Method for preparing nano-calcium carbonate whisker/hexagonal boron nitride nanocomposite material

A nano-composite material, hexagonal boron nitride technology, applied in the direction of calcium carbonate/strontium/barium, nitrogen compounds, chemical instruments and methods, etc., can solve the problems that the whisker size is not easy to control, does not reach the nano-scale, and has high equipment requirements, Achieve the effect of low cost, good high temperature resistance, safe and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

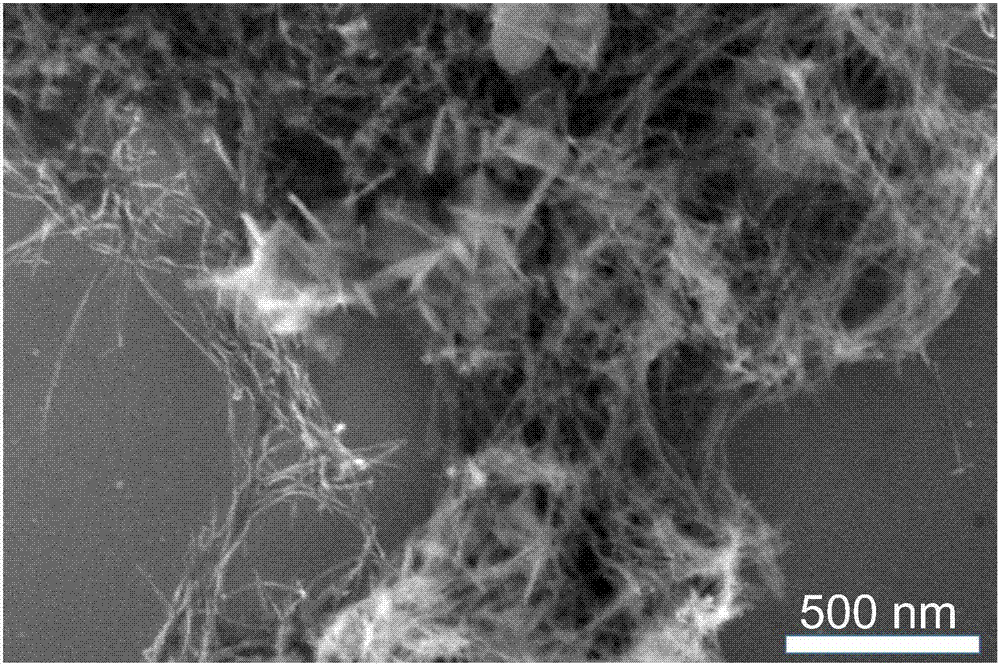

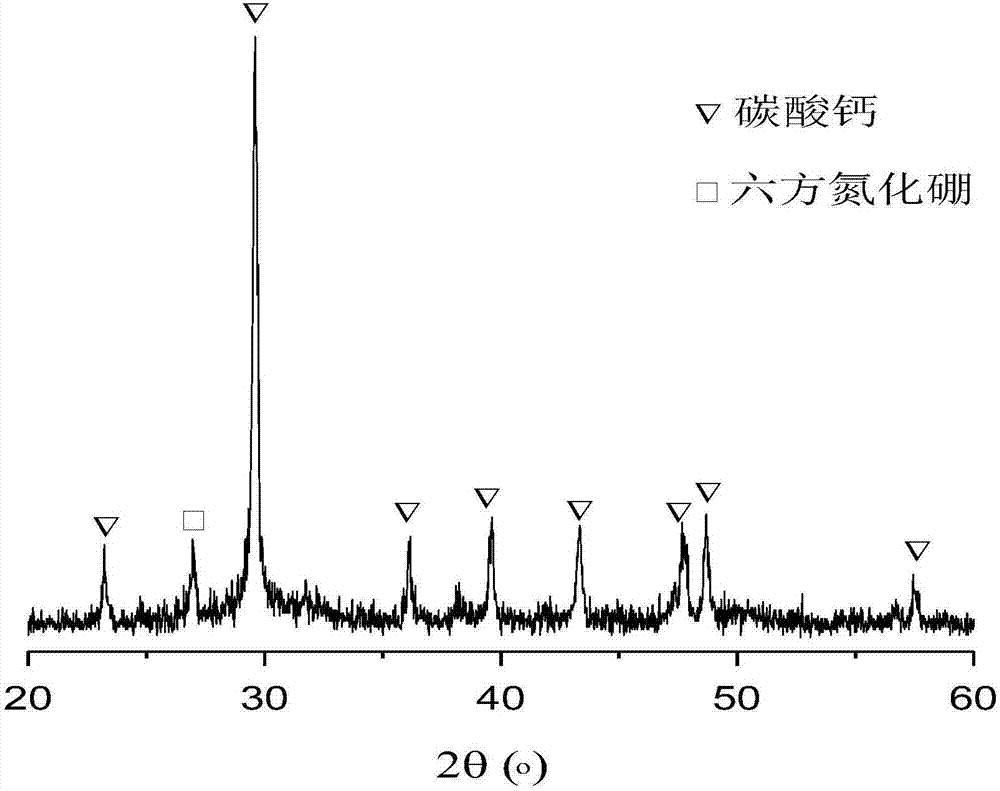

[0022] Weigh 8 g of commercially available hexagonal boron nitride powder and add it into 100 ml of deionized water for 8 h of ultrasonication. Pour the sonicated solution into a centrifuge tube and centrifuge at 8000 rpm for 5 minutes. Pour the supernatant into a beaker and dry it at 80 degrees Celsius to obtain a powder.

[0023] Weigh 2.2g calcium chloride and dissolve in 100ml deionized water. Weigh 100 mg of the above dried powder and add it into the calcium chloride solution, stir and heat. Weigh 2.1g of sodium carbonate and dissolve in 100ml of deionized water. After the mixed solution of calcium chloride and powder is heated to 30 degrees Celsius, sodium carbonate solution is added dropwise thereto at a speed of 1 ml / min, and the insulation is continued for 50 minutes after the dropwise addition is completed. Cool to room temperature when finished. The solution cooled to room temperature was poured into a centrifuge tube and washed five times by centrifugation at 6...

Embodiment 2

[0025] Weigh 8 g of commercially available hexagonal boron nitride powder and add it into 100 ml of deionized water for 8 h of ultrasonication. Pour the sonicated solution into a centrifuge tube and centrifuge at 8000 rpm for 5 minutes. Pour the supernatant into a beaker and dry it at 80 degrees Celsius to obtain a powder.

[0026] Weigh 4.4g calcium chloride and dissolve in 200ml deionized water. Weigh 200 mg of the above dried powder and add it into the calcium chloride solution, stir and heat. Weigh 4.2g of sodium carbonate and dissolve in 200ml of deionized water. After the mixed solution of calcium chloride and powder is heated to 40 degrees centigrade, sodium carbonate solution is added dropwise thereto at a speed of 2 ml / min, and the insulation is continued for 60 minutes after the dropwise addition is completed. Cool to room temperature when done. The solution cooled to room temperature was poured into a centrifuge tube and washed five times by centrifugation at 60...

Embodiment 3

[0028] Weigh 8 g of commercially available hexagonal boron nitride powder and add it into 100 ml of deionized water for 8 h of ultrasonication. Pour the sonicated solution into a centrifuge tube and centrifuge at 8000 rpm for 5 minutes. Pour the supernatant into a beaker and dry it at 80 degrees Celsius to obtain a powder.

[0029] Weigh 2.2g calcium chloride and dissolve in 100ml deionized water. Weigh 100 mg of the above dried powder and add it into the calcium chloride solution, stir and heat. Weigh 2.1g of sodium carbonate and dissolve in 100ml of deionized water. After the mixed solution of calcium chloride and powder is heated to 50 degrees Celsius, start to drop sodium carbonate solution therein at a speed of 3 ml / min, and continue to insulate for 70 minutes after the dropwise addition. Cool to room temperature when done. The solution cooled to room temperature was poured into a centrifuge tube and washed five times by centrifugation at 6000 rpm with deionized water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com