Patents

Literature

41results about How to "Promote nucleation growth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method for hybrid composite coating used for magnesium-based biological material surface medication

InactiveCN106011815AQuality improvementImprove bindingPharmaceutical delivery mechanismMetallic material coating processesBiocompatibility TestingBiological materials

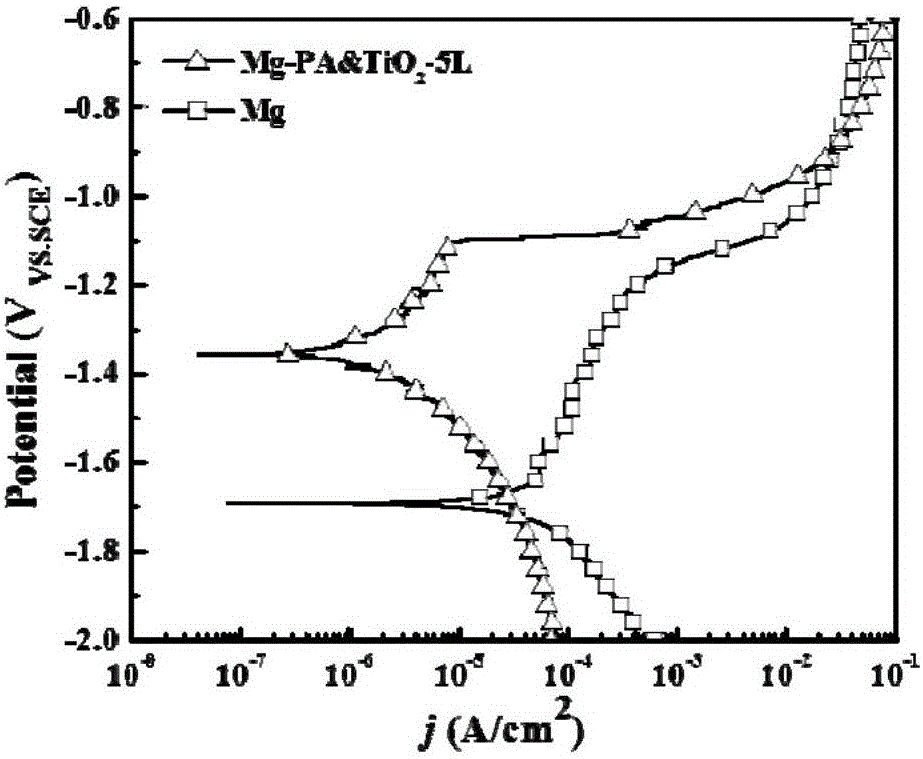

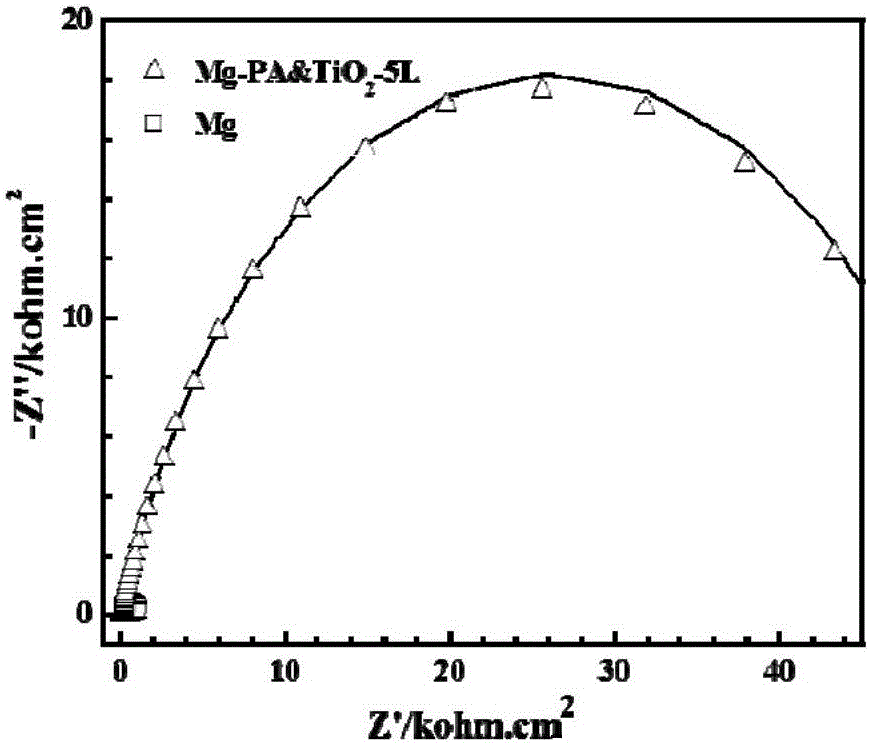

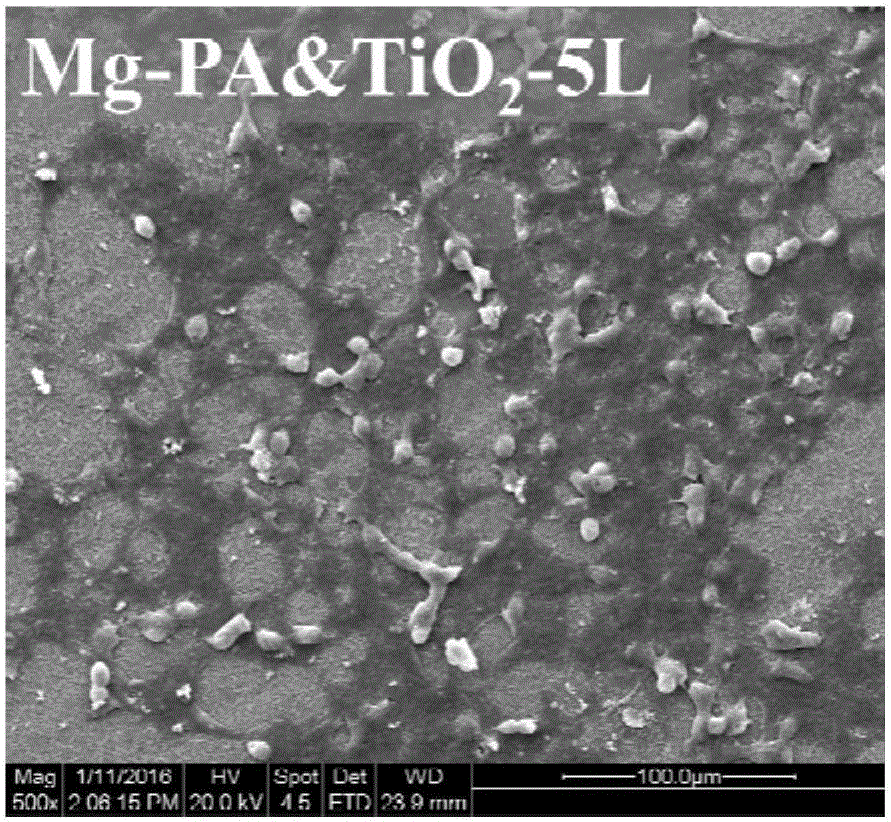

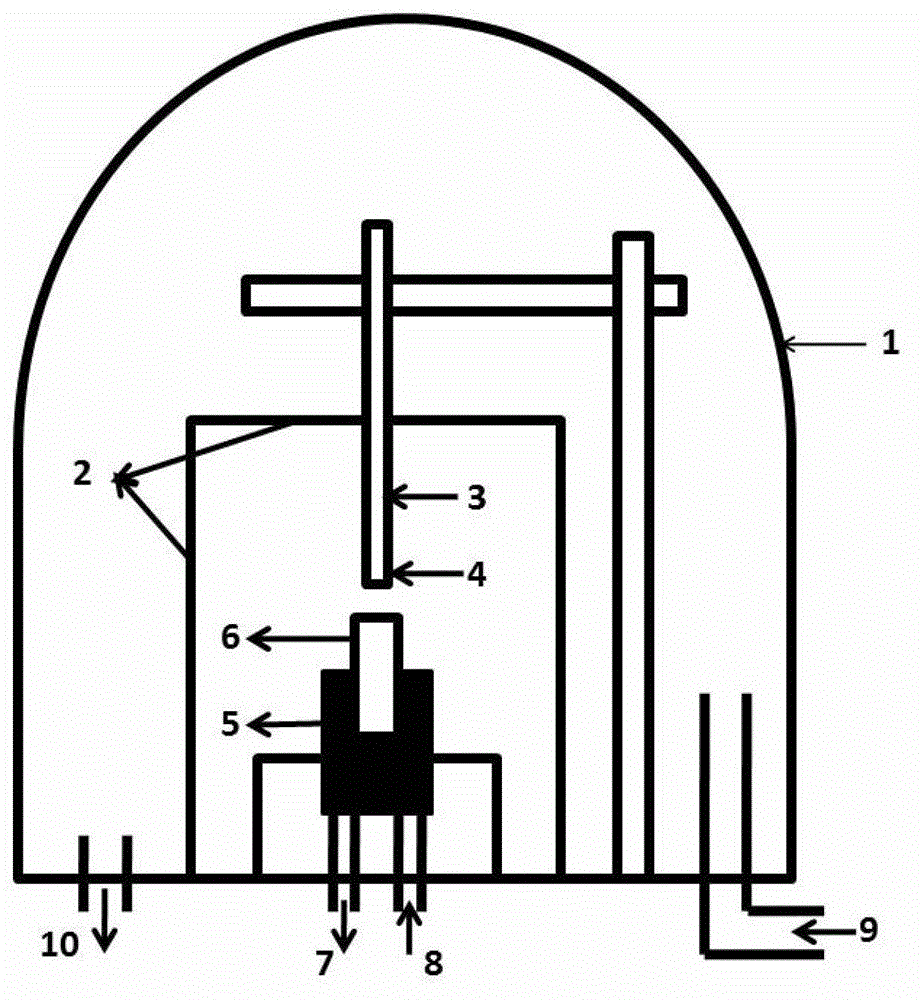

The invention discloses a preparation method for a hybrid composite coating used for magnesium-based biological material surface medication. The preparation method mainly comprises the following steps: A, grinding and polishing a magnesium-based biological material, cleaning the magnesium-based biological material, and vacuum-drying the magnesium-based biological material; B, soaking the magnesium-based biological material into a NaOH solution for 6-12 hours to obtain an alkaline-activated magnesium-based biological material; C, mixing a (NH4)2TiF6 solution with a H3BO3 solution to prepare an inorganic mixed solution with a pH being 2.7-2.9; preparing an organic solution with concentration being 2-10g / L, and regulating the pH value of the organic solution to 5-6, wherein the organic solution is a solution of phosphonic substances; D, soaking the magnesium-based biological material into the organic solution, and preserving the heat for 10-20 minutes at a temperature being 30-40 DEG C; E, soaking the magnesium-based biological material into the inorganic mixed solution, and preserving the heat for 30-40 minutes at a temperature being 45-55 DEG C; and F, repeating steps D and E for 1-10 times, thereby obtaining the hybrid composite coating. The coating prepared by the preparation method is good in binding force with the magnesium-based biological material, so that corrosion resistance and mechanical property of the magnesium-based biological material are improved, and therefore, the coating has very good biocompatibility; and the preparation method is gentle in preparation condition and is simple and controllable in process.

Owner:SOUTHWEST JIAOTONG UNIV

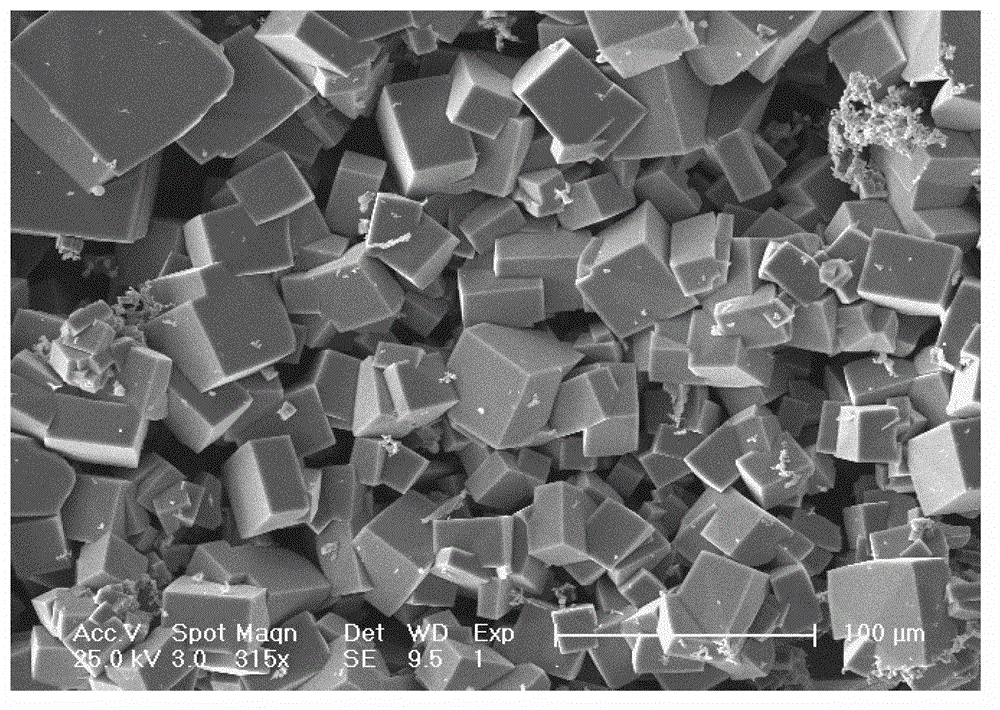

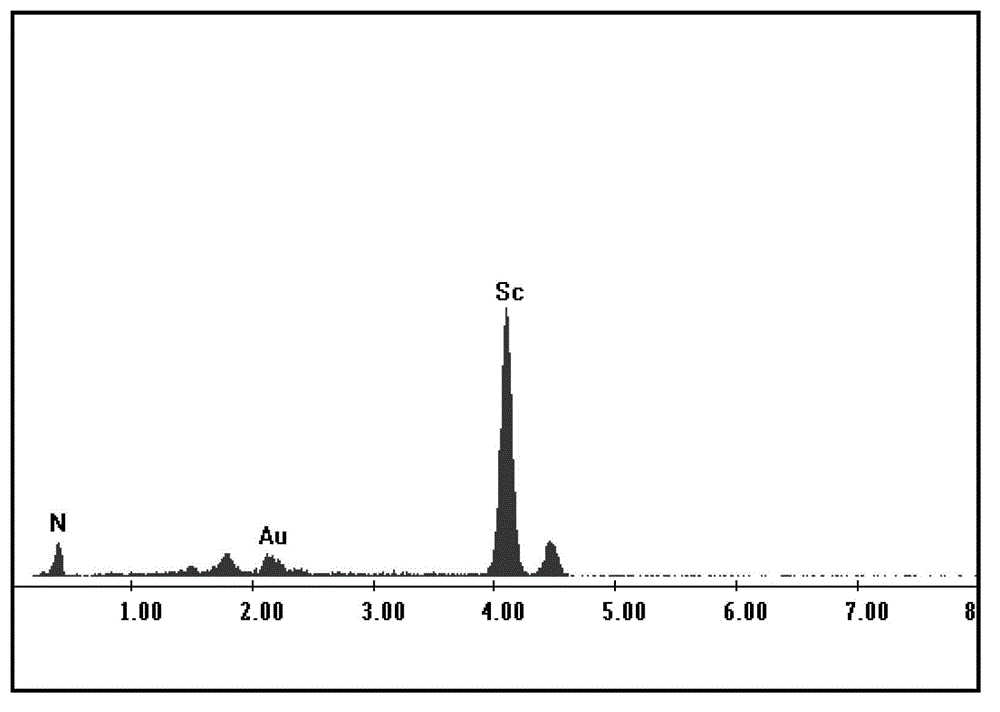

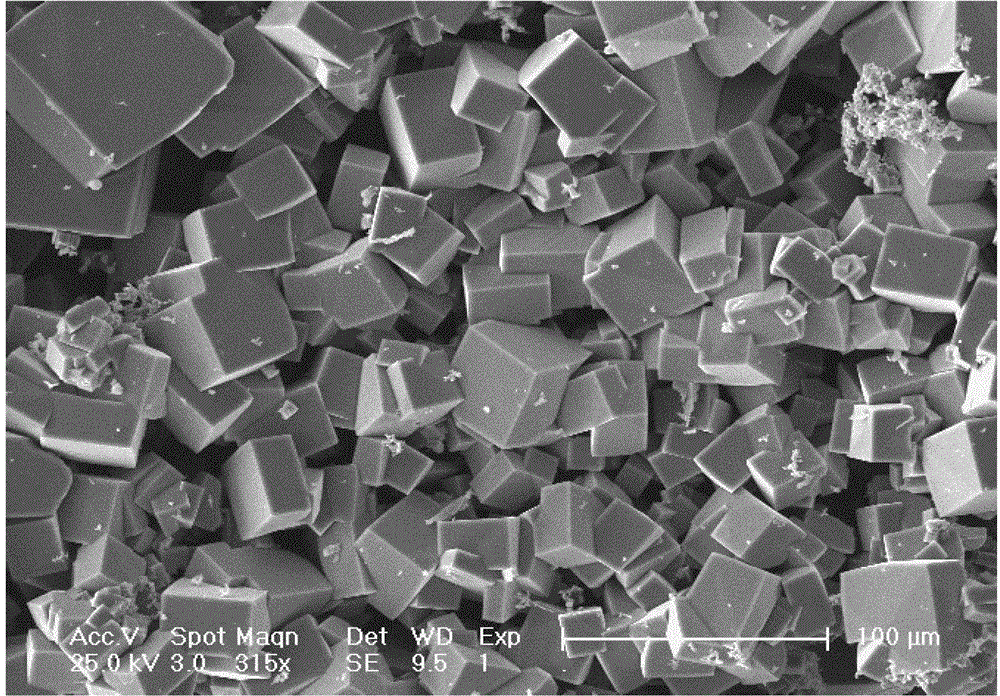

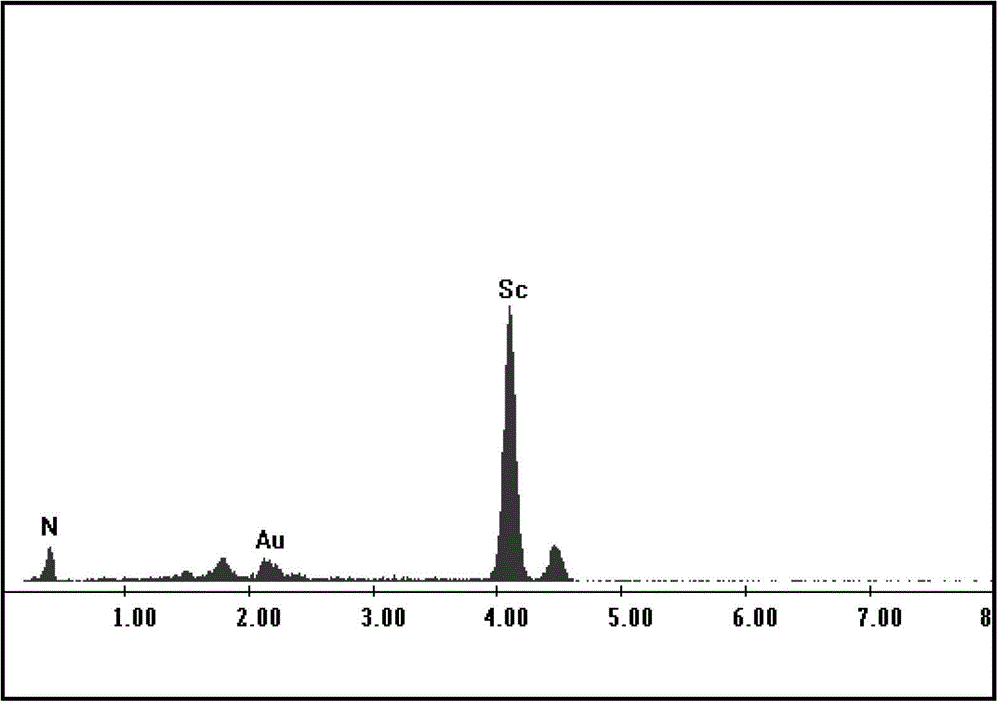

Preparation method of scandium nitride cubic crystal

InactiveCN102874775AWell-definedShape sharp and angularMaterial nanotechnologyNitrogen-metal/silicon/boron binary compoundsRare earthNitrogen gas

The invention provides a preparation method of scandium nitride cubic crystals, belonging to the technical field of preparation of a rare earth nitride nanometer material. The prepared scandium nitride cubic crystal comprises a regular cube or cuboid which has a flat and smooth surface and is uniform in appearance and dimension. With the adoption of the preparation method, the high-purity rare earth metal is directly reacted with nitrogen through a direct current arc plasma discharging device under the assistance of a high-temperature low-air pressure system condition and plasma, so as to prepare into powder with metallic luster and showing bluish green. According to the preparation method provided by the invention, the direct current arc plasma discharging device is utilized at the first time to synthesize scandium nitride cubic crystal which has high impurity and is uniform in appearance and dimension; the preparation method is simple, reliable, high in repeatability, short in reaction time, low in energy consumption, needs no the harsh vacuum condition, is environment-friendly, and has high output of products; and the scandium nitride cubic crystal has outstanding physical properties such as electricity, mechanics and the like, thus the scandium nitride cubic crystal can be widely applied in the fields of semiconductor devices and durable protecting coating and the like.

Owner:JILIN UNIV

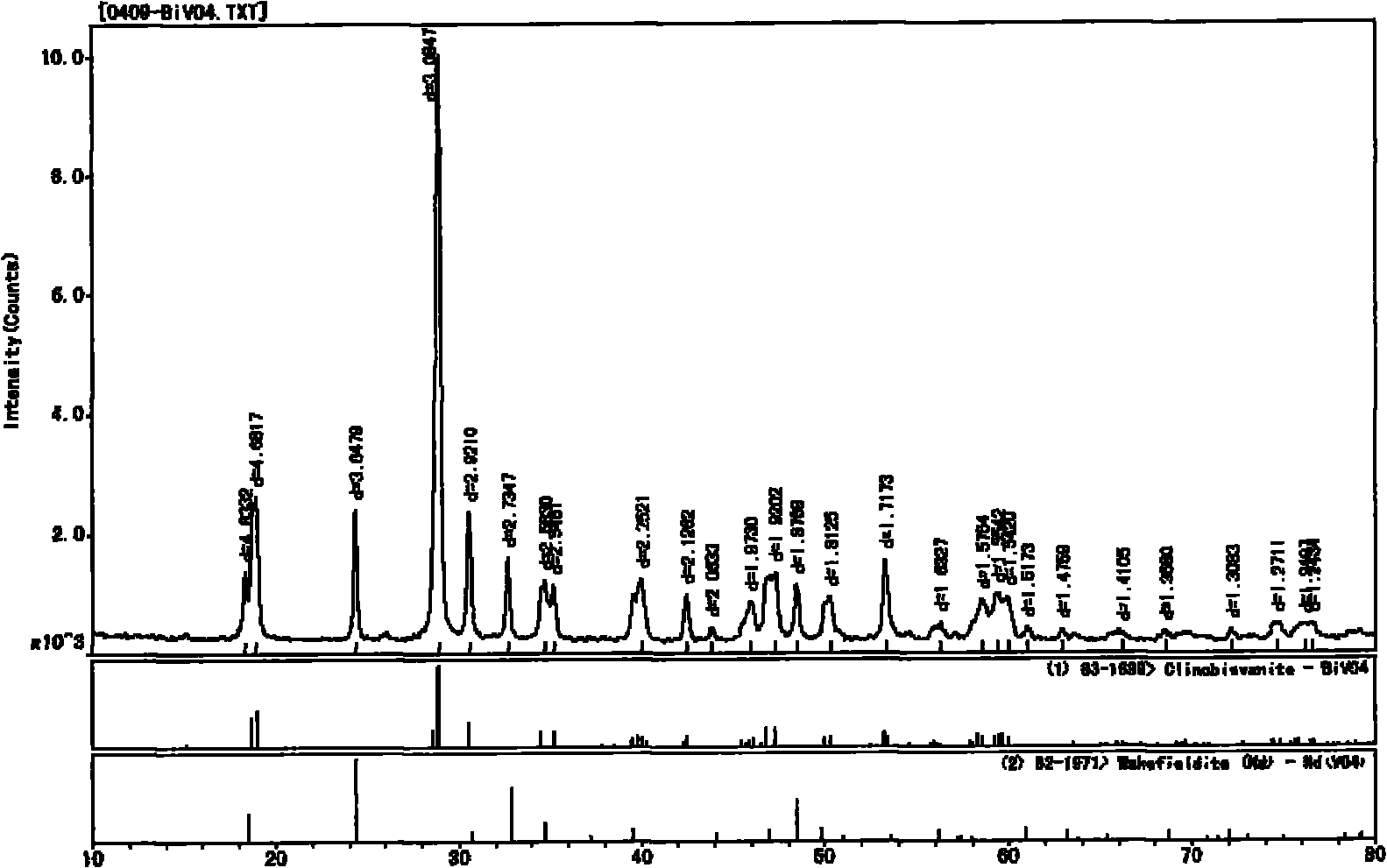

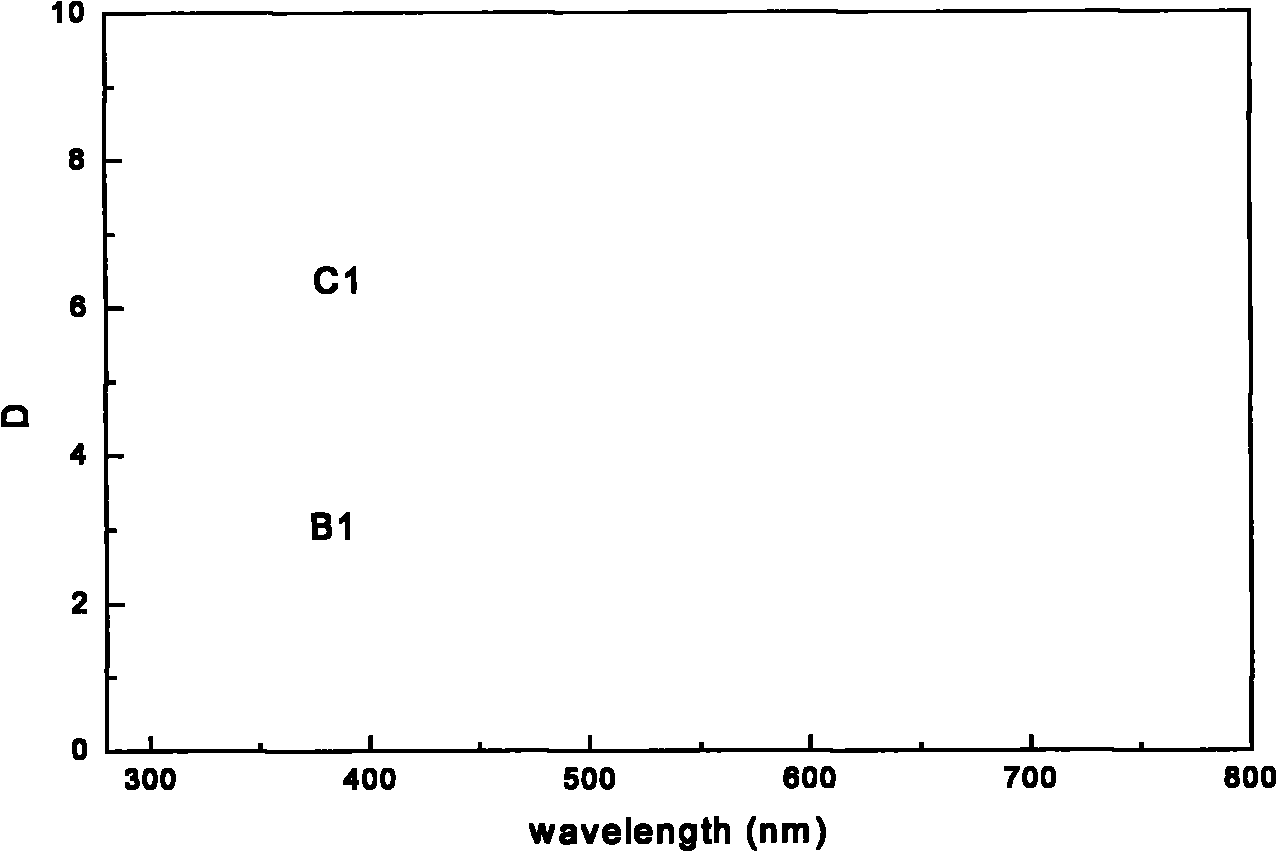

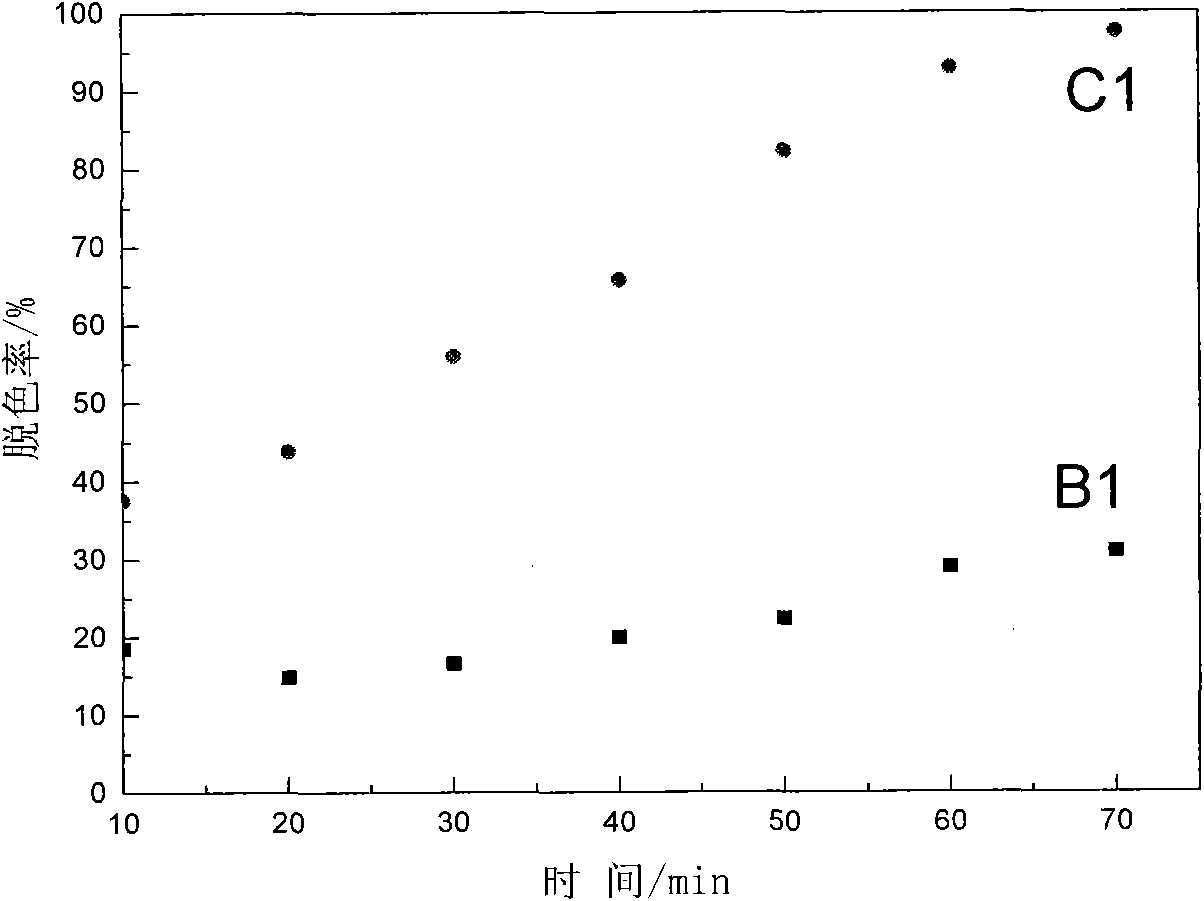

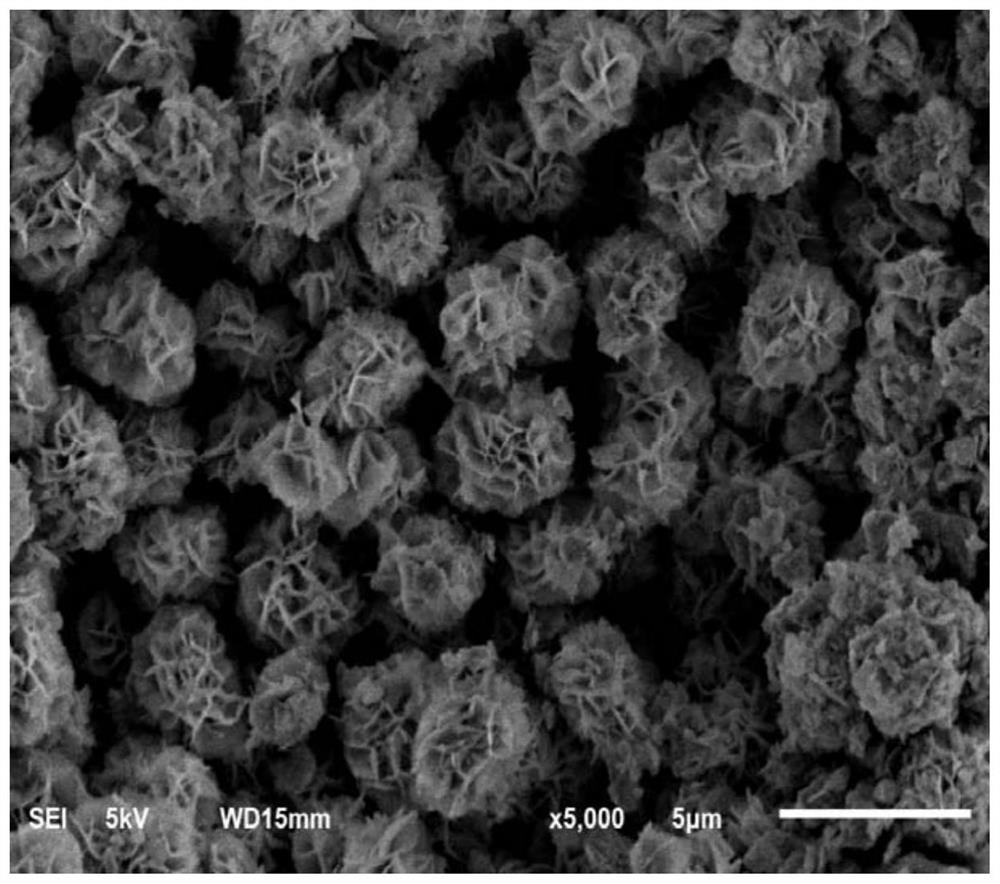

Ultrasonic chemical in-situ preparation method for phthalocyanine-sensitized vanadate nano-powder

InactiveCN101786023AGuaranteed sizeIntegrity guaranteedOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationBismuth vanadateCompound (substance)

The invention belongs to the technical field of photocatalysts, in particular to an ultrasonic chemical in-situ preparation method for phthalocyanine-sensitized vanadate nano-powder. The method comprises the following steps specifically: dissolving a bismuth-containing reactant A in 2 to 5 mol / L acidic diluting agent to obtain a reaction liquid A; dissolving a vanadate-containing reactant B in distilled water to obtain a reaction liquid B of which the concentration is the same as that of the reaction liquid A; adding phthalocyanine serving as a sensibilizer into the reaction liquid A; adjusting the pH value of the solution to be between 1 and 4 by using an alkaline diluting agent; adjusting the temperature of the reaction liquid A to be between 50 and 95 DEG C; holding the temperature for 2 to 4 hours; adding the reaction liquid B into the reaction liquid A dropwise; and performing an ultrasonic reaction on the mixed liquid for 2 to 4 hours to obtain a product. The bismuth vanadate photocatalyst prepared by the method has the characteristics of good uniformity and higher photocatalytic activity.

Owner:海门嘉濠建材贸易有限公司

High-speed, high-density and lower power consumption phase-change memory unit and preparation method thereof

InactiveCN103682089AImprove thermal stabilityLow thermal conductivityElectrical apparatusPhase-change memoryHigh density

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

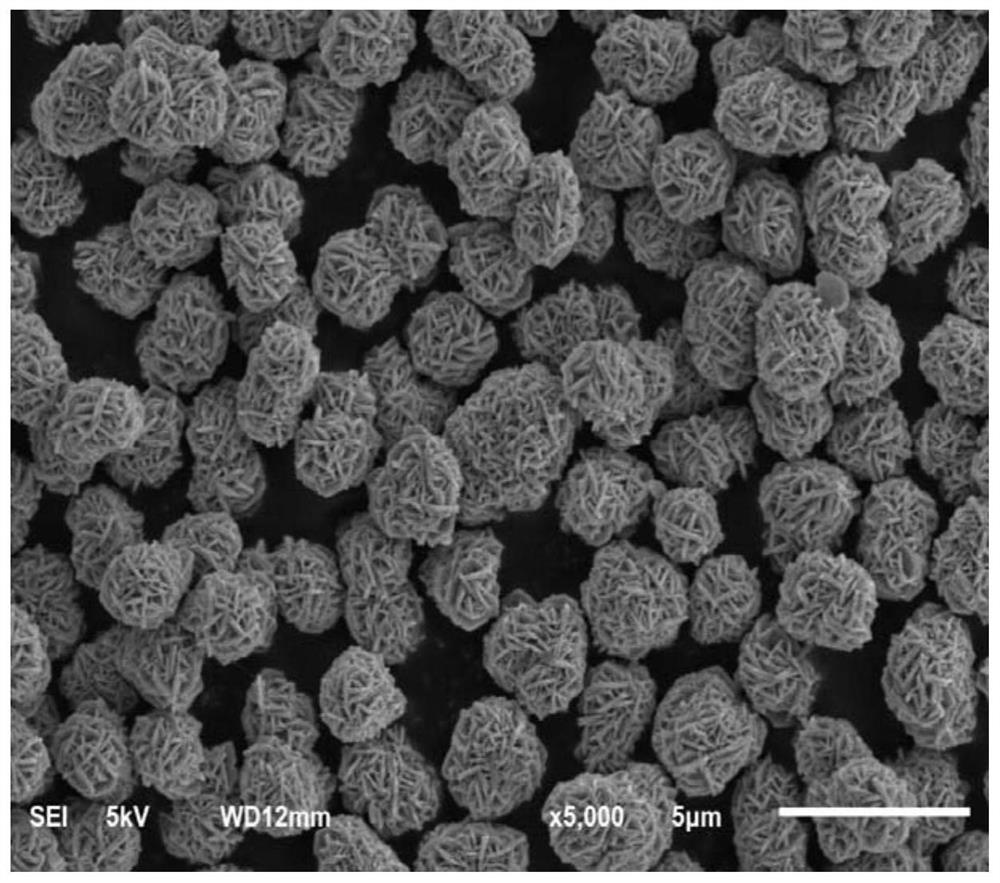

Small-particle ternary precursor and preparation method thereof

ActiveCN113735190APromote nucleation growthLow boiling pointSecondary cellsPositive electrodesPotassium hydroxideAqueous solution

The invention relates to a small-particle ternary precursor and a preparation method thereof, the ternary precursor is NixCoyMnzZrk (OH) 2, x is more than or equal to 0.70 and less than 0.98, y is more than 0 and less than 0.30, z is more than 0.01 and less than 0.30, k is more than 0.001 and less than 0.006, and x + y + z + k is equal to 1; and D50 is 3-5 [mu] m. The preparation method comprises the following steps: 1, preparing a mixed solution of Ni, Co, Mn, zircon salt, ethanol, hydrogen peroxide, an additive and urea; preparing a mixed salt solution of Ni, Co, Mn and zircon salt; preparing a sodium hydroxide or potassium hydroxide solution as a precipitator; and preparing an ammonia water solution as a complexing agent; 2, putting the mixed solution into a hydrothermal kettle, carrying out hydrothermal reaction at 120-200 DEG C for 12-18 hours, and carrying out centrifugal washing to obtain an intermediate; 3, adding the intermediate as a seed crystal into a reaction kettle, and adding a precipitator, pure water and a complexing agent to prepare a base solution; wherein the pH value of the base solution is 11.20-11.80, and the temperature is 55-75 DEG C; 4, continuously adding the mixed salt solution, a precipitant and a complexing agent into the reaction kettle at the flow speed of 200-800 mL / min for coprecipitation; and 5, carrying out filter pressing, washing and drying on the co-precipitation product to obtain the internally loose ternary precursor. By adding the zirconium element, the cycle performance is effectively improved. The prepared ternary positive electrode material can relieve volume expansion generated by charging and discharging, and the electrochemical performance is improved.

Owner:南通金通储能动力新材料有限公司

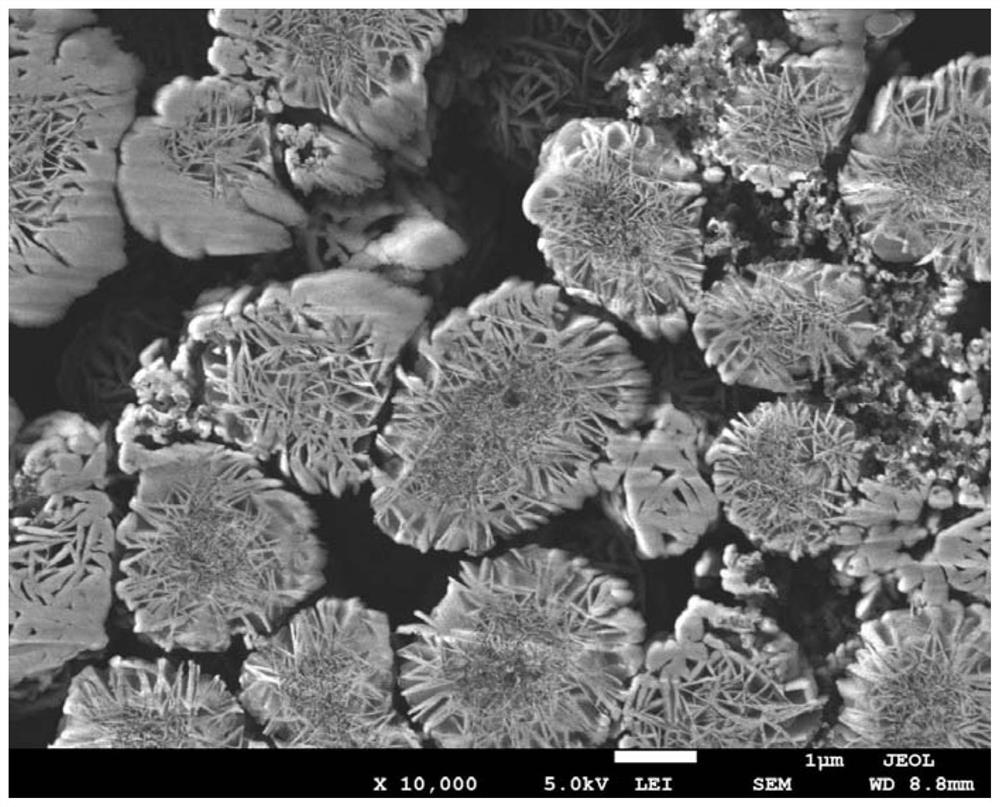

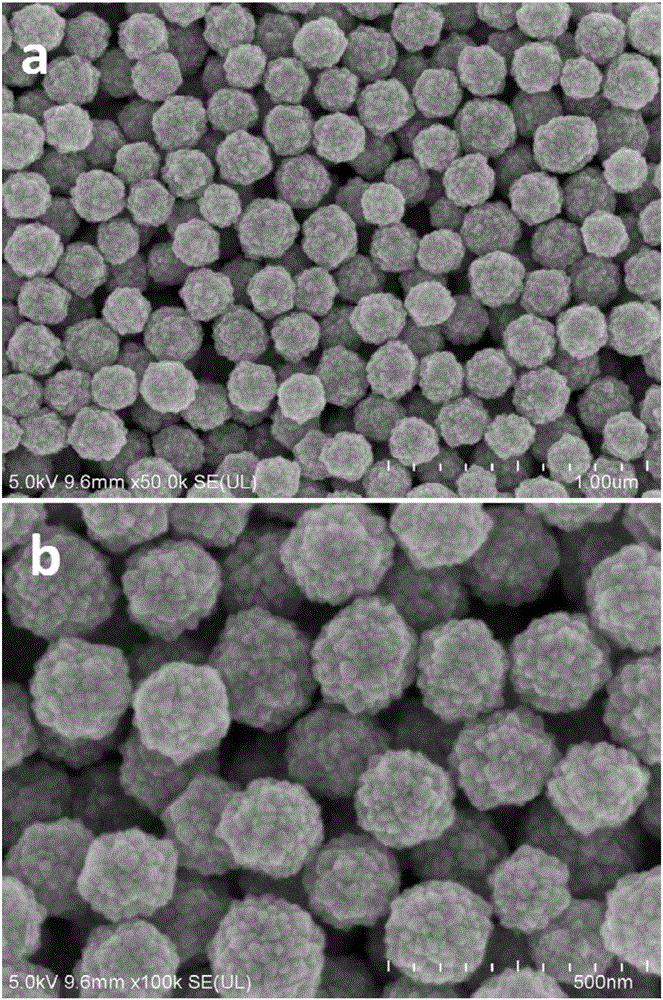

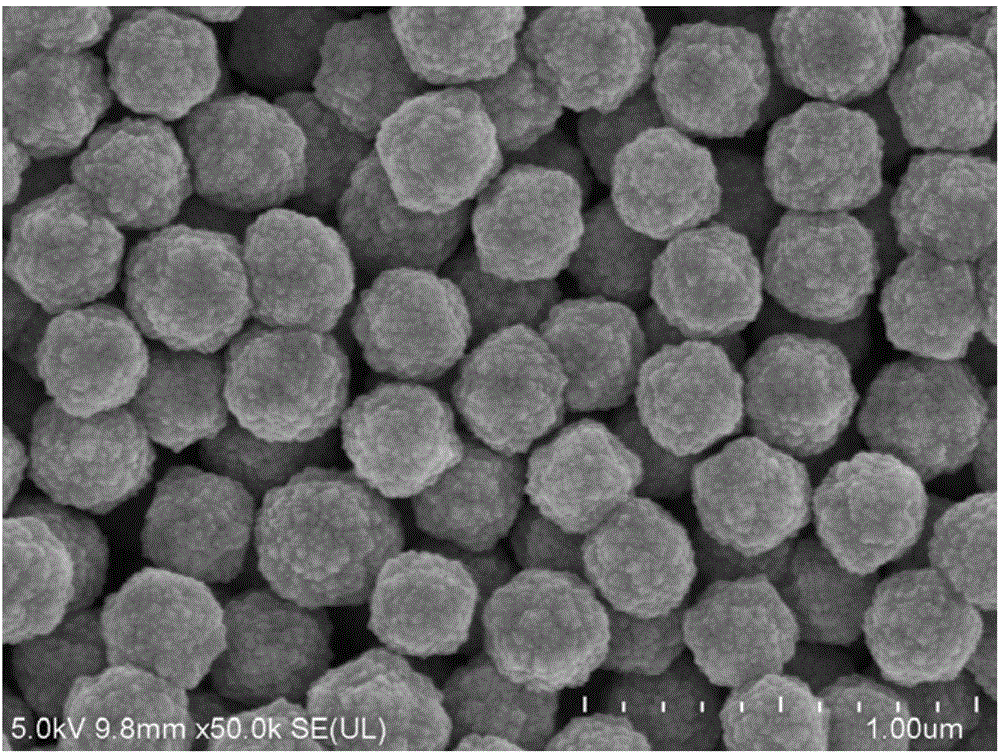

A Stannic Oxide Microballoon with Controllable Crystallite Dimension and its Preparation Method and Application

ActiveCN106277040AInhibit hydrolysisPromote nucleation growthLight-sensitive devicesSecondary cellsChemistryPhotocatalysis

This invention involves a kind of stannic oxide microballoon with controllable crystallite dimension and its preparation method and application. This stannic oxide microballoon is composed of stannic oxide microcrystal with fine crystallinity through self-assembly. The grain size of stannic oxide microcrystal is adjustable within range of 5-30nm. The diameter of stannic oxide microballoon is 200-400nm and its specific surface area >40m2 / g; During preparation, add concentrated hydrochloric acid and tin source into the mixed solution of normal propyl alcohol and water in order, forming the transparent homogeneous solution; Conduct solvothermal reaction; After the reaction ends, take out the sediment, wash and separate it. Being compared with the current technology, this invention has simple and easy process route, which does not need surface active agent. And the multilevel structure Sno2 microballoon with equally distributed dimension can be gotten through one-step method, which is composed of stannic oxide microcrystal through self-assembly. Also, the dimension of Sno2 microcrystal can be adjusted and controlled through adjusting the alcohol / water proportion in the reaction system. The microballoon has features of high specific area and submicron level dimension, which has wide application prospect in areas of solar cell, lithium ion battery and photocatalysis.

Owner:SHANGHAI UNIV OF ENG SCI

Preparation method of scandium nitride cubic crystal

InactiveCN102874775BPromote nucleation growthStable temperatureMaterial nanotechnologyNitrogen-metal/silicon/boron binary compoundsRare earthImpurity

The invention provides a preparation method of scandium nitride cubic crystals, belonging to the technical field of preparation of a rare earth nitride nanometer material. The prepared scandium nitride cubic crystal comprises a regular cube or cuboid which has a flat and smooth surface and is uniform in appearance and dimension. With the adoption of the preparation method, the high-purity rare earth metal is directly reacted with nitrogen through a direct current arc plasma discharging device under the assistance of a high-temperature low-air pressure system condition and plasma, so as to prepare into powder with metallic luster and showing bluish green. According to the preparation method provided by the invention, the direct current arc plasma discharging device is utilized at the first time to synthesize scandium nitride cubic crystal which has high impurity and is uniform in appearance and dimension; the preparation method is simple, reliable, high in repeatability, short in reaction time, low in energy consumption, needs no the harsh vacuum condition, is environment-friendly, and has high output of products; and the scandium nitride cubic crystal has outstanding physical properties such as electricity, mechanics and the like, thus the scandium nitride cubic crystal can be widely applied in the fields of semiconductor devices and durable protecting coating and the like.

Owner:JILIN UNIV

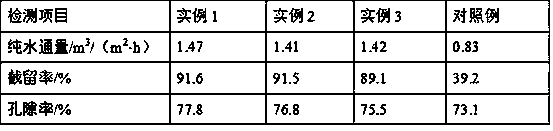

Method for preparing composite ultrafiltration membrane

InactiveCN108854572AImprove hydrophilicityIncrease membrane fluxMembranesSemi-permeable membranesPolyvinylidene fluorideUltrafiltration

The invention relates to a method for preparing a composite ultrafiltration membrane, and belongs to the technical field of water treatment. The composite ultrafiltration membrane is prepared by a sol-gel method. Silica and titanium dioxide are added to a casting solution, and the phase splitting process in the film formation process is controlled by means of the unique chain structure of the silica and the hydroxyl group on the surface thereof. The blending of nano titanium dioxide and a membrane material can enhance the hydrophilicity of the membrane, increase the membrane flux, improve theroughness of the membrane surface, delay membrane fouling, prolong the service life of the membrane, and reduce the operating cost of the membrane device. The porosity of the composite ultrafiltrationmembrane is gradually increased, and the water flux is gradually increased. A hydrogen bond may also be formed between polyvinylidene fluoride and cellulose micro / nano crystal, which enables the cellulose micro / nano crystal to be uniformly dispersed in a polyvinylidene fluoride solution, and have good interface bonding with the polyvinylidene fluoride, so that the composite membrane has certain strength and toughness, and thus the composite membrane exhibits good mechanical properties.

Owner:黄勇

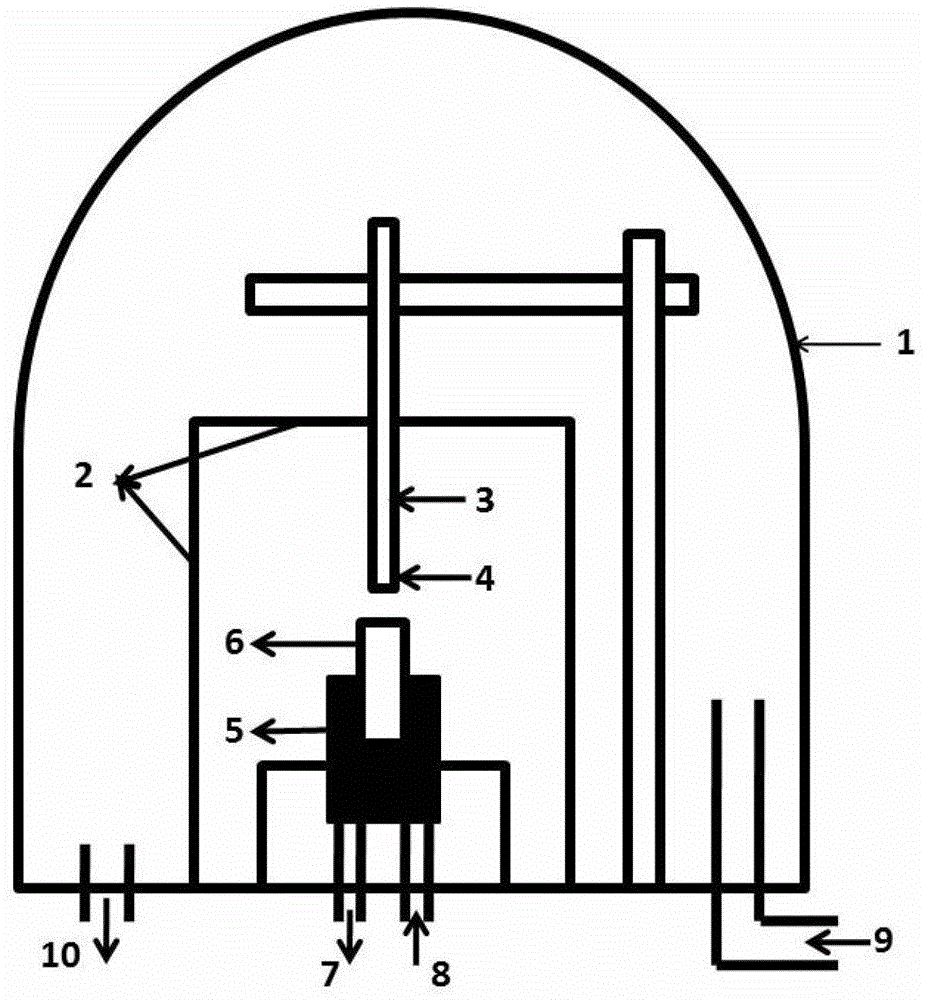

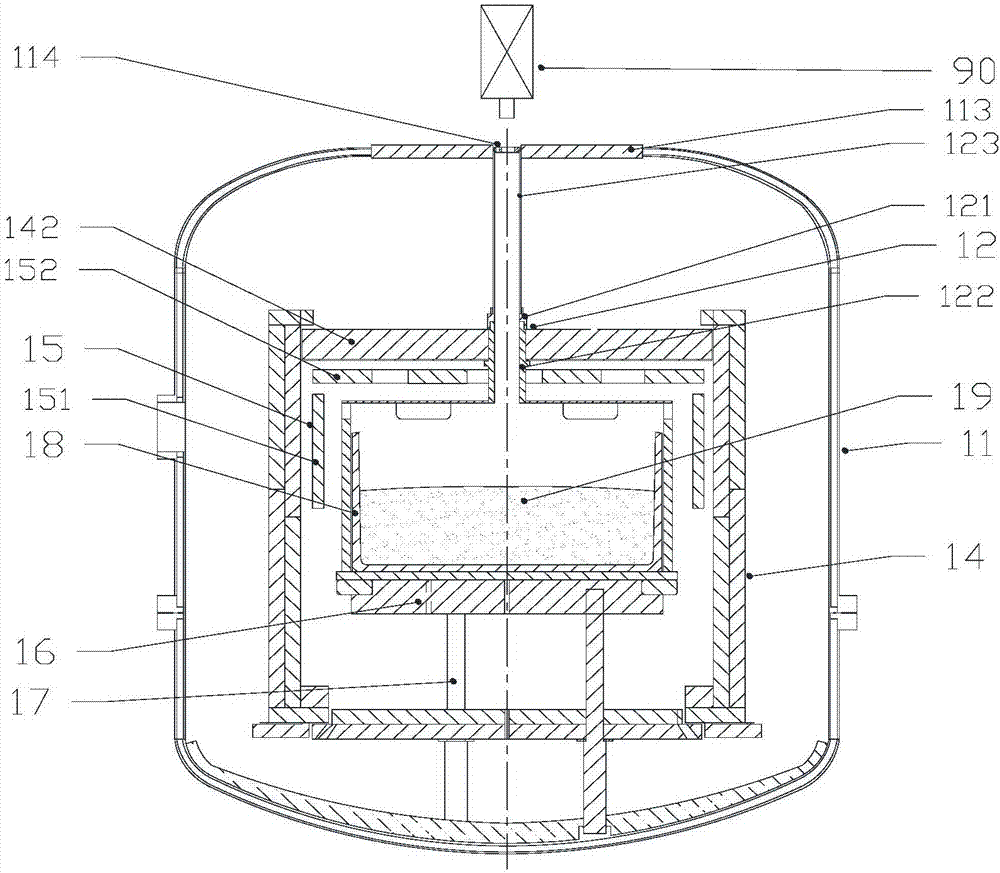

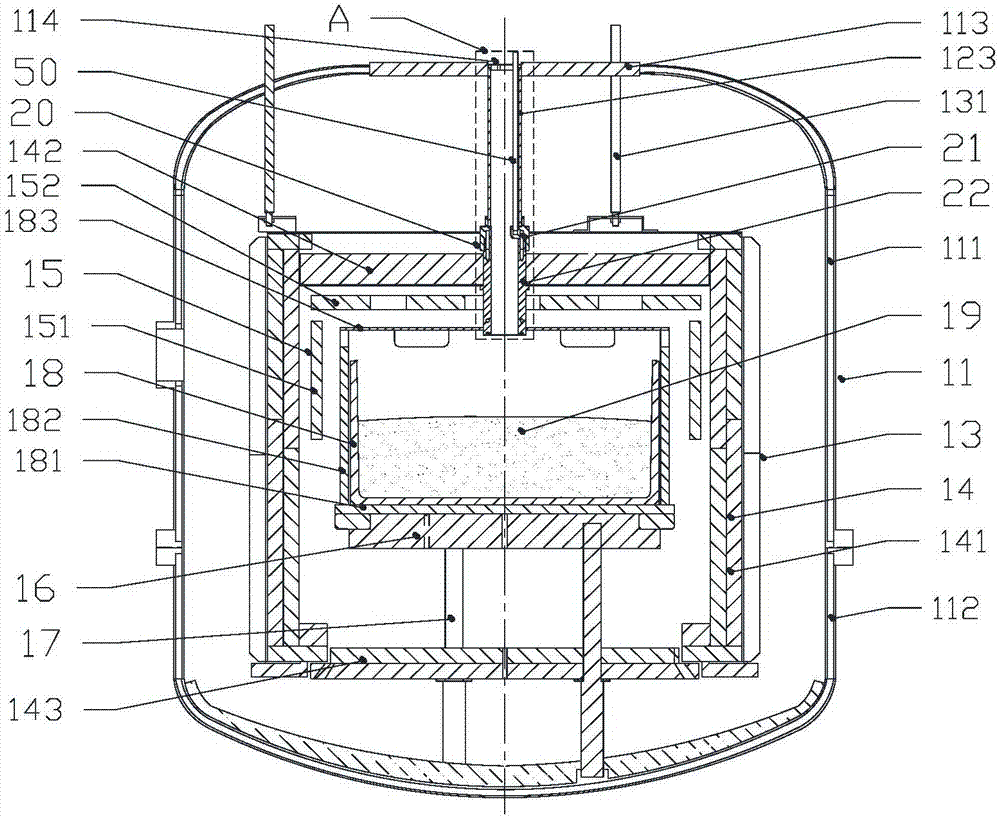

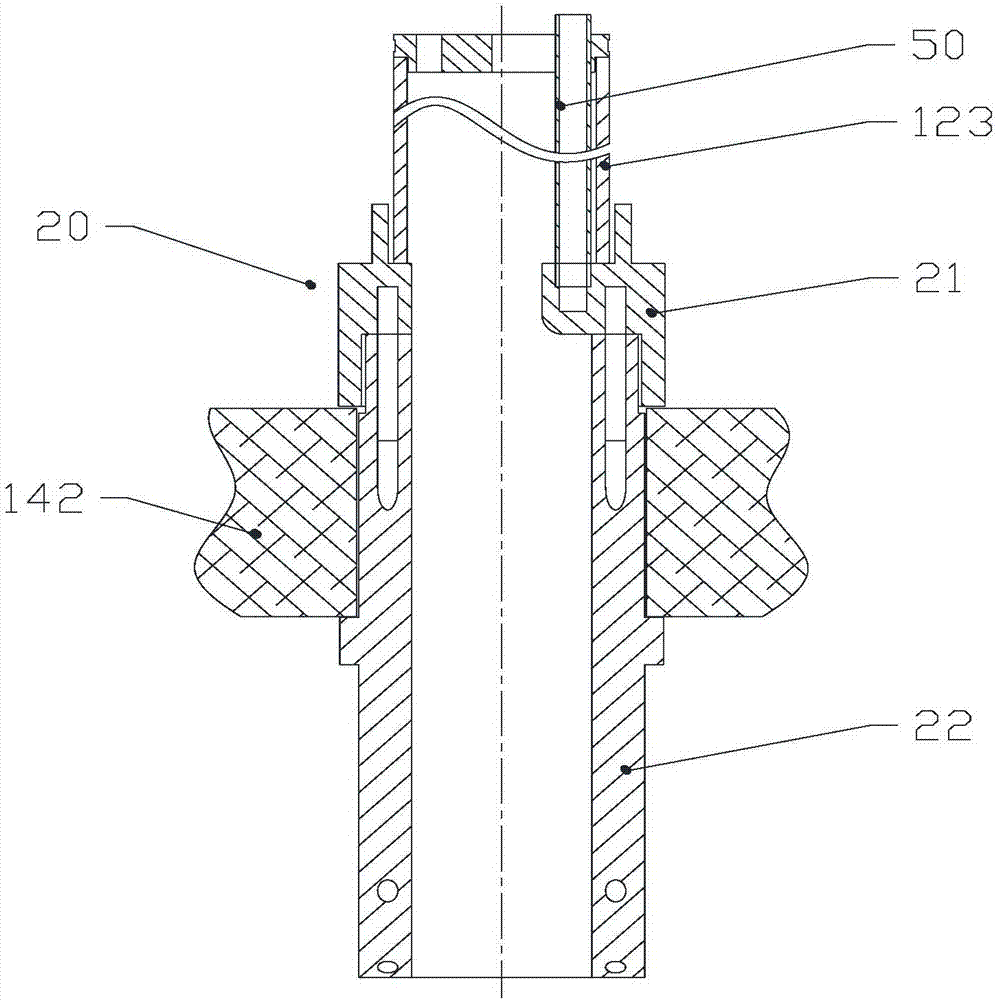

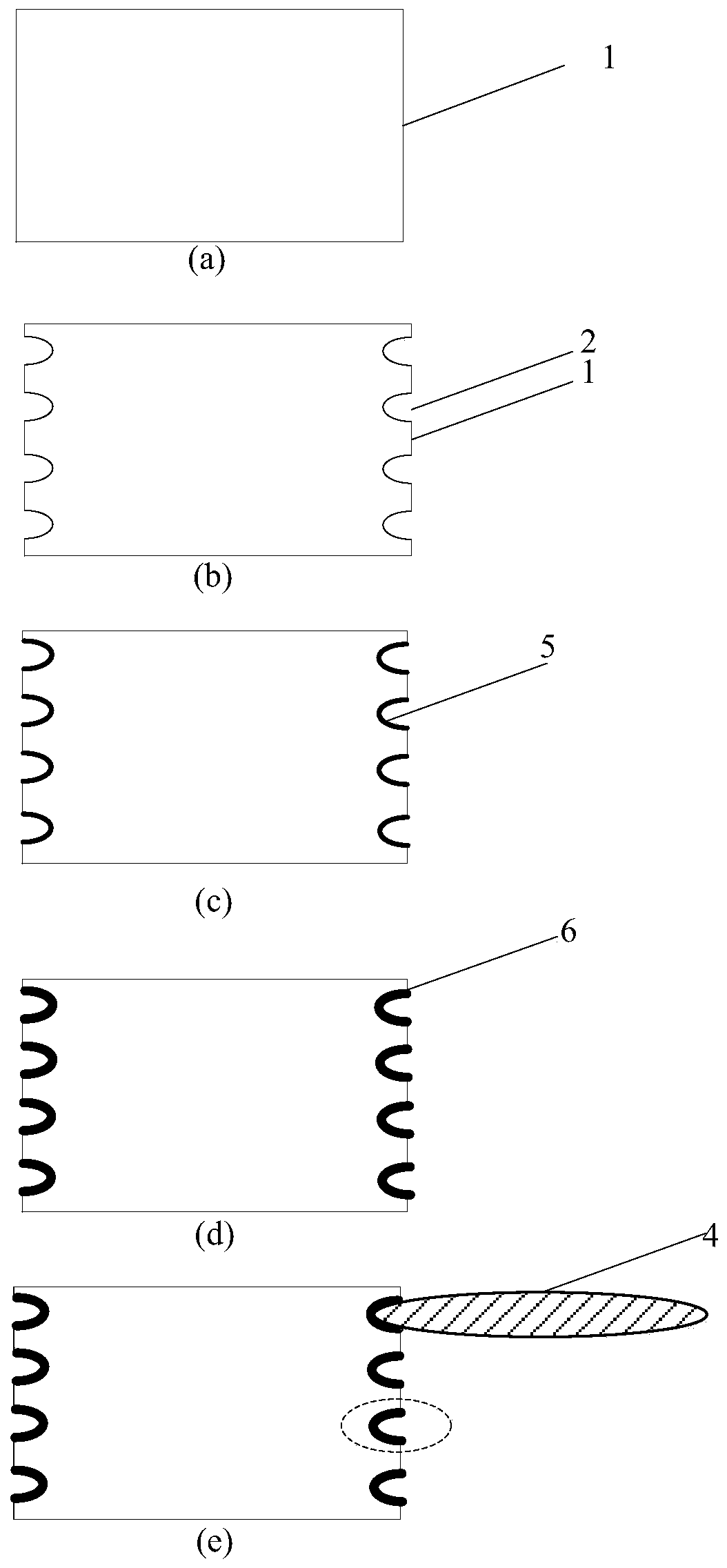

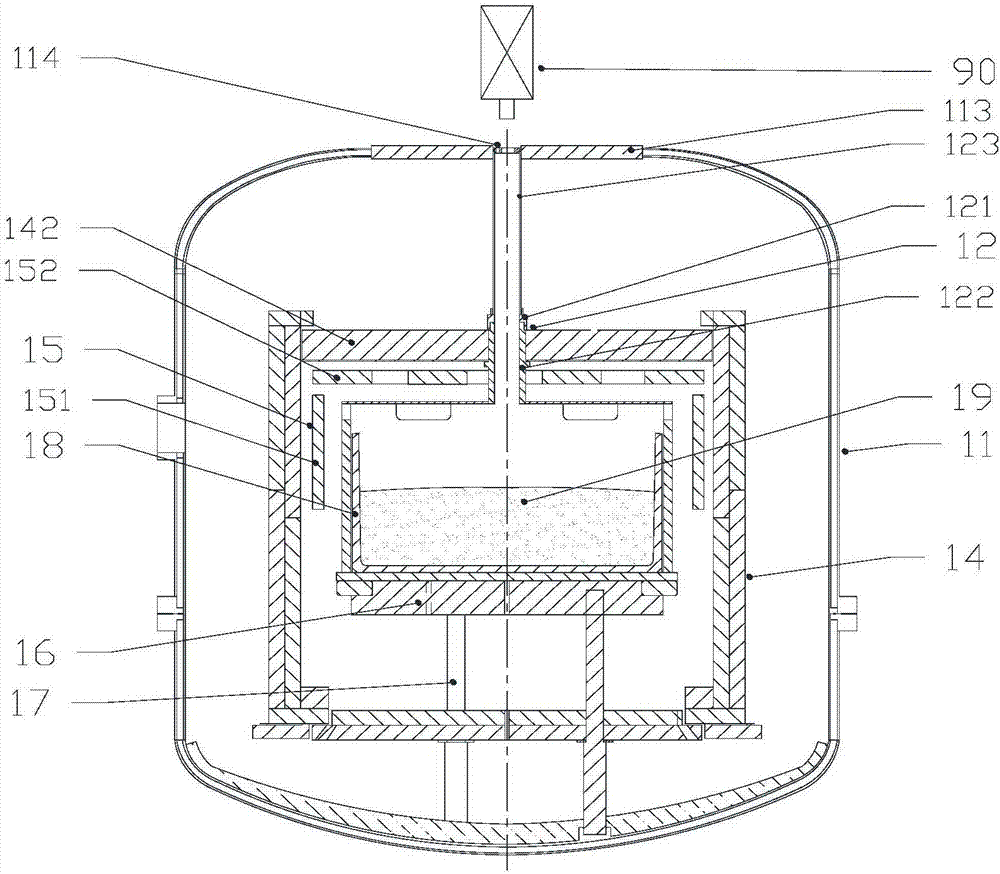

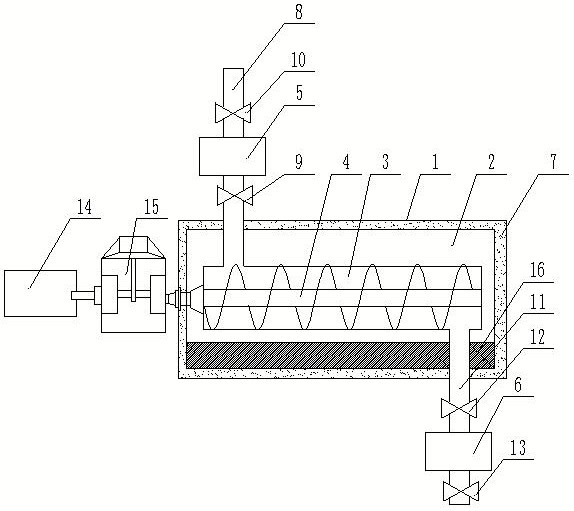

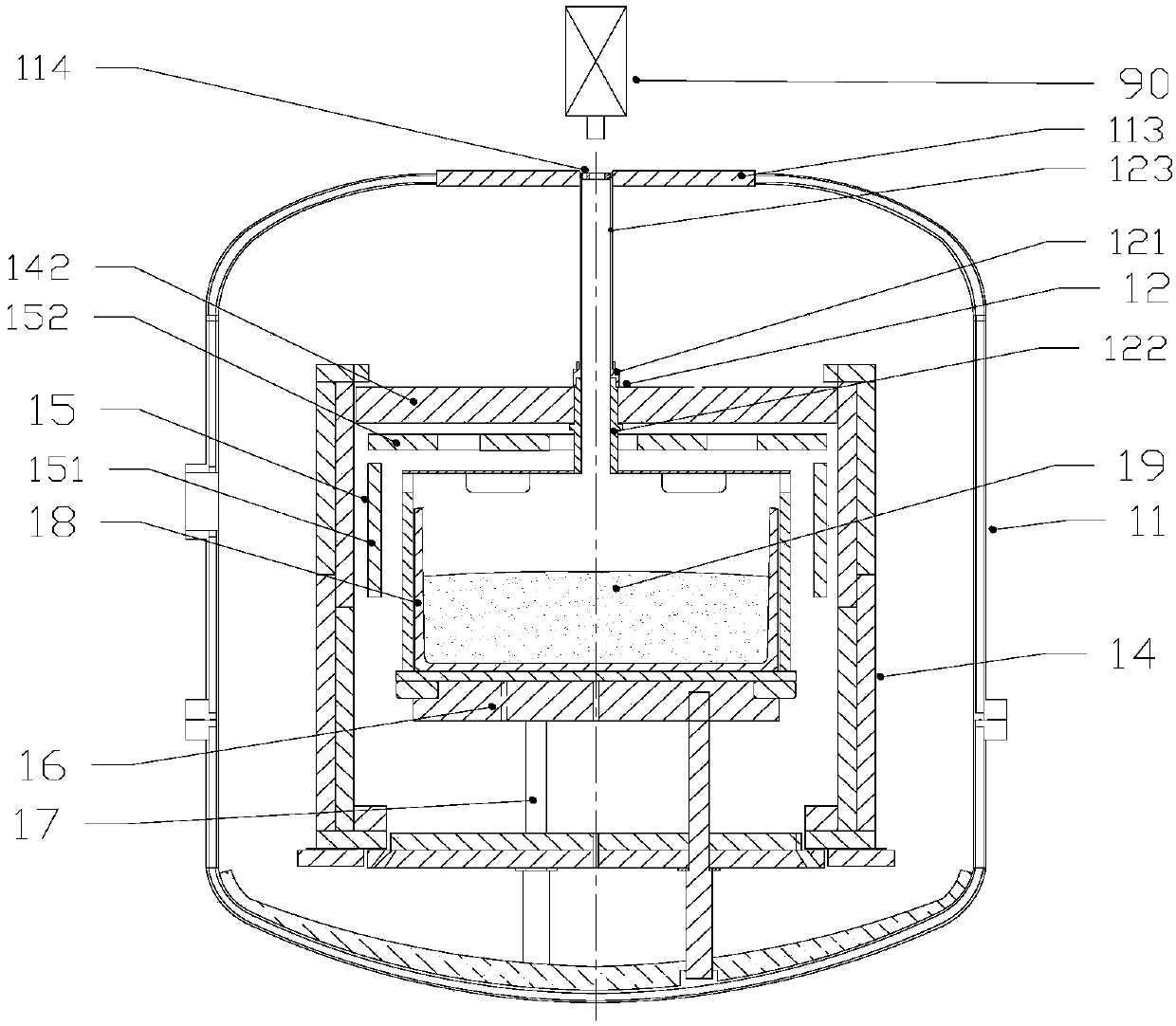

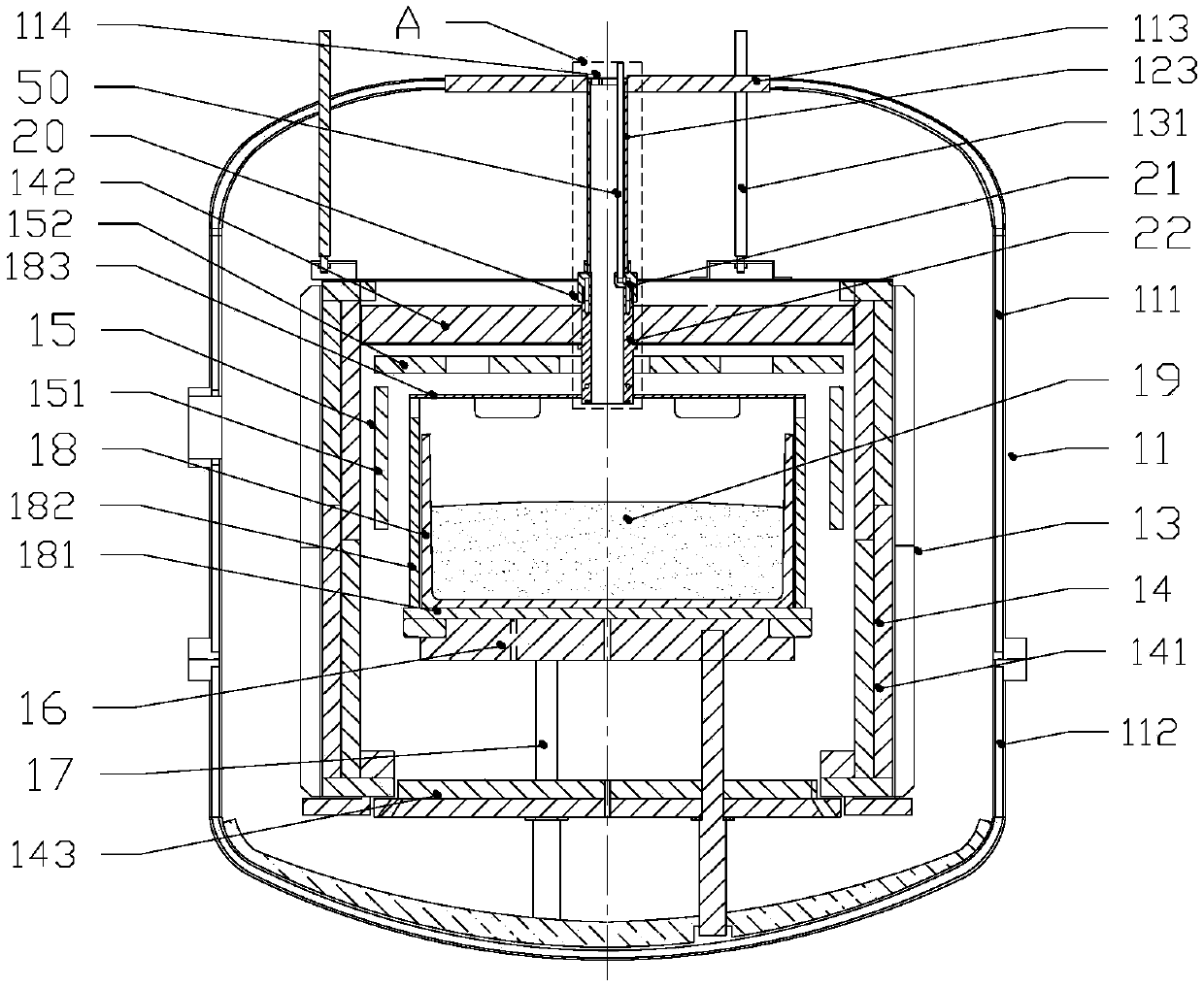

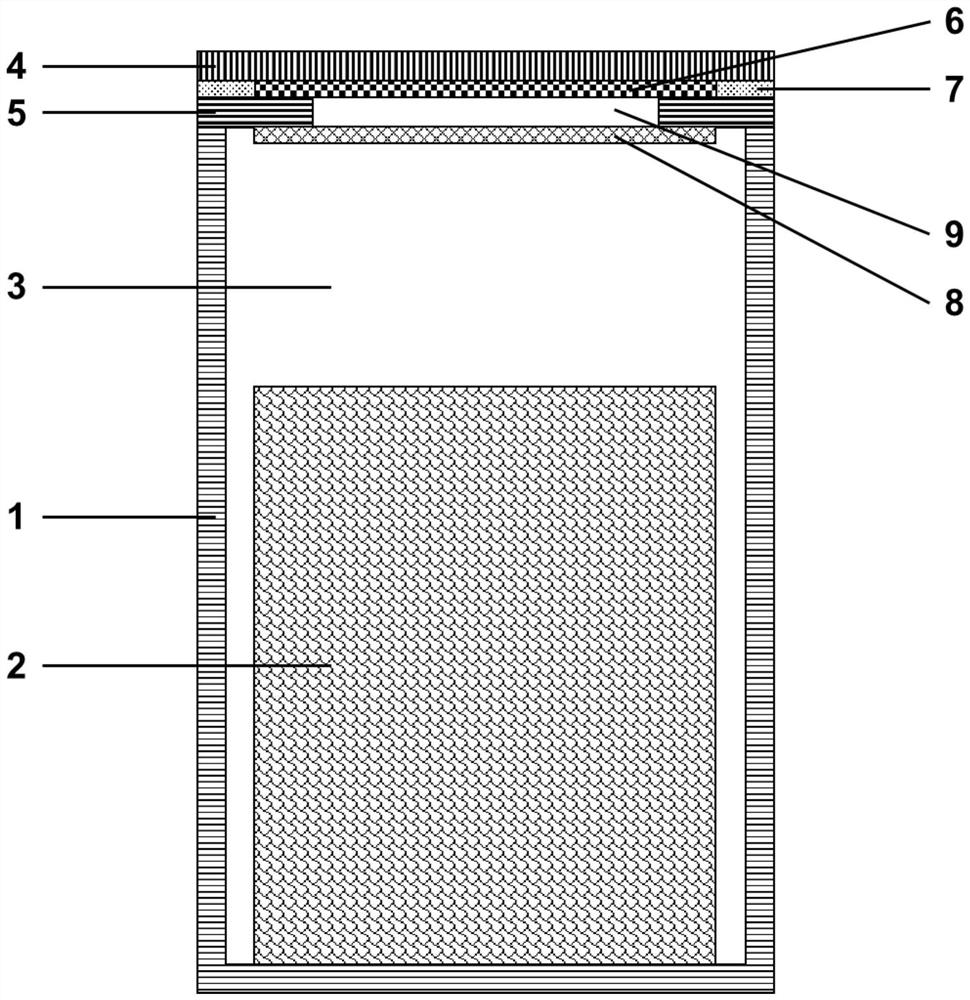

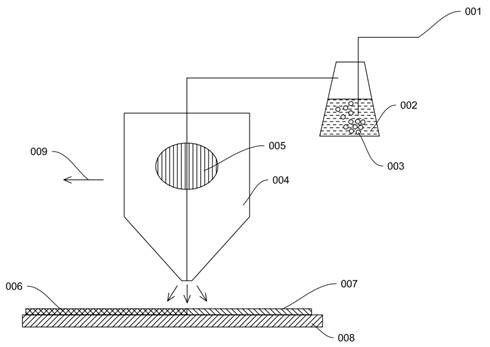

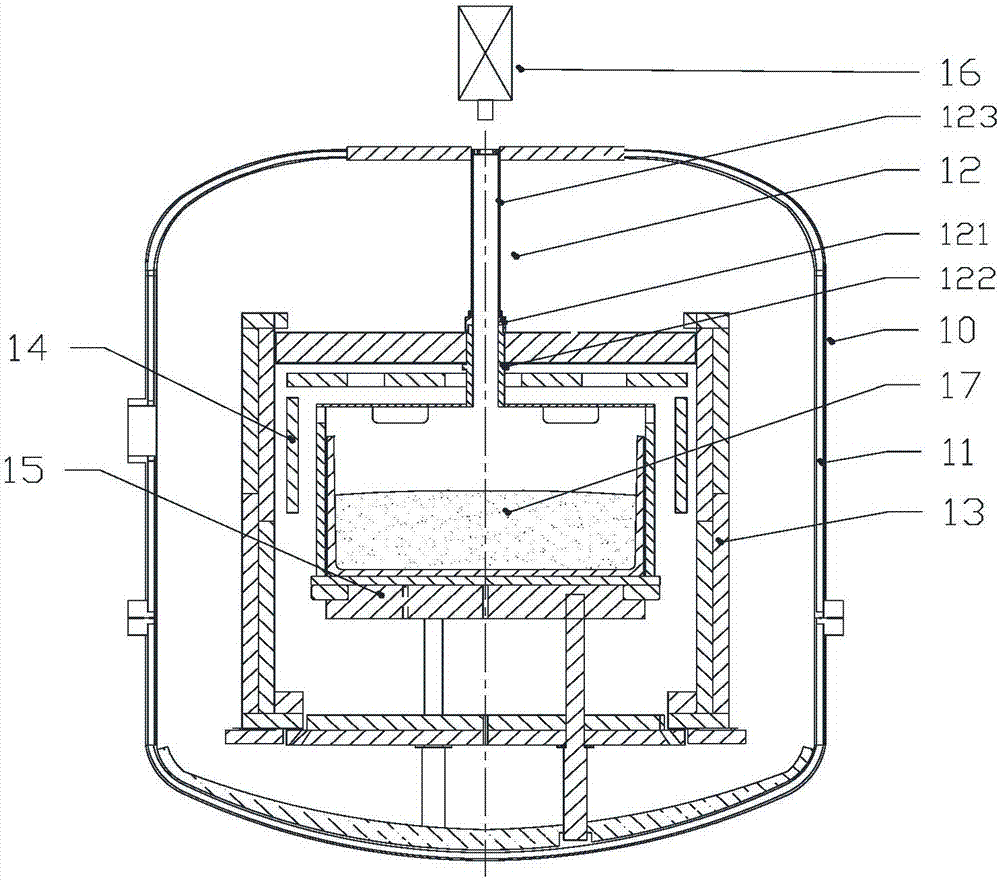

Polysilicon ingot furnace with diversion device

InactiveCN107385511AIncrease contact areaReduced chance of nucleationPolycrystalline material growthSingle crystal growth detailsEngineeringIngot

The invention discloses a polysilicon ingot furnace with a diversion device. The polysilicon ingot furnace comprises a heat insulation cage, a gas pipe and a diversion device. The diversion device is equipped with multiple diversion airways used for dividing input carrier gas into multiple outgoing carrier gas flows. The carrier gas flows are dispersedly and slantly blown to different areas on the surface of liquid silicon, thus effectively increasing contact area of the carrier gas and the surface of liquid silicon and minimizing heat per unit area by carrier gas flow. Thermal drop of liquid silicon in the area is reduced, degree of supercooling is decreased, and impurity nucleation and impurity formation caused by carrier gas are reduced. The outgoing carrier gas flows produce carrier gas stress to liquid silicon so as to drive liquid silicon to flow and to form a rotary flow field for circumferential flow. The rotary flow field is beneficial to transportation and uniform distribution of impurities in liquid silicon. An observation window at the top of the furnace has a field of view leading to the ingot furnace via the diversion device. Through the observation window, state inside the furnace can be observed, and a crystal measurement rod is inserted into the furnace. An infrared detector can detect the state of silicon materials inside the furnace, and the automatic crystal growth process is smoothly carried out.

Owner:陈鸽

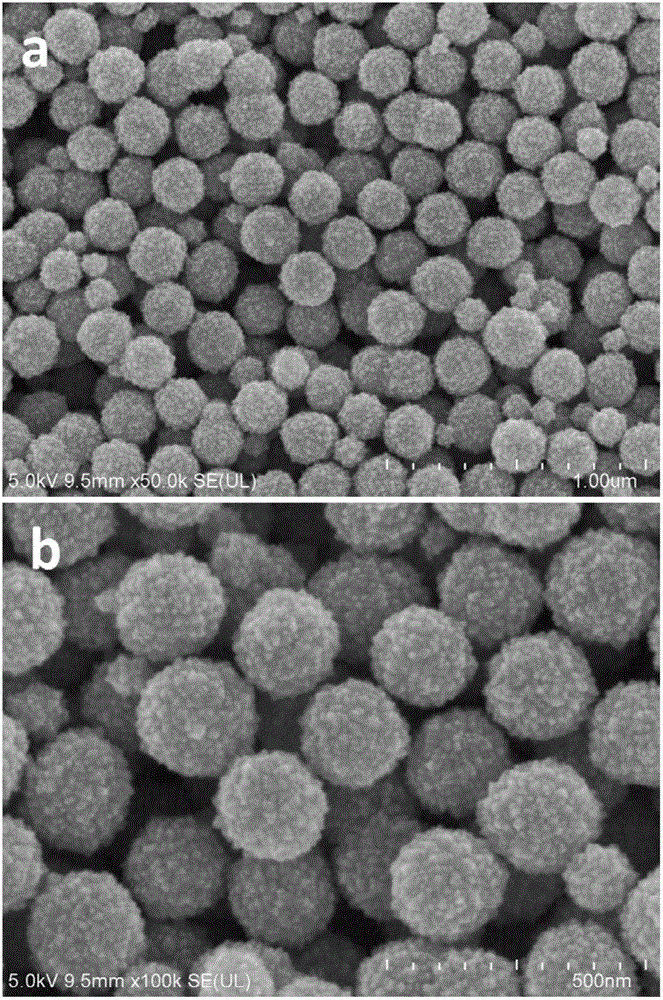

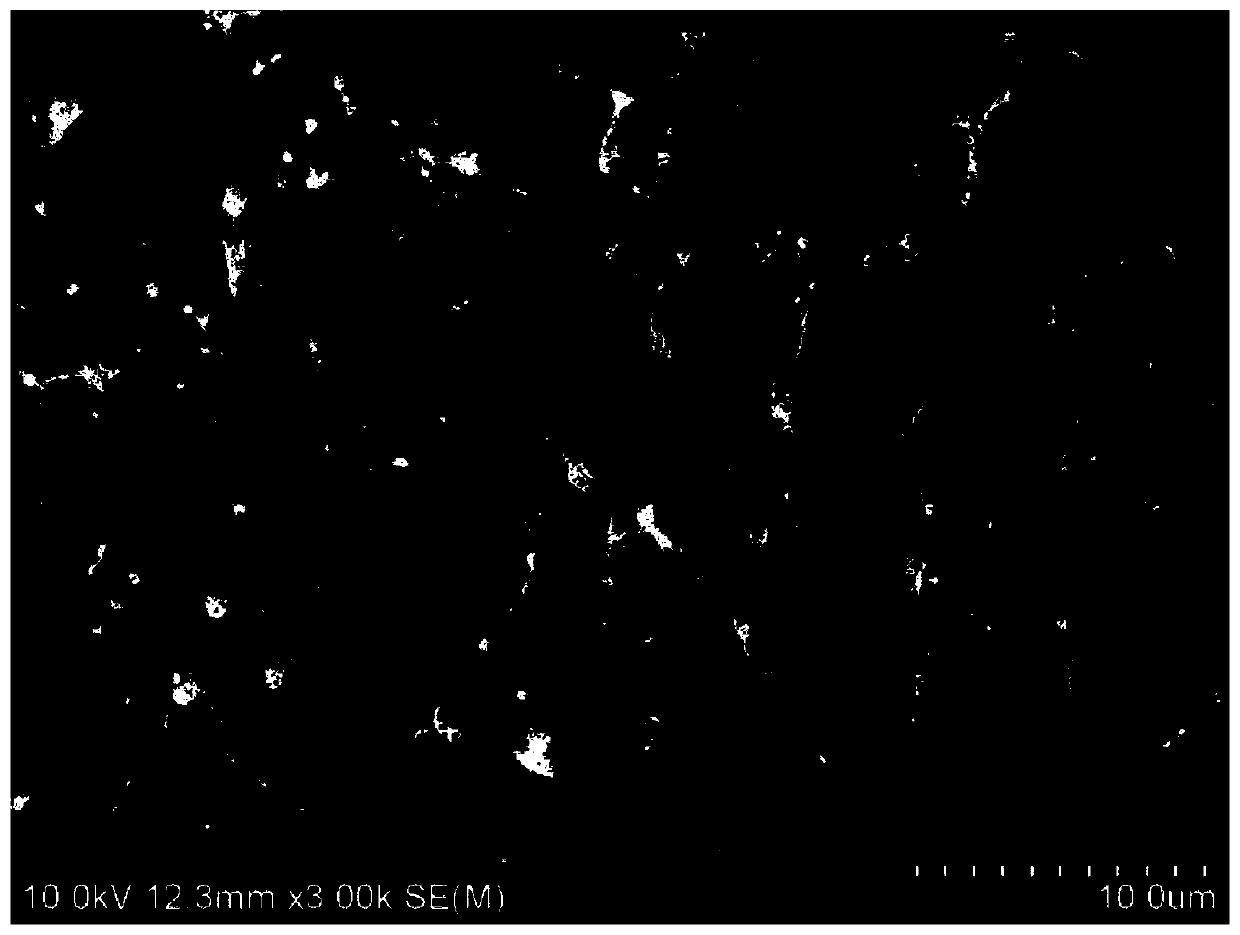

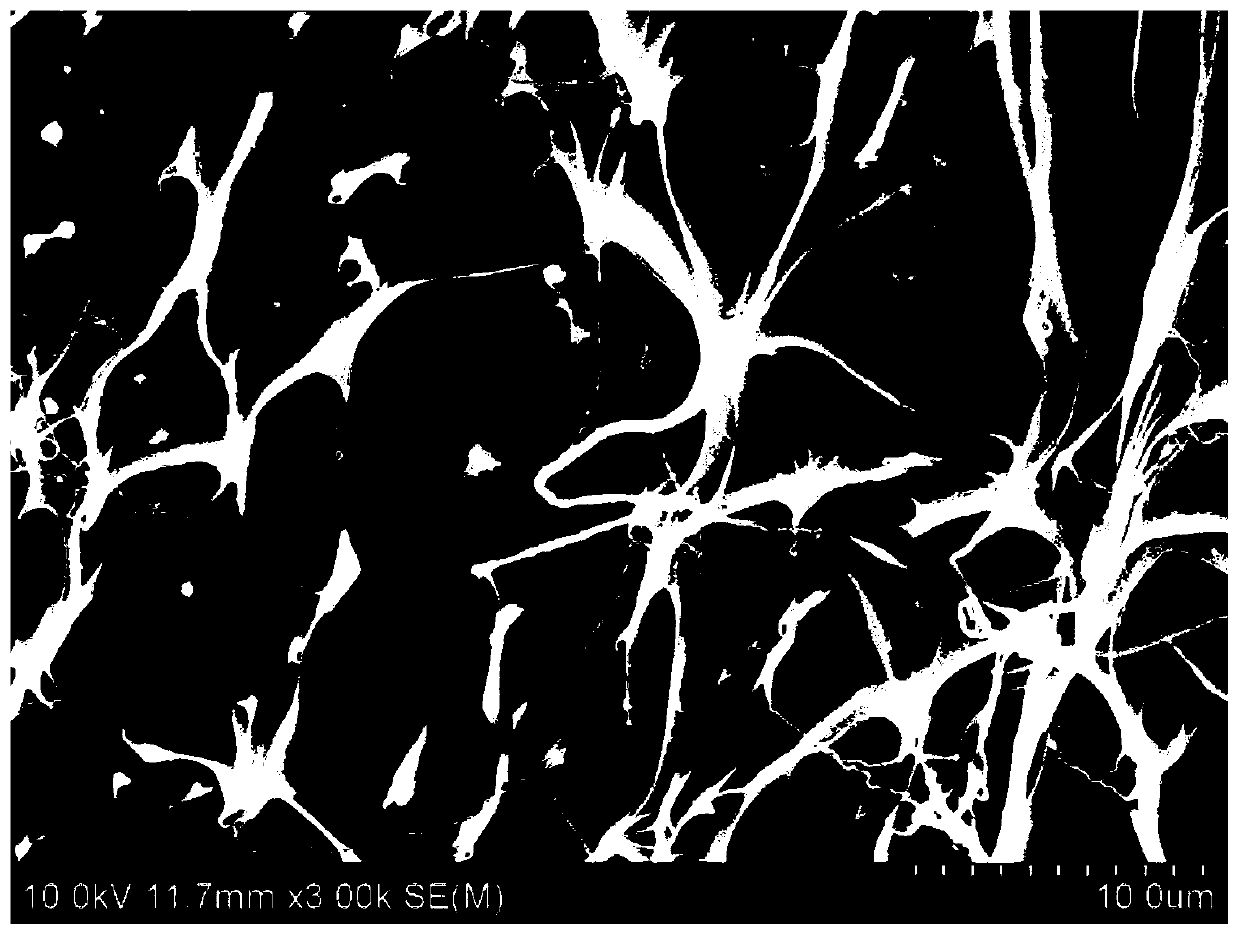

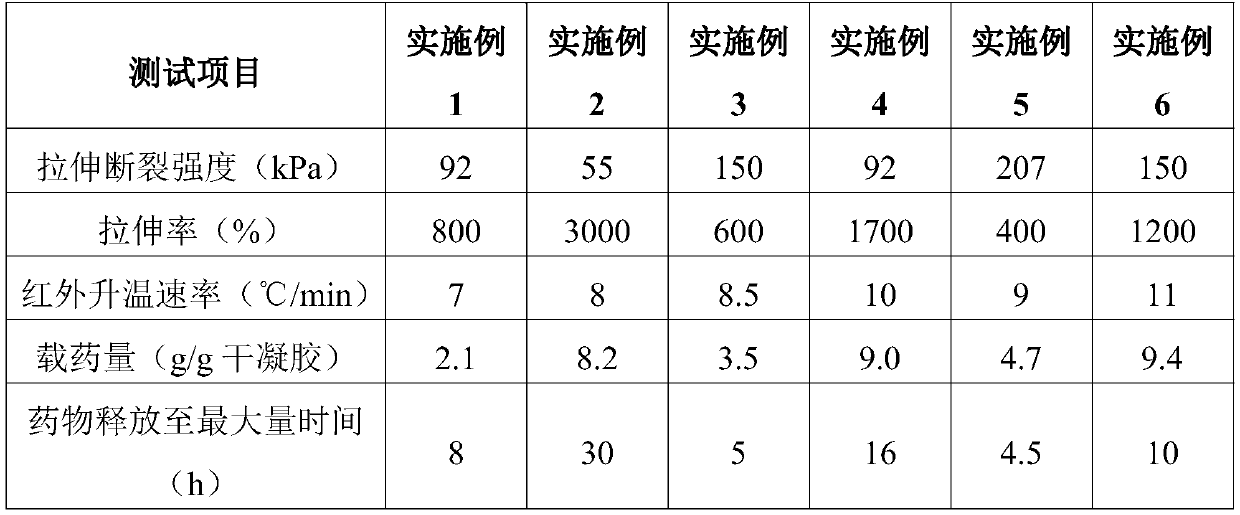

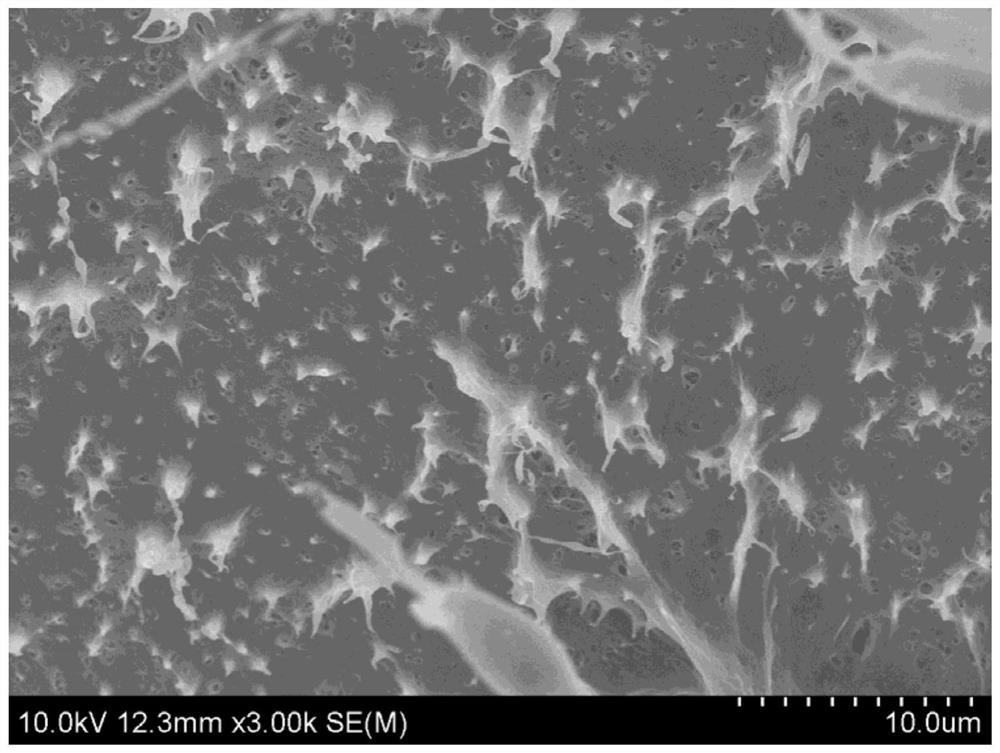

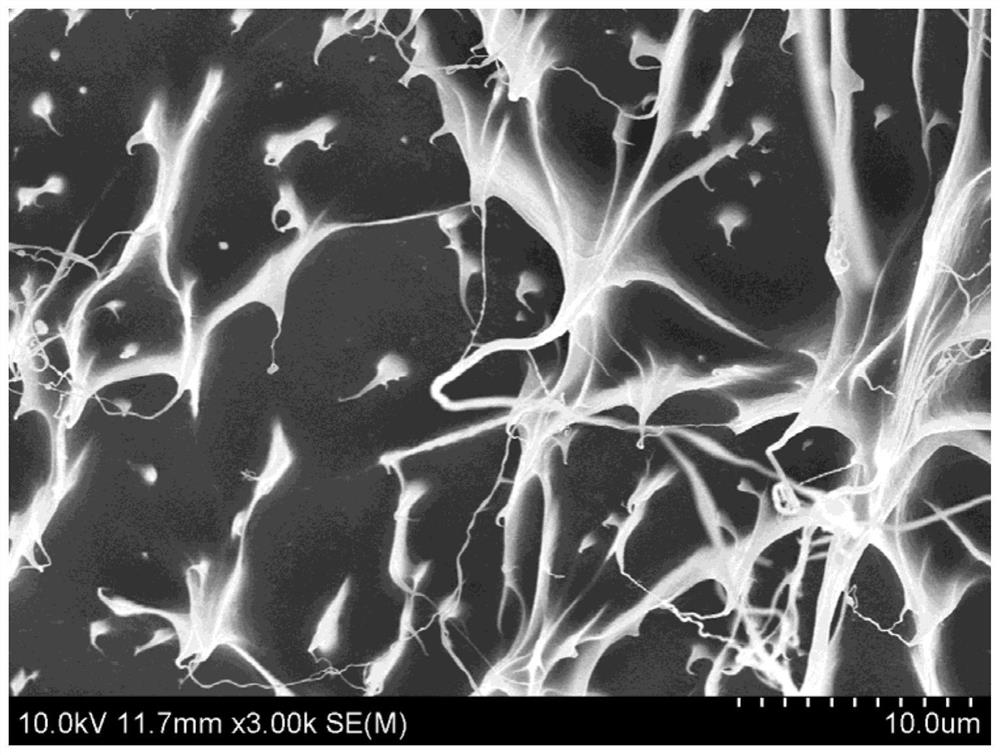

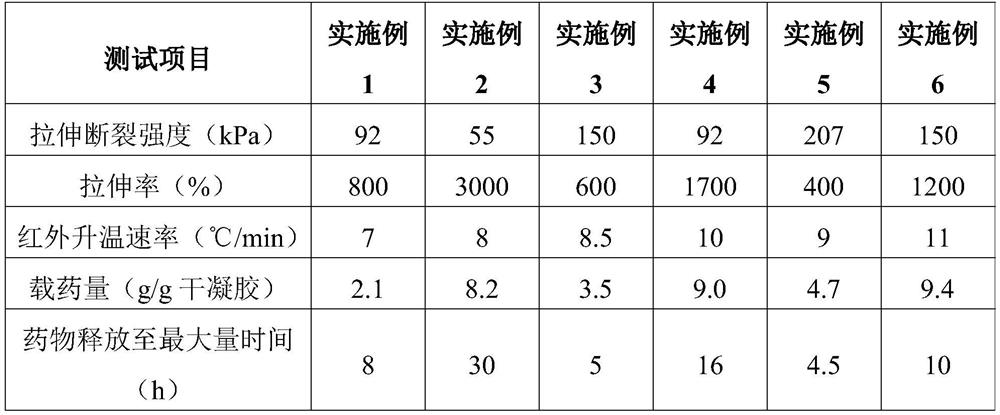

Preparation of photo-thermal response drug sustained-release hydrogel based on magnetic cellulose nanocrystals

ActiveCN110903432ATo achieve the effect of sustained releaseControlling Crosslink DensityDrug photocleavageAerosol deliveryPtru catalystAcid hydrolysis

The invention relates to a preparation method of photo-thermal response drug sustained-release hydrogel based on magnetic cellulose nanocrystals. The preparation method comprises the following steps:(1) preparing a CNC solution from plant raw materials by using an acid hydrolysis method; (2) introducing iron ions with different valence states into the CNC solution, and synthesizing magnetic nanoparticles in situ under an alkaline condition to obtain a colloidal solution; and (3) adding a polymer monomer, an initiator, a cross-linking agent and a catalyst into the colloidal solution obtained in the step (2), and reacting to obtain the target product. Compared with the prior art, the CNC solution is taken as a raw material, in-situ growth of the magnetic nanoparticles is taken as a basis, and different types of polymers with different contents are added, so that preparation of photo-thermal response drug-loaded hydrogel and light-operated drug release can be realized.

Owner:SHANGHAI JIAO TONG UNIV

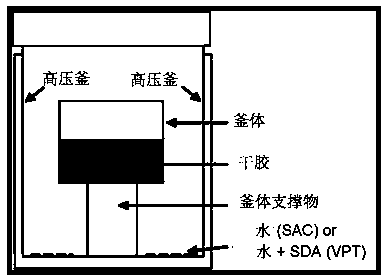

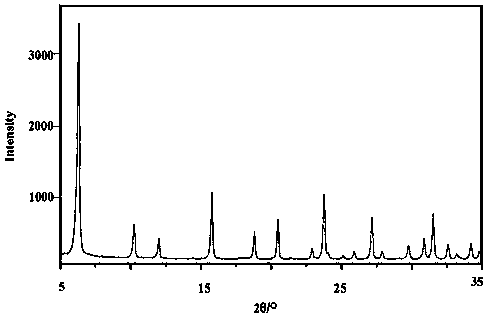

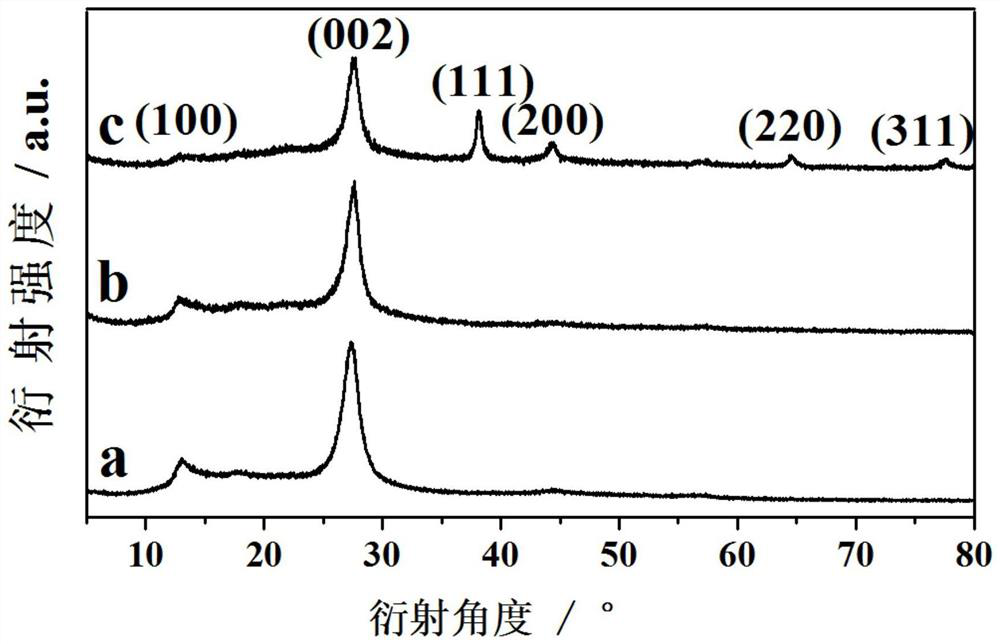

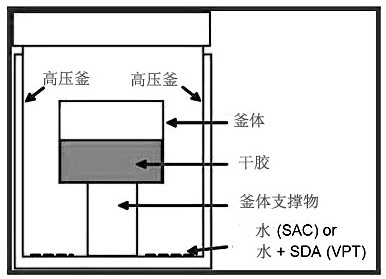

Method for preparing zeolite molecular sieve through quick crystallization of dry glue

ActiveCN110156045AUniform coordinationPromote nucleation growthFaujasite aluminosilicate zeoliteMolecular sieveCrystallinity

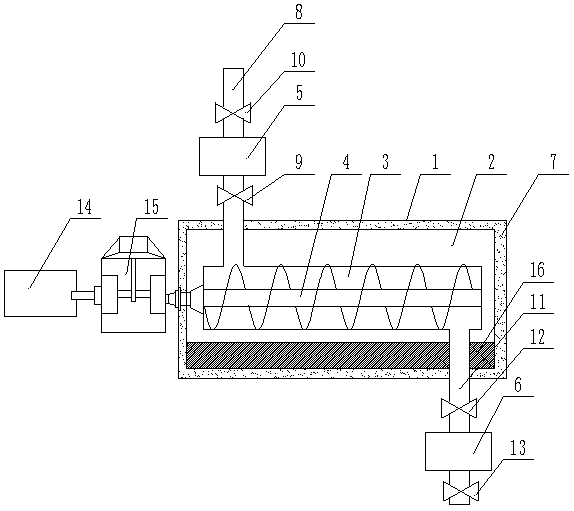

The invention discloses a method for preparing a zeolite molecular sieve through quick crystallization of dry glue, and relates to the field of molecular sieve solid phase synthesis. The method specifically comprises the following steps: adding an aluminum source and a fluoride into a silicon-aluminum type molecular sieve mother solution for crystallizing to obtain a silicon-aluminum type molecular sieve guiding agent; adding an alkali source, a silicon source, a template agent R and deionized water into the silicon-aluminum type molecular sieve guiding agent, uniformly carrying out mixing, and then carrying out drying to obtain dry glue powder; and crystallizing the dry glue powder in a steam atmosphere in a continuous crystallization kettle to obtain the zeolite molecular sieve, whereinthe crystallization time is 2-10 hours. The guiding agent disclosed by the invention is obtained by secondary crystallization, and is high in activity and strong in guiding action, so that the usage amount of the template agent can be reduced, crystallinity can be improved, generation of hybrid crystal phases formed by solid-phase synthesis is avoided, and the crystallization period is shortened.The continuous crystallization kettle can be used for continuous production without need of cooling and pressure relief, so that the required crystallization time is short, and efficiency and yield are high. The prepared zeolite molecular sieve is good in stability, high in crystallinity and high in silicon-aluminum ratio.

Owner:TAIYUAN DACHENG ENVIRONMENTAL ENERGY CHEM TECH

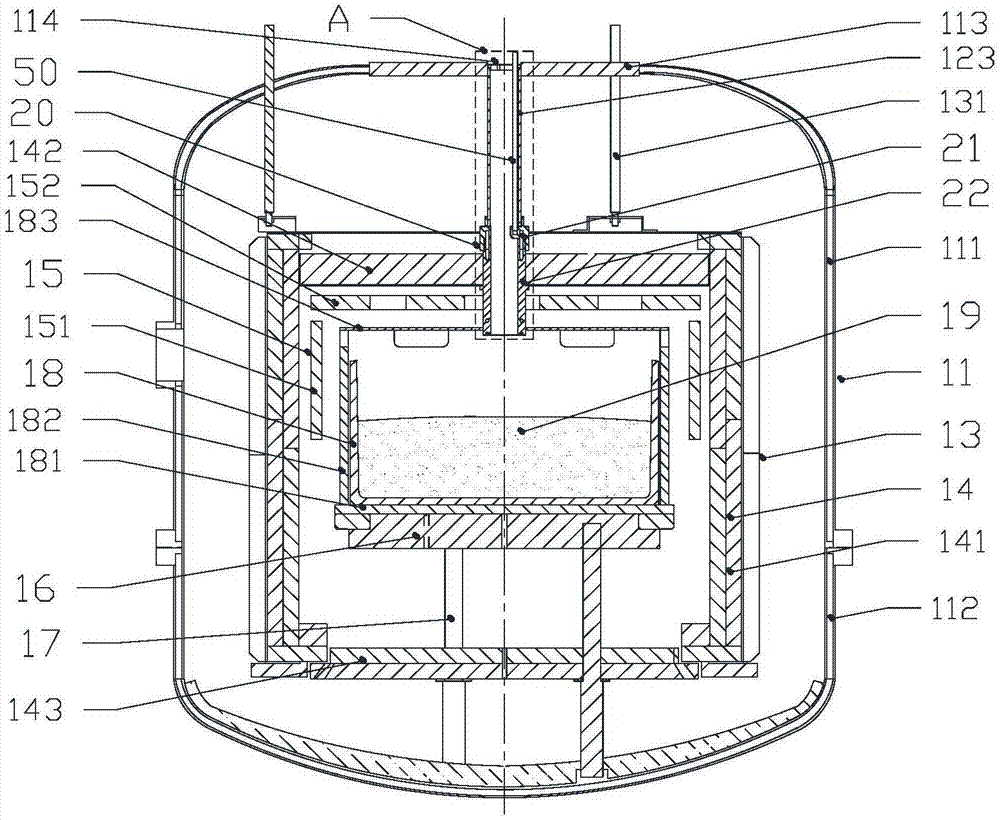

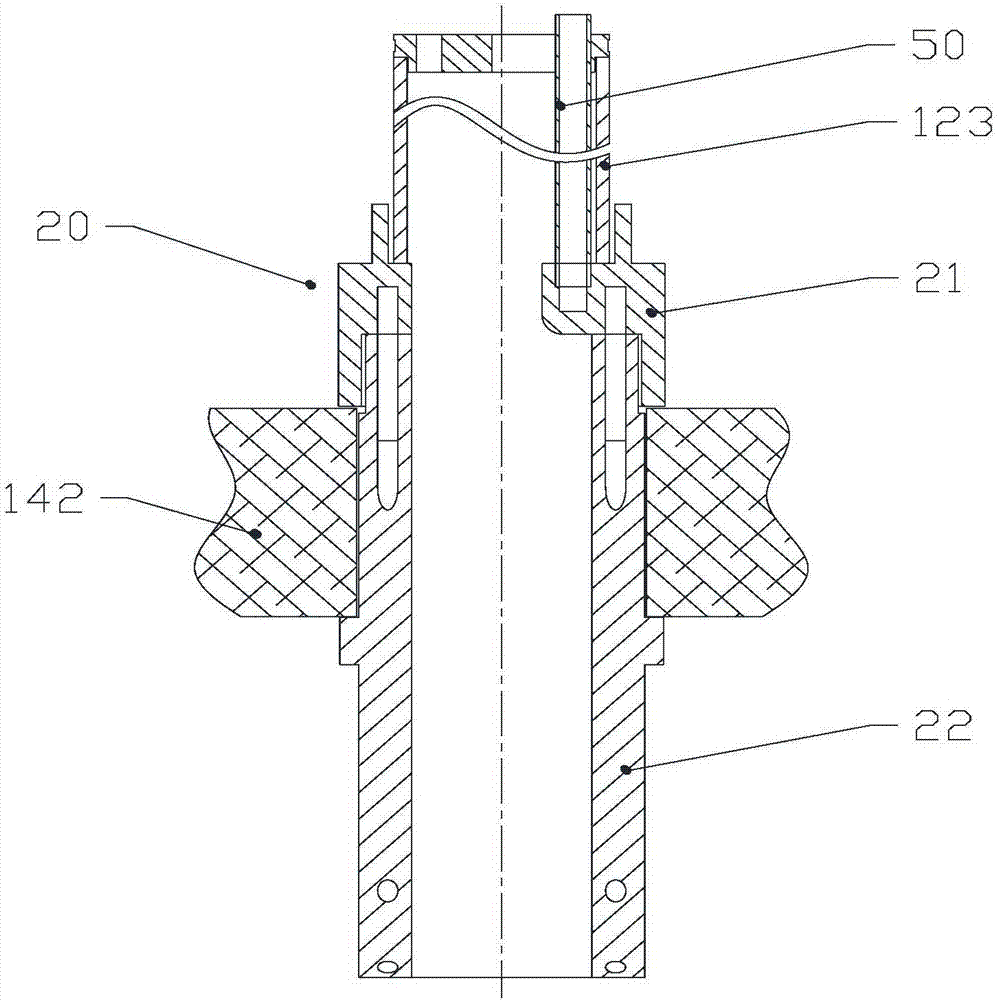

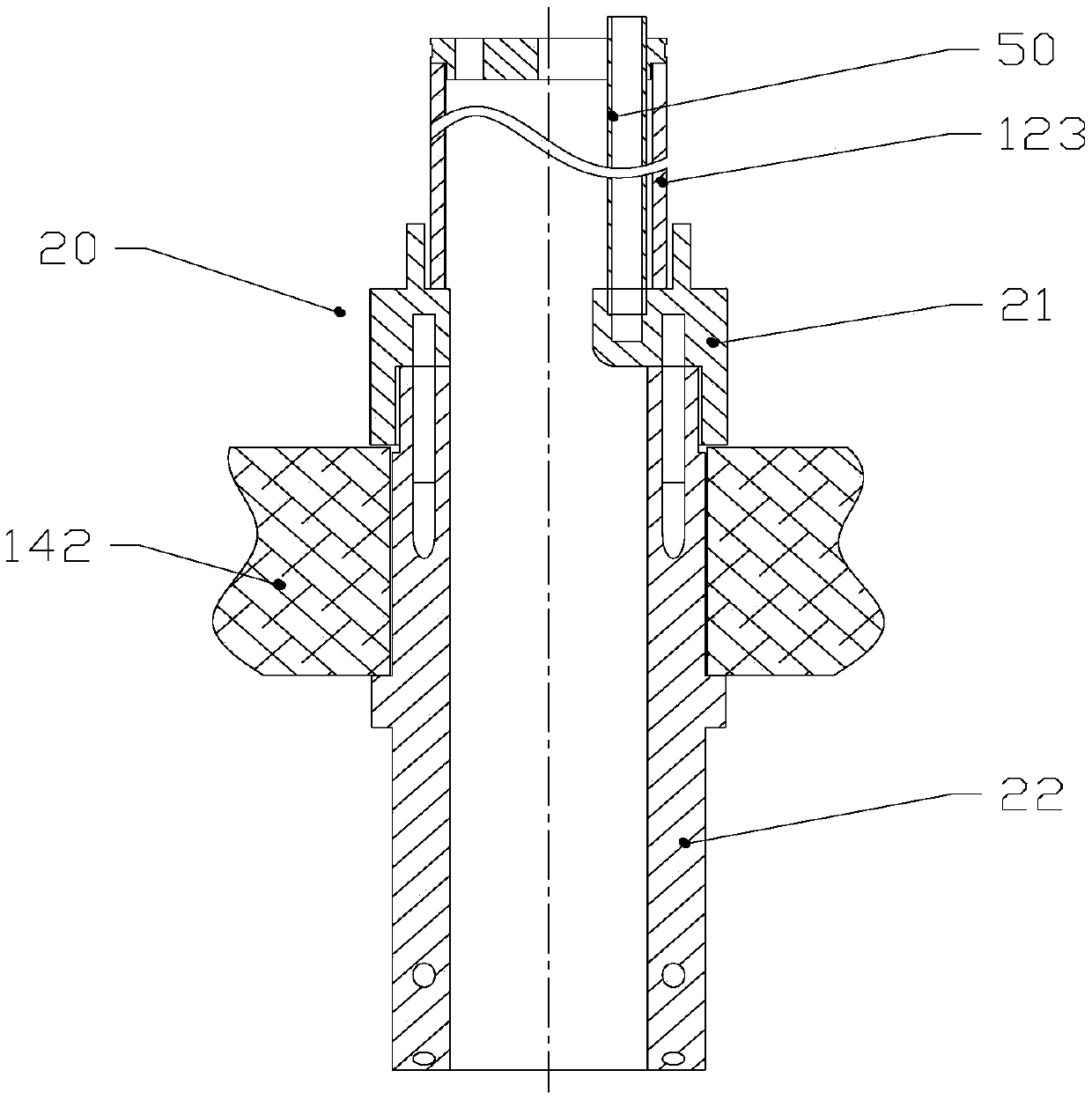

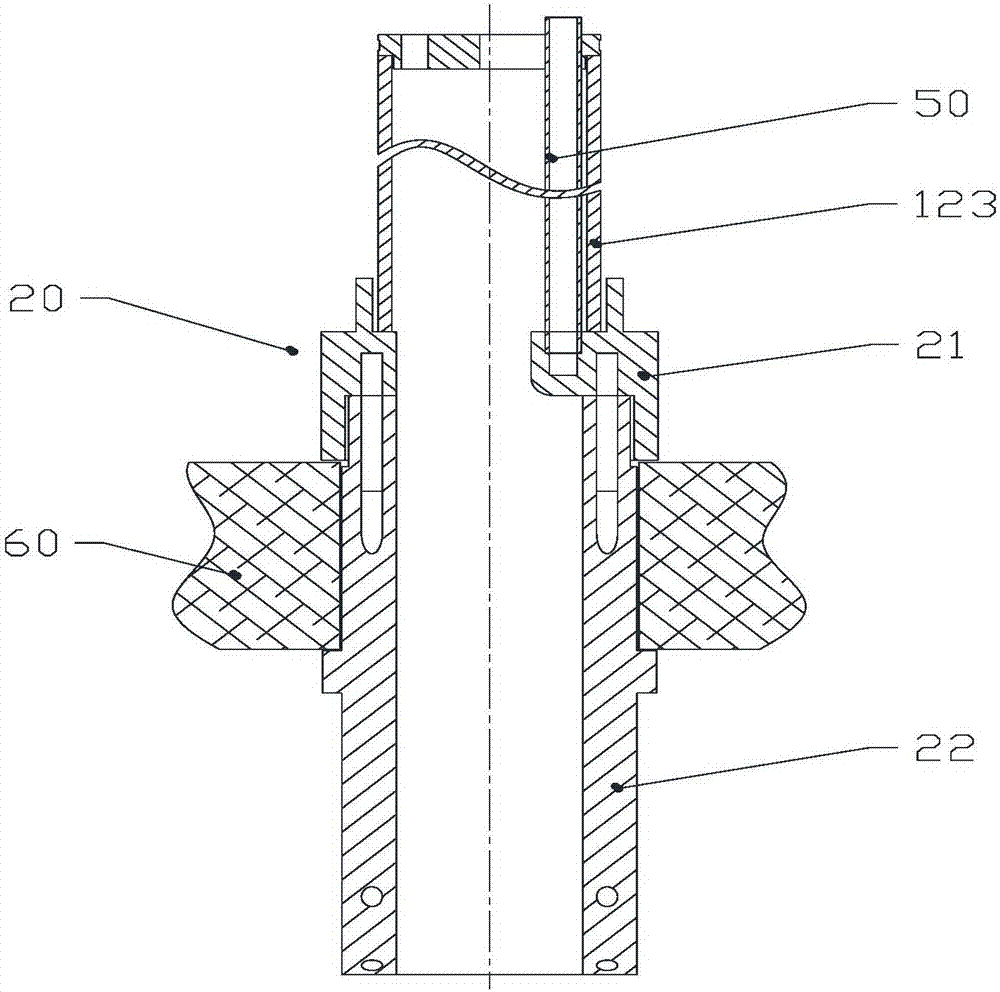

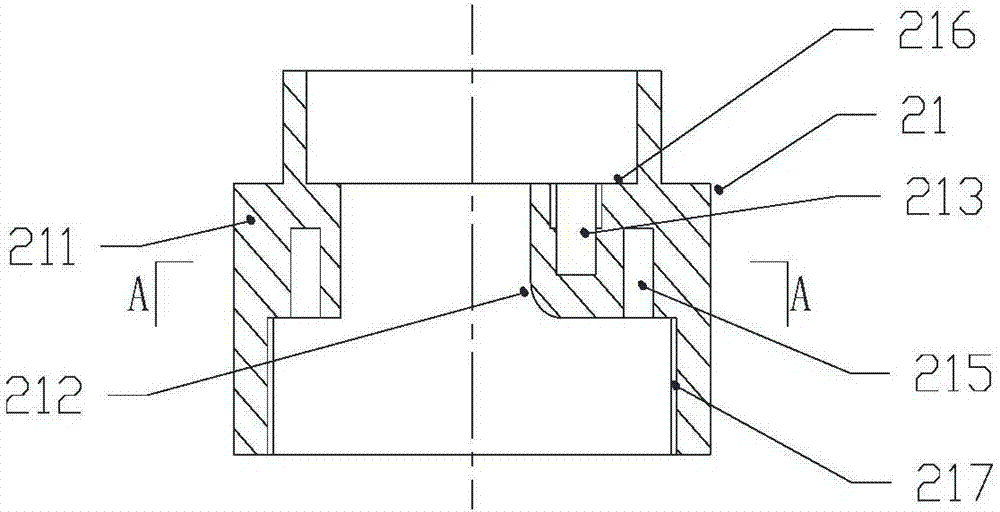

Drainage device capable of changing flow direction of carrier gas

InactiveCN108048903AEasy to operateMeasure growth ratePolycrystalline material growthSingle crystal growth detailsNatural convectionIngot

The invention belongs to the field of polycrystal casting units and particularly discloses a drainage device capable of changing the flow direction of carrier gas. The drainage device comprises a gasinlet part, a shunt part and a drainage part which are connected fixedly in sequence, wherein a gas inlet hole allowing the carrier gas to flow in is formed in the gas inlet part; a shunt cavity is formed in the shunt part; the drainage part comprises at least one drainage gas channel for changing the flow direction of the carrier gas; the gas inlet hole is communicated with the shunt cavity; a gas inlet of each drainage gas channel is communicated with the shunt cavity, and gas outlets are distributed in the same angular direction circumferentially. The drainage device is provided with a viewfield leading into an ingot furnace and drives the carrier gas to dispersedly blow different areas of the surface of liquid silicon, the contact are of the carrier gas and the surface of the liquid silicon is increased, and local area supercooling caused by the carrier gas and impurity formation promoted by the carrier gas are reduced; the carrier gas drives the liquid silicon to produce a rotating flow field, under the combined action of a natural convection flow field and the rotating flow field, impurity volatilization is promoted, local area enrichment of impurities in the liquid siliconis reduced, and radial electrical resistivity of crystals is distributed more uniformly.

Owner:陈鸽

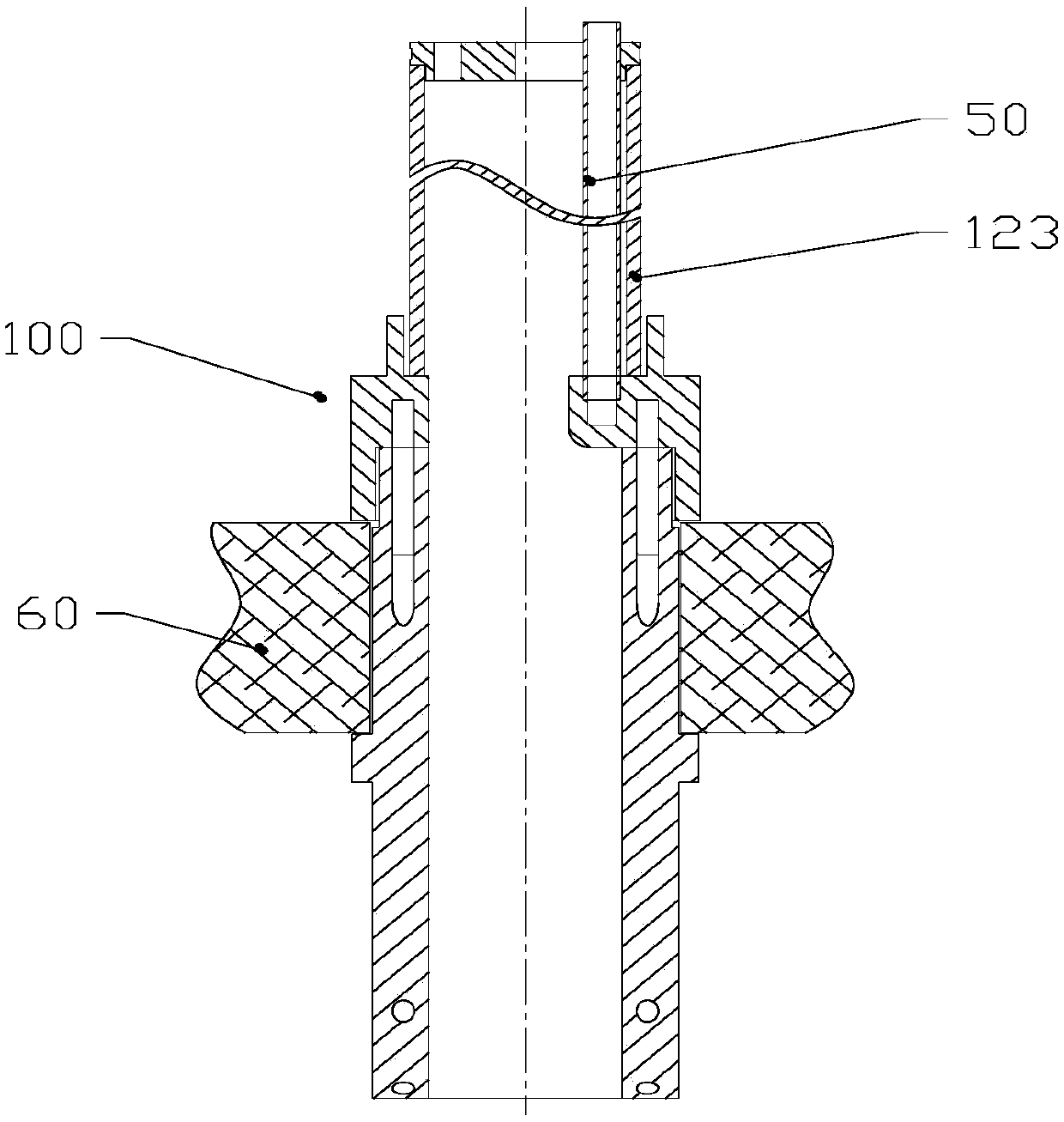

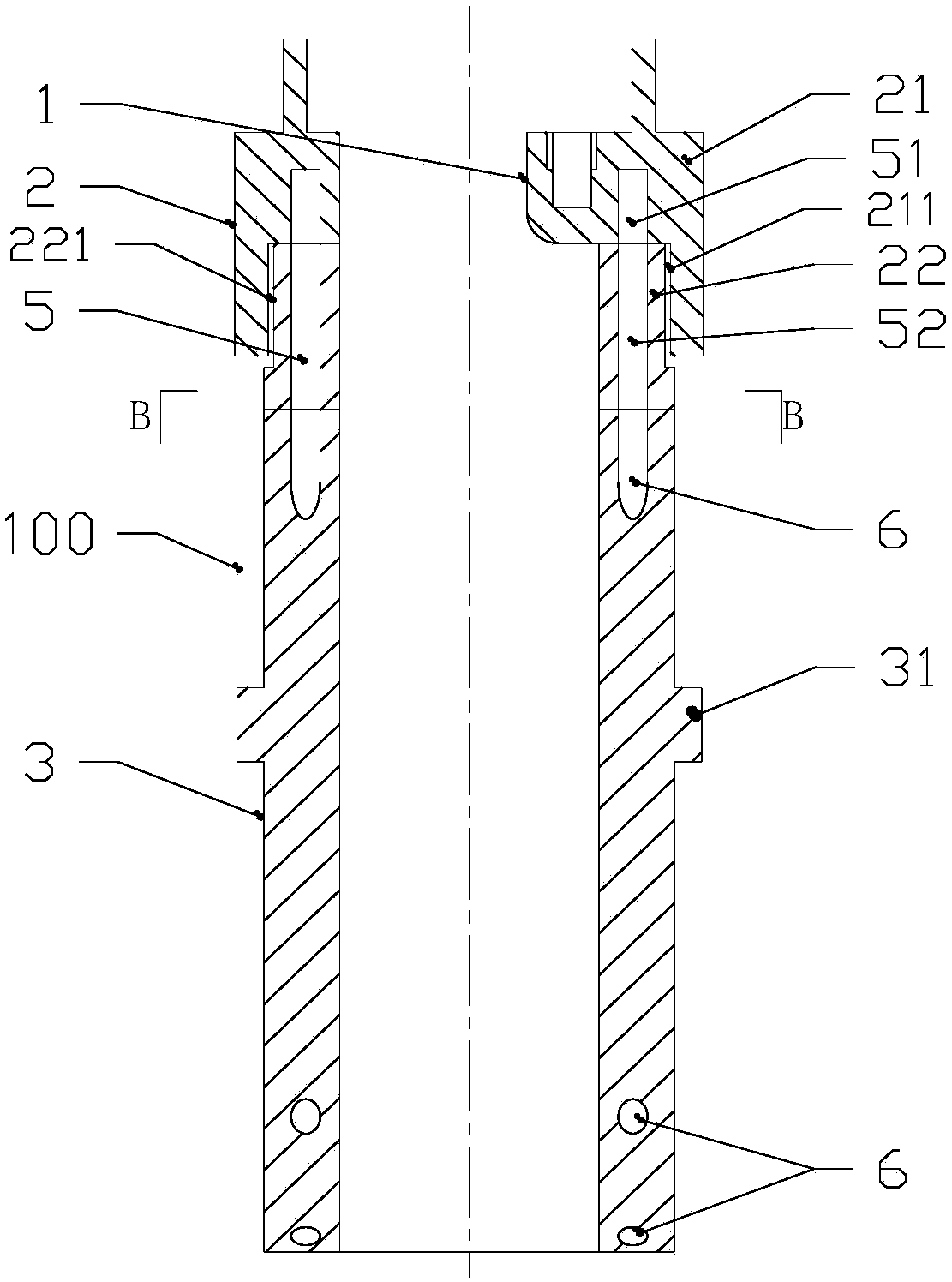

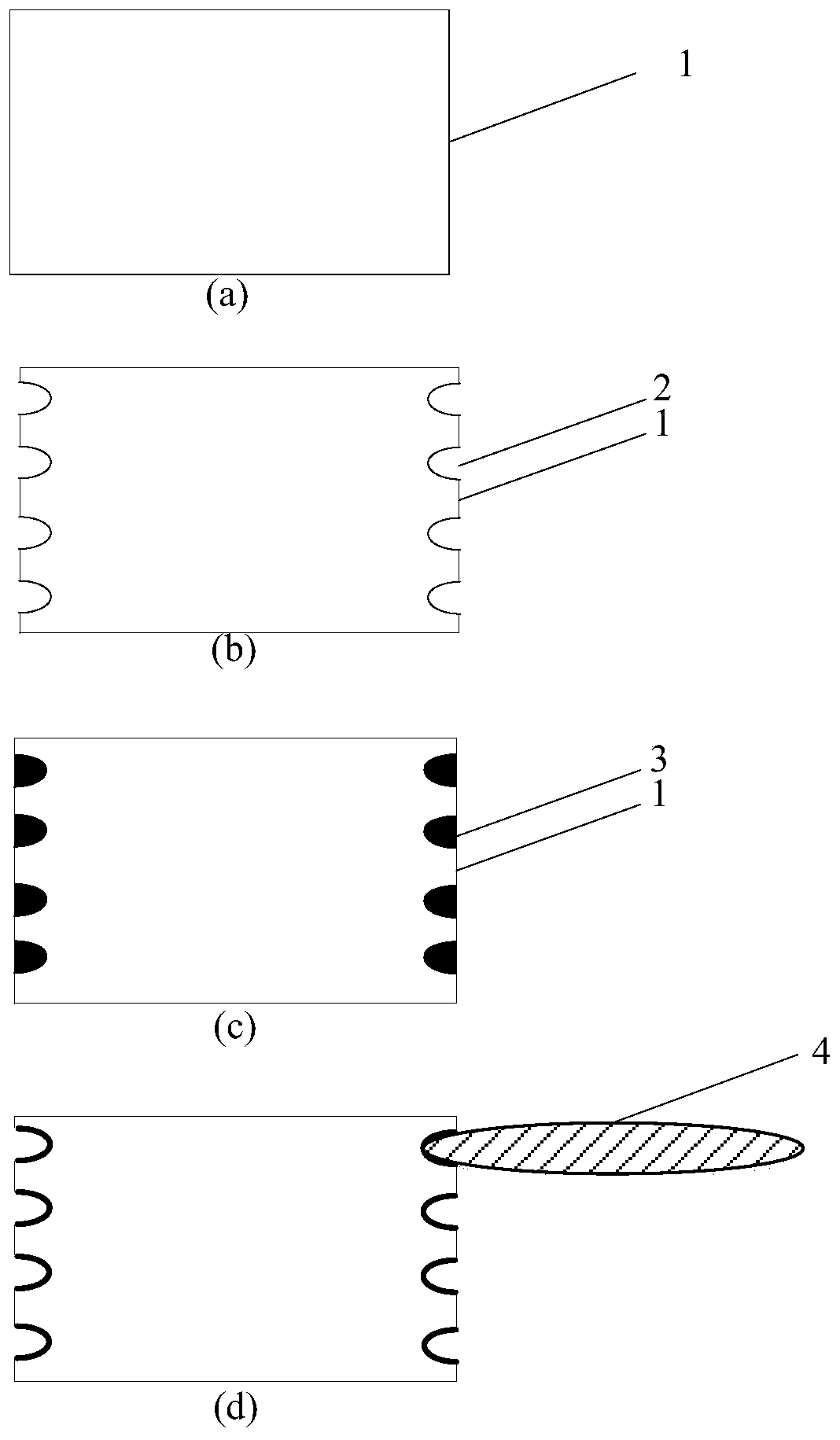

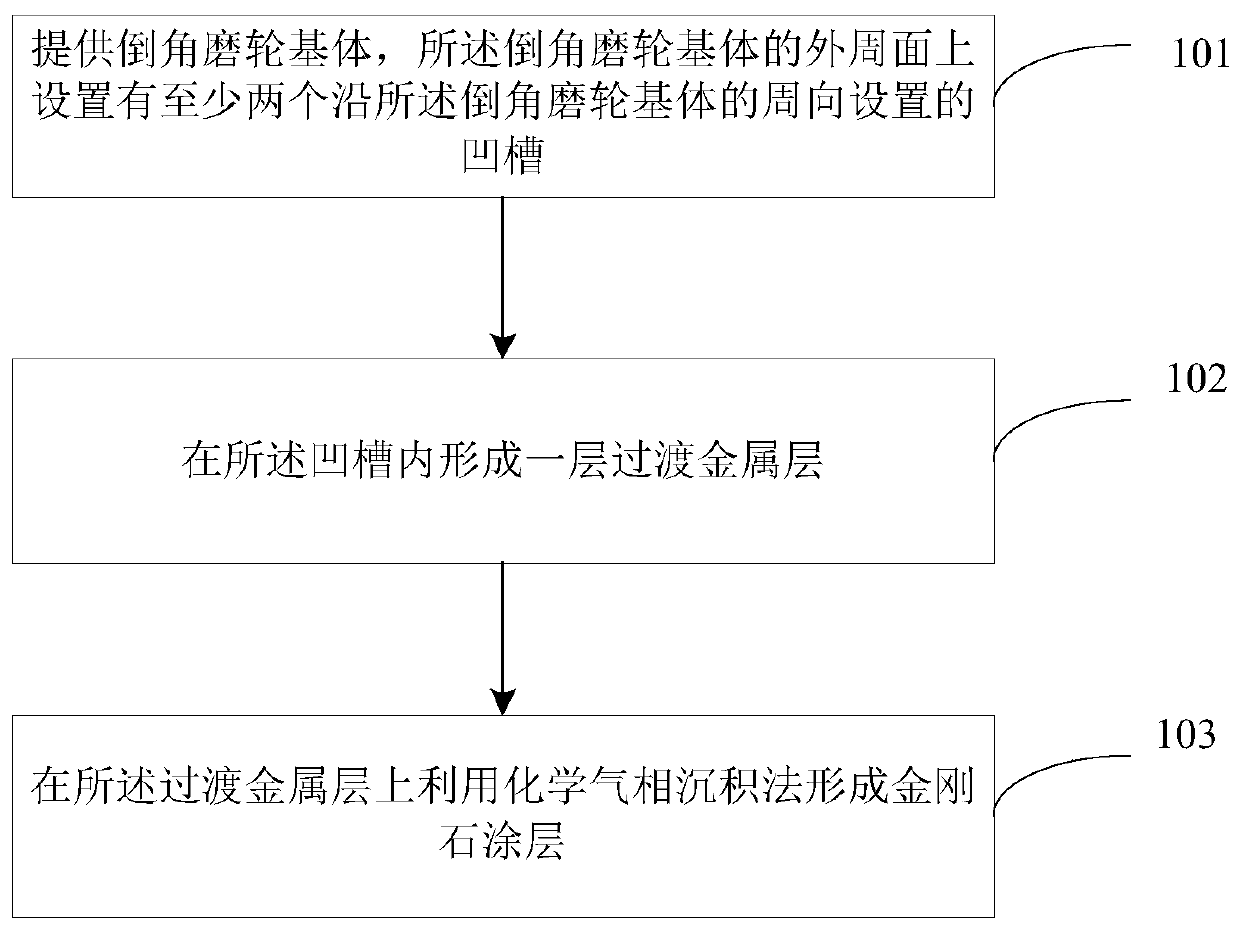

Chamfering abrasive wheel, preparation method thereof and wafer machining device

InactiveCN110757287AExtended service lifeReduce oxidationEdge grinding machinesVacuum evaporation coatingChemical vapor depositionSemiconductor technology

The invention provides a chamfering abrasive wheel, a preparation method thereof and a wafer machining device, and belongs to the technical field of semiconductors. The preparation method of the chamfering abrasive wheel comprises the steps that a chamfering abrasive wheel base body is provided, wherein at least two grooves in the circumferential direction of the chamfering abrasive wheel base body are formed in the outer circumferential surface of the chamfering abrasive wheel base body; a transition metal layer is formed in each groove; and then diamond coatings are formed on the transitionmetal layers through a chemical vapor deposition method.

Owner:XIAN ESWIN MATERIAL TECH CO LTD +1

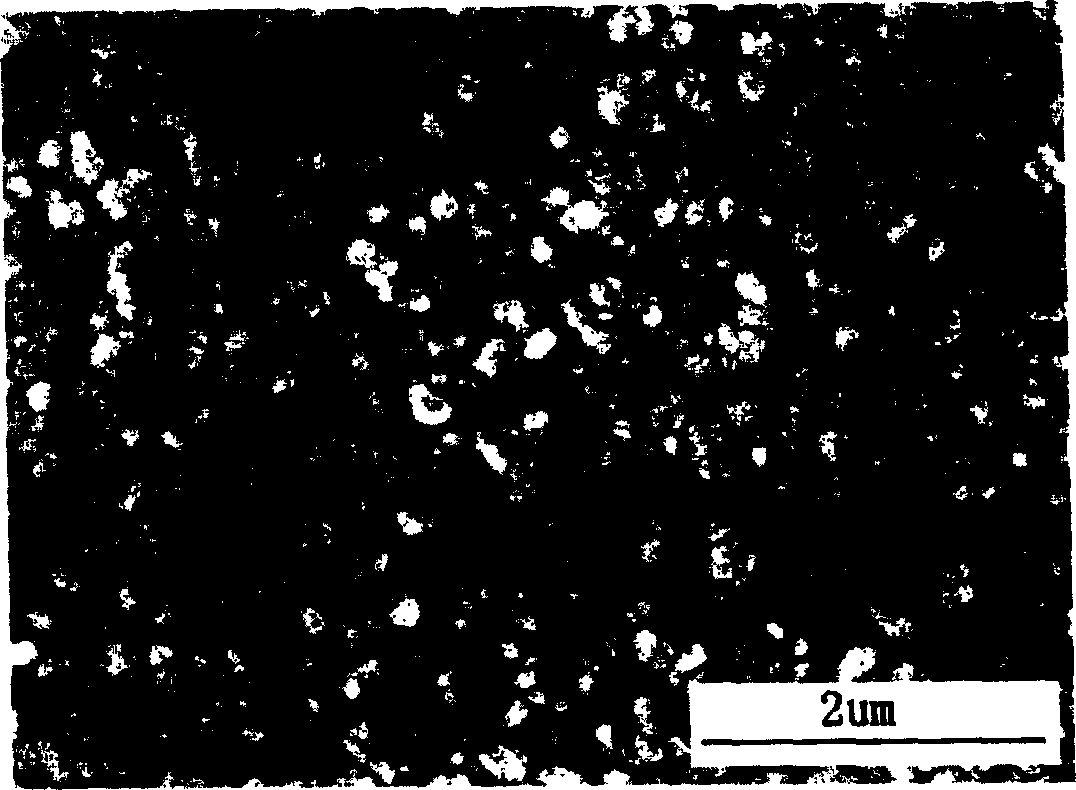

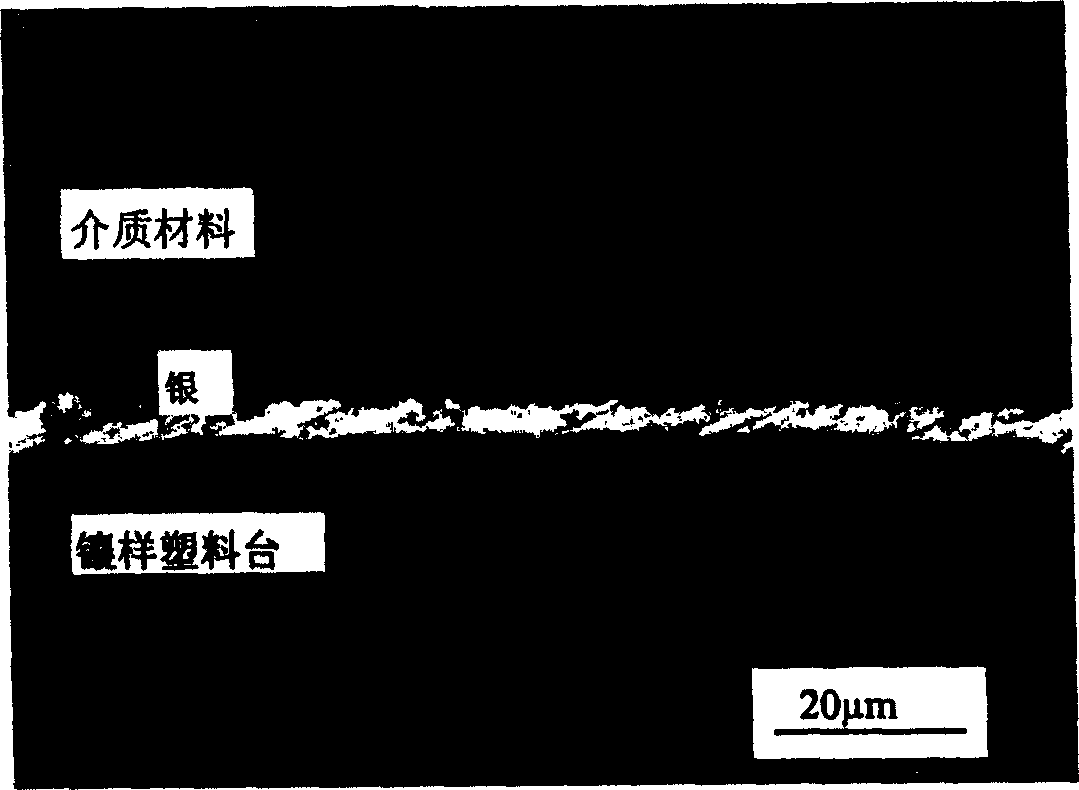

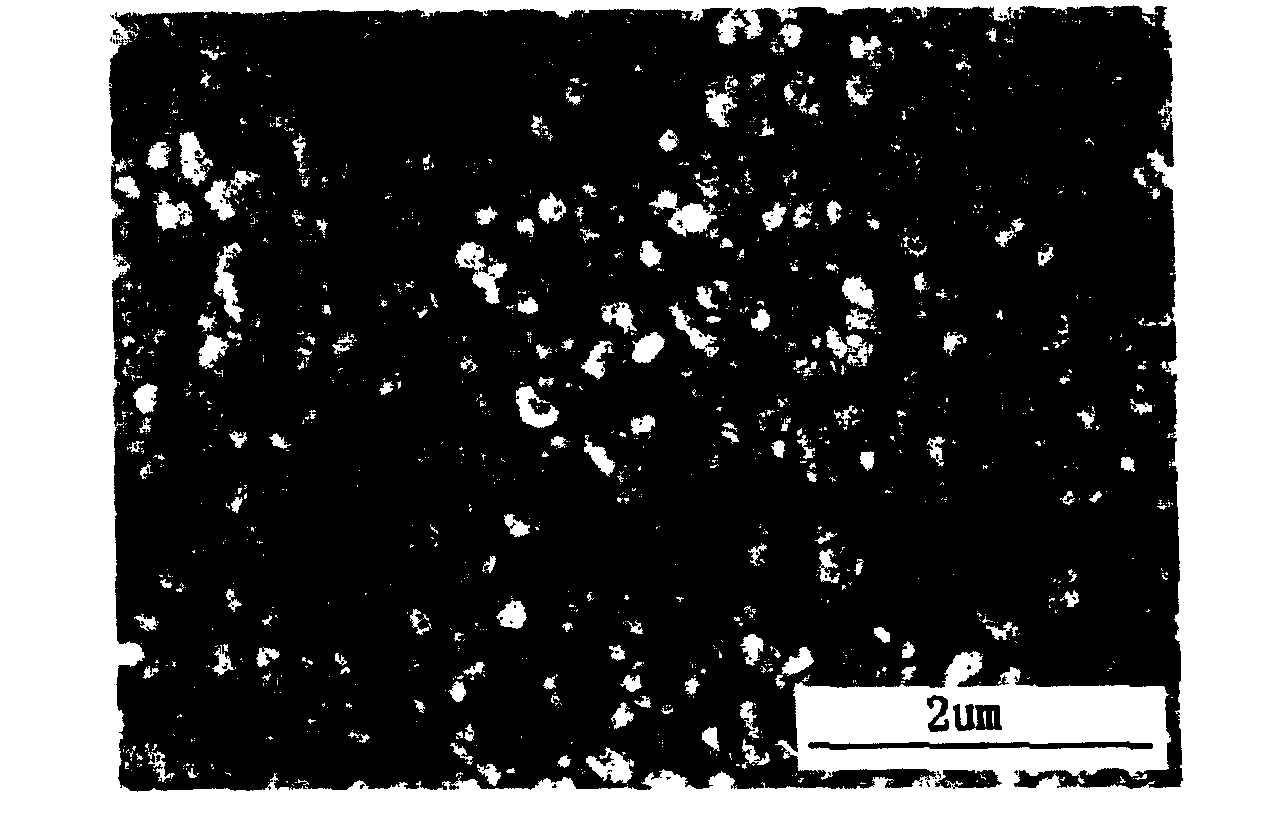

TaWN film in copper interlinked barrier layer material

InactiveCN100381609CInhibited DiffusionFacilitated DiffusionMetallic material coating processesInterconnectionCopper

A TaWN film used as the barrier material of copper interconnection contains W (13.6-22.7 Wt%), N (9) and Ta (rest). Its advantages are high adhesion and high power to resist against electronic migration.

Owner:SHANGHAI JIAOTONG UNIV +1

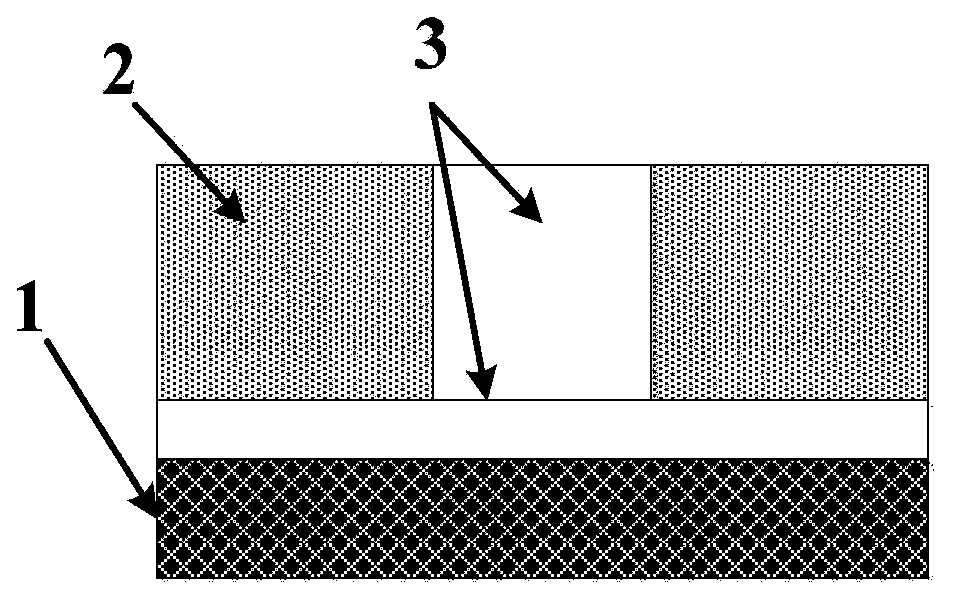

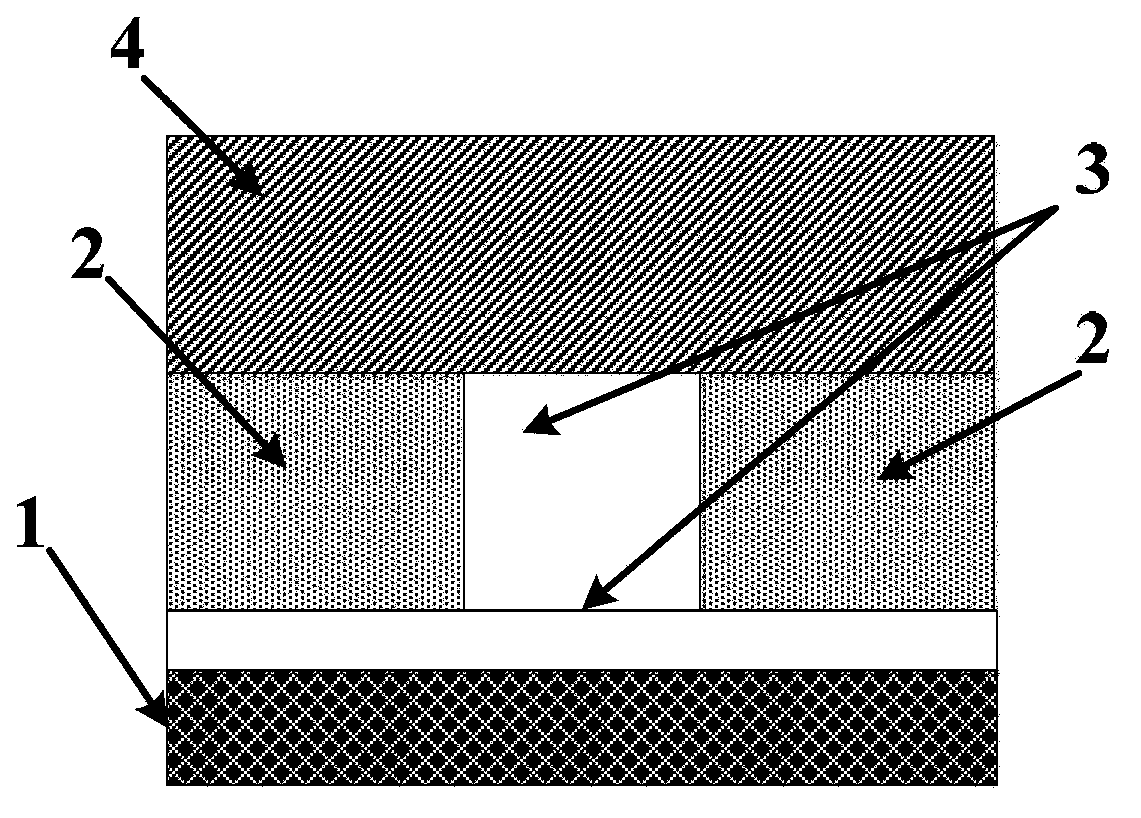

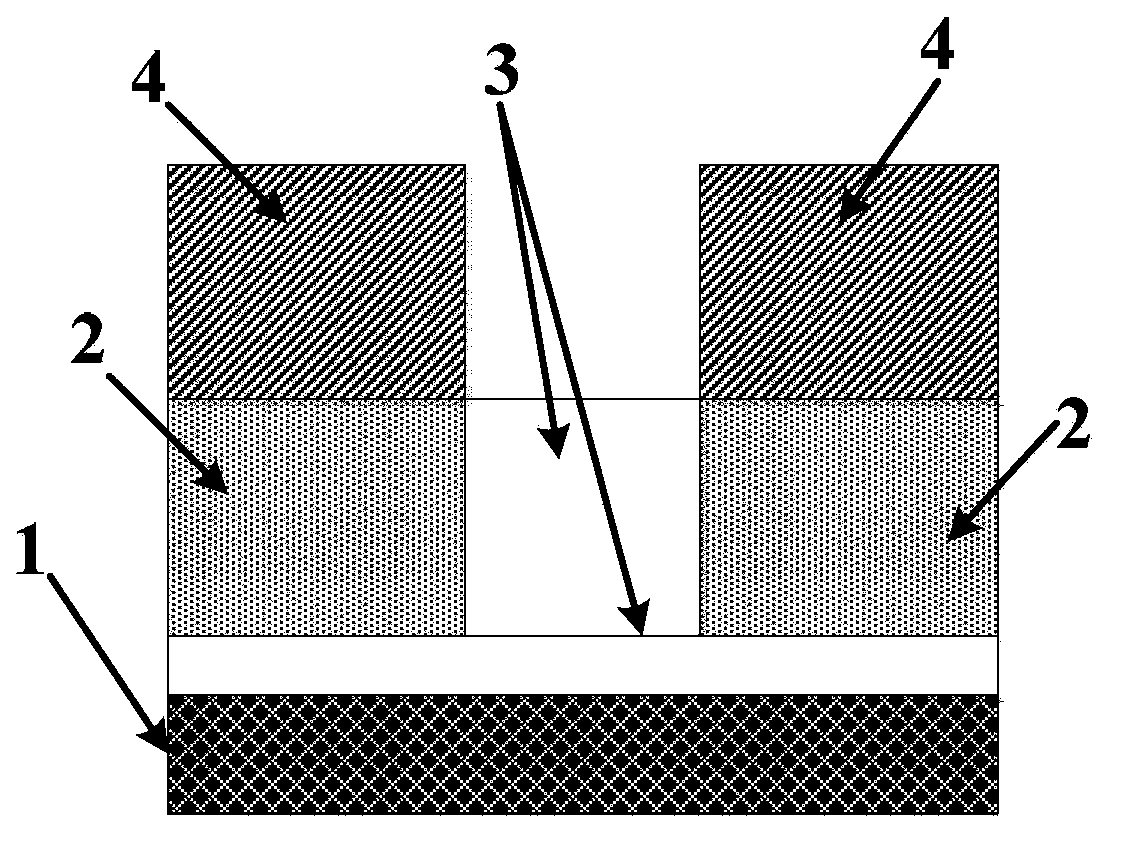

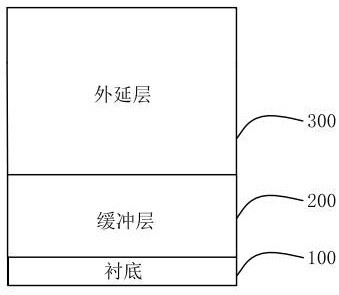

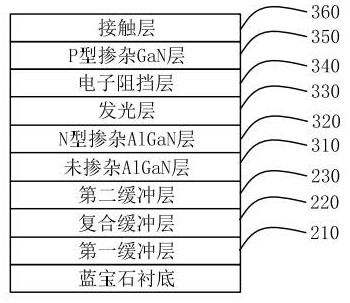

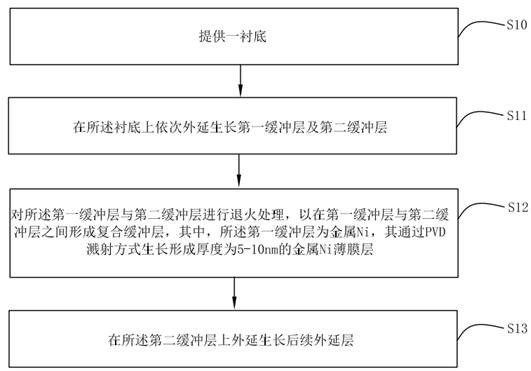

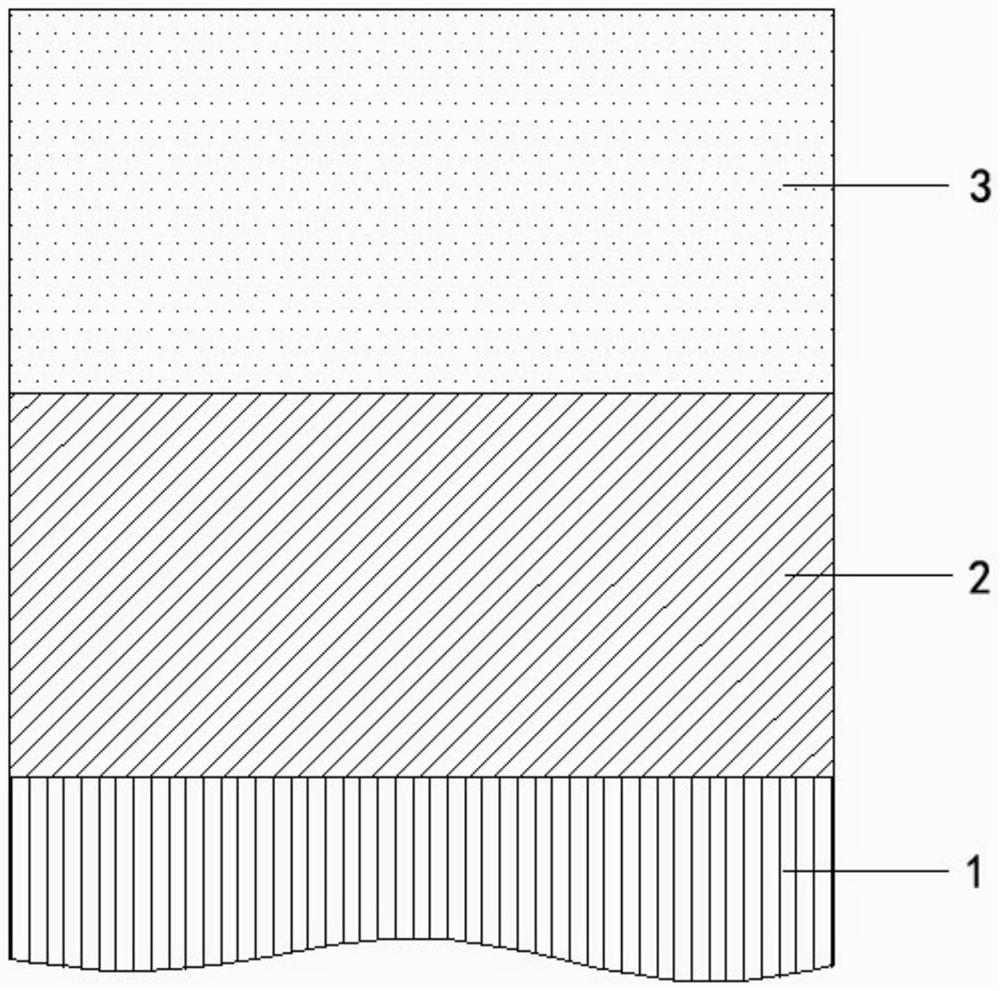

Epitaxial structure of light emitting diode and preparation method thereof

ActiveCN114335274ASolve the technical problem of poor crystal qualityImprove crystal qualityVacuum evaporation coatingSputtering coatingLattice mismatchUltraviolet lights

The invention provides an epitaxial structure of a light-emitting diode and a preparation method of the epitaxial structure, relates to the technical field of diodes, and is applied to a miniature light-emitting diode or an ultraviolet light-emitting diode. The epitaxial structure of the light-emitting diode comprises a substrate, a buffer layer and an epitaxial layer; the buffer layer is arranged between the substrate and the epitaxial layer, the buffer layer sequentially comprises a first buffer layer, a composite buffer layer and a second buffer layer, the first buffer layer is arranged on the substrate, the first buffer layer is made of metal Ni, and the first buffer layer grows in a PVD sputtering mode to form a metal Ni thin film layer with the thickness of 5-10 nm. According to the invention, the technical problem of poor crystal quality of an epitaxial layer of subsequent epitaxial growth caused by lattice mismatch generally existing in a light-emitting diode in the prior art can be solved.

Owner:JIANGXI ZHAO CHI SEMICON CO LTD

Polysilicon ingot furnace with diversion device

ActiveCN107385510AIncrease contact areaReduced local temperature dropPolycrystalline material growthSingle crystal growth detailsLiquid siliconAirflow

The invention discloses a polysilicon ingot furnace with a diversion device. The polysilicon ingot furnace comprises a heat insulation cage, a gas pipe and a diversion device. The diversion device is equipped with multiple diversion airways used for dividing input carrier gas into multiple outgoing carrier gas flows. The carrier gas flows are dispersedly and slantly blown to different areas on the surface of liquid silicon, thus effectively increasing contact area of the carrier gas and the surface of liquid silicon and minimizing heat per unit area by carrier gas flow. Thermal drop of liquid silicon in the area is reduced, degree of supercooling is decreased, and impurity nucleation and impurity formation caused by carrier gas are reduced. The outgoing carrier gas flows produce carrier gas stress to liquid silicon so as to drive liquid silicon to flow and to form a rotary flow field for circumferential flow. The rotary flow field is beneficial to transportation and uniform distribution of impurities in liquid silicon. An observation window at the top of the furnace has a field of view leading to the ingot furnace via the diversion device. Through the observation window, state inside the furnace can be observed, and a crystal measurement rod is inserted into the furnace. An infrared detector can detect the state of silicon materials inside the furnace, and the automatic crystal growth process is smoothly carried out.

Owner:新疆东方希望新能源有限公司

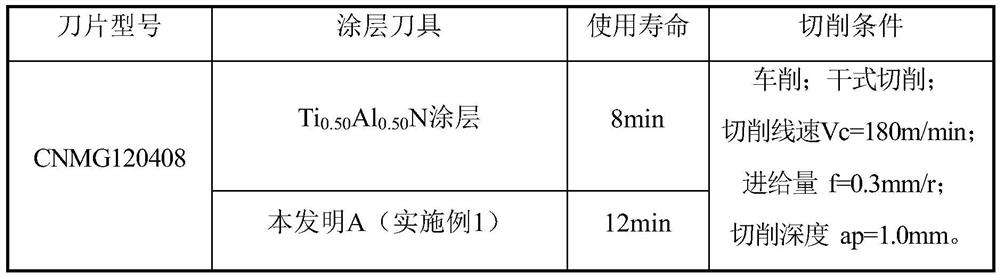

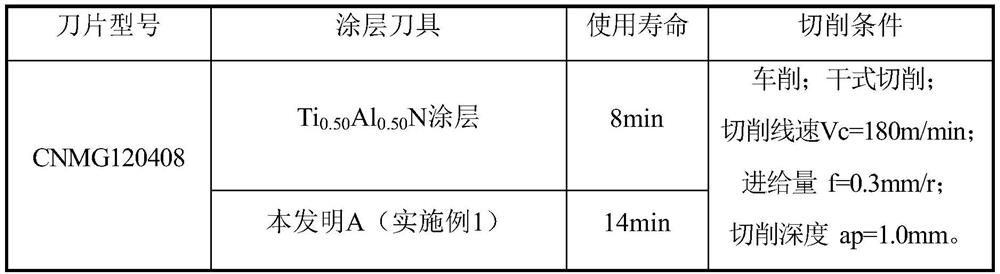

CrAlYO coated cutter and preparation method thereof

PendingCN113667933AImprove thermal stabilityImprove high temperature service capabilityVacuum evaporation coatingSputtering coatingOxidation resistantBonding strength

The invention discloses a CrAlYO coated cutter and a preparation method thereof. The coated cutter comprises a cutter substrate and a (Cr1-a-bAlaYb)2O3 layer which is deposited on the cutter substrate and is of a corundum structure. The preparation method comprises the following steps: pretreating the cutter substrate; then, selectively depositing a Ti1-xAlxN transition layer of a face-centered cubic structure; and depositing a CrAlYO coating. The coated cutter has high hardness, high abrasion resistance and excellent high-temperature oxidation-resistant property; furthermore, the bonding strength between the coating and the substrate is high; and the preparation method is simple in process and low in production cost.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

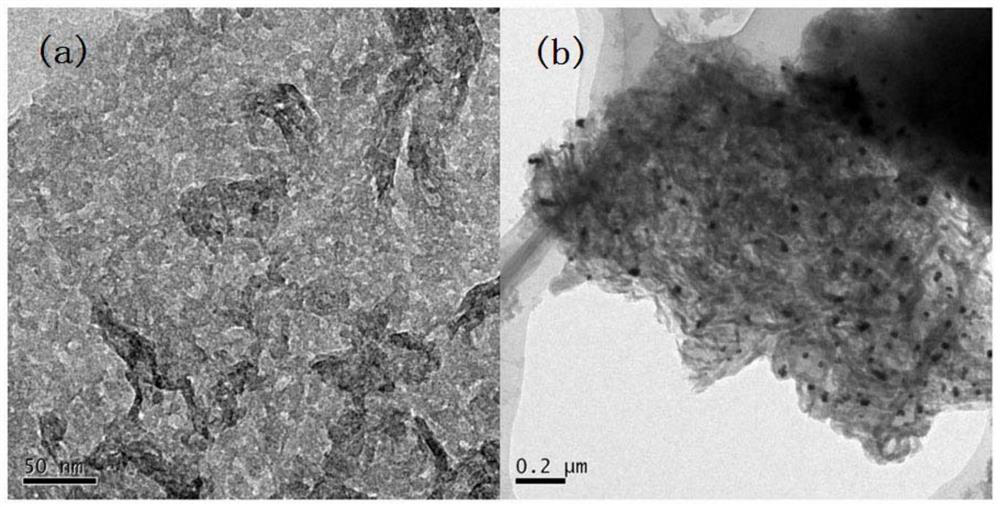

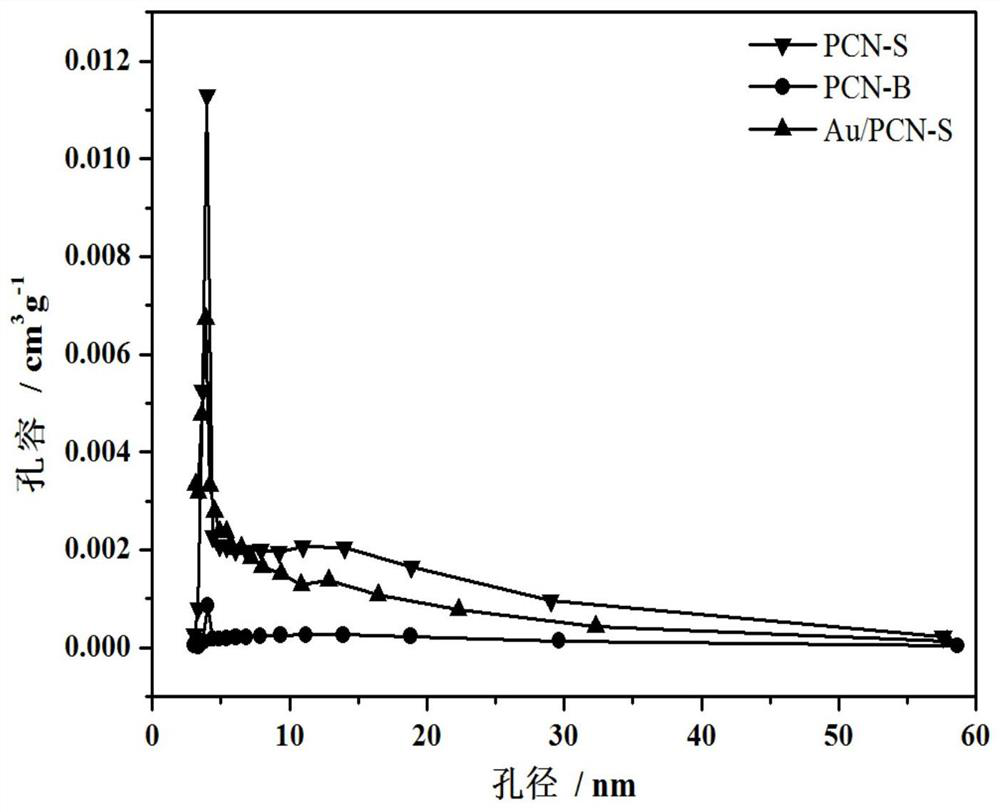

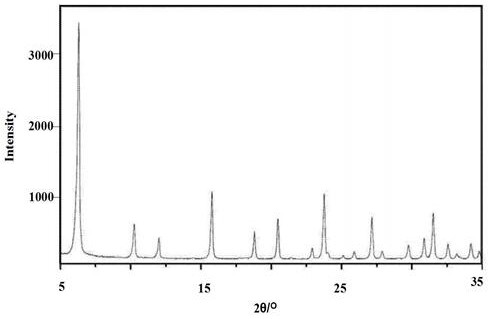

Phosphorus-hybridized graphitic carbon nitride nanosheets loaded with gold nanoparticles, and preparation method and application thereof

ActiveCN108906104BPromote absorptionImprove stabilityPhysical/chemical process catalystsMaterial electrochemical variablesLight energyCarbon nitride

The invention discloses a phosphorus hybrid graphite phase carbon nitride nanosheet loaded with gold nanoparticles and its preparation method and application. The phosphorus hybrid graphite phase carbon nitride nanosheet loaded with gold nanoparticles is made of phosphorus hybrid graphite. Phase carbon nitride nanosheets are used as carriers, and gold nanoparticles are loaded on their surfaces. The preparation method includes: preparing a dispersion liquid of phosphorus hybrid graphite phase carbon nitride nanosheets, and mixing it with a chloroauric acid solution to prepare the nanosheets of the present invention. The phosphorus hybrid graphite phase carbon nitride nanosheets loaded with gold nanoparticles of the present invention have the advantages of strong photoelectric ability, high stability, large specific surface area, regular and orderly pore diameter, good dispersion performance, and high light energy utilization rate, and its preparation method has the following advantages: It has the advantages of simple preparation process and low cost, and is suitable for large-scale preparation. The phosphorus hybrid graphite phase carbon nitride nanosheets loaded with gold nanoparticles of the present invention can be used as functional nanomaterials to detect or degrade environmental pollutants, can achieve good results, and have good application prospects.

Owner:HUNAN UNIV

A method for preparing zeolite molecular sieves by rapid crystallization of dry glue

ActiveCN110156045BUniform coordinationPromote nucleation growthFaujasite aluminosilicate zeoliteCrystallinitySolid-phase synthesis

Owner:TAIYUAN DACHENG ENVIRONMENTAL ENERGY CHEM TECH

A kind of polysilicon ingot casting furnace with diversion device

ActiveCN107385510BEasy to operateEasy to measurePolycrystalline material growthSingle crystal growth detailsIngotNucleation

Owner:新疆东方希望新能源有限公司

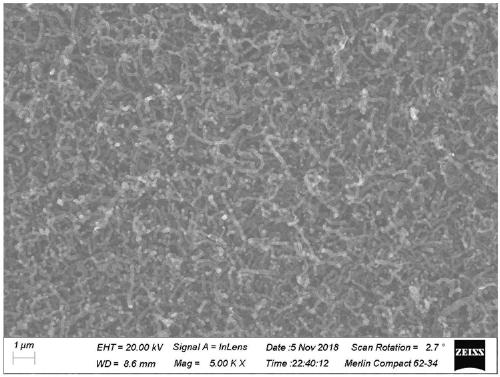

Preparation method of carbon nanoribbon anticorrosive layer on surface of stainless steel

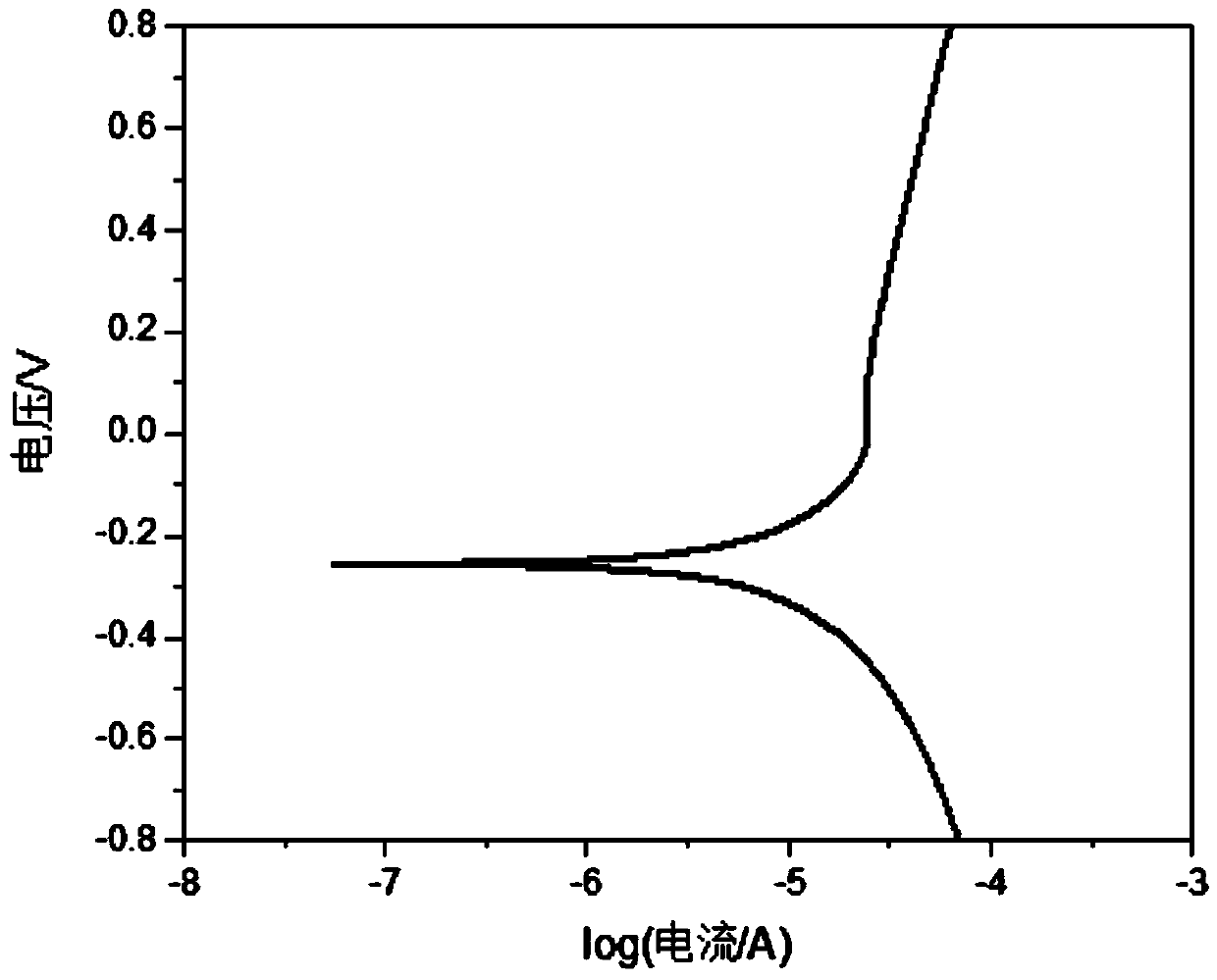

InactiveCN109554683APromote nucleation growthEfficient removalChemical vapor deposition coatingCollectors/separatorsFuel cellsGas phase

The invention relates to a preparation method of an anticorrosive layer on the surface of stainless steel, in particular to a preparation method of a carbon nanoribbon anticorrosive layer on the surface of the stainless steel. The preparation method aims to solve the problems of poor corrosion resistance of existing stainless steel materials in the acidic environment of fuel cells and short service life of the stainless steel in high-temperature fuel cells. The preparation method comprises the steps that 1, the stainless steel is placed in a vacuum device of plasma enhanced chemical vapor deposition, vacuumizing is carried out, argon gas is injected, and the surface of the stainless steel is etched under certain pressure, temperature and radio frequency power conditions; 2, after etching,a radio frequency power supply is turned off, argon gas and methane gas are injected, and deposition is carried out under certain pressure, temperature and radio frequency power conditions; and 3, after deposition, the radio frequency power supply and a heating power supply are turned off, the methane gas and the argon gas stop being injected, vacuum cooling is carried out to be in a room temperature, and then the preparation method of the carbon nanoribbon anticorrosive layer on the surface of the stainless steel is completed. The preparation method is used for preparing the carbon nanoribbonanticorrosive layer on the surface of the stainless steel.

Owner:HARBIN INST OF TECH

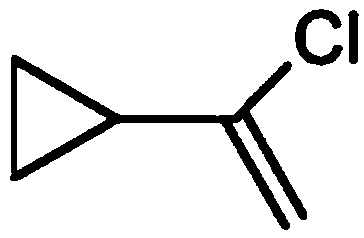

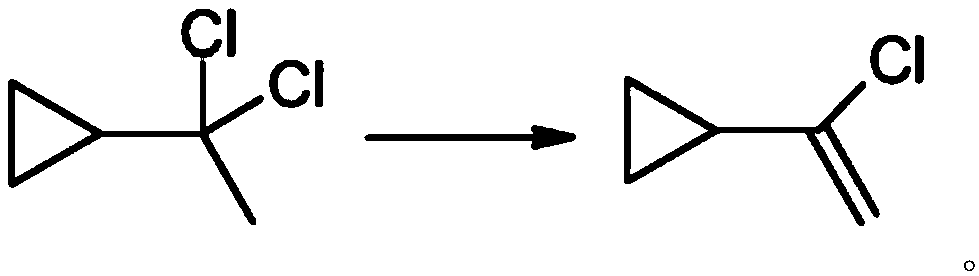

Preparing method of high-purity alpha-chloroethylene cyclopropane

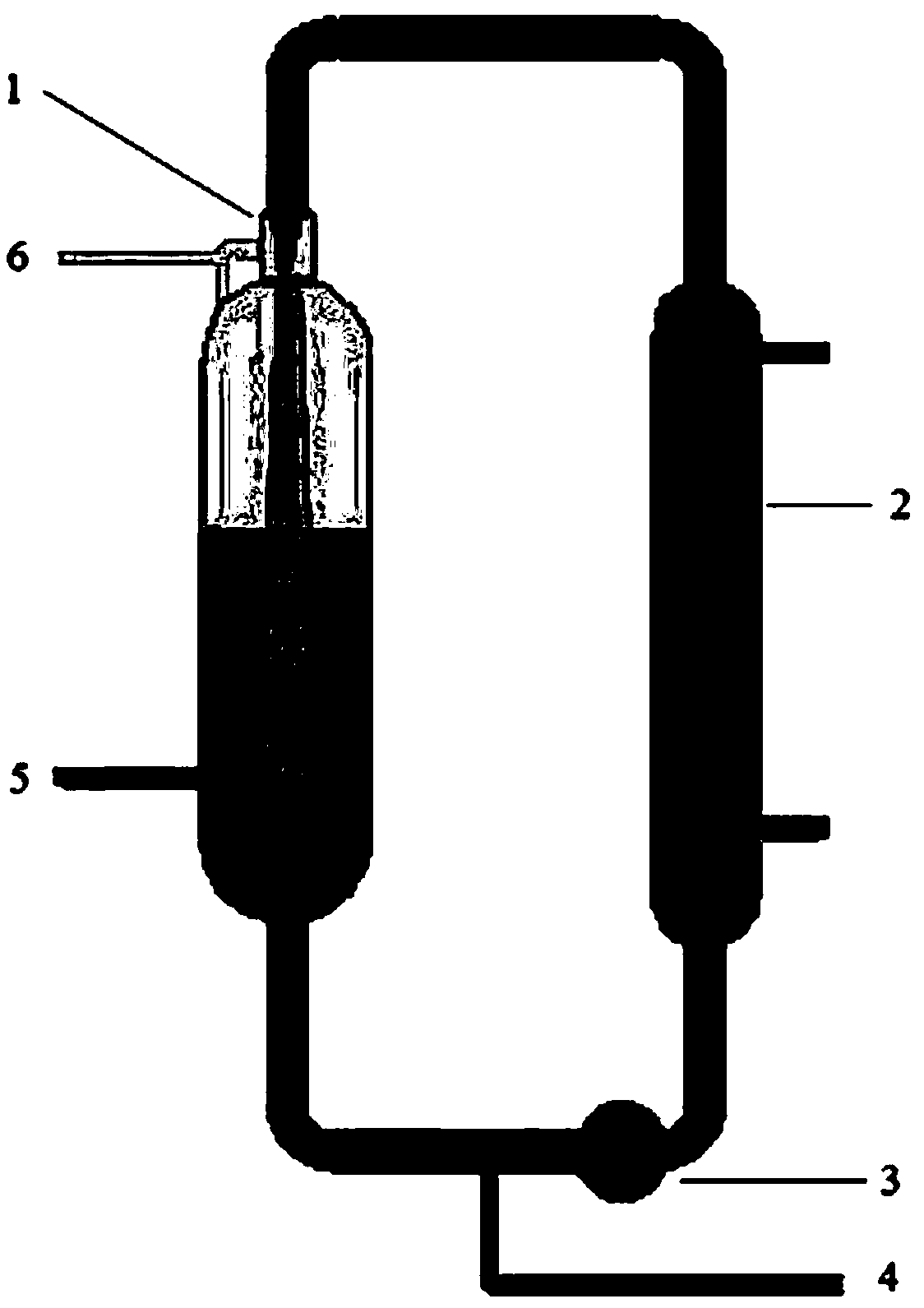

ActiveCN109608303AIncrease mass transfer rateEnhanced mass transferPreparation by hydrogen halide split-offCyclopropaneCirculating pump

The invention discloses a preparing method of high-purity alpha-chloroethylene cyclopropane. The preparing method comprises the steps of adding raw alpha-alpha-dichloro ethyl cyclopropane materials into a jetting loop reactor based on a Venturi effect, conducting deoxygenization, filling the reactor with inert gas for replacement protection, then starting vacuum, starting an external circulating pump for high-speed jetting mixing, controlling the temperature to be 20-80 DEG C, and slowly adding raw alkaline materials and a catalyst into the jetting loop reactor. According to the preparing method, the novel jetting loop reactor based on the Venturi effect is adopted, sufficient mass transfer and reactions can be achieved between an organic phase and the raw alkaline materials in a system, the reaction efficiency is greatly improved, the occurrence of side effects is lowered, and salt-type products obtained through the reactions can be quickly diffused from the reaction system under thestrong mass transfer function of high-speed jetting mixing; meanwhile, good nucleation growth can be achieved due to the existence of the catalysts, filtering is facilitated, and rightward steady proceeding of the reactions is facilitated.

Owner:JIANGSU YUXIANG CHEM

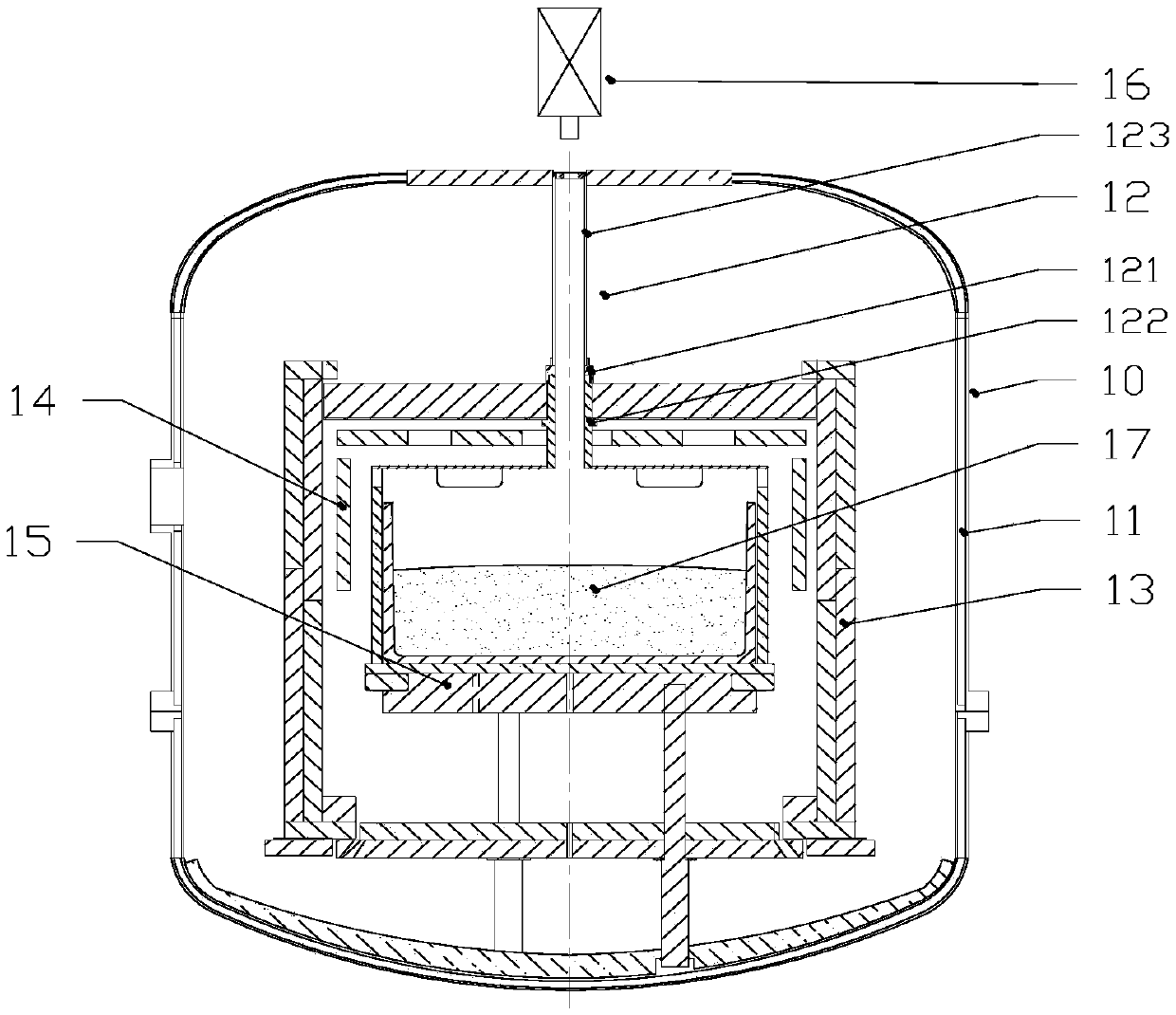

A kind of method for heterogenous growth of aln on sic seed crystal by pvt method

ActiveCN113564697BPromote nucleation growthIncrease the single crystal ratePolycrystalline material growthFrom condensed vaporsAdhesiveCondensed matter physics

Owner:PEKING UNIV

Formula and prepn process of glass ceramics for HF chip inductor

InactiveCN1189410CLow dielectric constantLow dielectric lossFixed signal inductancesInductorMixing ratio

The formula of nucleated glass ceramics for high-frequency chip inductor comprises five components of CaO, B2O3, SiO2, ZnO and P2O5, and their mixing ratio is: CaO 25-60 wt%, B2O3 10-50 wt%, SiO2 10-60 wt%, ZnO 1-10 wt% and P2O5 1-5 wt%. Said invented nucleated galss ceramics product possesses low dielectric constant (epsilon=4.9-5.5,1MHz), and its sintering temp. is lower (750-850 deg.C). The present invention also provides its preparation method.

Owner:TSINGHUA UNIV

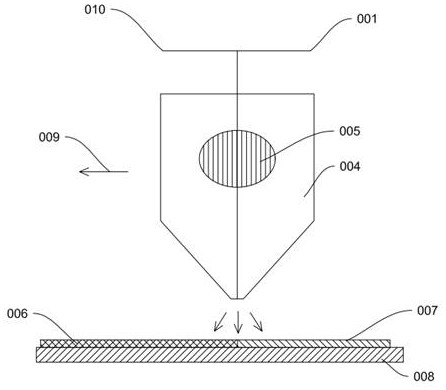

Perovskite thin film and preparation method thereof, perovskite solar cell, optoelectronic device

ActiveCN113991027BInduced oriented growthHigh crystallinitySolid-state devicesSemiconductor/solid-state device manufacturingPerovskite solar cellPhysical chemistry

The invention relates to the technical field of preparing photoelectric materials, in particular to a perovskite thin film and a preparation method thereof, a perovskite solar cell and a photoelectric device. The preparation method of the perovskite thin film includes the following steps: the perovskite precursor liquid forms a perovskite precursor liquid film on the substrate, the perovskite precursor liquid contains a first solvent and a perovskite precursor material; the mixed gas or The aerosol is fed into the air knife and dried to obtain a perovskite dry film, the mixed gas includes the vapor of the second solvent, the aerosol includes the second solvent and the vapor of the second solvent, and the second solvent and the first solvent are miscible; The perovskite dry film is annealed to prepare the perovskite film. Combining the anti-solvent method and the air knife blowing method can promote the nucleation and growth of perovskite materials, thereby preparing perovskite films with uniform crystallization, no holes, and high quality.

Owner:佛山仙湖实验室

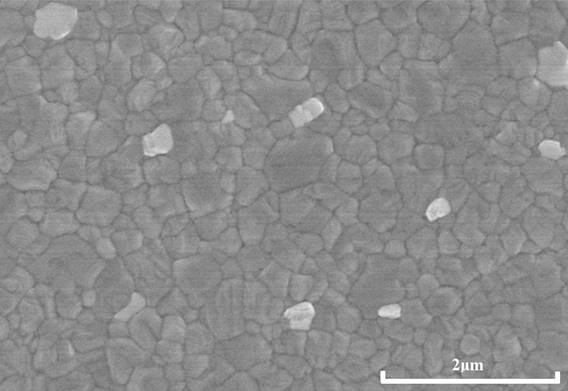

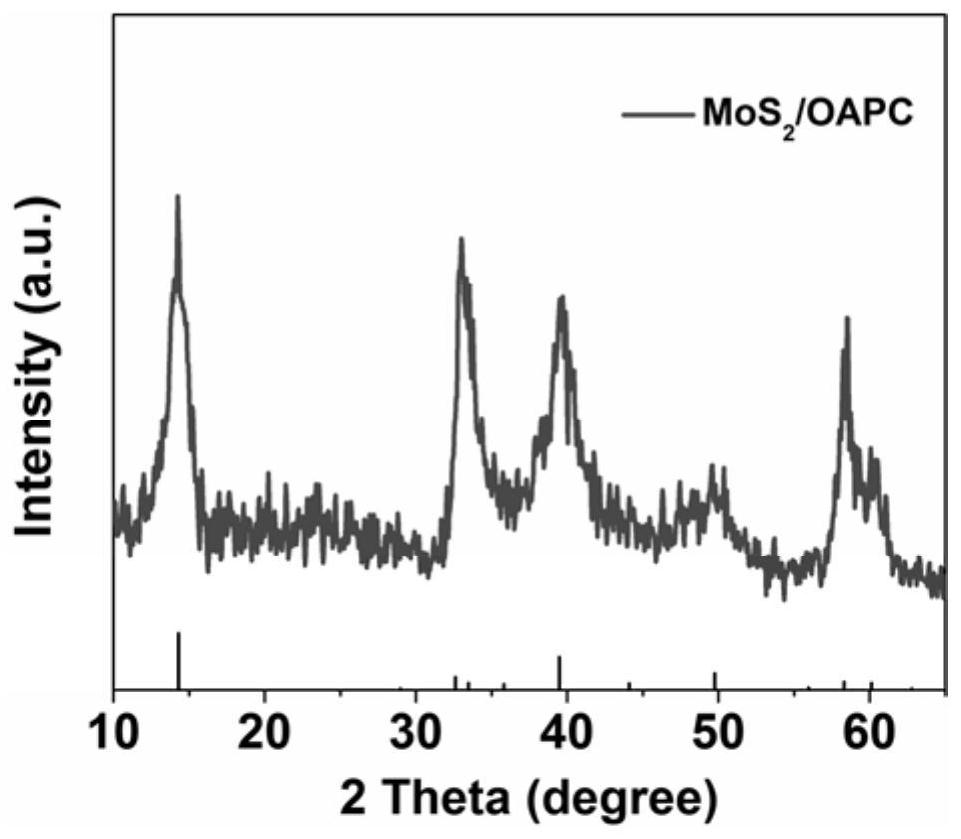

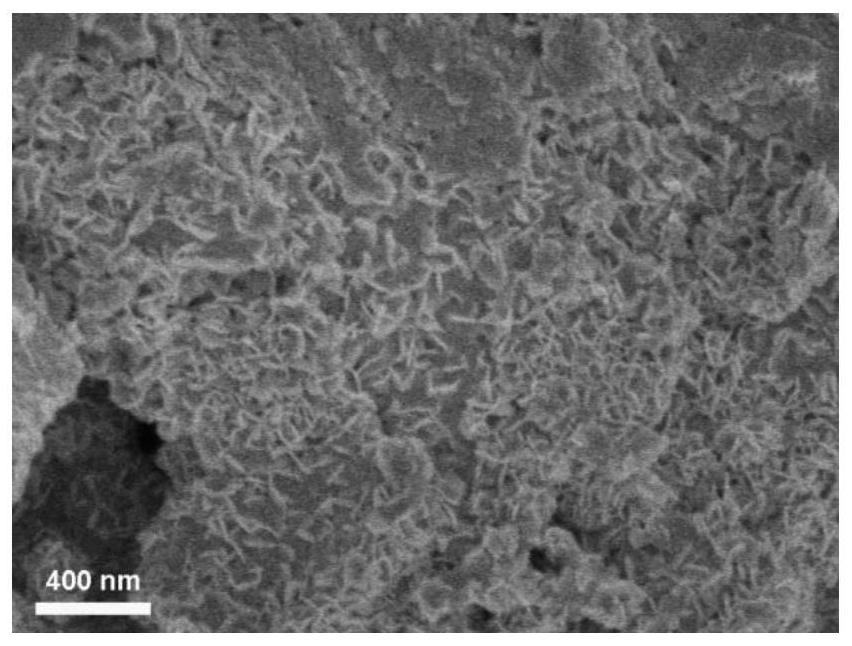

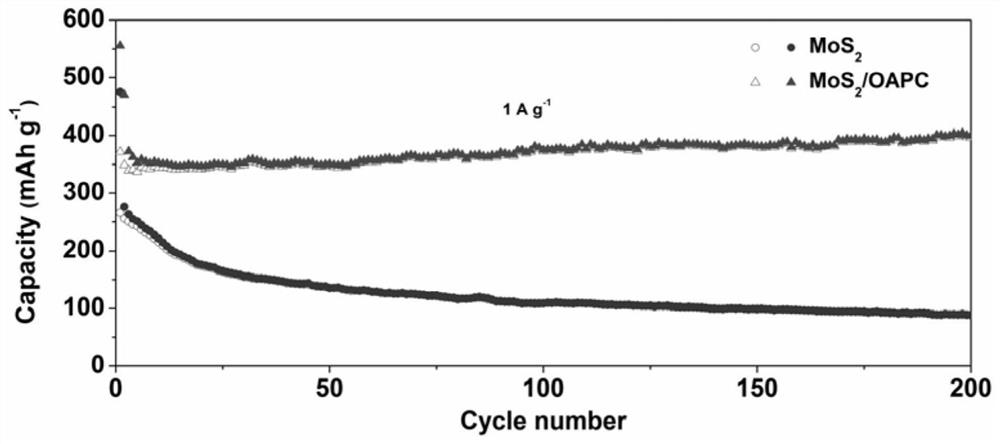

Crescent MoS2/oxidized pomace carbon sodium ion battery negative electrode material and preparation method thereof

InactiveCN113839019AReduce energy consumptionGood repeatabilityCell electrodesElectrolytic agentElectrical battery

The invention discloses a crescent MoS2 / oxidized pomace carbon sodium ion battery negative electrode material and a preparation method thereof. The preparation method comprises the following steps: preparing oxidized pomace carbon by a Hummers-like method; placing the oxidized pomace carbon as a carbon source and ammonium molybdate as a molybdenum source in water, stirring, and evaporating to dryness to obtain a preform; uniformly mixing the prefabricated body and sulfur powder for high-temperature solid-phase reaction to prepare the three-dimensional oxidized pomace carbon-supported crescent-shaped MOS2 negative electrode material, so that the volume expansion can be relieved, the electrolyte can be fully permeated, the short sodium ion and electron transmission distance is ensured, and the excellent sodium storage performance is shown; and the prepared material has high specific capacity and excellent cycling stability. The used carbon source is oxidized pomace carbon, pomace is recycled, and the hydrothermal-solid phase method is easy to operate, low in energy consumption, high in repeatability and suitable for large-scale production and preparation and has remarkable scientific significance in the aspect of sodium ion battery application.

Owner:SHAANXI UNIV OF SCI & TECH

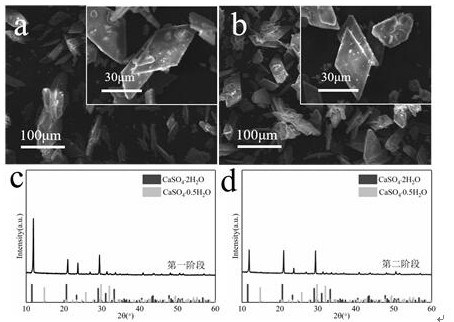

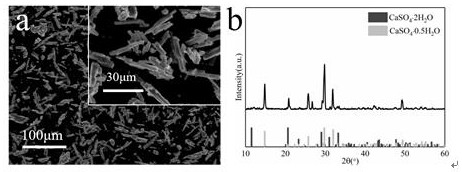

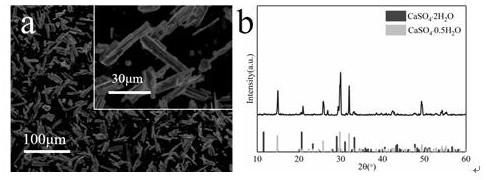

Method for converting calcium sulfate dihydrate into alpha-calcium sulfate hemihydrate in phosphoric acid dihydrate-hemihydrate wet extraction process

PendingCN113443614ARealize direct high value-added utilizationUniform shapeCalcium/strontium/barium sulfatesPhosphorus compoundsO-Phosphoric AcidInorganic sulphate

The invention discloses a method for converting calcium sulfate dihydrate into alpha-calcium sulfate hemihydrate in a phosphoric acid dihydrate-hemihydrate wet extraction process, which comprises the following steps of: 1, extracting phosphorite by sulfuric acid at low temperature, extracting phosphoric acid, and reacting to produce CaSO4. 2H2O; 2, increasing the temperature to 100 DEG C or above, the reaction process is in a crystal transformation stage, and on the premise that phosphoric acid is not separated and leached, generated CaSO4. 2H2O is converted into alpha-CaSO4. 5H2O with controllable morphology and length-diameter ratio by additionally adding a composite crystal transformation agent. According to the method disclosed by the invention, by utilizing the composite additive which mainly comprises the inorganic sulfate transforming agent, the organic acid, the organic acid salt buffering agent, the water-soluble dispersing agent and the auxiliary agent, flaky CaSO4. 2H2O is promoted to be transformed into columnar alpha-CaSO4. 5H2O on the premise of not separating phosphoric acid slurry in a one-step wet-process phosphoric acid production process. In the phosphoric acid production process, the direct high-added-value utilization of the dihydrate gypsum solid waste is realized.

Owner:EAST CHINA ENG SCI & TECH

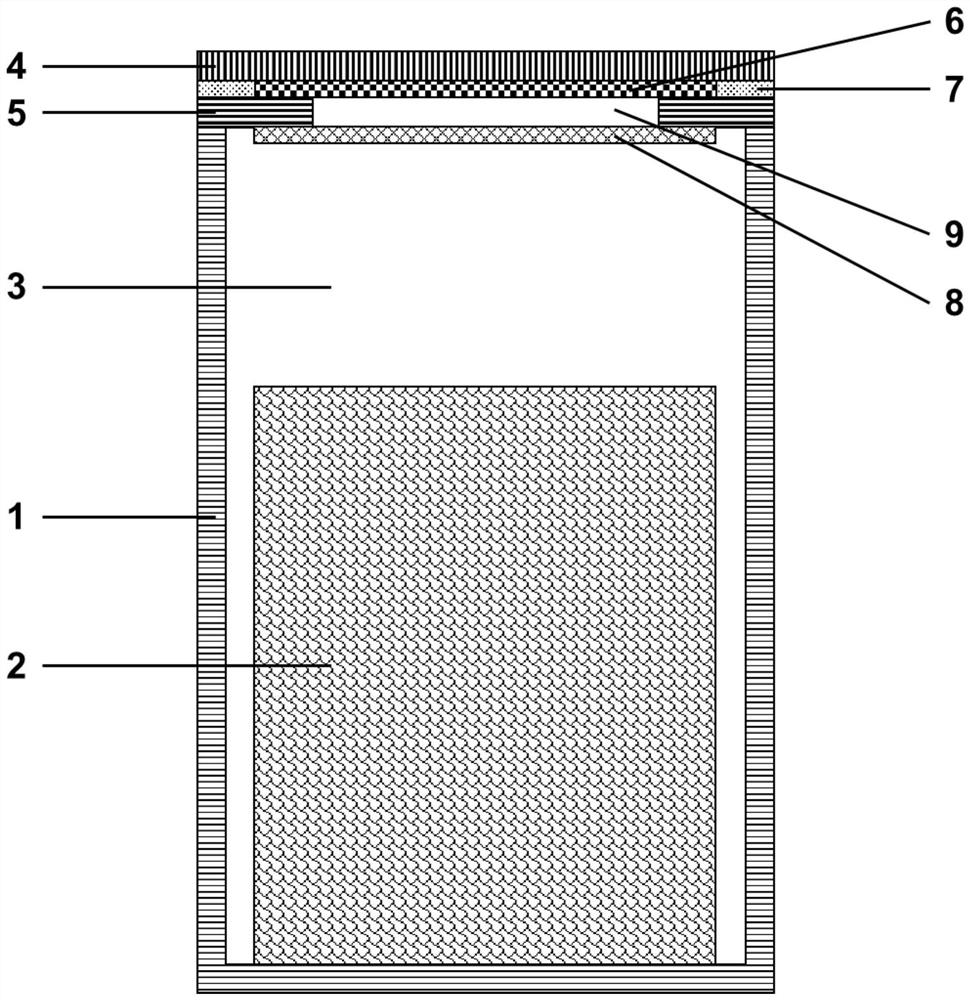

Method for heterogeneously growing AlN on SiC seed crystal via PVT (physical vapor transport) process

ActiveCN113564697APromote nucleation growthIncrease the single crystal ratePolycrystalline material growthFrom condensed vaporsSeed crystalAdhesive

The invention discloses a method for heterogeneously growing AlN on a SiC seed crystal via a PVT process. The method comprises the following steps: designing a crucible structure comprising a vapor saturation microcavity, wherein vacuumizing and inflating can be conducted in the microcavity; in an initial growth stage of AlN, inhibiting forward decomposition and sublimation of initial SiC and realizing growth of AlN by adopting the vapor saturation microcavity, inhibiting lateral sublimation of the initial SiC by covering of an adhesive with weak air holes, and allowing an AlN polycrystalline spacer to gradually sublimate from the back and to be deposited on the surface of the SiC; after sublimation of the polycrystalline spacer disappears, transporting Al atoms obtained by sublimation at AlN source powder to a growth surface; and after the AlN polycrystalline spacer and the AlN adhesive sublimate, allowing an AlN layer to cover the SiC seed crystal, and enabling the AlN adhesive on the side surface of the SiC to sublimate to leave a crucible area, thereby realizing lateral sublimation and decomposition of the SiC and gradual disappearing of the SiC seed crystal layer and obtaining the SiC-free AlN seed crystal. By adopting the method disclosed by the invention, the crack-free AlN seed crystal with high single crystal rate and low impurity content can be prepared.

Owner:PEKING UNIV

Flow guiding device for polycrystal ingot-casting furnace

ActiveCN107513763AEasy to operateIncrease contact areaPolycrystalline material growthSingle crystal growth detailsIngot castingMechanical engineering

The invention discloses a flow guiding device for a polycrystal ingot-casting furnace. The flow guiding device comprises a matching and connecting drum and a flow guiding drum which are axially connected, wherein the matching and connecting drum comprises a hollow matching and connecting drum part and a gas feeding platform part, the drum wall of the matching and connecting drum part is internally provided with a first buffering cavity which is concentric with the matching and connecting drum part and is provided with an opening at the lower end; a gas feeding hole is formed in the gas feeding platform part and is communicated with the first buffering cavity; the drum wall of the upper end part of the flow guiding drum is internally provided with a second buffering cavity which is provided with an opening at the upper end surface and corresponds to the first buffering cavity; the drum wall of the flow guiding drum is internally provided with at least one flow-guiding gas channel which extends downwards from the lower end surface of the second buffering cavity along a cylindrical spiral line, and an outlet of the flow-guiding gas channel is positioned at the lower end part of the flow guiding drum. The flow guiding device disclosed by the invention has a visual field leading into the ingot-casting furnace, and by the flow guiding device, carrier gas is sprayed to liquid silicon in a dispersed manner, so that the contact surface of the carrier gas and the liquid silicon is enlarged, local supercooling caused by the carrier gas and impurity formation enhanced by the carrier gas are reduced; and simultaneously, a rotary flow field is generated in the process that the carrier gas drives the liquid silicon, so that the impurity volatilization is promoted.

Owner:JIANGSU XIYI HIGH NEW DISTRICT TECH DEV CO LTD

Preparation of photothermally responsive drug sustained-release hydrogel based on magnetic cellulose nanocrystals

ActiveCN110903432BPromote nucleation growthFacilitate phase transitionDrug photocleavageAerosol deliveryControlled drugsPtru catalyst

The present invention relates to a preparation method of a photothermal response drug slow-release hydrogel based on magnetic cellulose nanocrystals, comprising the following steps: (1) preparing a CNC solution from a plant material by acid hydrolysis; (2) adding it to the CNC solution, Introduce iron ions of different valence states, and synthesize magnetic nanoparticles in situ under alkaline conditions to obtain a colloidal solution; (3) add polymer monomers, initiators, crosslinking agents and Catalyst, reaction, that is, to obtain the target product. Compared with the prior art, the present invention uses CNC solution as the raw material, based on the in-situ growth of magnetic nanoparticles, and by adding different contents and different types of polymers, the preparation of photothermally responsive drug-loaded hydrogels and photothermal response can be realized. controlled drug release.

Owner:SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com