Preparation method of silk quilt

A silk quilt and silk technology, which is applied in the field of home textiles, can solve the problems of unsatisfactory indicators such as silk cotton bulkiness and tension, luster, color, feel, texture, etc., and achieve excellent and stable quality, shortened preparation process time, Effect of improving sleep quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

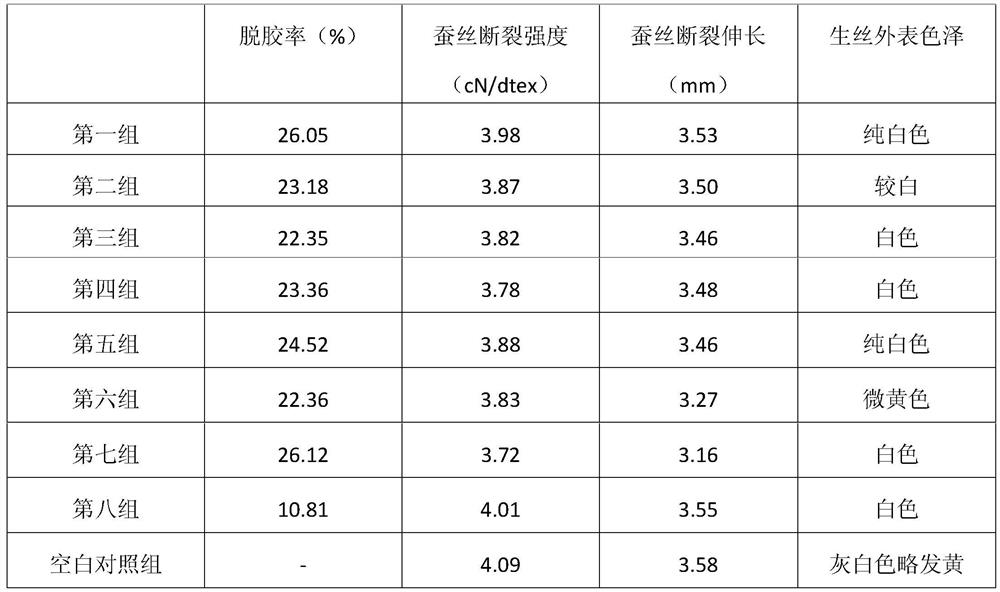

Examples

Embodiment 1

[0030] The present embodiment provides a kind of preparation method of silk quilt, and this preparation method comprises the following steps:

[0031](1) Preparation of silk: place the 5th instar silkworm on a flat silk spinning bed, and after the silk is exhausted, remove the silkworm, remove impurities, and obtain silk for subsequent use; the feeding density of silkworms is: put in per square meter of flat silk spinning bed Silkworm 3kg. In addition, after the silkworms are placed on the flat spinning bed, uniform scattered light is kept in the spinning room to promote the even distribution of silkworms on the flat spinning bed. Low-light shrimp spins quietly;

[0032] (2) Refining: dry the silk obtained in step (1), then immerse the dried silk in deionized water with a bath ratio of 1:55, and then carry out water degumming treatment for 25 minutes under high temperature and high pressure conditions; wherein, drying The treatment is to dry at 50°C for 20 minutes, and then ...

Embodiment 2

[0038] The present embodiment provides a kind of preparation method of silk quilt, and this preparation method comprises the following steps:

[0039] (1) Preparation of silk: place the 5th instar silkworm on a flat silk spinning bed, and after the silk is exhausted, remove the silkworm, remove impurities, and obtain silk for subsequent use; the feeding density of silkworms is: put in per square meter of flat silk spinning bed Silkworm 3kg. In addition, after the silkworms are placed on the flat spinning bed, uniform scattered light is kept in the spinning room to promote the even distribution of silkworms on the flat spinning bed. Low-light shrimp spins quietly;

[0040] (2) Refining: dry the silk obtained in step (1), then immerse the dried silk in deionized water with a bath ratio of 1:55, and then carry out water degumming treatment under high temperature and high pressure for 27 minutes; The treatment is to dry at 55°C for 25 minutes, and then dry at 65-68°C for 37 minu...

Embodiment 3

[0046] The present embodiment provides a kind of preparation method of silk quilt, and this preparation method comprises the following steps:

[0047] (1) Preparation of silk: place the 5th instar silkworm on a flat silk spinning bed, and after the silk is exhausted, remove the silkworm, remove impurities, and obtain silk for subsequent use; the feeding density of silkworms is: put in per square meter of flat silk spinning bed Silkworm 3kg. In addition, after the silkworms are placed on the flat spinning bed, uniform scattered light is kept in the spinning room to promote the even distribution of silkworms on the flat spinning bed. Low-light shrimp spins quietly;

[0048] (2) Refining: dry the silk obtained in step (1), then immerse the dried silk in deionized water with a bath ratio of 1:55, and then carry out water degumming treatment for 30 minutes under high temperature and high pressure conditions; wherein, drying The treatment is to dry at 60°C for 30 minutes, and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com