Patents

Literature

86results about How to "Shorten manufacturing process time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

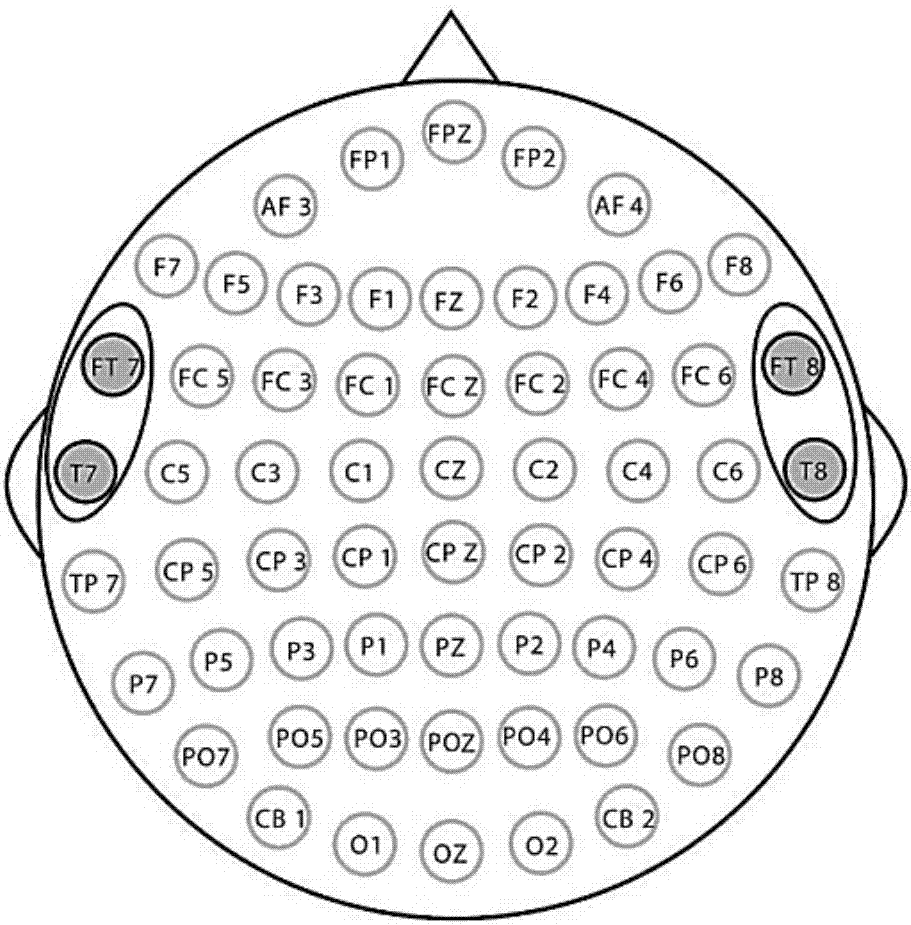

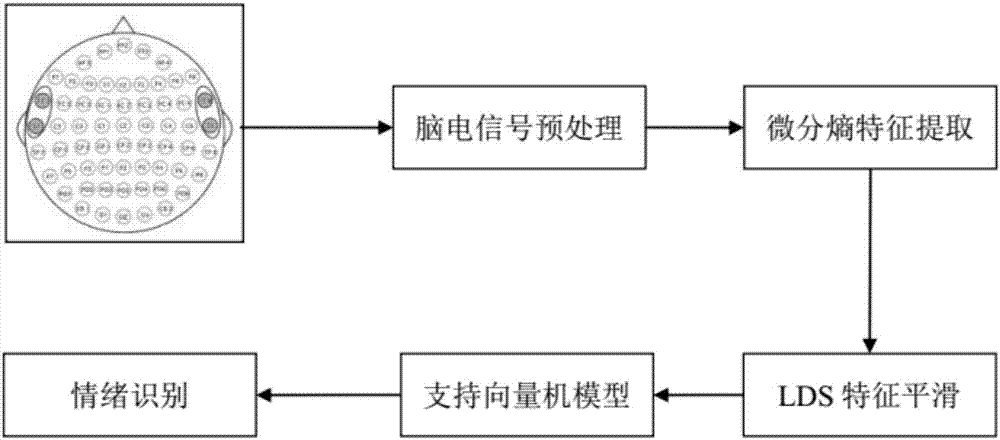

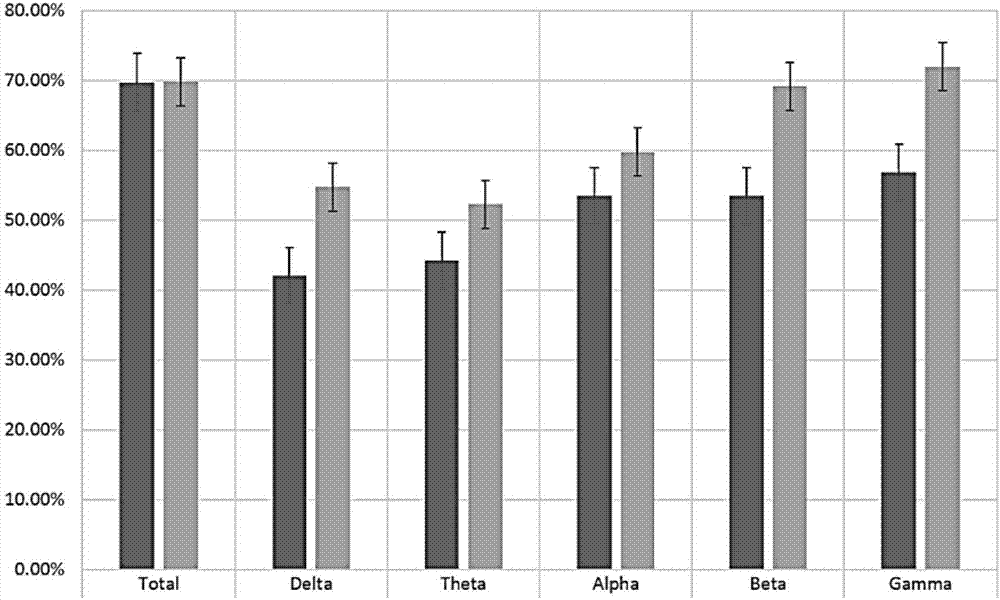

Feature recognition system and method for electroencephalogram signals

ActiveCN107157477AHigh speedReduce dimensionalitySensorsPsychotechnic devicesElectroencephalogram featureMood state

Provided are a feature recognition system and method for electroencephalogram signals. The method comprises the following steps: utilizing four conduction electrodes of a temporal area above ears to collect original brain electrical signals in different emotion states of different people and forming a sample set; obtaining electroencephalogram feature data from the sample set by pre-processing and extracting features; carry out smoothing operation on electroencephalogram feature data to obtain a training sample used for training a support vector machine so that an emotion recognition classifier is obtained. The feature recognition system and method for electroencephalogram signals have the following beneficial effects: under the premise that acquisition cost and complexity of electroencephalogram are greatly reduced, the feature recognition system and method can maintain higher emotion recognition accuracy and provide useful reference on emotion recognition by wearable equipment.

Owner:上海零唯一思科技有限公司

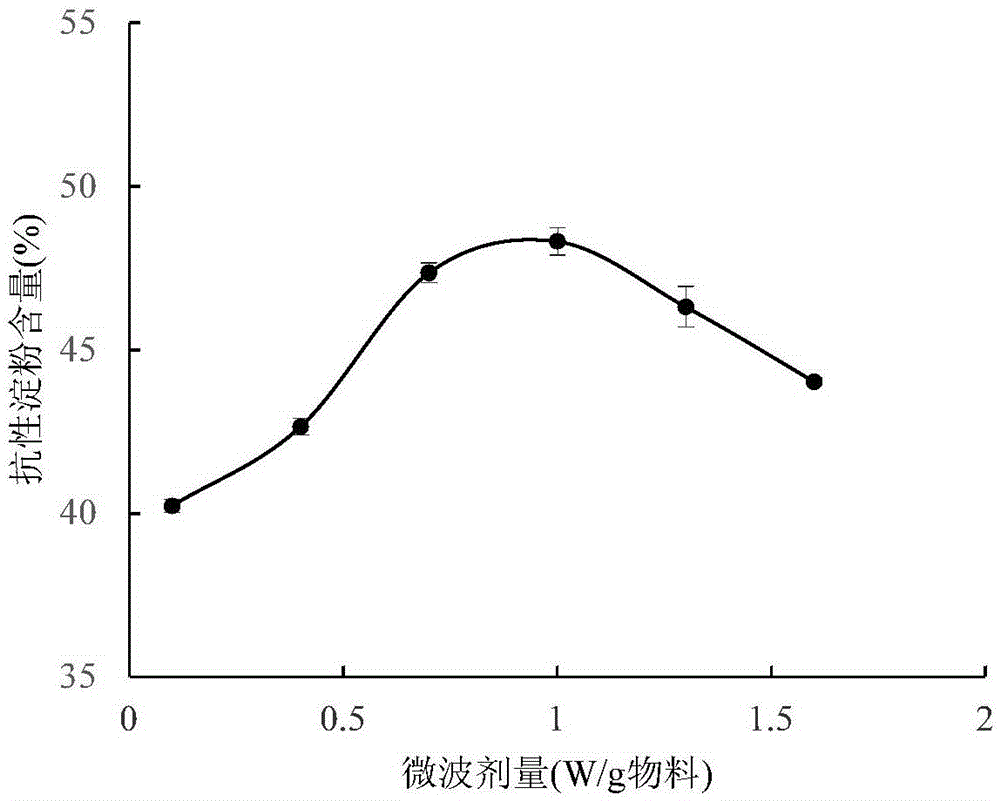

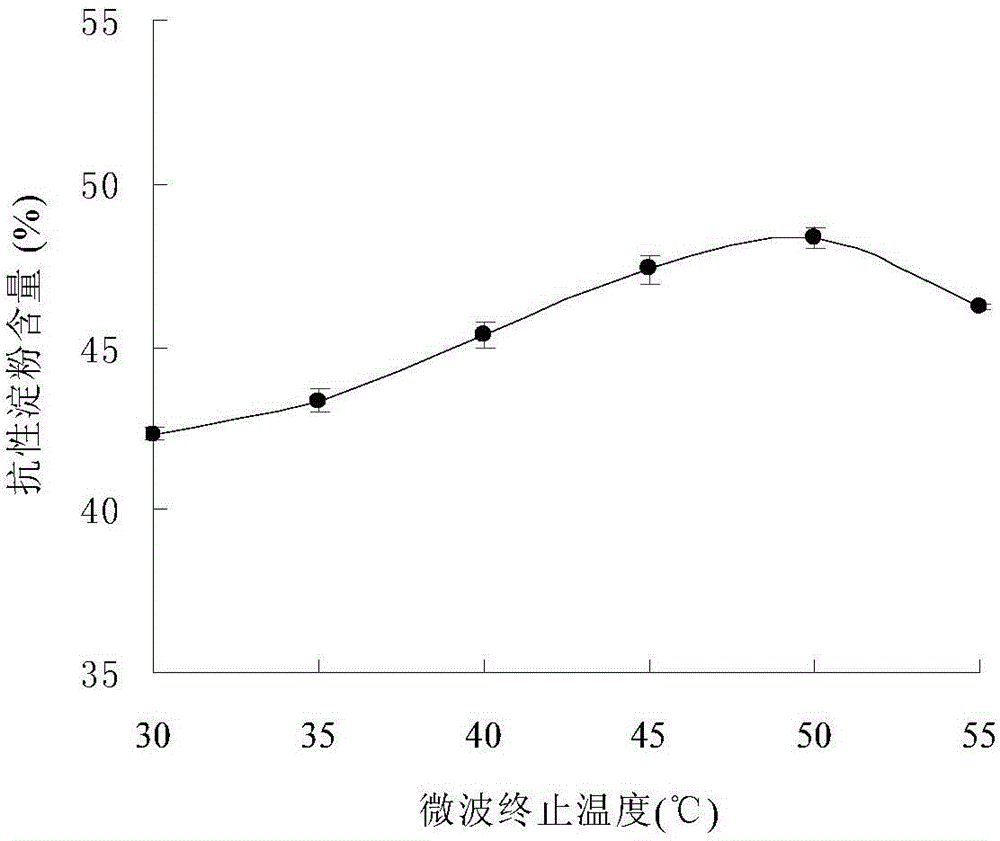

Method for preparing resistant starch employing microwave technology

The invention belongs to the field of deep processing of starch, and particularly relates to a method for preparing resistant starch employing a microwave technology. The method is characterized by comprising the following steps: (1) preparing a starch emulsion from raw starch, and pregelatinizing the starch by virtue of microwave; (2) carrying out autoclaving treatment on the pregelatinized material at proper temperature and pressure, cooling materials, and hydrolyzing the starch with heat-resistant alpha-amylase and pullulanase until the chain length is 20-120DP; (3) paving the material on a flat plate, storing at 4 DEG C for 3-5 hours, heating the material to 30-50 DEG C by virtue of the microwave, cooling to a room temperature, repeating the temperature circulating process for 2-4 times until the moisture content of the starch is smaller than 14%, crushing and sieving to obtain resistant starch A; and (4) adding water to the resistant starch A, carrying out thermal treatment, adjusting the pH to be 1.5-2, carrying out oscillating reaction, adjusting the pH to be 7-8, adding pancreatin for enzymolysis, filtering and drying a filter cake by airflow until the moisture content is smaller than 14%, and crushing and sieving through a 100-mesh sieve, so as to obtain high-purity resistant starch B.

Owner:HUAZHONG AGRI UNIV

Rice grain brewing type instant convenient porridge and preparation method thereof

ActiveCN103652592AEnhanced anti-retrofit propertiesFor long-term storageFood dryingFood ultrasonic treatmentMonoglycerideSucrose

The invention belongs to the technical field of food processing, and relates to rice grain brewing type instant convenient porridge and a preparation method thereof. The method comprises the following technical steps of: preparing raw materials; preparing raw material soak solution; carrying out ultrasonic immersion; dewatering; curing; drying until the moisture content is less than 10%; packaging. The raw material soak solution is prepared from the following components in parts by weight: 0.1-0.9 part of citric acid, 0.02-0.5 part of sodium carbonate, 0.1-1.5 parts of beta-cyclodextrine, 0.1-0.9 part of monoglyceride, 0.1-0.3 part of sucrose fatty acid ester and 100 parts of water. According to the raw material soak solution, the raw returning resistance of rice grains can be enhanced, the convenient porridge can be favorably stored for a long time, the brewing type instant convenient porridge rehydration time is shortened, the effective nutritional ingredients of raw materials can be sufficiently reserved, and the edible quality of the instant convenient porridge is improved. The preparation method for the rice grain brewing type instant convenient porridge, which is disclosed by the invention, has the advantages of simple operation, no need of rice frying and low-temperature freezing operation, high production efficiency and small energy consumption and is favorable for industrialized production, the manufacture technology time is shortened, and the production cost is lowered.

Owner:INNER MONGOLIA YINGPAN LIANGNONG ANIMAL HUSBANDRYIND CO LTD

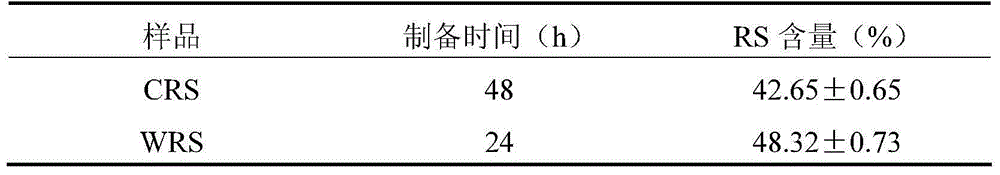

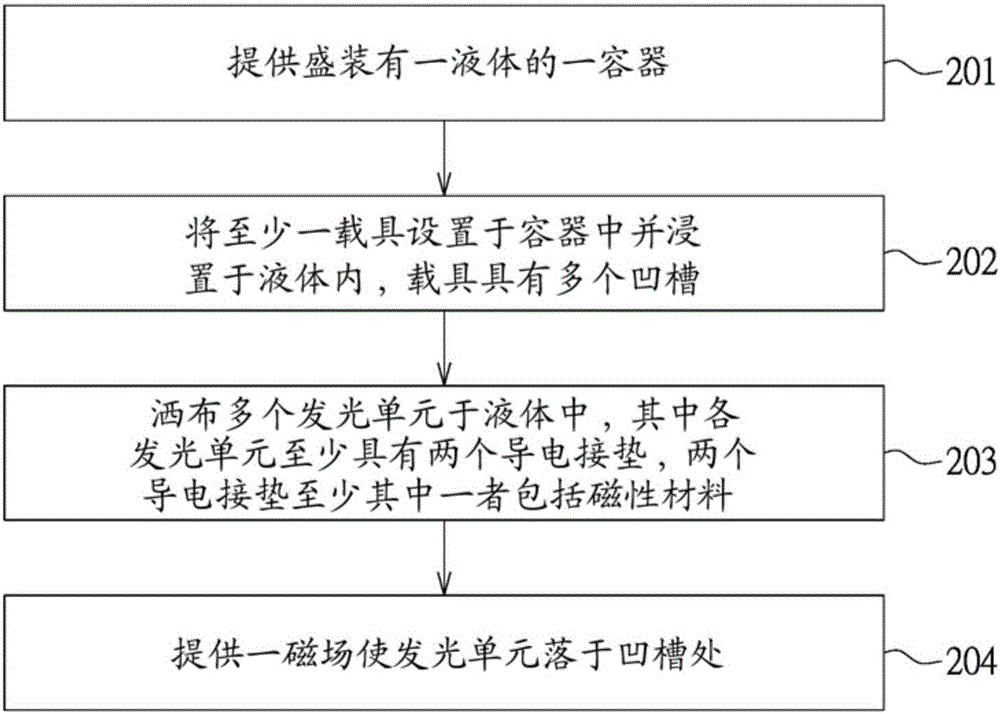

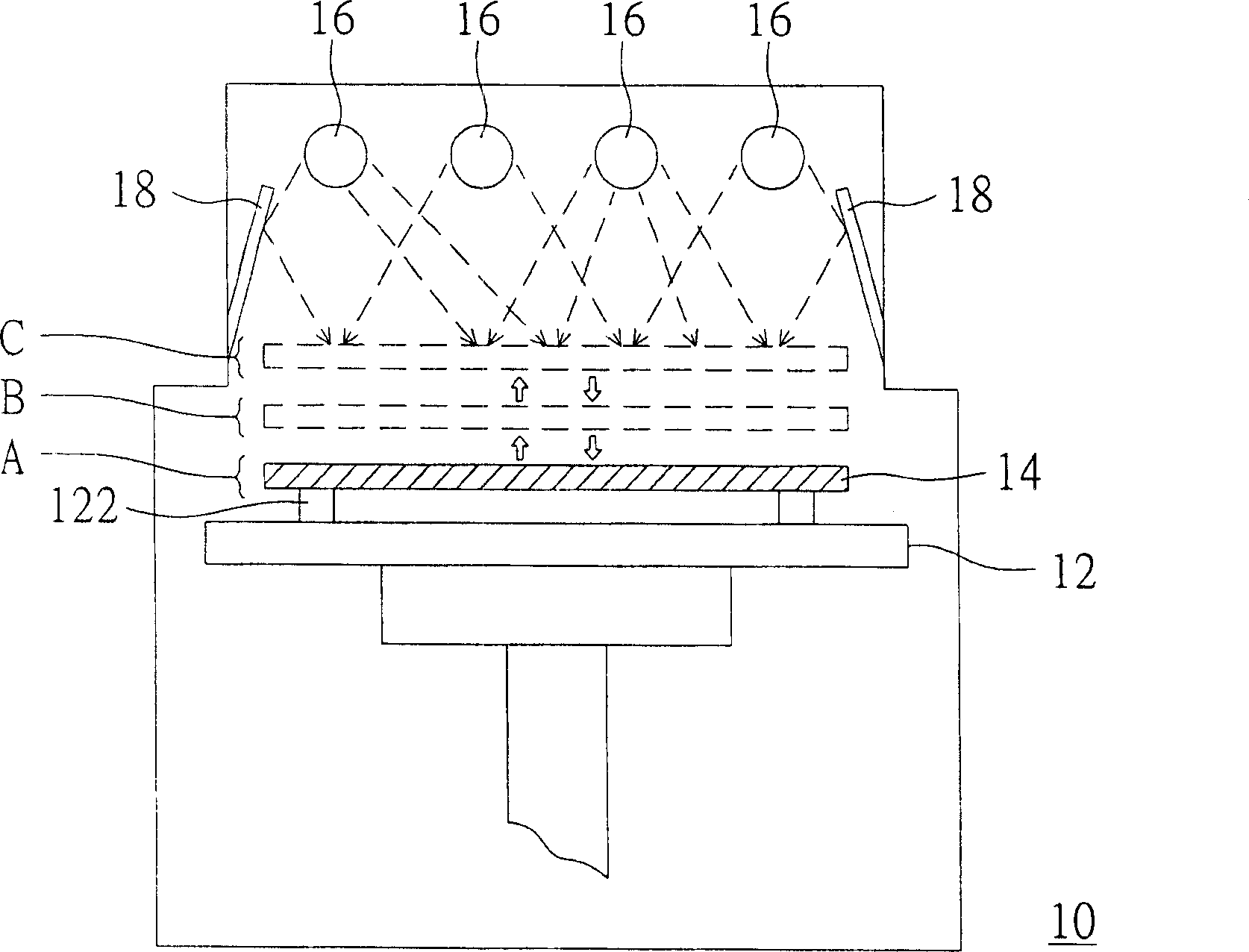

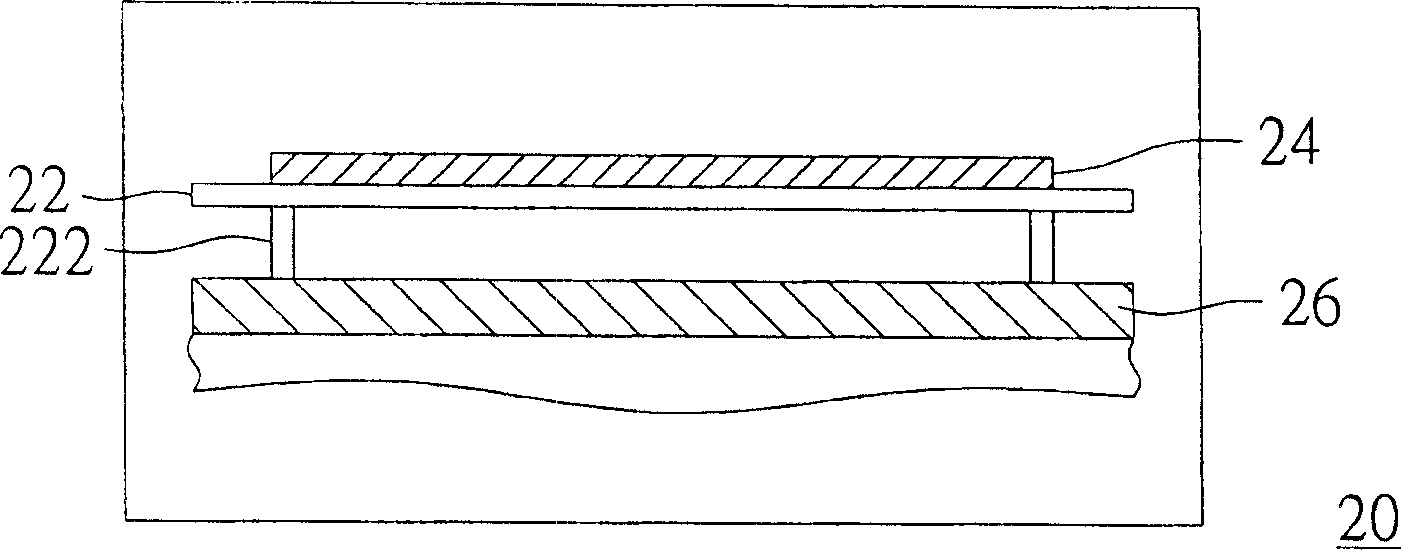

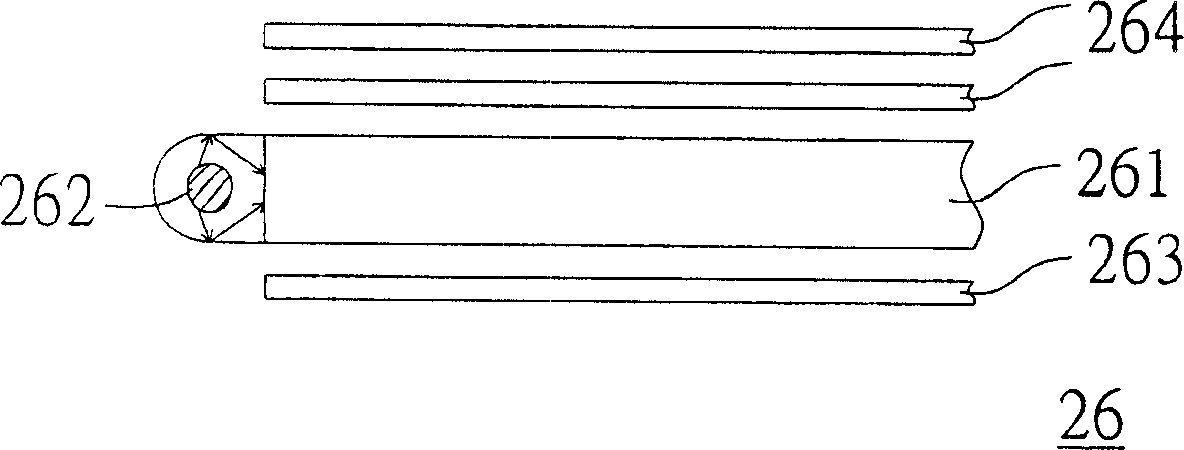

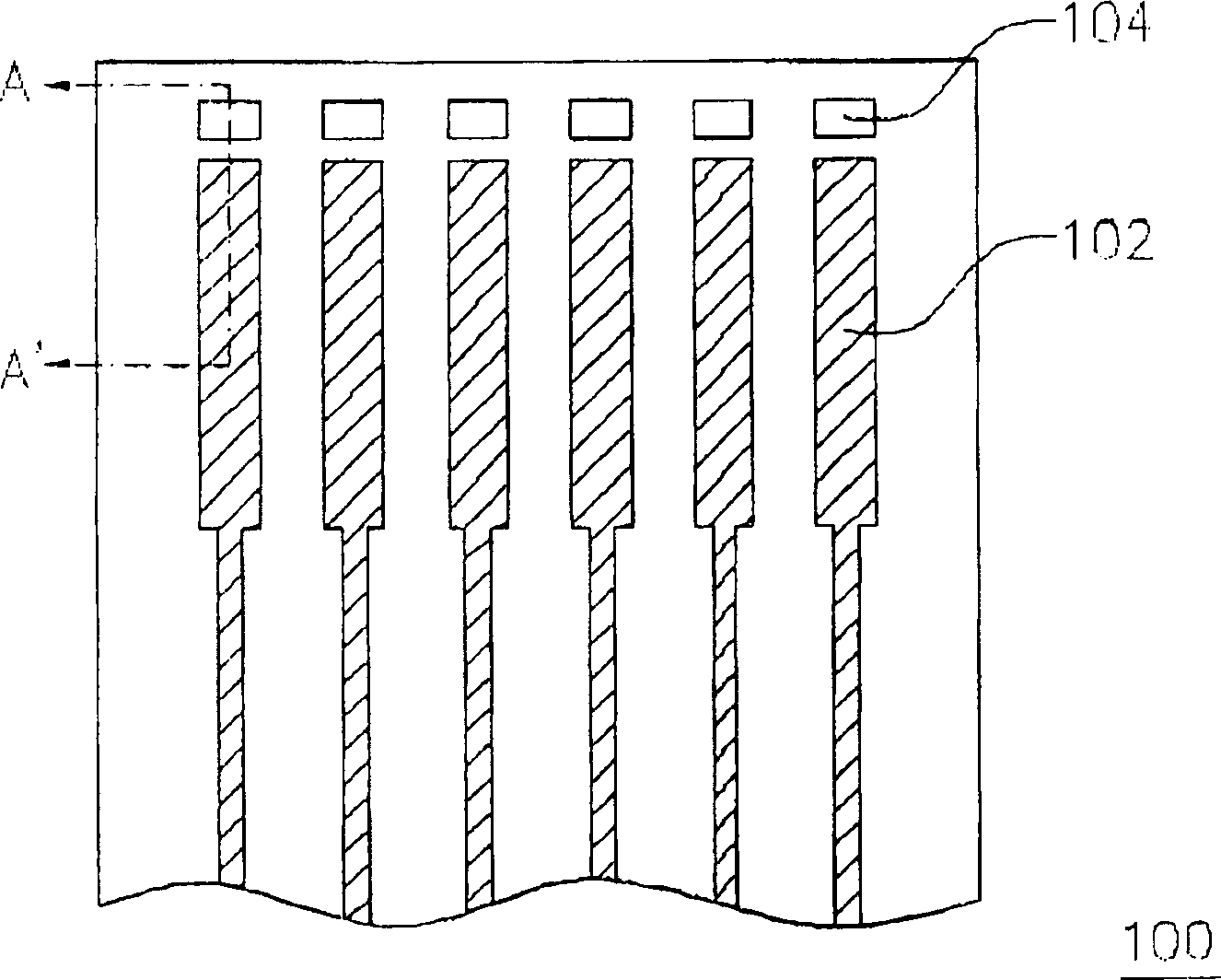

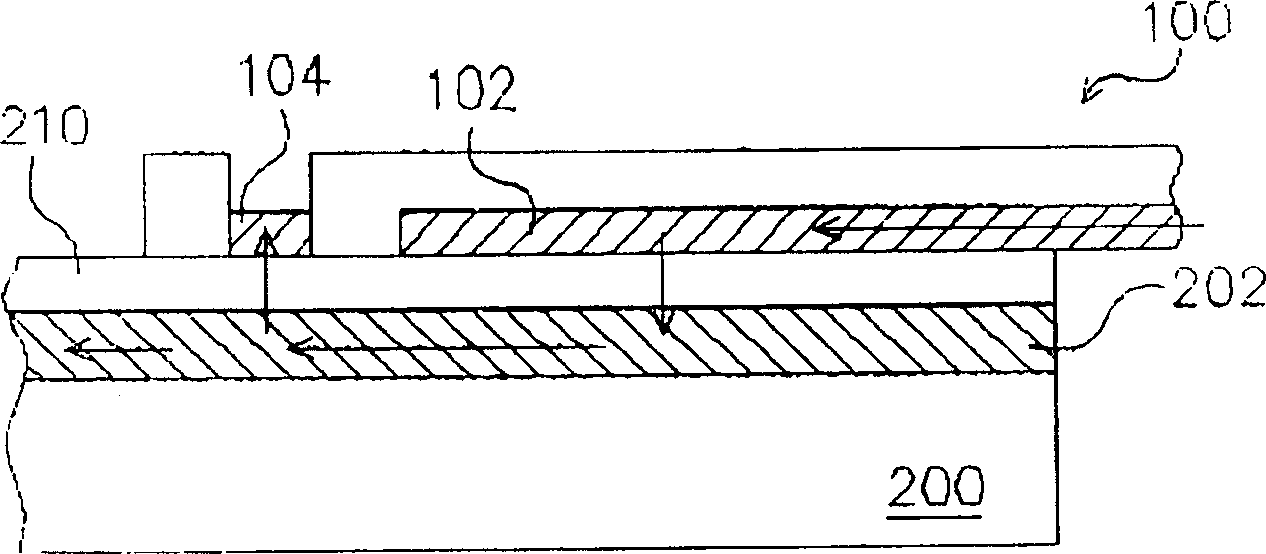

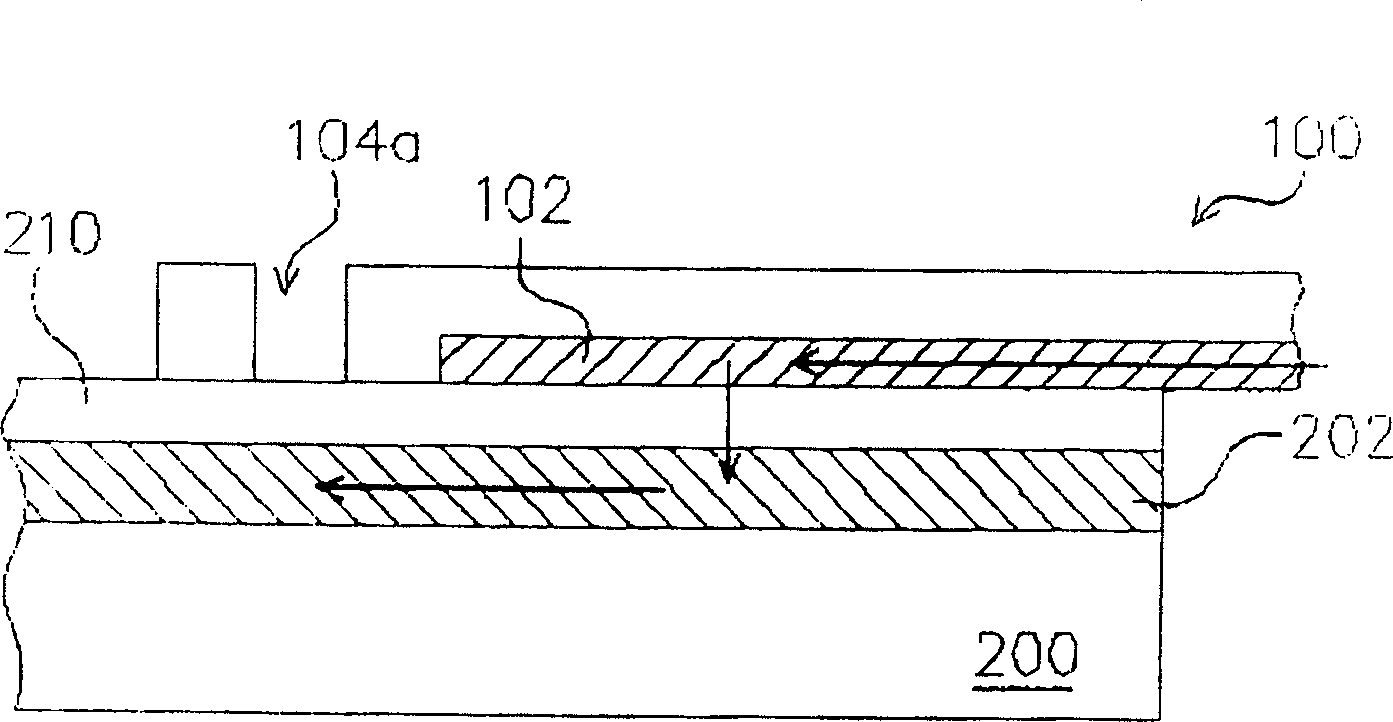

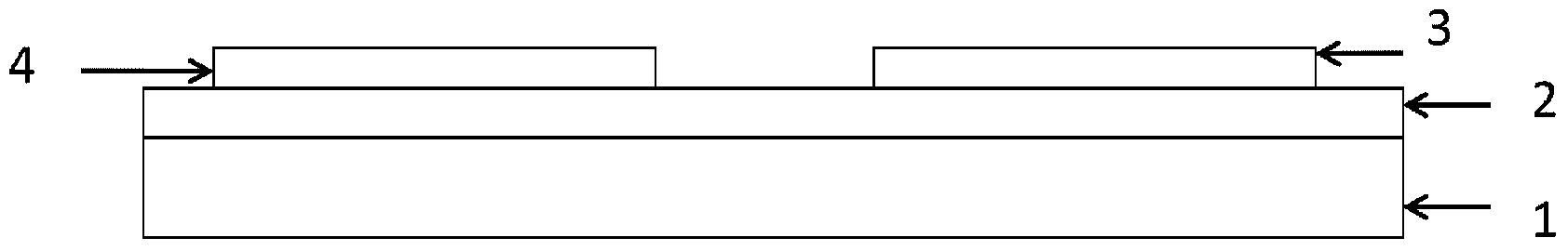

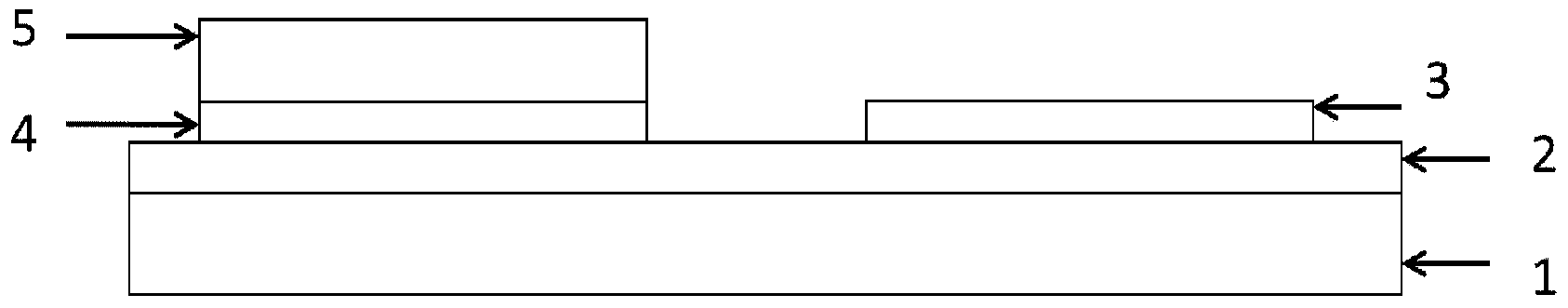

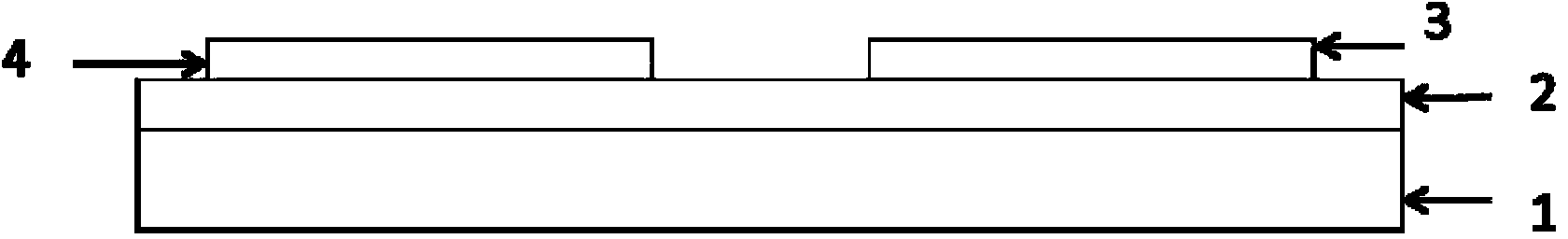

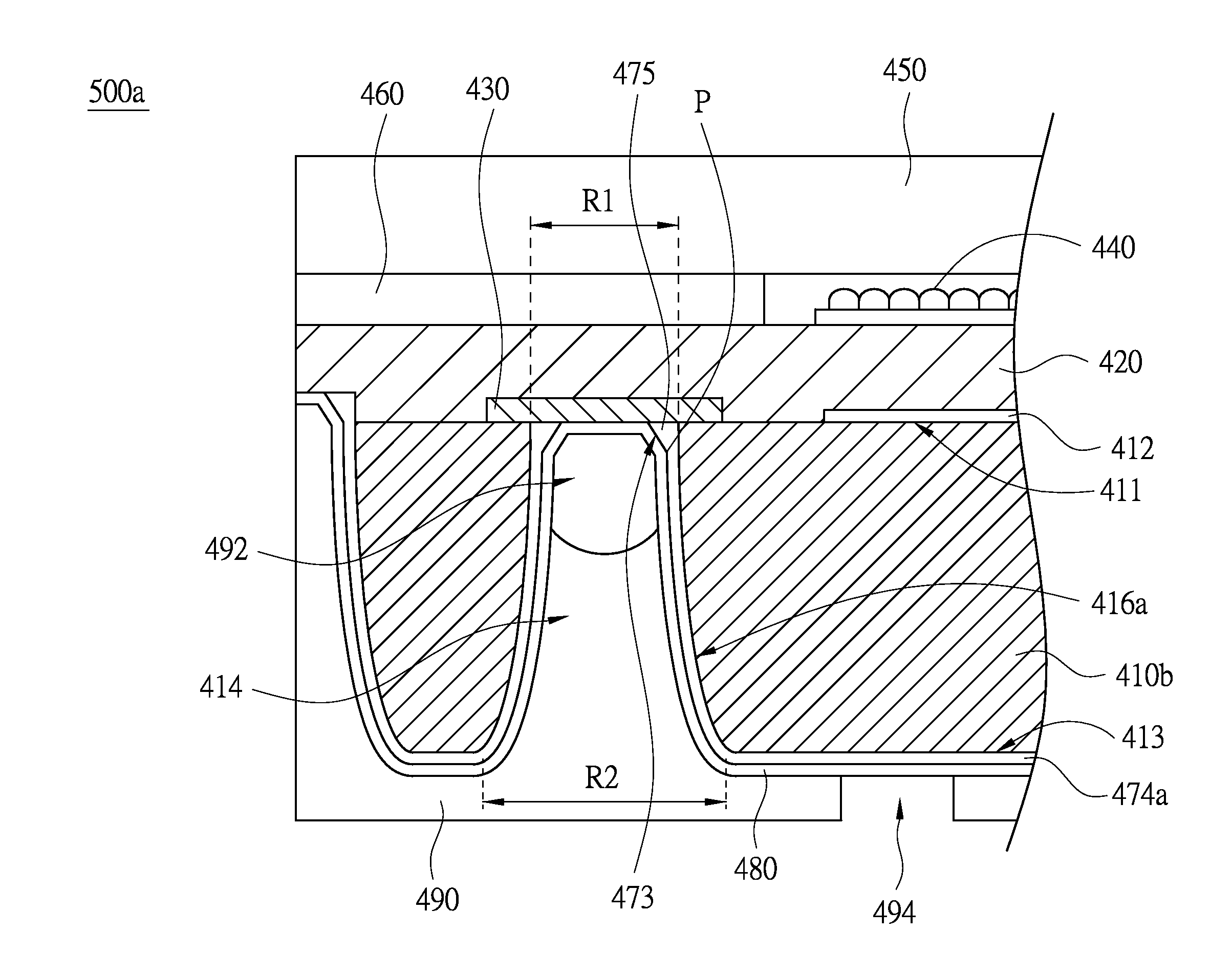

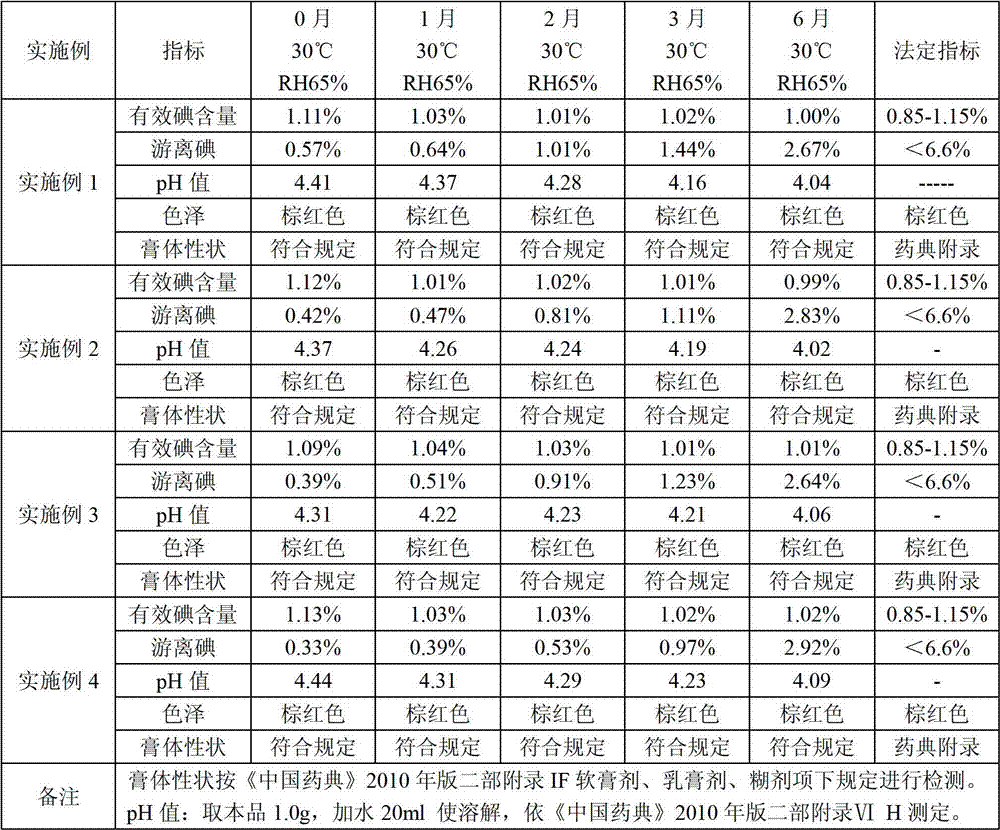

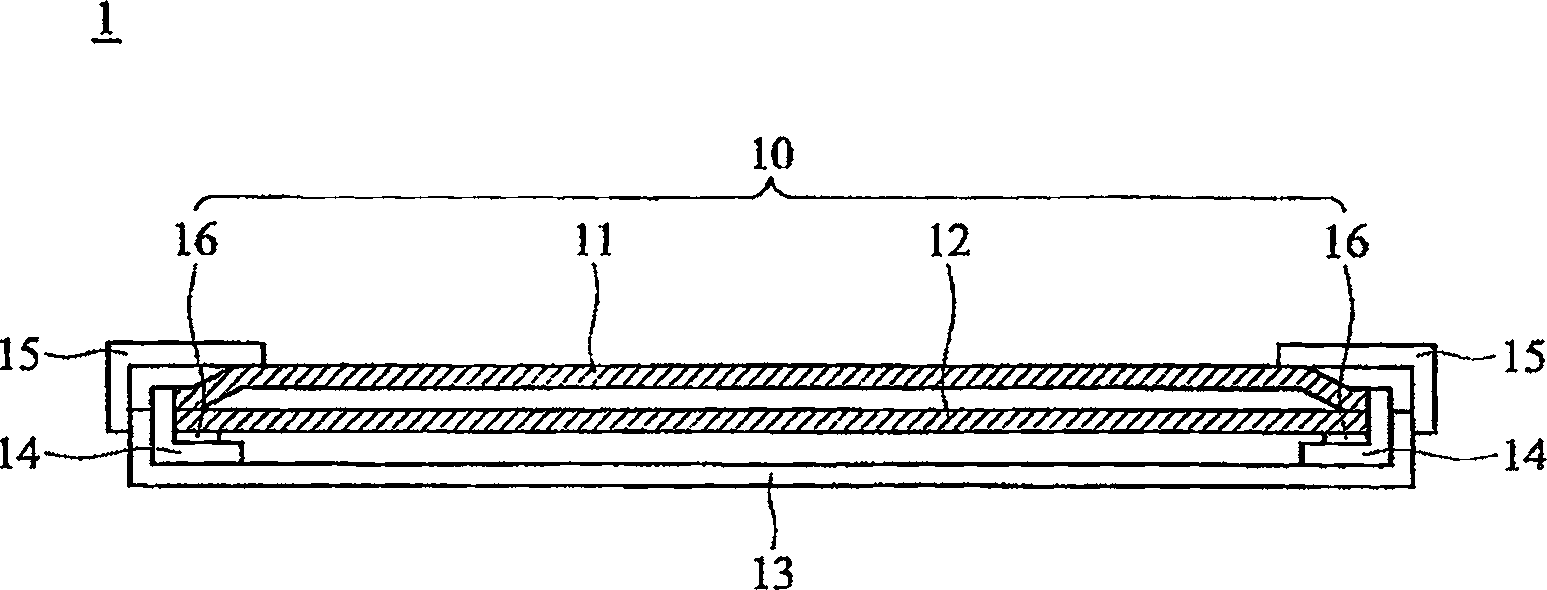

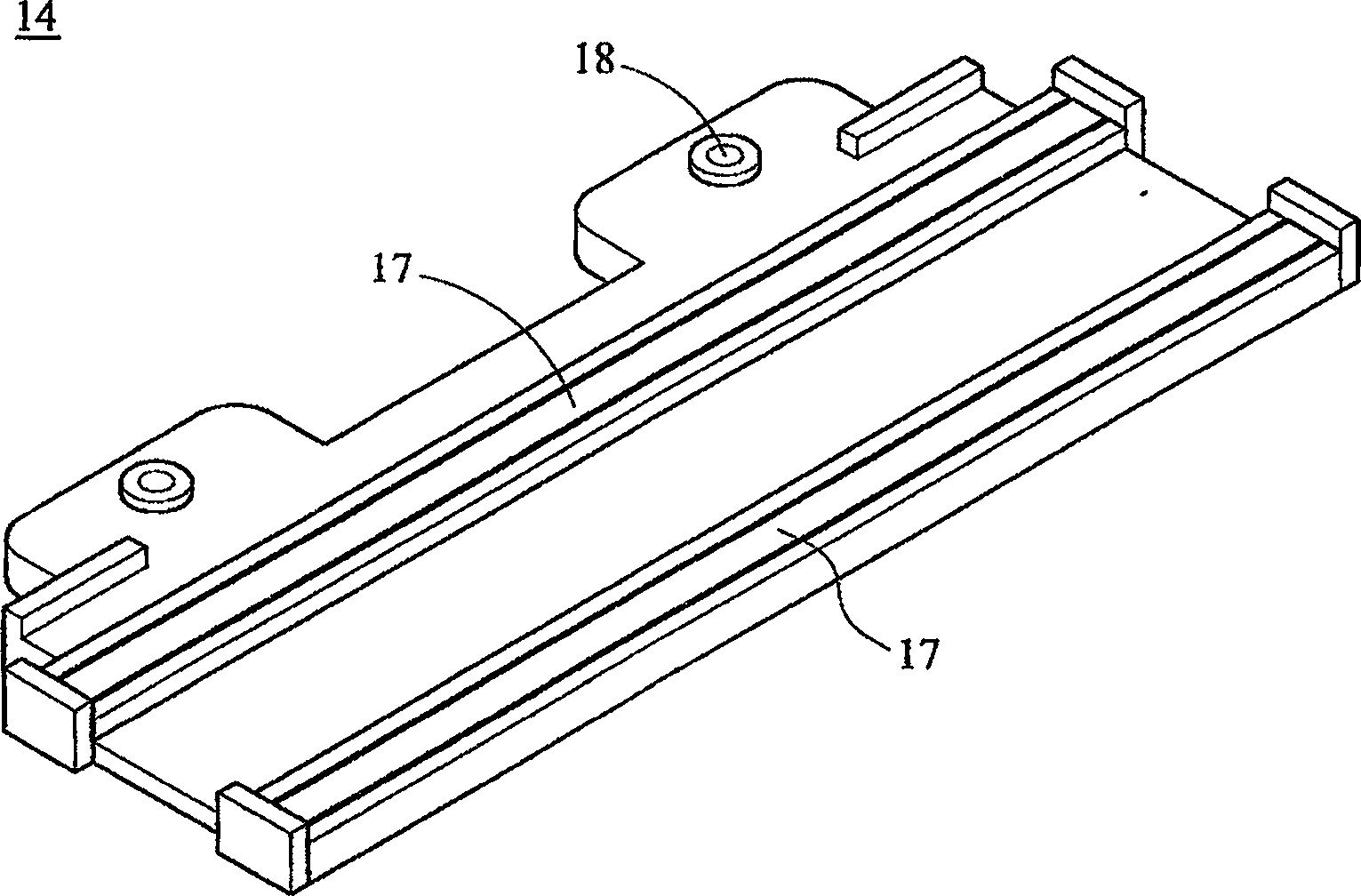

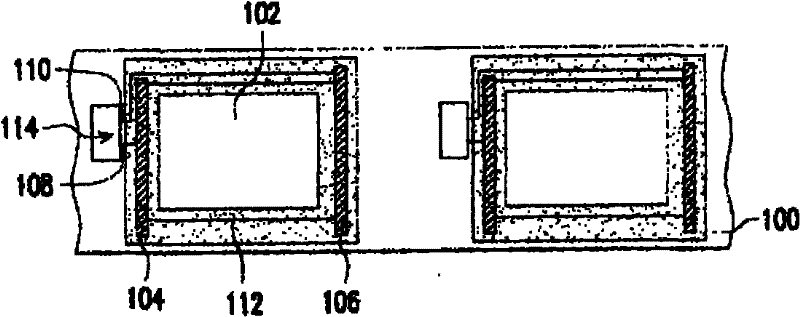

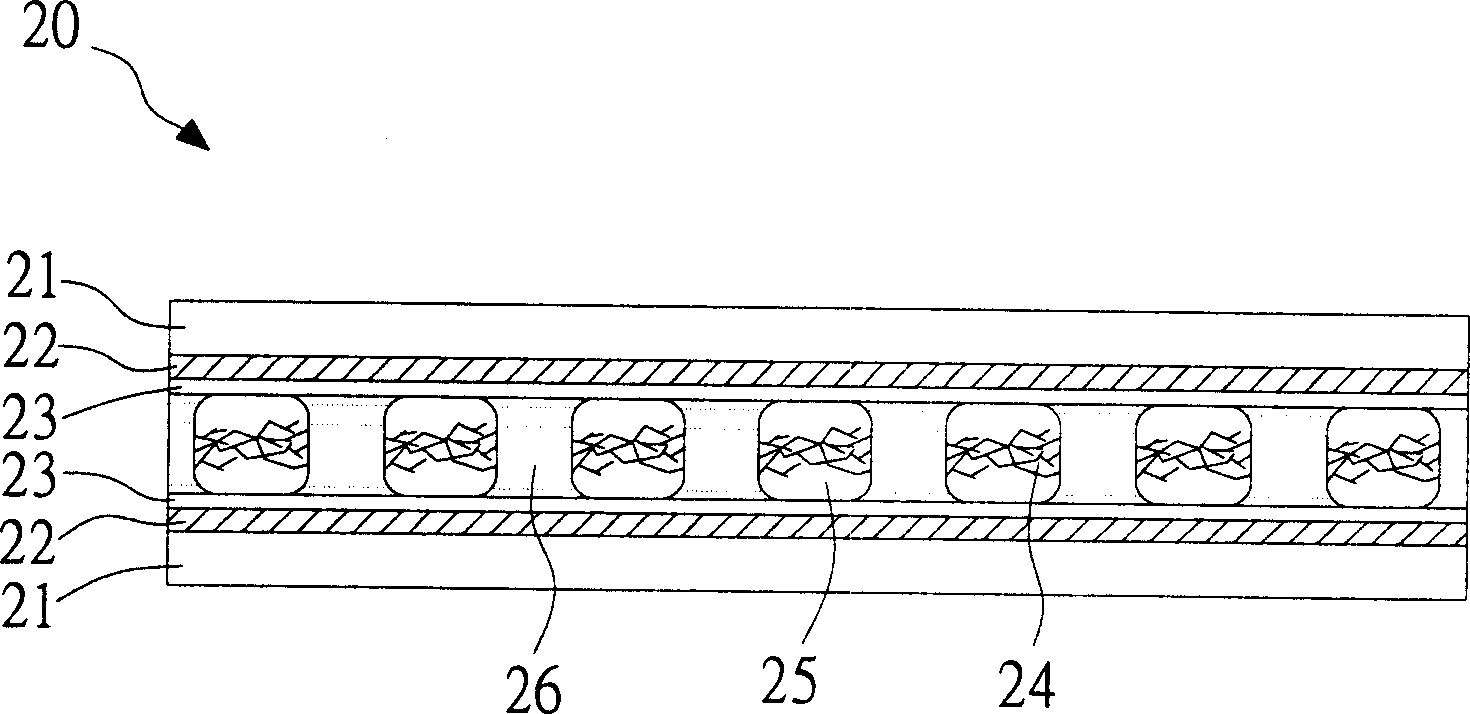

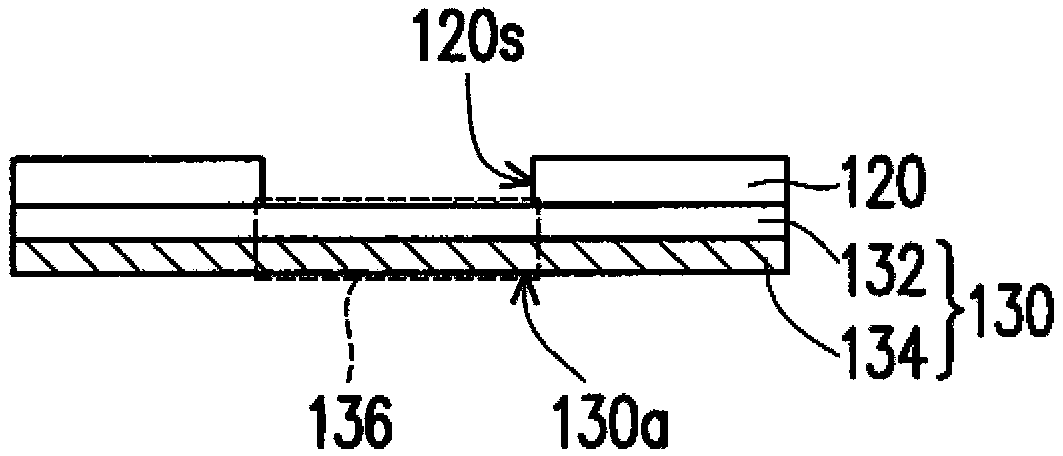

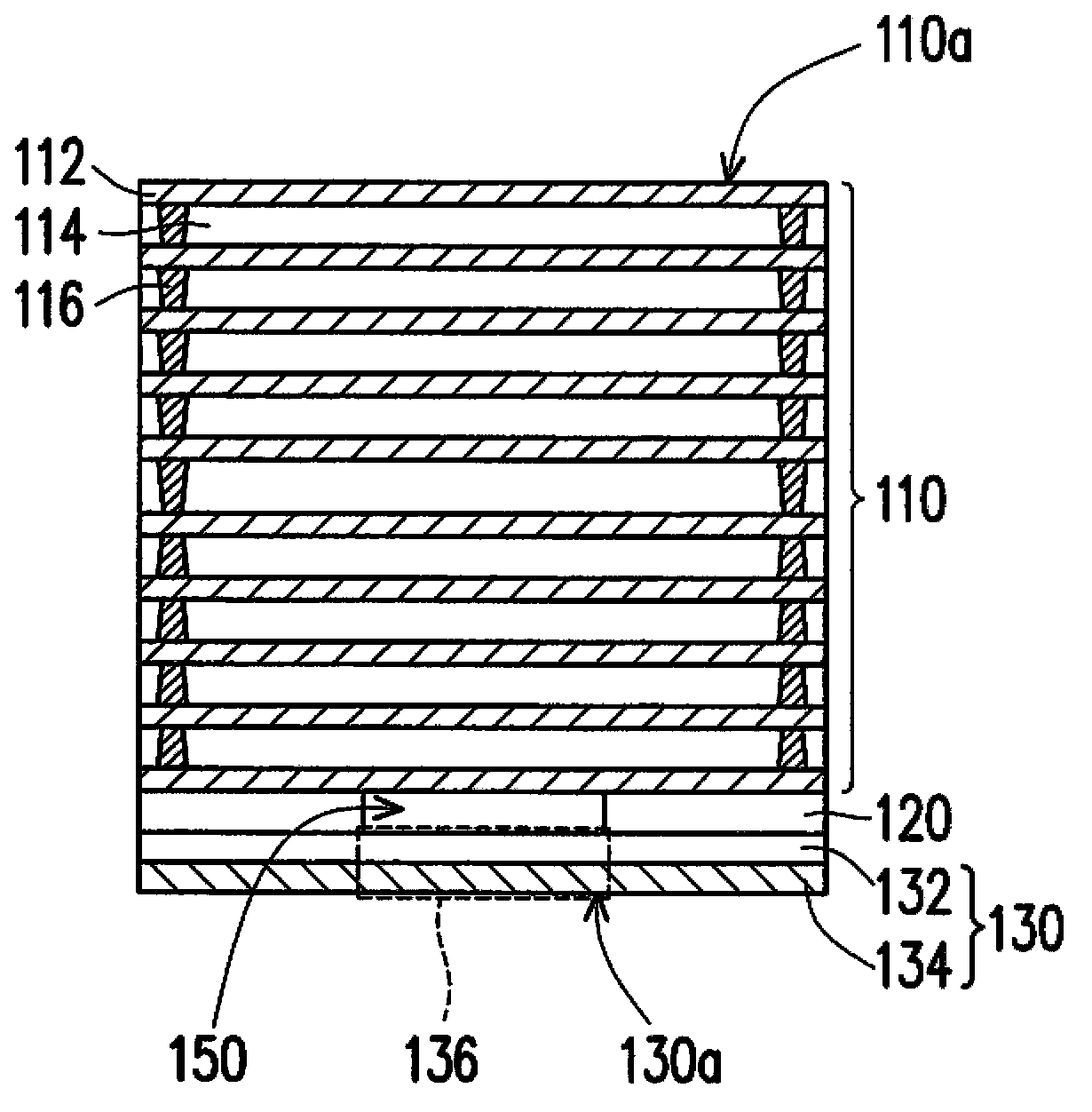

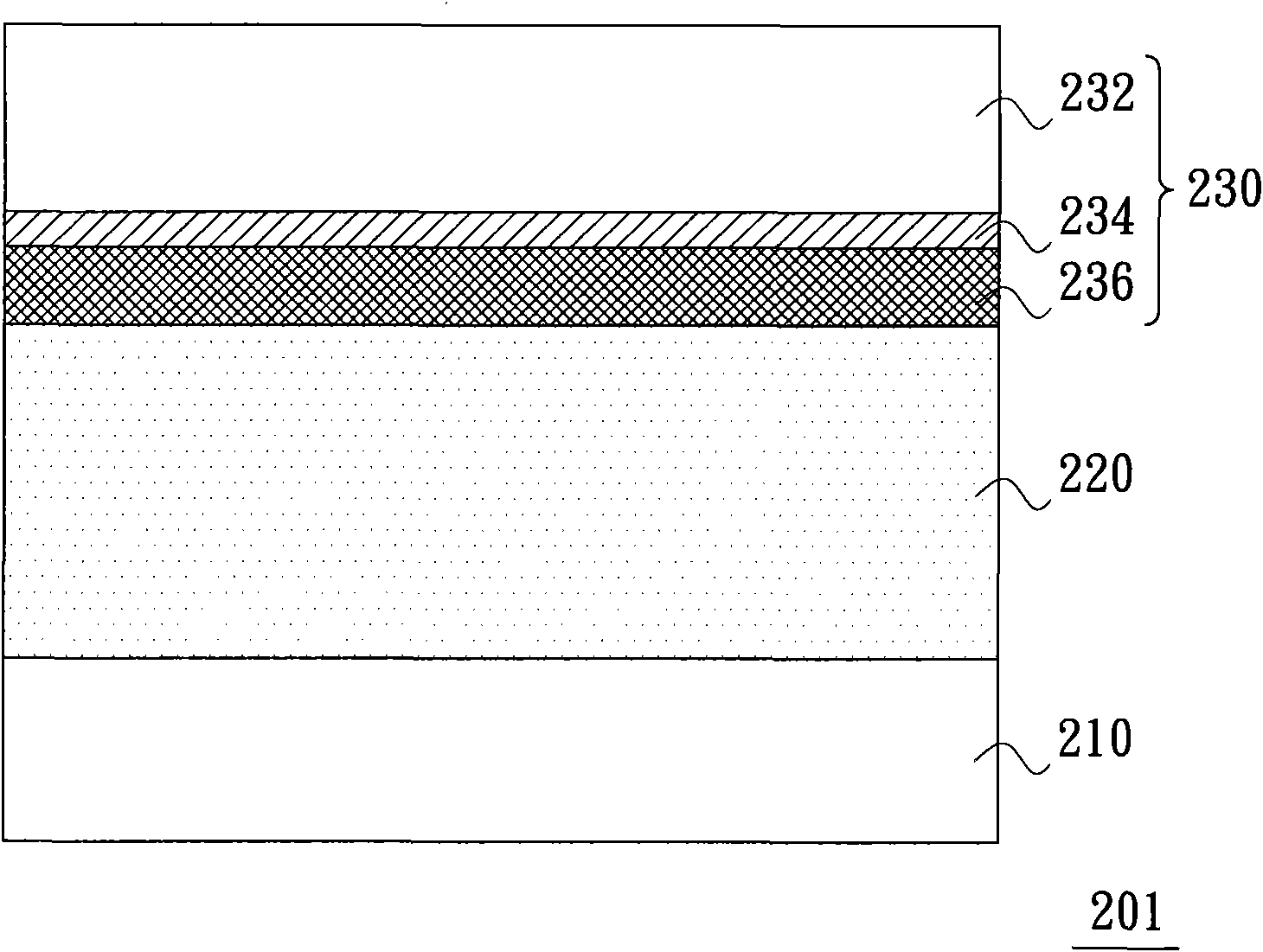

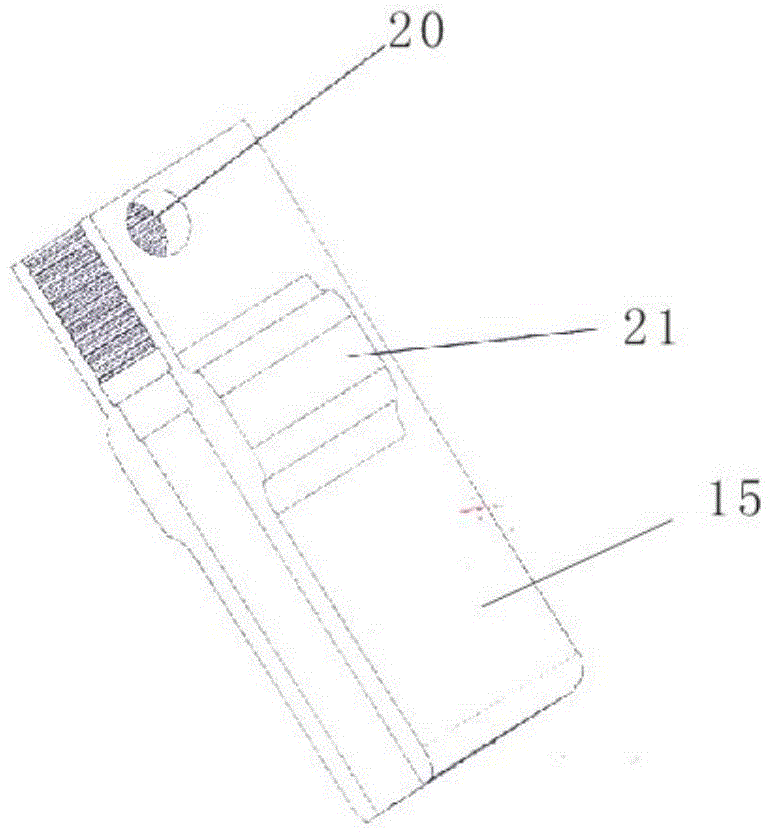

Micro luminous display device and manufacturing method thereof

ActiveCN106816451AShorten manufacturing process timeQuick sortingStatic indicating devicesSolid-state devicesElectricityEngineering

The invention discloses a micro luminous display device and a manufacturing method thereof. The manufacturing method comprises the following steps: providing a tank containing a liquid; disposing at least a carrying plate with several recessed regions in the tank, and the carrying plate being immersed in the liquid; dropping several lighting devices into the liquid, wherein each of the lighting devices includes at least two conductive pads, and one of the two conductive pads includes a magnetic material; applying a magnetic field for the lighting devices and the lighting devices will dispose within the recessed regions of the carrying plate; removing the carrying plate with the lighting devices out of the tank, and electrically assembling the lighting devices to an array substrate.

Owner:INNOLUX CORP

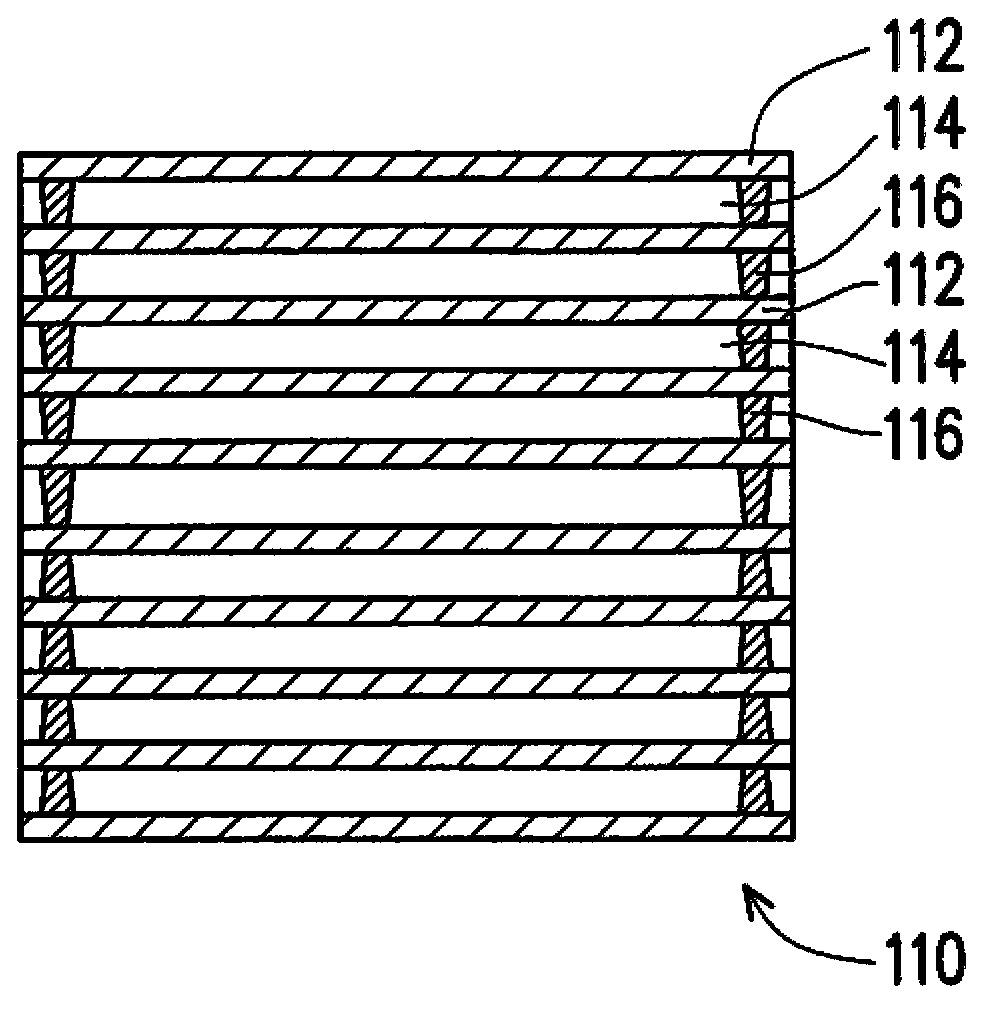

UV curing apparatus for group substrate

InactiveCN1869794AImprove uniformityIncrease illuminationNon-linear opticsIdentification meansIlluminanceUV curing

An ultraviolet curing apparetus consists of a bearing unit for bearing a pair of mother board and an optical unit for curing a pair of said mother board. It is featured as forming optical unit by a backlight unit set at one side of bearing unit and used to let light shine on pair of said mother board uniformly, forming said backlight unit by a light source and a substrate.

Owner:INNOLUX CORP

Method for testing flexible circuit board connection qualification and flexible circuit board with testing pad

InactiveCN1548971AHigh yieldReduce time to abnormal causeElectronic circuit testingPrinted circuit detailsElectricityEngineering

Owner:TPO DISPLAY

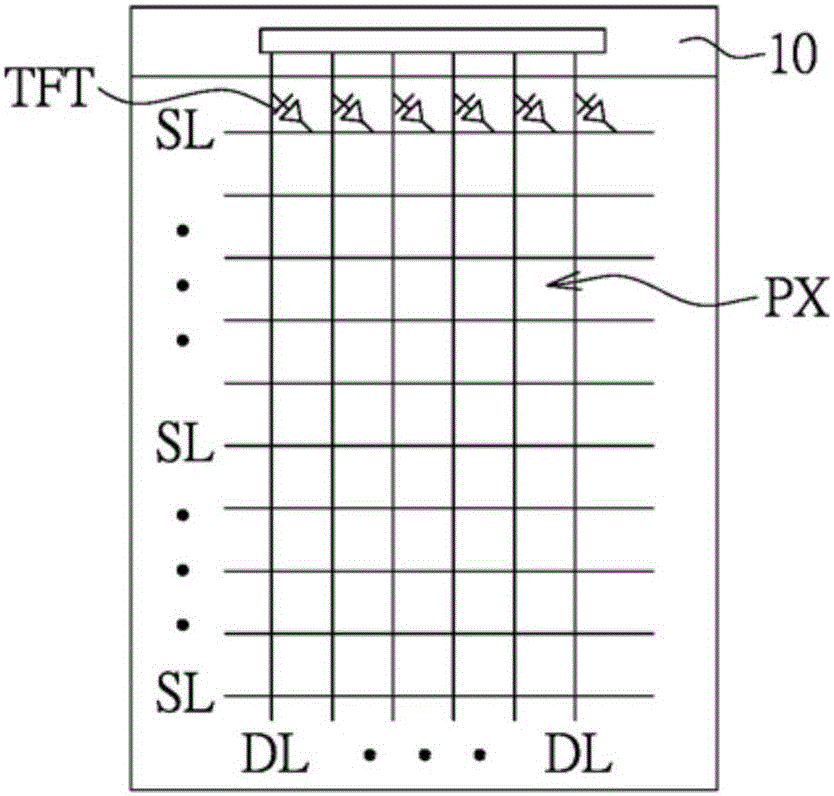

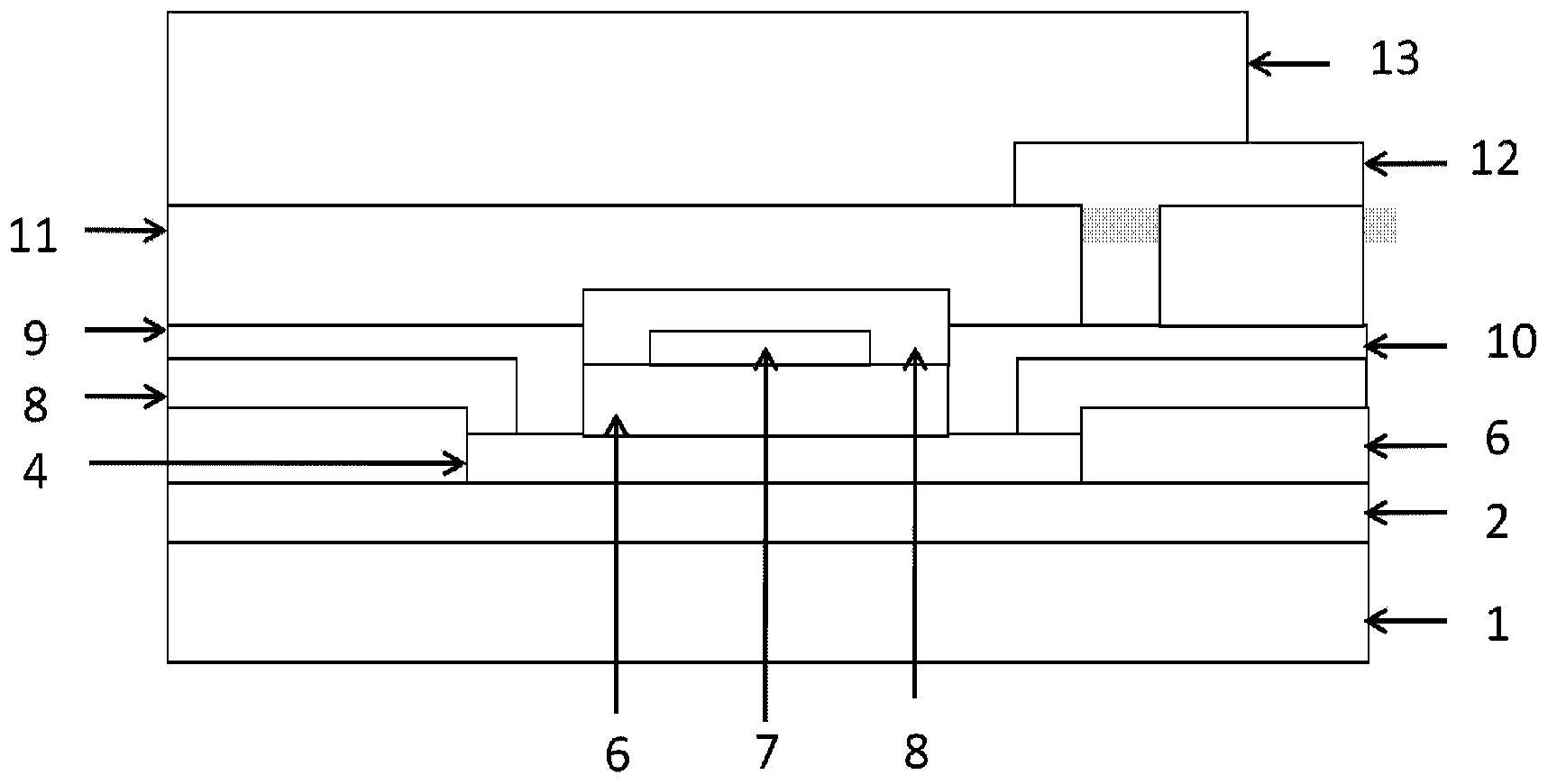

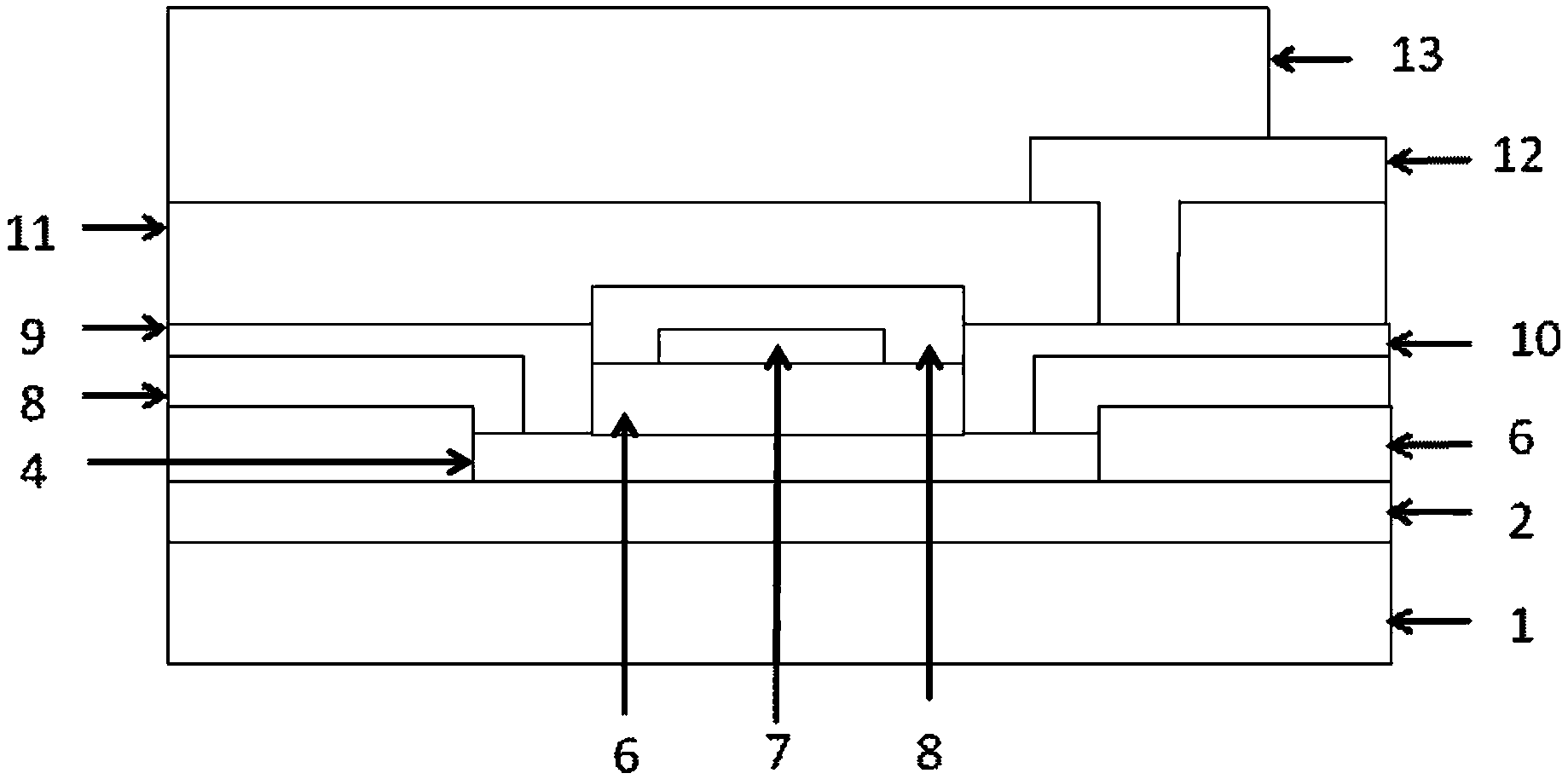

Low-temperature poly-silicon TFT array substrate, manufacturing method thereof and display device

ActiveCN104078424AThe number of photolithography processes is reducedImprove processing yieldSolid-state devicesSemiconductor/solid-state device manufacturingCapacitanceTransistor array

The invention discloses a low-temperature poly-silicon TFT array substrate, a manufacturing method of the low-temperature poly-silicon TFT array substrate and a display device. The manufacturing method comprises the steps that based on the step type photoresist technology, a poly-silicon active layer and a poly-silicon storage capacitor lower electrode plate are formed on the substrate at the same time on the basis of the primary photolithography technique; a gate insulation layer is formed on the poly-silicon active layer and the poly-silicon storage capacitor lower electrode plate; a metal layer is formed on the gate insulation layer, and is etched to form a grid electrode, a grid wire connected with the grid electrode, a source electrode, a drain electrode and a data line connected with the source electrode and the drain electrode; a passivation layer, a photoresist layer and a pixel electrode layer are formed in sequence, picture composition fabrication processing is carried out on the passivation layer, the photoresist layer and the pixel electrode layer, inter-layer insulation layer via holes and patterns of a pixel electrode are formed on the basis of the primary photolithography technique; a pixel definition layer is formed on the pixel electrode. According to the low-temperature poly-silicon TFT array substrate, the manufacturing method of the low-temperature poly-silicon TFT array substrate and the display device, the frequency of the photolithography technique on the low-temperature poly-silicon TFT array substrate is reduced, the technique yield is improved, and technique cost is lowered.

Owner:BOE TECH GRP CO LTD

Forming method for solar energy cell substrate suede structure

InactiveCN1933188AShorten manufacturing process timeReduce manufacturing costFinal product manufactureSemiconductor/solid-state device manufacturingRough surfaceAcid erosion

This invention relates to a method for forming flannel surface structure on the positive of a solar energy cell including: 1, blasting the positive of a silicon chip with SiC sand to remove some films such as SiN, TiN and SiC films on the positive of the silicon chip to expose bug Si layer, and rough surface is formed on the positive of the Si chip with the roughness greater than 0.3 mum and the back keeps smooth, 2, dipping the Si chip with rough surface at the positive into an acid erosion solution, the chip processed by acid has rough surface and the back becomes smooth, 3, cleaning.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Array substrate manufacturing method, array substrate and display device

InactiveCN104078423AReduce the number of patterning processesReduce process complexitySolid-state devicesSemiconductor/solid-state device manufacturingManufacturing technologyInsulation layer

The invention provides an array substrate manufacturing method, an array substrate and a display device. The array substrate manufacturing method includes the steps of forming patterns of an active layer, a grid insulation layer, a grid and a grid line with the once layout technology; forming a passivation layer on a substrate where the active layer, the grid insulation layer, the grid and the grid line are formed, and forming a via hole in the passivation layer with the once layout technology; forming patterns of a data line, a source, a drain and a pixel electrode on the substrate where the passivation layer is formed with the once layout technology, wherein the drain makes contact with the active layer through the via hole. By means of the array substrate manufacturing method, the array substrate and the display device, the number of times of the layout technology adopted in the low temperature polycrystalline silicon array substrate manufacturing technology process is decreased, the technology complexity is accordingly lowered, and the technology cost is reduced while the manufacturing technology time is shortened.

Owner:BOE TECH GRP CO LTD

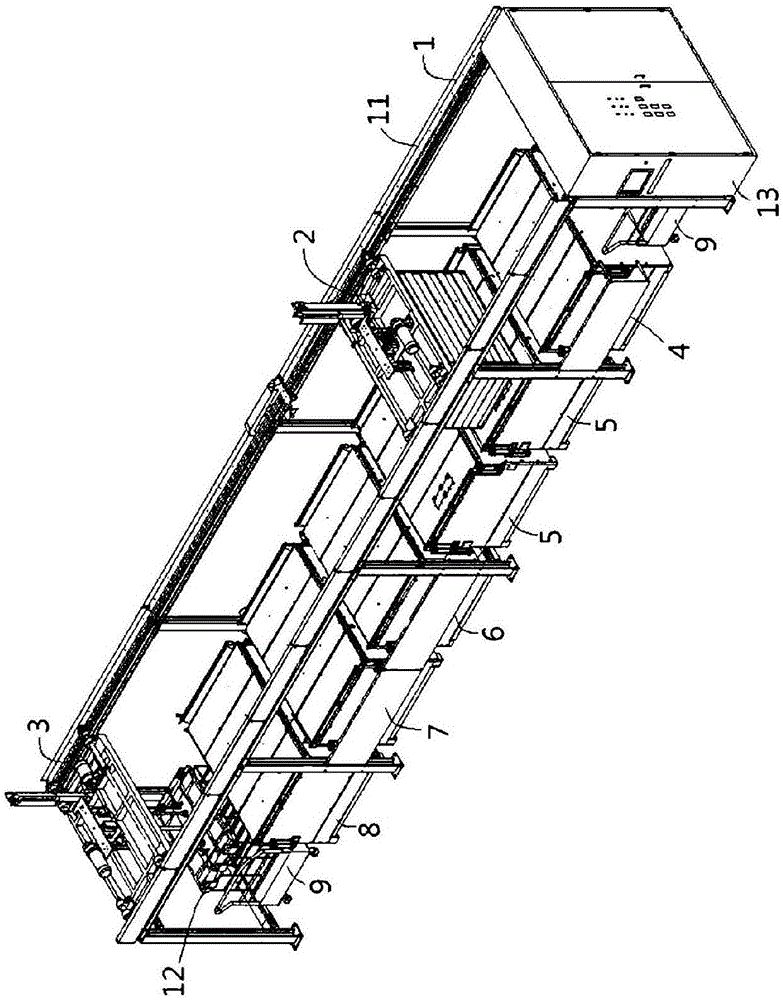

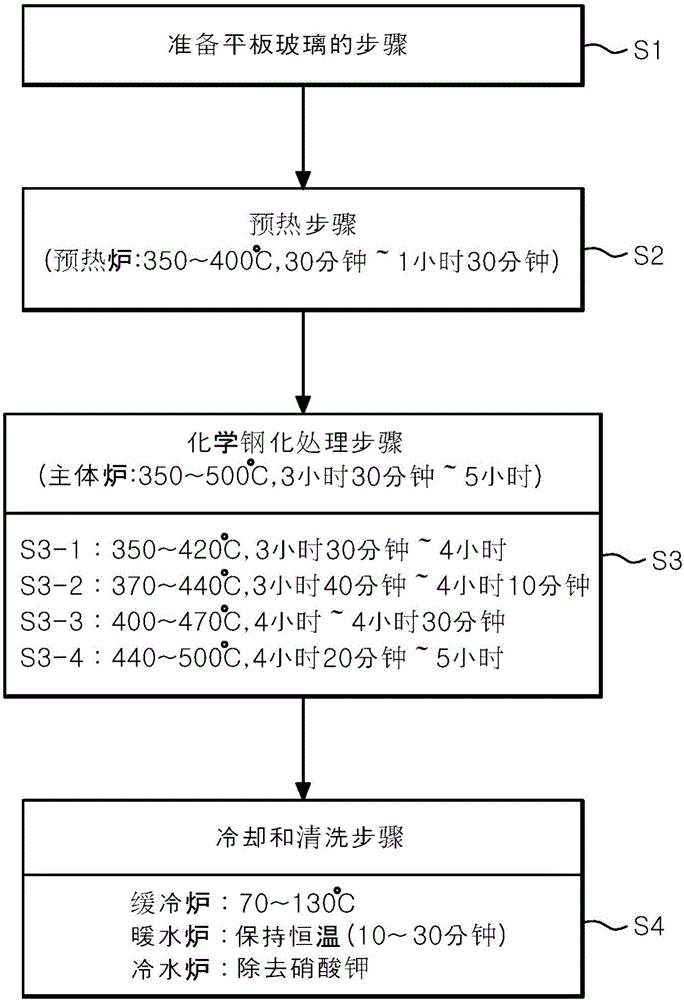

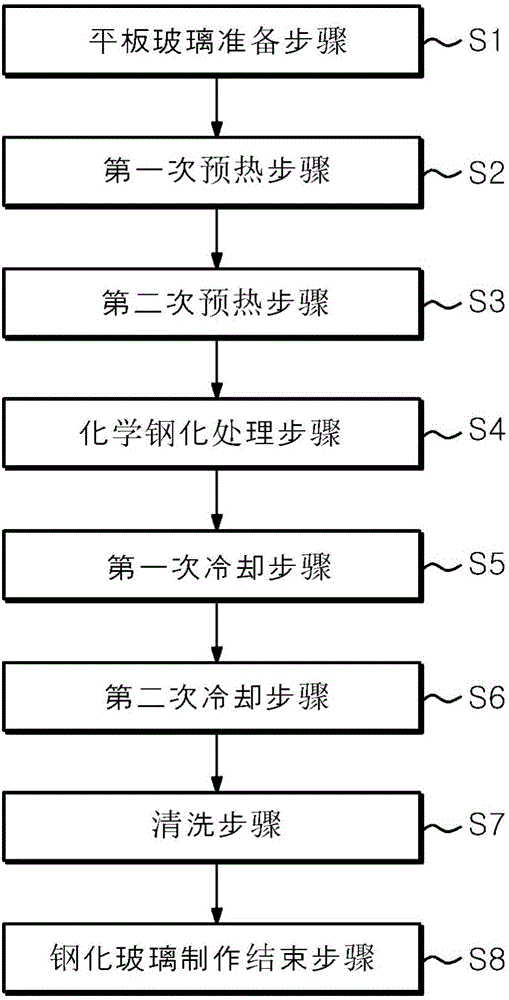

Device for manufacturing tempered glass using chemical strengthening and manufacturing method therefor

InactiveCN106029587AShorten manufacturing process timeHigh yieldGlass transportation apparatusGlass tempering apparatusFlat glassPotassium nitrate

The present invention relates to a device for manufacturing tempered glass using chemical strengthening and a manufacturing method therefor. The present invention manufactures tempered glass by raising the temperature of plate glass and preheating the plate glass at first and second preheating units step by step; substituting with potassium ions within a potassium nitrate solution of a chemical strengthening unit; cooling the plate glass through first and second slow cooling processes at first and second slow cooling units; and cleaning the plate glass by fine bubbles while securing stability of the glass at a cleaning unit. Due to this feature, the present invention can maximally shorten the process time for manufacturing tempered glass to considerably enhance yield and improve defect rate, and further can manufacture all types of plate glass such as thin plate glass and thick plate glass into chemically tempered glass regardless of the standard of plate glass.

Owner:金浩权

Concentrated Liuwei dihuang pill preparation method

ActiveCN102920882ASpeed up contactImprove transfer rateDigestive systemPill deliveryBiotechnologyLiu Wei Di Huang

The present invention provides a concentrated Liuwei dihuang pill preparation method. According to the method, the existing preparation method is improved so as to effectively improve component transfer rate and paste yield, save energy consumption and reduce active ingredient loss.

Owner:JIUZHITANG

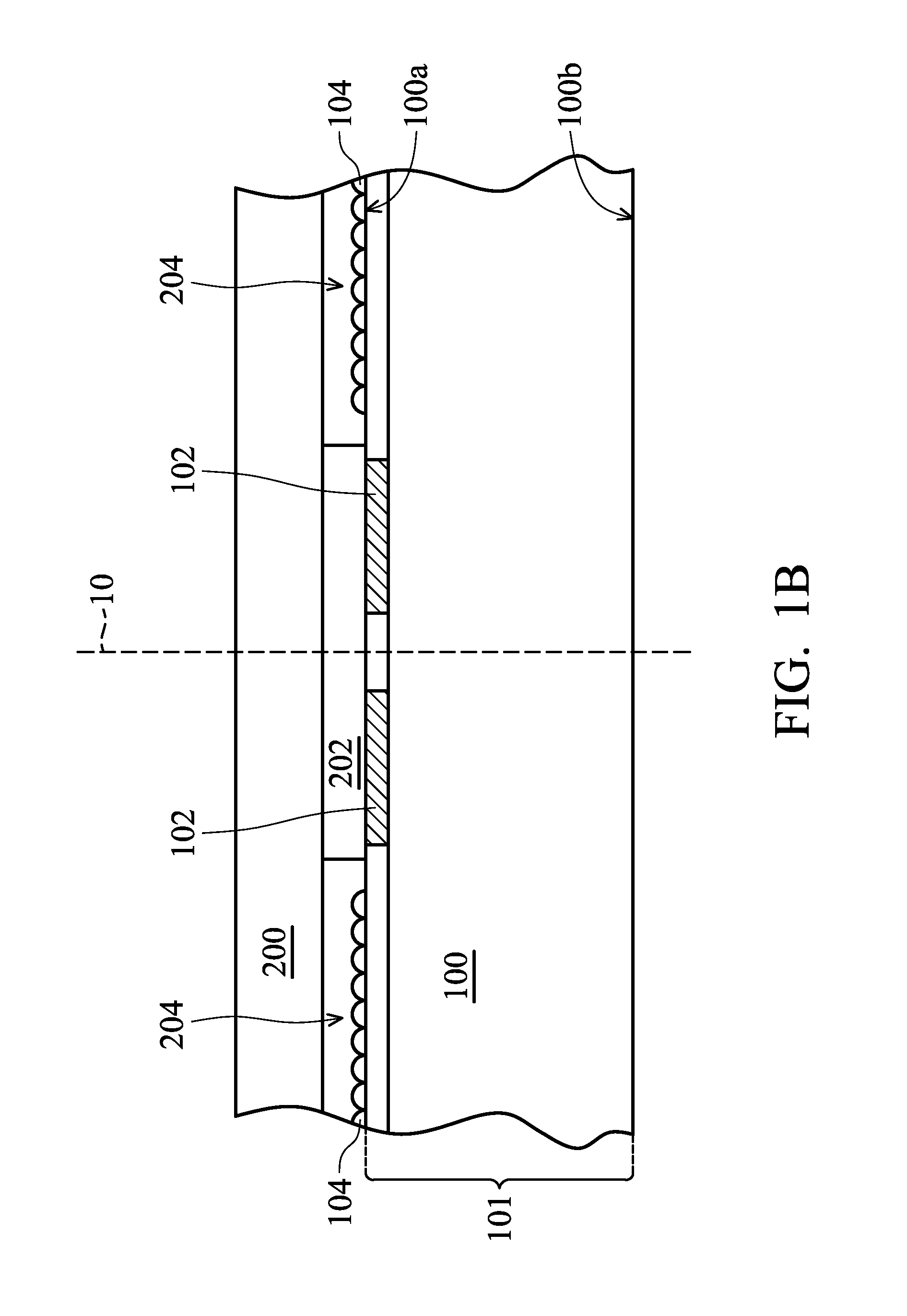

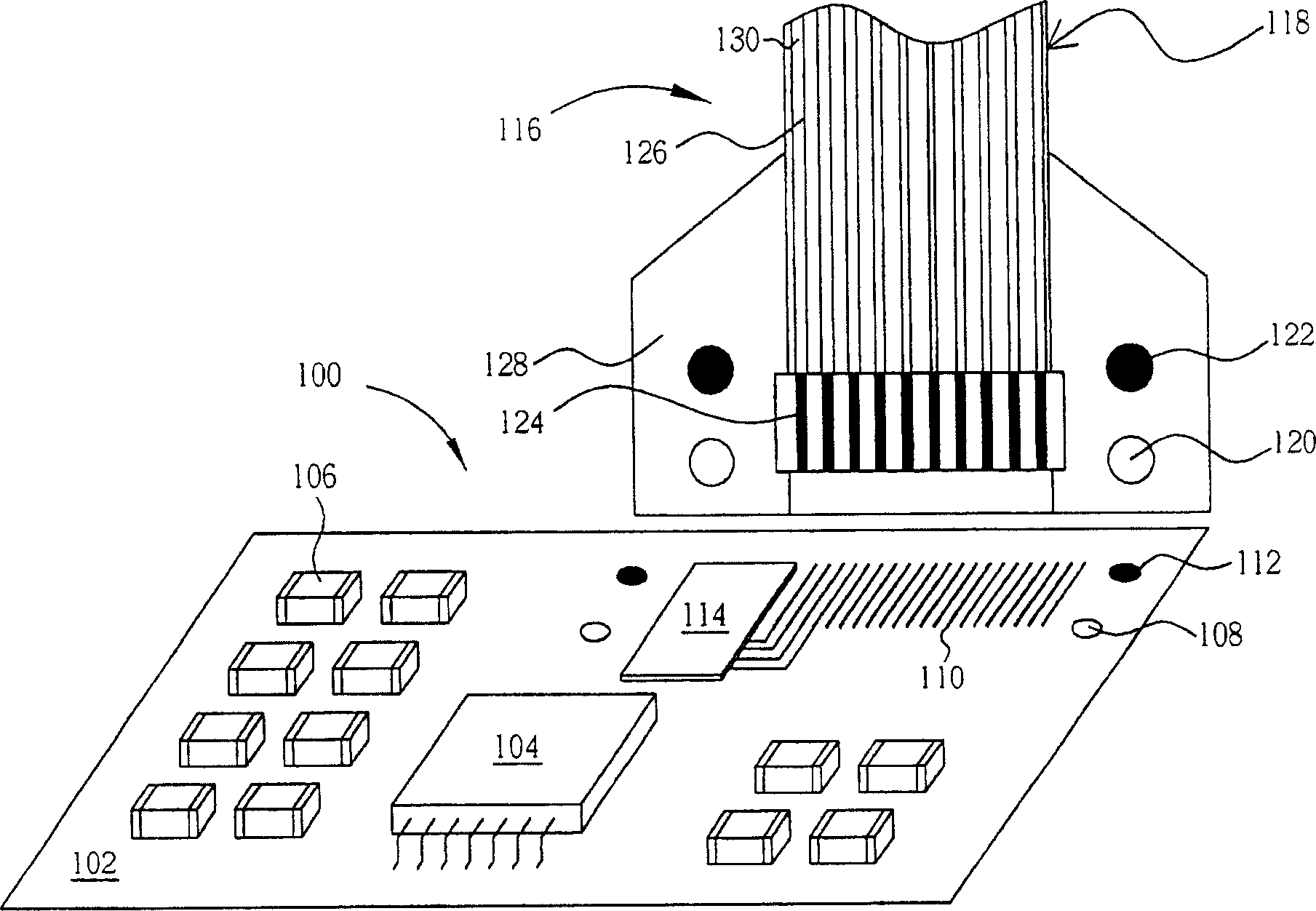

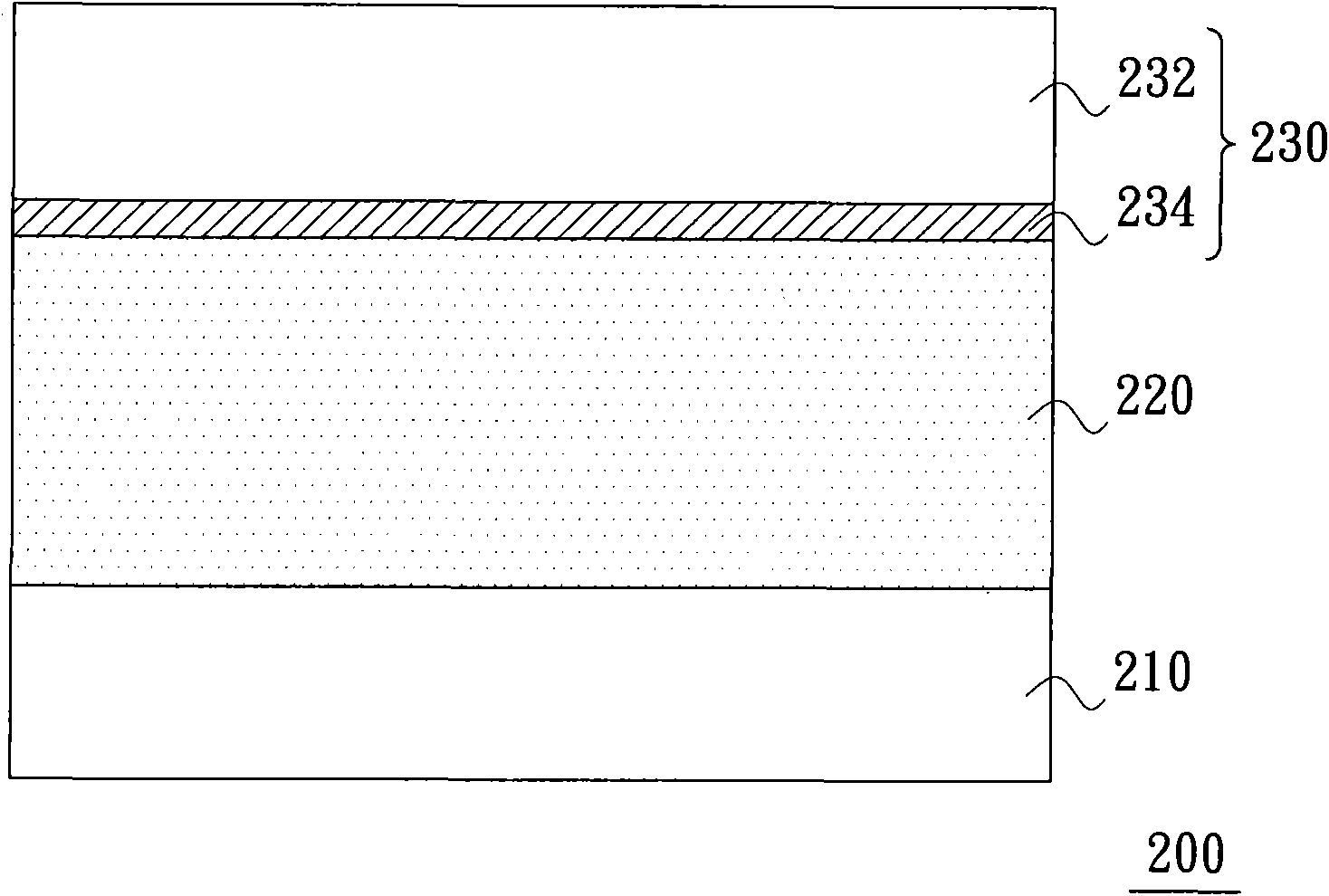

Chip package and fabrication method thereof

ActiveUS20150041995A1Low manufacturing process costShorten manufacturing process timeSemiconductor/solid-state device detailsSolid-state devicesEngineeringProtection layer

A fabrication method of a chip package includes the following steps. A wafer structure having a wafer and a protection layer is provided. The first opening of the wafer is aligned with and communicated with the second opening of the protection layer. A first insulating layer having a first thickness is formed on a conductive pad exposed from the second opening, and a second insulating layer having a second thickness is formed on a first sidewall of the protection layer surrounding the second opening and a second sidewall of the wafer surrounding the first opening. The first and second insulating layers are etched, such that the first insulating layer is completely removed, and the second thickness of the second insulating layer is reduced.

Owner:XINTEC INC

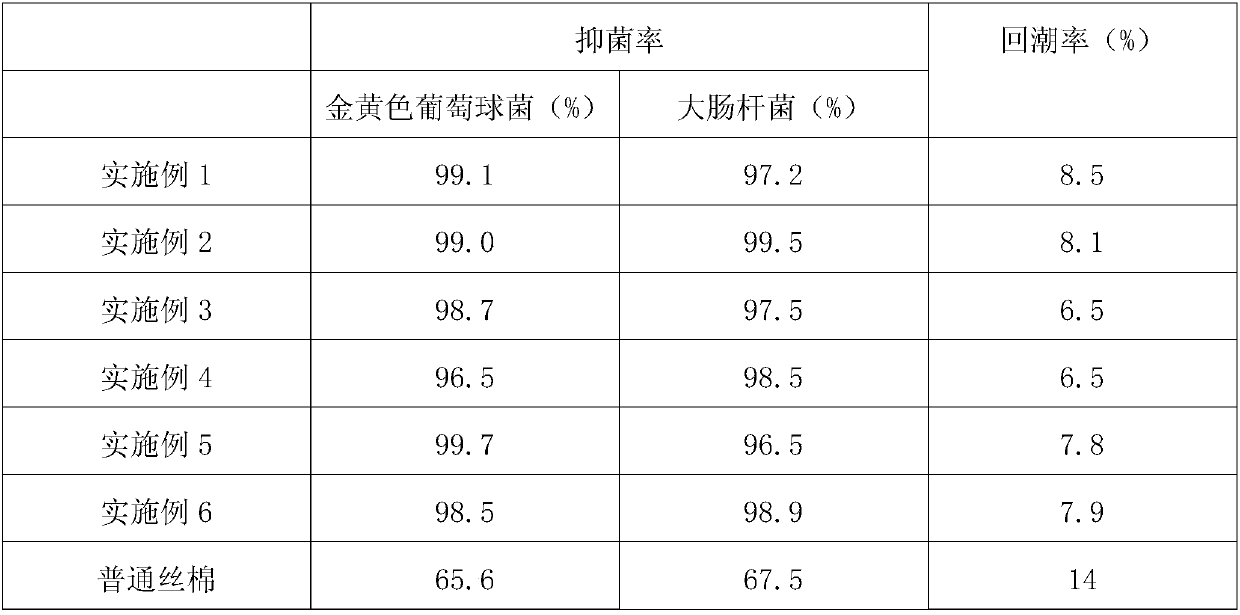

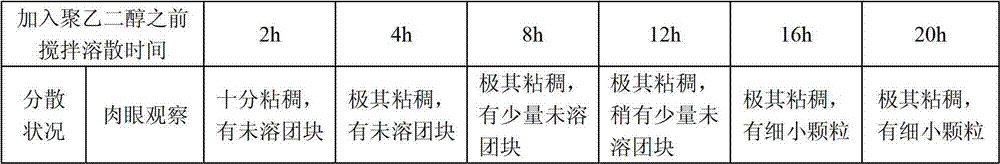

Method for preparing healthcare silk quilt

InactiveCN107669043AIncrease productivityImprove antibacterial propertiesBlanketBiochemical fibre treatmentFiberHusk

The invention belongs to the technical field of silk quilts, and discloses a method for preparing a healthcare silk quilt. The method comprises the following steps that 1, silkworm cocoon raw materials are manually screened; 2, the silkworm cocoon raw materials are dried; 3, after husks on the outermost layers of dried silkworm cocoons are removed, the cocoons are peeled and made into silk pieces;4, the silk pieces are soaked, stirred, cleaned and dehydrated; 5, the dehydrated silk pieces and a degumming agent are placed in a cocoon cooking machine to be stewed, then the silk pieces are fastcleaned with cold water for cooling, then the silk pieces are placed in a drying machine to be dehydrated, and the silk pieces are dried till the water content ranges from 10% to 15%; 6, a finishing agent and natural aromatic are sprayed to the surfaces of the silk pieces; 7, the silk pieces are stretched and spread into multiple layers, and a layer of cotton fibers soaked with the natural aromatic is spread between every two layers; 8, a cotton kneading machine is used for planishing, and the healthcare silk quilt is obtained. The production efficiency is high, and the prepared healthcare silk quilt is good in filling power and tension, and has the healthcare functions of resisting bacteria, preventing mites, preventing insects and the like.

Owner:YIZHOU ZHUANGGE SILK

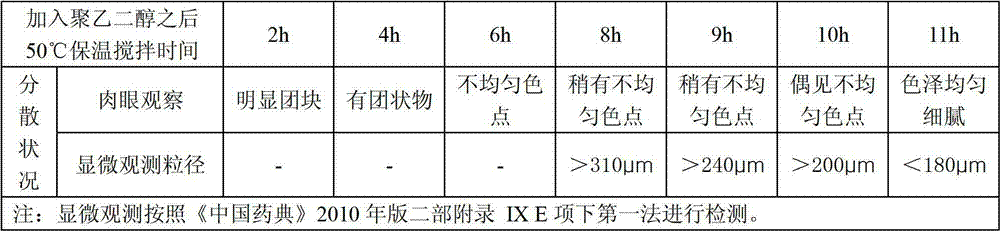

Povidone iodine ointment and preparation method thereof

ActiveCN102885852AControl content lossShorten manufacturing process timeAerosol deliveryOintment deliveryGlycerolPolyethylene glycol

The invention relates to the technical fields of medicinal preparations and preparation methods thereof and particularly discloses a formula of povidone iodine ointment of full water-soluble matrix and a preparation method thereof. The povidone iodine ointment consists of the following components in percentage by weight: 10 percent of povidone iodine, 0.1 to 0.5 percent of potassium iodate, 20 to 31 percent of polyethylene glycol-400, 20 to 30 percent of polyethylene glycol-4000, 5 to 15 percent of xylitol or sorbitol serving as a matrix protecting agent, 15 to 20 percent of glycerol, 0.5 to 2.0 percent of sodium dodecyl sulfate, and 7.5 to 15 percent of purified water. By using unique protective methods and means, the technical problem of low stability in preparation and storage processes of the ointment after the povidone iodine and the water-soluble polyethylene glycol matrix are mixed is solved, the povidone iodine ointment with good performance advantages is prepared, the manufacturing time is greatly shortened, the working efficiency is improved, and the povidone iodine ointment is suitable for large-scale production.

Owner:武汉迪奥药业有限公司

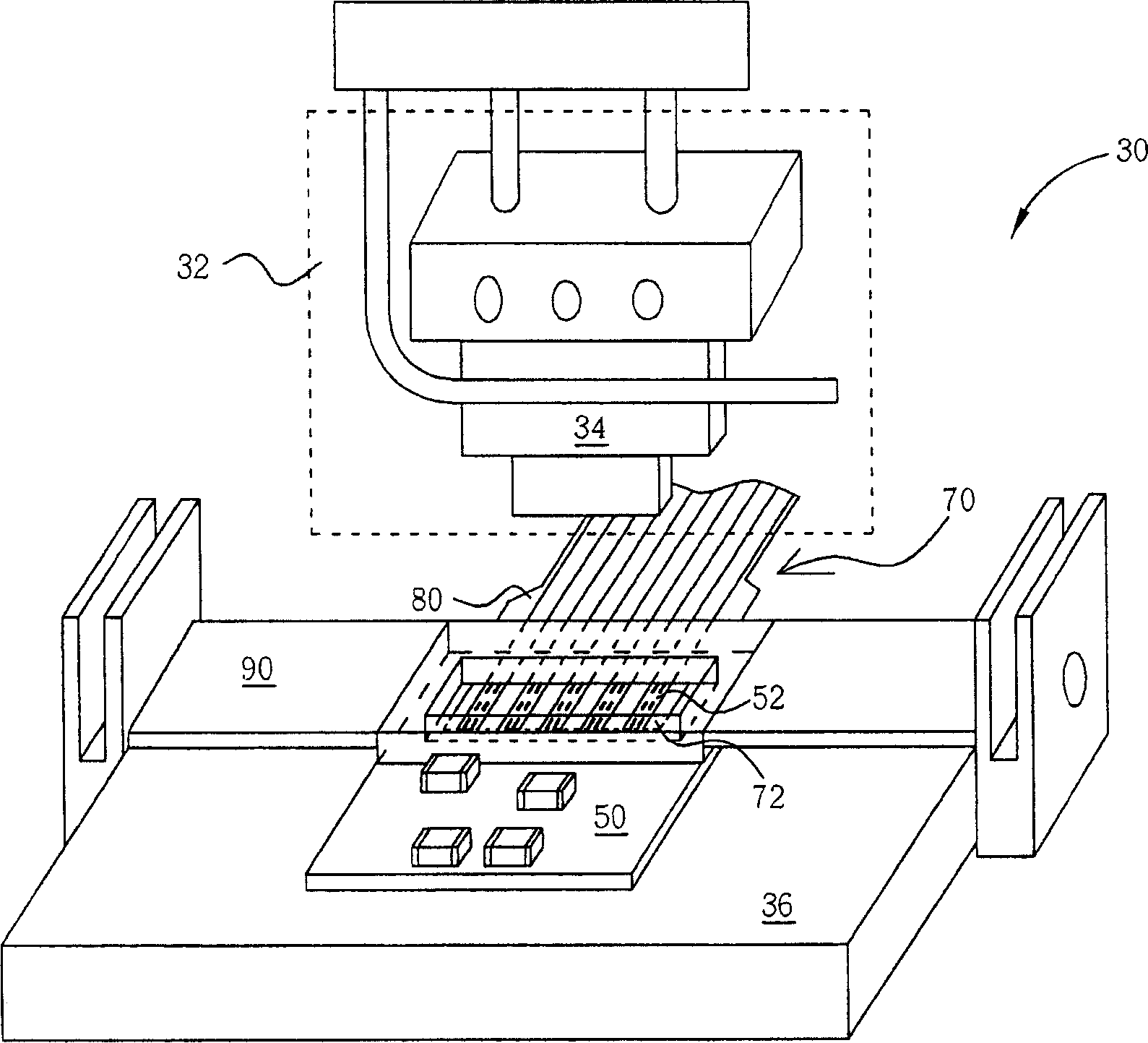

Hot-press

A hot pressing machine is composed of at least one lower die block with a temp-adjustable heater, and at least one movable upper die block with a hot pressing unit.

Owner:ORIENT SEMICON ELECTRONICS

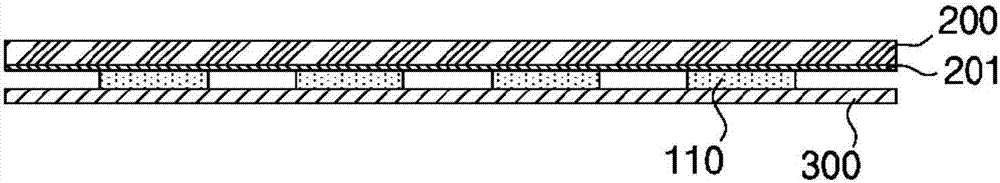

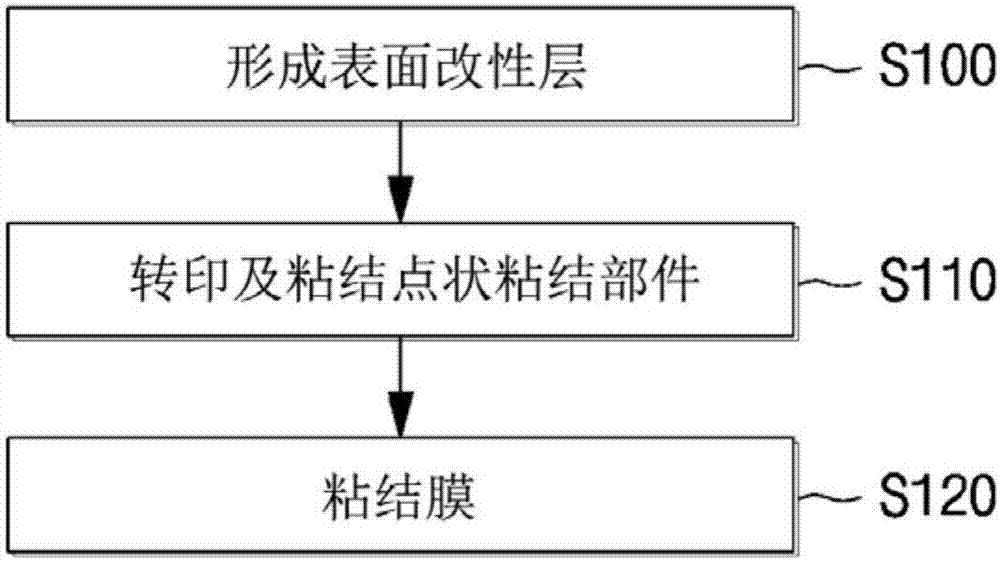

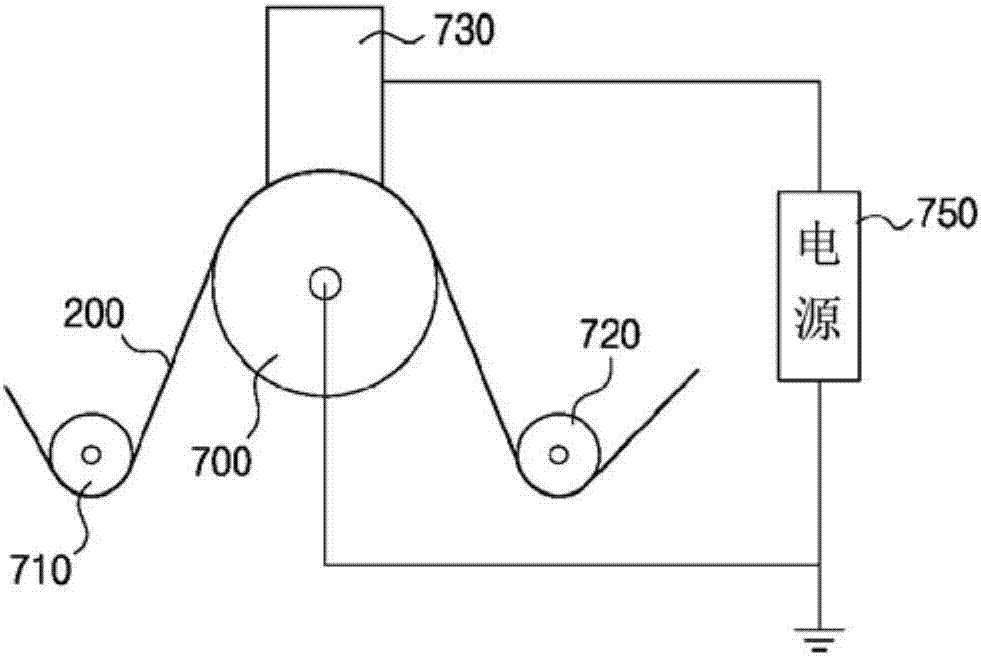

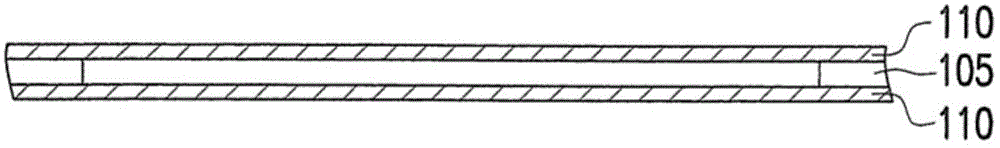

Waterproof and moisture permeable fabric, and manufacturing method therefor

ActiveCN107107546AReduce the bonding areaAvoid deformationLamination ancillary operationsFibre treatmentEngineeringMoisture

Owner:AMOGREENTECH CO LTD

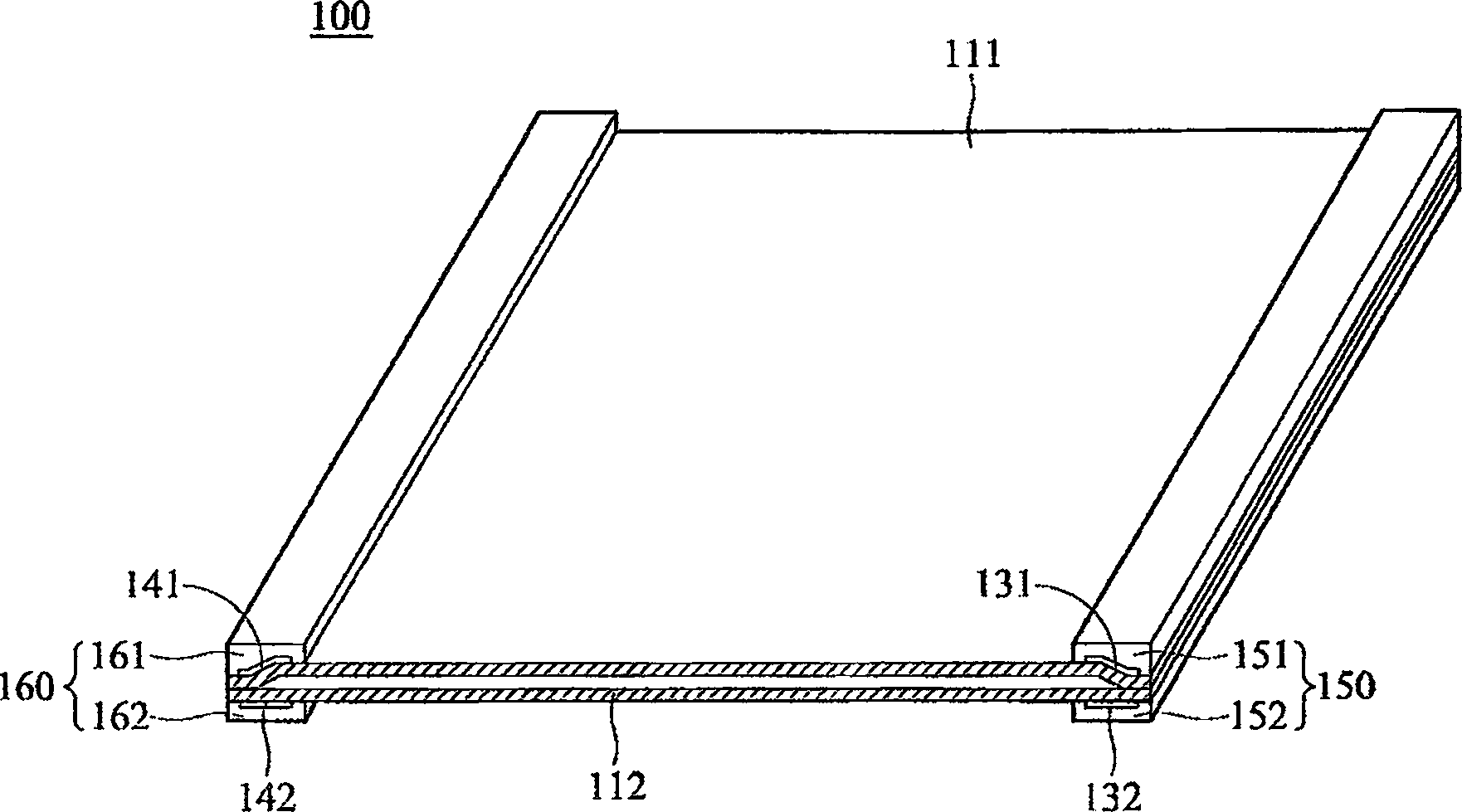

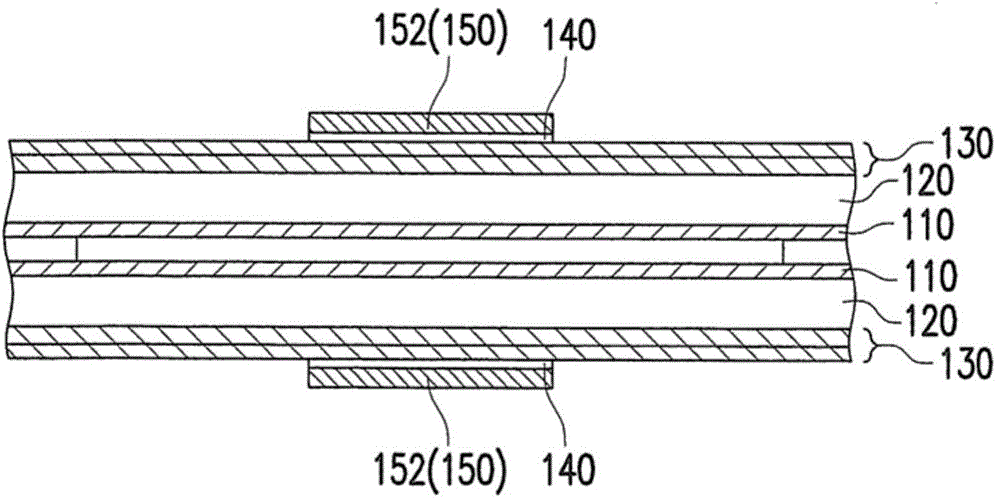

Backlight module, and plane lamp

The present invention relates to a plane lamp. It includes first baseplate, second baseplate, first external electrode, second external electrode, first packaging material and second packaging material. The first baseplate is superimposed on second baseplate, first external electrode is placed on the external surface of said first baseplate and second baseplate, and is close to a first side of said plane lamp, said second external electrode is placed on the external surface of said first baseplate and said second baseplate, and is close to a second side of said plane lamp. Said first external electrode is covered with said first packaging material and said second external electrode is covered with said second packaging material.

Owner:AU OPTRONICS CORP

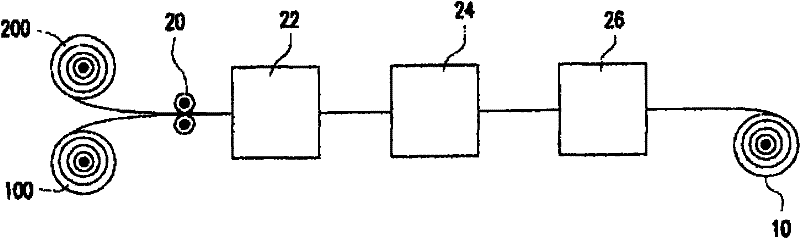

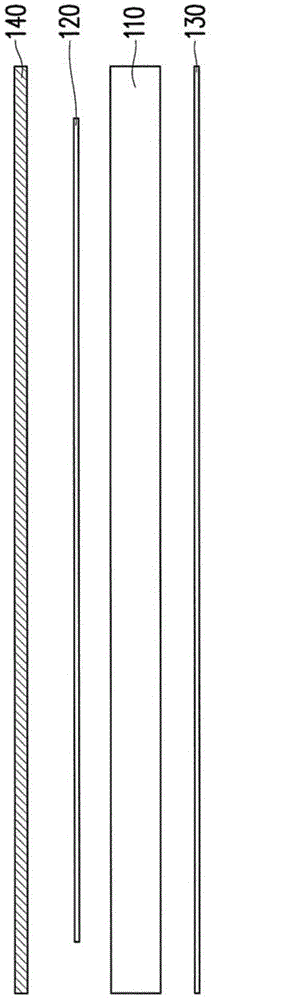

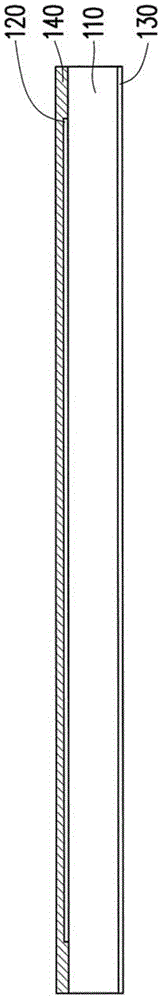

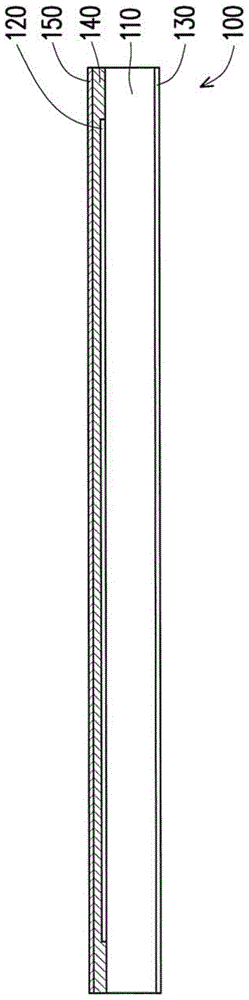

Touch panel roll and manufacturing method thereof

InactiveCN102193664AShorten manufacturing process timeEasy to shipInput/output processes for data processingTouch panelElectrical and Electronics engineering

The invention discloses a touch panel roll and a manufacturing method thereof. The method comprises a step of providing first and second structure rolls. A forming method of the first structure roll comprises steps of forming an opening in a first flexible substrate and extending a lead electrically connected with each electrode to the opening. A forming method of the second structure roll comprises steps of forming the lead electrically connected with each electrode and an independent lead corresponding to the lead in the first structure roll on a transparent conductive layer, wherein one ends of the leads are positioned at a position corresponding to the opening. The method also comprises a step of compressing the first structure roll and the second structure roll in a roll-to-roll mode.

Owner:IND TECH RES INST

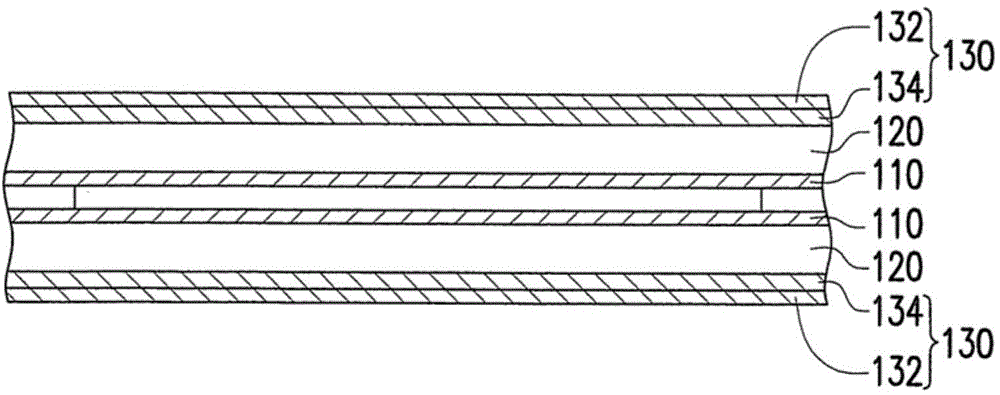

Packaging substrate and manufacturing method thereof

ActiveCN104576402AThin Package ThicknessShorten manufacturing process timePrinted circuit detailsSemiconductor/solid-state device detailsMetallurgyMetal foil

The invention discloses a manufacturing method for a packaging substrate. The method comprises the following steps: jointing two substrate metal layers; pressing two supporting layers on the substrate metal layers respectively; arranging two release metal films on the supporting layers respectively, wherein each release metal film comprises a first metal foil layer and a second metal foil layer which can be separated from each other; forming two first patterned metal layers on the release metal films respectively, wherein each first patterned metal layer comprises a connecting pad pattern; forming two dielectric layers on the release metal films respectively and covering the corresponding first patterned metal layers, wherein a conducting hole is formed in each dielectric layer and the dielectric layers are connected with the corresponding connecting pad patterns respectively; forming two second patterned metal layers on the dielectric layers respectively, wherein the second patterned metal layers at least cover the upper surfaces of the corresponding conducting holes; separating the substrate metal layers to form two packaging substrates independent of each other.

Owner:SUBTRON TECH

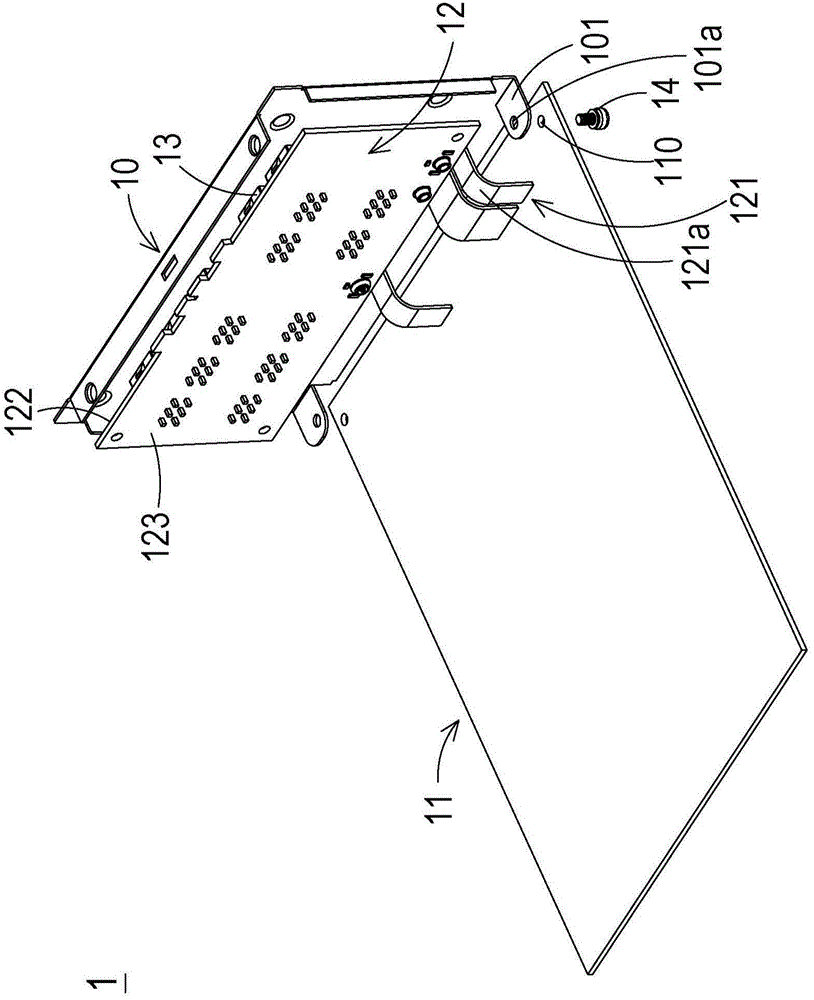

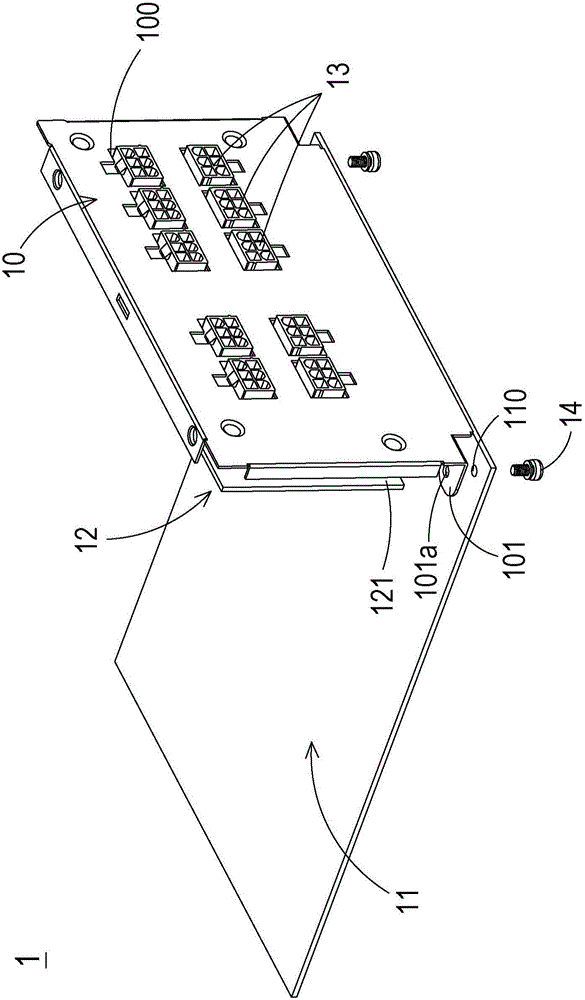

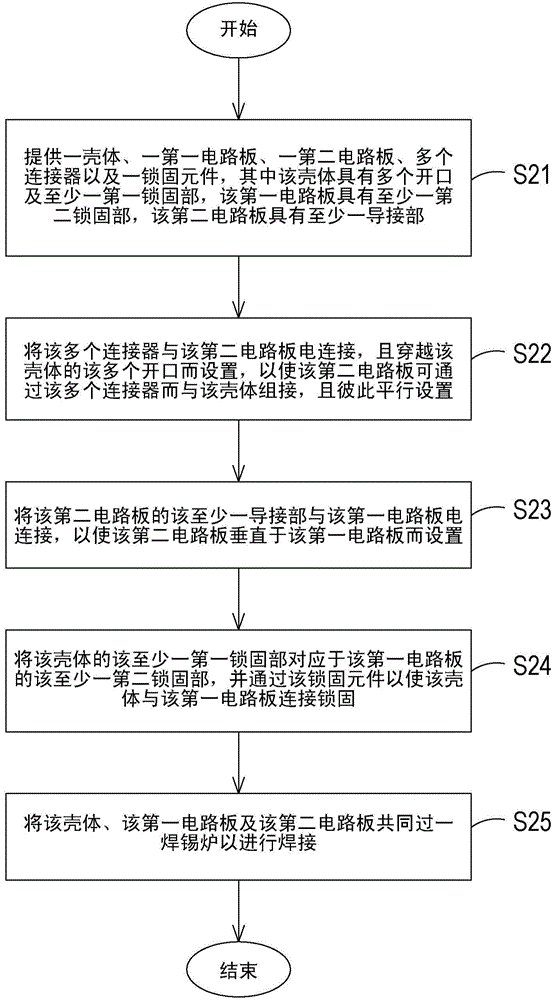

Circuit board combination and assembly method thereof

InactiveCN105792515AWide applicabilityImprove structural strengthPrinted circuit assemblingCoupling device connectionsEngineeringUltimate tensile strength

The invention discloses a circuit board combination and an assembly method thereof. The circuit board combination comprises a shell, a first circuit board, a second circuit board and a locking element, wherein the shell comprises a plurality of openings and a first locking part; the first circuit board comprises a second locking part; the second circuit board comprises a docking part; a plurality of connectors are electrically connected with the second circuit board and are arranged through the plurality of openings of the shell, so that the second circuit board is connected with the shell through the plurality of connectors and the second circuit board and the shell are arranged in parallel; and the docking part of the second circuit board is electrically connected with the first circuit board, so that the second circuit board is arranged vertically to the first circuit board, and the first locking part of the shell is connected and locked corresponding to the second locking part of the first circuit board through the locking element. Application of the circuit board combination is relatively wide; the shell is relatively simply and conveniently connected and fixed to the first circuit board and the second circuit board; the manufacturing process time can be shortened; the production cost is reduced; and the overall structural strength of the circuit board combination can be strengthened.

Owner:DELTA ELECTRONICS INC

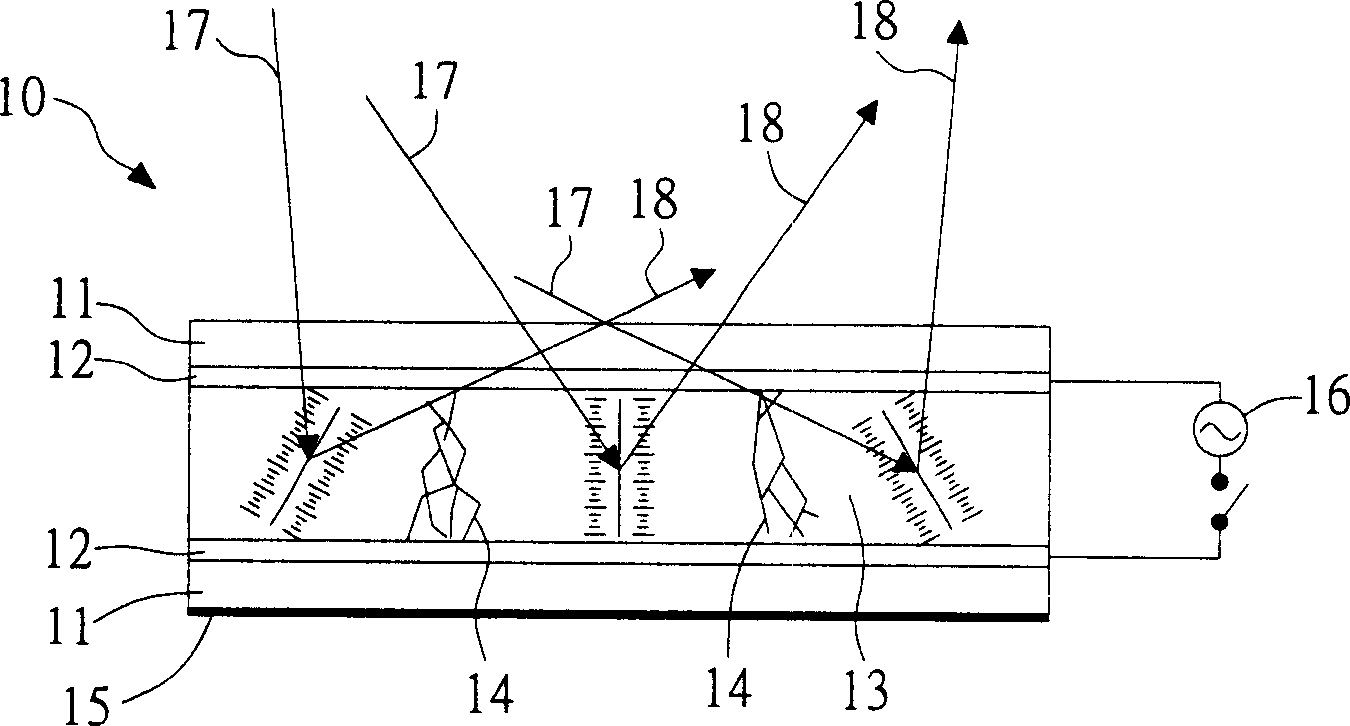

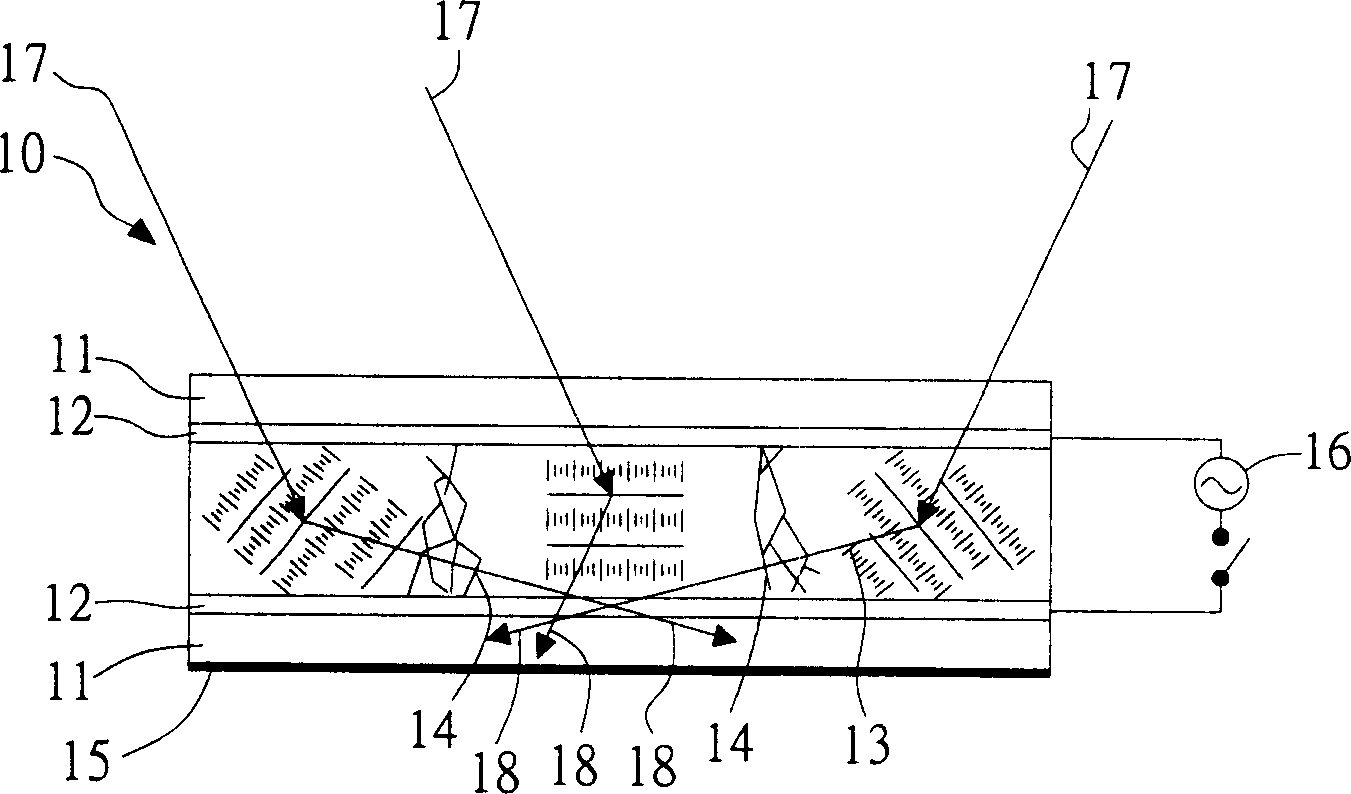

Black-white cholesterol liquid crystal display and its producing method

ActiveCN1749836AShorten manufacturing process timeHigh mechanical strengthStatic indicating devicesPhotomechanical exposure apparatusLiquid-crystal displayCholesteric liquid crystal

The present invention relates to black-white cholesterol LCD and its production process. Exposure technology is adopted to complete the light polymerization / phase separation manufacture process, and further to form polymer wall and polymer diffused to cholesterol LCD area. The present invention has short technological process, high mechanical strength of interval between LCD unit and high brightness and contrast of the black-white LCD.

Owner:上海虹夏光电科技有限公司

Flexible and hard composite circuit board and manufacturing method thereof

ActiveCN103987207AThin and lightShorten manufacturing process timePrinted circuit assemblingPrinted circuits structural associationsFlexible circuitsEngineering

The invention discloses a flexible and hard composite circuit board and a manufacturing method thereof. The manufacturing method provides a circuit board. An insulating layer and a flexible circuit board are provided. The insulating layer is arranged on the flexible circuit board. The insulating layer is provided with an opening and the opening exposes part of the flexible circuit board. A plurality of first conductive holes are formed in the insulating layer, wherein one end of each first conductive hole is connected with the flexible circuit board. The hard circuit board, the insulating layer and the flexible circuit board are laminated so that the insulating layer is connected between the hard circuit board and the flexible circuit board. An enclosed area is defined among the opening of the insulating layer, the hard circuit board and the soft circuit board. The other end of each first conductive through hole is connected with the hard circuit board. The enclosed area is used as a positioning reference point to remove part of the hard circuit board above the opening so as to expose part of the flexible circuit board.

Owner:UNIMICRON TECH CORP

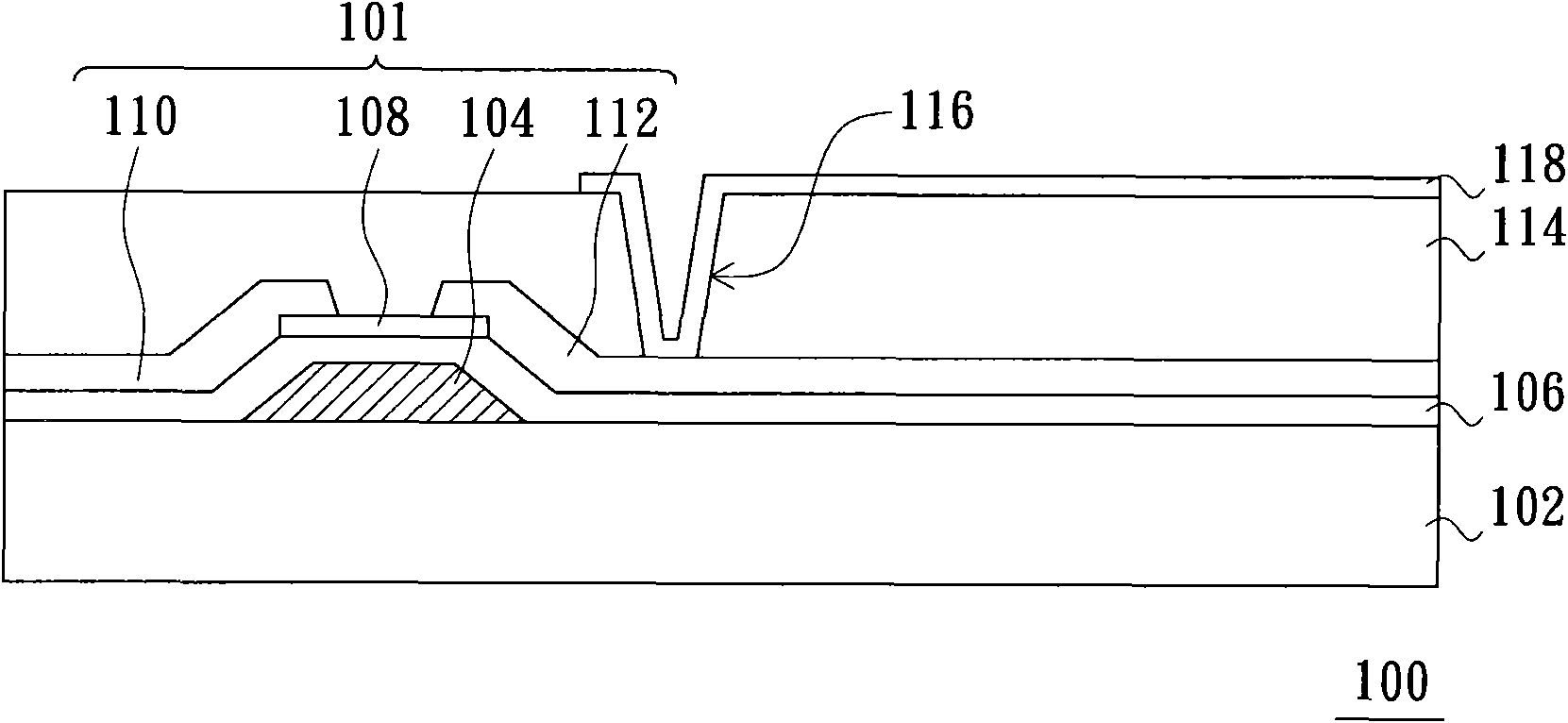

Display and thin film transistor array substrate and thin film transistors thereof

ActiveCN102054873AAvoid leakage currentOmit patterning manufacturing processTransistorSolid-state devicesDisplay deviceDielectric layer

The invention relates to a display and a thin film transistor array substrate and thin film transistors thereof. The display comprises the thin film transistor array substrate, an optically transparent electrode substrate and a display dielectric layer arranged between the thin film transistor array substrate and the optically transparent electrode substrate, wherein the thin film transistor array substrate comprises a plurality of thin film transistors with oxide semiconductor layers; grid electrodes and grid insulating layers of the thin film transistors are arranged on the substrate respectively; the grid electrodes are covered by the grid insulating layers; the oxide semiconductor layers cover on the grid insulating layers conformally and are provided with channel regions positioned above the grid electrodes; and source electrodes and drain electrodes of the thin film transistors are arranged on the oxide semiconductor layers respectively and are positioned on the two sides of each channel region. The oxide semiconductor layers are made of optically transparent materials, so that a manufacturing process for patterning the oxide semiconductor layers can be eliminated in a display manufacturing process so as to save manufacturing cost and shorten the time of the manufacturing process.

Owner:E INK HLDG INC

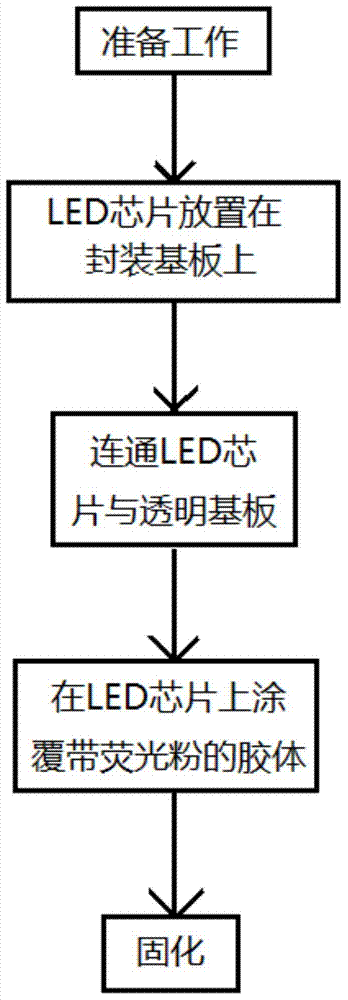

LED packaging method

InactiveCN103579459AImprove uniformityShorten the timeSemiconductor devicesHeat conductingEngineering

The invention relates to an LED packaging method. The LED packaging method comprises the following steps that (1) a transparent substrate and a heat-conducting light-reflecting gasket are manufactured, and a light-reflecting cup is arranged on the transparent substrate; (2) the heat-conducting light-reflecting gasket is arranged at the bottom of the light-reflecting cup of the transparent substrate, and an LED chip is arranged on the heat-conducting light-reflecting gasket; (3) one end of a wire is welded to the LED chip, and the other end of the wire is welded to the bottom of the light-reflecting cup so that the LED chip and the transparent substrate can be in conduction; (4) powder slurry is formed by fluorescent powder and colloid, after stir is carried out, the powder slurry directly coats the LED chip, the transparent substrate is placed into a centrifuge, and the fluorescent powder sinks to the bottom of the colloid through powerful centrifugal force generated through high-speed rotation of a rotor of the centrifuge; (5) an infrared irradiator directly irradiates the LED chip so that the colloid can be solidified. According to the LED packaging method, consistency between the color temperature and the emitting color is ensured, and the time consumed in the process of LED packaging and solidification can be effectively and greatly reduced.

Owner:桂林机床电器有限公司

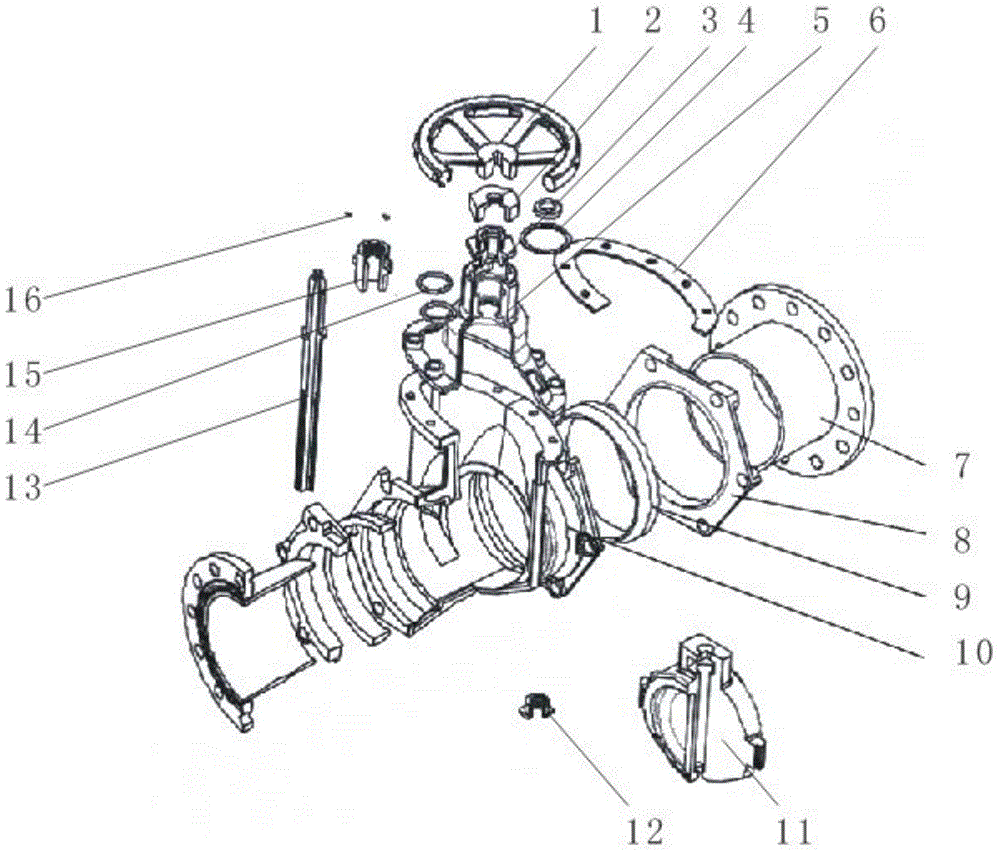

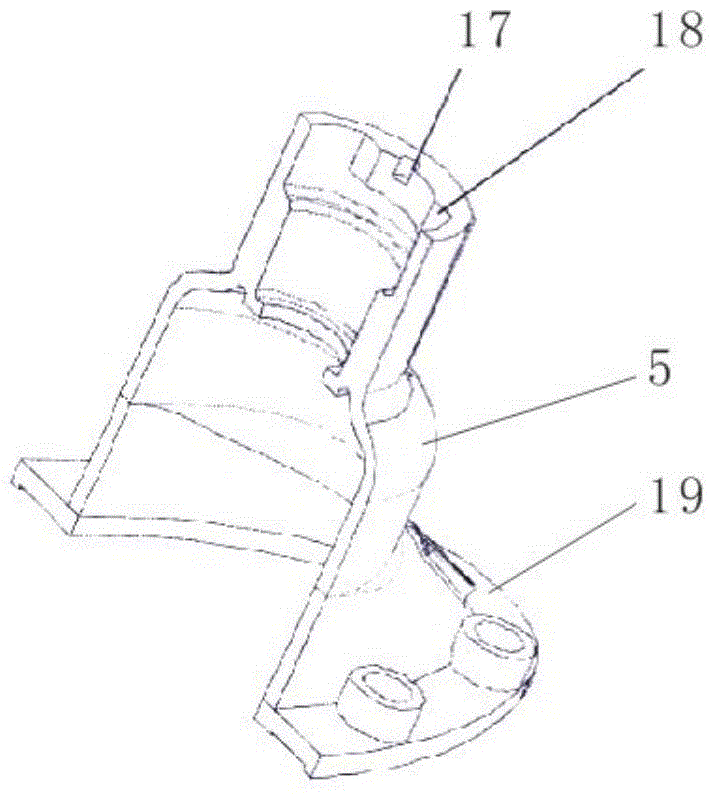

Inorganic-machining vacuum evanescent mode cast telescopic gate valve

InactiveCN105202209AReduce investmentDry sand modeling fastSlide valveValve housingsManufacturing technologyEvanescent mode

The invention relates to an inorganic-machining vacuum evanescent mode cast telescopic gate valve. A valve cover is fixedly installed at the upper end of a valve body in a sealed mode, a wedge disc is installed in the middle of the valve body in a guiding mode, a valve rod is fixedly installed at the upper end of the middle of the wedge disc and extends upwards out of the valve cover, a lock nut is installed coaxially in the middle of the valve rod in an engaged mode and coaxially embedded into the upper end of the valve cover, and a middle connection nut and a pressing nut are sequentially installed on the part, at the upper end of the lock nut, of the valve rod in a sleeving mode and fixedly installed on the valve cover in a locked mode. Telescopic joints are installed at the two ends of a flowing channel of the valve body respectively, one end of the inner side of each telescopic joint penetrates into the valve body in a coaxial mode, the telescopic joints are sleeved with pressing ring flanges connected with the valve body in a sealed mode, and pressing ring seal gaskets are pressed between the parts, on the inner sides of the pressing ring flanges, of the valve body and the telescopic joints in a sleeving mode. The valve cover can be formed in a one-off cast mode, flange connection is not needed at the valve rod, the requirement for raw materials is lowered, the manufacturing technology is simple, manufacturing technology time is effectively shortened, and working efficiency is improved.

Owner:AIMEITE TIANJIN FLUID CONTROL EQUIP CO LTD

Package Substrate And Manufacturing Method Thereof

ActiveCN106158667AReduce manufacturing costShorten manufacturing process timeFlexible coversWrappersConductive materialsCopper foil

The present invention discloses a package substrate and a manufacturing method thereof. The manufacturing method comprises that: a first base is formed; a plurality of metal bumps is formed on the first base by plating; a second base having an upper and an lower surfaces, a core dielectric layer, a first and a second copper foil layers and a plurality of containing cavities is provided; an adhesive layer is formed on walls of the containing cavities; the first and the second bases are laminated so that the metal bumps are disposed inside the containing cavities; afirst base is removed; a plurality of blind via holes extending from the upper surface to the metal bumps is formed; a conductive material layer is formed on the first and the second copper foil layers, wherein the conductive material layer fills the blind via holes so as to define a plurality of conductive through via holes; the conductive material layer is patterned to form a first and a second patterned metal layers.

Owner:SUBTRON TECH

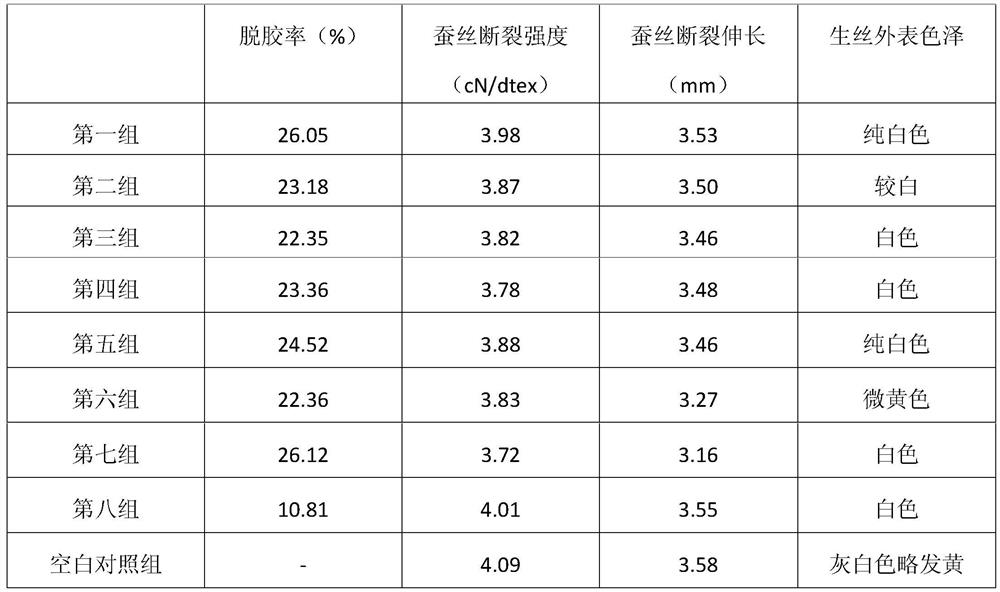

Preparation method of silk quilt

ActiveCN112401598AIncrease productivityExcellent and stable qualityBlanketBiochemical fibre treatmentAntibiosisEngineering

The invention relates to the technical field of home textiles, in particular to a preparation method of a silk quilt. The preparation method of the silk quilt comprises the following steps of (1) silkpreparation, (2) refining, (3) rinsing, (4) modification, (5) drying and (6) silk quilt preparation. The silk quilt prepared through the method is high in production efficiency, excellent and stablein quality, safe in operation process, easy and convenient to operate and capable of saving resources, compared with a traditional preparation process, the preparation process time is shortened, the production cost is reduced, the prepared silk is fragrant, pleasant, good in cotton bulkiness and tension and good in whiteness. Meanwhile, the health-care functions of antibiosis, mite prevention, insect prevention and the like are realized.

Owner:广西农投时宜农业科技有限公司 +2

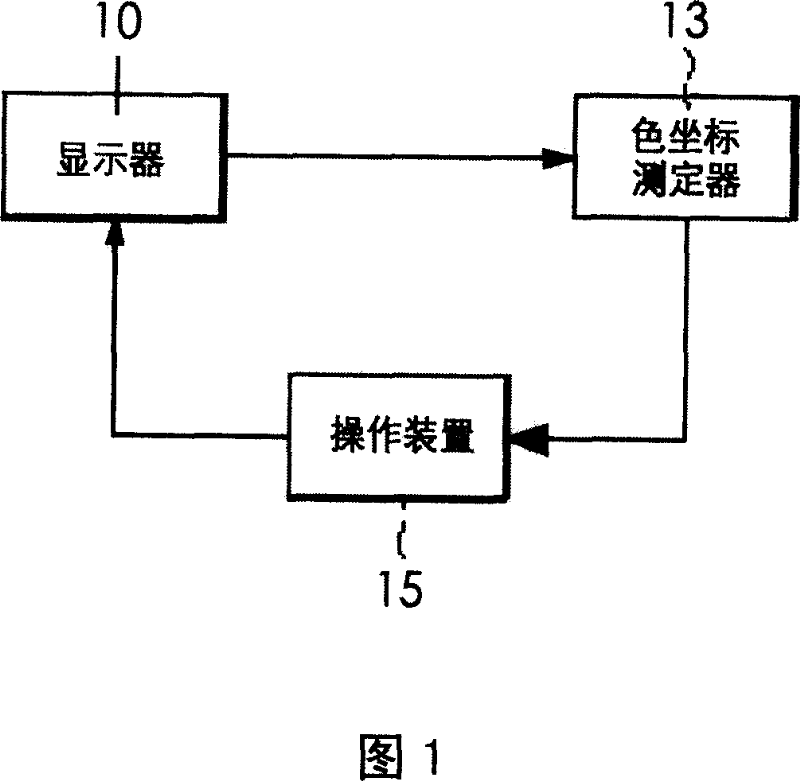

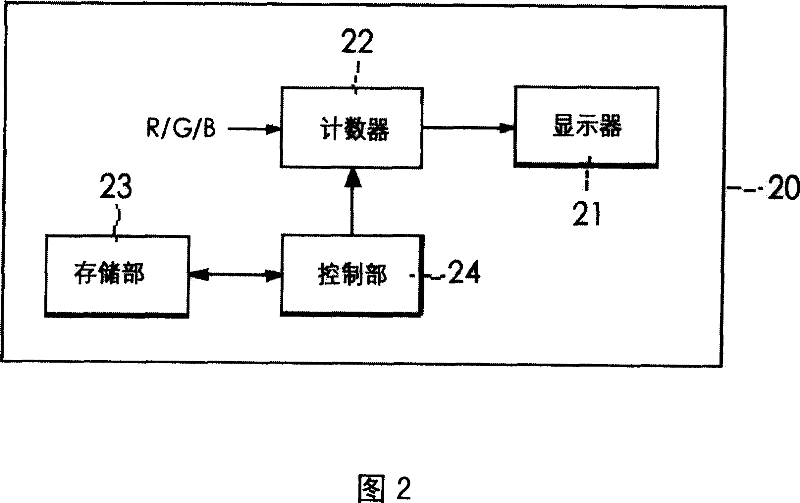

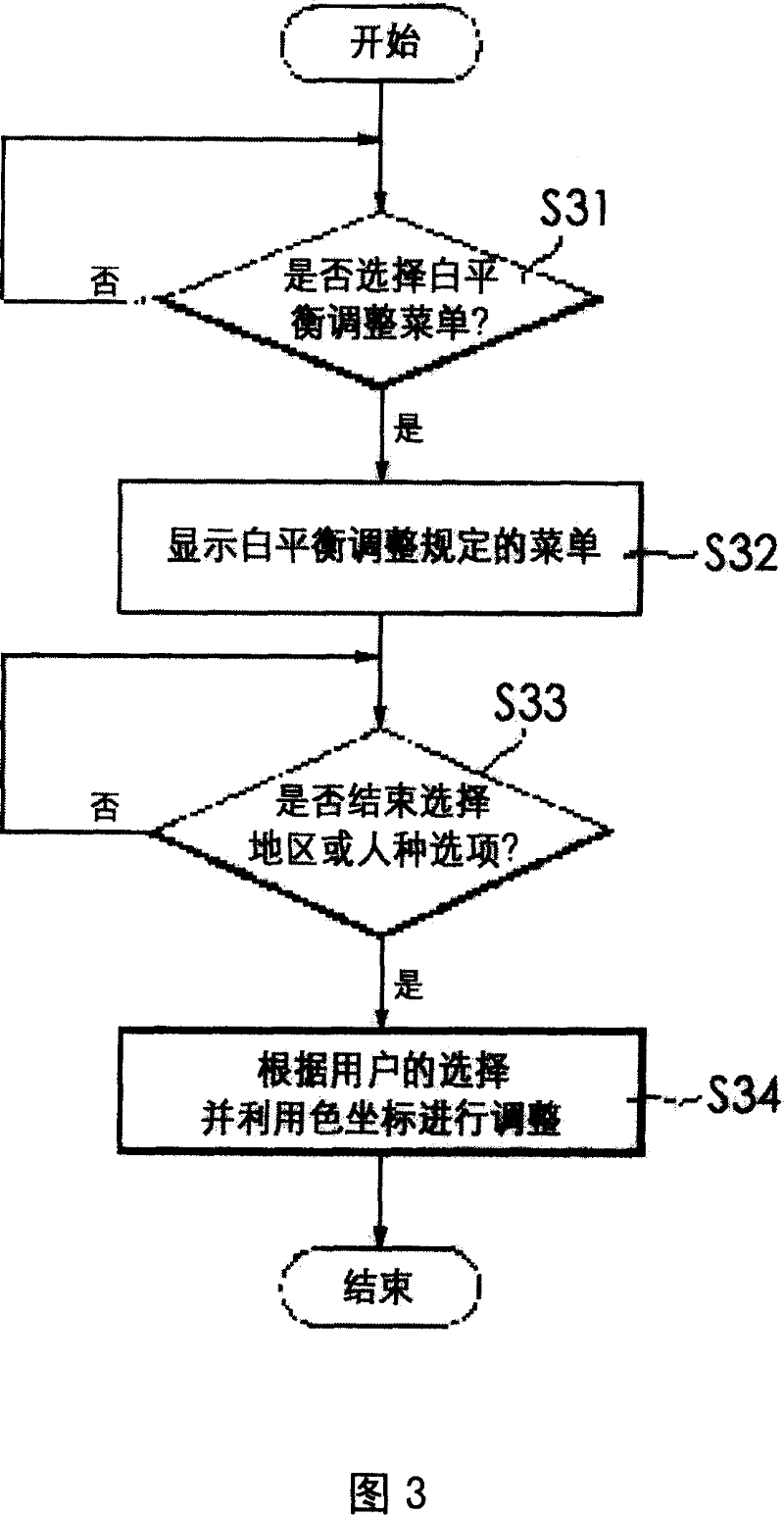

White balance adjustment apparatus of display device and methods therefor

InactiveCN101043635AReduce processing timeIncrease productivityColor signal processing circuitsDisplay deviceContrast ratio

The display white balance adjustment device comprises: a counter to control R / G / B contrast according to external gain, a memory to store at least one color coordinate information, and a controller to adjust the white balance according to user selected reference. This invention reduces total process time, improves production efficiency, and is very convenient for application.

Owner:NANJING LG TONGCHUANG COLOR DISPLAYS SYST CO LTD

Rice grain brewing type instant convenient porridge and preparation method thereof

ActiveCN103652592BEnhanced anti-retrofit propertiesFor long-term storageFood dryingFood ultrasonic treatmentSucroseManufacturing technology

The invention belongs to the technical field of food processing, and relates to rice grain brewing type instant convenient porridge and a preparation method thereof. The method comprises the following technical steps of: preparing raw materials; preparing raw material soak solution; carrying out ultrasonic immersion; dewatering; curing; drying until the moisture content is less than 10%; packaging. The raw material soak solution is prepared from the following components in parts by weight: 0.1-0.9 part of citric acid, 0.02-0.5 part of sodium carbonate, 0.1-1.5 parts of beta-cyclodextrine, 0.1-0.9 part of monoglyceride, 0.1-0.3 part of sucrose fatty acid ester and 100 parts of water. According to the raw material soak solution, the raw returning resistance of rice grains can be enhanced, the convenient porridge can be favorably stored for a long time, the brewing type instant convenient porridge rehydration time is shortened, the effective nutritional ingredients of raw materials can be sufficiently reserved, and the edible quality of the instant convenient porridge is improved. The preparation method for the rice grain brewing type instant convenient porridge, which is disclosed by the invention, has the advantages of simple operation, no need of rice frying and low-temperature freezing operation, high production efficiency and small energy consumption and is favorable for industrialized production, the manufacture technology time is shortened, and the production cost is lowered.

Owner:INNER MONGOLIA YINGPAN LIANGNONG ANIMAL HUSBANDRYIND CO LTD

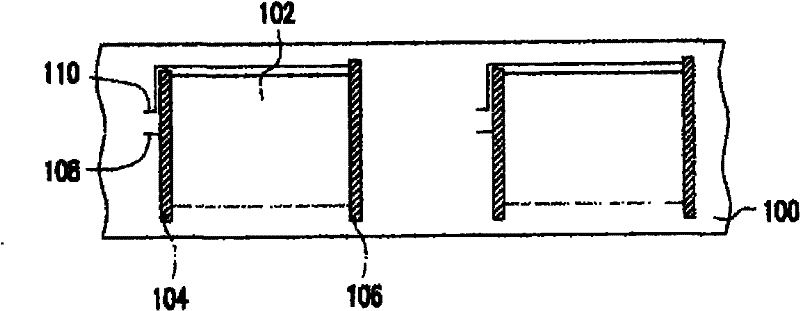

Sealing structure of liquid-crystal displaying panel and producing process thereof

InactiveCN1325983CLow costShorten manufacturing process timeStatic indicating devicesSemiconductor/solid-state device manufacturingLiquid-crystal displayEngineering

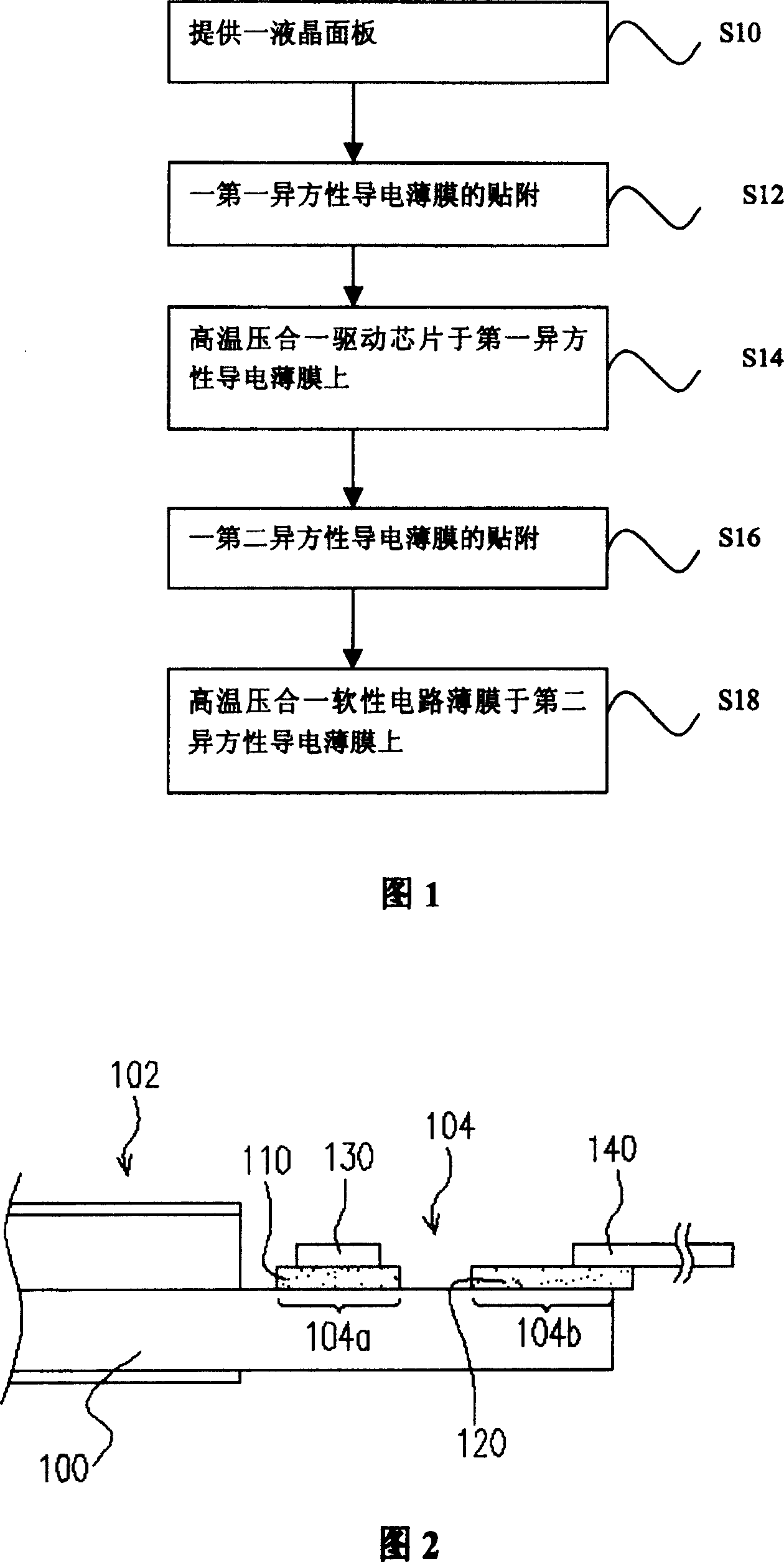

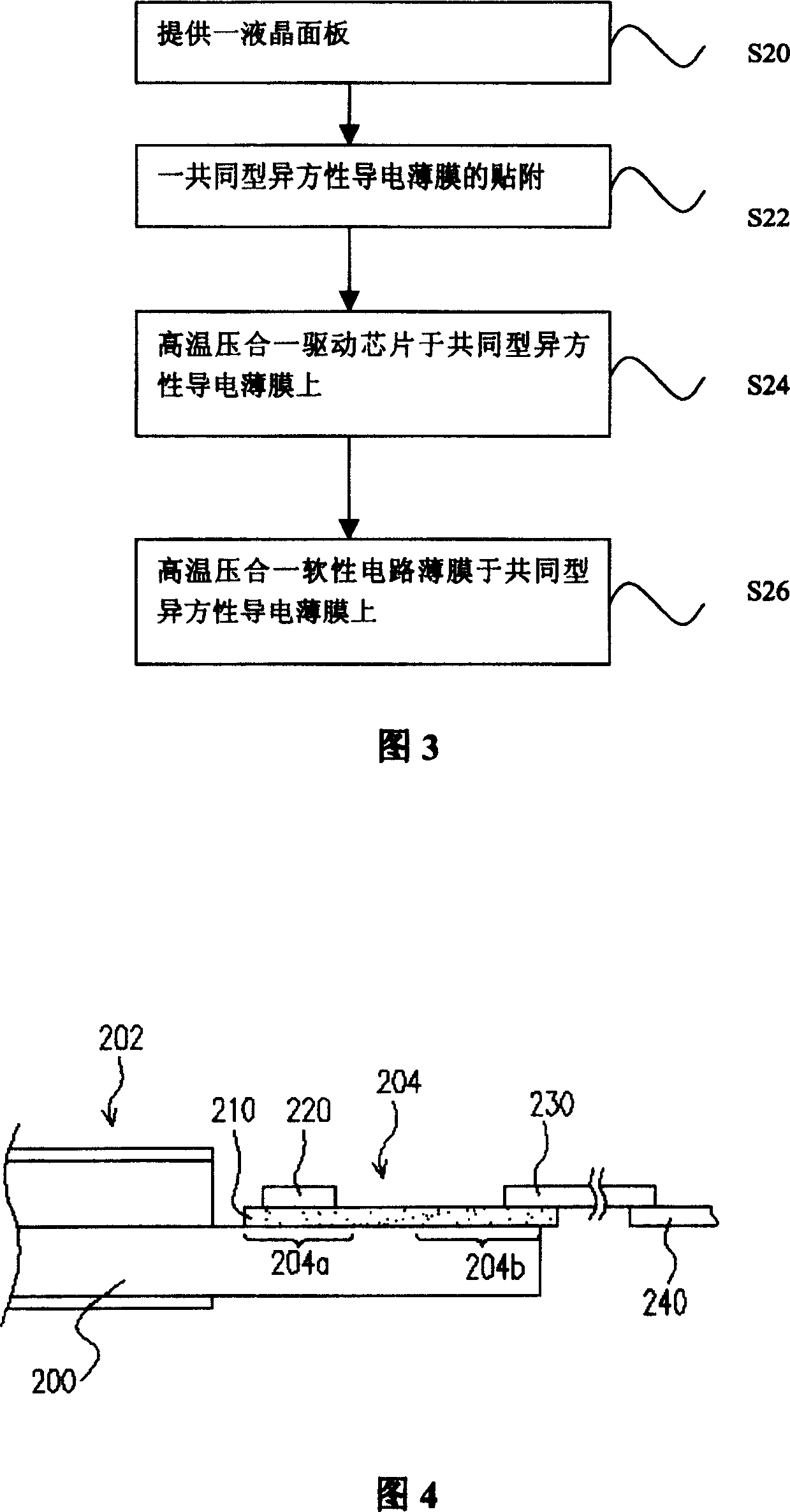

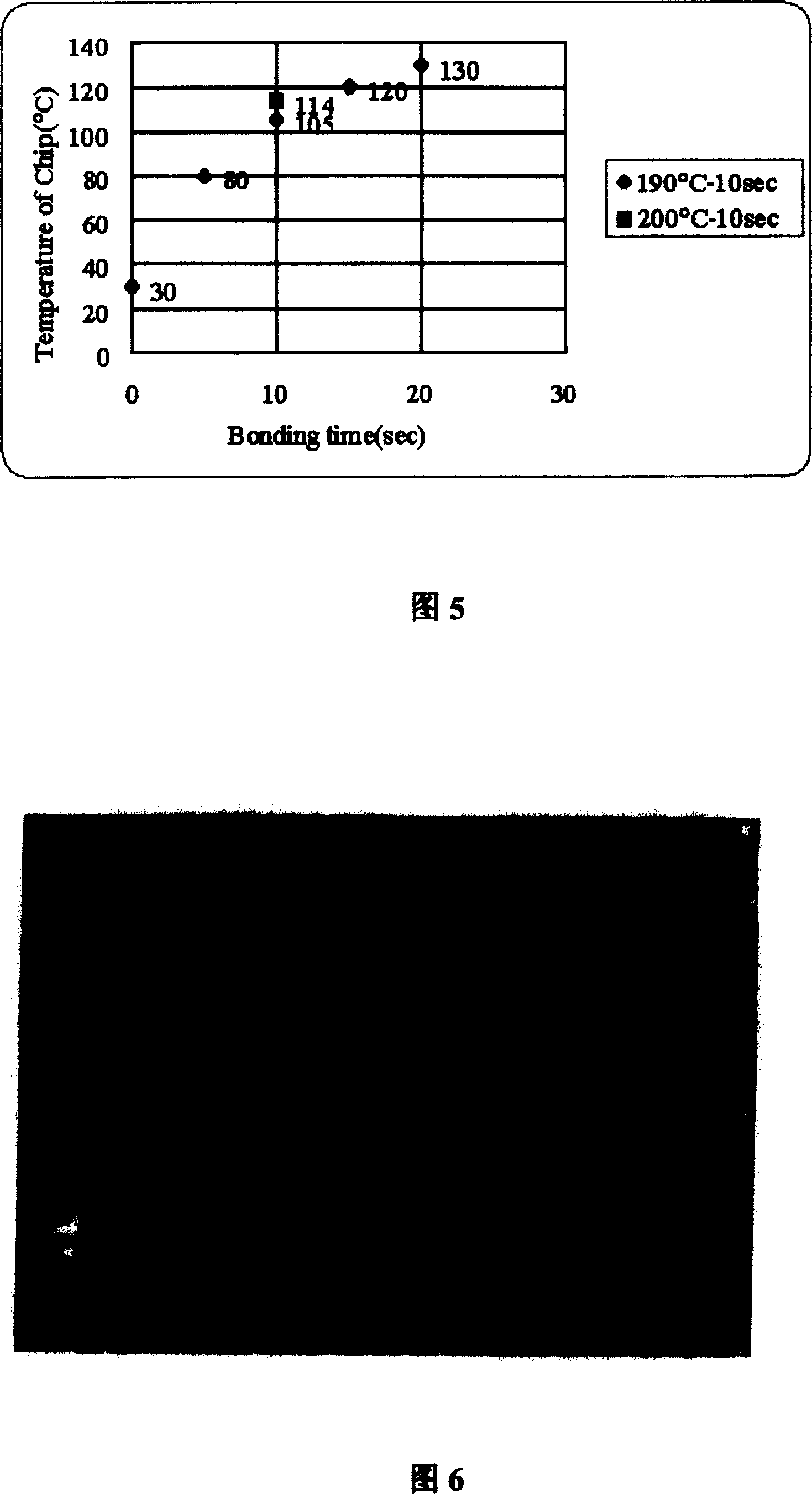

In the present invention, a shared type of heterodirectivity conduction film is snuggled up to nondisplaying area of liquid crystal display panel so driving chip and soft circuit film set on shared type of heterodirectivity conduction film are electric-connected with circuit on non displaying area; thus only one step of snuggling is required in packaging procedure since shard type of heterodirectivity conduction film provided by the present invention is applied.

Owner:AU OPTRONICS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com