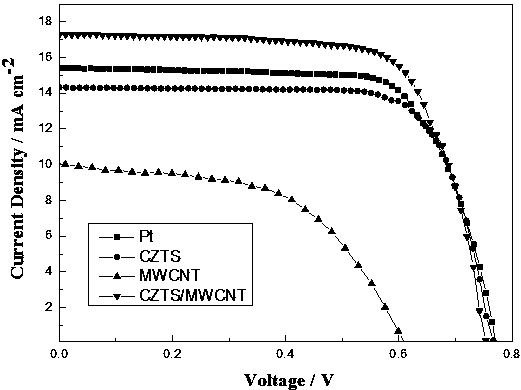

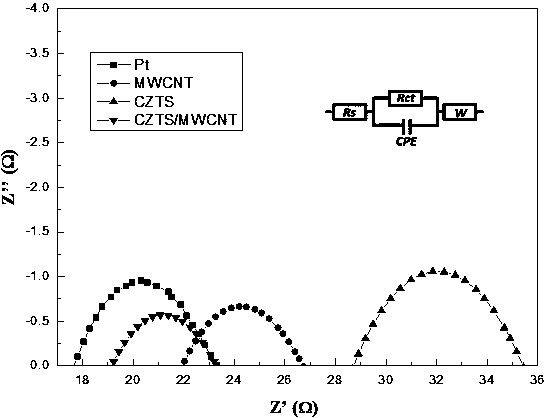

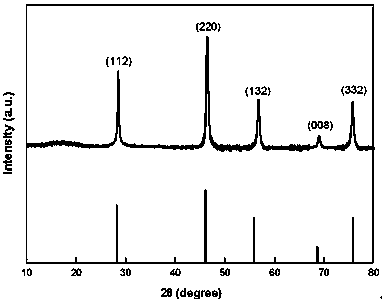

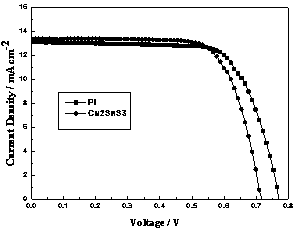

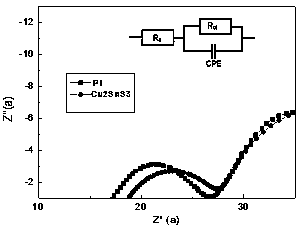

Cu2ZnSnS4 / MWCNT nano composite counter electrode for dye-sensitized solar cell and preparation method thereof

InactiveCN103794373AThe preparation process is simple and safeLow cost of preparationMaterial nanotechnologyElectrolytic capacitorsIonSolvent

The invention relates to a Cu2ZnSnS4 / MWCNT nano composite counter electrode for a dye-sensitized solar cell and a preparation method thereof. The method comprises following steps that: (1) a hot solvent method is used to synthesize a Cu2ZnSnS4 nanoparticle with a diameter of 200 to 300 nanos; (2) an MWCNT is immersed in a sulfuric acid and nitric acid mixed solution, so as to improve dispersibility of the mixed solution; (3) a Cu2ZnSnS4 / MWCNT nano composite material is stirred and carries out ultrasonic processing so that the composite material is mixed evenly, and the Cu2ZnSnS4 / MWCNT is dissolved in deionized water and forms "ink" by the ultrasonic processing; and (4) a spinning coating method is used so that black "ink" is coated on a conductive substrate, and then the Cu2ZnSnS4 / MWCNT composite counter electrode is obtained by annealing in 450 to 550 DEG C for 0.5 to 2 hours. According to the method, the Cu2ZnSnS4 / MWCNT having good corrosion resistance serves as the counter electrode of the dye-sensitized solar cell, so as to achieve the large surface area, good catalytic and conductive properties, and low production cost; and the battery which is manufactured with adoption of the preparation method, has the same photoelectric conversion efficiency as the battery based on a conventional Pt electrode, is suitable for application to the dye-sensitized solar cell, and is beneficial to the industrialization development of the dye-sensitized solar cell.

Owner:CHINA UNIV OF MINING & TECH

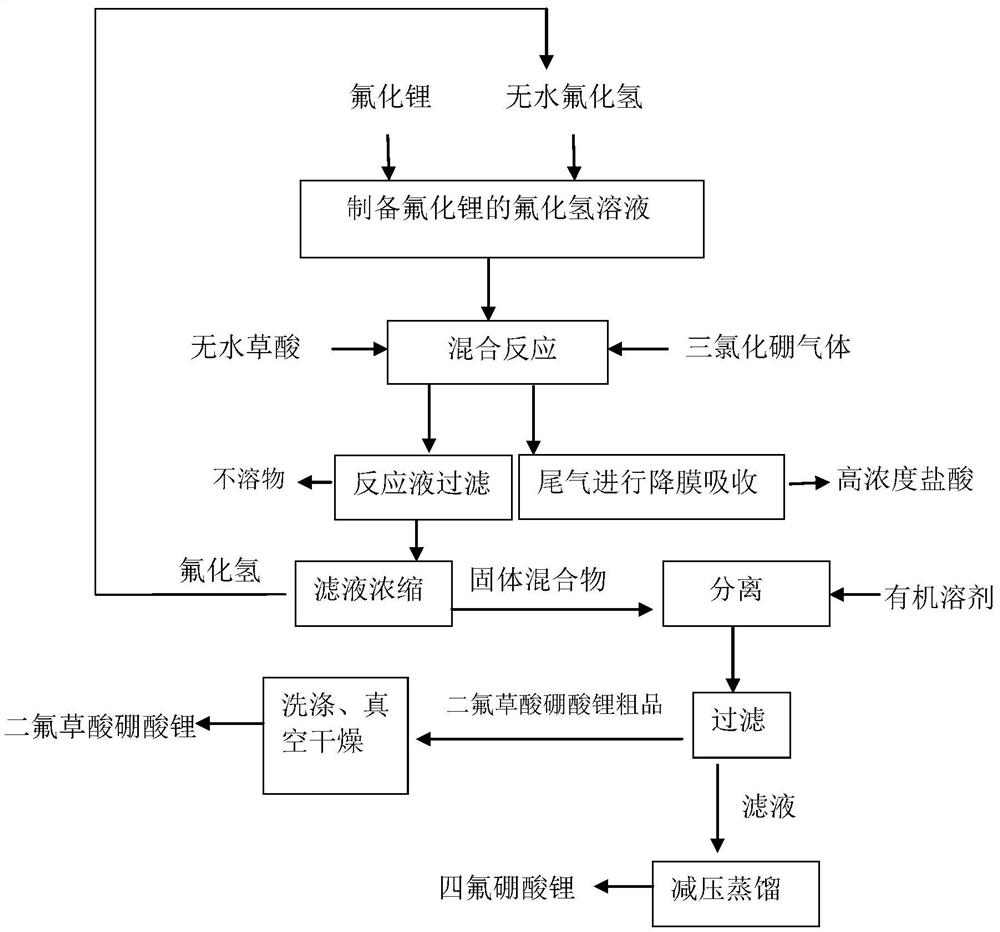

Preparation method of lithium difluoroborate

ActiveCN112480153AImprove qualityUniform responseGroup 3/13 element organic compoundsHydrogen fluorideBoron trichloride

The invention belongs to the technical field of lithium ion battery materials, and particularly relates to a preparation method of lithium difluoroborate. The preparation method of lithium difluoroborate comprises the following steps: subjecting a hydrogen fluoride solution of lithium fluoride to reacting with boron trichloride and oxalic acid at 5-20 DEG C to obtain a hydrogen fluoride solution containing lithium difluoroborate and lithium tetrafluoroborate, removing a solvent to obtain a solid mixture oflithium difluoroborate and lithium tetrafluoroborate, and carrying out separation and purification to obtain lithium oxalyldifluoroborate. The invention provides a novel process for preparing lithium difluoroborate, the operation process is simple and safe, and the prepared lithium difluoroborate is high in purity and suitable for industrial production.

Owner:DO FLUORIDE CHEM CO LTD

Cu3SnS4 nano-material counter electrode for dye-sensitized solar cell and preparing method thereof

InactiveCN103714976AThe photoelectric conversion efficiency is quiteThe preparation process is simple and safeMaterial nanotechnologyLight-sensitive devicesSolventCell based

The invention relates to a Cu3SnS4 nano-material counter electrode for a dye-sensitized solar cell and a preparing method thereof. The preparing method includes the first step of compounding Cu3SnS4 nano-particles with diameters ranging from 200 nanometers to 300 namometers in a hot solvent method, the second step of dissolving the Cu3SnS4 nano-particles in deionized water and forming 'ink' through ultrasonic processing, the third step of coating a conductive substrate with the black 'ink', then, carrying out annealing for 0.5-2h at the temperature from 450 DEG C to 550 DEG C, and finally the mesoporous Cu3SnS4 counter electrode can be obtained. According to the method, mesoporous Cu3SnS4 with good corrosion resistance is adopted as the counter electrode of the dye-sensitized solar cell, the specific area is large, catalytic performance is good and production cost is low. The photoelectric conversion efficiency of the cell prepared through the method is equal to that of a cell based on a traditional Pt electrode, and the method is suitable for being applied in the dye-sensitized solar cell and beneficial for industrialization development of the dye-sensitized solar cell.

Owner:CHINA UNIV OF MINING & TECH

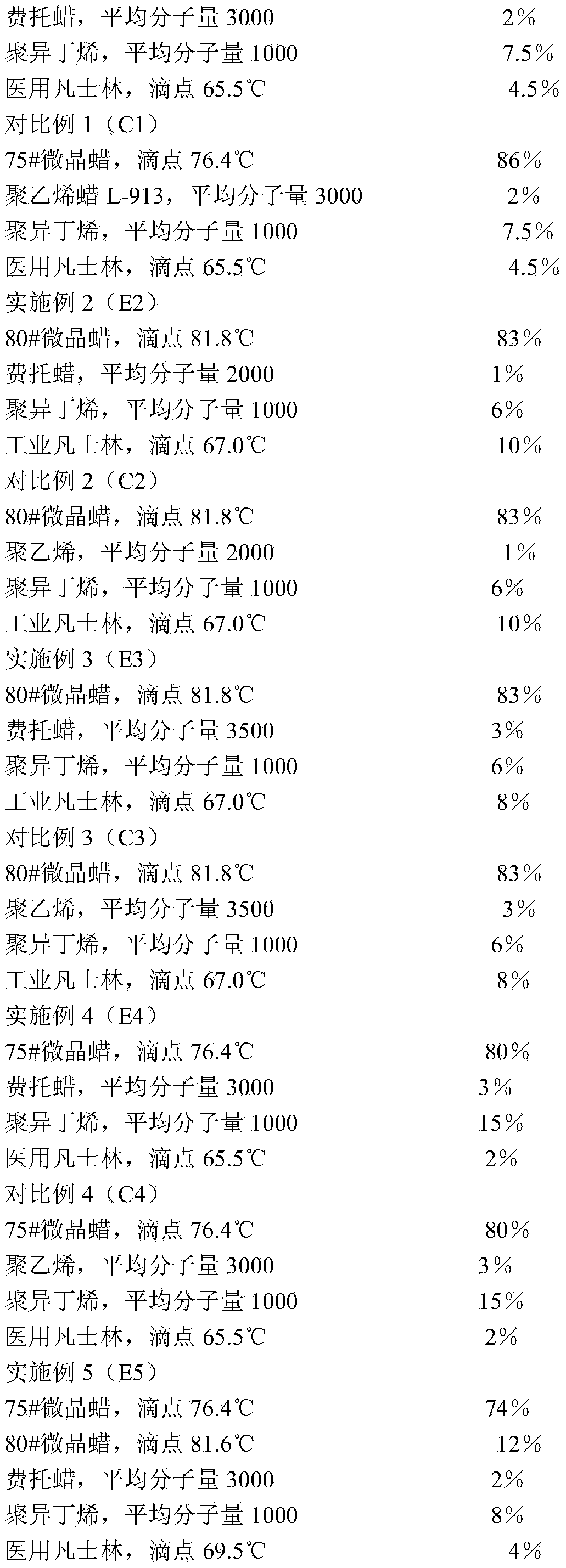

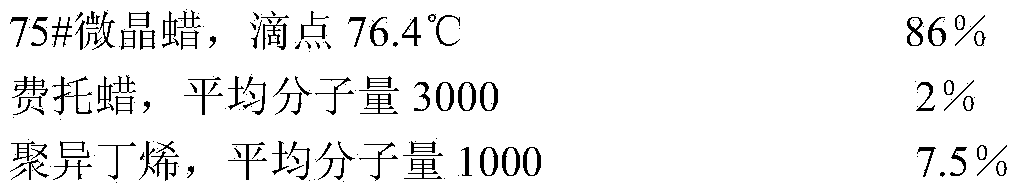

High-temperature-resistant anticorrosive transformer

ActiveCN103937274AHigh drop melting pointImprove protectionInductances/transformers/magnets manufactureTransformerMoisture resistance

The invention relates to a high-temperature-resistant anticorrosive transformer which is formed by filling insulation potting wax with favorable liquid flowability into transformer gaps. The insulation potting wax comprises 72-88% of petroleum wax, 1-6% of Fischer-Tropsch wax, 1-20% of tackifier and 1-20% of vaseline. The high-temperature-resistant anticorrosive transformer has the characteristics of excellent high temperature property, excellent corrosion resistance, favorable electric properties, favorable moisture resistance and the like. The insulation potting wax is not only suitable for insulation impregnation potting of electronic transformers and high-frequency transformers, but also suitable for insulation impregnation potting of inductive coils and other special coils for electronic components.

Owner:JIANGSU HUASHENG ELECTRICAL CO LTD

Insulating potting wax composition

ActiveCN104004365AHigh drop melting pointImprove protectionOther chemical processesTransformerMoisture resistance

The invention relates to an insulating potting wax composition. The composition comprises 72-88% of petroleum wax, 1-6% of Fischer-Tropsch wax, 1-20% of tackifiers and 1-20% of vaseline. The insulating potting wax composition has the characteristics of excellent high temperature performance and corrosion resistance, excellent electrical performance, good moisture resistance and the like, and is not only suitable for insulating impregnating and potting of electronic transformers and high frequency transformers but also suitable for insulating impregnating and potting of inductance coils and other special coils for electronic components.

Owner:江苏汤湖通讯设备有限公司

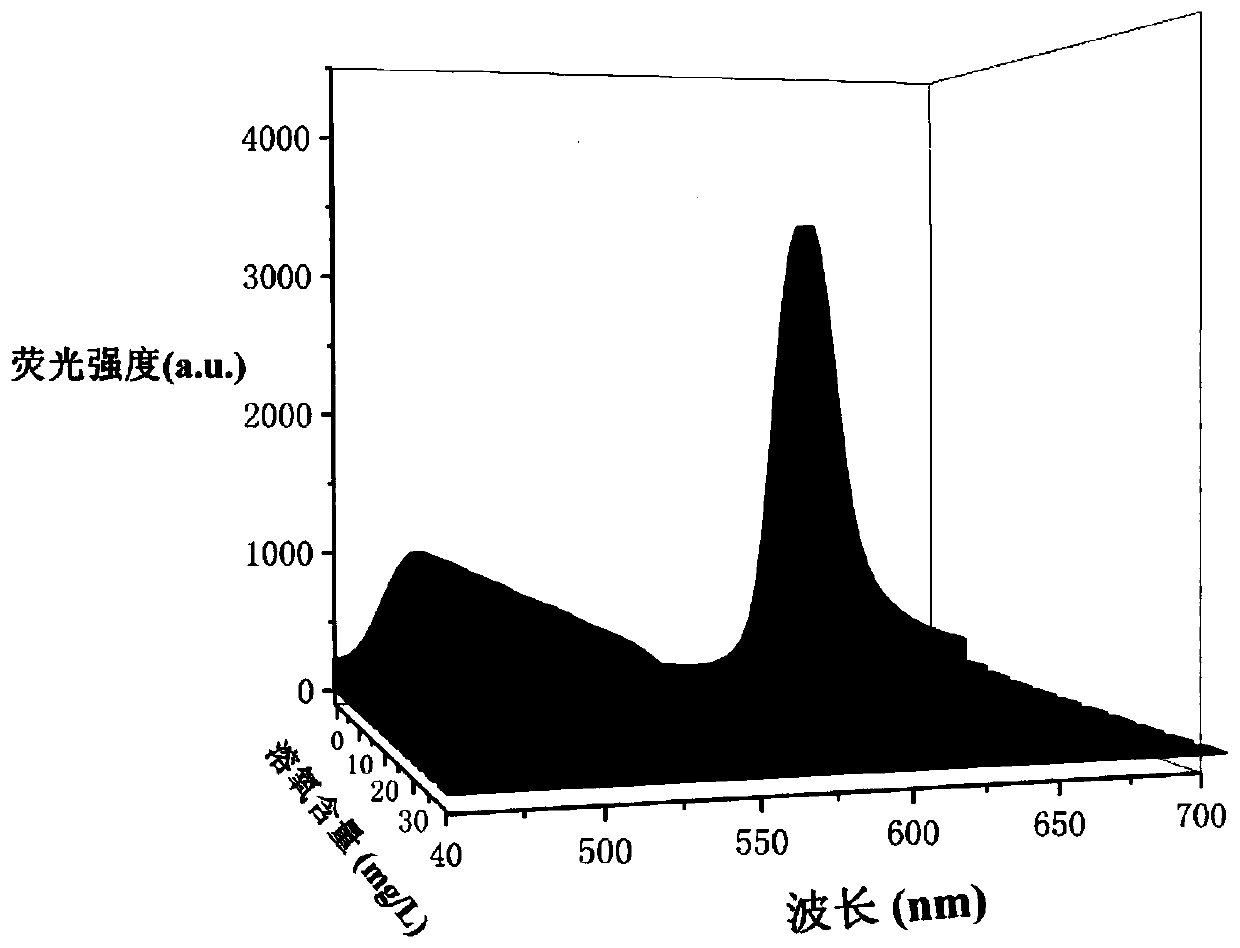

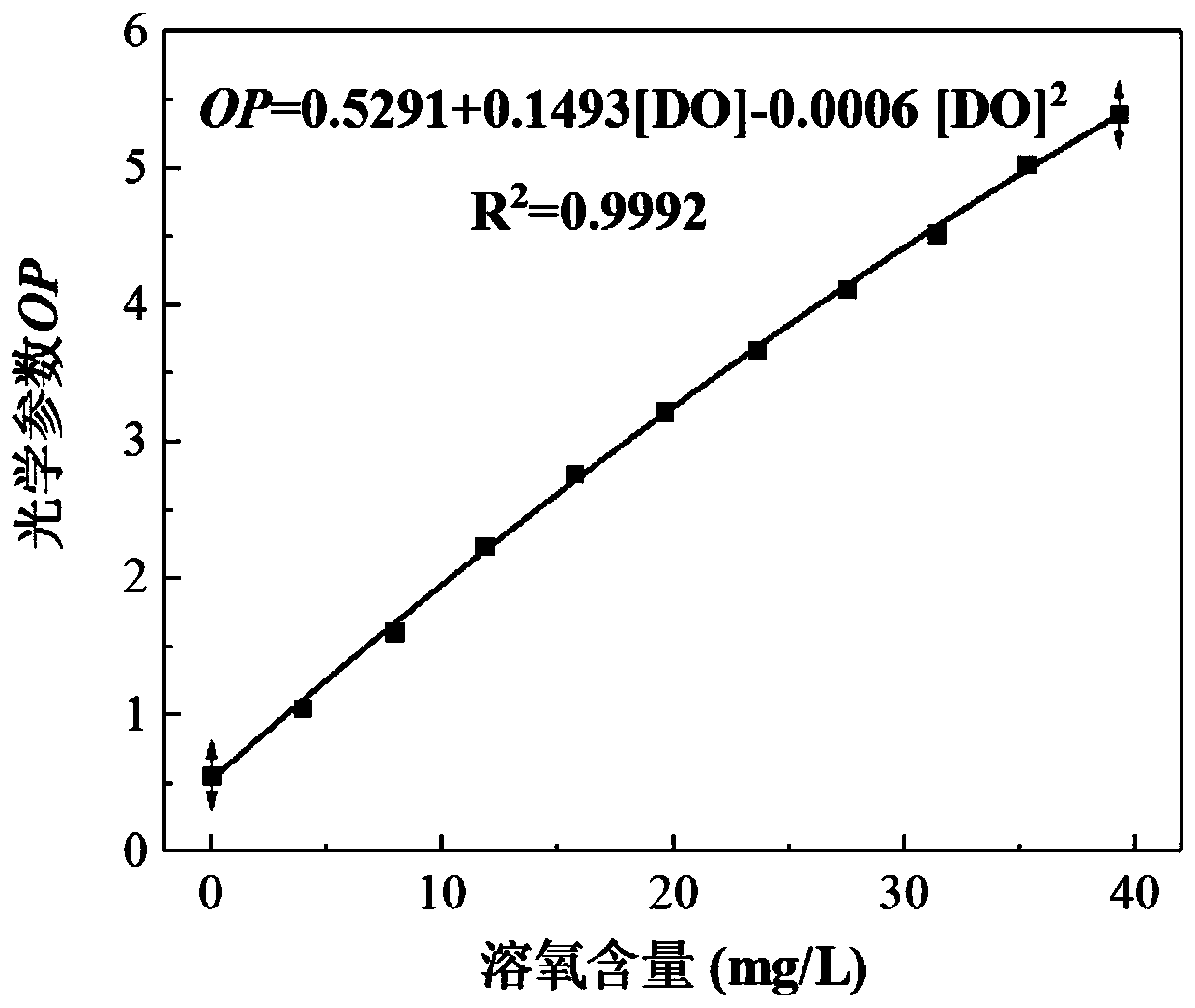

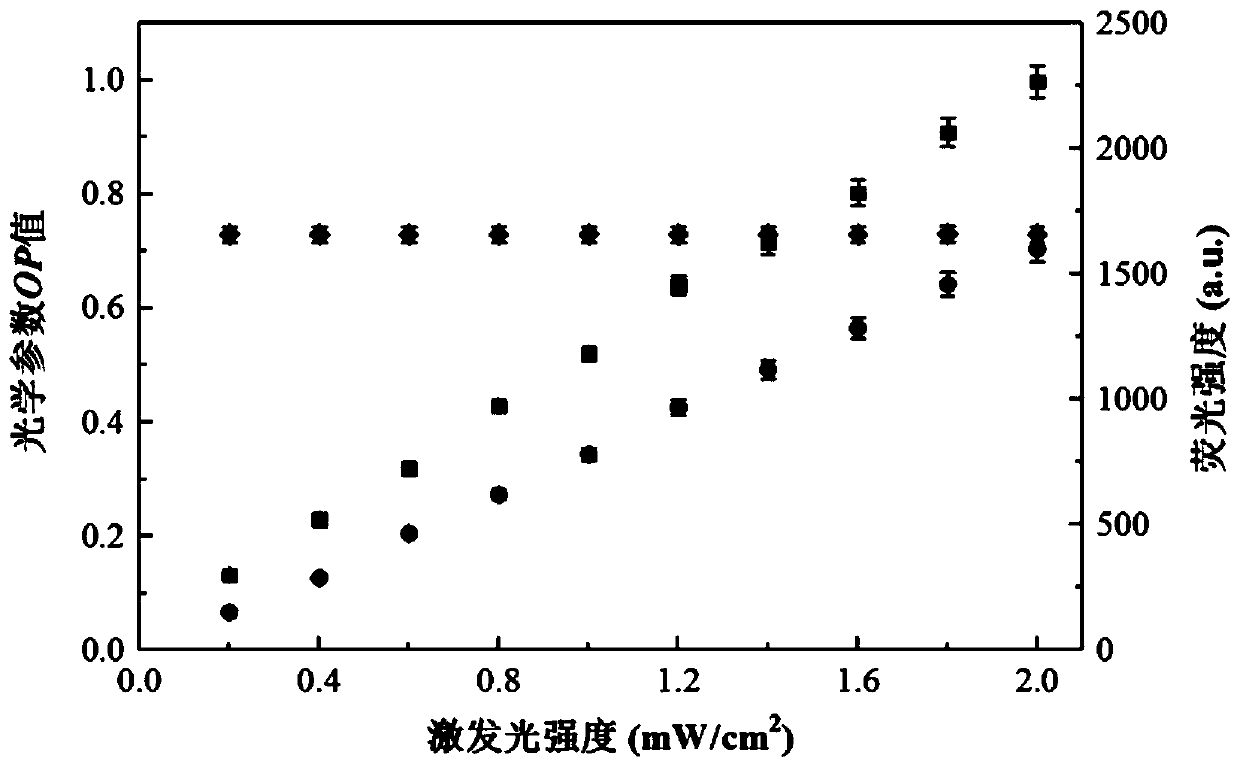

Preparation method of ratio oxygen sensing film for detecting contents of dissolved oxygen

ActiveCN110108683AGood ratiometric oxygen sensing performanceHigh linear correlationFluorescence/phosphorescenceChemistryToluene

The invention discloses a preparation method of a ratio oxygen sensing film for detecting the contents of dissolved oxygen, relates to the preparation method of the ratio oxygen sensing film, and aimsat solving the problem that the existing ratio oxygen sensing methods are high in cost and bad in photo-bleaching resistance due to the reason that to-be-tested water samples are polluted and cannotbe recovered. The method comprises the steps of 1, uniformly dispersing azobisisobutyronitrile solution in St / TFEMA mixed solution, copolymerizing the mixed solution under nitrogen protection to obtain copolymer solution, and carrying washing and suction filtration; 2, mixing PtOEP / toluene solution with C6 / toluene solution to obtain mixed indicator solution, re-dissolving the copolymer solution intoluene to obtain copolymer / toluene solution, mixing the copolymer / toluene solution with the mixed indicator solution, applying the obtained mixed solution on a quartz plate, and carrying out dryingto obtain the ratio oxygen sensing film. The ratio oxygen sensing film can be recycled for multiple times, has no pollution to the environment, and has photo-bleaching resistance. The method is used in the field of dissolved oxygen detection.

Owner:HARBIN INST OF TECH

Metallic oxide thin film transistor and preparation method thereof

InactiveCN109767988AIncrease capacitanceQuality improvementTransistorSemiconductor/solid-state device manufacturingOxide thin-film transistorCharge carrier mobility

The invention belongs to the field of thin film transistors, and relates to a metallic oxide thin film transistor and a preparation method thereof. The thin film transistor includes an insulating substrate, a gate electrode, a gate insulating layer, a metallic oxide semiconductor layer, a source electrode and a drain electrode. The insulating substrate is located at the bottommost layer of an organic thin film transistor, the gate electrode, the gate insulating layer and the metallic oxide semiconductor layer are sequentially stacked on the insulating substrate from bottom to top, and the source electrode and the drain electrode are separately located above the metallic oxide semiconductor layer. According to the preparation method of the metallic oxide semiconductor thin film, the performance and carrier mobility of a ZnO-based thin film transistor prepared by an aqueous solution method in the prior art are improved by adding an alkali metal compound to a polymeric precursor solution,the preparation process is simple, the production cost is low, and the whole process temperature is controlled within 300 DEG C.

Owner:XIAN JIAOTONG LIVERPOOL UNIV

Preparation method of electrochromic intelligent molybdenum trioxide-tungsten oxide core-shell nano- array energy storage electrode

ActiveCN110981216AThe preparation process is simple and safeNo pollution in the processCoatingsCapacitanceElectrochemistry

The invention discloses a preparation method of an electrochromic intelligent molybdenum trioxide-tungsten oxide core-shell nano-array energy storage electrode, and relates to a preparation method ofa core-shell nano-array energy storage electrode. The invention aims to solve the problems of low tap density and poor electrochemical stability caused by extremely easy agglomeration and easy disordered accumulation of the nano material due to increased surface energy caused by nanocrystallization of the existing nano material with capacitance and electrochromic properties. The method comprises the following steps: 1, cleaning a transparent conductive substrate; 2, preparing a molybdenum trioxide nano array; and 3, preparing a core-shell molybdenum trioxide-tungsten oxide nano array materialto obtain the electrochromic intelligent molybdenum trioxide-tungsten oxide core-shell nano- array energy storage electrode. The electrochromic intelligent molybdenum trioxide-tungsten oxide core-shell nano -array energy storage electrode can be obtained.

Owner:HARBIN UNIV OF COMMERCE

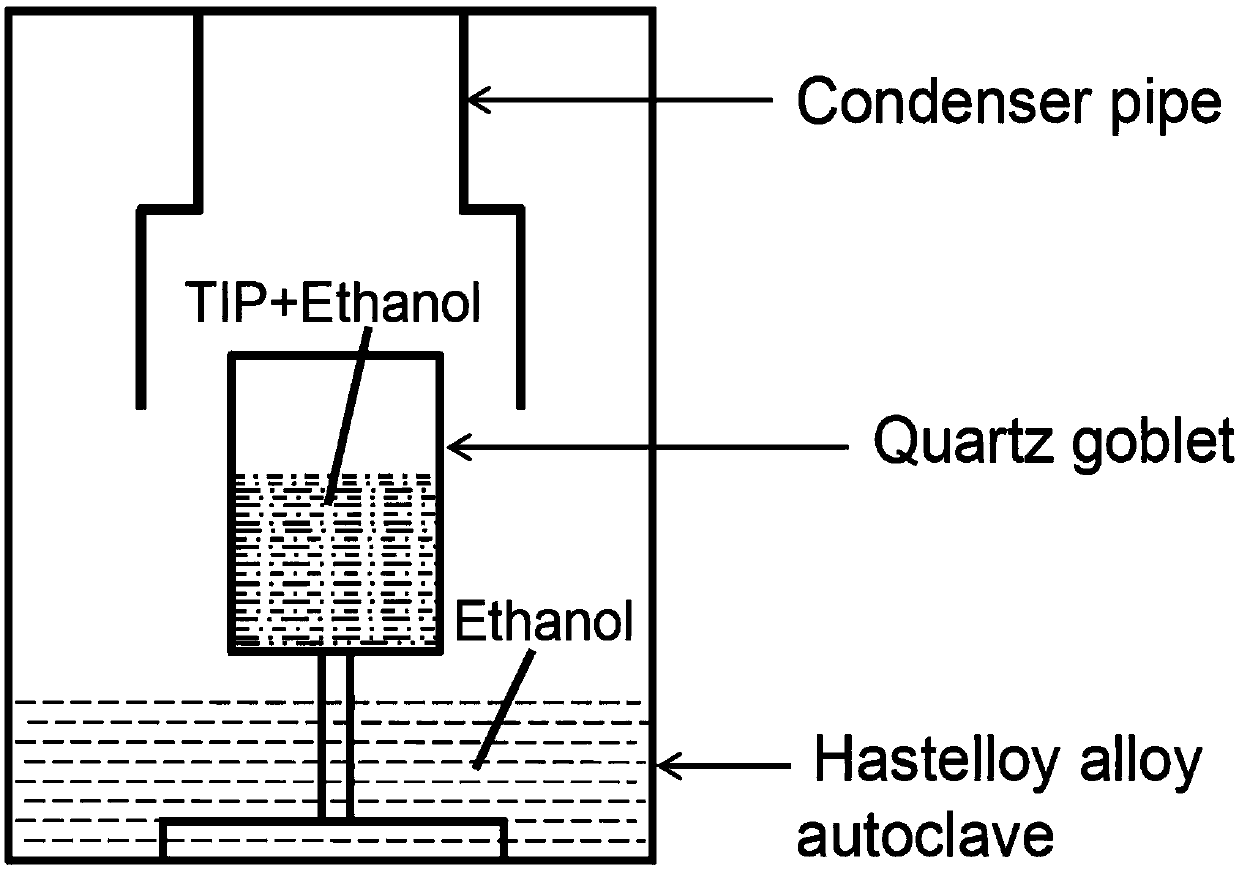

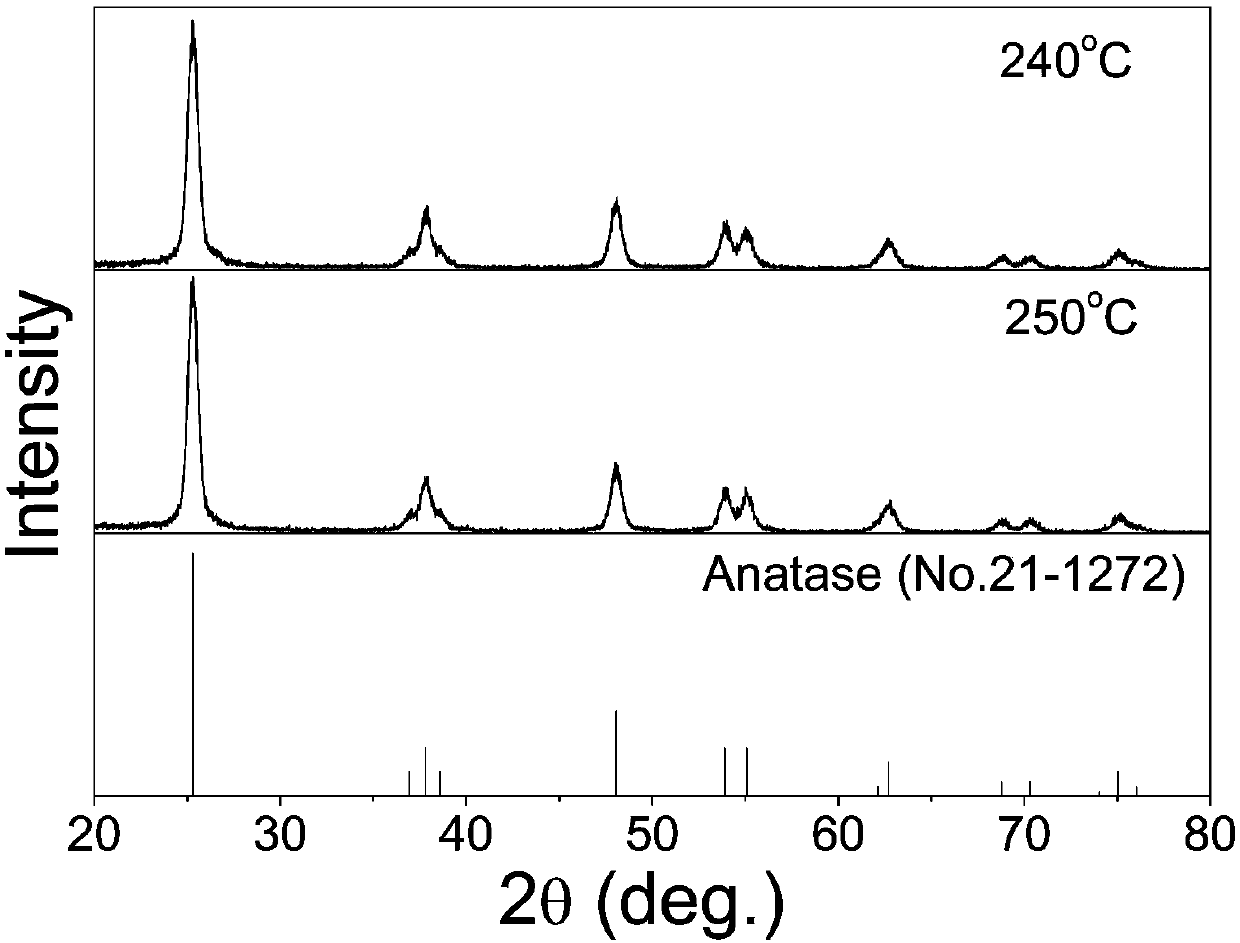

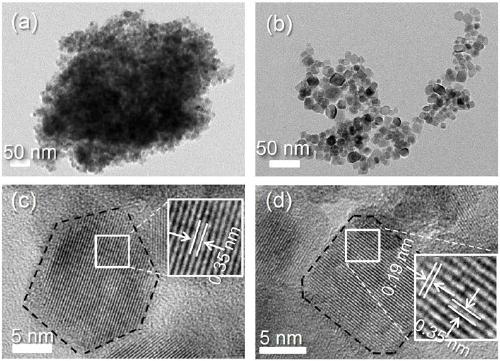

Method for preparation of TiO2 by steam hot solution evaporation

InactiveCN110156073AReduce the rate of hydrolysisHigh crystallinityPhysical/chemical process catalystsTitanium dioxideOrganic solventLiquid state

The invention discloses a method for preparation of TiO2 by steam hot solution evaporation. The method includes: dripping a titanium salt into an organic solvent, performing magnetic stirring and mixing, transferring the mixture into a standing quartz cup, then adding an organic solvent into a Hadtelloy alloy reaction kettle, and putting the standing quartz cup into the reaction kettle, carrying out steam hydrothermal reaction for 5h, then introducing cooling water to a condenser pipe in the reaction kettle to rapidly lower the temperature inside the kettle, after cooling to room temperature,taking out the product from the cup, when the product in the cup is in a solid state, performing levigating to obtain a TiO2 photocatalyst, and when the product in the cup is in a liquid state, conducting solid-liquid separation, then adding ethanol and performing washing, and then conducting drying in a vacuum oven to obtain the TiO2 photocatalyst. The TiO2 photocatalyst obtained by the method provided by the invention has the characteristics of excellent catalytic performance and simple and safe preparation process, and has good application prospects in the field of photocatalysis.

Owner:ANHUI UNIVERSITY

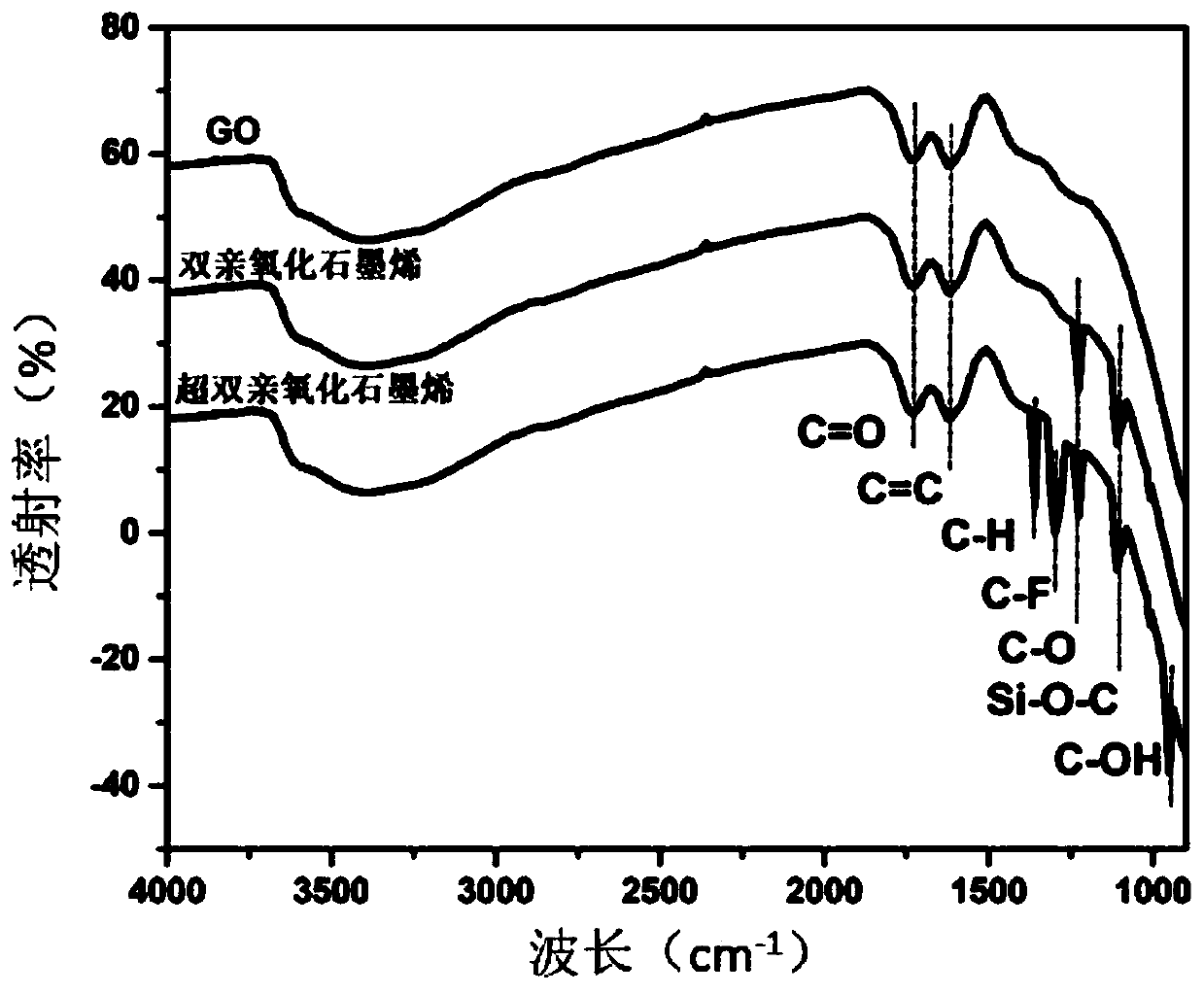

Super-amphiphilic graphene oxide as well as preparation method and application thereof

ActiveCN110683534AImprove hydrophilicityImprove lipophilicityHydrogenGrapheneLipophilicityGraphite oxide

The invention discloses super-amphiphilic graphene oxide as well as a preparation method and application thereof. The preparation method of the super-amphiphilic graphene oxide comprises the followingsteps: mixing a graphene oxide dispersion with a solution with a hydrophobic modifier, and performing a reaction I under the action of a template agent, so as to obtain an amphiphilic graphene oxidedispersion; mixing the amphiphilic graphene oxide dispersion with a solution with a hydrophilic modifier so as to obtain a mixed liquid, and performing a reaction II, so as to obtain the super-amphiphilic graphene oxide. By adopting the preparation method disclosed by the invention, hydrophobic modified graphene oxide is combined with hydrophilic modified graphene oxide, then the super-amphiphilicgraphene oxide with excellent hydrophilcity and lipophilicity is prepared, the solvent dispersibility of the graphene oxide can be improved, and further application of the graphene oxide can be promoted.

Owner:NINGBO FENGCHENG ADVANCED ENERGY MATERIALS RES INST CO LTD

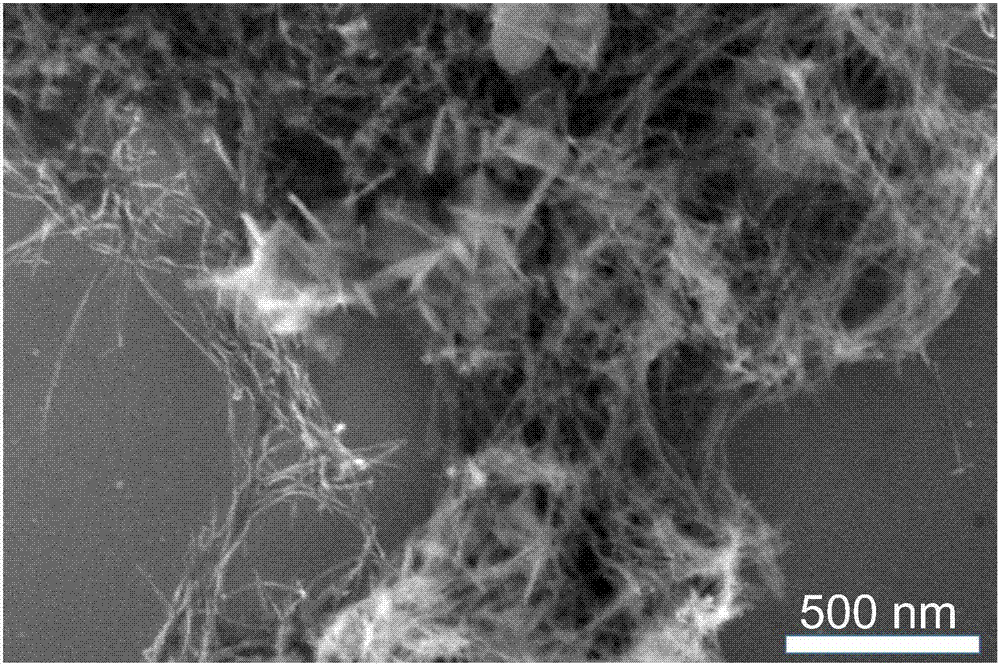

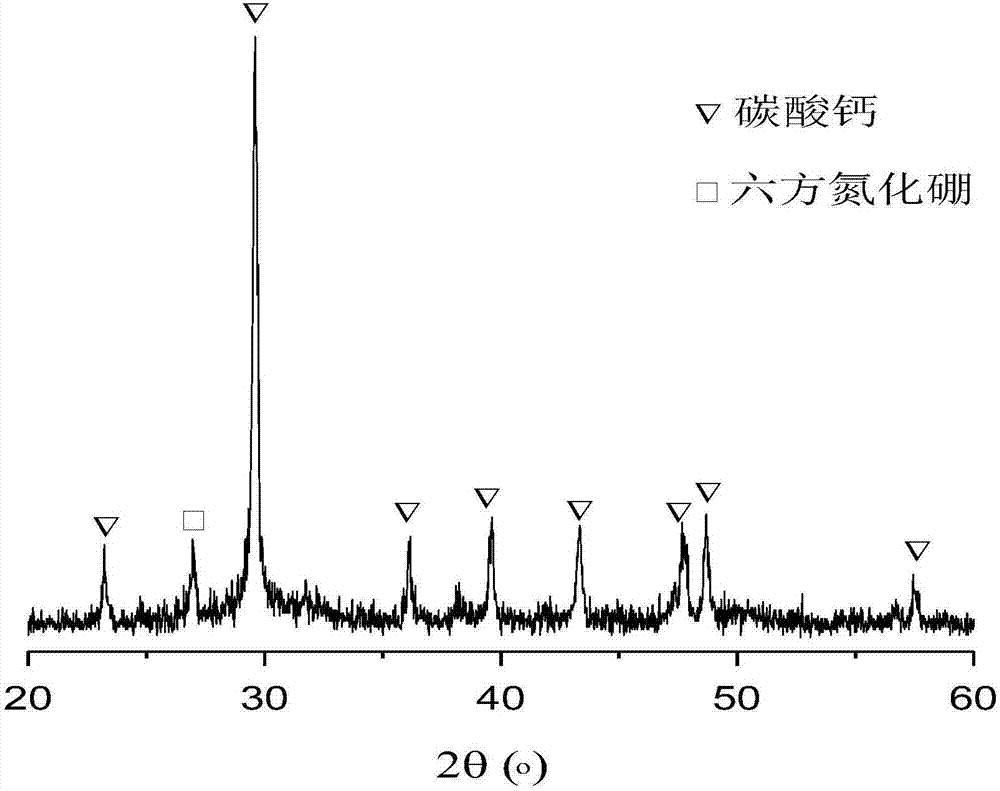

Method for preparing nano-calcium carbonate whisker/hexagonal boron nitride nanocomposite material

ActiveCN107539965AThe preparation process is simple and safeLow costCalcium/strontium/barium carbonatesNitrogen compoundsTemperature resistanceDiameter ratio

The invention relates to a method for preparing a nano-calcium carbonate whisker / hexagonal boron nitride nanocomposite material. The method comprises stripping hexagonal boron nitride through a simpleultrasonic method, adding the stripped precursor into a calcium chloride solution and synthesizing the nano-calcium carbonate whisker / hexagonal boron nitride nanocomposite material through a simple solution method. The method is simple and safe, realizes a low cost, needs a low temperature and can synthesize calcium carbonate whisker having diameters of about 50nm and good overall uniformity. Thenano-calcium carbonate whisker in the nano-calcium carbonate whisker / hexagonal boron nitride nanocomposite material has a length-diameter ratio of 25-50 satisfying the industrial application requirement. The hexagonal boron nitride has strong oxidation resistance, high temperature resistance and good mechanical properties. The material performances are further improved in application.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com