Specific acidic plastic plate for photovoltaic diamond wire cutting and preparation method thereof

A photovoltaic diamond and wire cutting technology, which is applied in the field of plastic plate preparation, can solve the problems of sticking rigid wires, inconvenient recycling of silicon materials and backing plates, and easy occurrence of clogged filter bags, so as to prevent air bubbles and static electricity, facilitate cutting and silicon materials Effects of recycling and cost reduction of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

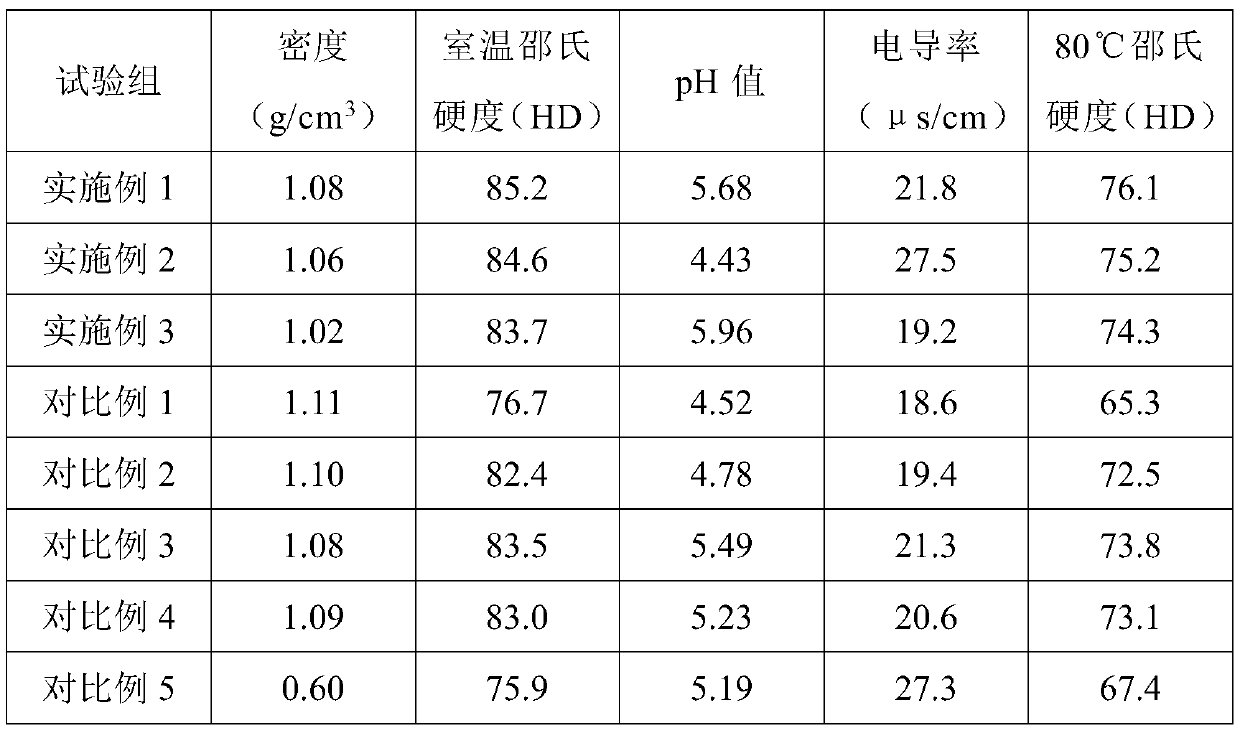

Examples

Embodiment approach

[0036] 1. Experimental equipment

[0037] Mixer (with adjustable speed stirring device), twin-screw extrusion granulator (with automatic temperature control device, cooling device, vacuum device), dryer (with adjustable speed stirring device, automatic Temperature control device, cooling device), single screw extrusion molding machine (with automatic temperature control device, cooling device, vacuum device).

[0038] 2. Preparation before the experiment

[0039] Clean the mixer, twin-screw extrusion granulation, dryer, and single-screw extruder to ensure that there are no other materials or impurities that affect the reaction.

[0040] 3. Preparation formula of specific photovoltaic diamond wire cutting acidic plastic board: in mass percentage, including ABS resin 72.3-87.4%, PMMA resin 5.615.9%, EAA resin 2.9-5.6%, compatibilizer 2-4%, Organic acid 0.5-0.8%, antioxidant 0.2-0.8%, inorganic filler 0.5-5%, surfactant 0.2-0.6%;

[0041] The compatibilizer includes MBS resin;

[0042] Th...

Embodiment 1

[0052] 1. Experimental equipment

[0053] Mixer (with adjustable speed stirring device), twin-screw extrusion granulator (with automatic temperature control device, cooling device, vacuum device), dryer (with adjustable speed stirring device, automatic Temperature control device, cooling device), single screw extrusion molding machine (with automatic temperature control device, cooling device, vacuum device).

[0054] 2. Preparation before the experiment

[0055] Clean the mixer, twin-screw extrusion granulation, dryer, and single-screw extruder to ensure that there are no other materials or impurities that affect the reaction.

[0056] 3. Preparation formula of specific photovoltaic diamond wire cutting acidic plastic board: in mass percentage, including ABS resin 81.8%, PMMA resin 6.3%, compatibilizer 2%, EAA resin 5.6%, organic acid 0.8%, antioxidant 0.6%, inorganic filler 2.3%, surfactant 0.6%;

[0057] The compatibilizer is MBS resin;

[0058] The organic acid is phthalic acid;

[...

Embodiment 2

[0067] 1. Experimental equipment

[0068] Mixer (with adjustable speed stirring device), twin-screw extrusion granulator (with automatic temperature control device, cooling device, vacuum device), dryer (with adjustable speed stirring device, automatic Temperature control device, cooling device), single screw extrusion molding machine (with automatic temperature control device, cooling device, vacuum device).

[0069] 2. Preparation before the experiment

[0070] Clean the mixer, twin-screw extrusion granulation, dryer, and single-screw extruder to ensure that there are no other materials or impurities that affect the reaction.

[0071] 3. Preparation formula of specific photovoltaic diamond wire cutting acidic plastic board: in mass percentage, including ABS resin 72.3%, PMMA resin 15.9%, compatibilizer 2.8%, EAA resin 4.3%, organic acid 0.6%, antioxidant 0.5%, 3.2% inorganic filler, 0.4% surfactant;

[0072] The compatibilizer is MBS resin;

[0073] The organic acid is succinic acid;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com