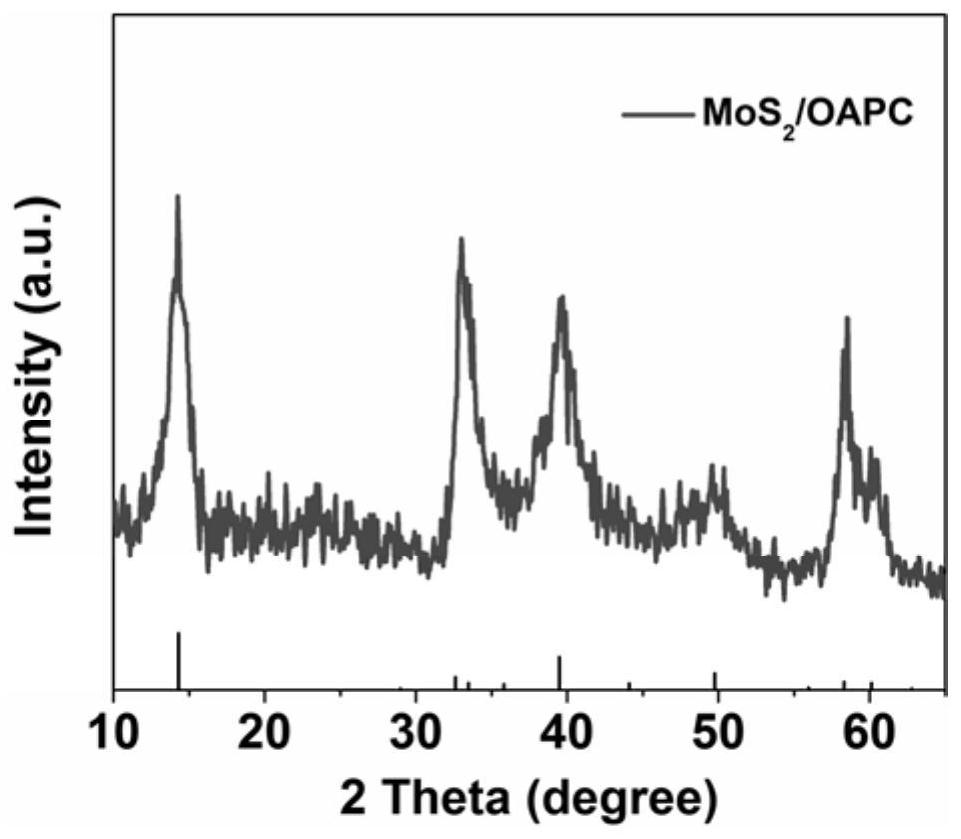

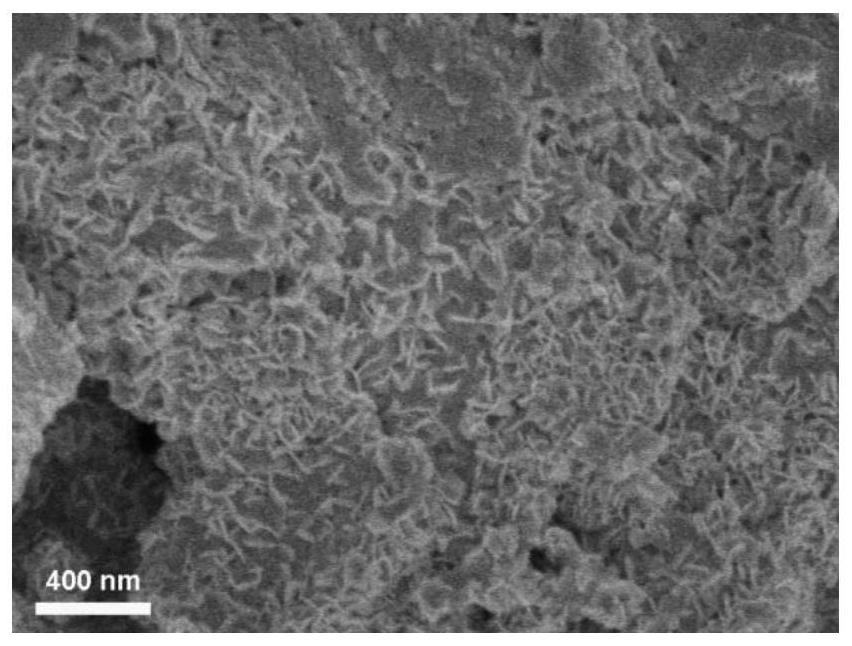

Crescent MoS2/oxidized pomace carbon sodium ion battery negative electrode material and preparation method thereof

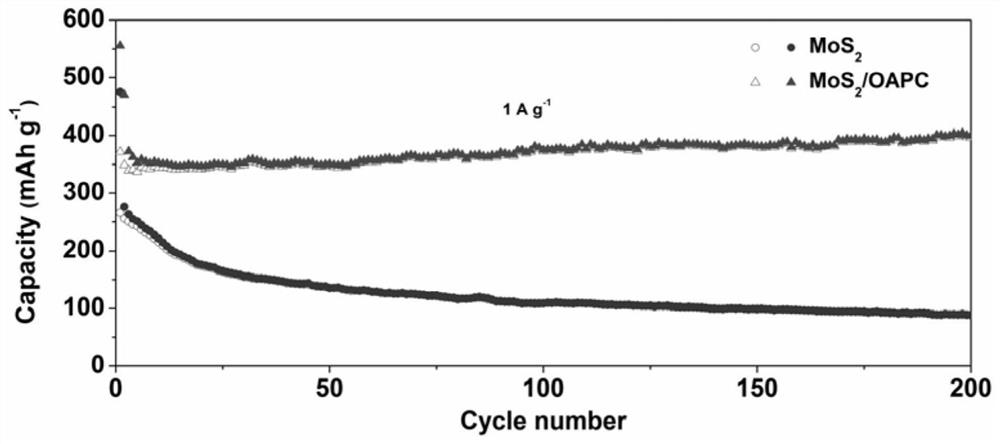

A sodium-ion battery and negative electrode material technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of unsatisfactory material performance, complicated preparation process, unfriendly environment, etc., achieve excellent sodium storage performance, simple operation, The effect of improving the stability of sodium storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The present invention provides a crescent MoS 2 The preparation method of oxidized pomace carbon sodium ion battery negative electrode material specifically comprises the following steps:

[0029] (1) preparing oxidized pomace carbon by the Hummers method, comprising the following steps:

[0030] (a) Weigh pomace carbon and sodium nitrate with a mass ratio of (2-6):1 and put them into concentrated sulfuric acid, specifically put 1.40-4.20 g of pomace carbon and 0.70 g of sodium nitrate in a beaker of 35-98 mL of concentrated sulfuric acid Put it in an ice bath to cool, keep it at 0°C for 0.5-2.5h, then slowly add 5.0-17.0g of potassium permanganate to it, and stir at 10°C for 1h;

[0031] (b) Transfer the beaker to a constant temperature water bath at 35°C and stir for 2 hours;

[0032] (c) Slowly add 196-531mL of ultra-pure water, continue stirring at 98°C for 2 hours, then add 100-180mL of 30% hydrogen peroxide solution while stirring until the bubbles disappear, to...

Embodiment 1

[0040] Include the following steps:

[0041] (1) preparing oxidized pomace carbon by the Hummers method, comprising the following steps:

[0042] (a) Weigh 1.40g of pomace carbon and 0.70g of sodium nitrate in a beaker of 35mL of concentrated sulfuric acid, put it in an ice bath and cool it at 0°C, keep it for 0.5h, slowly add 5.0g of potassium permanganate to it, at 10 ℃ stirring reaction for 1h;

[0043] (b) Transfer the beaker to a constant temperature water bath at 35°C and stir for 2 hours;

[0044] (c) Slowly add 196mL of ultrapure water, continue stirring at 98°C for 2h, then add 100mL of 30% hydrogen peroxide while stirring until the bubbles disappear, to remove unreacted potassium permanganate;

[0045] (d) centrifuge at 2500rpm while it is hot, centrifuge the filtrate and decant the supernatant, then use 50mL of 5% HCl and deionized water in turn to wash the remaining solid material at least three times until neutral;

[0046] (e) Subsequently, the material is dri...

Embodiment 2

[0050] Include the following steps:

[0051] (1) preparing oxidized pomace carbon by the Hummers method, comprising the following steps:

[0052] (a) Weigh 2.1g of pomace carbon and 0.70g of sodium nitrate in a beaker of 50mL of concentrated sulfuric acid, put it in an ice bath and cool it at 0°C, keep it for 1h, slowly add 8.0g of potassium permanganate to it, and heat it at 10°C The reaction was stirred for 1 h.

[0053] (b) Transfer the beaker to a constant temperature water bath at 35°C and stir for 2 hours;

[0054] (c) Slowly add 280mL of ultrapure water, continue stirring at 98°C for 2 hours, then add 120mL of 30% hydrogen peroxide and stir until the bubbles disappear, so as to remove unreacted potassium permanganate;

[0055] (d) centrifuge at 2500rpm while it is hot, centrifuge the filtrate and decant the supernatant, then wash the remaining solid material with 5% HCl 70mL and deionized water successively for at least three times until neutral;

[0056] (e) Subsequ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com