Patents

Literature

74 results about "Residual phosphorus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

As a result, little soil phosphorus is lost by leaching. This fixed, residual phosphorus remains in the rooting zone and will be slowly available to succeeding crops. Soil erosion and crop removal are the significant ways soil phosphorus is lost.

Process for the pre-treatment of vegetable oils for physical refining

ActiveUS20040005399A1Speed up the processFatty acids production/refiningTea extractionMicroorganismActivated carbon

The present invention relates to a simple and economically attractive process for the pretreatment of vegetable oils which involves (a) enzymatic degumming with commercially available phospholipase A1 from the sources like Aspergillus oryzae microorganism, (b) bleaching of the enzymatically degummed oil using bleaching earth and activated carbon, and (c) dewaxing (in case of rice bran oil) of degummed and bleached oil at lower temperature to obtain oil with less than 5 ppm of residual phosphorus which is amenable for physical refining.

Owner:COUNCIL OF SCI & IND RES

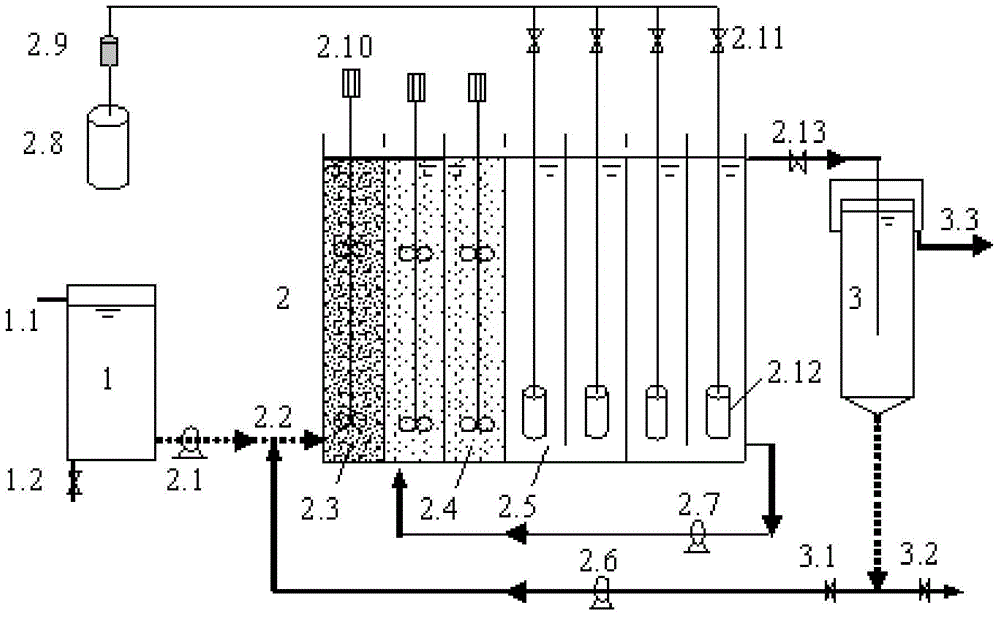

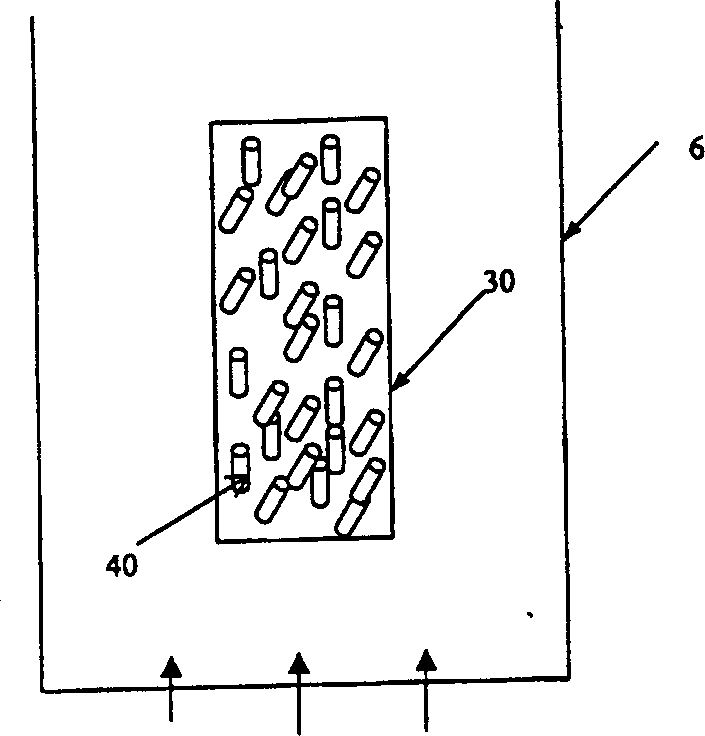

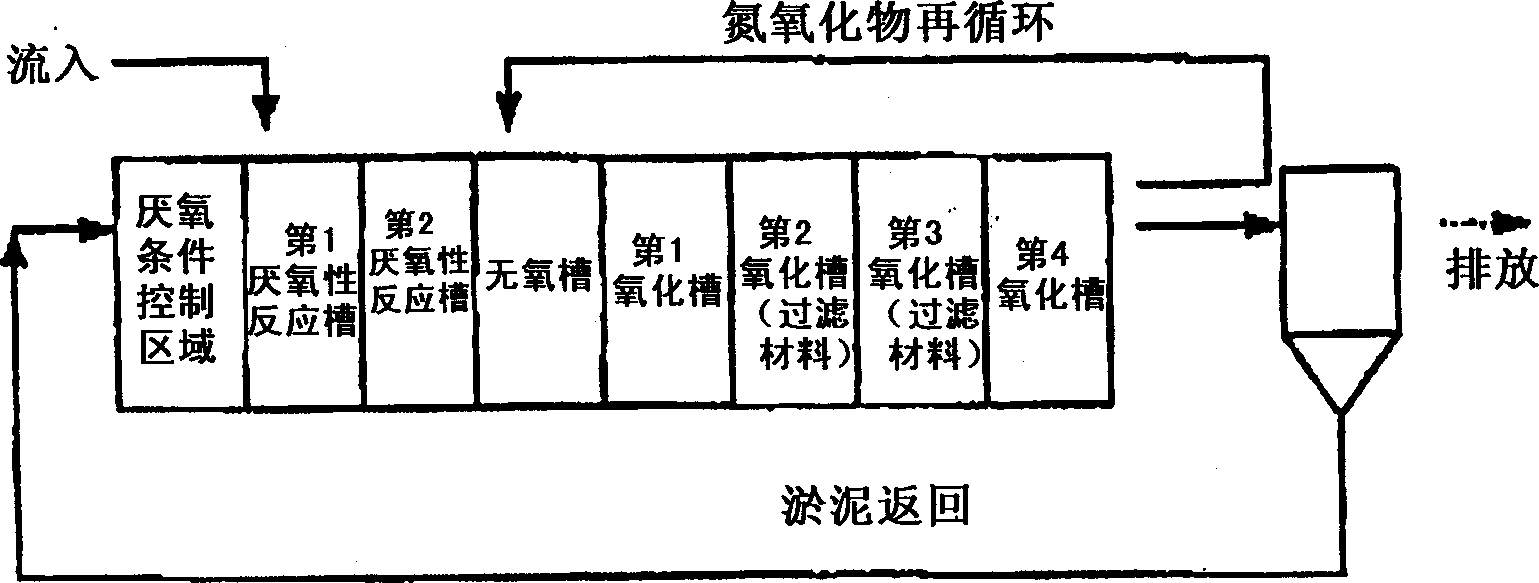

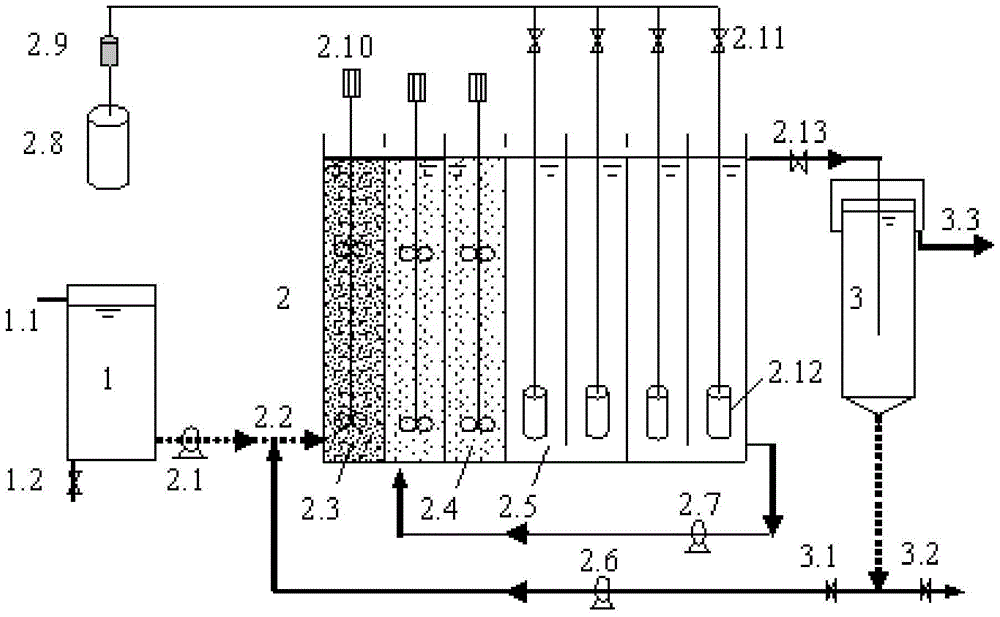

Autotrophic nitrogen removal method for biological phosphorus removal of urban sewage based on short-cut denitrification for providing nitrite

ActiveCN104556376AReduced oxygen demandReduce operating energy consumptionTreatment with aerobic and anaerobic processesSludgeAmmonia-oxidizing bacteria

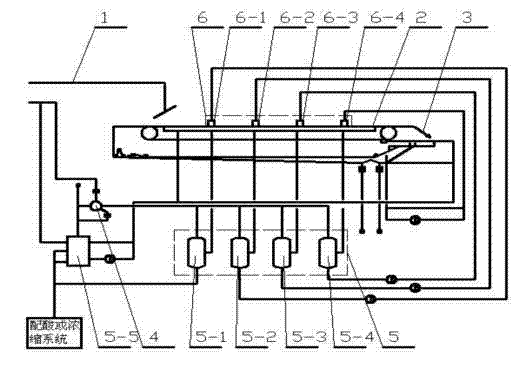

The invention discloses an autotrophic nitrogen removal method for biological phosphorus removal of urban sewage based on short-cut denitrification for providing nitrite. The method comprises the following steps: firstly feeding urban sewage into an anaerobic zone of a biological phosphorus removal nitrogen removal reactor, wherein short-cut denitrification is firstly carried out on denitrifying bacteria on a biological membrane so as to reduce nitrate nitrogen in return sludge to nitrite nitrogen, anaerobic ammonium oxidation bacteria on the biological membrane further convert nitrite nitrogen and nitrite nitrogen into nitrogen while anaerobic phosphorus release is carried out on phosphorus-accumulating bacteria in floc sludge; then feeding the sewage into the anaerobic zone again, wherein short-cut denitrification is carried out on the denitrifying bacteria on the biological membrane so as to reduce nitrate nitrogen in return sludge to nitrite nitrogen, and anaerobic ammonium oxidation bacteria on the biological membrane further convert nitrite nitrogen and nitrite nitrogen into nitrogen; then feeding the sewage into an aerobic zone and ammonia oxidizing bacteria and nitrite oxidizing bacteria in the floc sludge oxidize residual ammonia nitrogen in the sludge to nitrate nitrogen; and finally, implementing residual phosphorus removal and autotrophic nitrogen removal of urban sewage of a continuous flow, wherein the treatment energy consumption of an urban sewage plant is reduced.

Owner:BEIJING UNIV OF TECH

Process for the preparation of rice bran oil low in phosphorous content

InactiveUS6706299B2Simple and economical and fast processReduce processing stepsFatty-oils/fats refiningCheese manufacturePhosphoric acidPulp and paper industry

Owner:COUNCIL OF SCI & IND RES

Process for the pre-treatment of vegetable oils for physical refining

ActiveUS7494676B2Speed up the processFatty acids production/refiningTea extractionMicroorganismActivated carbon

The present invention relates to a simple and economically attractive process for the pretreatment of vegetable oils which involves (a) enzymatic degumming with commercially available phospholipase A1 from the sources like Aspergillus oryzae microorganism, (b) bleaching of the enzymatically degummed oil using bleaching earth and activated carbon, and (c) dewaxing (in case of rice bran oil) of degummed and bleached oil at lower temperature to obtain oil with less than 5 ppm of residual phosphorus which is amenable for physical refining.

Owner:COUNCIL OF SCI & IND RES

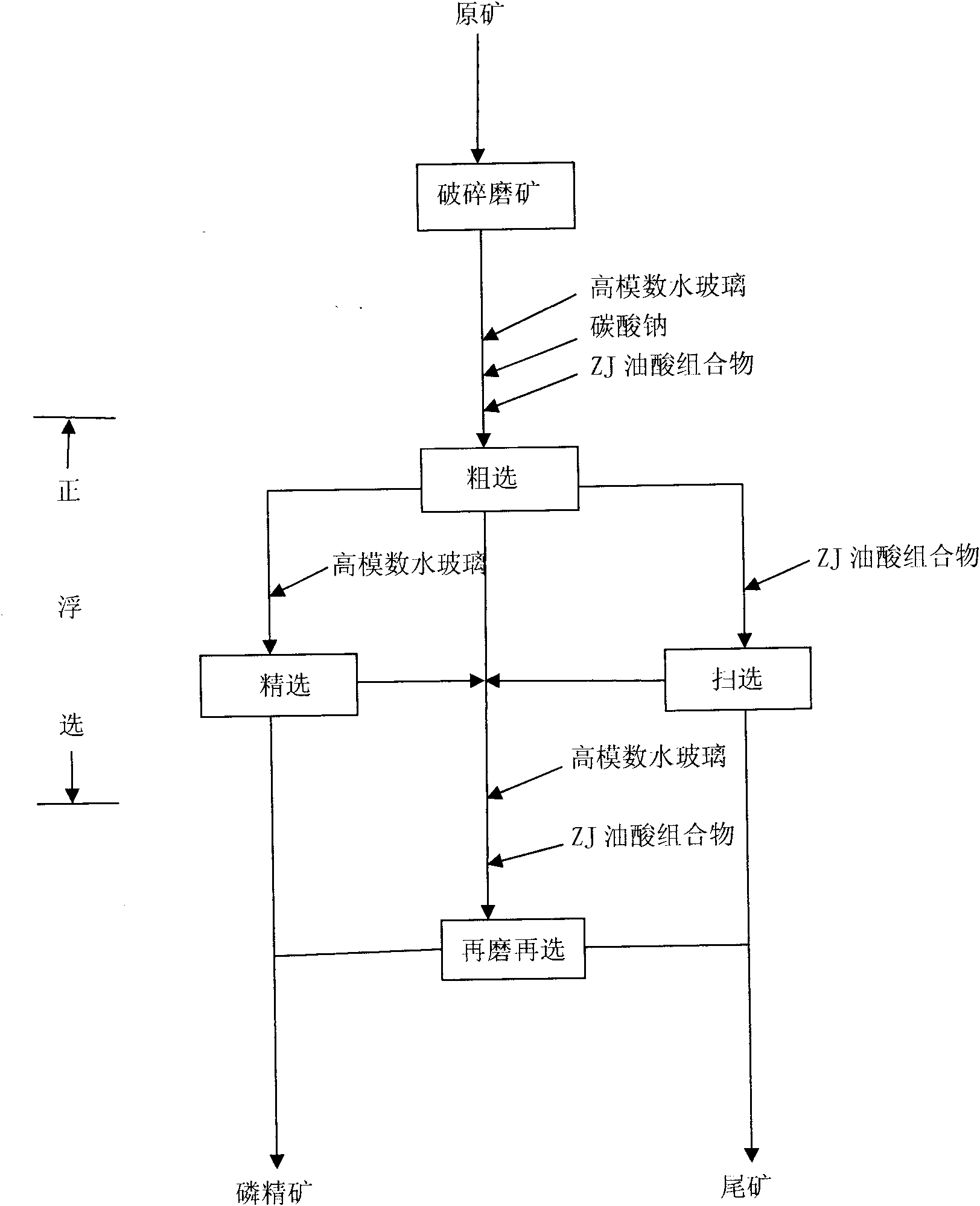

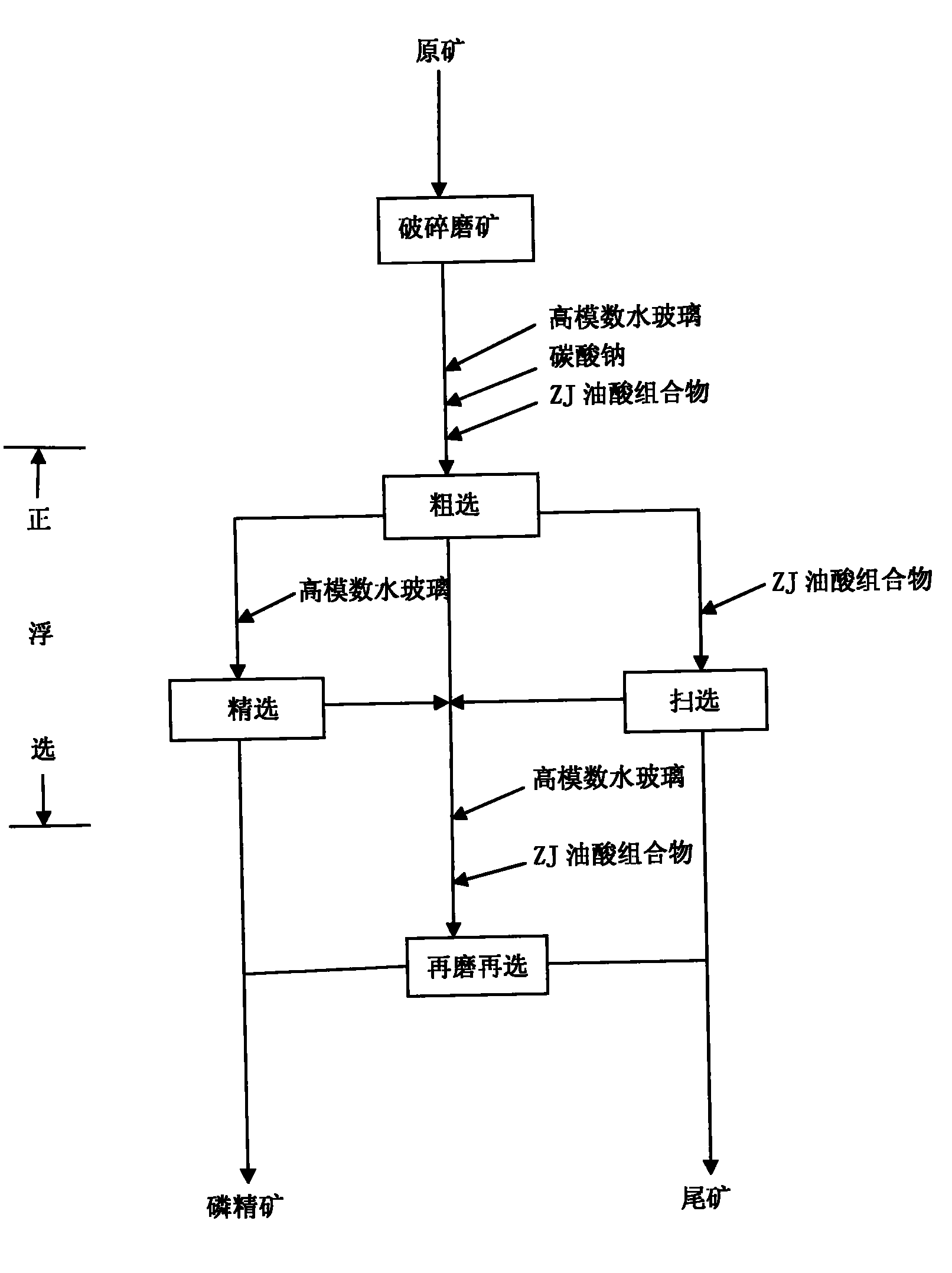

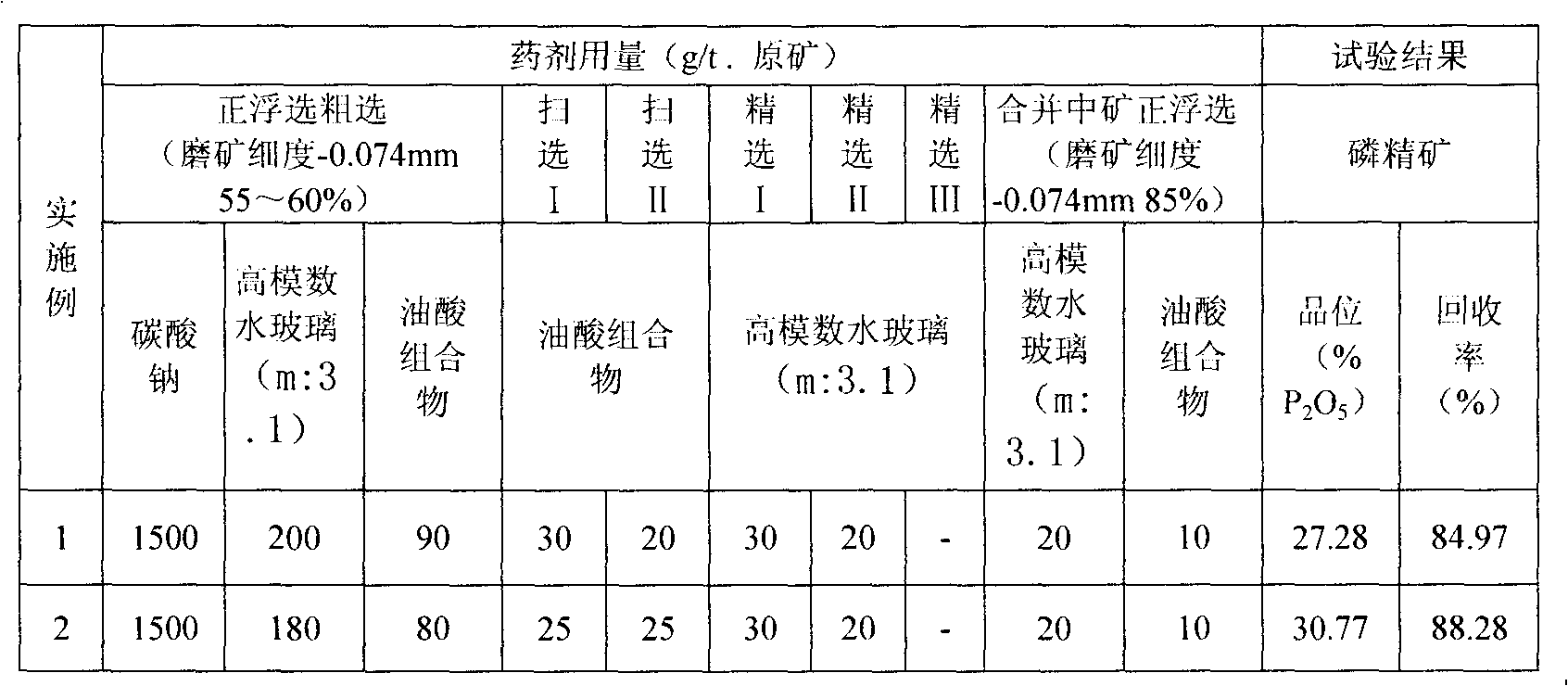

Positive flotation method of low grade refractory phosphate ores

The invention relates to a positive flotation method of low grade refractory phosphate ores. The method comprises the following specific steps: 1. crushing and grinding ores: grinding raw ore according to the grinding density of 1:1 to -0.074mm of 55-60% tailings discarding fineness; 2. performing positive flotation: firstly, roughing, namely adding depressant sodium carbonate, big modulus sodiumsilicate and collector ZJ oleic acid composite, stirring to obtain roughing concentrate, roughing middlings and roughing tailings; secondly, concentrating, namely adding big modulus sodium silicate in the roughing concentrate to perform 3-4 times of concentrations and obtain concentrating middlings and phosphorus product concentrate; thirdly, scavenging, namely adding ZJ oleic acid composite in the roughing tailings to perform 2-3 times of scavengings and obtain scavenging middlings and tailings; and 3. regrinding and reprocessing, namely further dissociating ores, and reprocessing to obtain tailings and residual phosphorus concentrate. The invention is characterized in that the ore grinding cost is low, the dosage of reagents is low, the ZJ oleic acid composite is easy to prepare and is convenient to use, the separating effect of phosphorus ores and gangue mineral is obvious, the separation indexes are good, etc; and the method is especially suitable to be used in the flotation of silicon-poor deposition-calcium phosphorite type phosphate ores with a concentration of P2O5 of less than 20%.

Owner:ZIJIN MINING GROUP

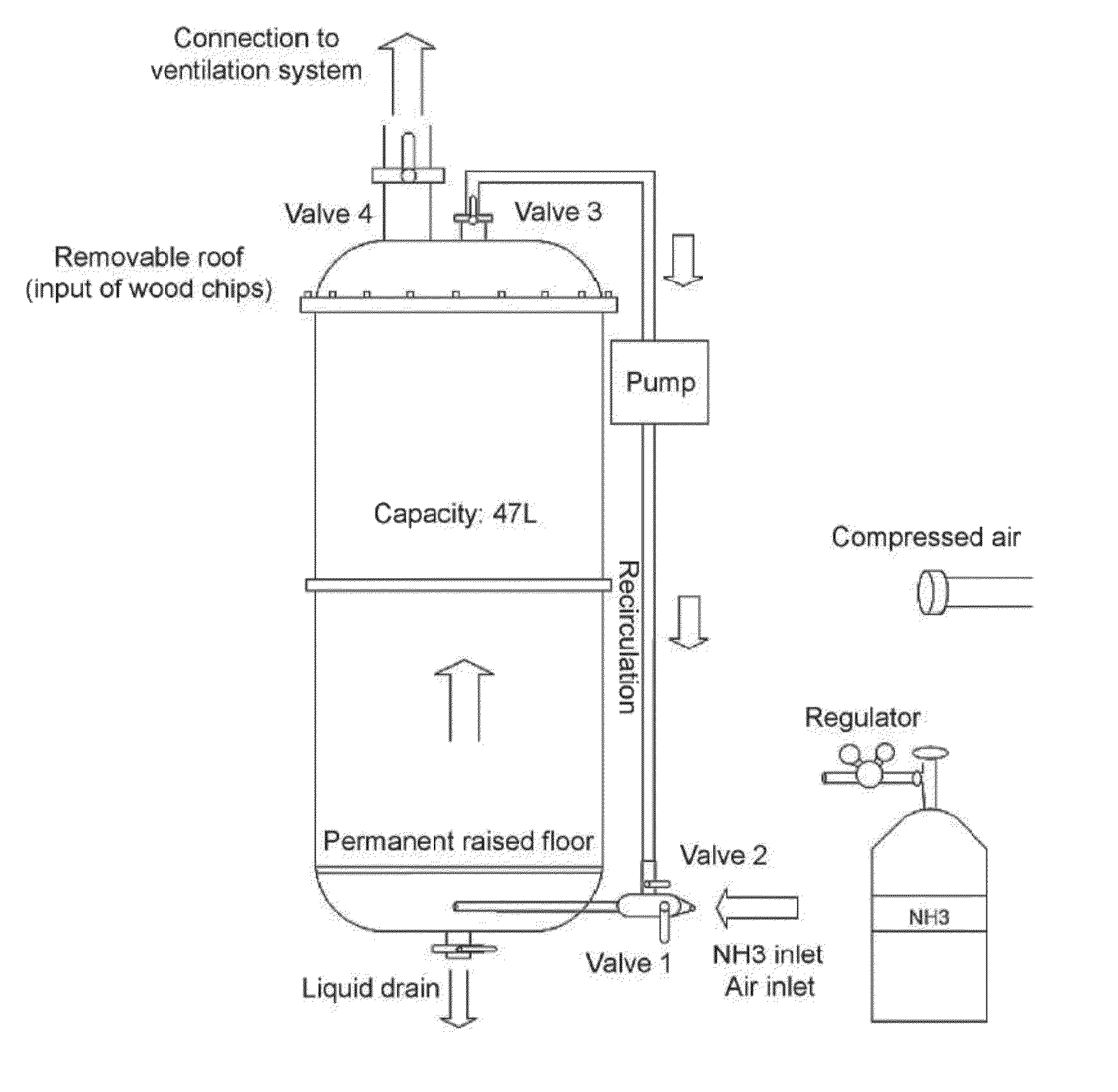

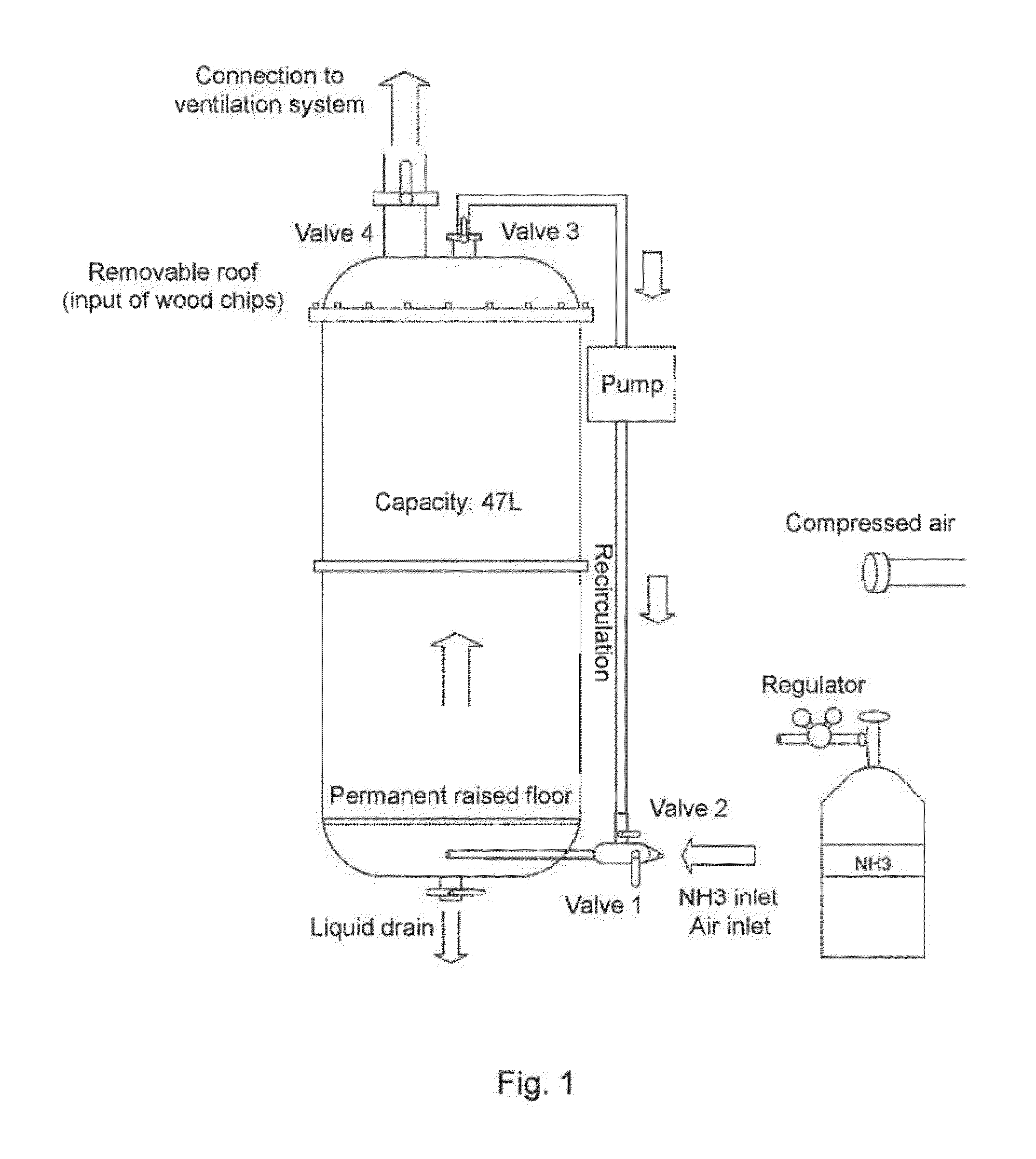

System and method for treating waste water by means of passive phosphorus capture

ActiveUS20150353400A1Treatment using aerobic processesWaste water treatment from animal husbandryWater useAluminium hydroxide

The invention relates to a system and a method for treating waste water using a passive phosphorus-capture filter lined with wood activated by the impregnation of a metal in the form of hydroxide, more specifically aluminum hydroxide or iron hydroxide. This system demonstrates phosphorus removal performances which are very closely linked to the release of iron and which support the observation that iron releases follow a cyclical trend. The method according to the invention also clearly demonstrates the cyclical nature of the reduction of phosphorus, directly linked to the same cycle of iron release at the outlet. When the medium is aerobic, it can precipitate the released iron in the form of hydroxide and thereby limit the release of iron into the outflow water and consequently its residual phosphorus. This model thus allows the service life of the system to be extended, while simultaneously taking advantage of the precipitation / solubilisation cycle of the iron observed in the medium under reducing conditions.

Owner:CENT DE RES & DEV IND DU QUEBEC

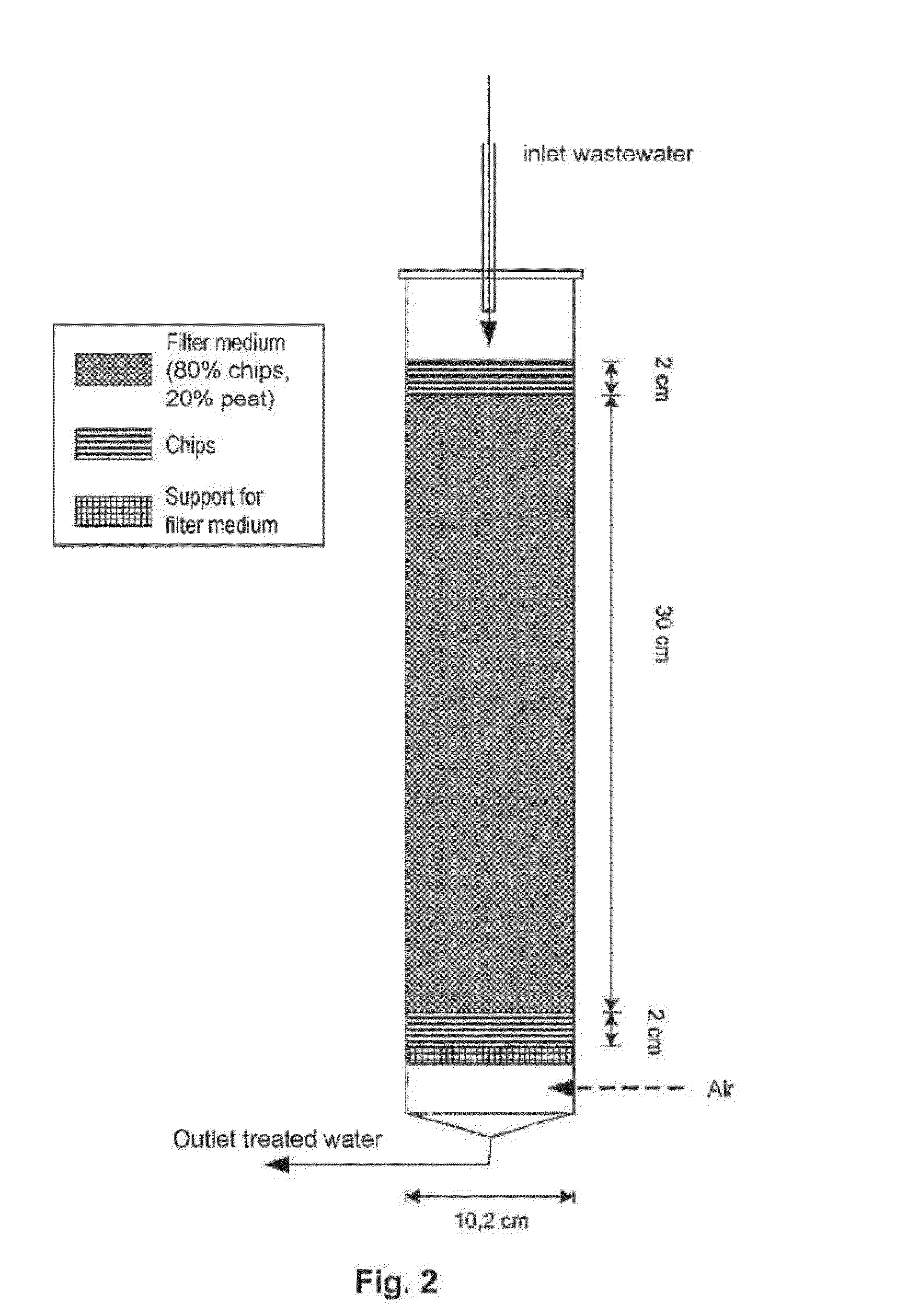

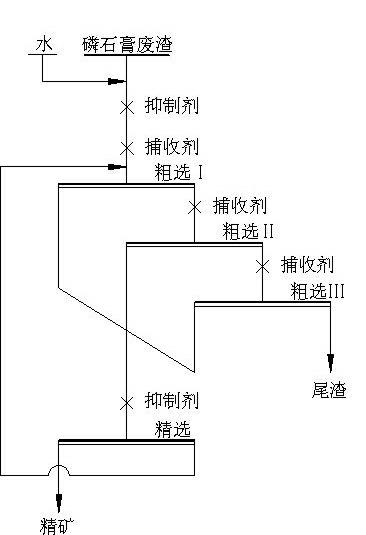

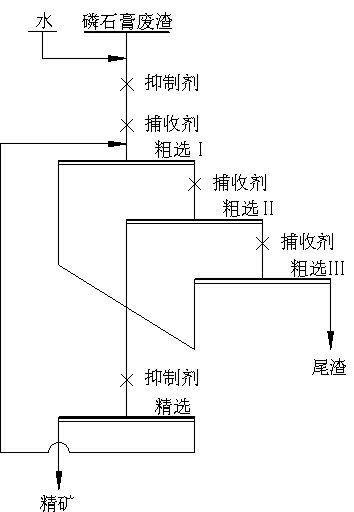

Flotation method for waste residue of phosphate gypsum

The invention relates to a flotation method for waste residue of phosphate gypsum. The method is characterized by comprising the following steps of: adding water into the waste residue of the phosphate gypsum; controlling the mass concentration of ore pulp and performing flotation in a flotation machine, wherein flotation adopts 2 to 5 times of rough flotation and 1 to 2 times of fine flotation; adding a retardant and a collecting agent to perform first time rough flotation; performing 1 to 4 times of rough flotation, wherein the collecting agent is added during each time of rough flotation; and combining a rough flotation foam product, and adding the retardant to perform 1 to 2 times of fine flotation, wherein fine flotation foam is high-quality phosphate gypsum of flotation concentrate, a product in a fine flotation groove is used as middling ore to be returned for the first time of rough flotation, the retardant is water glass, and the collecting agent is acetate or hydrochloride of alkyl fatty amine with carbon atomic number of between 8 and 18. By the flotation method, any treatment on the waste residue of the phosphate gypsum is not required, and the water is only required to be added for size mixing; and by soluble P2O5 impurity (residual phosphorus) in the phosphate gypsum and an appropriate flotation agent, the impurity content of the phosphate gypsum can be obviously reduced, and the recycling of the waste residue of the phosphate gypsum is realized.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

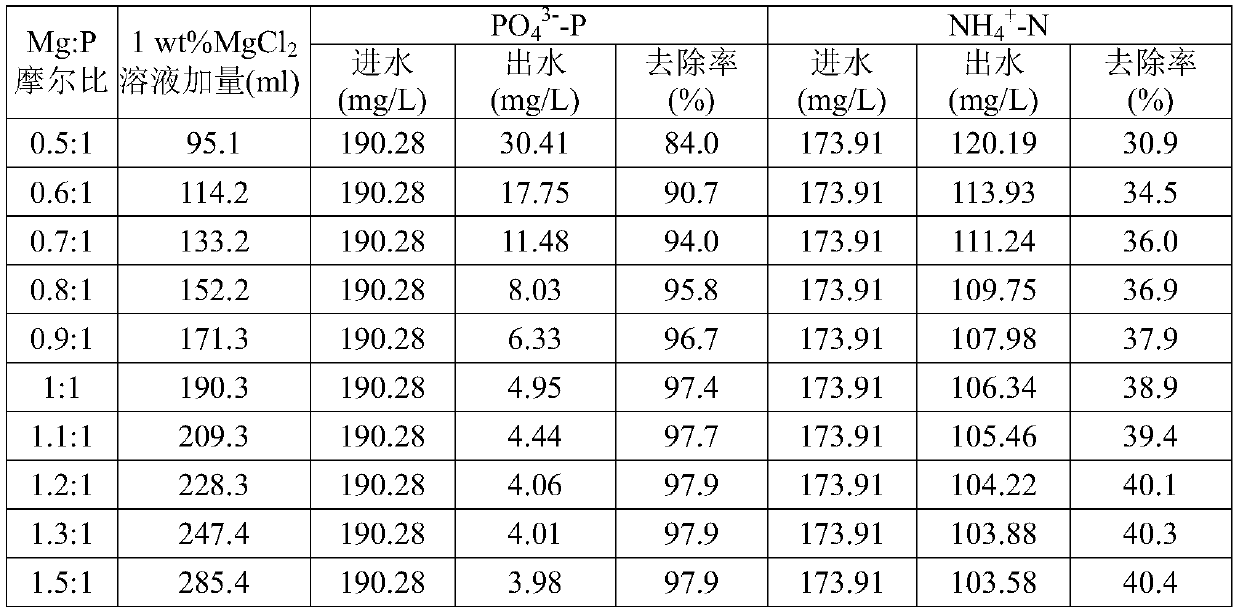

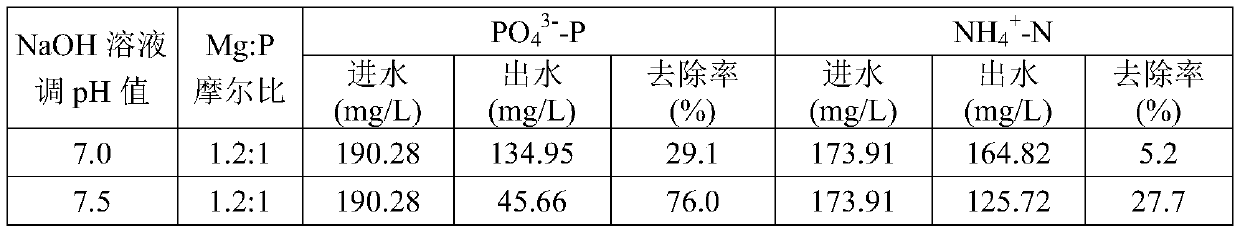

Circular treatment method and process system for fluorine-containing high-ammonia-nitrogen industrial wastewater

InactiveCN109250842AReduce concentrationReduce the types of dosingWater contaminantsMultistage water/sewage treatmentProcess systemsHigh concentration

The invention provides a new circular treatment method for simultaneously removing fluorinions and ammonia from fluorine-containing high-ammonia-nitrogen industrial wastewater. The fluorine removing agent provides a phosphorus source for precipitation and ammonia removal simultaneously, the type of agent addition is reduced, and the concentration of residual phosphorus in effluent is reduced. Magnesium-process desulfurized wastewater in thermal power plants or old brine after potassium extraction in salt lakes can be used as a magnesium source instead of conventional magnesium salt reagents, waste is treated by waste, other industrial wastewater is recycled in an ammonia removal process, and the sustainable development circular economy treatment technology is achieved. At the same time, provided is a circular treatment system for the fluorine-containing high-ammonia-nitrogen industrial wastewater. Microwave radiation replaces a traditional heating process, the heating rate is fast, theheating is uniform, the pyrolysis time of struvite is greatly shortened, and the ammonia gas concentration obtained by decomposition is high. After acid recovery, a high-concentration ammonia salt solution can be obtained. The investment and operation cost of the whole set of circular treatment system for the fluorine-containing high-ammonia-nitrogen industrial wastewater is low. The concentration of fluorinions and ammonia nitrogen in the treated effluent is stable, the removal rate of the fluorinions can reach 98%, and the removal rate of ammonia nitrogen can reach 97% or more.

Owner:国能朗新明环保科技有限公司

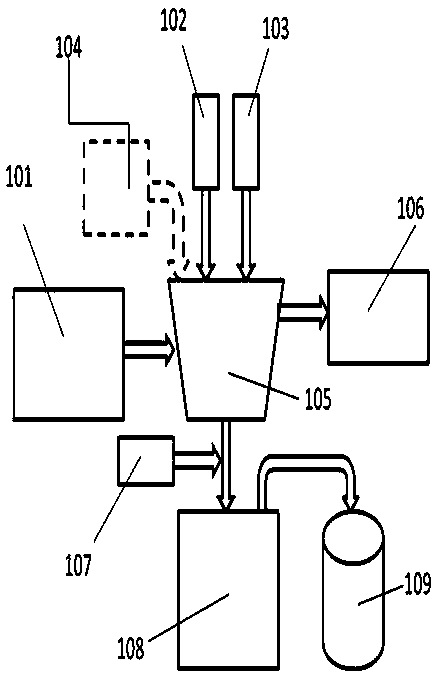

Purification treatment method of wet-process phosphoric acid

InactiveCN101602498AHigh quality phosphoric acidRaw materials are easy to getPhosphorus compoundsPhosphatePhosphoric acid

The invention discloses a purification treatment method of wet-process phosphoric acid, which comprises the following steps: firstly analyzing contents of fluorine and sulfur trioxide in the wet-process phosphoric acid; secondly adding the wet-process phosphoric acid to a reactive tank; according to the analytical data, calculating and taking white carbon black and sodium carbonate in the quantity of defluorination; calculating and taking powdered rock phosphate in the quantity of desulfurization; respectively throwing the white carbon black, the sodium carbonate and the powdered rock phosphate in a solid phase into the purification reactive tank and stirring; thirdly leading saturated vapour into the purification reactive tank; controlling the reaction temperature and the time of materials; obtaining reactive materials; fourthly using a pump to send the reactive materials into a groove of a plate and frame filter press; directly using filter liquor which is purified wet-process phosphoric acid after filter pressing to produce feed-grade calcium biphosphate; fifthly placing filter cakes after filter pressing into a surge tank; adding clear water to prepare the filter cakes into slurry; using the pump to send the slurry into an extraction tank; and recovering residual phosphorus. The invention has the advantages of high impurity removal efficiency, small phosphorus loss, easy obtainment of impurity removing agents, low cost and easy operation control; moreover, purified wet-process phosphoric acid can be directly used for producing feed-grade calcium biphosphate.

Owner:云南新龙矿物质饲料有限公司

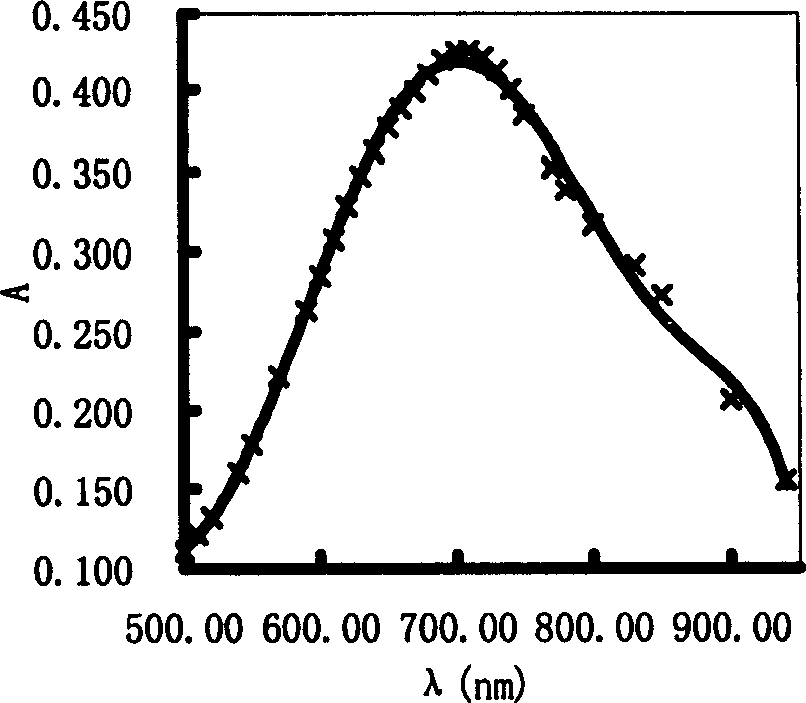

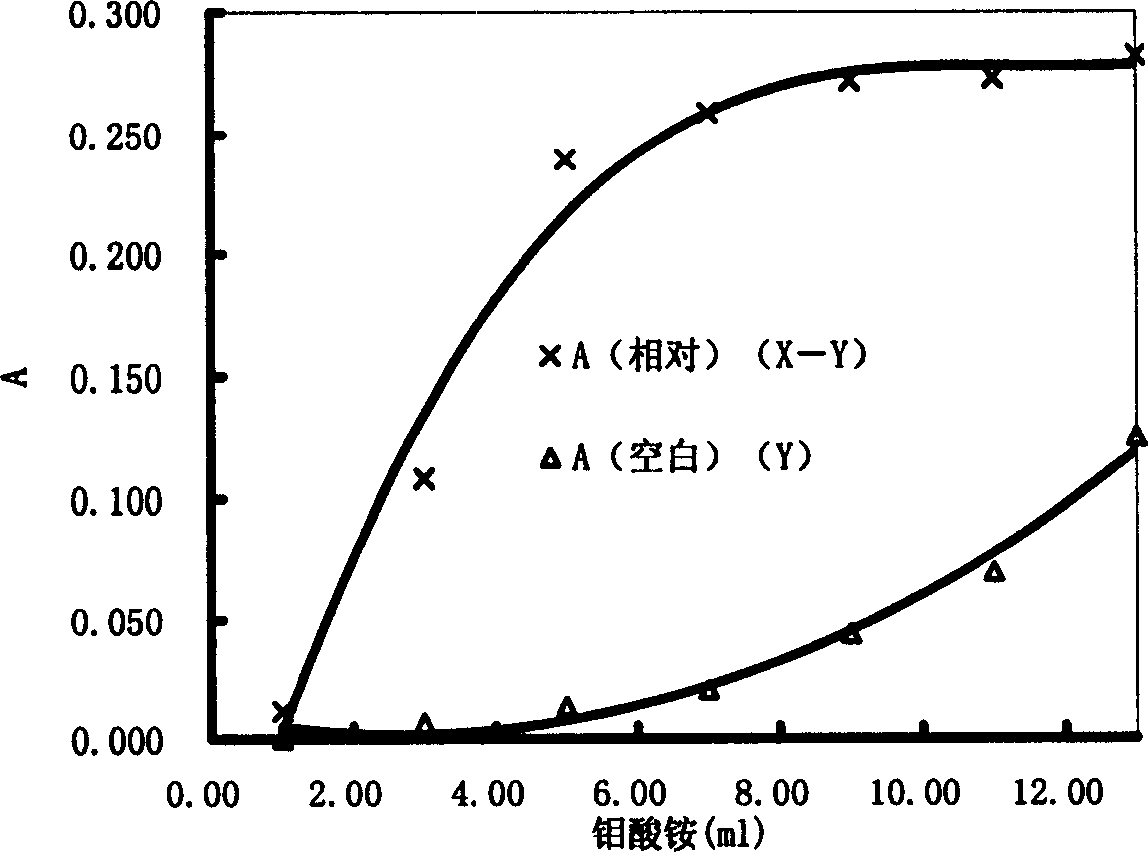

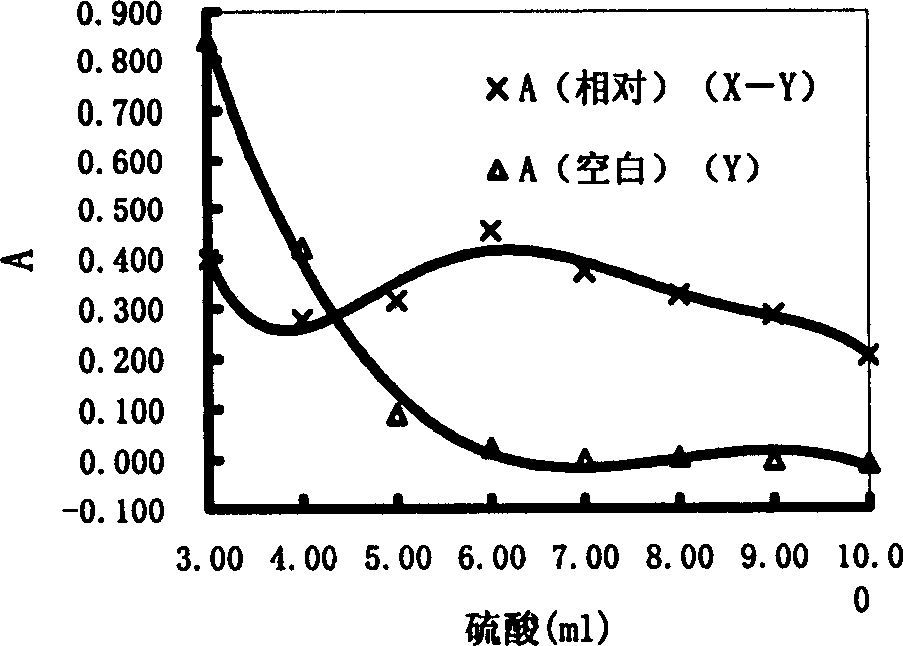

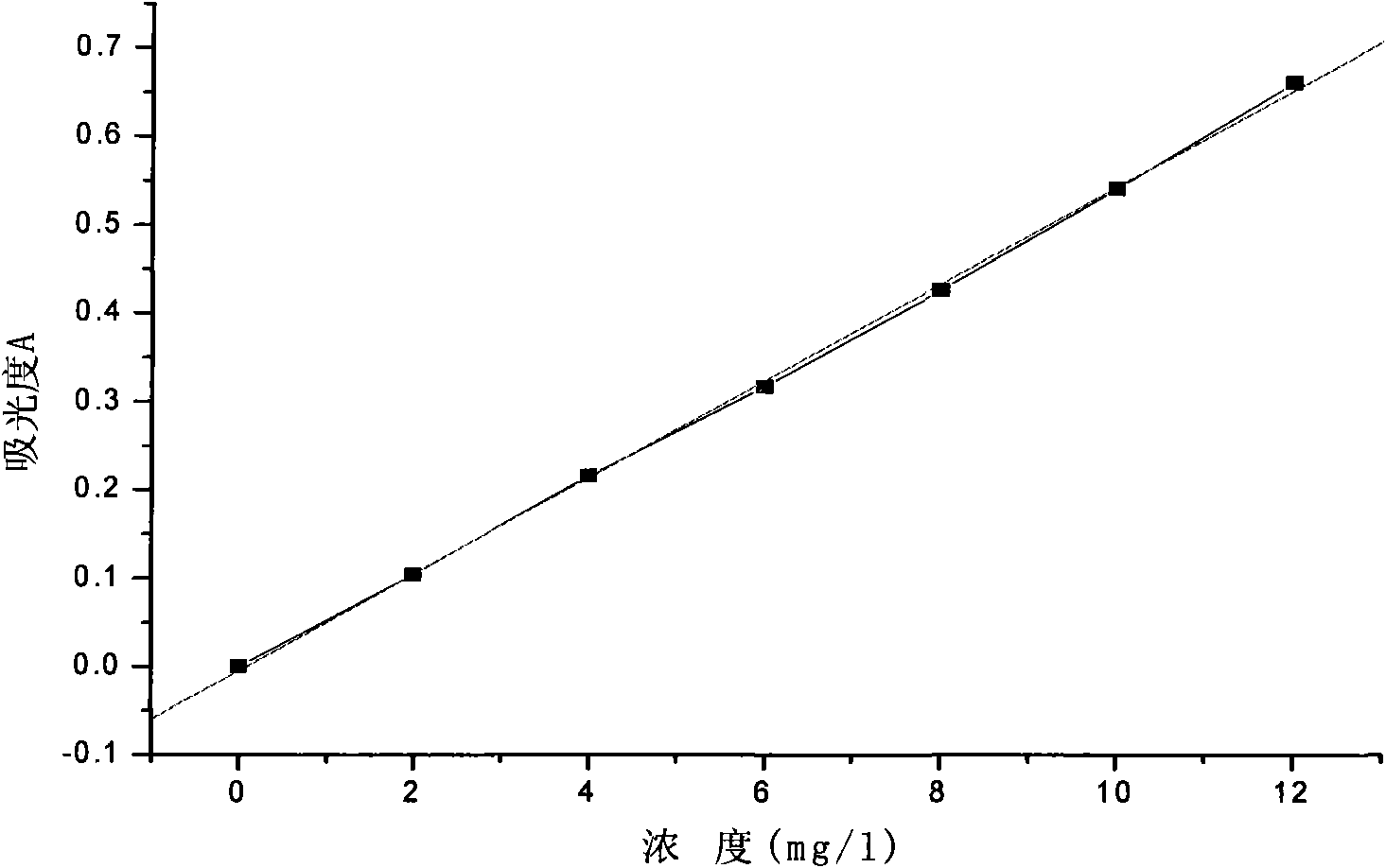

Spectrophotometry for measuring residual phosphorus content in benzoxazole class polyfibre or film

InactiveCN1558216AAccurate measurementEasy to operateMaterial analysis by observing effect on chemical indicatorColor/spectral properties measurementsBenzoxazoleFiber

The spectrophotometric process of measuring the residual phosphate amount in polybenzoazole fiber or film includes the following steps: dissolving the polybenzoazole fiber in strong protonic acid, adding precipitant to precipitate polymer, collecting phosphoric acid solution, adding alkali to regulate solution pH to neutrality, adding molybdate, regulating with acid matter to proper acidity for color development reaction, adding reductant to convert the measured component into colored compound and final absorbency measurement. The process has simple instrument used, simple operation, high feasibility and high precision, and may be used in lab and factory.

Owner:EAST CHINA UNIV OF SCI & TECH

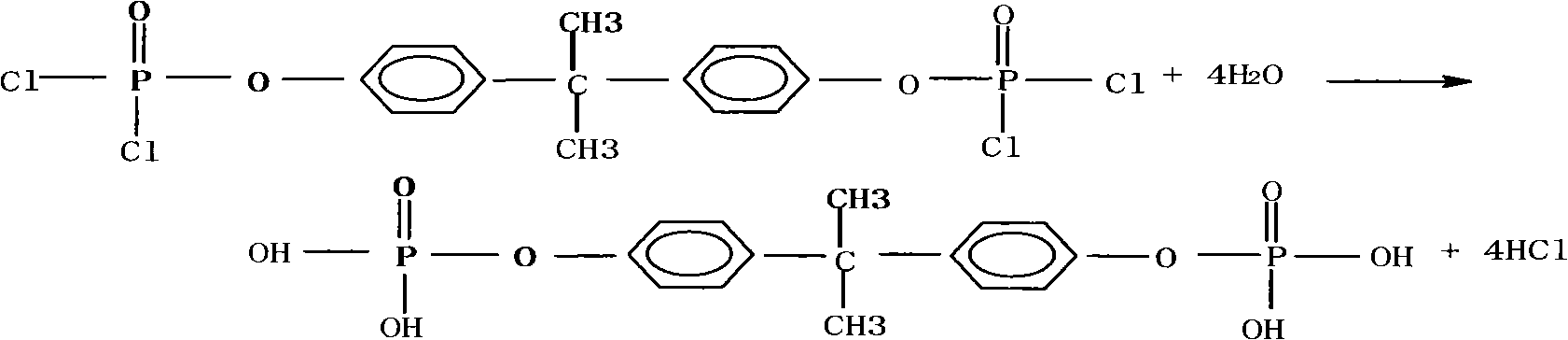

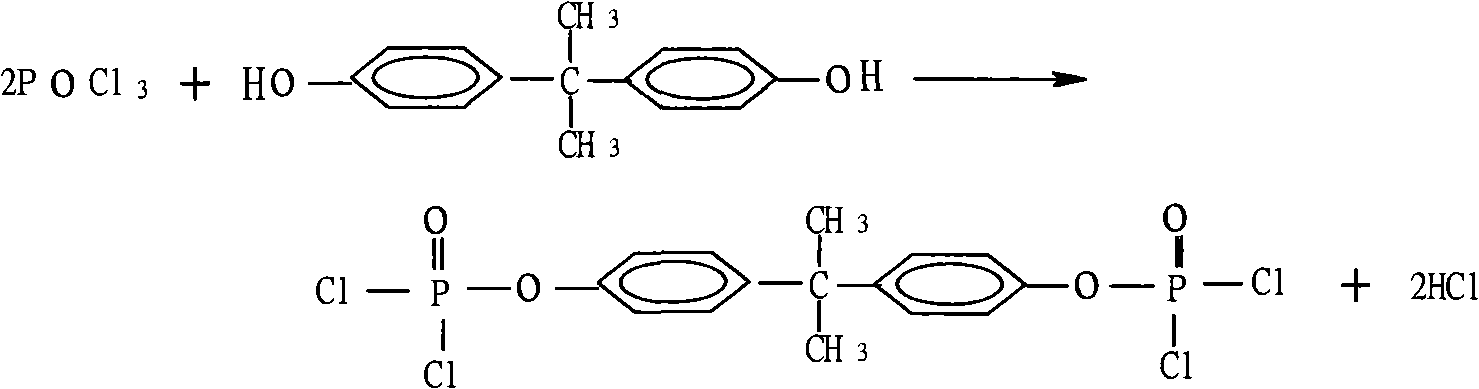

Method for quantitatively analyzing residual phosphorus oxychloride

ActiveCN101825561AEasy to operateColor/spectral properties measurementsPhosphoric acidAmmonium metavanadate

The invention relates to a method for quantitatively analyzing residual phosphorus oxychloride. The method comprises the following steps of: rapidly weighing a phosphorus oxychloride sample and fully hydrolyzing the phosphorus oxychloride sample in chilled brine to form orthophosphoric acid; refrigerating a hydrolyzed sample at the temperature of between 20 below zero and 10 DEG C, and slowly leaching the sample by using filter paper to separate phosphoric acid from an organic acid component; performing color development and color comparison on filtrate, wherein a color developing condition is that: color developing time is between 3 and 5 minutes; color developing temperature is room temperature; and a color developing medium is prepared by adding 8mL HNO3, 25mL 0.04mol / L solution of ammonium molybdate and 12.5mL 0.02mol / L solution of ammonium metavanadate into a 250mL volumetric flask respectively; measuring a light absorption value with a cuvette having an optical path of 1 centimeter by using color developing liquid into which the sample is not added as reference solution at a position of 420 nanometers; and calculating the concentration of discharged phosphorus in comparison to the standard working curve of phosphorus and converting the concentration into the content of the phosphorus oxychloride. The method is simple to operate, rapid and correct, and suitable for analyzing a fire retardant synthesized by using the phosphorus oxychloride as a raw material.

Owner:PETROCHINA CO LTD

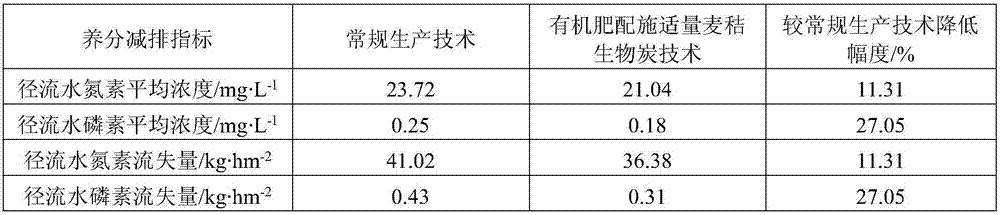

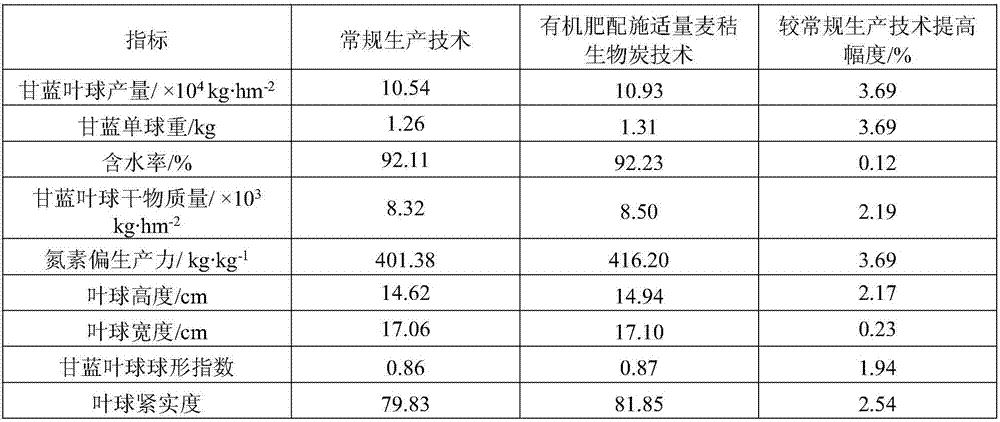

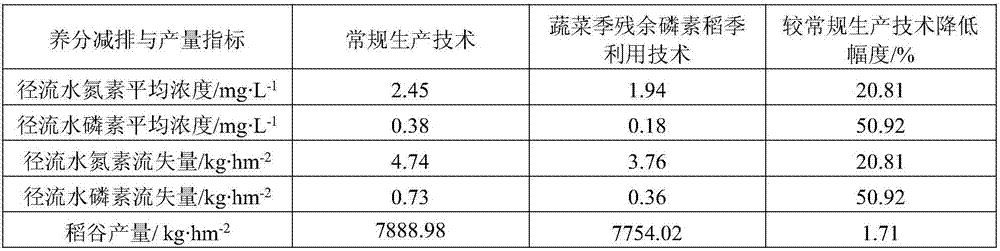

Method for nutrient emission reduction and crop stable yield maintenance in vegetable and rice crop rotation field

InactiveCN107056505AThe product is in good conditionSimple and fast operationExcrement fertilisersFertilising methodsLoss rateGrowing season

The invention discloses a method for nutrient emission reduction and crop stable yield maintenance in a vegetable and rice crop rotation field and belongs to the technical field of agricultural non-point source pollution control and crop production. Particularly, in the production process of the vegetable and rice crop rotation field, the effects of vegetable and rice crop rotation field soil runoff nitrogen and phosphorus nutrient emission reduction, crop stable and high yields and commodity character improvement are realized by the aid of the vegetable season appropriate biochar combined application technology and the vegetable season residual phosphorus rice season utilization technology. With the adoption of the technology, the rice crop rotation field soil runoff water nitrogen and phosphorus concentrations are reduced by 20.81% and 50.92% respectively, and the rice whole growing season nitrogen and phosphorus loss amounts are remarkably reduced by 20.81% and 50.92% respectively. Further, with the adoption of the technology, the vegetable and rice crop rotation field nitrogen and phosphorus runoff annual loss amounts are remarkably reduced by 12.88% and 42.24% respectively, and the vegetable and rice crop rotation field nitrogen and phosphorus runoff loss rates are remarkably reduced by 12.28% and 20.88% respectively. At the same time, with the adoption of the technology, the crop high and stable yields can be maintained, the cabbage head sphericity index and the compactness are improved by 1.94% and 2.54% respectively, and the cabbage commodity character is remarkably improved.

Owner:JIANGSU ACAD OF AGRI SCI

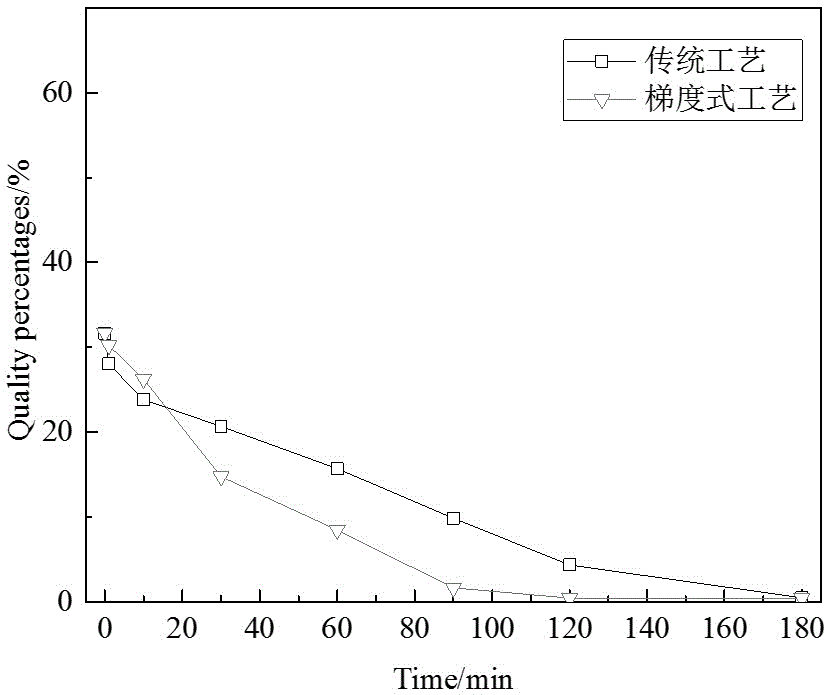

Gradient technology method for wet process phosphoric acid production

ActiveCN106395774AReduce extraction timeReduce residual phosphorus contentPhosphorus compoundsPhosphatePhosphoric acid

The invention relates to a gradient technology method for wet process phosphoric acid production. Phosphate ore acidolysis digestion includes three stages, wherein the first stage is a quick reaction stage, the second stage is a stable reaction stage, and the third stage is a solid grain growing stage; in the quick reaction stage, hyperphosphate mixed acid solution of which the molar ratio of phosphoric acid to sulfuric acid is 1:0.5-1:1 is added; in the stable reaction stage, high-sulfur mixed acid solution of which the molar ratio of phosphoric acid to sulfuric acid is 0:1-0.5:1 is added; in the grain growing stage, the temperature of a crystallization tank is lowered, calcium sulphate dihydrate crystal in ardealite is accelerated to form particles with a large particle size; residual phosphorus content in the ardealite is smaller than 1.9%. According to the method, ground phosphate rock digestion time is shortened by 50%, the residual phosphorus content in the obtained ardealite can be lowered by 20% or more, and a filtering rate can be improved by 30% or more.

Owner:ANHUI LIUGUO CHEM CO LTD +1

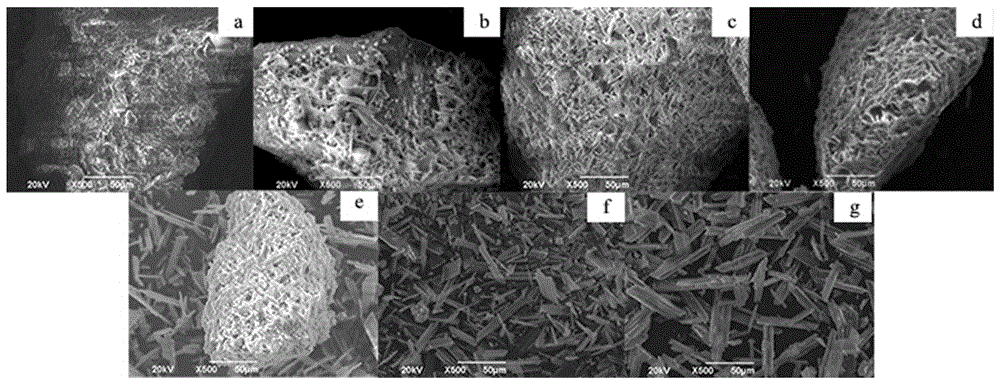

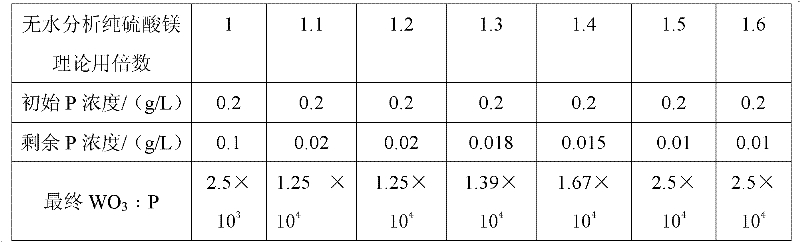

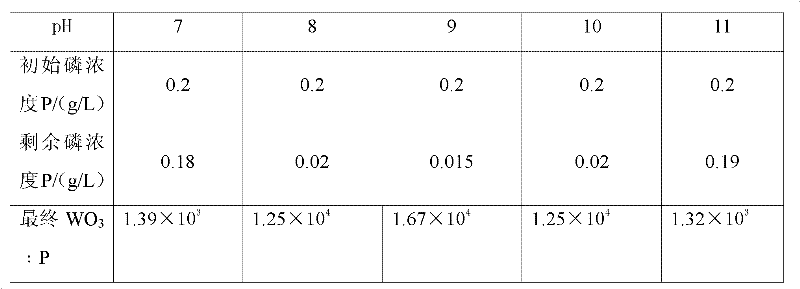

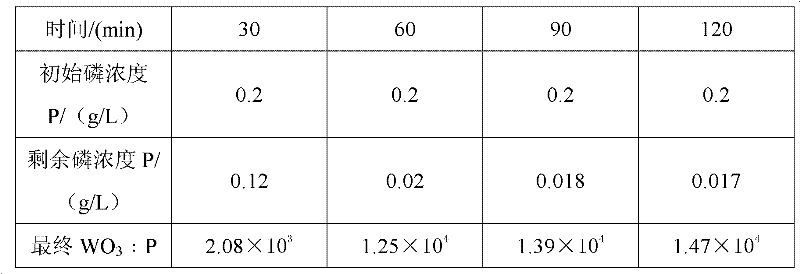

Method for dephosphorizing low-phosphorus ammonium tungstate solution

The invention relates to a method for dephosphorizing a low-phosphorus ammonium tungstate solution. The method comprises the following steps of: adding phosphate into complicated black and white tungsten ore which cannot be dephosphorized by using calcium carbonate to perform low-alkali decomposition, directly performing the ion exchange process, dephosphorizing and transforming through ion exchange to obtain a solution of ammonium tungstate in which the concentration of residual phosphorus is 0 to 1g / L, adding anhydrous analytically pure magnesium sulfate into the solution of ammonium tungstate, and dephosphorizing to ensure that the phosphorus is transformed into an insoluble compound and is precipitated, tungsten still remains in the solution and other impurity elements are not introduced at the same time so as to fulfill the aim of separating the phosphorus and the tungsten. Process conditions are that: the using amount of the anhydrous analytically pure magnesium sulfate is 1.1 to 1.5 times the theoretical using amount; the pH value is 8 to 10; the reaction time is 1 hour; and the reaction temperature is normal temperature.

Owner:江西翔鹭钨业有限公司

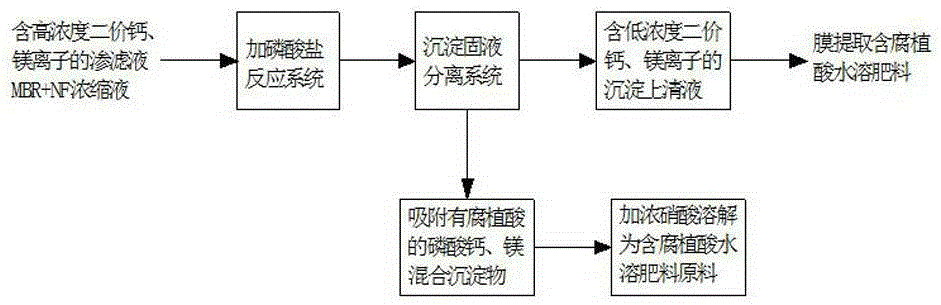

Method for removing and recycling high-concentration Ca<2+> and Mg<2+> in leachate MBR and NF concentrate

ActiveCN105293662AReduce concentrationEasy extractionWater/sewage treatment by flocculation/precipitationWater/sewage treatment by sorptionHigh concentrationPhosphate

The invention discloses a method for removing and recycling high-concentration Ca<2+> and Mg<2+> in garbage leachate MBR and NF concentrate. According to the method, phosphate radicals are used to react with Ca<2+> and Mg<2+> in the MBR and NF concentrate to produce a precipitate mixture, and then solid-liquid separation is carried out to effectively remove Ca<2+> and Mg<2+>; moreover, the content of residual phosphate radicals in a supernatant obtained after precipitation is low; and sediment can be used as a raw material for water-soluble fertilizer containing humic acid after dissolving by nitric acid, so reclamation is realized. The method is advanced, practical and economic, has simple flow, uses simple equipment, occupies a small area of land and does not pose secondary pollution.

Owner:FUZHOU UNIV

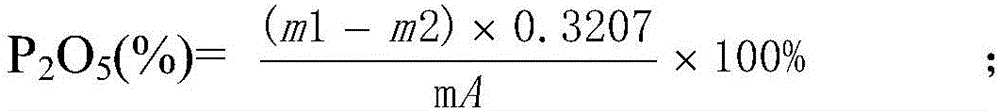

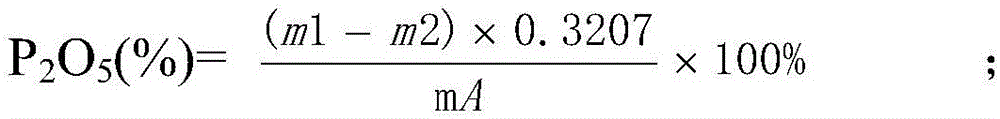

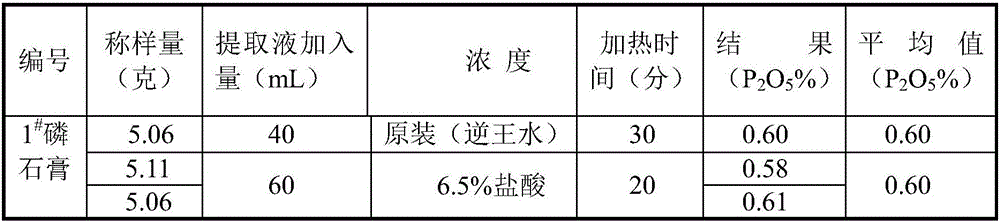

Method for measuring residual phosphorus content in wet process phosphate phosphorus gypsum

InactiveCN106644810AReduce pollutionEasy for precipitation detectionWeighing by removing componentPhosphatePhosphoric acid

The invention discloses a method for measuring the residual phosphorus content in wet process phosphate phosphorus gypsum. The method comprises the following operation steps of (1) taking wet phosphorus gypsum samples; performing water washing to the neutral state; then, transferring the materials into a beaker; next, adding hydrochloric acid; heating the materials to a slight boiling state; cooling the materials to the room temperature; then, transferring the materials to a volume bottle; maintaining the constant volume; uniformly shaking the materials; directly performing filtering without washing; (2) sucking partial filter liquid into the breaker; adding dilute nitric acid; heating the materials to be about to boil; taking down the breaker; adding quimociac precipitators during stirring; slowing heating the materials until the upper layer solution is clear and bright; (3) taking down the breaker; performing still standing and cooling to room temperature; then, performing filtering; washing precipitates to be neutral; drying the precipitates; cooling the precipitates in a drier to the room temperature; performing weighing; calculating the mass percentage of phosphorus pentoxide in the sample. The method has the advantages that little low-concentration hydrochloric acid is used for replacing lefort aqua regia to realize the extraction of residual phosphorus in the phosphorus gypsum. The method provided by the invention has the advantages that the acid types are few; the consumption is low; the environment pollution and the equipment corrosion are low; the energy is saved; the time is saved, and the like.

Owner:YUNNAN PHOSPHATE CHEM GROUP CORP

Combined efficient dephosphorization treatment method of waste water

InactiveCN109912076ARealize resource utilizationReduce the risk of eutrophicationClimate change adaptationWater contaminantsSlagResource utilization

The invention relates to the technical field of sewage treatment and particularly discloses a combined efficient dephosphorization treatment method of waste water. The treatment method comprises the following steps: feeding a magnesium source into the waste water containing nitrogen and phosphorus to form a struvite sediment, performing primary separation to form low-concentration phosphorus-containing waste water, continuing to feed an iron source and a flocculant into the separated waste water to form a polyferric sediment, performing secondary separation to form waste water containing a little residual phosphorus, and continuing to feed steel slag into the separated waste water to form a phosphorus attached steel slag sediment, wherein the waste water after the secondary separation canreach a secondary phosphorus-containing emission standard; and the waste water after the tertiary separation can reach a primary phosphorus-containing emission standard. The method employs an organiccombination of a struvite sedimentation method, a polyferric sulfate dephosphorization method, a flocculation sedimentation method and a steel slag absorption dephosphorization method, achieves the purpose of efficient dephosphorization of the waste water, and ensures that the treated waste water can discharged to reach the standard; at the same time, the struvite sediment and the polyferric sediment are collected, dried and crushed and become an agricultural slow-release fertilizer; and resource utilization of phosphorus in the waste water is achieved.

Owner:江西中江环保集团股份有限公司

Method for synchronously degumming and deacidifying phospholipase and lipase

InactiveCN108048212AImprove degumming problemGood deacidification effectFatty-oils/fats refiningPhospholipasePhospholipid

The invention discloses a method for synchronously degumming and deacidifying phospholipase and lipase. The method is characterized by adding the phospholipase, the lipase and phytosterol into soybeancrude oil simultaneously to obtain a synchronous degumming and deacidifying optimum response parameter; the method can be used for simultaneously removing phospholipids and free fatty acid in the soybean crude oil and generating phytosterol ester; under the technological process, the degumming and deacidifying effects of soybean oil are relatively good, the residual phosphorus content of the soybean oil is 10.5mg / kg, the acid value is 1.510mgKOH / g, and the phytosterol ester content is 1.657g / 100g. The method can be used for reducing the refining working procedures of the soybean oil, the refining time is reduced, the oxidation degree of grease is lowered, meanwhile, the functional soybean oil rich in the phytosterol ester can be obtained, the functionality and oxidation resistance of thegrease are increased, and the economic benefit of grease industry is improved.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

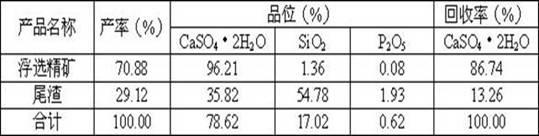

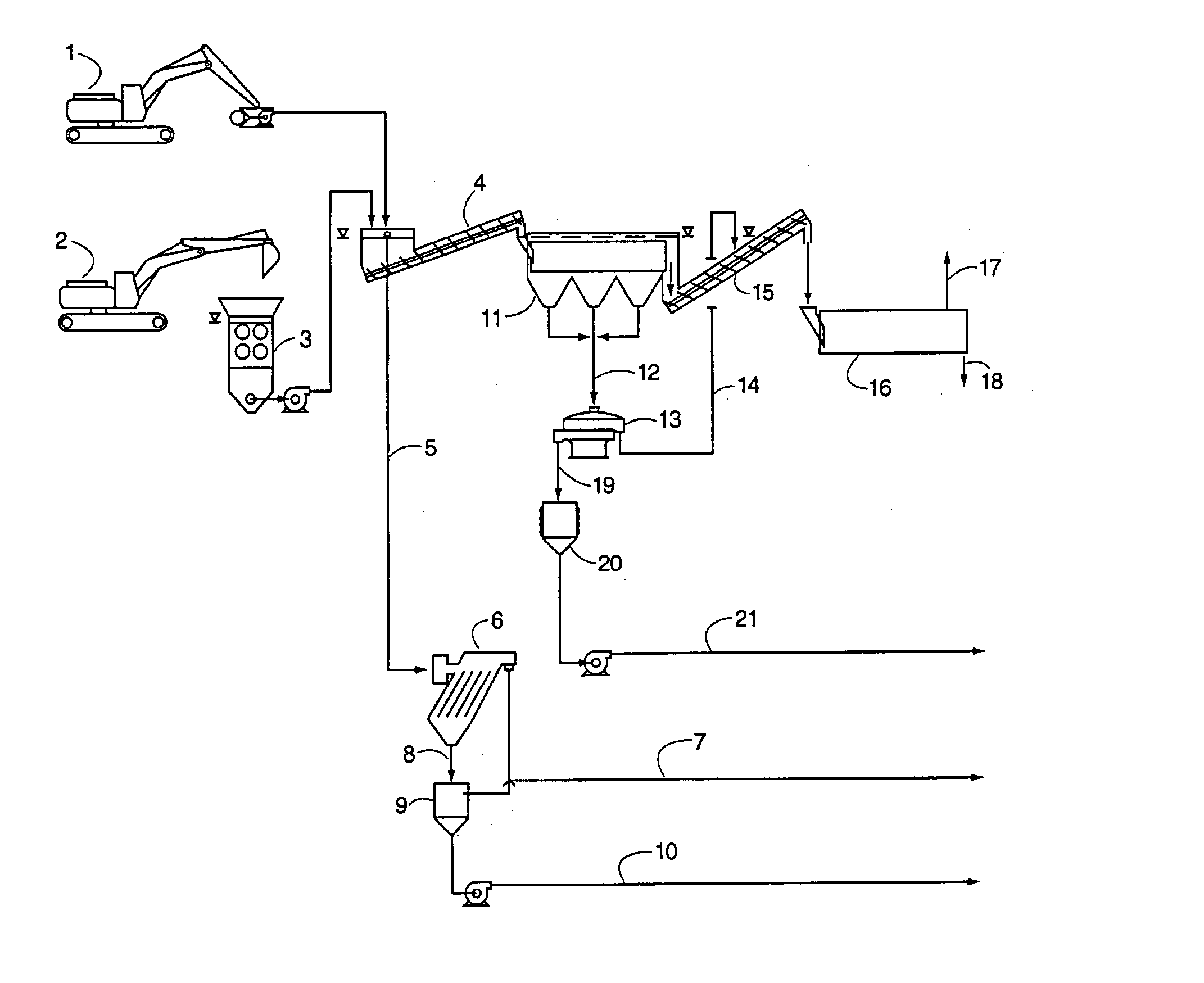

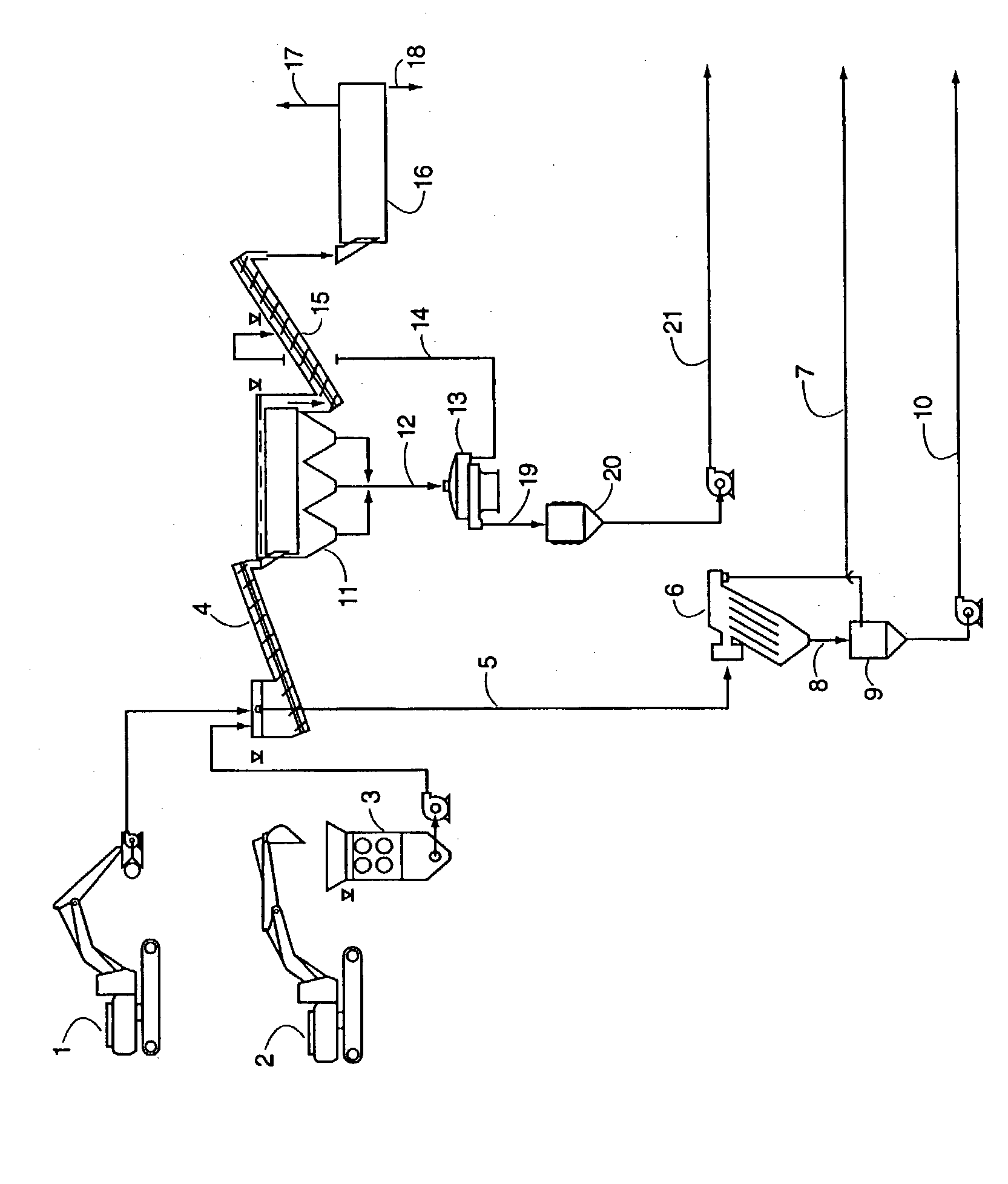

Continuous activated carbon washing and drying device

ActiveCN103539117AReduce residual phosphorusImprove dehydration efficiencyCarbon compoundsActivated carbonFiltration

The invention relates to a continuous activated carbon washing and drying device. The continuous activated carbon washing and drying device comprises a carbon slurry supplying device, a belt-type filter, a blanking hopper, a vacuum absorption and filtration device, a vacuum tank, a washing and spraying device and pipelines for connection, wherein the running direction of the belt-type filter is taken as the criterion, the carbon slurry supplying device is arranged at the front upper part of the belt-type filter; the blanking hopper is arranged at the rear lower part of the belt-type filter; the washing and spraying device is arranged above the belt-type filter; the lower part of the belt-type filter is provided with the vacuum tank which is connected with the belt-type filter through a pipeline and is also connected with the washing and spraying device as well as the vacuum absorption and filtration device. The device washes (extracts) phosphoric acid which is the residual of phosphoric acid liquids with different gradients in clearances of activated carbon, meanwhile dehydrates washed activated carbon by adopting a vacuum negative pressure suction filtration mode, and reduces the residual phosphorus quantity of the activated carbon which is collected by acid pickling so as to further reduce the consumption quantity of phosphoric acid in activated carbon production; dehydrating is conducted by adopting a vacuumizing mode, so that the dehydrating efficiency of activated carbon is improved.

Owner:徐州华睿炭材料科技有限公司

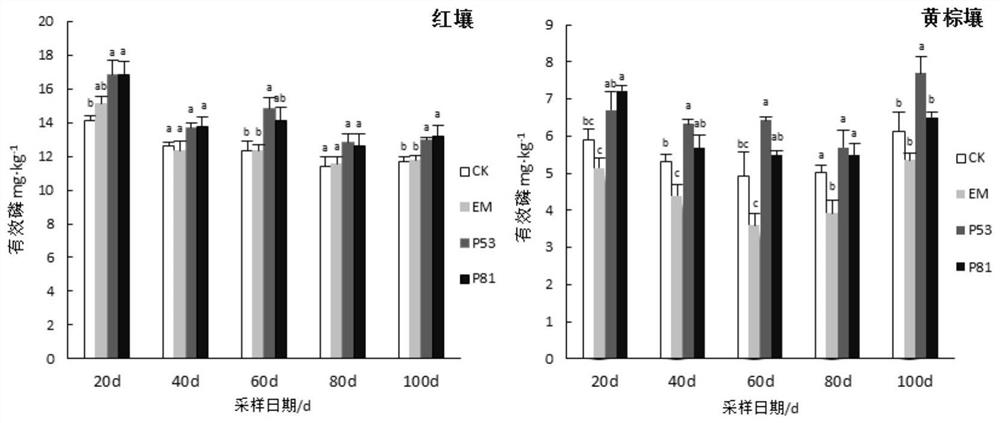

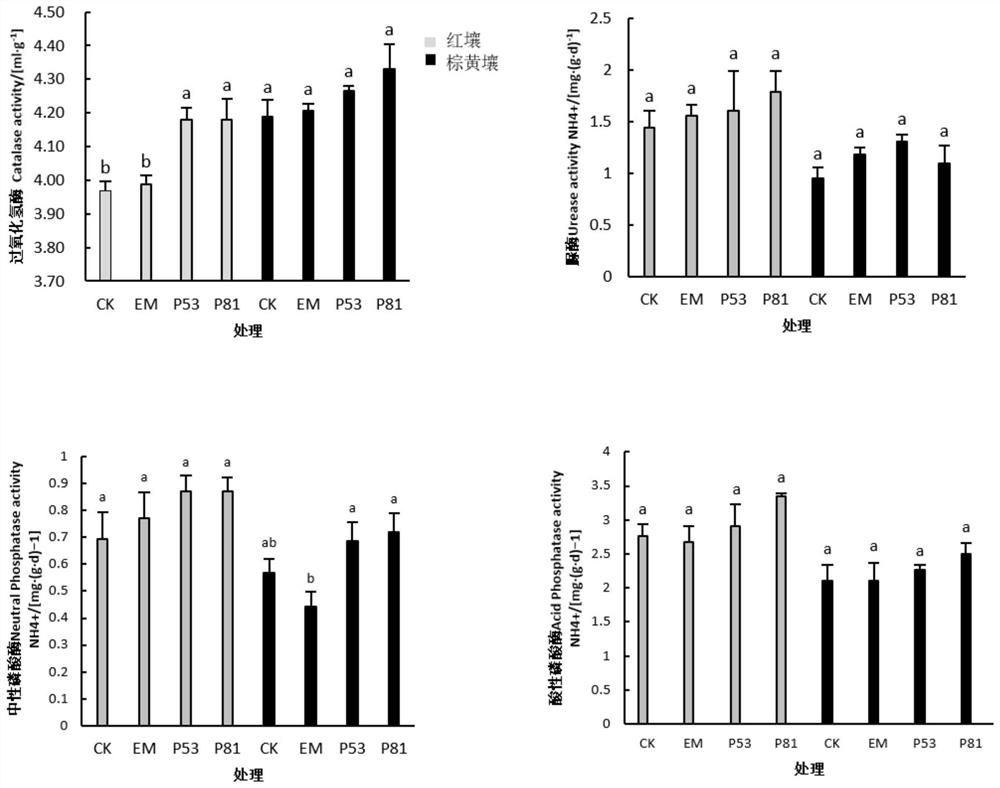

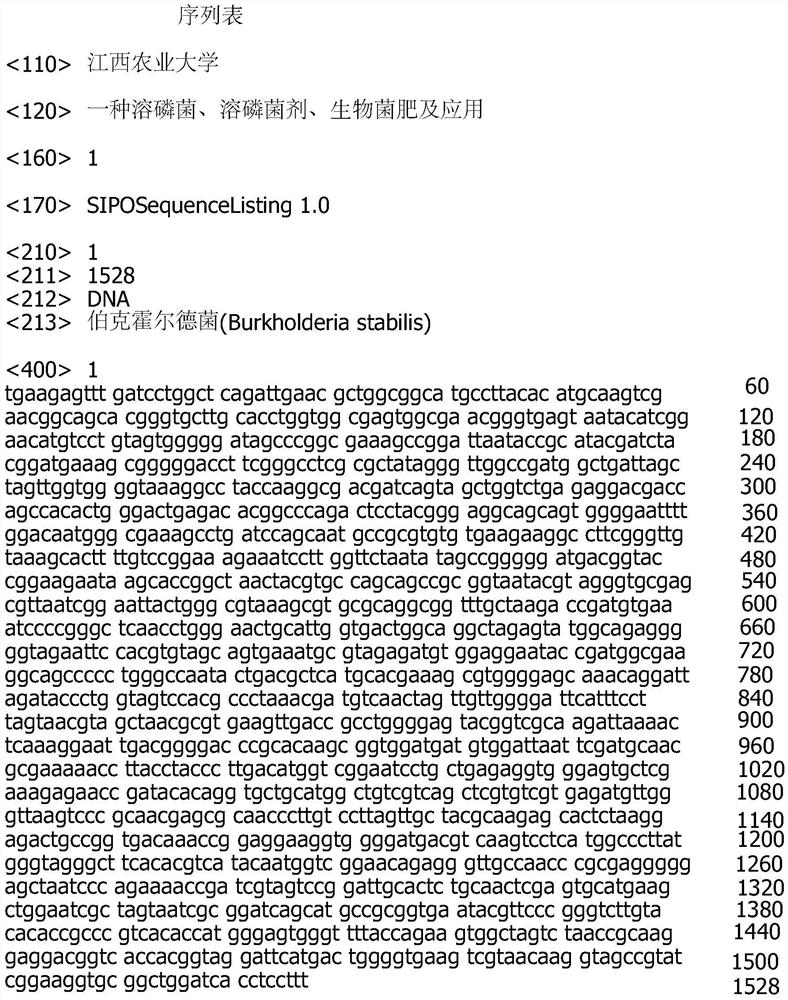

Phosphorus-solubilizing bacterium, phosphorus-solubilizing bacterium agent and biological bacterial fertilizer, and application thereof

ActiveCN112280702AIncrease the diameterIncrease contentBacteriaMicroorganism based processesSodium bicarbonatePhosphate

Owner:JIANGXI AGRICULTURAL UNIVERSITY

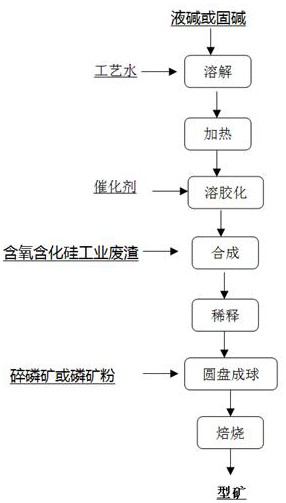

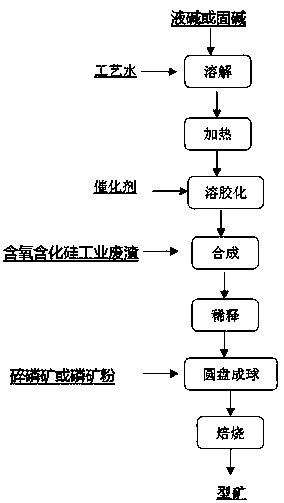

A preparation method of phosphate rock powder or crushed phosphate rock binder and a molded ore production method

Owner:KUNMING UNIV OF SCI & TECH

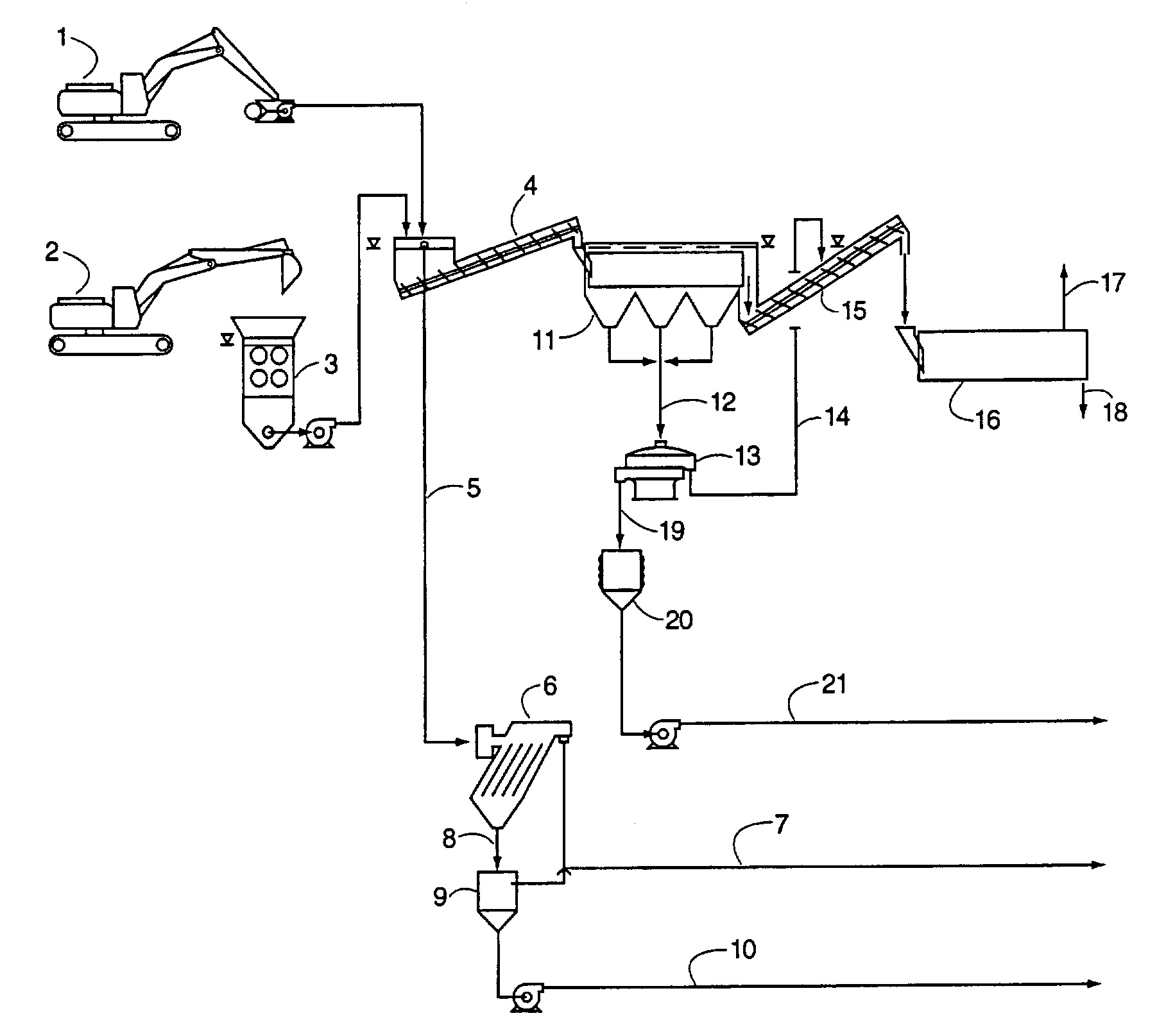

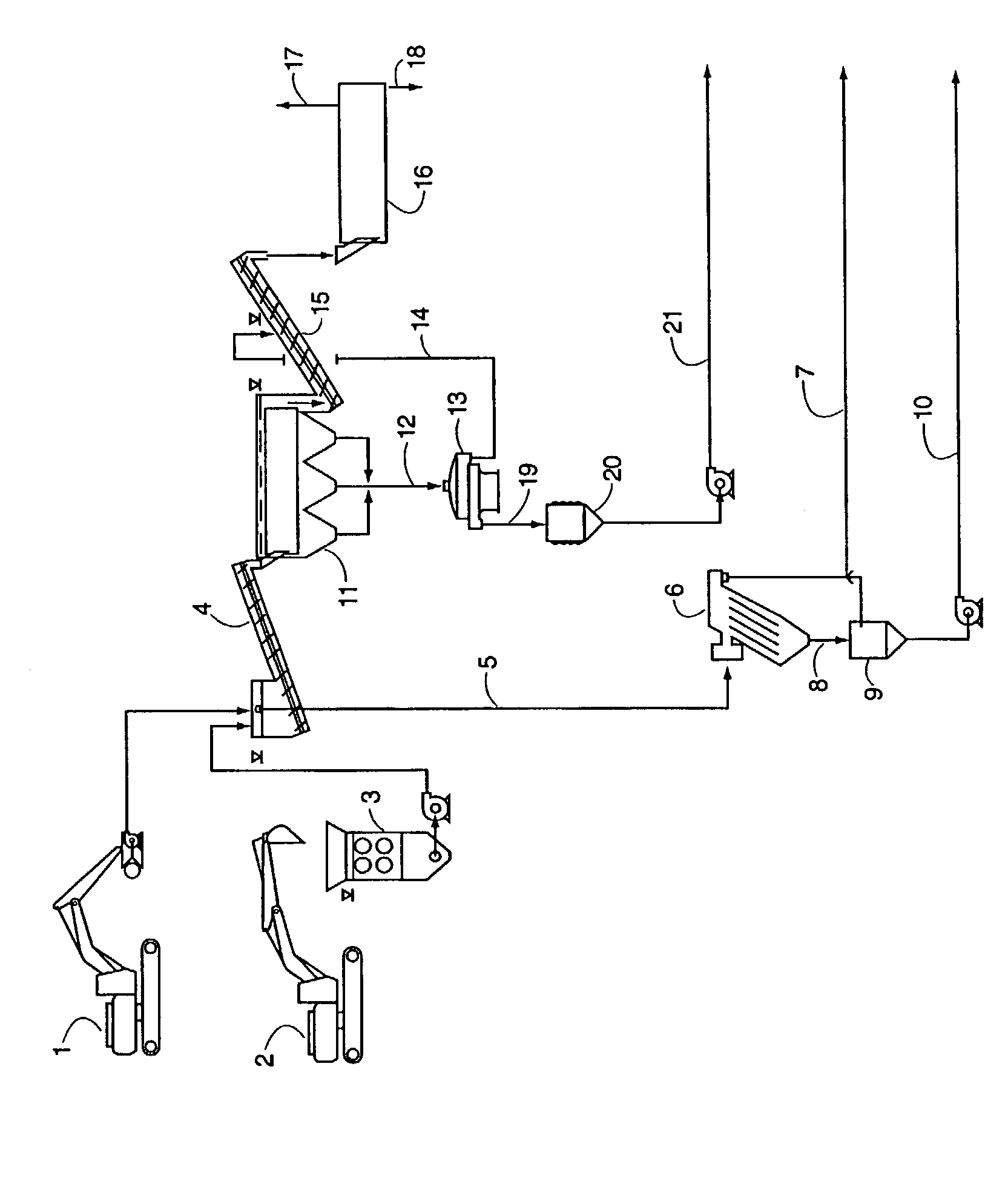

A process for total environmental remediation of a phosphorus contaminated site

ActiveUS20040241073A1Easy to handleGives cleanWaste water treatment from quariesSludge treatment by de-watering/drying/thickeningSludgeEnvironmental remediation

A process is disclosed for recovering elemental phosphorus from an aqueous sludge and converting the residue into non-hazardous waste. The sludge is separated into (1) a slurry of water containing suspended phosphorus and dirt particles and (2) coarse solids. A flocculating agent is added to the slurry to agglomerate the suspended phosphorus and dirt particles, which are recovered from the water and are heated to melt elemental phosphorus particles. A coalescing agent is added to coalesce the melted elemental phosphorus, which is separated from the dirt particles. The coarse solids are mixed with hot water to melt the phosphorus sludge, which is separated from inert solids. The solids are heated to burn any residual elemental phosphorus. The separated molten phosphorus sludge is stirred with a solution of chromic acid to recover the phosphorus as a separate phase. A reducing agent is added to the remaining water and solids to reduce the Cr<+6 >to Cr<+3>. Finally, an alkali is added to the water and solids to react the residual phosphorus and form phosphorous compounds. The reaction mass is filtered and the filter cake can be placed in a landfill as a non-hazardous waste.

Owner:GLENN SPRINGS HLDG

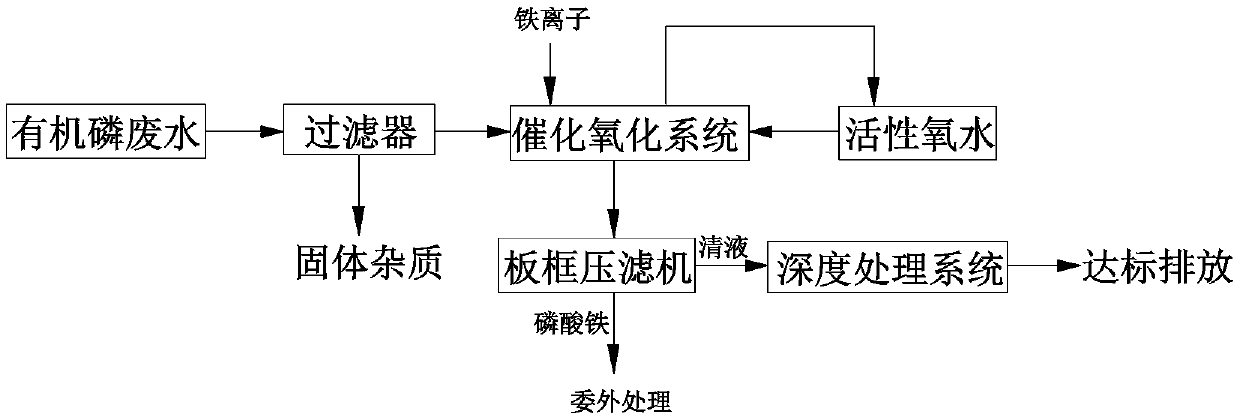

Organophosphorus wastewater treatment process

PendingCN110590047ACompliance with emission standardsWater contaminantsTreatment involving filtrationTreatment effectPhosphate

The invention discloses an organophosphorus wastewater treatment process. The process comprises the following steps: S1, pumping organophosphorus wastewater into a filter by a pump, and filtering outsolid impurities in the organophosphorus wastewater by a filter; S2, filling a catalytic oxidation system with a catalytic oxidation filler in advance; S3, pumping the organophosphorus wastewater subjected to solid impurity removal into the catalytic oxidation system, pumping active oxygen water into the catalytic oxidation system, reacting the catalytic oxidation filler and the active oxygen water to generate hydroxyl free radicals, and quickly converting organophosphorus in the organophosphorus wastewater into phosphates by the hydroxyl free radicals; and S5, pumping the treated liquid in the catalytic oxidation system into a plate-and-frame filter press to obtain a filter cake and a clear liquid, pumping the clear liquid into an advanced treatment system filled with resin, adsorbing residual phosphorus in the clear liquid by the resin, and detecting the total phosphorus content of phosphates in the clear liquid to be 0.5mg / l. The process has the advantages that the total phosphoruscontent of phosphates in the wastewater can be reduced to 0.5mg / l, the treatment procedures are few, and the treatment effect is good.

Owner:四川蓝魔方环境科技有限公司

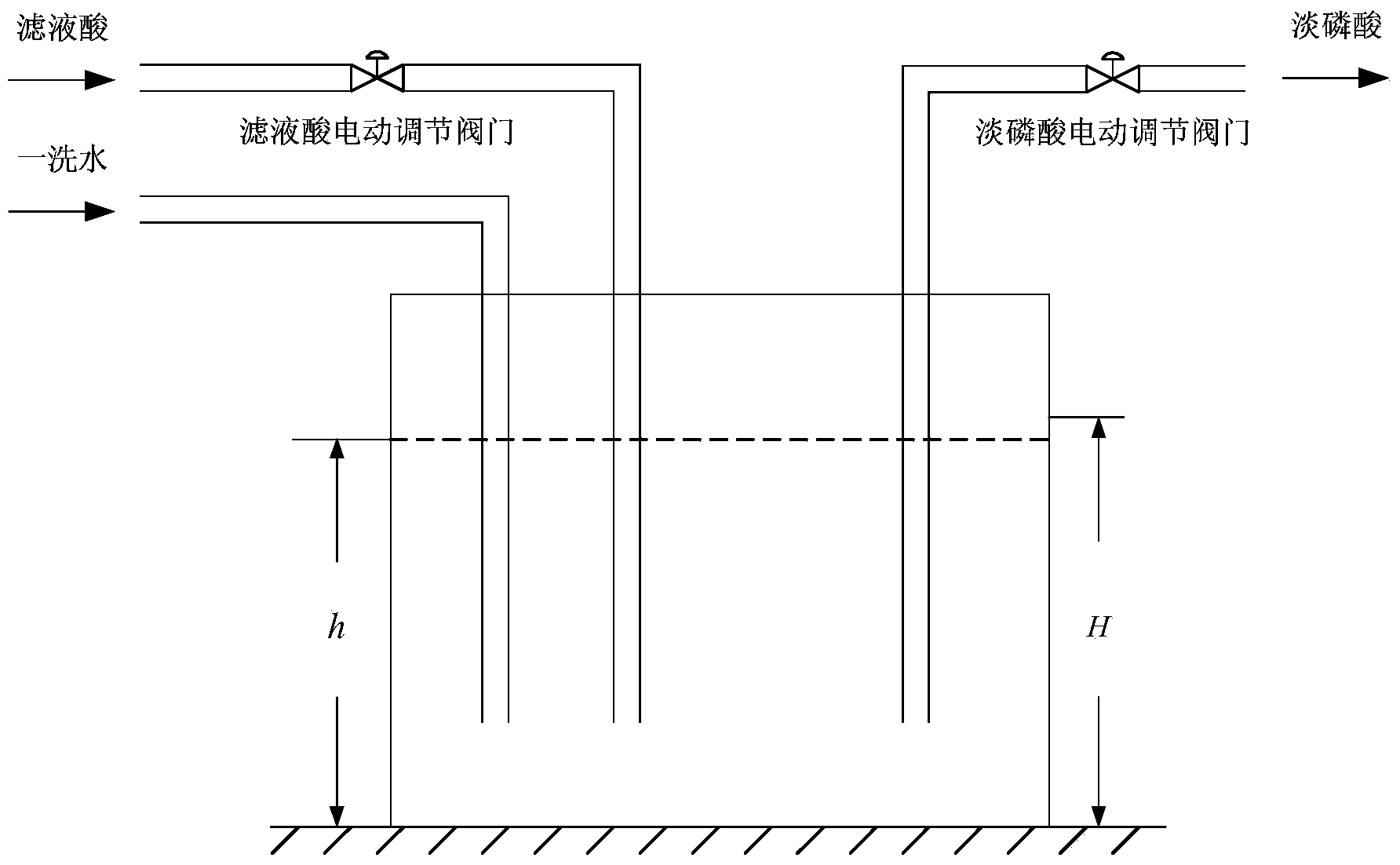

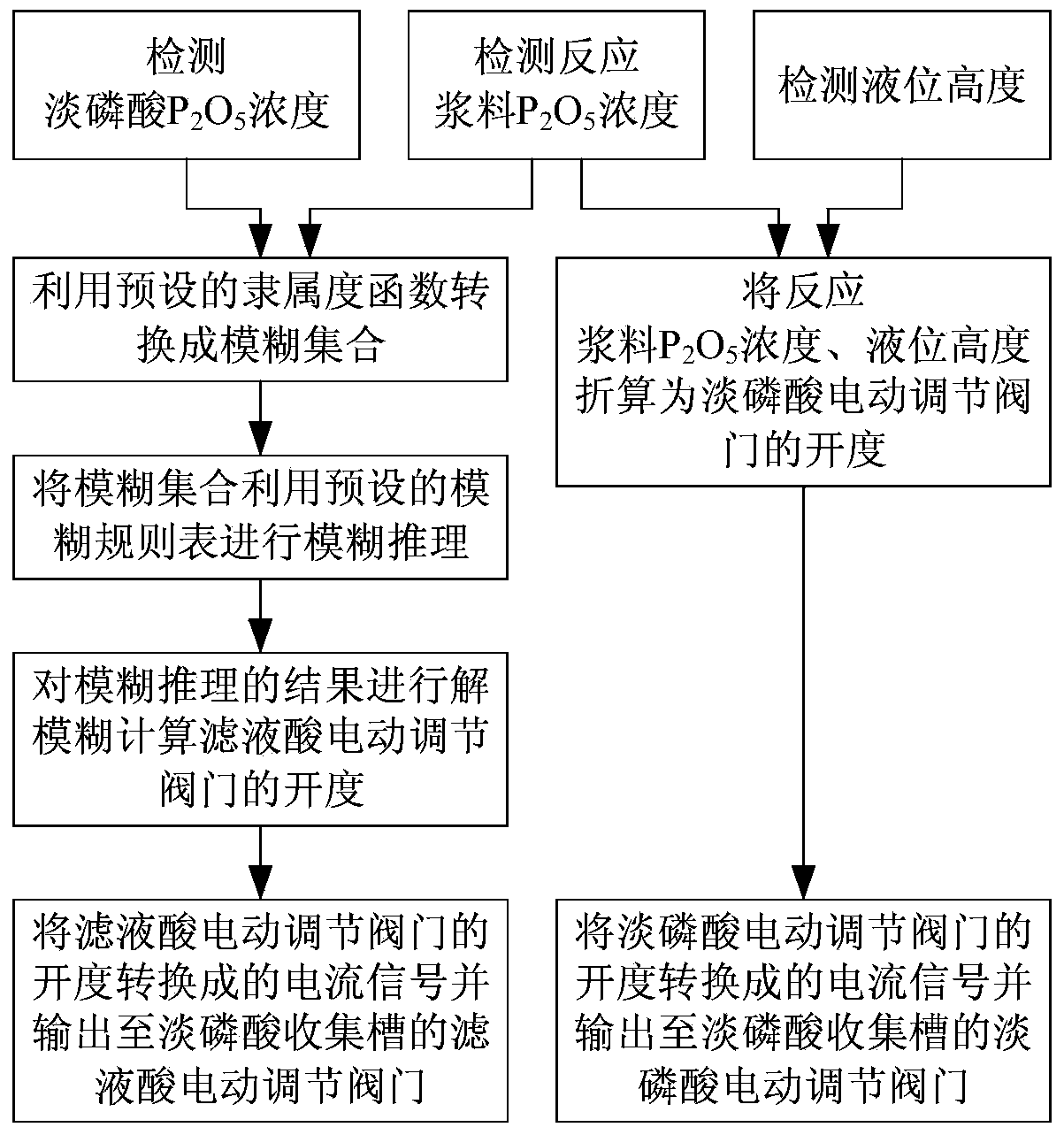

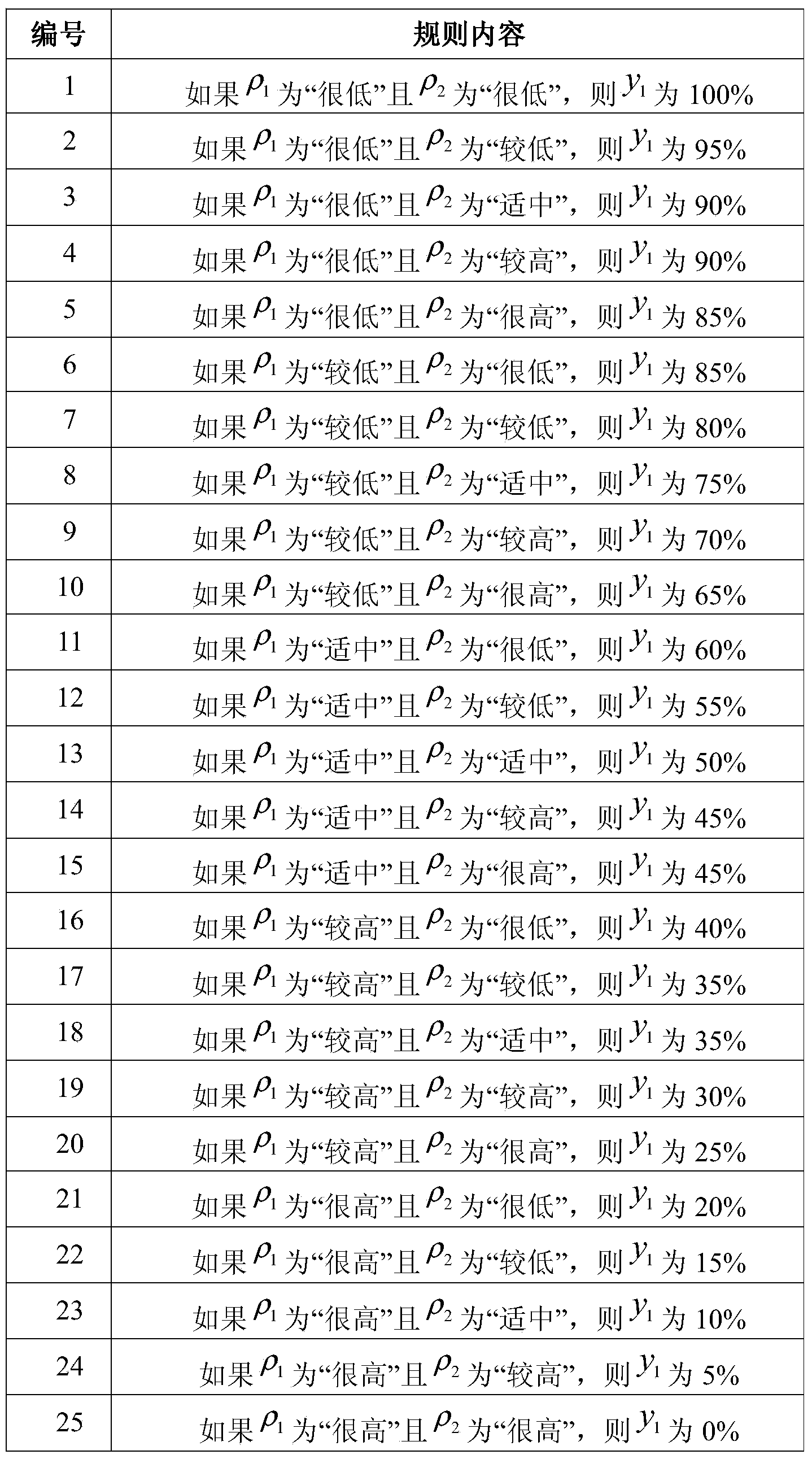

Concentration and flow control method used in recovery of diluted phosphoric acid by virtue of phosphoric ore pulp filter device

InactiveCN104291285AGuaranteed stabilityControl effective controlPhosphoric acidFuzzy inferencePower flow

The invention discloses a concentration and flow control method used in recovery of diluted phosphoric acid by virtue of a phosphoric ore pulp filter device. The concentration and flow control method comprises the following implementation steps: detecting a diluted phosphoric acid P2O5 concentration, a reaction slurry P2O5 concentration and the height of a liquid level in a diluted phosphoric acid collection tank of the phosphoric ore pulp filter device; respectively converting the diluted phosphoric acid P2O5 concentration and the reaction slurry P2O5 concentration into a fuzzy set by virtue of a predetermined subordinating degree function, carrying out fuzzy inference and defuzzification calculation by virtue of a predetermined fuzzy rule list to obtain the opening of a filtrate acid electric regulating valve, converting the opening into current signals and inputting to the filtrate acid electric regulating valve; converting the reaction slurry P2O5 concentration and the height of the liquid level into the opening of a diluted phosphoric acid electric regulating valve, converting the opening into current signals and inputting to the diluted phosphoric acid electric regulating valve. By virtue of the concentration and flow control method, the stability of process indexes can be effectively improved, the filtration effect of the reaction slurry is improved, the residual phosphorus in phosphogypsum is decreased and the environmental pollution is reduced, the automation degree is high and the operation is simple and reliable.

Owner:HENGYANG NORMAL UNIV

Aluminum oxidation wastewater treatment method and method for preparing ferric phosphate from wastewater

PendingCN111977833ASolve processing problemsHigh purityMultistage water/sewage treatmentWater/sewage treatment by neutralisationO-Phosphoric AcidPhosphate

The invention relates to an aluminum oxidation wastewater treatment method and a method for preparing ferric phosphate from wastewater. The treatment method comprises the following steps of taking water from mixed discharged phosphoric acid-containing wastewater in an aluminum oxidation process, adding alkali liquor to perform neutralizing adjustment, setting the pH value to 2.4-3.0, adding a certain amount of ferric salt into a secondary stirring tank, adding an oxidizing agent, and performing stirring and mixing in the stirring tank to generate ferric phosphate precipitate; and after separation, obtaining ferric phosphate with relatively high purity, neutralizing clear liquid with lime milk, controlling the pH value to 9.5-10.5, performing secondary precipitation, precipitating residualphosphate radicals in a calcium phosphate mode, meanwhile precipitating aluminum, fluorine and nickel ions in waste liquid synchronously, further performing mud-water separation, adding quantitative sodium hypochlorite into the clear liquid, performing aeration, oxidizing ammonia nitrogen in water, performing blowing-off, and enabling the pH value of outlet water to be 7-9. The final outlet watercan reach the national emission standard through treatment, and phosphate is effectively recovered in a precipitation mode.

Owner:东阳市维隆环保科技有限公司

Preparation method of powdered phosphorite or smashed phosphorite adhesion agent and production method of formed ore

ActiveCN108249411AHigh viscosityHigh strengthRaw phosphate material treatmentResource utilizationSlag

The invention relates to a preparation method of a powdered phosphorite or smashed phosphorite adhesion agent and a production method of a formed ore and belongs to the technical field of comprehensive mineral resource utilization. The powdered phosphorite or smashed phosphorite adhesion agent is prepared by taking an industrial by-product mainly comprising silicon oxide as a raw material and adding caustic soda and a catalyst. The adhesion agent and powdered phosphorite or smashed phosphorite are subjected to disc balling and calcining to form raw material, namely the formed ore, for production of yellow phosphorus by an electric furnace method. According to the methods, a production process is simple; equipment is mature; the investment is low; the methods are convenient to operate; theformed ore is high in strength; tail gas not subjected to any purification treatment can be used as a heat source; the cost is low; at the same time, a reduction rate of the phosphorus can also be increased; a residual phosphorus content in slag is reduced; and the method is particularly applicable to the characteristic that the future production of the yellow phosphorus by the electric furnace method takes a washed ore as a raw material.

Owner:KUNMING UNIV OF SCI & TECH

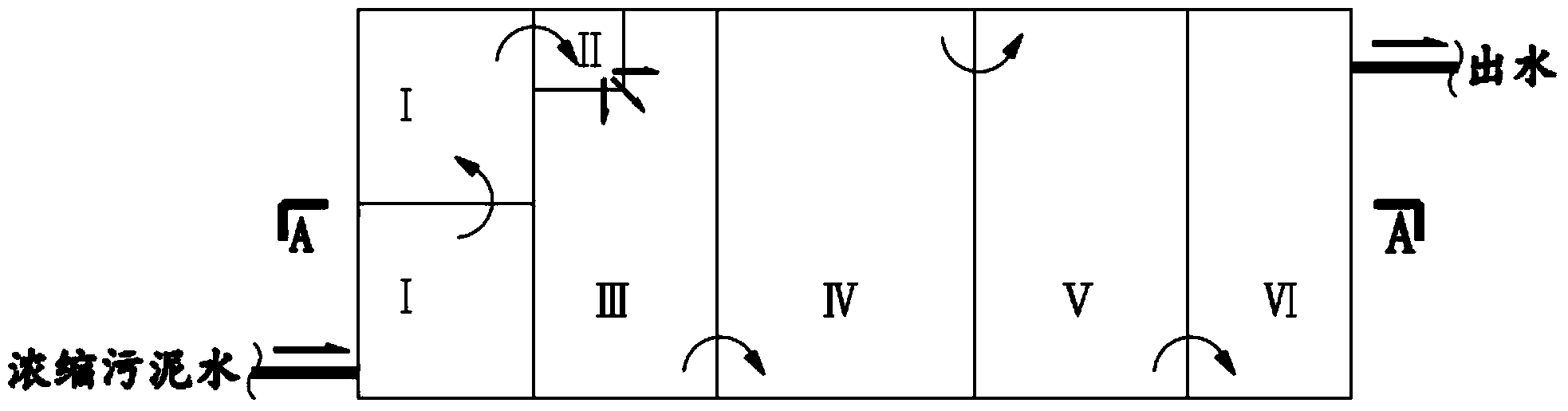

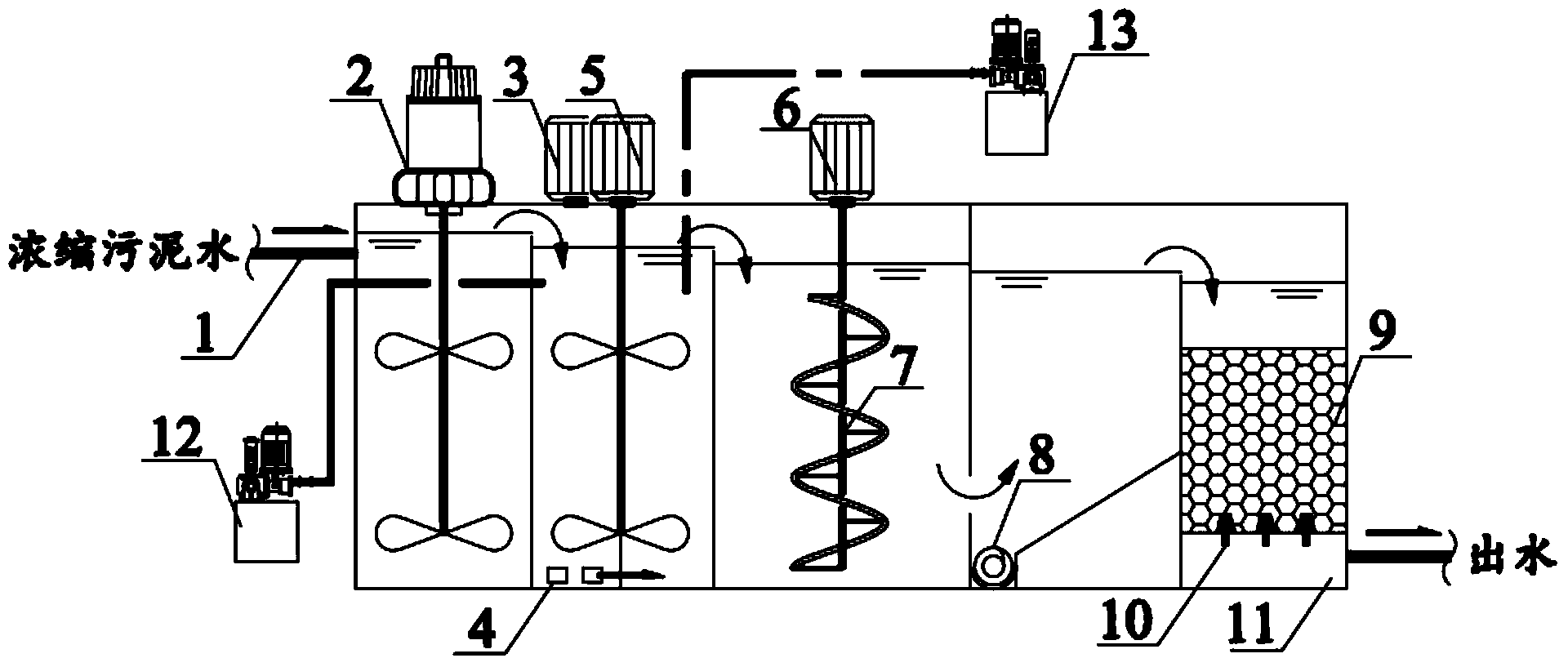

Method and device for synchronous phosphorus removal and turbidity removal of thickened sludge water

ActiveCN103819025AEasy to handleSimple and fast operationMultistage water/sewage treatmentFlocculationSludge

A method for synchronous phosphorus removal and turbidity removal of thickened sludge water comprises the following steps: stirring at high speed to perform homogenization treatment on sludge flocs in the thickened sludge water; adding a flocculating agent into the thickened sludge water subjected to homogenization treatment to realize quick flocculation; performing coagulation reaction on the thickened sludge water subjected to flocculation reaction to realize further densification of particle sludge produced in the coagulation reaction; performing solid-liquid separation on muddy water mixture subjected to densification, discharging the particle sludge through a spiral conveyor, collecting treated water through a collecting tank and further removing residual phosphorus in the water through adsorption to finally enable the outlet water to meet the discharge standards. The invention further provides a device for synchronous phosphorus removal and turbidity removal of the thickened sludge water. By the method and the device provided by the invention, the synchronous phosphorus removal and turbidity removal effect on the thickened sludge water in a sewage treatment plant is realized, the treatment cost is low, the treatment efficiency is high and the consumed time is short.

Owner:SHAANXI URSTAR ENVIRONMENTAL SCI & TECH

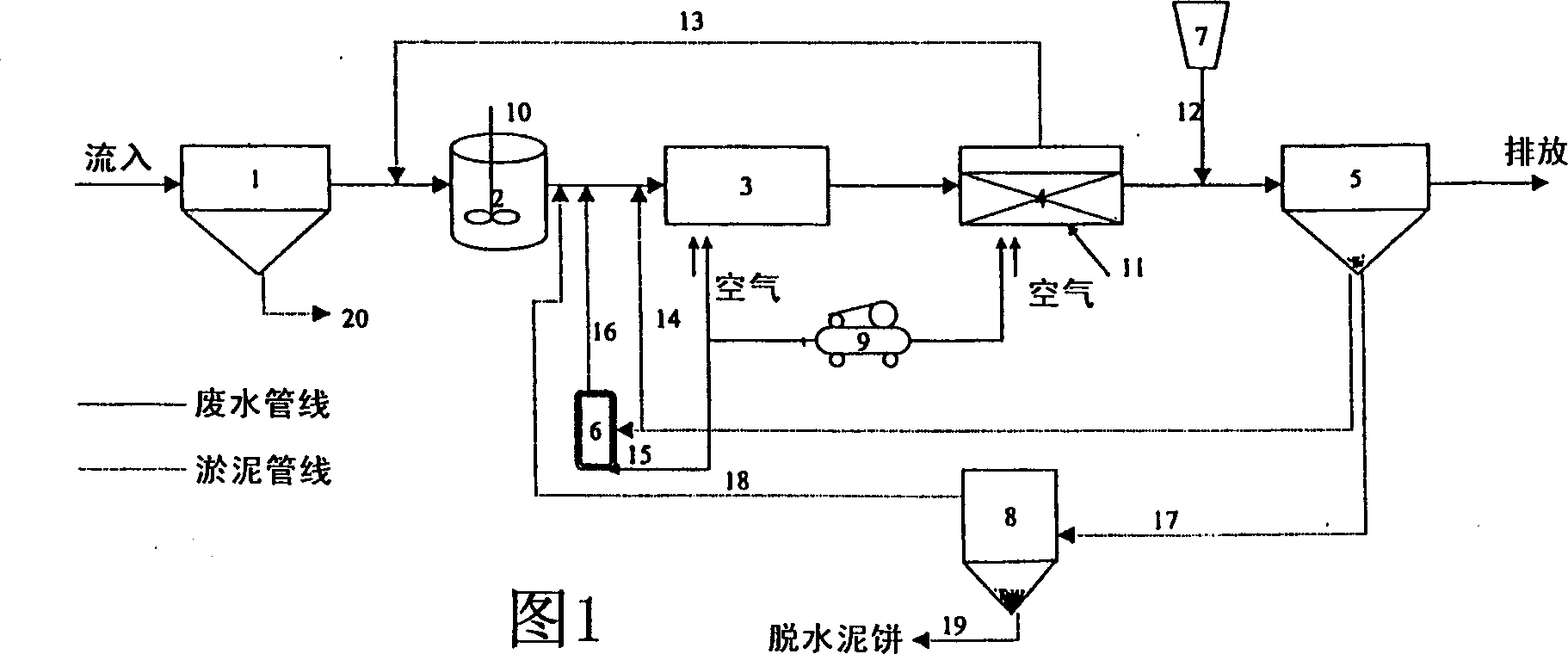

Method for biochemically treating wastewater

InactiveCN1350985ASludge treatment by de-watering/drying/thickeningTreatment using aerobic processesAtmospheric airSludge

A method for effectively treating organic matter and nutriments such as nitride and phosphide in wastewater. The treatment comprises follow parts of: a settling tank for separating sand and debris in wastewater by deposition; an anaerobic tank comprising a simple and contact aeration tanks for denitrification of returned sludge in which the nitrogen is converted from ammonia (NH4) to nitrite (NO3) by oxidation, with a carbon source of feeding wasterwater in anaerobic condition to convert nitrogen element to nitrogen gas by adding a denitrogenation oxidation bacterium and discharging the nitrogen gas to air; a biopond equipped with a biomake and an aeration device for activating microorganisms and supplying activated microorganisms into the simple and contact aeration tanks; the simple aeration tank for decomposing organics and for converting ammonia (NH4) to nitrite (NO3); the contact aeration tank for decomposing residual organics and for converting residual ammonia (NH4) to nitrite (NO3) by microorganisms attached to media; a sedimentation tank for settling sludge and for removing residual phosphorus by using coagulation; and a concentration tank for deposited sullage dehydrating to improve concentration.

Owner:KOREA INST OF SCI & TECH

Process for total environmental remediation of a phosphorus contaminated site

ActiveUS6955796B2Waste water treatment from quariesSludge treatment by de-watering/drying/thickeningSludgeEnvironmental remediation

A process is disclosed for recovering elemental phosphorus from an aqueous sludge and converting the residue into non-hazardous waste. The sludge is separated into (1) a slurry of water containing suspended phosphorus and dirt particles and (2) coarse solids. A flocculating agent is added to the slurry to agglomerate the suspended phosphorus and dirt particles, which are recovered from the water and are heated to melt elemental phosphorus particles. A coalescing agent is added to coalesce the melted elemental phosphorus, which is separated from the dirt particles. The coarse solids are mixed with hot water to melt the phosphorus sludge, which is separated from inert solids. The solids are heated to burn any residual elemental phosphorus. The separated molten phosphorus sludge is stirred with a solution of chromic acid to recover the phosphorus as a separate phase. A reducing agent is added to the remaining water and solids to reduce the Cr+6 to Cr+3. Finally, an alkali is added to the water and solids to react the residual phosphorus and form phosphorous compounds. The reaction mass is filtered and the filter cake can be placed in a landfill as a non-hazardous waste.

Owner:GLENN SPRINGS HLDG

Biological Phosphorus Removal Autotrophic Nitrogen Removal Method Based on Short-cut Denitrification to Provide Nitrite in Municipal Wastewater

ActiveCN104556376BReduced oxygen demandReduce operating energy consumptionTreatment with aerobic and anaerobic processesAmmonia-oxidizing bacteriaDenitrifying bacteria

The invention discloses an autotrophic nitrogen removal method for biological phosphorus removal of urban sewage based on short-cut denitrification for providing nitrite. The method comprises the following steps: firstly feeding urban sewage into an anaerobic zone of a biological phosphorus removal nitrogen removal reactor, wherein short-cut denitrification is firstly carried out on denitrifying bacteria on a biological membrane so as to reduce nitrate nitrogen in return sludge to nitrite nitrogen, anaerobic ammonium oxidation bacteria on the biological membrane further convert nitrite nitrogen and nitrite nitrogen into nitrogen while anaerobic phosphorus release is carried out on phosphorus-accumulating bacteria in floc sludge; then feeding the sewage into the anaerobic zone again, wherein short-cut denitrification is carried out on the denitrifying bacteria on the biological membrane so as to reduce nitrate nitrogen in return sludge to nitrite nitrogen, and anaerobic ammonium oxidation bacteria on the biological membrane further convert nitrite nitrogen and nitrite nitrogen into nitrogen; then feeding the sewage into an aerobic zone and ammonia oxidizing bacteria and nitrite oxidizing bacteria in the floc sludge oxidize residual ammonia nitrogen in the sludge to nitrate nitrogen; and finally, implementing residual phosphorus removal and autotrophic nitrogen removal of urban sewage of a continuous flow, wherein the treatment energy consumption of an urban sewage plant is reduced.

Owner:BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com