Formula and prepn process of glass ceramics for HF chip inductor

A glass-ceramic, chip technology, applied in the direction of inductors, fixed inductors, fixed signal inductors, etc., can solve the problems of development lag, affecting the overall development of electronic products, etc., to promote nucleation growth and reduce sintering temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

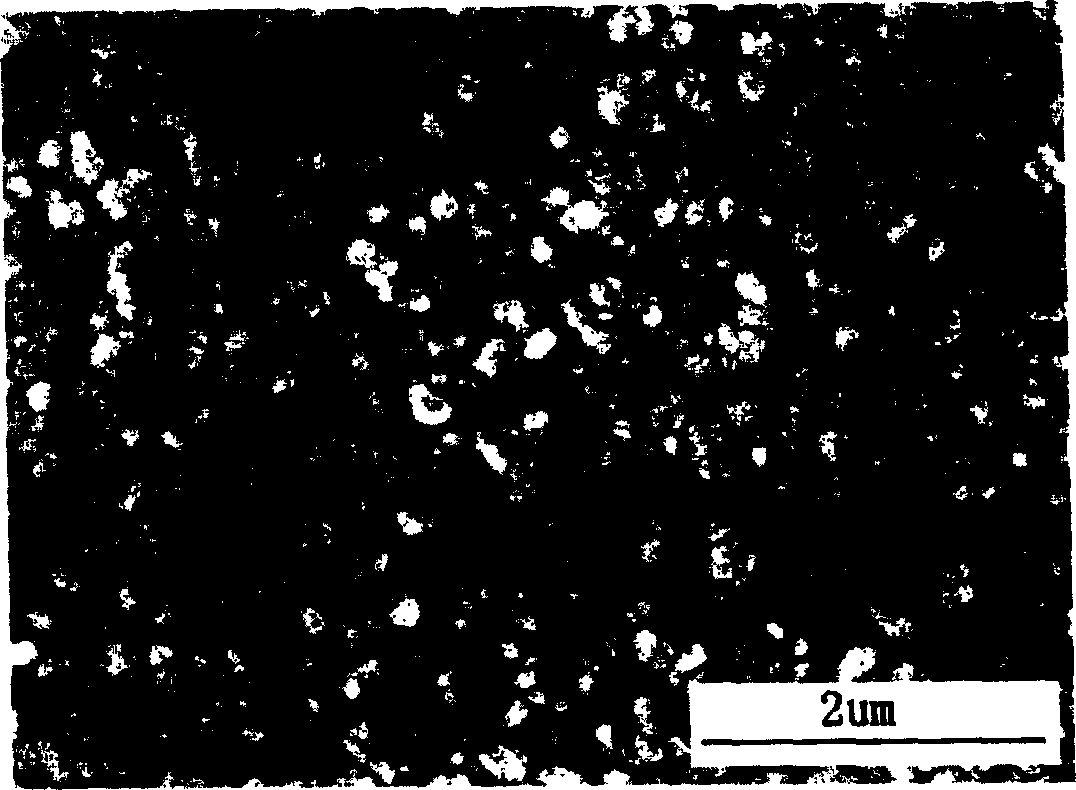

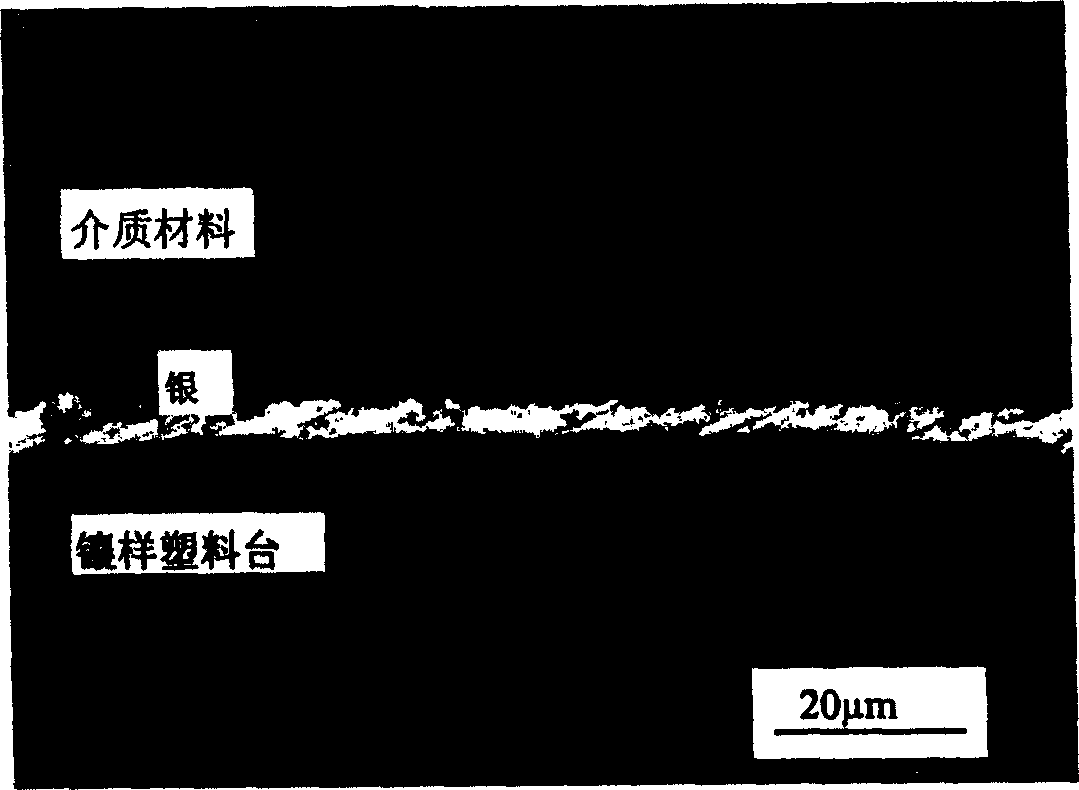

[0023] Weigh CaO (40wt%) by weight percentage, B 2 o 3 (18wt%), SiO 2 (38wt%), ZnO (2.5wt%) and P 2 o 5 (1.5 wt%). After ball milling for 3 hours to mix the materials evenly, dry it at 70°C, put it into a platinum crucible, melt the glass (1350°C, keep it warm for 2 hours), and quench the molten glass into distilled water to obtain a transparent cullet. The cullet was subjected to wet ball milling (the ratio of glass to ethanol was 1:1 for 24 hours) so that the powder was glass powder NO1 with an average particle size of 1.0 μm, and the glass-ceramic material of the present invention was obtained. After granulation (the ratio of glass-ceramic material powder and 5% polyvinyl butyral is 60 / 40) and drying, it is dry-pressed at a pressure of 1.5 tons. The dry-pressed tablet was first degummed at 550°C (4 hours of heat preservation), then rapidly heated to 850°C (heating rate of 10°C / min) and held for 2 hours, and then a glass-ceramic with good dielectric properties was obtai...

Embodiment 2

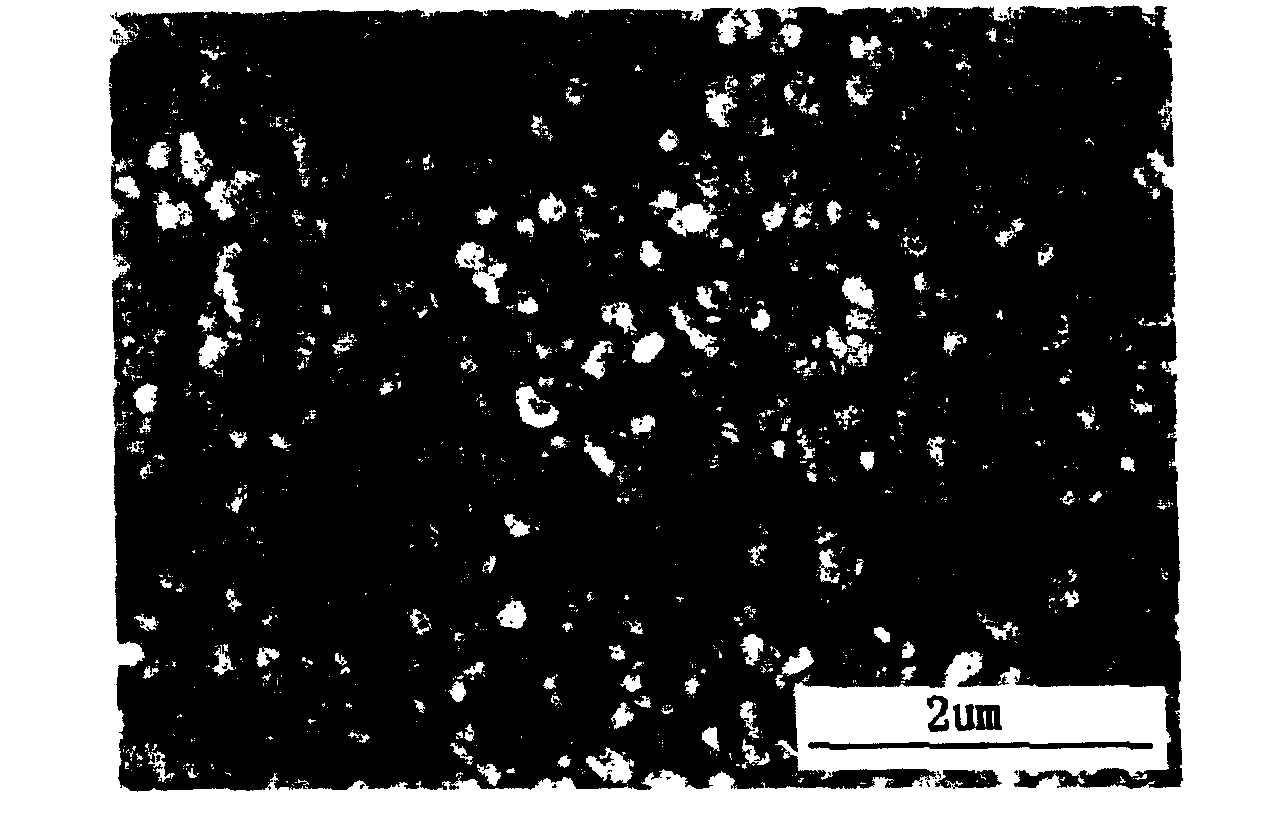

[0025] Weigh CaO (42wt%) by weight percentage, B 2 o 3 (31wt%), SiO 2 (24wt%), ZnO (0.5wt%) and P 2 o 5 (2.5 wt%). After ball milling for 3 hours to mix the material evenly, dry it at 70°C, put it into a platinum crucible, melt the glass (1400°C, keep it warm for 2 hours), and quench the molten glass into distilled water to obtain a transparent cullet. The cullet is subjected to wet ball milling (the ratio of glass to ethanol is 1:1 for 24 hours) to obtain the glass ceramic powder NO2 of the present invention. After granulation (the ratio of glass-ceramic material powder and 5% polyvinyl butyral is 60 / 40) and drying, it is dry-pressed at a pressure of 1.5 tons. The dry-pressed tablet was first degummed at 550°C (4 hours of heat preservation), and then rapidly heated to 780°C (heating rate of 10°C / min) and held for 1.5 hours to obtain a glass-ceramic with good dielectric properties, as shown in Table 1. Show.

Embodiment 3

[0027] Weigh CaO (46wt%) by weight percentage, B 2 o 3 (26wt%), SiO 2 (23wt%), ZnO (3.5wt%) and P 2 o 5 (1.5 wt%). After ball milling for 3 hours to mix the material evenly, dry it at 70°C, put it into a platinum crucible, melt the glass (1380°C, keep it warm for 2 hours), and quench the molten glass into distilled water to obtain a transparent cullet. The cullet is subjected to wet ball milling (the ratio of glass to ethanol is 1:1 for 24 hours) to obtain the glass ceramic powder NO3 of the present invention. After granulation (the ratio of glass-ceramic material powder and 5% polyvinyl butyral is 60 / 40) and drying, it is dry-pressed at a pressure of 1.5 tons. The dry-pressed tablet was first degummed at 550°C (4 hours of heat preservation), and then rapidly heated to 800°C (heating rate of 10°C / min) and held for 2 hours to obtain a glass-ceramic with good dielectric properties, as shown in Table 1. Show.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com