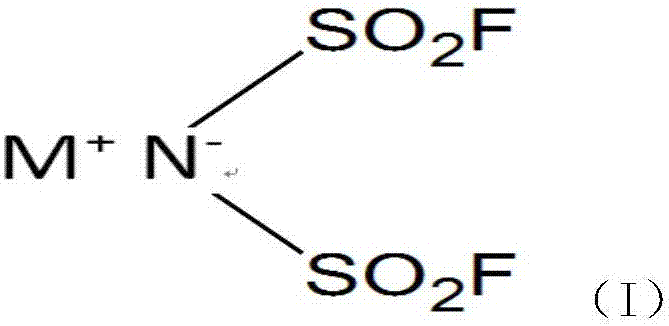

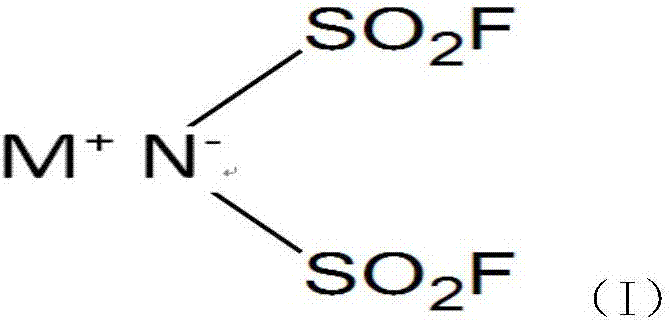

Preparation method of bis(fluorosulfonyl)imide salt

A technology of bisfluorosulfonimide salt and bisfluorosulfonimide, which is applied in the field of preparation of bisfluorosulfonimide salt, and can solve problems such as increased risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Add 200ml of butyl acetate and 10.92g (0.13mol) of aluminum fluoride to a 500ml three-necked flask A, add 40.67g (0.19mol) of dichlorosulfonimide dropwise in an ice-water bath, and react 6 at room temperature after the dropwise addition is complete. Hour.

[0022] Add 130g of 30wt% lithium nitrilotriacetate aqueous solution in the 500ml three-necked bottle B, gradually add the reaction solution in the above-mentioned three-necked bottle A dropwise, react at room temperature for 3 hours after the dropwise addition, then separate the liquids, and use butyl acetate for the aqueous phase The ester was extracted twice, the extract was combined with the organic phase, most of the solvent butyl acetate was distilled off, dichloromethane was added to precipitate, and filtered to obtain 24.04 g of white powdery lithium bisfluorosulfonyl imide. The yield of lithium bisfluorosulfonyl imide is 82%, and the content of aluminum ion in lithium bisfluorosulfonyl imide is 7ppm.

Embodiment 2

[0024] Add 200ml of butyl acetate and 15.96g (0.19mol) of aluminum fluoride to a 500ml three-necked flask A, add 40.67g (0.19mol) of dichlorosulfonimide dropwise in an ice-water bath, and react at room temperature for 8 Hour.

[0025] Add 115.56g of 50wt% dilithium ethylenediaminetetraacetic acid salt (Mw=304.109) aqueous solution in the 500ml three-necked bottle B, gradually add the reaction solution in the above-mentioned three-necked bottle A dropwise, and react at room temperature for 5 hours after the dropwise addition is completed. Then separate the liquids, extract the aqueous phase twice with butyl acetate, combine the extract with the upper organic phase, distill off most of the solvent butyl acetate, add dichloromethane to precipitate, filter to obtain white powdery lithium bisfluorosulfonimide 29.19 g. The yield of lithium bisfluorosulfonyl imide is 89%, and the content of aluminum ion in lithium bisfluorosulfonyl imide is 15ppm.

Embodiment 3

[0027] Add 500ml of butyl acetate to a 1000ml three-necked bottle A, add dropwise 85.62g (0.4mol) of dichlorosulfonimide, and add 29.39g (0.35mol) of aluminum fluoride (Mw=83.98) after the dropwise addition, at room temperature React for 5 hours.

[0028] Add 115g of 30wt% lithium metaphosphate (Mw=85.91) aqueous solution in 1000ml three-necked bottle B, gradually add dropwise the reaction solution in the above-mentioned three-necked bottle A, react at room temperature for 6 hours after the dropwise addition, then separate the liquid, the water phase Extracted twice with butyl acetate, combined the extract with the upper organic phase, distilled off most of the solvent butyl acetate, added dichloromethane to precipitate, and filtered to obtain 43.38 g of white powdery lithium bisfluorosulfonyl imide. The yield of lithium bisfluorosulfonyl imide is 80%, and the content of aluminum ion in lithium bisfluorosulfonyl imide is 17ppm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com