Patents

Literature

33results about How to "Improve degumming problem" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

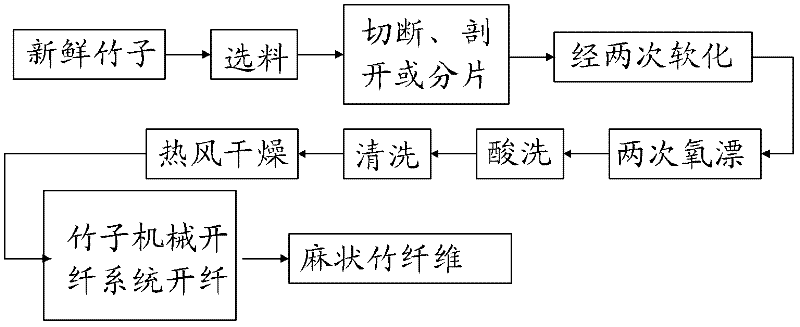

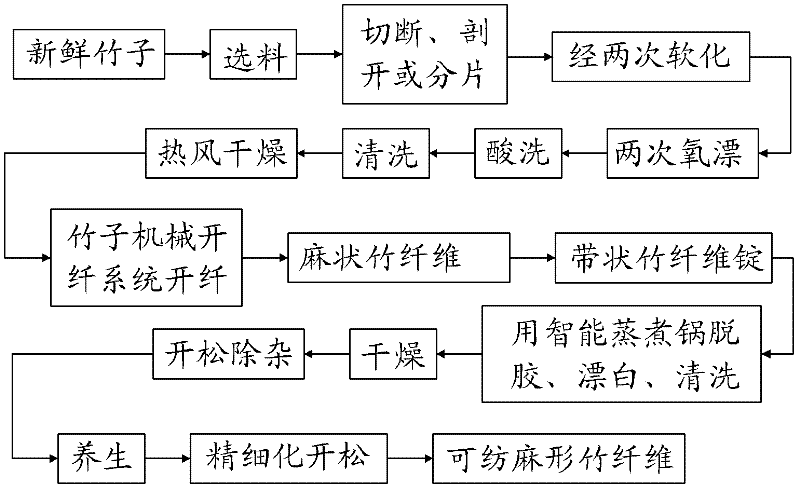

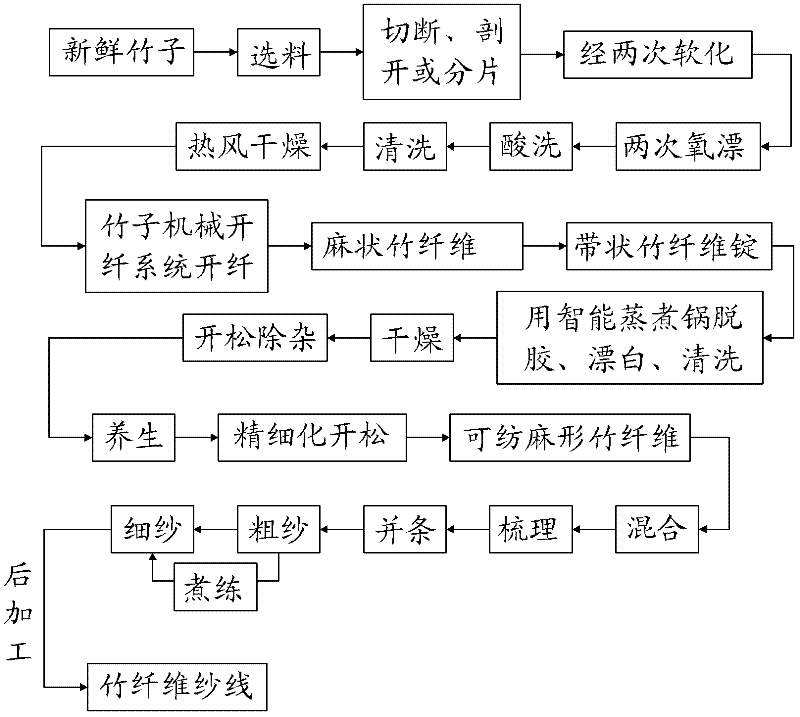

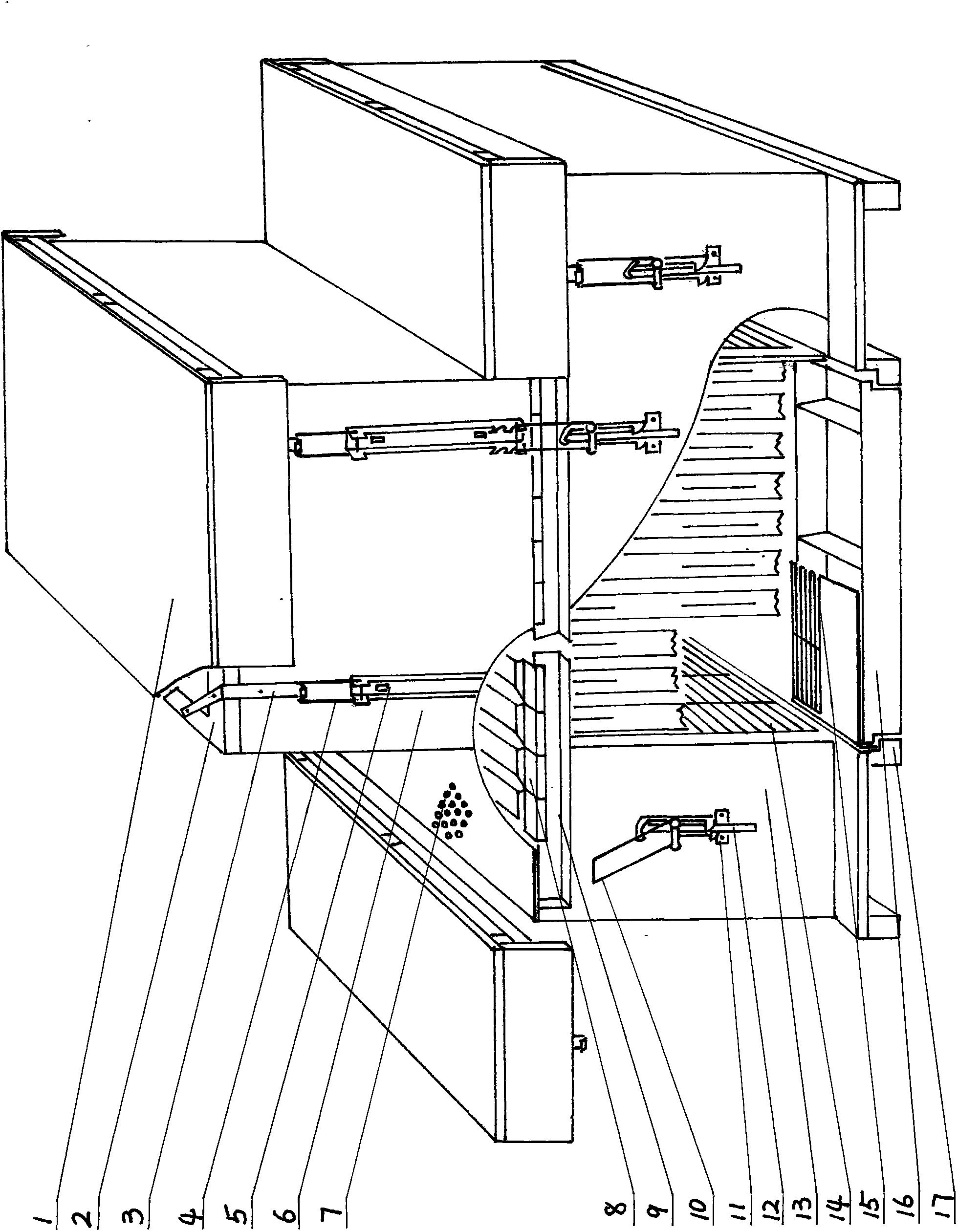

Production process for linen bamboo fibers, spinnable linen bamboo fibers and bamboo fiber yarns

ActiveCN102242403AQuality improvementHigh strengthVegetable materialMechanical fibre separationYarnSoftening

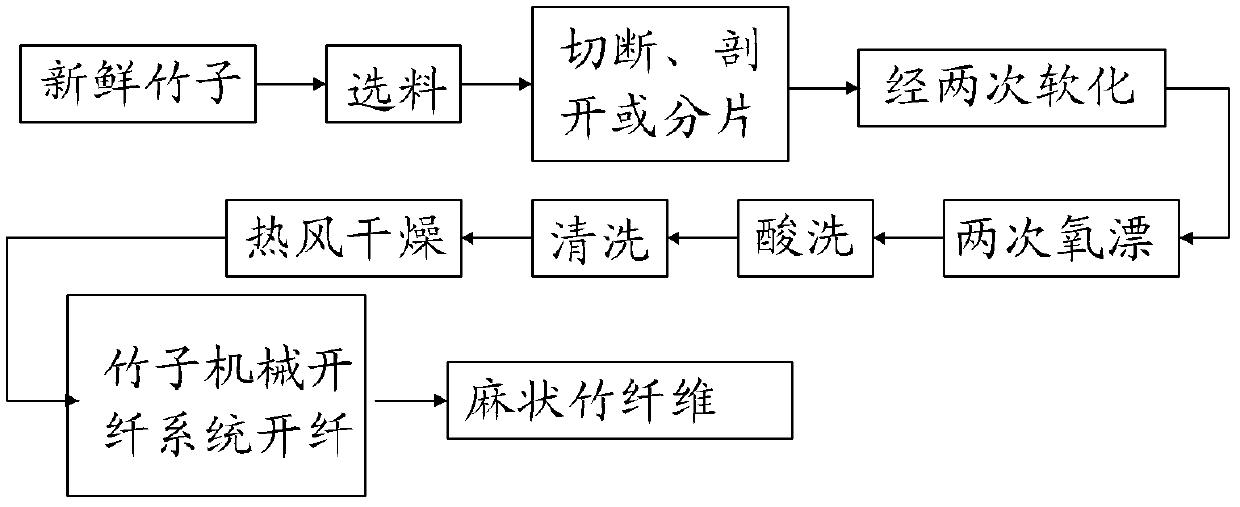

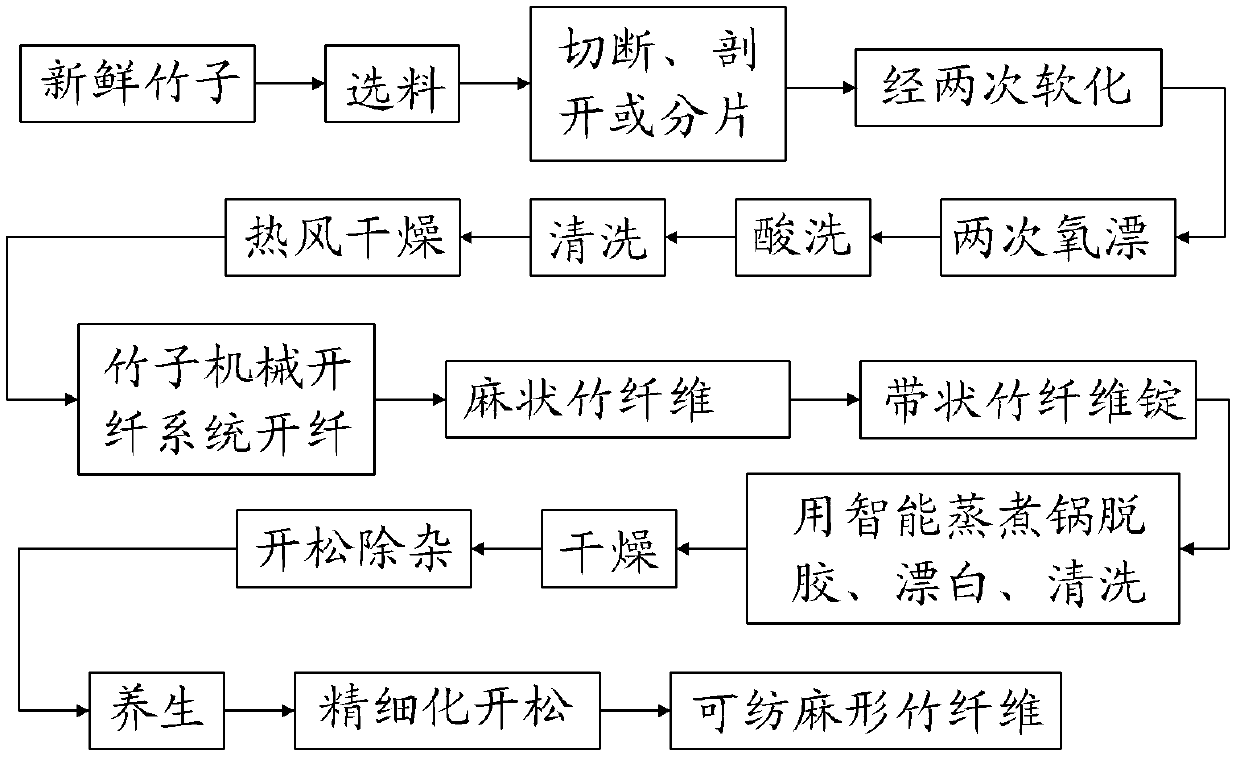

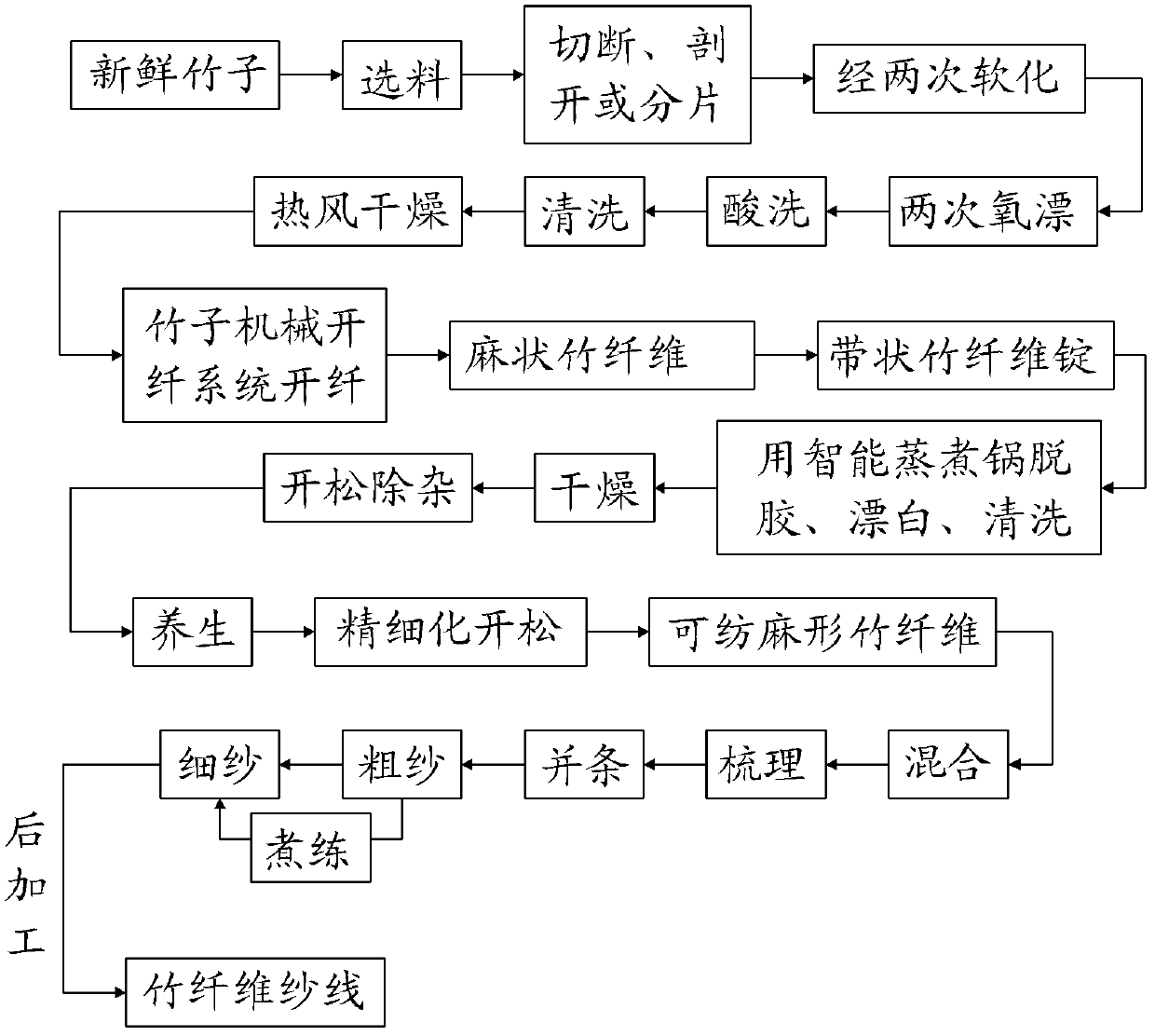

The invention relates to a production process for linen bamboo fibers, spinnable linen bamboo fibers and bamboo fiber yarns. The production process comprises the following steps: sawing a fresh bamboo into pieces according to a certain length and then respectively soaking the pieces in different biologic softening solutions or cooking the pieces in specially prepared softening solutions at high temperature; after cleaning the pieces, heating and airing the pieces, and then feeding the pieces into a bamboo mechanical splitting system, thereby preparing the linen bamboo fibers; processing the linen bamboo fibers into strip-shaped bamboo fiber spindles; putting the strip-shaped bamboo fiber spindles into an intelligent steam cooker in turn, thereby degumming, bleaching and cleaning the strip-shaped bamboo fiber spindles; after drying the strip-shaped bamboo fiber spindles, opening and removing impurities, thereby acquiring the spinnable linen bamboo fibers; and sending the spinnable linen bamboo fibers into a yarn-forming integrated system, and performing the processes of opening, cotton-blending, carding, drawing and yarn-forming, thereby finally acquiring the bamboo fiber yarns. The bamboo fibers prepared by using the production process are linen, longer, thinner, more uniform and softer. The average fineness of the bamboo fibers can reach 400-600 metric counts. The bamboo fibers can be purely spun or fully blended with fibers such as cotton, linen, and the like.

Owner:ZHEJIANG FORESTRY UNIVERSITY +1

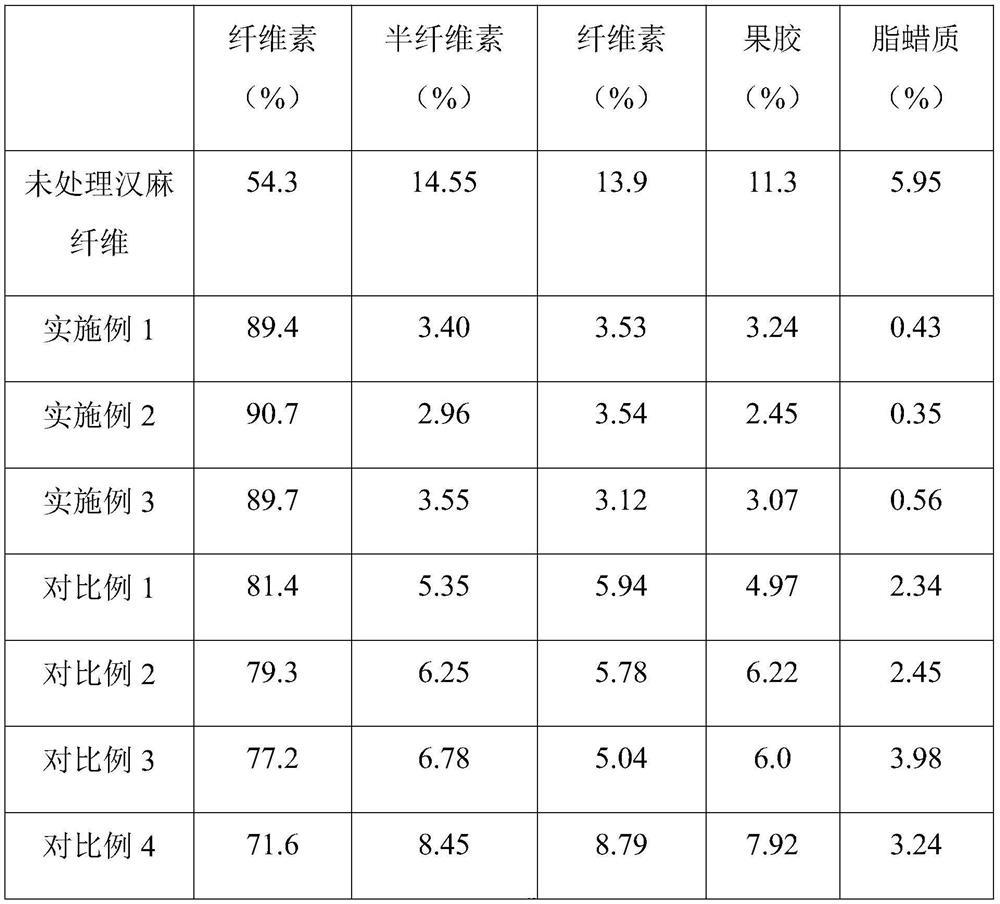

Degumming method of fabric

The invention relates to a degumming method for hemp fiber, in particular to a method for combined application of chemical with super critical CO2 fluid degumming. Wherein, before carrying out super critical CO2 fluid degumming, the hemp fiber first goes through chemical treatment, then super critical degumming is carried out under low and hi pressure respectively. The invention can obviously reduce the non-cellulose composition for example lignin, etc. in hemp fiber, is of an ideal degumming effect, with obviously improved cellulose ratio, very good softening effect of fiber, hence improved process quality of hemp fiber; the invention additionally overcomes the shortcoming associated with prior degumming way such as high pollution, etc., and is of high economic efficiency.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME

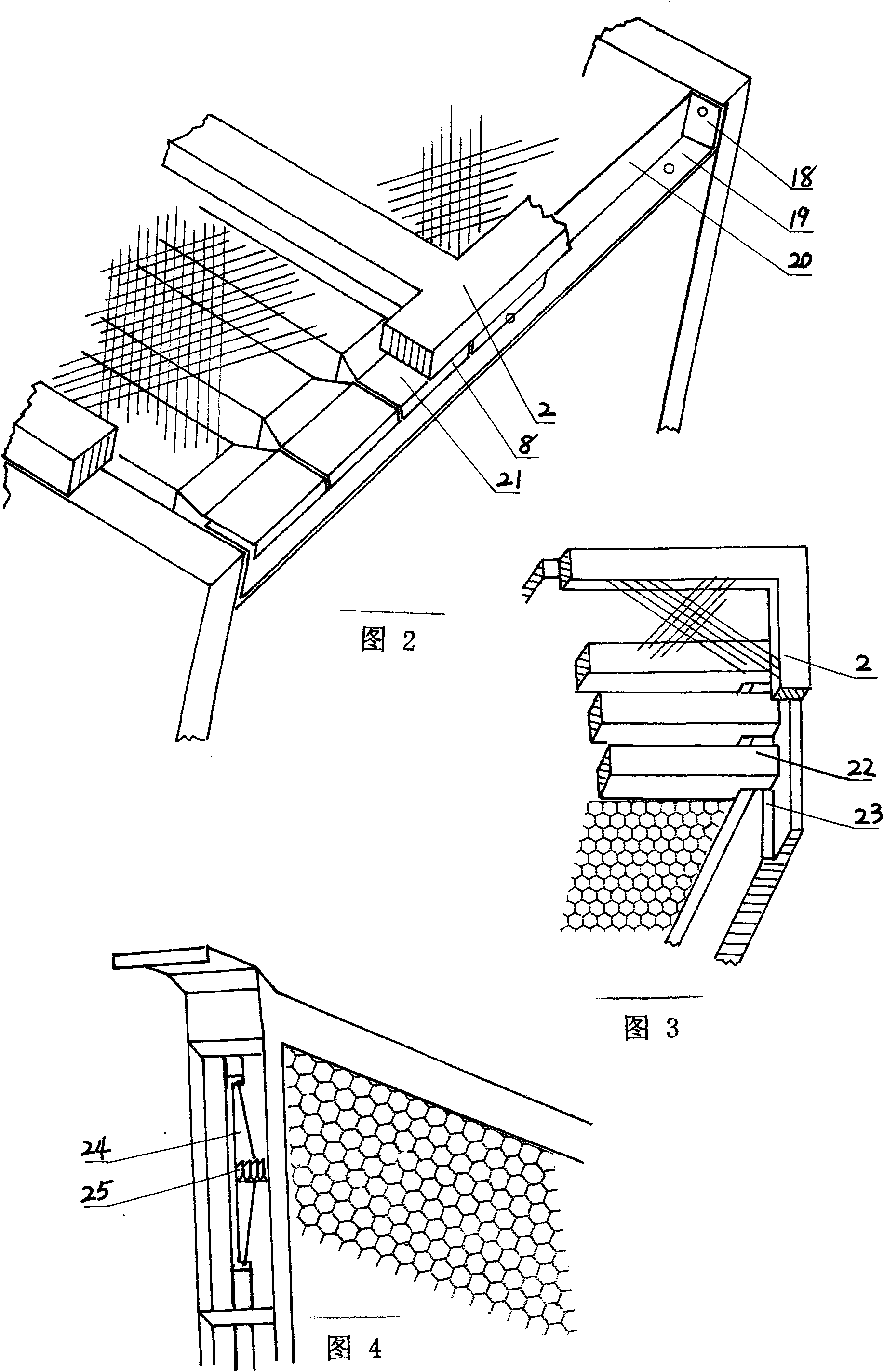

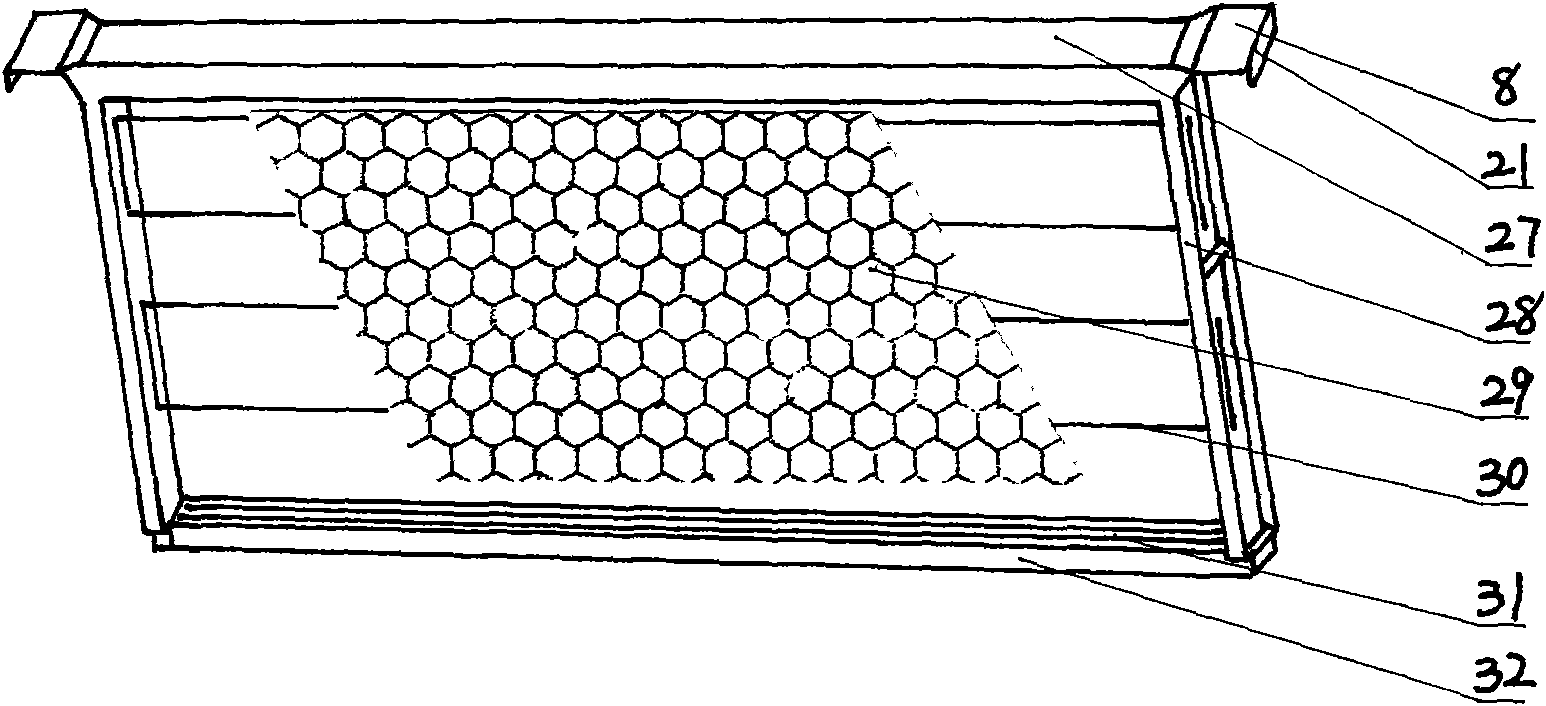

Horizontal and super combined beehive

InactiveCN101897300AImprove work efficiencyIncrease productionBeehivesHoney collectionWaxEngineering

A horizontal and super combined beehive comprises a wide-comb box, a frame support, a powder-releasing cover, a pollen box, a connector, a degummed drape, an inserted frame, an integrated frame and a wax comb foundation with suspension loops. The wide-comb box is characterized in that the both ends of the box are used as the breeding areas for two swarms of bees, a super is supported above the middle production area, frame queen excluders are used to form a working bee centralized production area, the areas are covered; the powder-releasing cover is bottomless, pollens and honey on a powder-leaking railing pedal with anti-theft gantry boxes on both sides directly leak in the pollen box at the bottom; the connected box is coarsely adjusted by a multi-teeth hook and finely adjusted and connected firmly by a screw crow bar through screws; the laps and edgings of the inserted frame are integrated, an upper beam and a lower beam are inserted in the upper and lower grooves of two edgings to integrate, the upper beam is thin, the lower beam and the edgings are provided with grooves to be inserted in the comb foundation; a wide hook with the same width and an adjuster are hung on the wax comb foundation for tightening; the laps are integrated with a frame-distance clip and connected with the upper beam through a downward slope, the tops of comb-forming frame supports are butted to each other and are tightly pressed by the degummed drape and the inner frame of the box cover, the distance of the frames is standard so that people can not stung by bees; and the top of each lap is provided with a handle, thus the laps can be fast gripped outside the box. The wide-comb box can be used to multiply the efficiency, thus being suitable to be used for beekeeping around the world.

Owner:汪修建

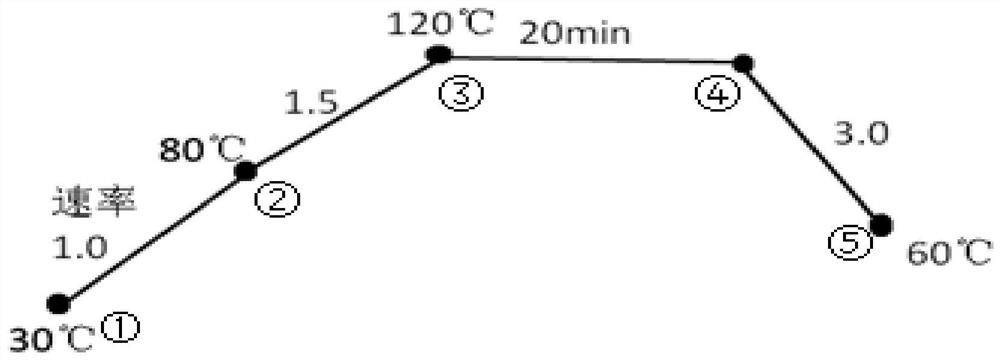

Method for producing washable fresh silkworm cocoon silk floss winter coat

InactiveCN104195647ASimple processing methodSimple equipmentSucessive textile treatmentsSilk filament obtainingBiologic ProductsBiological product

The invention discloses a method for producing a washable fresh silkworm cocoon silk floss winter coat. The method for processing silk floss winter coat raw materials through silkworm light defective cocoons includes the following steps of fresh cocoon treatment, alkali soaking, cocoon silk stripping, washing and dewatering, dipping in a degumming agent, washing and dewatering, dipping in a softening agent, dipping in silk protective essence, washing and dewatering, and drying. According to the method for processing the silk floss winter coat raw materials through fresh silkworm cocoons, the high-quality silk floss winter coat and fresh pupas are acquired, processed silk floss is soft and clean, the processing method and equipment are simple, production efficiency is high, production cost is low, the quality of the fresh pupas is good, and the pupas are good raw materials of food and biological products.

Owner:YIZHOU ZHUANGGE SILK

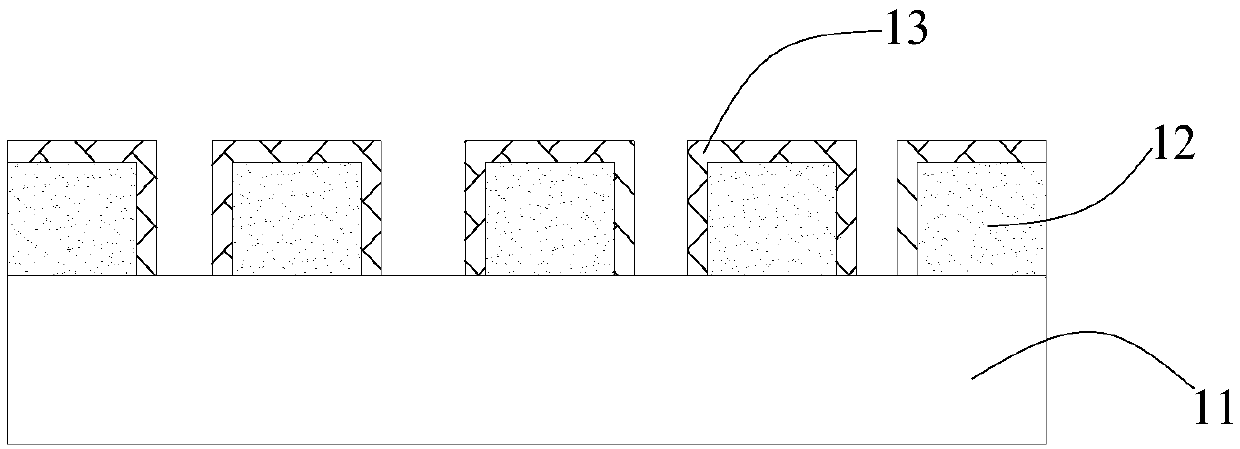

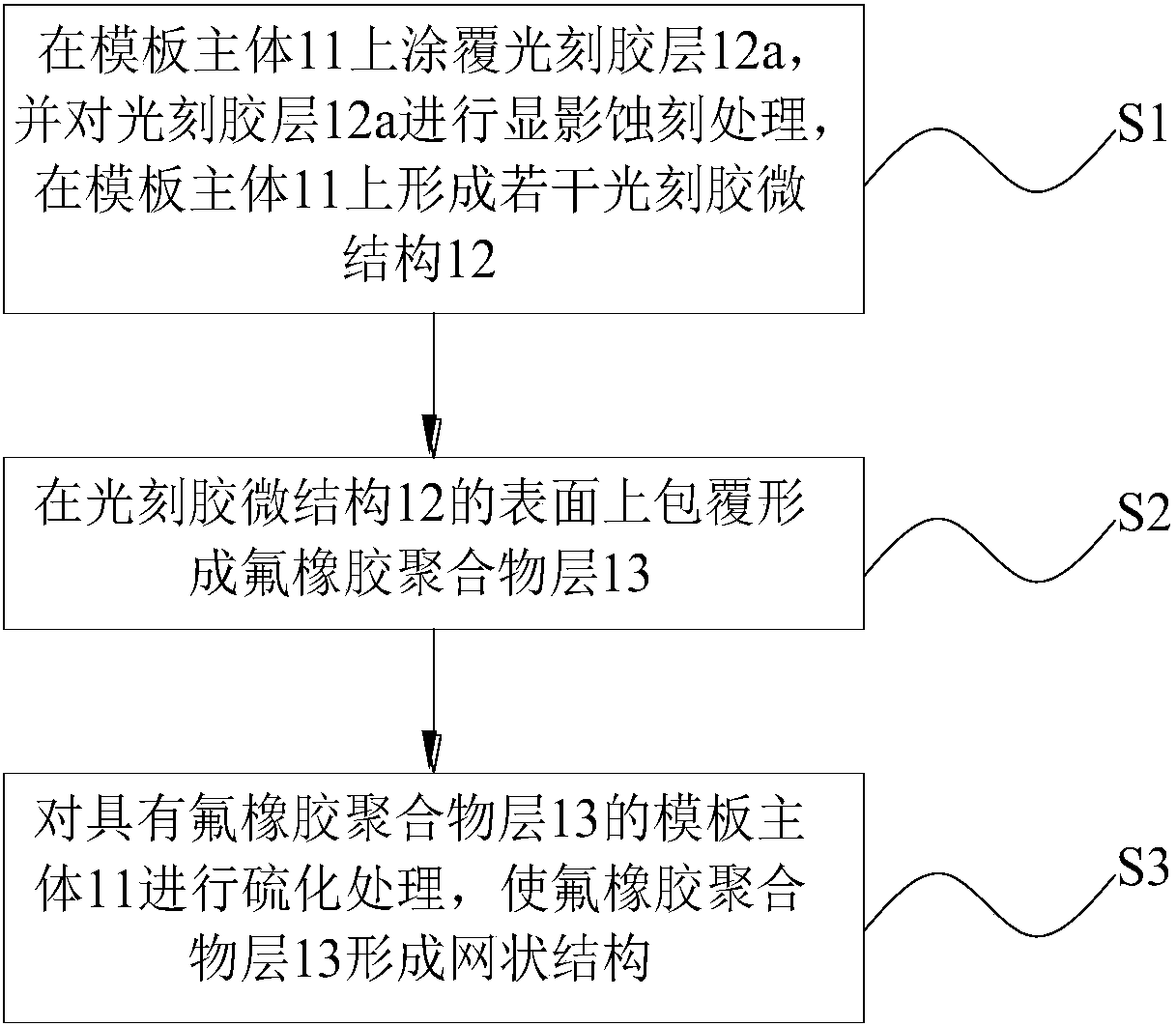

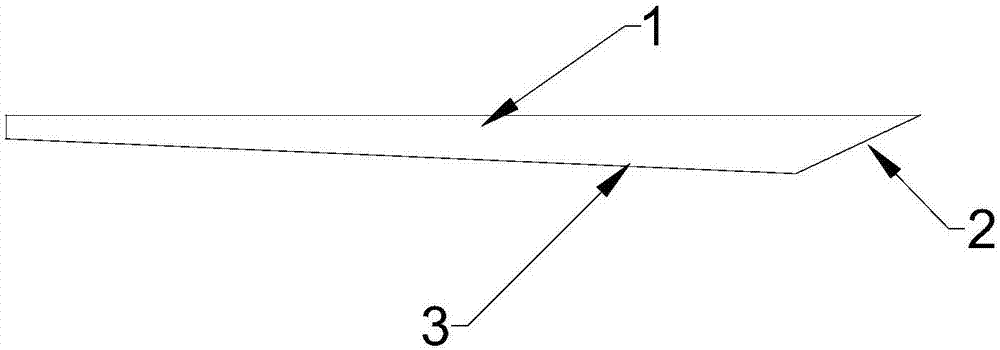

Nano-imprint template as well as making method and application thereof

InactiveCN107643652AAvoid deformationImprove the quality of workmanshipSemiconductor/solid-state device manufacturingNanotechnologyPolymer scienceProcess quality

The invention discloses a nano-imprint template. The nano-imprint template comprises a template main body, a plurality of photoresist microstructures and a fluorine rubber polymer layer, wherein the plurality of photoresist microstructures are arranged on the template main body; the fluorine rubber polymer layer coats outer layers with the photoresist microstructures; a bonding effect exists between the fluorine rubber polymer layer and the template main body, so that the fluorine rubber polymer layer is fixedly connected to the surface of the template main body. The nano-imprint template disclosed by the invention can play a role in protecting the photoresist microstructures in order to prevent the nano-imprint template from being deformed during use, so that the process quality of nano-imprint is enhanced; moreover, the oil resistance and corrosion resistance of the imprinting surface of the nano-imprint template can be improved, the surface has lower surface energy, and the problemof degumming can be effectively improved in an imprinting process. The invention also discloses a making method of the nano-imprint template and application of the nano-imprint template to making of amicro-structure substrate. Through the application method, the microstructure dimension and shape of a formed microstructure substrate can be ensured.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

Detachable epoxy adhesive for multi-wire cutting and preparation method thereof

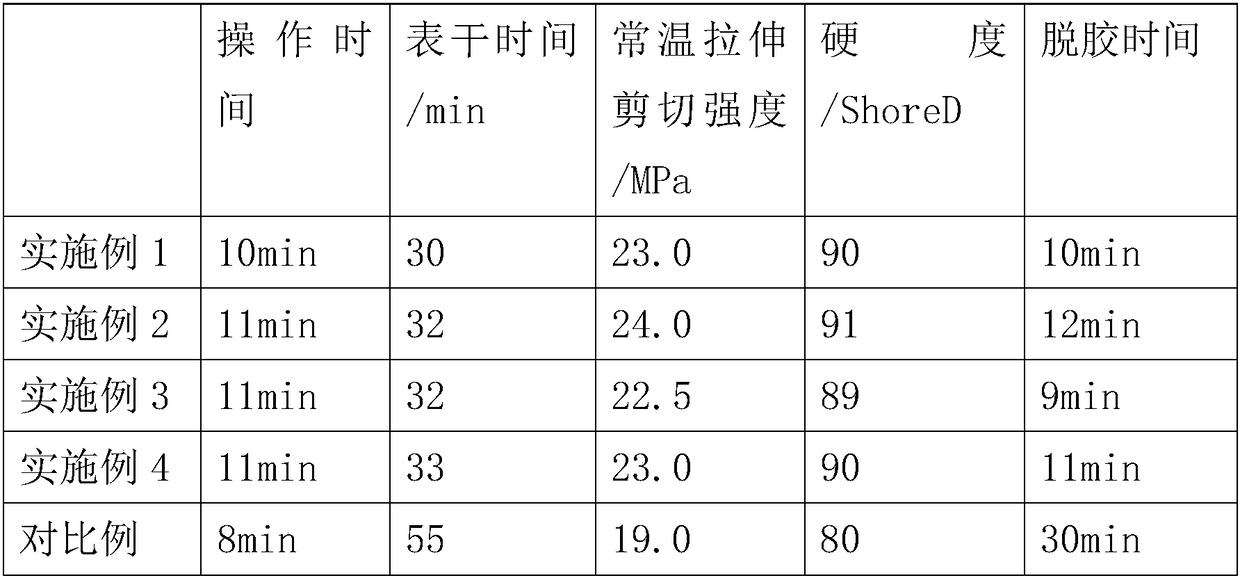

PendingCN108219723AHigh hardnessReduce chippingNon-macromolecular adhesive additivesMacromolecular adhesive additivesWire cuttingChemistry

The invention discloses a detachable epoxy adhesive for multi-wire cutting. The detachable epoxy adhesive comprises two components A and B, wherein the component A and the component B are matched according to a mass ratio of 1 to 1, and the component A is prepared from the following raw materials by mass percent: 30-60% of epoxy resin, 5-10% of toughener, 15-30% of filler, and 1-3% of blue pulp; the component B is prepared from the following raw materials by mass percent: 15-50% of polythiol curing agent, 10-30% of modified amine curing agent, 1-2% of accelerator, 1-5% of diluent, 15-30% of filler, and 1-3% of yellow pulp. The detachable epoxy adhesive disclosed by the invention has the beneficial effects that: 1, the components A and B have low viscosity after mixing and have excellent handleability; 2, the surface drying time of the components A and B is fast after mixing, thereby meeting the high efficiency requirements of the photovoltaic industry; 3, after the end of the cutting,a silicon wafer can be degummed faster and the degumming efficiency is improved.

Owner:康达新材料(集团)股份有限公司

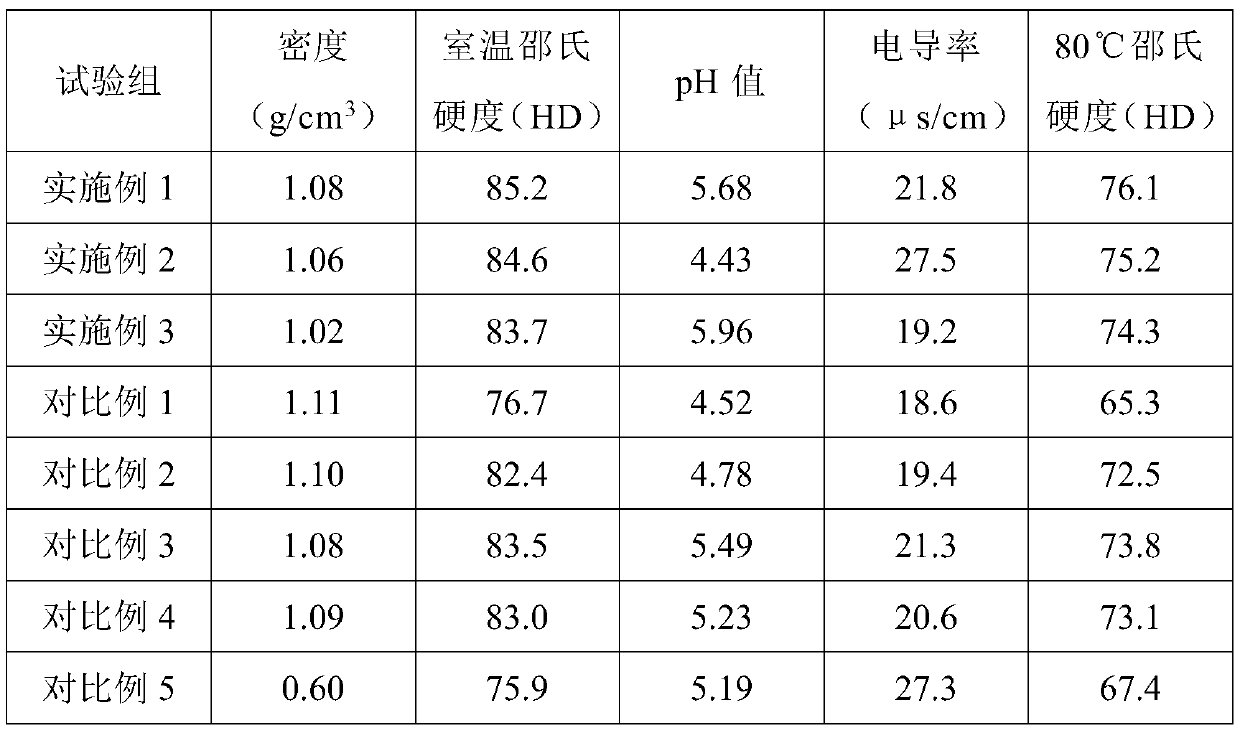

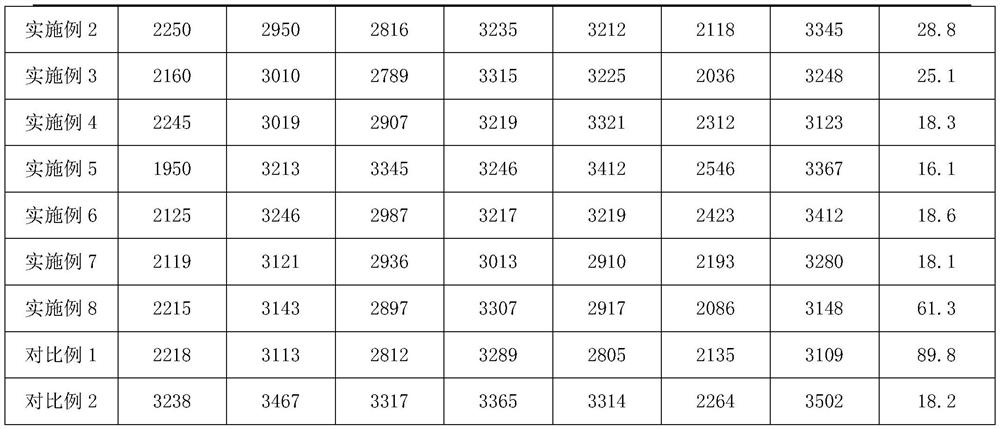

Specific acidic plastic plate for photovoltaic diamond wire cutting and preparation method thereof

The invention discloses a specific acidic plastic plate for photovoltaic diamond wire cutting and a preparation method thereof. The plastic plate comprises the following raw materials: matrix resin and an auxiliary agent, and is prepared through the steps of raw material mixing, granulation, extrusion molding, polishing, cutting, detection, packaging and the like. The plastic plate prepared by theinvention meets the requirement of a large circulation system of a diamond wire cutting process, is easy to recycle, can be recycled, and meets the environmental protection requirement of continuousutilization; in a silicon rod cutting process using the diamond wire, impurities adhering to the diamond wire are reduced, the abrasion probability of the diamond wire is reduced, the cost is saved, the superior product rate of silicon wafers is increased, and therefore the production efficiency is effectively improved. Compared with the prior art, the prepared plastic plate is better in shore hardness and equivalent in pH value and conductivity, and has remarkable progress.

Owner:广西拓源新材料有限公司

Refining technology of rice bran oil

InactiveCN105132150AReduce pollutionProtect physiologically active substancesFatty-oils/fats refiningOxidation stabilityRice Bran Extract

The invention provides a refining technology of rice bran oil, and relates to the technical field of grease processing. The refining technology comprises six steps: pretreatment, degumming, deacidification, decoloring, deodorizing, and de-waxing. The provided refining technology can reduce the loss of oryzanol and obtain a high oryzanol retention rate. Moreover, the prepared oil product has good oxidation stability.

Owner:崇州市白头甘泉工业油脂厂

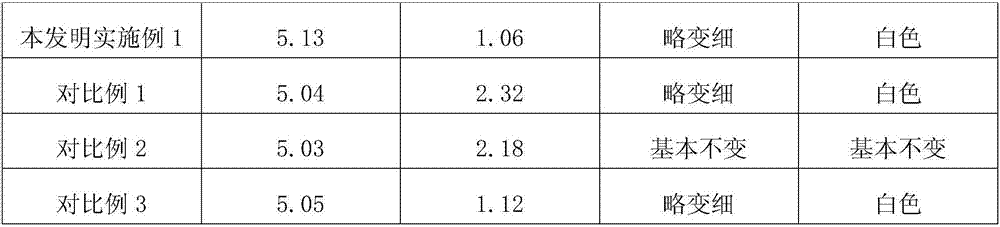

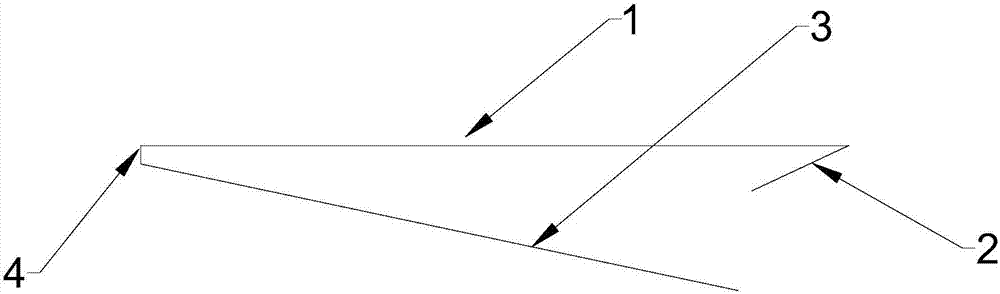

Primer, polymer pre-laid waterproof coiled material and preparation method of polymer pre-laid waterproof coiled material

PendingCN114149766AImprove degumming problemGood dimensional stabilityUnderground chambersFilm/foil adhesive primer layersPolymer scienceButadiene Dioxide

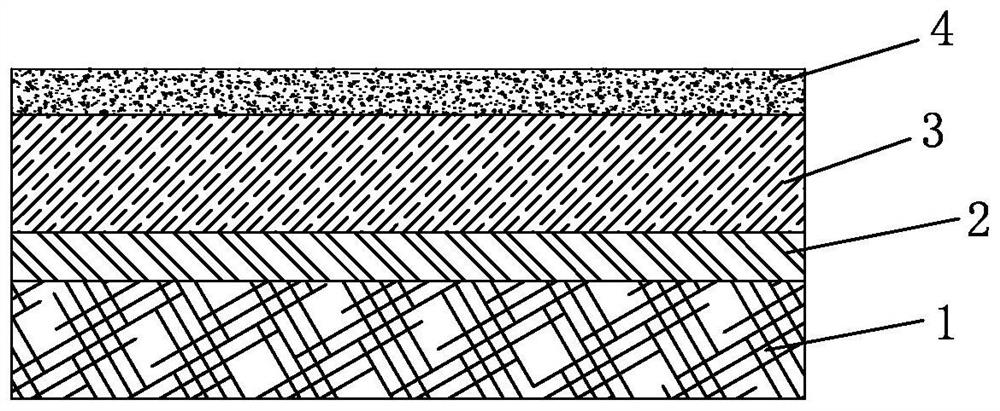

The invention relates to a primer, a polymer pre-laid waterproof coiled material and a preparation method, the polymer pre-laid waterproof coiled material comprises a base material layer, a primer layer, an adhesive layer and an anti-sticking layer which are sequentially stacked, and the raw material formula of the primer adopted by the primer layer comprises a first emulsion and a second emulsion, the first emulsion is one or a combination of more of a butadiene-acrylic acid copolymer emulsion and a butadiene-methacrylic acid copolymer emulsion, and the second emulsion is rubber latex. Compared with an existing high-molecular pre-laid waterproof roll, the high-molecular pre-laid waterproof roll has the advantages that by using the specific primer, the degumming rate is greatly reduced in the using process; and meanwhile, compared with the existing high-molecular pre-paved waterproof roll, the high-molecular pre-paved waterproof roll disclosed by the invention also has excellent dimensional stability and tensile strength retention rate after high-temperature thermal aging.

Owner:JIANGSU CANLON BUILDING MATERIALS

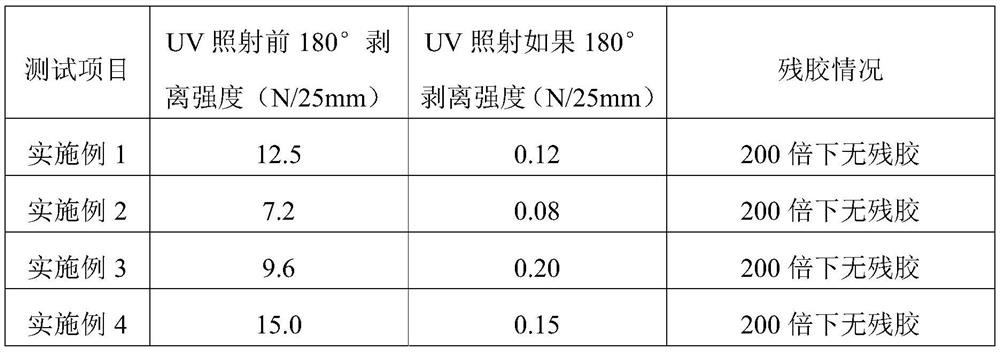

Adhesive releasing method

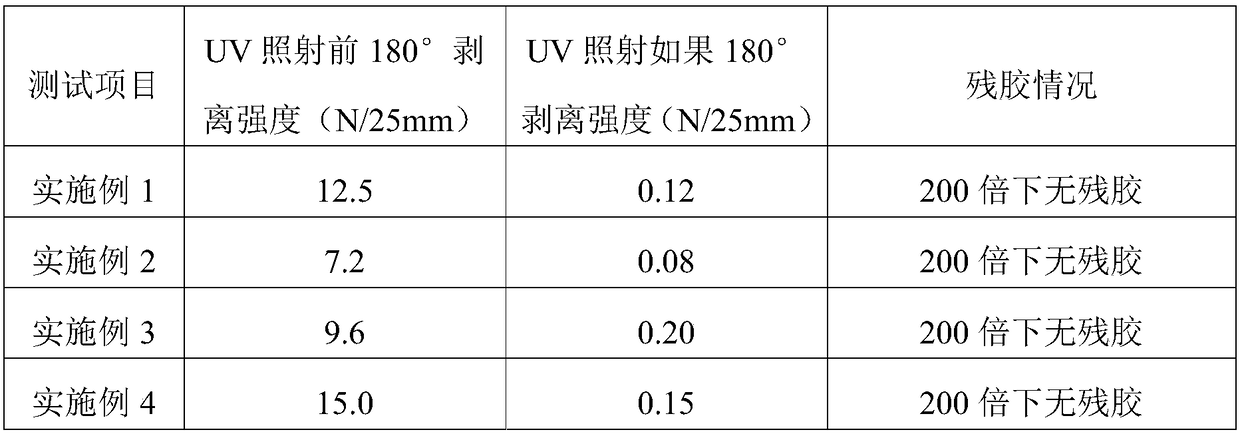

ActiveCN108864975AModerate peel strengthLow peel strengthNon-macromolecular adhesive additivesFilm/foil adhesivesAdhesiveChemistry

The invention provides an adhesive releasing method. The adhesive releasing method comprises the following steps of (A) sticking a UV (ultraviolet) visbreaking film to the surface requiring adhesive releasing; (B) radiating the UV visbreaking film by UV, and removing the UV visbreaking film, wherein the 180-degree releasing strength of the UV visbreaking film is 7 to 15N / 25mm before radiation by UV. The adhesive releasing method has the advantages that the residual adhesive at the surface of the adhered object can be efficiently and conveniently removed at lower risk, the adhesive releasing effect is good, and the residue rate of residual adhesive is low.

Owner:WEISHIDA SEMICON TECH ZHANGJIAGANG

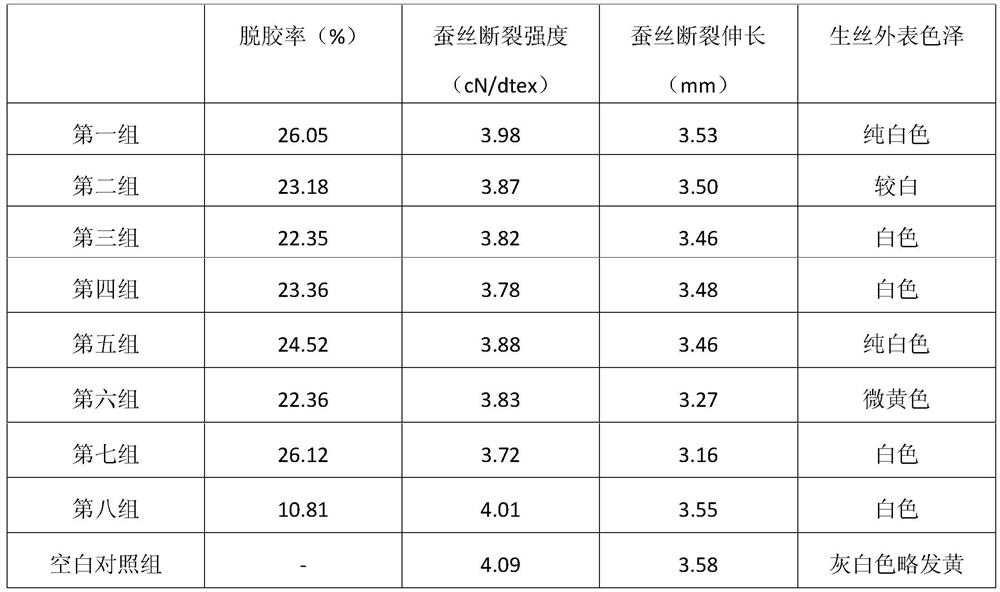

Preparation method of silk quilt

ActiveCN112401598AIncrease productivityExcellent and stable qualityBlanketBiochemical fibre treatmentAntibiosisEngineering

The invention relates to the technical field of home textiles, in particular to a preparation method of a silk quilt. The preparation method of the silk quilt comprises the following steps of (1) silkpreparation, (2) refining, (3) rinsing, (4) modification, (5) drying and (6) silk quilt preparation. The silk quilt prepared through the method is high in production efficiency, excellent and stablein quality, safe in operation process, easy and convenient to operate and capable of saving resources, compared with a traditional preparation process, the preparation process time is shortened, the production cost is reduced, the prepared silk is fragrant, pleasant, good in cotton bulkiness and tension and good in whiteness. Meanwhile, the health-care functions of antibiosis, mite prevention, insect prevention and the like are realized.

Owner:广西农投时宜农业科技有限公司 +2

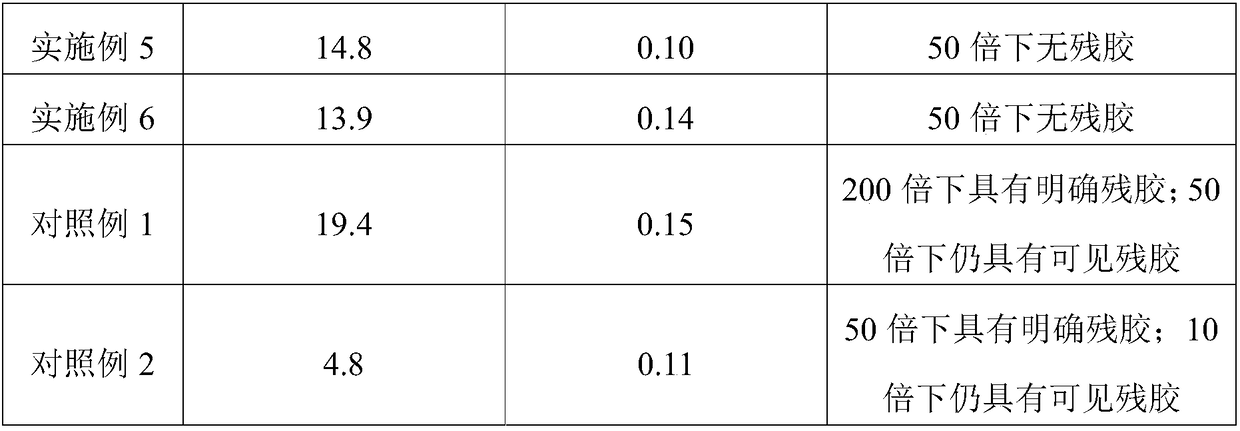

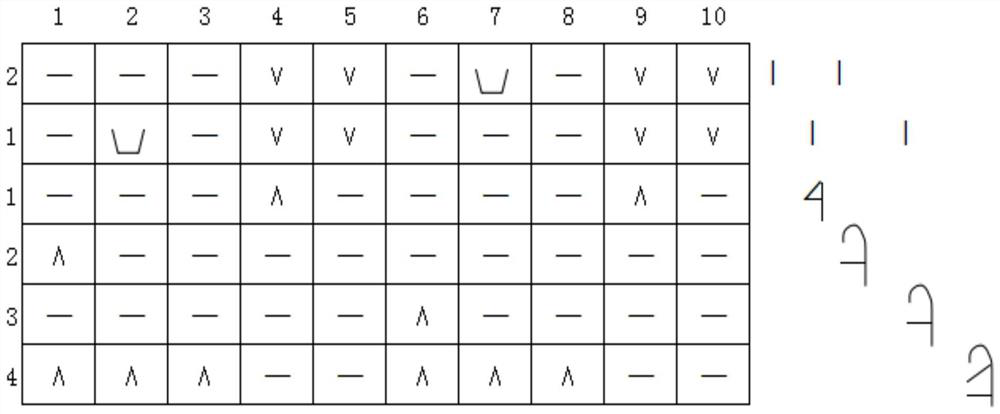

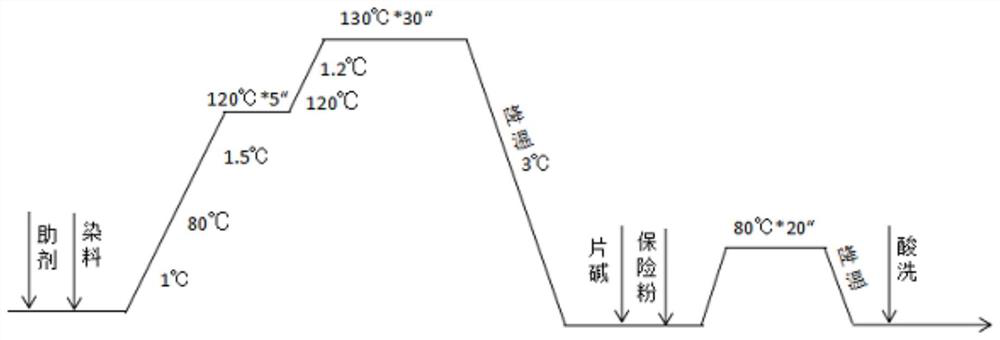

Multi-color network combination processing process for mulberry silk

ActiveCN108085816AUniform swellingAchieve partial degummingDe-gumming silkYarnAtmospheric pressureStrength loss

The invention discloses a multi-color network combination processing process for mulberry silk and belongs to the technical field of mulberry silk materials. The processing process includes: degumming, wherein the specification of the to-be-degummed mulberry silk is 23dtex raw mulberry silk f1*5 380twist / meterS, the degumming includes semi-degumming and biological enzyme processing which are performed on a cone dyeing machine, the components of the semi-degumming include a refining agent with the mass concentration being 2g / L and sodium carbonate with the mass concentration being 1g / L, the bath ratio is 1:18, semi-degumming temperature is 95 DEG C, and semi-degumming time is 30 minutes; the biological enzyme processing uses silk liquid protease with the activity being 16.0KNPU / g and the mass concentration being 4g / L, biological enzyme processing temperature is 45 DEG C, and biological enzyme processing time is 90 minutes; dyeing; spooling; performing network combination, wherein threeboiled-off mulberry silk of different colors are subjected to network combination on a network combination machine, processing speed is 800rpm, nozzle air pressure is 0.3MPa, network tension is 14CN,and the three-color network silk with 2 network nodes per centimeter and the specification being 23dtex boiled-off colored mulberry silk f1*5 380twist / meterS*3 is obtained after the network combination. By the processing process easy in processing, the obtained mulberry network silk is small in strength loss.

Owner:DALI SILK ZHEJIANG

Novel printable mobile phone rear cover inner explosion-proof membrane and preparation method thereof

ActiveCN113025227AImproves substrate adhesion propertiesImprove degumming problemNon-macromolecular adhesive additivesEster polymer adhesivesUltraviolet lightsUv absorber

The invention discloses a novel printable mobile phone rear cover inner explosion-proof film which sequentially comprises a PE protective film layer, a printable layer, a PET base material layer, an optical adhesive layer and a release film layer from bottom to top; the optical adhesive layer contains an epoxy curing agent, an ultraviolet absorber and a coupling agent; the ultraviolet light absorber is selected from one or more of an ultraviolet light absorber UV-P, an ultraviolet light absorber UV-234, an ultraviolet light absorber UV-329 and an ultraviolet light absorber UV-531, and the coupling agent is selected from one or more of a silane coupling agent KH-550, a silane coupling agent KH-560, a silane coupling agent KH-570 and a silane coupling agent KH-580. The explosion-proof film has high peel strength to mobile phone rear cover glass, the peel strength can reach 2000 gf / in or above, the explosion-proof film still has stable peel strength under the environments of high temperature, low temperature, 65 / 95, salt mist, QUV and the like, and no adhesive residue phenomenon is generated; the silane coupling agent is added into the optical adhesive layer, so that the base material adhesive force performance of the optical adhesive is greatly improved, and the degumming problem of the explosion-proof membrane is solved.

Owner:浙江日久新材料科技有限公司

Clean and environment-friendly flax degumming method

InactiveCN110983449AFast degummingImprove degumming problemMechanical fibre separationFibre treatment to obtain bast fibreWastewaterProcess engineering

The invention discloses a clean and environment-friendly flax degumming method. The method comprises the following steps of: 1, pretreating flax raw stems; 2, carrying out water bath soaking; 3, carrying out hemicellulase soaking; 4, carrying out water bath soaking again; and 5, carrying out mixed enzyme liquid retting and degumming. Generated wastewater is little, the smell is light, and the pollution to the surrounding environment is little.

Owner:沈金标

Preparation technique of sisal fiber

InactiveCN106868605AHigh degumming rateLow residual glue rateVegetable materialMechanical fibre separationCorona dischargeSisal fiber

The invention belongs to the technical field of textile processing, and particularly relates to a preparation technique of a sisal fiber. The degumming technique comprises the following steps: pretreatment, corona discharge treatment, ultrasonic oscillation, degradation by bacteria, impurity removal, secondary ultrasonic treatment, water washing, pressing, oil supply, forming and drying. By performing the corona discharge treatment, ultrasonic treatment, degradation by bacteria and secondary ultrasonic treatment on the sisal fiber, the degumming technique of sisal has better effects than the traditional single chemical degumming process or mechanical degumming process, has the advantages of lower gum residue rate and lower lignin content, and satisfies the sisal deep processing technique demands. In addition, no chemical reagent is adopted expect the acetic acid and a small amount of sodium hydroxide, so the polluted wastewater discharge is low, and thus, the technique is a green environment-friendly technological process.

Owner:GUANGXI XIUMEI ZHUANGXIANG ENERGY ENVIRONMENTAL PROTECTION CO LTD

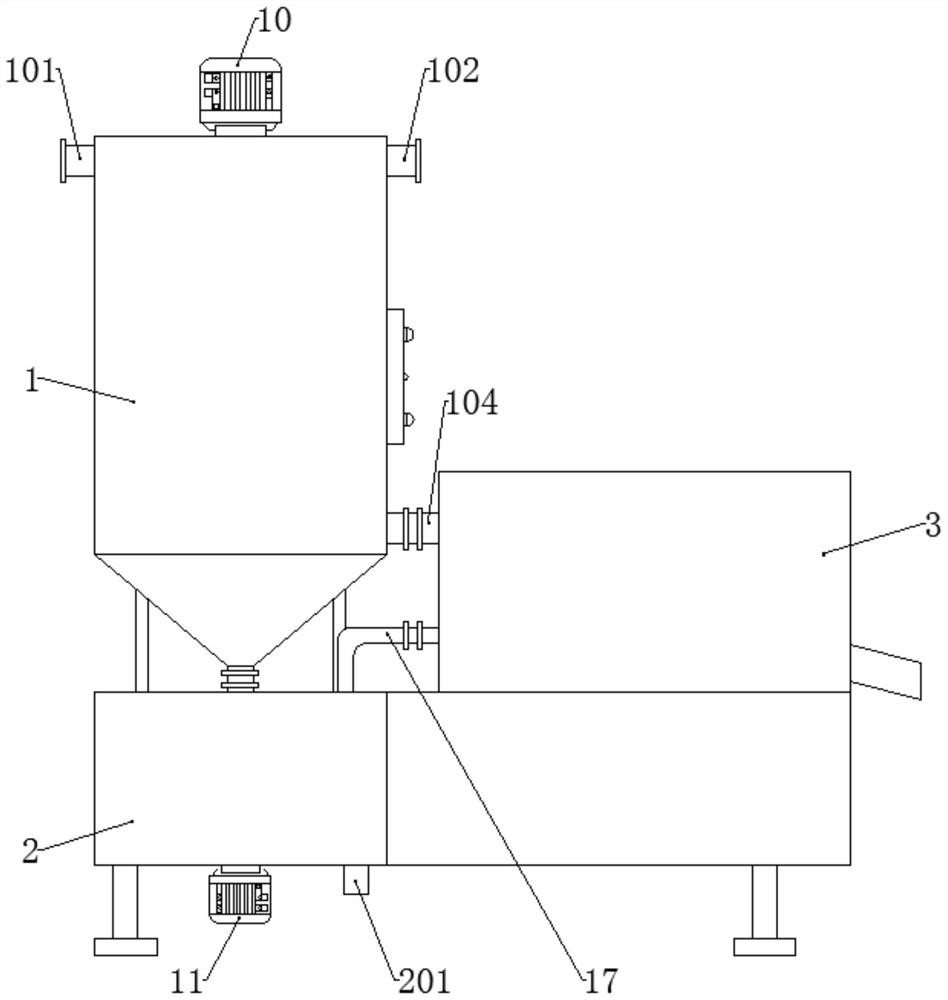

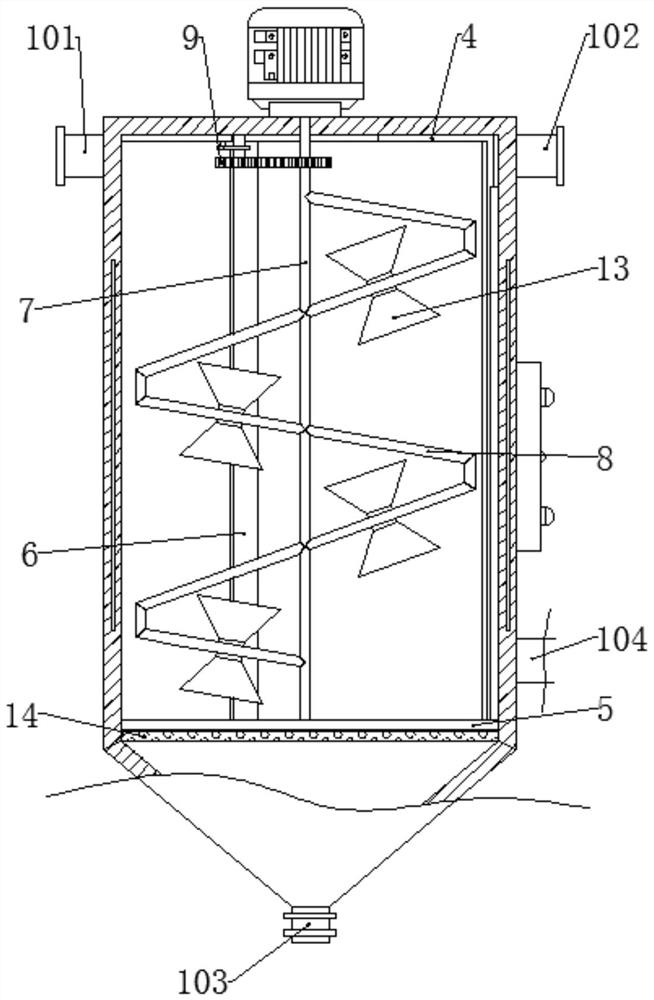

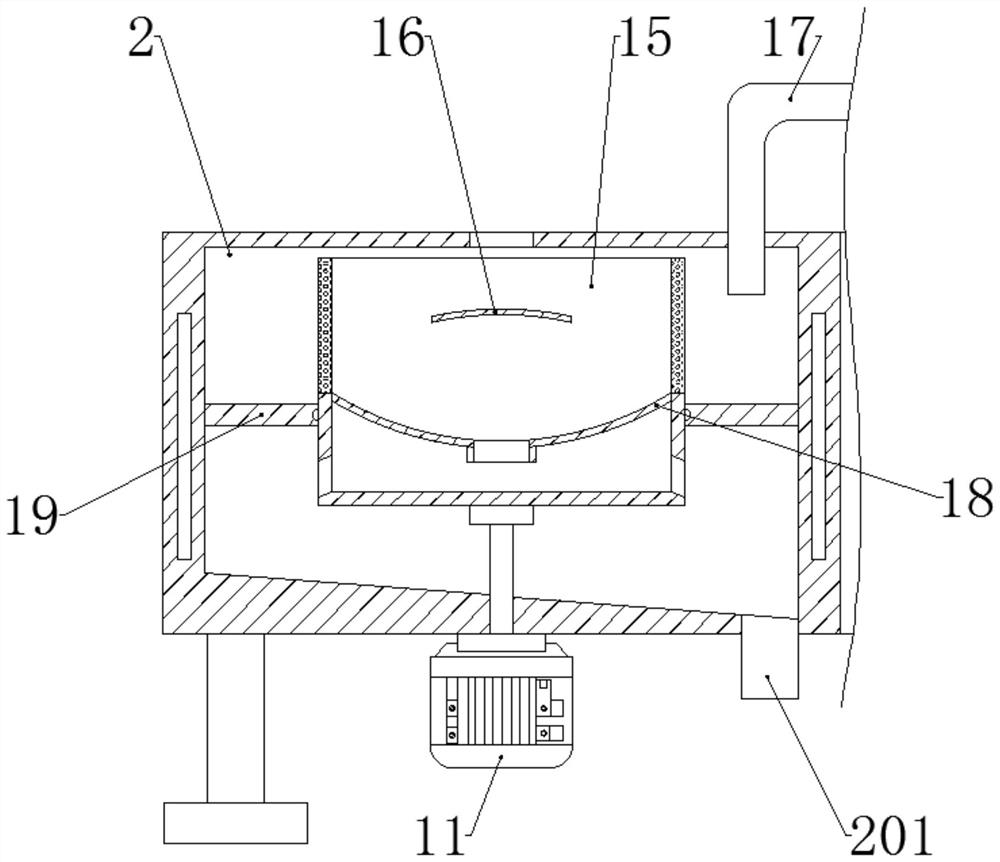

Tea oil production equipment and processing technology

The tea oil production equipment comprises a hydration tank main body, an oil foot box and a vacuum drying tank, an oil inlet pipe and an ingredient inlet pipe are arranged at the top of the hydration tank main body, a filter plate is installed on the lower portion in the hydration tank main body, and the interior of the hydration tank main body is divided into a stirring area and a settling area by the filter plate; a stirring device and a rotary drum are installed in the stirring area, the stirring device is located in the rotary drum, the portion, at the bottom of the stirring area, of the hydration tank body is connected with the vacuum drying tank through an oil outlet pipe, an annular partition plate is fixed in the foots box, and a centrifugal barrel is rotatably installed in the middle of the annular partition plate; the interior of the oil foot box is divided into a top oil cavity and a bottom oil foot cavity by the annular partition plate. The degumming and impurity-removing device has the advantage of good degumming and impurity-removing effects, and can be used for fully separating oil foots.

Owner:安徽山里郎生态农业股份有限公司

Environment-friendly novel hemp fiber degumming technology

PendingCN114381810AFully moistenedImprove solubilityFibre treatment to obtain bast fibreEngineeringAqueous solubility

The invention discloses an environment-friendly novel hemp fiber degumming technology, and relates to the technical field of textile processing. When the hemp fiber degumming technology is carried out, firstly, the hemp fibers are subjected to ultrasonic pretreatment, and then sulfydryl chitosan treatment, irradiation treatment and steam explosion compound enzyme treatment are carried out; colloid is crushed through ultrasonic pretreatment, part of water-soluble impurities are removed, degumming is facilitated, sulfydryl chitosan and calcium ions in calcium pectate are chelated to generate soluble ammonium salt, and the solubility of pectin is increased; a gelatinous layer on the surface of the fiber is damaged through irradiation, and tiny cracks are generated on the surface; the steam flash explosion compound enzyme treatment overcomes the defect of long time consumption of enzyme degumming treatment, so that the colloid in the hemp fibers is completely separated, and the degumming rate is increased.

Owner:TUNGGA LINENANDCOTTON CO LTD

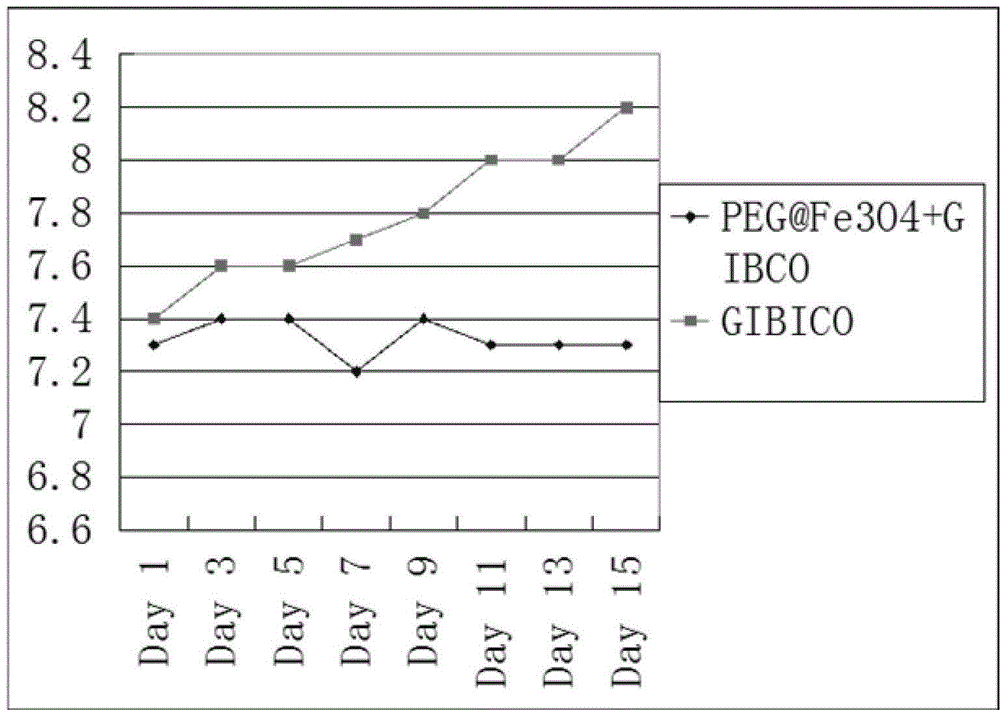

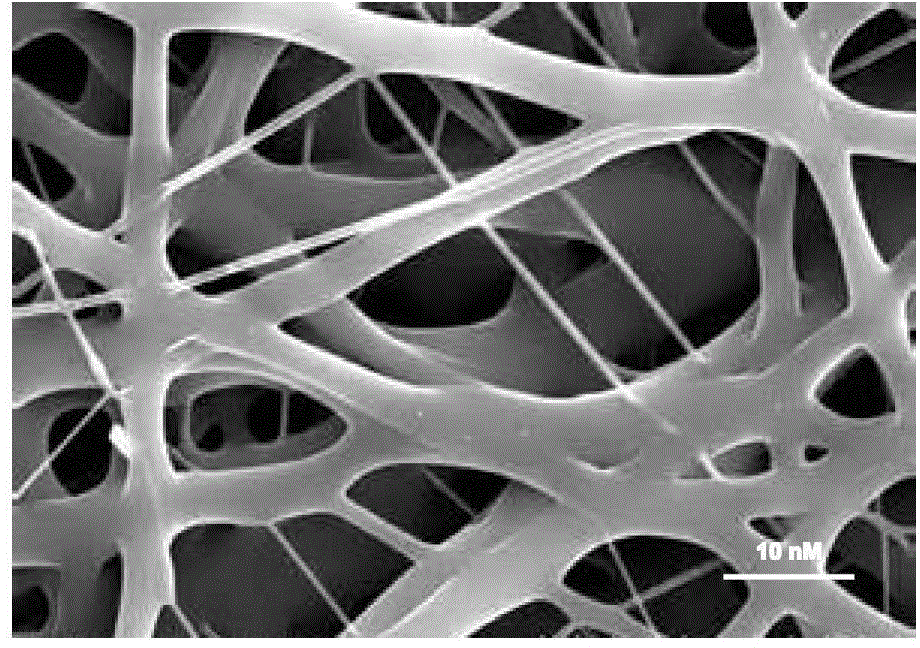

3D (three-dimensional) cell culture material and application thereof

ActiveCN104818252AConducive to rapid growthPromote growth and developmentSkeletal/connective tissue cellsTumor/cancer cellsBiophysicsPolyethylene glycol

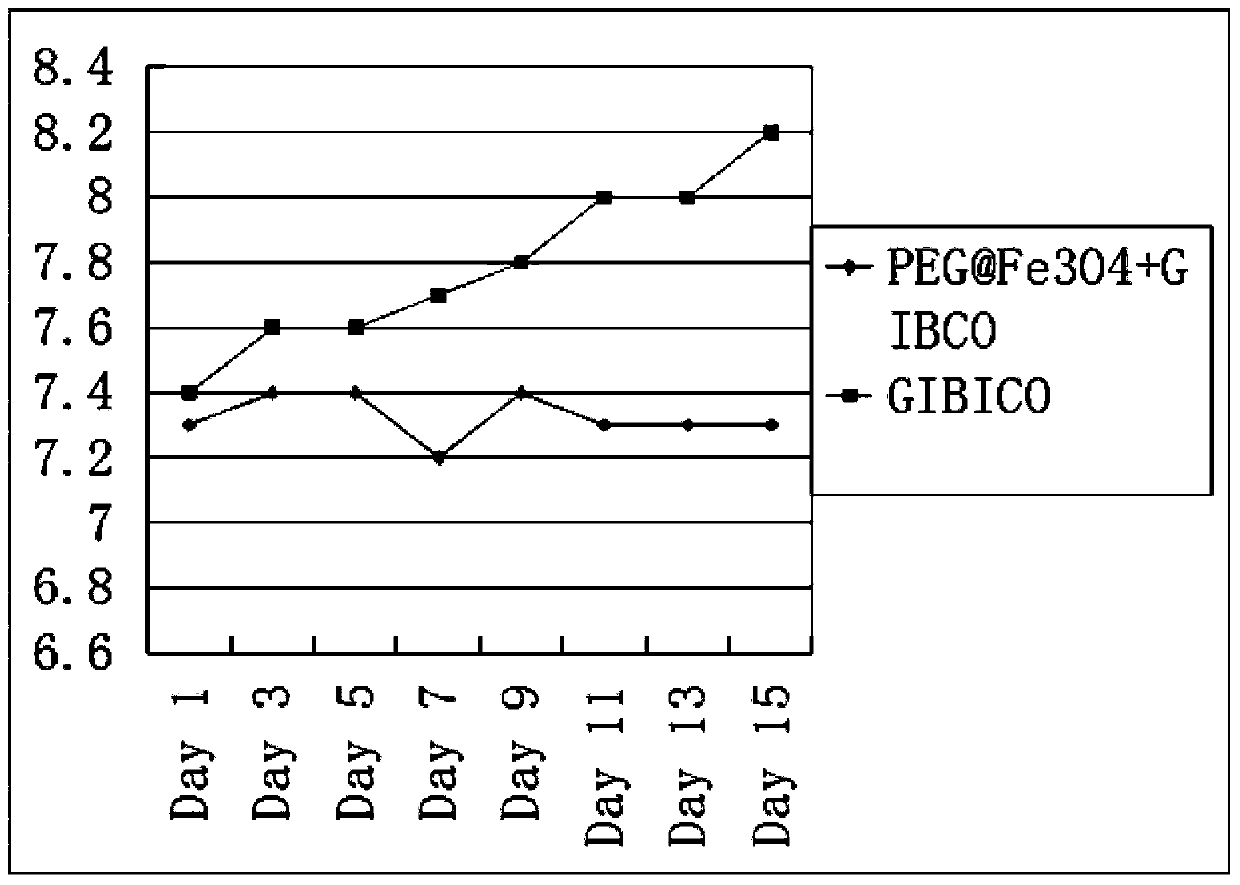

The invention discloses a 3D (three-dimensional) cell culture material and application thereof. The 3D cell culture material comprises PEG (polyethylene glycol) 8000@Fe<3>O<4>, PEG400@Fe<3>O<4> and NH2@Fe<3>O<4>. The 3D cell culture material and the application have the advantages that the pH (potential of hydrogen) of micro-environments and the activity and the concentration of cell factors can be kept by the 3D cell culture material for a long time, and accordingly the 3D cell culture material is favorable for fast growing and proliferating cells and maintaining the activity of the cells; the cell factors can be conveniently and easily fixed by the aid of nano-particles NH2@Fe<3>O<4> in the 3D cell culture material, and proteins of the cell factors can be combined with external residues of micelle by the aid of hydrogen bonds under the condition of low-concentration glutaraldehyde; the problem of low culture efficiency due to dissociation of proteins in water bases can be solved; excellent suppression and culture effects for tumor cells and stem cell differentiation can be realized by the 3D cell culture material; culture requirements of different primary mammal cells can be met.

Owner:GUANGZHOU SAGENE BIOTECH

Production process for linen bamboo fibers, spinnable linen bamboo fibers and bamboo fiber yarns

ActiveCN102242403BQuality improvementHigh strengthVegetable materialMechanical fibre separationYarnFiber

The invention relates to a production process for linen bamboo fibers, spinnable linen bamboo fibers and bamboo fiber yarns. The production process comprises the following steps: sawing a fresh bamboo into pieces according to a certain length and then respectively soaking the pieces in different biologic softening solutions or cooking the pieces in specially prepared softening solutions at high temperature; after cleaning the pieces, heating and airing the pieces, and then feeding the pieces into a bamboo mechanical splitting system, thereby preparing the linen bamboo fibers; processing the linen bamboo fibers into strip-shaped bamboo fiber spindles; putting the strip-shaped bamboo fiber spindles into an intelligent steam cooker in turn, thereby degumming, bleaching and cleaning the strip-shaped bamboo fiber spindles; after drying the strip-shaped bamboo fiber spindles, opening and removing impurities, thereby acquiring the spinnable linen bamboo fibers; and sending the spinnable linen bamboo fibers into a yarn-forming integrated system, and performing the processes of opening, cotton-blending, carding, drawing and yarn-forming, thereby finally acquiring the bamboo fiber yarns. The bamboo fibers prepared by using the production process are linen, longer, thinner, more uniform and softer. The average fineness of the bamboo fibers can reach 400-600 metric counts. The bamboo fibers can be purely spun or fully blended with fibers such as cotton, linen, and the like.

Owner:ZHEJIANG FORESTRY UNIVERSITY +1

A kind of 3D cell culture material and its application

ActiveCN104818252BInhibition of differentiationKeep aliveSkeletal/connective tissue cellsTumor/cancer cells3D cell culturePolyethylene glycol

The invention discloses a 3D (three-dimensional) cell culture material and application thereof. The 3D cell culture material comprises PEG (polyethylene glycol) 8000@Fe<3>O<4>, PEG400@Fe<3>O<4> and NH2@Fe<3>O<4>. The 3D cell culture material and the application have the advantages that the pH (potential of hydrogen) of micro-environments and the activity and the concentration of cell factors can be kept by the 3D cell culture material for a long time, and accordingly the 3D cell culture material is favorable for fast growing and proliferating cells and maintaining the activity of the cells; the cell factors can be conveniently and easily fixed by the aid of nano-particles NH2@Fe<3>O<4> in the 3D cell culture material, and proteins of the cell factors can be combined with external residues of micelle by the aid of hydrogen bonds under the condition of low-concentration glutaraldehyde; the problem of low culture efficiency due to dissociation of proteins in water bases can be solved; excellent suppression and culture effects for tumor cells and stem cell differentiation can be realized by the 3D cell culture material; culture requirements of different primary mammal cells can be met.

Owner:GUANGZHOU SAGENE BIOTECH

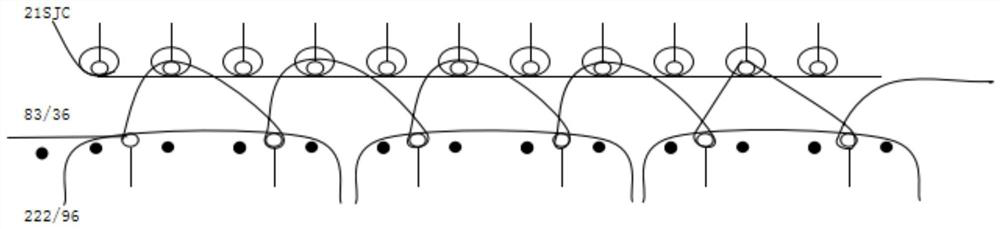

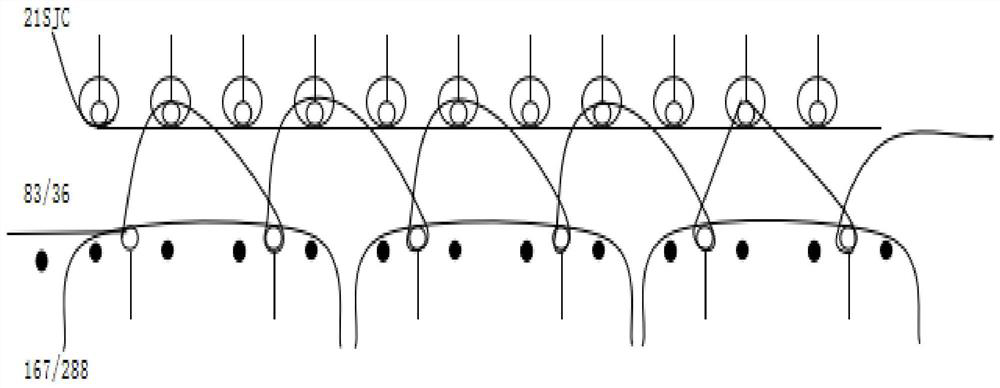

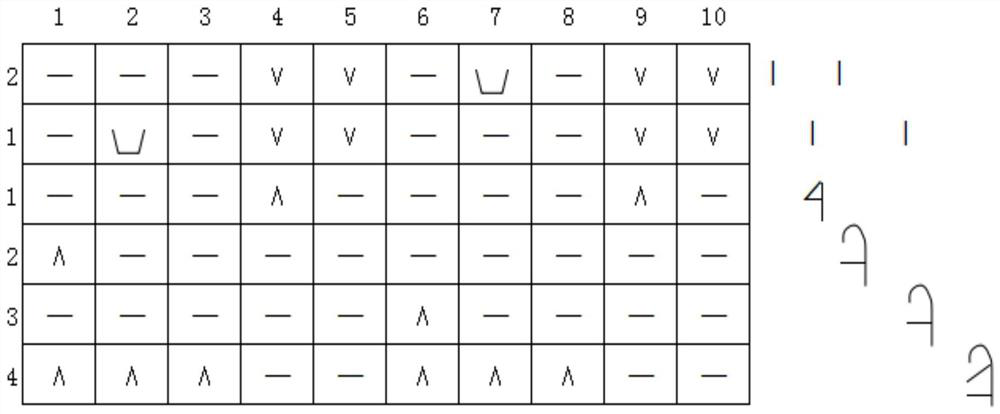

Leather and fur integrated cloth and production process

ActiveCN112593336ASoft touchShorten manufacturing cycle timeWeft knittingHeating/cooling textile fabricsEngineeringProcess engineering

The invention belongs to the field of design and production processes of knitted weft-knitted fabrics, and particularly relates to leather and fur integrated cloth and a production process. The leather and fur integrated cloth is made of a weft-knitted double-faced machine structure, 222dtex / 96F polyester filament yarn is adopted on the front face of the leather and fur integrated cloth, 21SJC isadopted on the back face of the leather and fur integrated cloth, and 83dtex / 36F polyester filament yarn is adopted as a middle connecting yarn. The weft-knitted double-faced cloth structure is adopted, stress on the two faces of loops is balanced, the structure is stable, the cloth cover is smoother, the hand feeling is soft, and breathability and water absorption are better; and the fabric has various characteristics of a composite fabric, the defects that the composite fabric is hard in hand feeling, prone to degumming and bubbling and not environmentally friendly are overcome, the fabric manufacturing and production period is shortened, and the production cost is reduced.

Owner:JIANGSU XINKAISHENG ENTERPRISE DEV +2

Refining liquid for silk grey cloth

InactiveCN111005212AShort refining timeImprove degumming problemFibre treatmentSodium dithionitePhosphate

The invention discloses a refining liquid for silk grey cloth. The refining liquid is composed of the following components in parts by mass of 3 parts of sodium carbonate, 12 parts of sodium silicate,15 parts of fatty acid polyoxyethylene ester, 25 parts of sodium carbonate, 8 parts of sodium dithionite, 5 parts of octyl phosphate, 5 parts of sodium hydrosulfite, 4 parts of dimethyl silicone oil,3 parts of penetrant, 1 part of orange oil and 150 parts of ionic water. The refining liquid for the silk grey cloth is convenient to refine and favorable for following-process dyeing.

Owner:ZHEJIANG TONGHUI TEXTILE

A kind of preparation method of silk quilt

ActiveCN112401598BIncrease productivityExcellent and stable qualityBiochemical fibre treatmentBlanketPolymer scienceEngineering

The invention relates to the technical field of home textiles, in particular to a method for preparing a silk quilt. The preparation method of the silk quilt of the present invention comprises the following steps: (1) preparation of silk, (2) refining, (3) rinsing, (4) modification, (5) drying and (6) preparation of silk quilt. The silk quilt prepared by the method of the present invention has high production efficiency, excellent and stable quality, safe operation process, easy operation, and resource saving. Compared with the traditional preparation process, the preparation process time is shortened and the production cost is reduced. Silk has a pleasant fragrance, good bulkiness and tension, and good whiteness. It also has health functions such as antibacterial, anti-mite, and insect-proof.

Owner:广西农投时宜农业科技有限公司 +2

a degumming method

ActiveCN108864975BModerate peel strengthLow peel strengthNon-macromolecular adhesive additivesFilm/foil adhesivesPolymer scienceAdhesive

The invention provides an adhesive releasing method. The adhesive releasing method comprises the following steps of (A) sticking a UV (ultraviolet) visbreaking film to the surface requiring adhesive releasing; (B) radiating the UV visbreaking film by UV, and removing the UV visbreaking film, wherein the 180-degree releasing strength of the UV visbreaking film is 7 to 15N / 25mm before radiation by UV. The adhesive releasing method has the advantages that the residual adhesive at the surface of the adhered object can be efficiently and conveniently removed at lower risk, the adhesive releasing effect is good, and the residue rate of residual adhesive is low.

Owner:WEISHIDA SEMICON TECH ZHANGJIAGANG

Tool facilitating ink box chip removal

The invention relates to the technical field of ink boxes, in particular to a tool facilitating ink box chip removal. The tool is characterized by comprising a first metal sheet and a second metal sheet; one end of the first metal sheet is inwards bent to form a hook-shaped shovel piece, the other end of the first metal sheet is connected with one end of the second metal sheet through a connecting piece, and the relative distance is formed between the other end of the first metal sheet and one end of the second metal sheet; and when the first metal sheet and the second metal sheet are compressed, the other end of the second metal sheet makes contact with the free end of the shovel piece in a connection manner. Compared with the prior art, the shovel piece can stretch in from the attached edge of a chip and clamp the chip for tearing, the shovel piece can be further heated, adhesion glue of the chip can be conveniently removed through the heat degree, and separating and tearing are easier.

Owner:上海浩叠电子科技有限公司

Multi-color grid-connected processing technology of mulberry silk

ActiveCN108085816BUniform swellingAchieve partial degummingDe-gumming silkYarnPolymer scienceBiology

The invention discloses a multi-color network combination processing process for mulberry silk and belongs to the technical field of mulberry silk materials. The processing process includes: degumming, wherein the specification of the to-be-degummed mulberry silk is 23dtex raw mulberry silk f1*5 380twist / meterS, the degumming includes semi-degumming and biological enzyme processing which are performed on a cone dyeing machine, the components of the semi-degumming include a refining agent with the mass concentration being 2g / L and sodium carbonate with the mass concentration being 1g / L, the bath ratio is 1:18, semi-degumming temperature is 95 DEG C, and semi-degumming time is 30 minutes; the biological enzyme processing uses silk liquid protease with the activity being 16.0KNPU / g and the mass concentration being 4g / L, biological enzyme processing temperature is 45 DEG C, and biological enzyme processing time is 90 minutes; dyeing; spooling; performing network combination, wherein threeboiled-off mulberry silk of different colors are subjected to network combination on a network combination machine, processing speed is 800rpm, nozzle air pressure is 0.3MPa, network tension is 14CN,and the three-color network silk with 2 network nodes per centimeter and the specification being 23dtex boiled-off colored mulberry silk f1*5 380twist / meterS*3 is obtained after the network combination. By the processing process easy in processing, the obtained mulberry network silk is small in strength loss.

Owner:DALI SILK ZHEJIANG

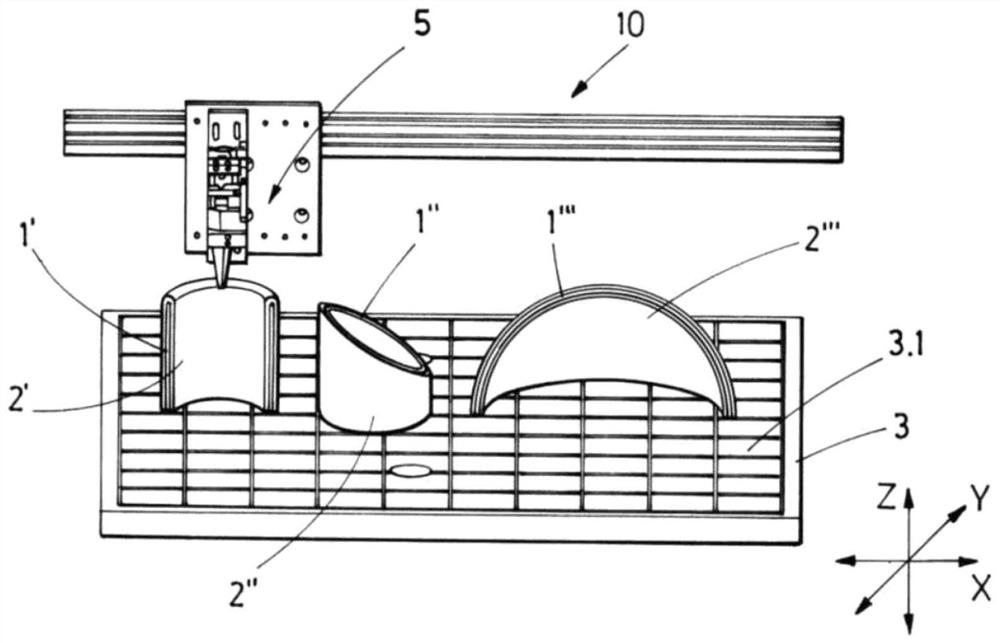

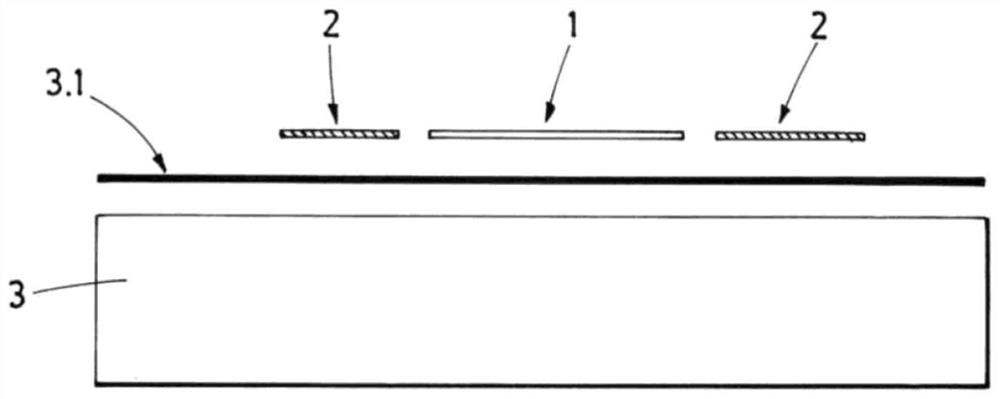

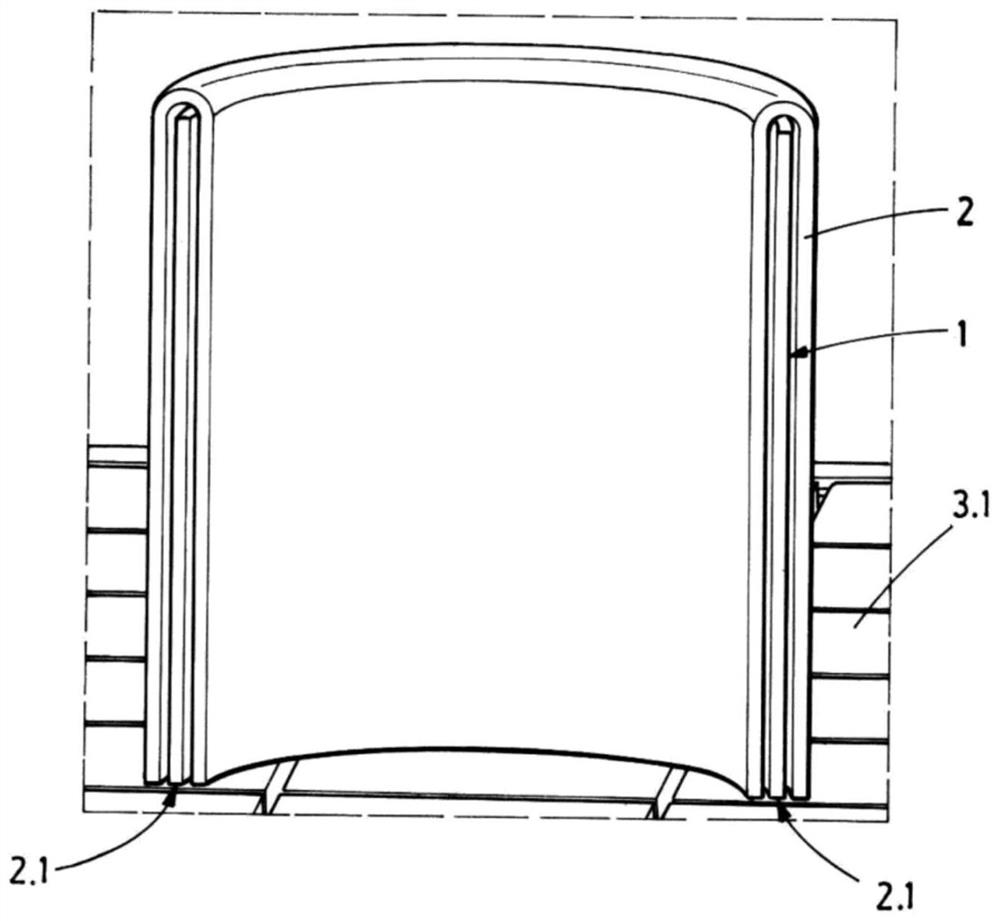

Method for manufacturing part layer-upon-layer using additive manufacturing technology and pressing system

PendingCN113370520AImprove structural performanceEasy to enter waterManufacturing platforms/substratesManufacturing heating elementsElastomerManufacturing technology

The invention relates to a method for manufacturing a part layer-upon-layer using an additive manufacturing technology. The method comprises the following steps: printing the part together with an elastomeric enclosure shaped thereto leaving a gap free of material therebetween, the elastomeric enclosure comprising at least one opening; heating the ensemble of the printed part and elastomeric enclosure or keeping an operating printing temperature; applying vacuum by the at least one opening of the elastomeric enclosure so that the elastomeric enclosure deflates thus exerting pressure to the printed part; and maintaining the printed part under vacuum and heat during a predefined time. The invention also relates to a pressing system for printed parts manufactured layer by layer using additive manufacturing techniques.

Owner:AIRBUS OPERATIONS SL

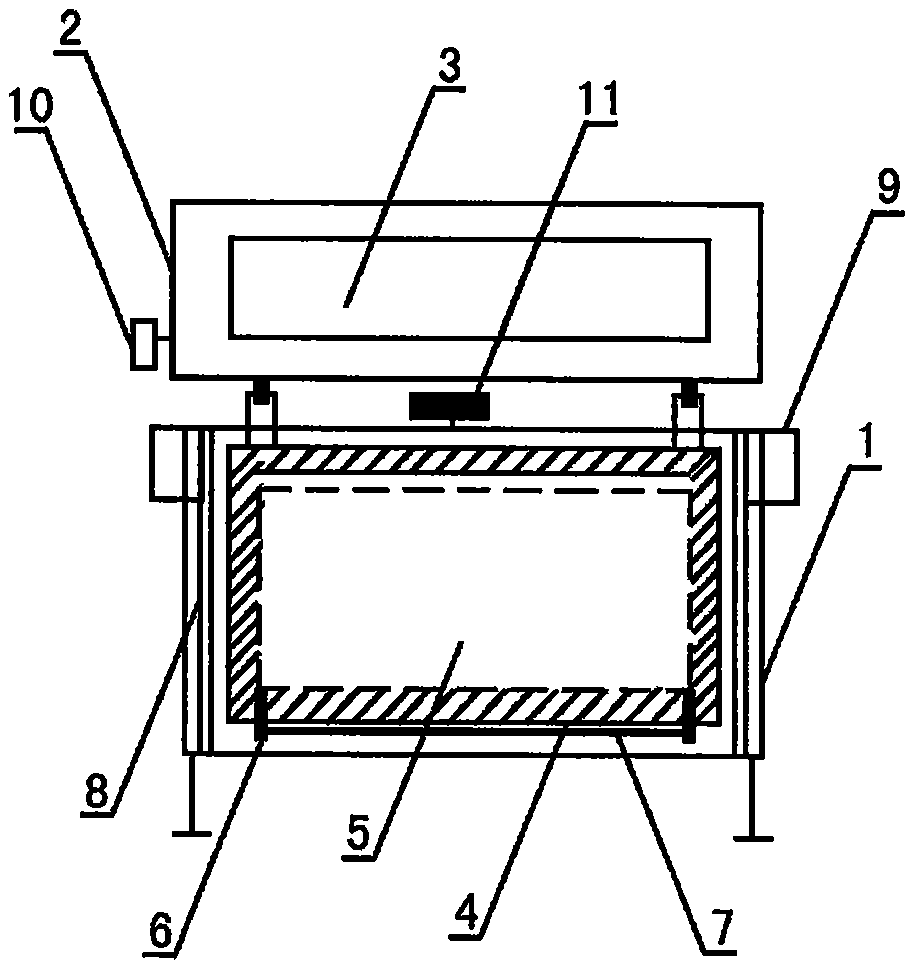

Paper surface degumming device capable of being separated wholly

InactiveCN107193307ASimple structure designDegummed completeSimultaneous control of multiple variablesEconomic benefitsThermostat

The paper surface degumming device that can be separated as a whole includes a body (1), a cover device (2) is arranged on the upper part of the body (1), and a heating sheet (3) is arranged on the inner surface, and the cover body is connected with the degumming structure including a temperature control base (4), the storage area (5), the positioning slider (6), the rail shifting device (7), the humidification component (8) is located on both sides of the body (1) and connected with the corresponding water storage device (9) respectively. The required degumming paper surface is positioned and processed, and the corresponding temperature is adjusted according to the temperature characteristics of the latex before the overall detachment is carried out; a prompting device (10) is provided on the left side of the cover device (2); multiple temperature and humidity sensing modules are distributed in the body (1), Set the corresponding code to transmit the detection data to the central control device (11); the appearance structure design is simple, and the intelligent temperature adjustment operation can be carried out according to the characteristics of the unused colloid to ensure the complete degumming and provide convenience for rework. economic benefits.

Owner:XINCHANG YULIN STREET DONGCHEN MACHINERY FACTORY

Double face leather cloth and production process thereof

ActiveCN112626689ASoft touchShorten manufacturing cycle timeWeft knittingHeating/cooling textile fabricsPolymer scienceEngineering

The invention belongs to the field of design and production processes of knitted weft-knitted fabric, and particularly relates to double face leather cloth and a production process thereof. The double face leather cloth is made of a weft knitting double-faced structure, wherein the front face of the double face leather cloth adopts 167 dtex / 288F polyester filament yarn, the back face adopts 21SJC, and connecting yarn adopts 83 dtex / 36F. According to the cloth, the weft knitting double-faced cloth structure is adopted, stress on the two faces of the loops is balanced, the structure is stable, the cloth cover is smoother, the hand feeling is soft, breathability and water absorption are better, the cloth has various characteristics of composite cloth, the defects that the composite cloth is hard in hand feeling, prone to degumming and bubbling and not environmentally friendly are overcome, the cloth manufacturing and production period is shortened, and the production cost is reduced.

Owner:JIANGSU XINKAISHENG ENTERPRISE DEV +2

Degumming method of fabric

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com