Method for preparation of TiO2 by steam hot solution evaporation

A technology of hot solution and steam, applied in chemical instruments and methods, chemical/physical processes, titanium oxide/hydroxide, etc., can solve problems such as unfavorable photocatalytic degradation performance, explosion hazard, and difficult control of hydrolysis process, etc. Effect of photocatalytic performance, improvement of photoresponse range, and promotion of exposed growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

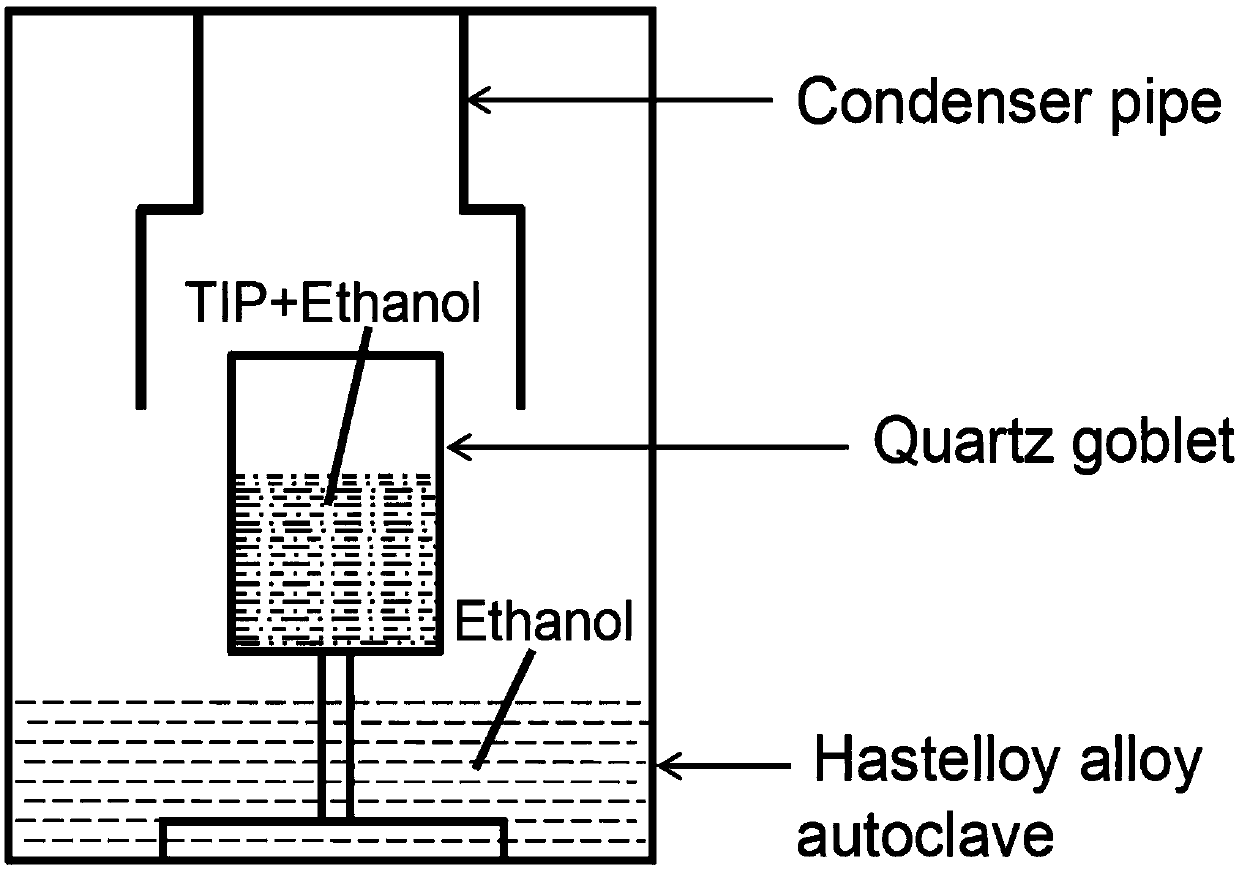

[0025] (1) Take 4 mL of isopropyl titanate (TIP), drop it into 96 mL of ethanol, and stir it magnetically for 30 minutes.

[0026] (2) Transfer the solution in step (1) to a 120mL quartz high foot.

[0027] (3) Weigh 200mL of ethanol into a 1000mL high-temperature and high-pressure reactor, and put the quartz cup in (2) into the high-temperature and high-pressure reactor. Carry out following condition reaction respectively subsequently:

[0028] The reaction was carried out at 240° C. for 5 hours. After the solution is cooled, there will be a small amount of liquid precipitate in the quartz cup, and the product obtained by centrifugation will be washed with absolute ethanol for 4-5 times, then the supernatant will be poured off, and the resulting precipitate will be placed in a vacuum drying oven at 60 °C for 12 hours to obtain TiO 2 Nanoparticles①;

[0029] The reaction was carried out at 250° C. for 5 hours. After the solution is cooled, the product in the cup is a dry ...

Embodiment 2

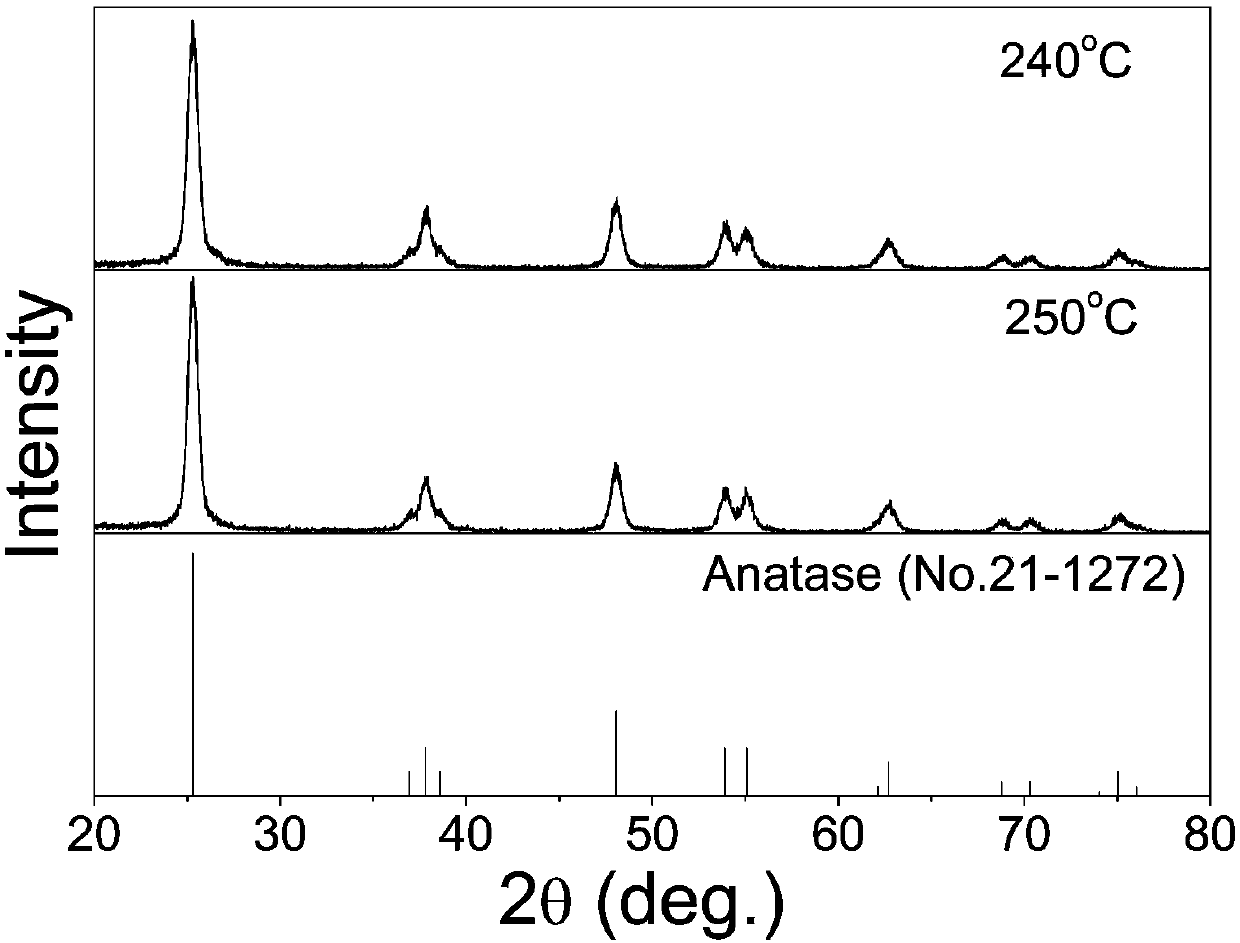

[0032] (1) Test TiO with X-ray polycrystal diffractometer (XRD; Smartlab9KW) 2 For the X-ray diffraction pattern of nanoparticles, see figure 2 . Depend on figure 2 Medium TiO 2 The position and relative intensity of the nanoparticle diffraction peaks are compared with the standard PDF card No.21-1272, which shows that the TiO we prepared 2 The crystal structure of nanoparticles is tetragonal anatase phase.

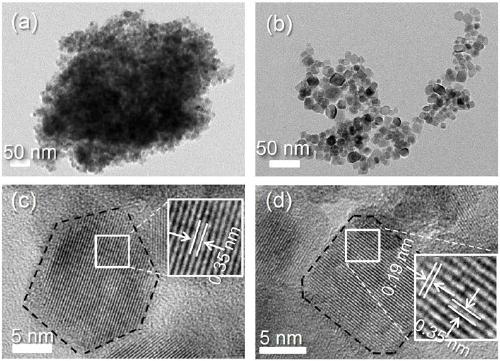

[0033] (2) Characterization of TiO prepared at 240°C by transmission electron microscope (JEOLJEM-2100) 2 The transmission electron microscope (TEM) picture of the nanoparticle (i.e. particle ①), see image 3 (a); Characterization of TiO at 250°C 2 Transmission electron micrograph (TEM) of nanoparticles (i.e. particles ②), see image 3 (b); Characterization of 250°C TiO 2 High-resolution transmission electron micrographs (HRTEM) of nanoparticles, see Fig. 3(c) and (d)

[0034] Depend on image 3(a) and image 3 (b) It can be seen that the prepared TiO 2 Nano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| band gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com