Method for converting calcium sulfate dihydrate into alpha-calcium sulfate hemihydrate in phosphoric acid dihydrate-hemihydrate wet extraction process

A technology of calcium sulfate dihydrate and calcium sulfate hemihydrate, applied in chemical instruments and methods, phosphorus compounds, calcium/strontium/barium compounds, etc., can solve problems such as low additional utilization value, reduced separation rate, waste of sulfur resources, etc. Achieve the effect of uniform crystal growth size and shape, uniform shape and size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

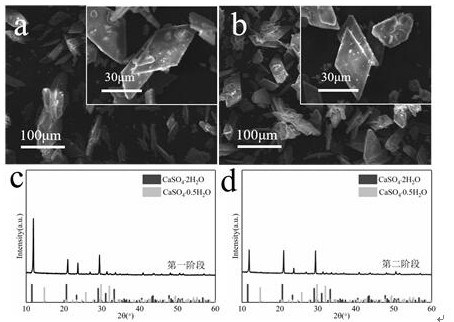

[0045] The invention provides a kind of method that calcium sulfate dihydrate converts calcium sulfate hemihydrate into α-calcium sulfate hemihydrate in the process of dihydrate-semiwater wet leaching phosphoric acid, such as Figure 1-6 As shown, the embodiment of the present invention uses the phosphate rock of a phosphate rock in a certain area of Hubei as raw material, and the composition Wt (%) of the phosphate rock is as follows:

[0046] Element P 2 o 5

MgO CaO Al 2 o 3

Fe 2 o 3

K 2 o

N 2 o

SiO 2

F other content / % 31.18 1.07 45.51 2.88 3.16 3.20 1.63 2.64 2.73

[0047] The first stage: at low temperature (≤85°C), phosphate ore is extracted by sulfuric acid, phosphoric acid is extracted, and CaSO is produced by reaction at the same time 4 2H 2 O (calcium sulfate dihydrate).

[0048] The second stage: raise the temperature to above 100°C, and the reaction process is in the crystal transform...

Embodiment 2

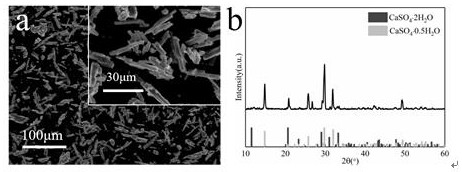

[0056] Using the same phosphate rock as in Example 1 as the raw material, the reaction conditions in the first stage are the same, but the compound additive is added in three steps in the second stage. %; add 10-25% of the total amount of compound additives in the stable transformation stage of 8-120min; add 5-25% of the total amount of compound additives in the crystal growth stage of 120-150min.

[0057] The conversion agent, buffering agent and phase transfer agent in the composite additive are mixed components, wherein the conversion agent is sodium sulfate accounting for 40% of the total composite additive; the buffering agent is succinic acid accounting for 2.5% of the total composite addition and The total amount of 2.5% oxalic acid; the phase transfer agent selects polyethylene glycol accounting for 2.5% of the total amount of compound addition and polyvinyl alcohol accounting for 2.5% of the total amount of compound addition; the auxiliary agent is water; the mass of t...

Embodiment 3

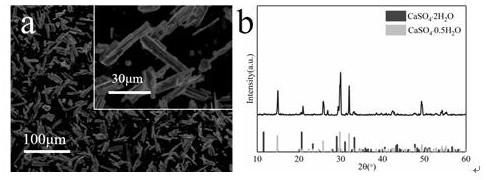

[0061] Using the same phosphate rock as in Example 1 as the raw material, the reaction conditions in the first stage are the same, but the compound additive is added in three steps in the second stage. %; add 10-25% of the total amount of compound additives in the stable transformation stage of 8-120min; add 5-25% of the total amount of compound additives in the crystal growth stage of 120-150min.

[0062] The conversion agent, buffering agent and phase transfer agent in the composite additive are mixed components, wherein the conversion agent is potassium sulfate accounting for 40% of the total composite additive; the buffering agent is succinic acid and 2.5% of the total composite additive The total amount of 2.5% oxalic acid; the phase transfer agent selects polyethylene glycol accounting for 2.5% of the total amount of compound addition and polyvinyl alcohol accounting for 2.5% of the total amount of compound addition; the auxiliary agent is water; the mass of the compound ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com