CrAlYO coated cutter and preparation method thereof

A coating and cutting tool technology, applied in the field of CrAlYO coated cutting tools and its preparation, can solve problems such as cracked surface, coating peeling, pores, etc., and achieve the effects of low production cost, improved thermal stability, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

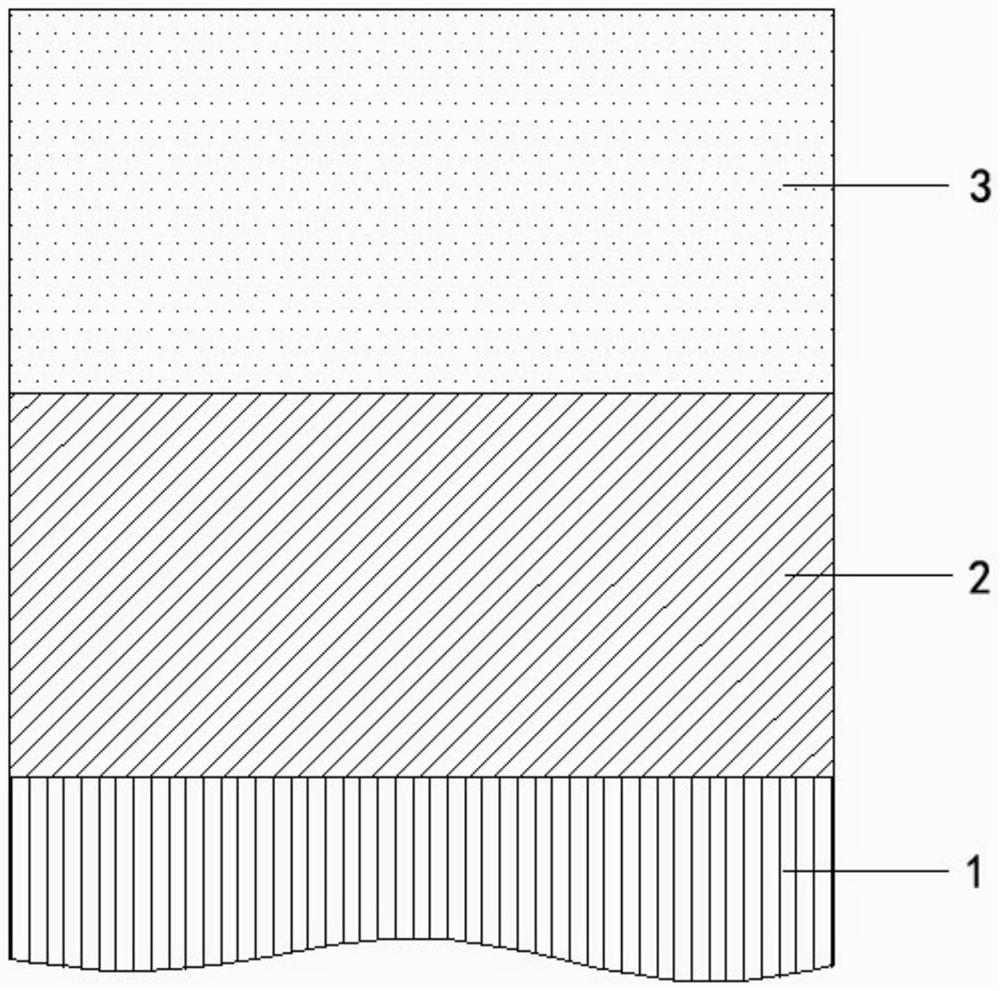

[0030] A kind of CrAlYO coating tool of the present invention, as figure 1 As shown, including the tool substrate 1 and the CrAlYO coating deposited on the tool substrate 1, the CrAlYO coating is specifically (Cr 1-a-b al a Y b ) 2 o 3 Layer 3, (Cr 1-a-b al a Y b )2 o 3 In layer 3, a=0.5, b=0.03, and the thickness is 1.0 μm.

[0031] In this embodiment, the crystal structure of CrAlYO coating is corundum Al 2 o 3 The structure of the hexagonal phase.

[0032] In this embodiment, Ti is also deposited between the tool substrate 1 and the CrAlYO coating. 1-x Al x N transition layer 2, Ti 1-x Al x In the N transition layer 2, x=0.5, the thickness is 2.0 μm, Ti 1-x Al x The crystal structure of the N transition layer 2 is a face centered cubic structure.

[0033] In this embodiment, the cutter base 1 adopts a cemented carbide blade whose model is CNMG120408.

[0034] A kind of preparation method of the CrAlYO coated cutting tool of above-mentioned present embodime...

Embodiment 2

[0044] A kind of CrAlYO coating tool of the present invention, as figure 1 As shown, including the tool base 1 and the (Cr 1-a-b Al a Y b ) 2 o 3 Layer 3, tool substrate 1 and (Cr 1-a-b Al a Y b ) 2 o 3 Ti was also deposited between layers 3 1-x Al x N transition layer 2, where Ti 1-x Al x In the N transition layer 2, x=0.5, the thickness is 2.0 μm, (Cr 1-a-b Al a Y b ) 2 o 3 In layer 3, a=0.7, b=0.01, and the thickness is 1.0 μm.

[0045] In the present embodiment, the XRD detection result shows that Ti 1-x Al x The N transition layer 2 is a single-phase cubic structure, (Cr 1-a-b Al a Y b ) 2 o 3 Layer 3 is a single-phase corundum structure.

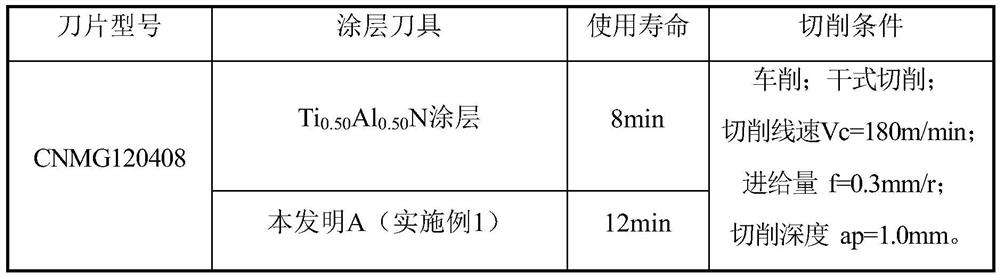

[0046] The CrAlYO coated tool A prepared in this example and the reference product were subjected to a comparative experiment of continuous turning of stainless steel (1Cr18Ni9Ti), and the results of the comparative experiment are shown in Table 2 below.

[0047] The comparative experimental effect of the CrAl...

Embodiment 3

[0051] A kind of CrAlYO coating tool of the present invention, as figure 1 As shown, including the tool base 1 and the (Cr 1-a-b Al a Y b ) 2 o 3 Layer 3, tool substrate 1 and (Cr 1-a-b Al a Y b ) 2 o 3 Ti was also deposited between layers 3 1-x Al x N transition layer 2, where Ti 1-x Al x In the N transition layer 2, x=0.67, the thickness is 1.5 μm, (Cr 1-a-b Al a Y b ) 2 o 3 In layer 3, a=0.3, b=0.005, and the thickness is 1.5 μm.

[0052] In the present embodiment, the XRD detection result shows that Ti 1-x Al x The N transition layer 2 is a single-phase face-centered cubic structure, (Cr 1-a- b Al a Y b ) 2 o 3 Layer 3 has a single-phase corundum structure (hexagonal phase).

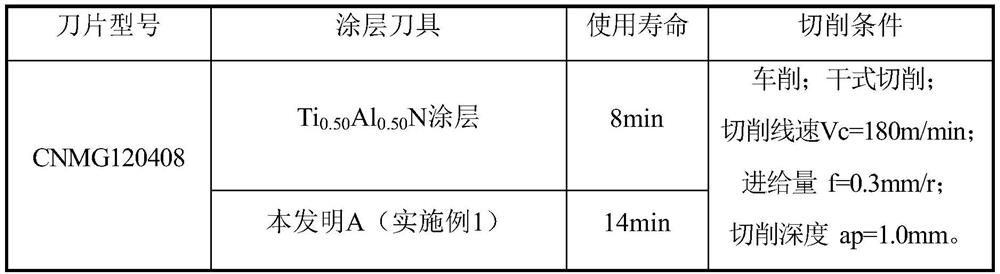

[0053] The CrAlYO coated tool A prepared in this example and the reference product were subjected to a comparative experiment of continuous turning of stainless steel (1Cr18Ni9Ti), and the results of the comparative experiment are shown in Table 3 below.

[0054] The compar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com