Method for preparing composite ultrafiltration membrane

An ultrafiltration membrane and filter residue technology, applied in the field of water treatment, can solve the problems of short service life, inconvenient preparation process, low water permeability of ultrafiltration membrane, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

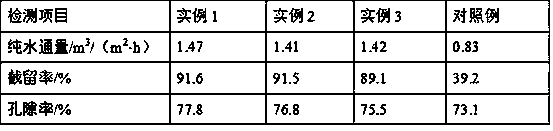

Examples

example 1

[0024] Soak the filter paper in deionized water, crush it with a mixer and filter to obtain a filter residue, add a 10% ethanol solution at a mass ratio of 1:10, stir it magnetically, wash it three times with deionized water, and filter to obtain a filter paper pulp ; grind 5 times with a grinder, then homogenize 5 times with a high-pressure homogenizer to obtain cellulose pulp; mix hydrochloric acid and sulfuric acid at a volume ratio of 1:2 to obtain a mixed acid, and immerse the cellulose pulp in In the mixed acid, stir at a constant temperature at 80°C water bath temperature for 1h to obtain a mixed slurry, wash it with deionized water until neutral to obtain a colloidal solution, filter it with suction, dry it in an oven at 80°C for 1h, and pulverize it with a ball mill to obtain a crystal powder ; In parts by weight, take 10 parts of polyvinylidene fluoride, 3 parts of crystal powder, 3 parts of nanomaterials, 10 parts of polyvinyl alcohol, 40 parts of N, N-dimethylacetam...

example 2

[0026] Soak the filter paper in deionized water, crush it with a mixer, and filter to obtain a filter residue, add a 10% ethanol solution at a mass ratio of 1:10, stir it magnetically, wash it with deionized water for 4 times, and filter to obtain a filter paper pulp ; grind 5 times with a grinder, then homogenize 5 times with a high-pressure homogenizer to obtain cellulose pulp; mix hydrochloric acid and sulfuric acid at a volume ratio of 1:2 to obtain a mixed acid, and impregnate the cellulose pulp in In the mixed acid, stir at a constant temperature at 85 ° C for 1 h to obtain a mixed slurry, wash it with deionized water until neutral, obtain a colloidal solution, filter it with suction, dry it in an oven at 85 ° C for 1 h, and pulverize it with a ball mill to obtain a crystal powder ; In parts by weight, take respectively 15 parts of polyvinylidene fluoride, 5 parts of crystal powder, 4 parts of nanomaterials, 12 parts of polyvinyl alcohol, 50 parts of N, N-dimethylacetamid...

example 3

[0028]Soak the filter paper in deionized water, crush it with a mixer and filter it to obtain a filter residue, add a 10% ethanol solution in a mass ratio of 1:10, stir it magnetically, wash it with deionized water for 5 times, and filter it to obtain a filter paper pulp ; grind 5 times with a grinder, then homogenize 5 times with a high-pressure homogenizer to obtain cellulose pulp; mix hydrochloric acid and sulfuric acid at a volume ratio of 1:2 to obtain a mixed acid, and immerse the cellulose pulp in In the mixed acid, stir at a constant temperature for 2 hours at a water bath temperature of 90°C to obtain a mixed slurry, wash it with deionized water until neutral to obtain a colloidal solution, filter it with suction, dry it in an oven at 90°C for 2 hours, and pulverize it with a ball mill to obtain a crystal powder ; In parts by weight, respectively weigh 20 parts of polyvinylidene fluoride, 7 parts of crystal powder, 5 parts of nanomaterials, 14 parts of polyvinyl alcoho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com