Patents

Literature

158results about How to "Reduce the bonding area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Soft Single-Ply Tissue

ActiveUS20100051218A1Low breaking lengthIncreased durabilityCellulosic pulp after-treatmentNon-fibrous pulp additionBiomedical engineeringPaper sheet

A soft single-ply tissue sheet is produced by making a textured, high bulk, through dried tissue sheet and calendering the sheet with a high level of compression energy to substantially reduce the bulk and impart improved properties to the sheet.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Soft single-ply tissue

ActiveUS7935221B2Low breaking lengthIncreased durabilityCellulosic pulp after-treatmentNon-fibrous pulp additionBiomedical engineering

A soft single-ply tissue sheet is produced by making a textured, high bulk, through dried tissue sheet and calendering the sheet with a high level of compression energy to substantially reduce the bulk and impart improved properties to the sheet.

Owner:KIMBERLY-CLARK WORLDWIDE INC

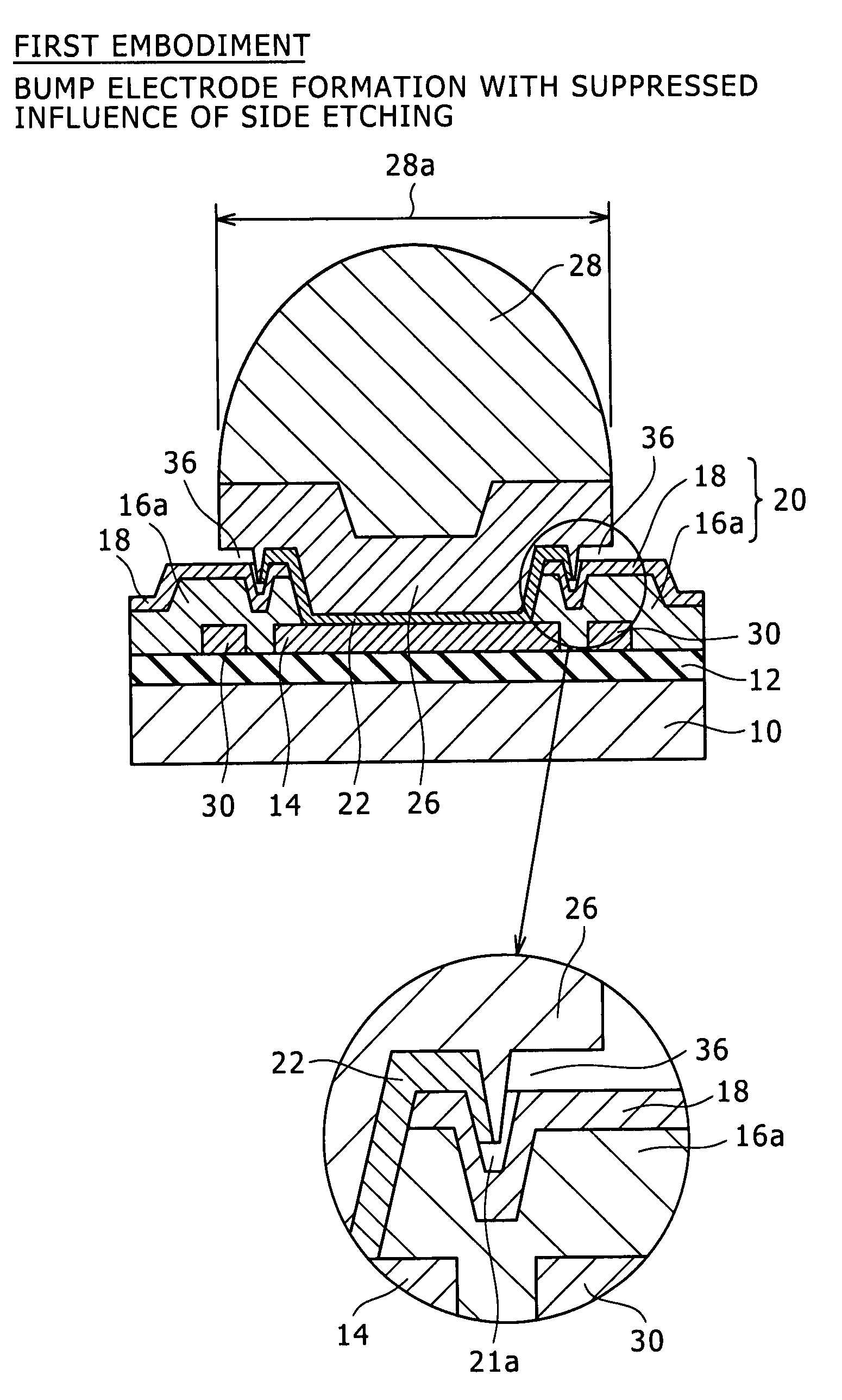

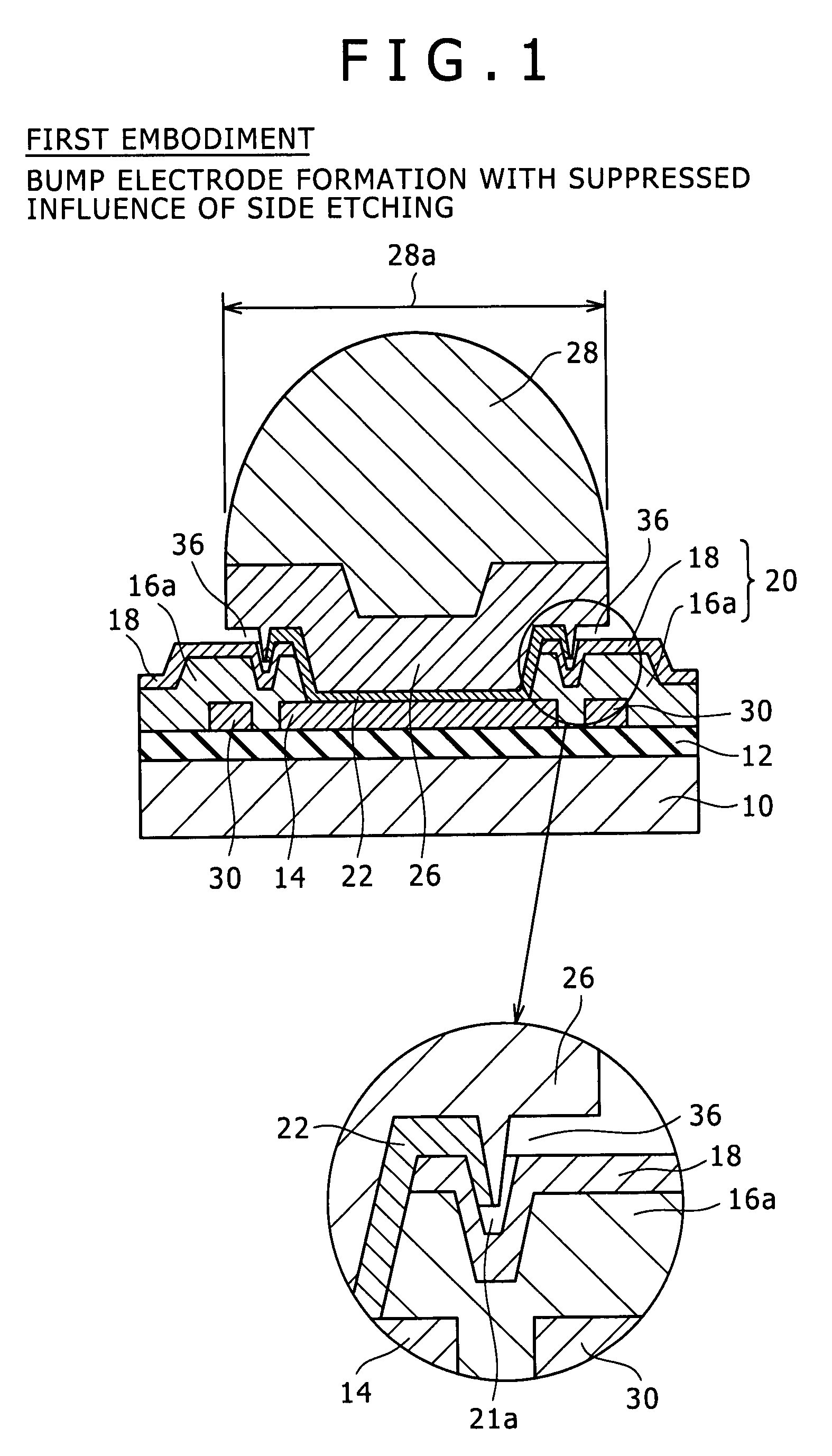

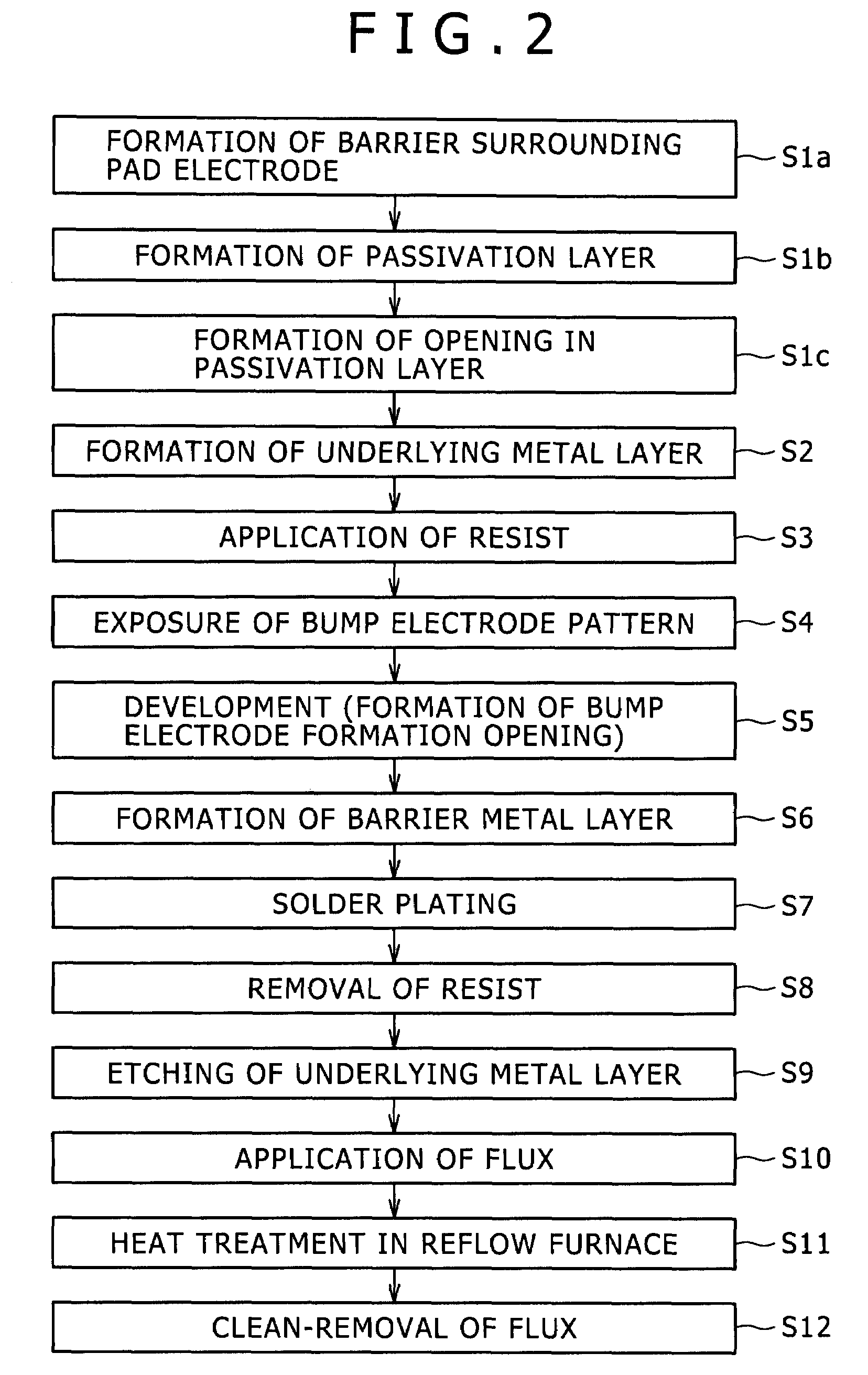

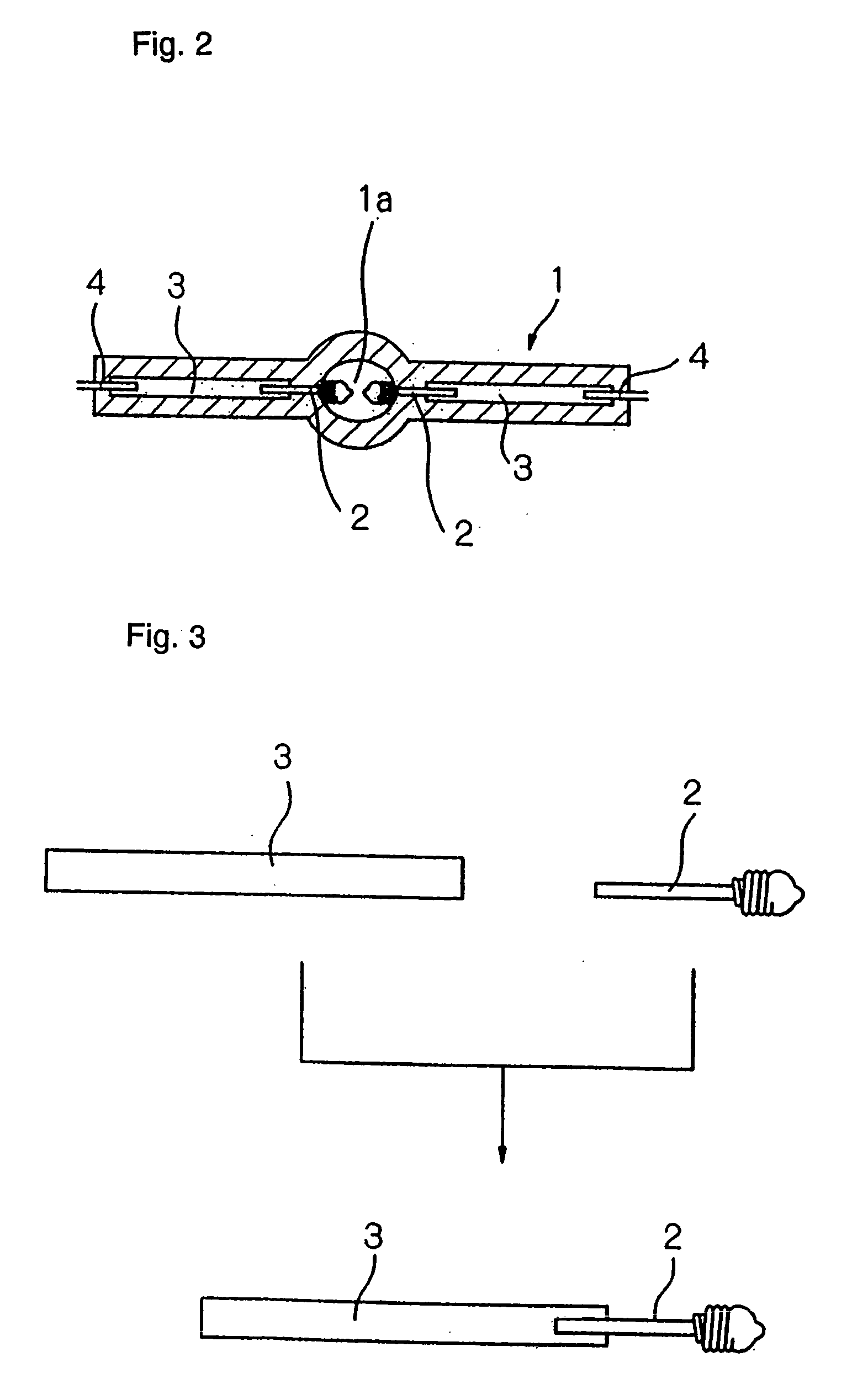

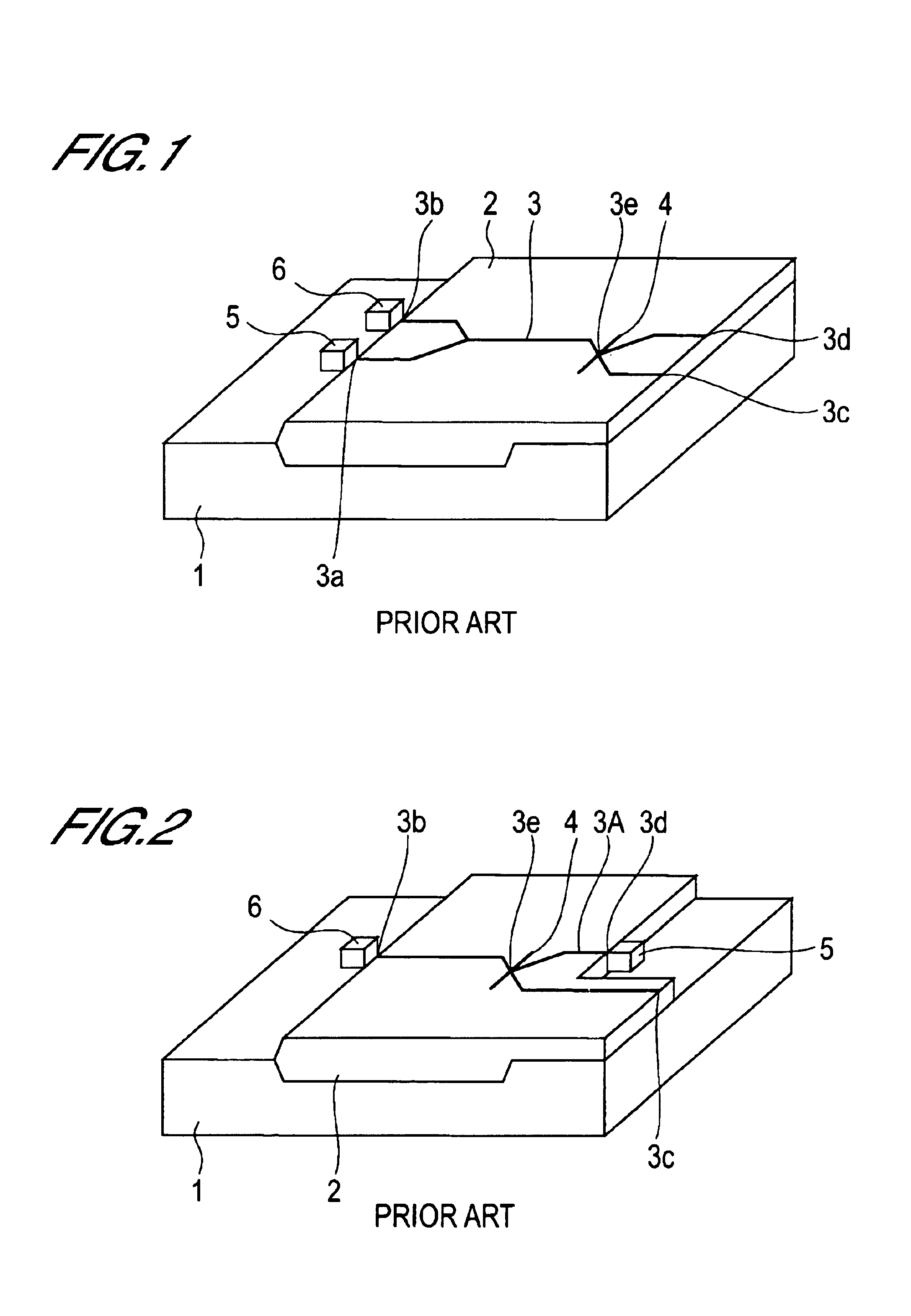

Electronic component, semiconductor device employing same, and method for manufacturing electronic component

ActiveUS7728431B2Avoid loss of bond strengthReduce the bonding areaSemiconductor/solid-state device detailsSolid-state devicesElectronic componentSemiconductor

Herein disclosed an electronic component having a passivation layer in which an opening that exposes a part of a pad electrode is formed, an underlying metal layer formed on the pad electrode and the passivation layer, and a barrier metal layer formed on the underlying metal layer for an external connection electrode, the electronic component including a recess or / and a projection configured to be provided under the barrier metal layer outside or / and inside the opening, the underlying metal layer being formed on the recess or / and the projection and having a surface shape that follows the recess or / and the projection.

Owner:SONY CORP

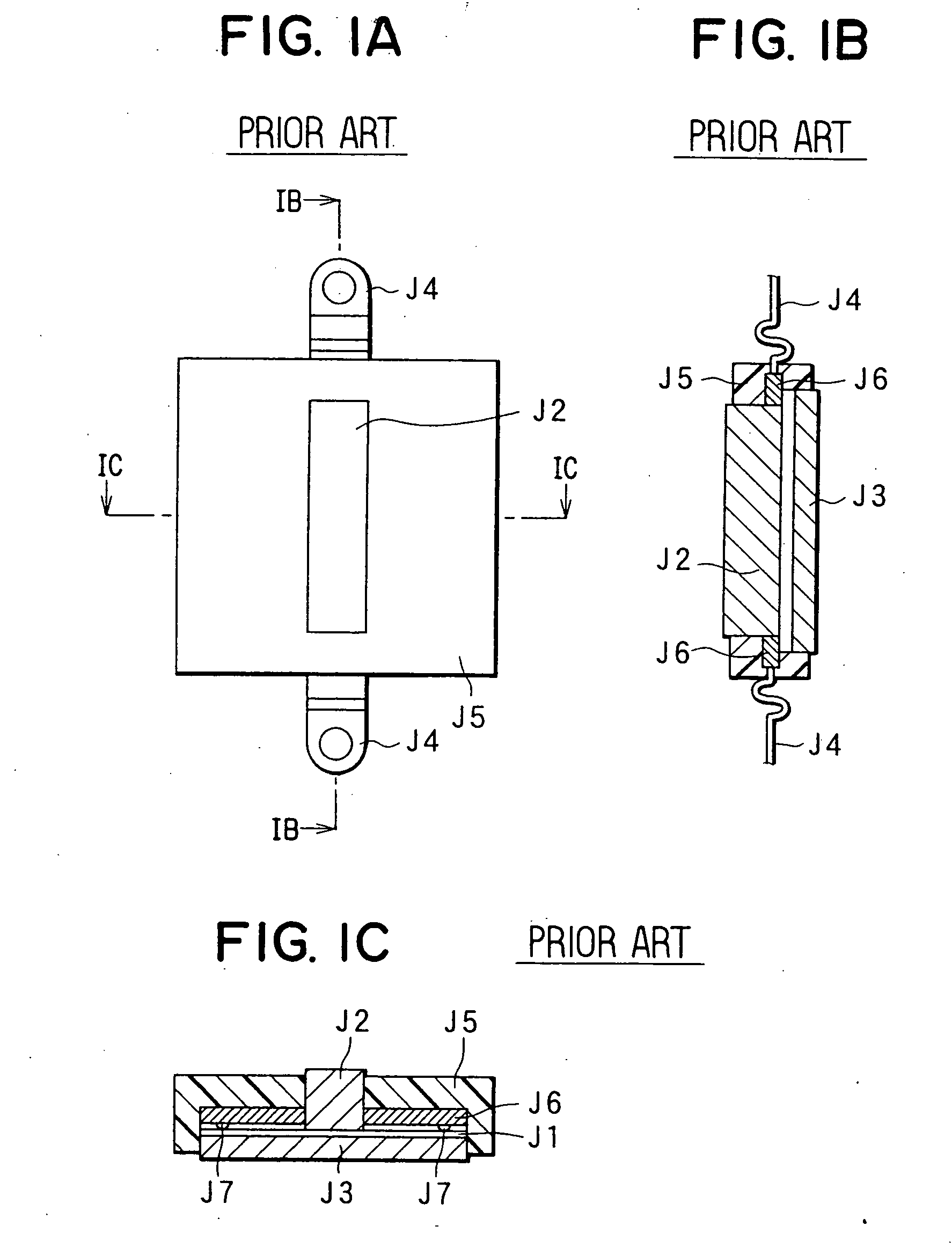

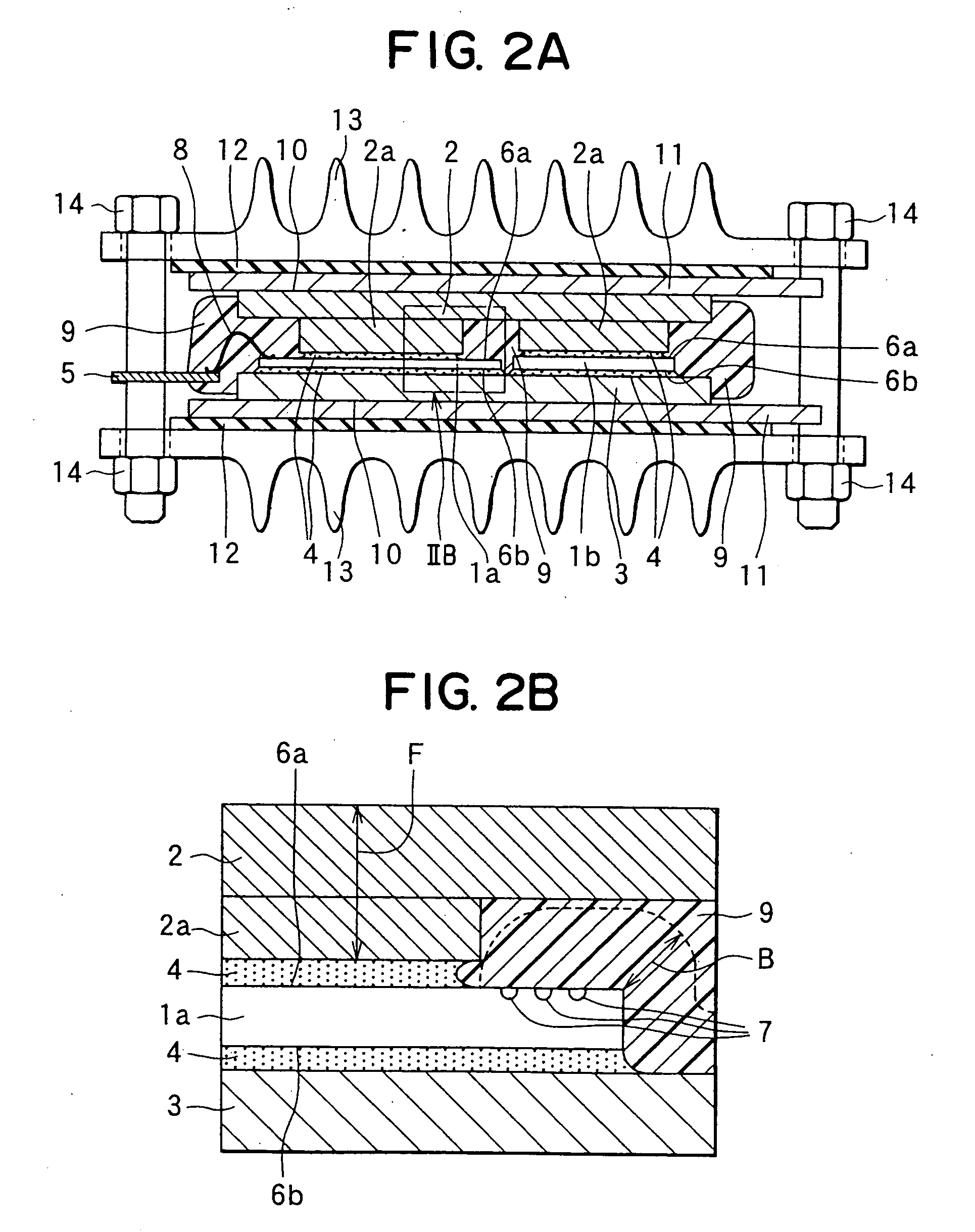

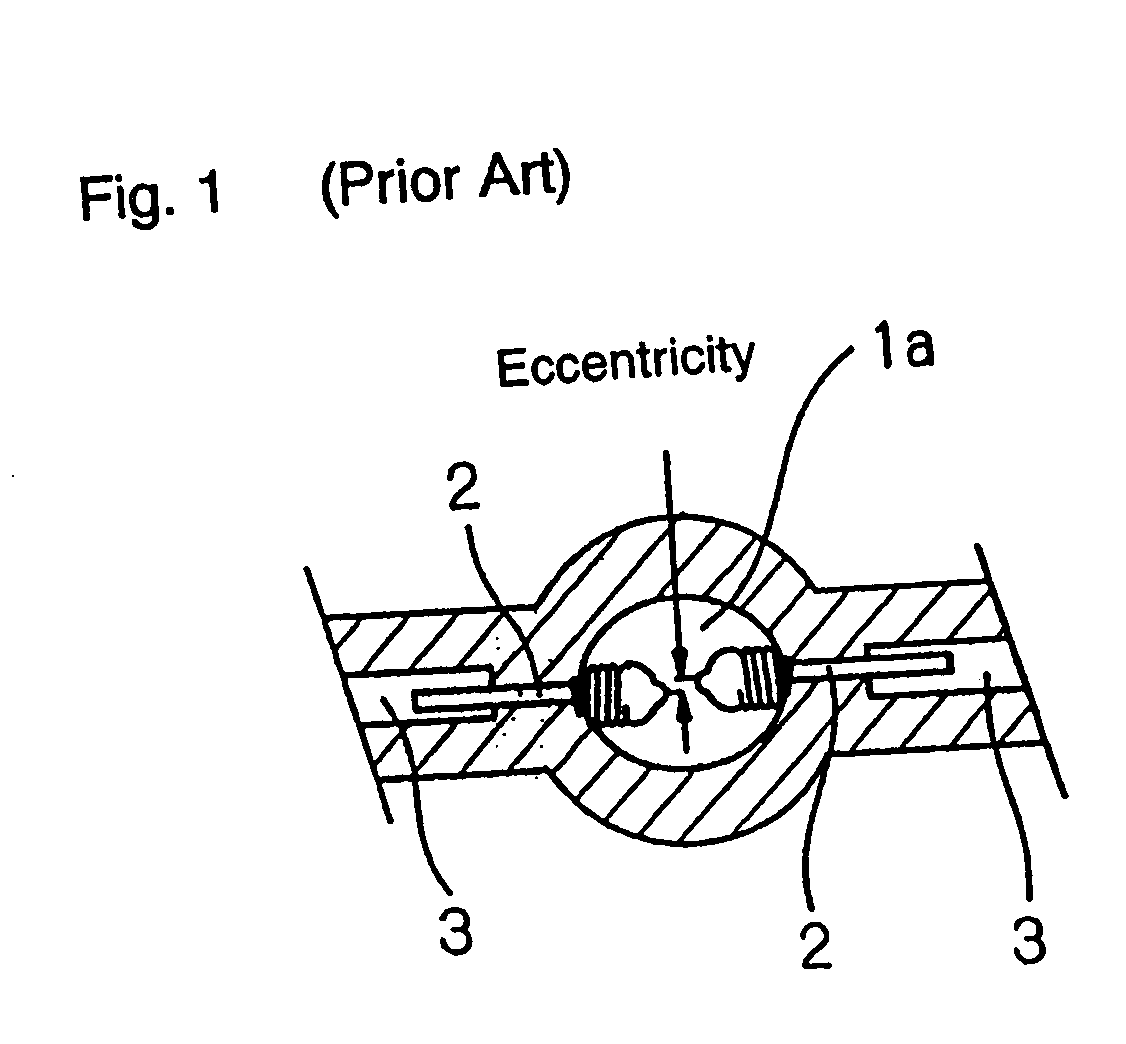

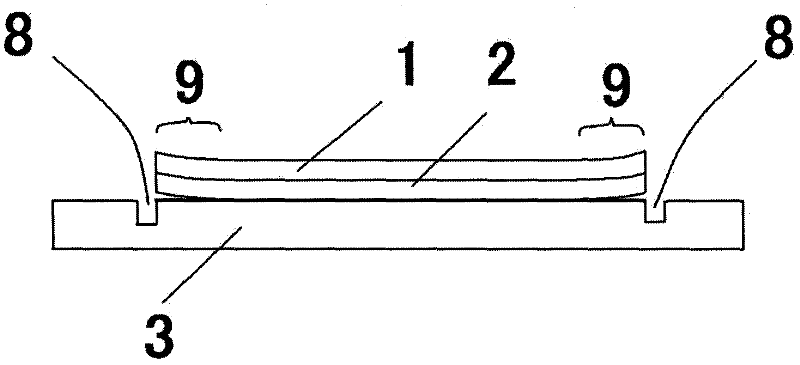

Anodic bonding method and electronic device having anodic bonding structure

InactiveUS7153758B2Good close adhesionBond be not deteriorateLamination ancillary operationsLaminationAnodic bondingElectrical conductor

In anodic bonding between a conductor or semiconductor and glass, in order to attain good adhesion at a lower bonding temperature than usual and improve the toughness at its boundary to obtain higher reliability for a bonded portion even in a case where bonded members are warped or dust is present at the bonding boundary, a soft metal film is formed on the surface of a conductor or semiconductor on which an active metal film having high reactivity with oxygen is formed, whereby a warp or dust, if any, can be absorbed by the deformation of the soft metal film, thereby to improve the adhesion at the boundary. Adhesion at the bonding boundary is improved even at a low bonding temperature of, e.g., about 200° C. Further, the toughness at the bonding boundary can be improved to increase reliability by roughening the bonded surface on the side of the glass.

Owner:HITACHI LTD

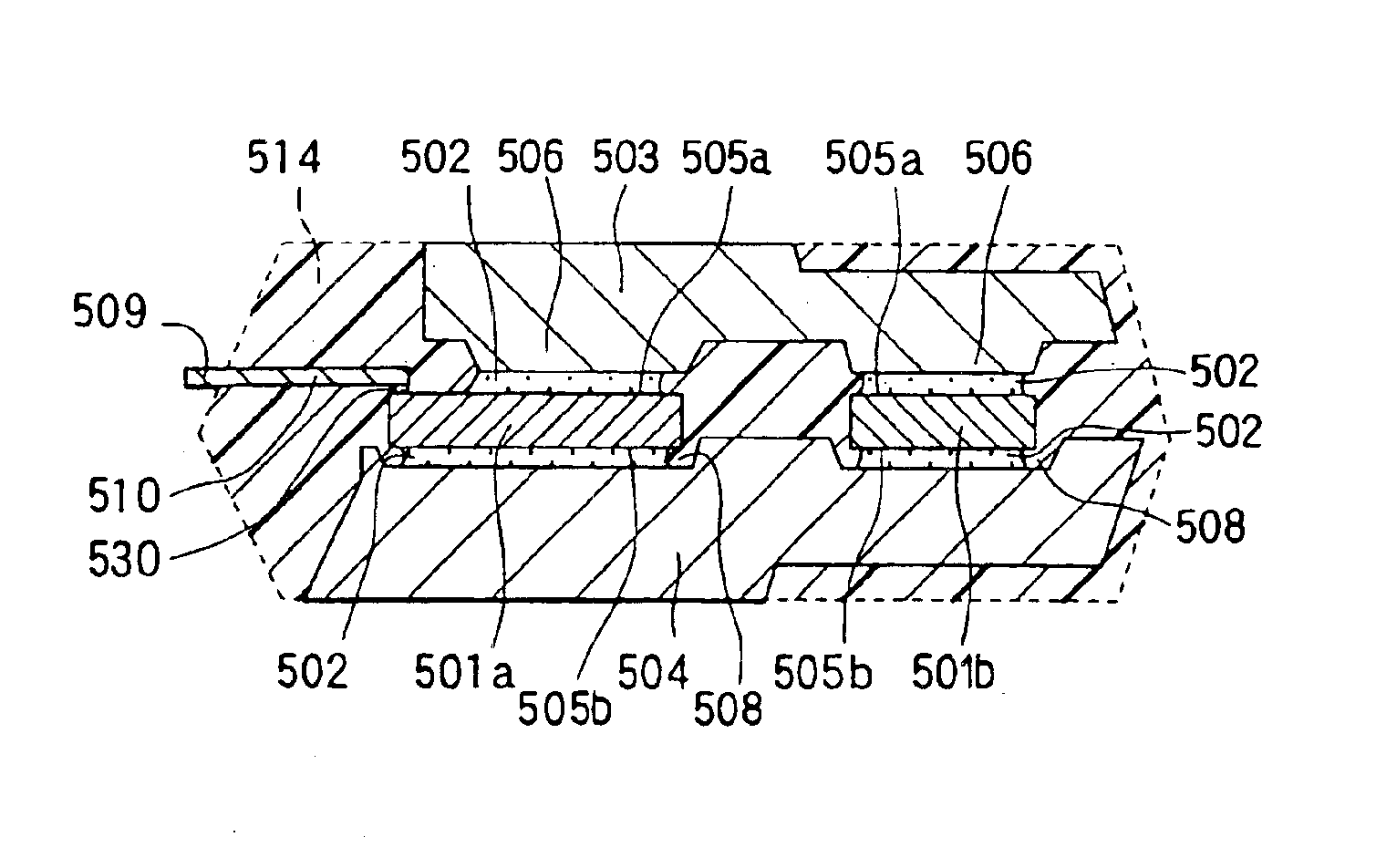

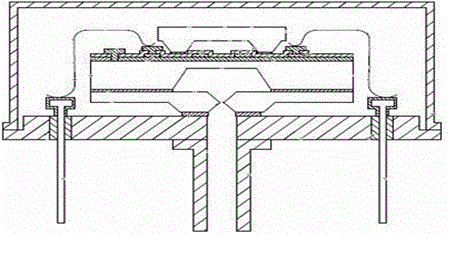

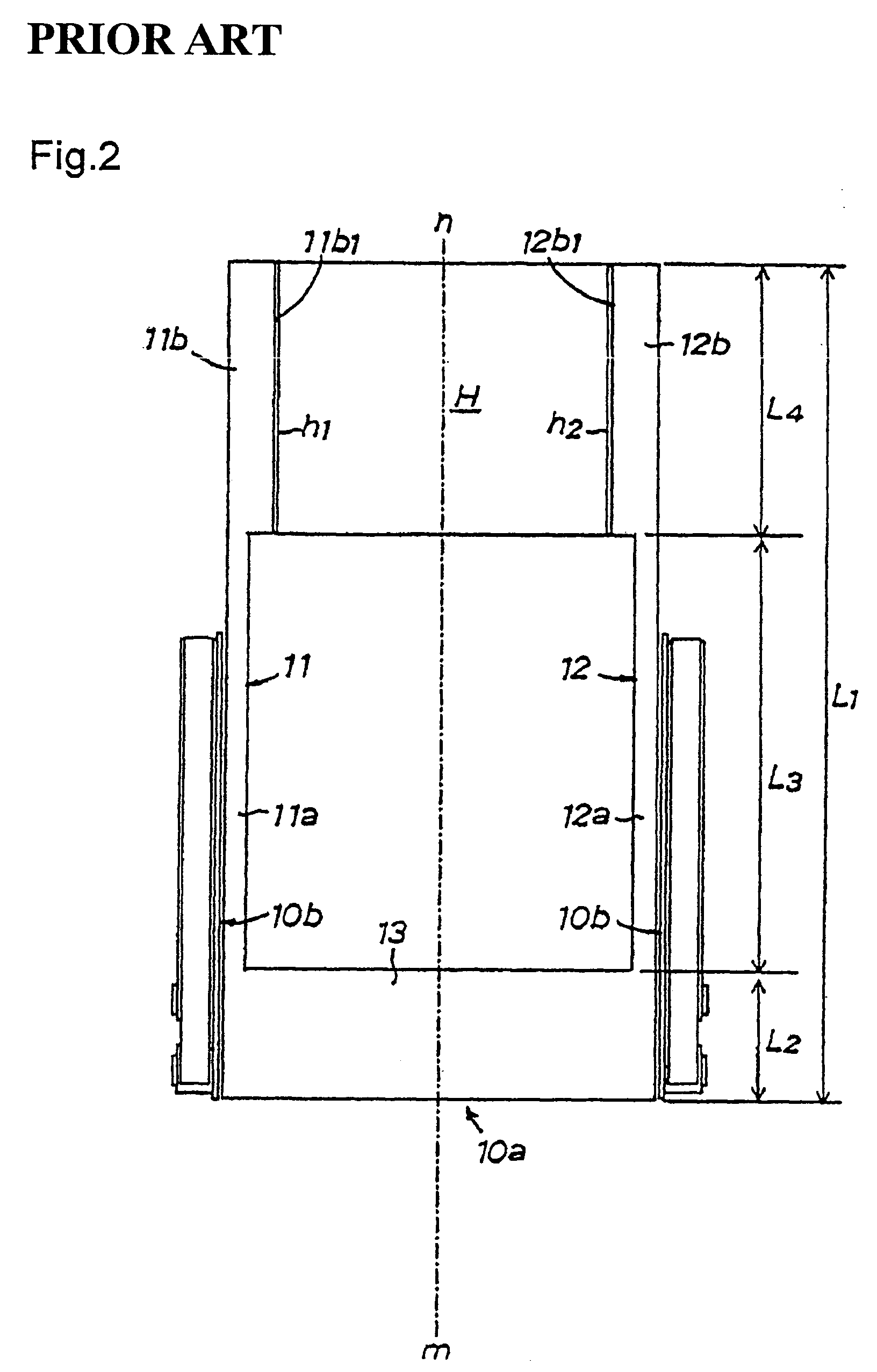

Semiconductor device having radiation structure

InactiveUS6891265B2Avoid it happening againImproved radiation propertySemiconductor/solid-state device detailsSolid-state devicesMetallic materialsSemiconductor chip

A semiconductor device includes two semiconductor chips that are interposed between a pair of radiation members, and thermally and electrically connected to the radiation members. One of the radiation members has two protruding portions and front ends of the protruding portions are connected to principal electrodes of the semiconductor chips. The radiation members are made of a metallic material containing Cu or Al as a main component. The semiconductor chips and the radiation members are sealed with resin with externally exposed radiation surfaces.

Owner:DENSO CORP

Semiconductor device having radiation structure

InactiveUS20050167821A1Improve conductivityImprove propertiesSemiconductor/solid-state device detailsSolid-state devicesDevice materialMetallic materials

A semiconductor device includes two semiconductor chips that are interposed between a pair of radiation members, and thermally and electrically connected to the radiation members. One of the radiation members has two protruding portions and front ends of the protruding portions are connected to principal electrodes of the semiconductor chips. The radiation members are made of a metallic material containing Cu or Al as a main component. The semiconductor chips and the radiation members are sealed with resin with externally exposed radiation surfaces.

Owner:DENSO CORP

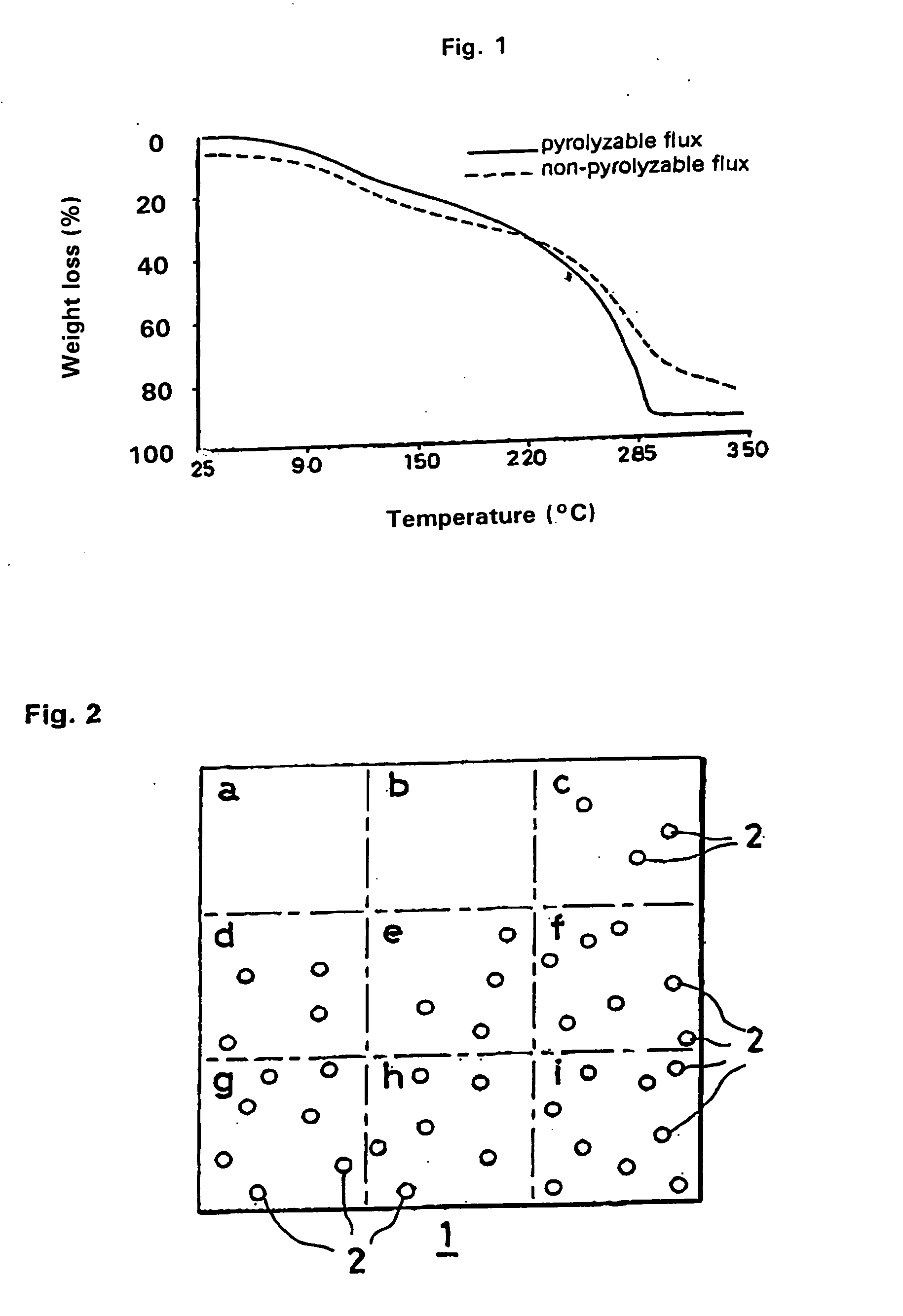

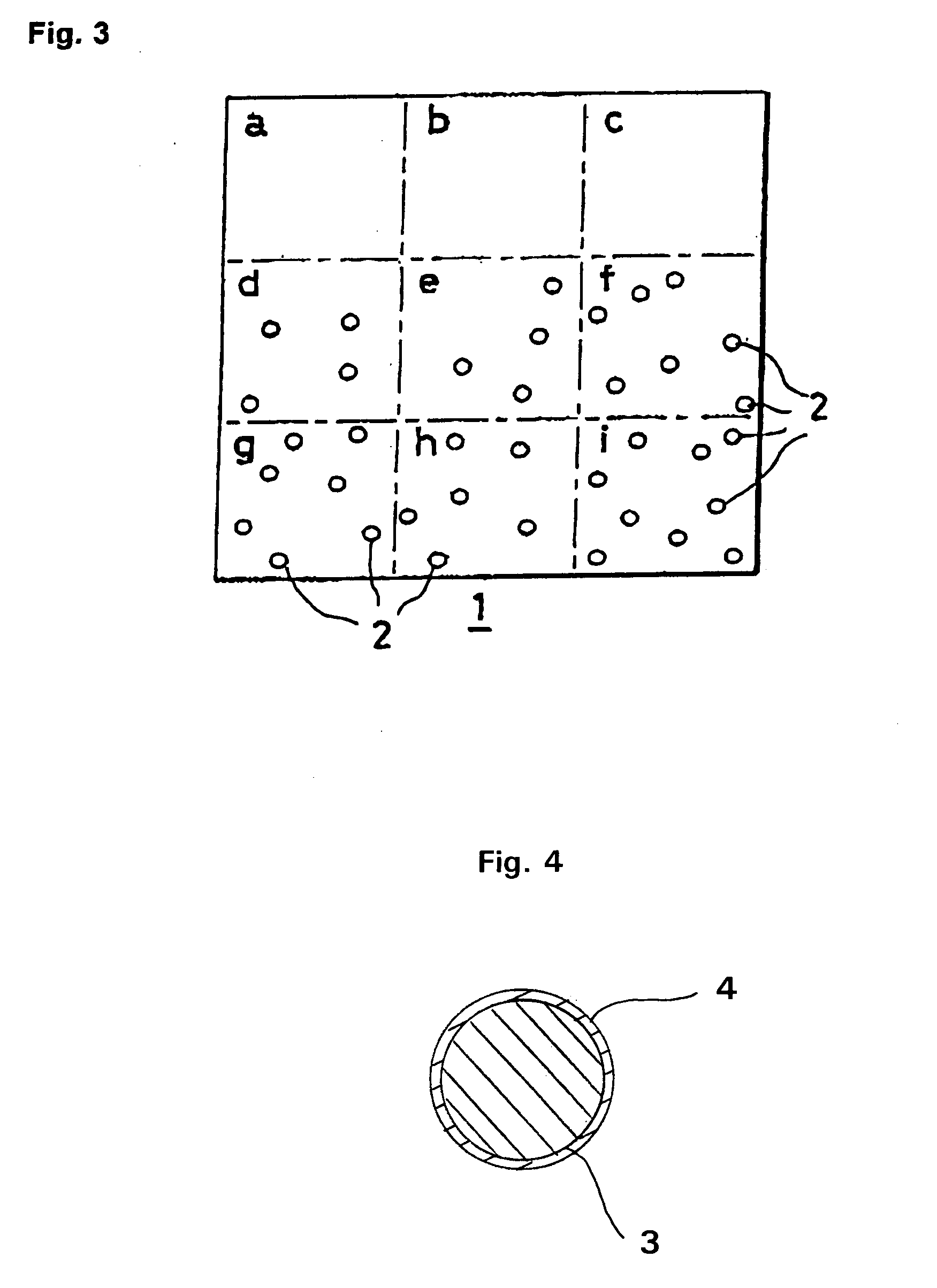

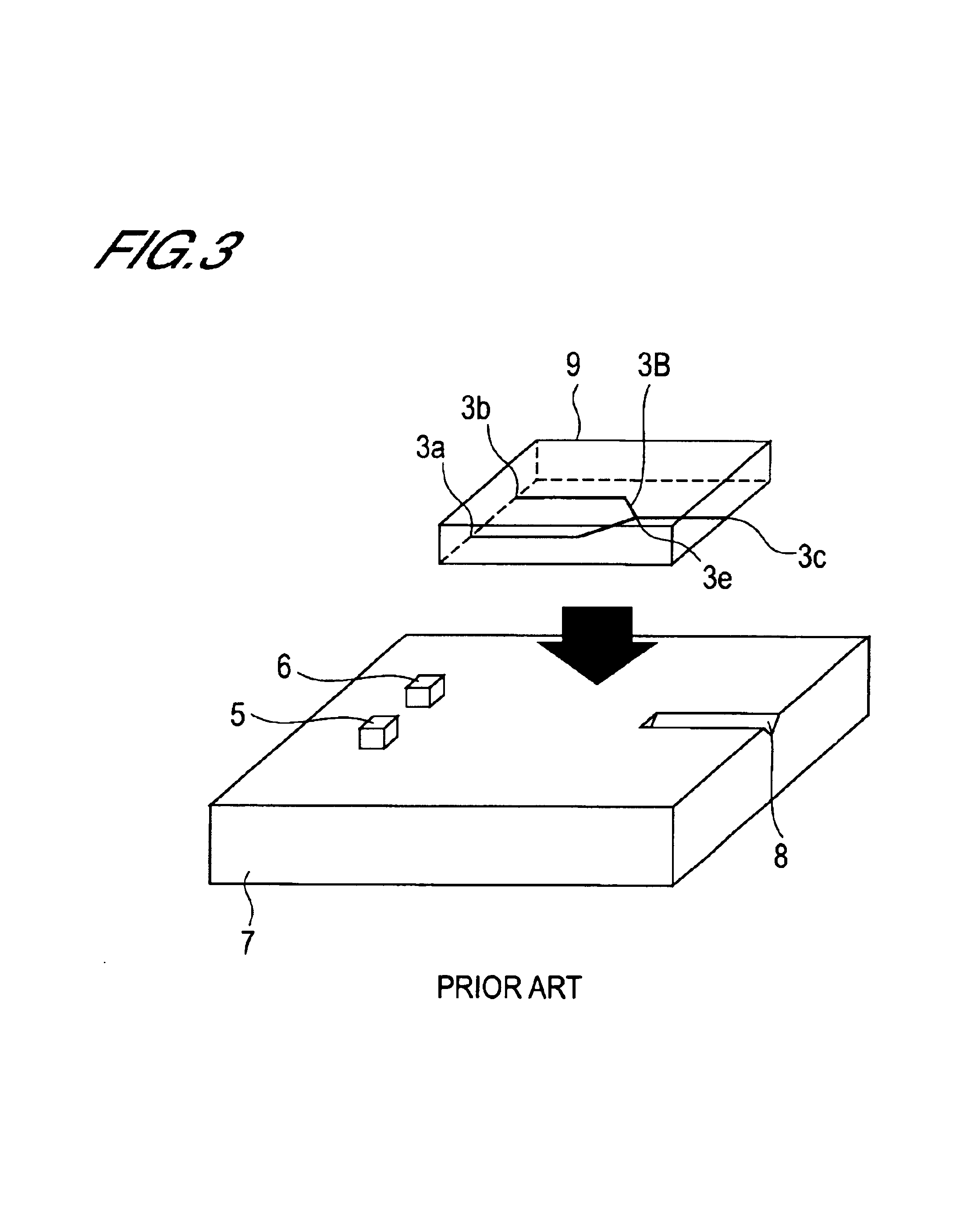

Solder preform and a process for its manufacture

ActiveUS7793820B2Reduce the bonding areaReduce heatTransportation and packagingSolid-state devicesAlloyMaterials science

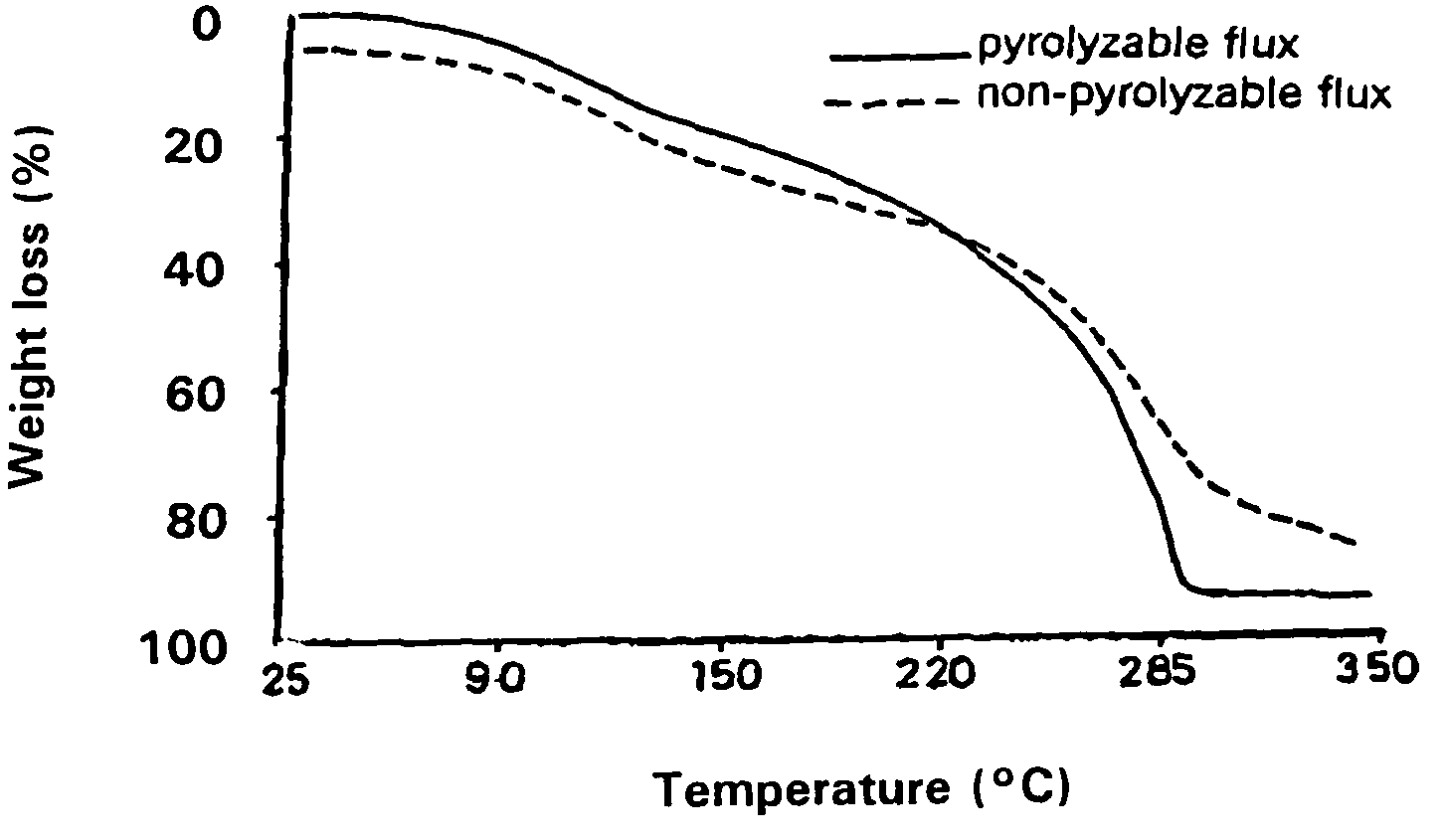

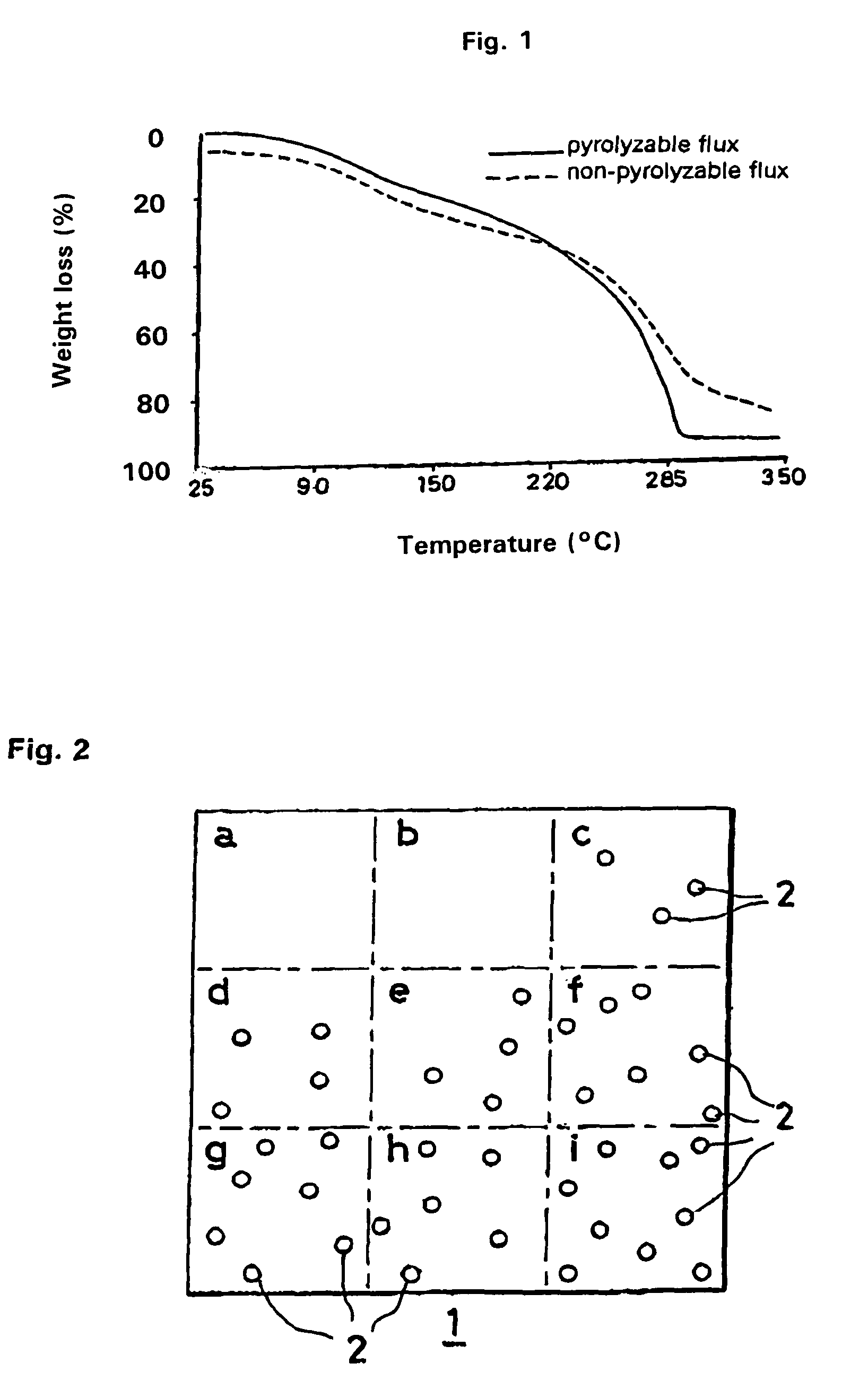

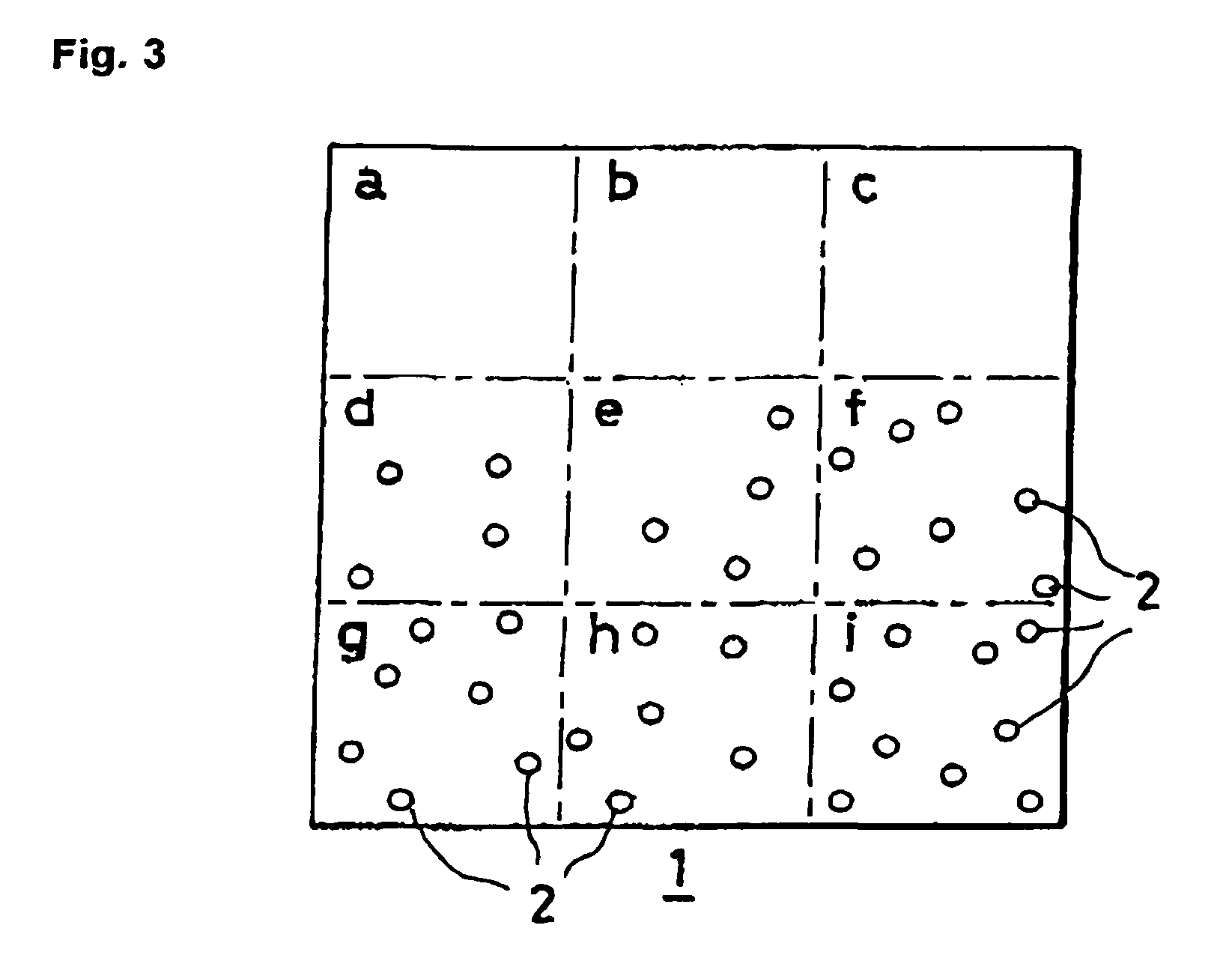

A mixed mother alloy is prepared from a solder mixture comprising a pyrolyzable flux and high melting point metal particles, the mixed mother alloy is charged into a large amount of molten solder and stirred, and a billet is prepared. The billet can then be extruded, rolled, and punched to form a pellet or a washer, for example.

Owner:SENJU METAL IND CO LTD +1

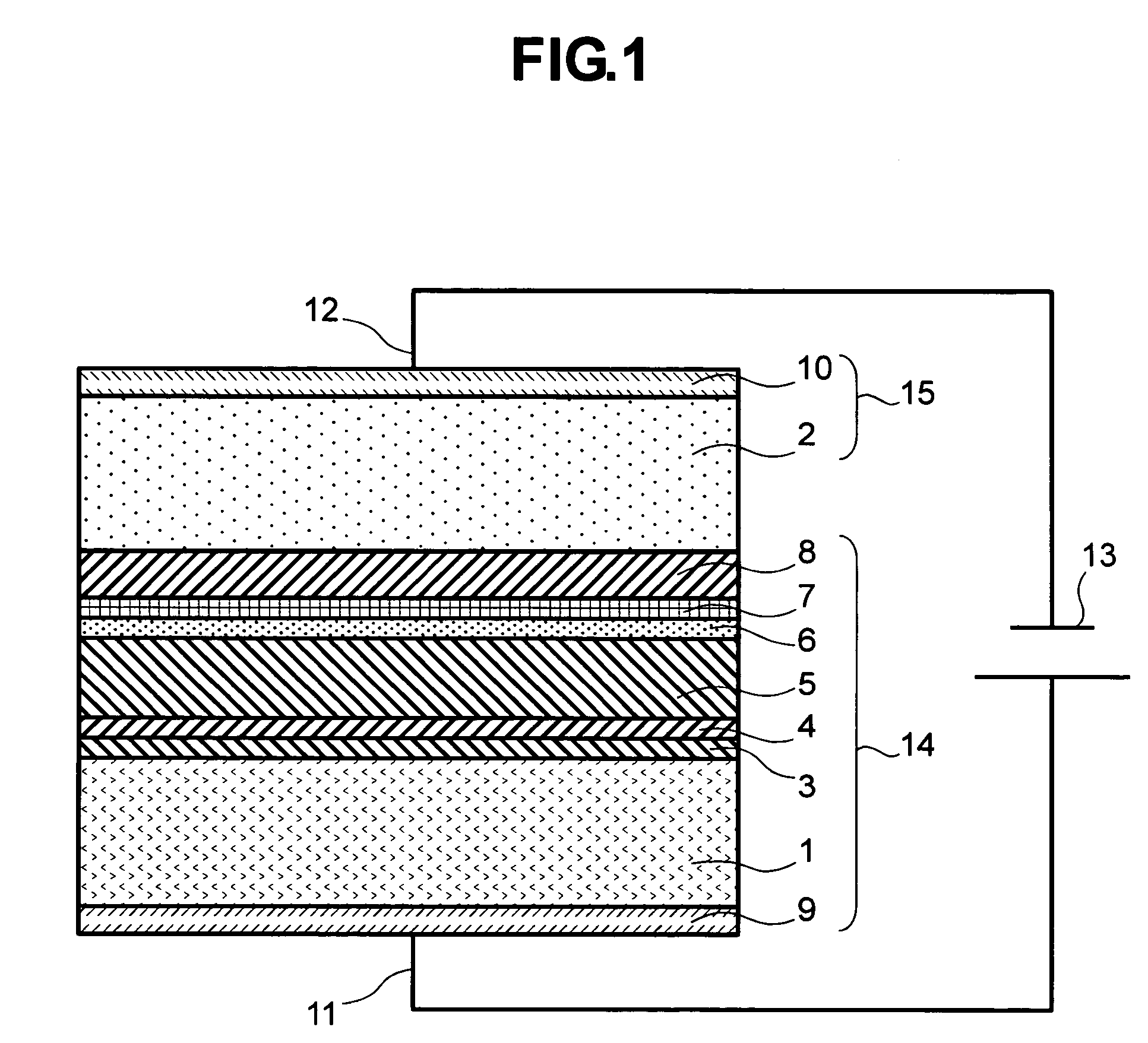

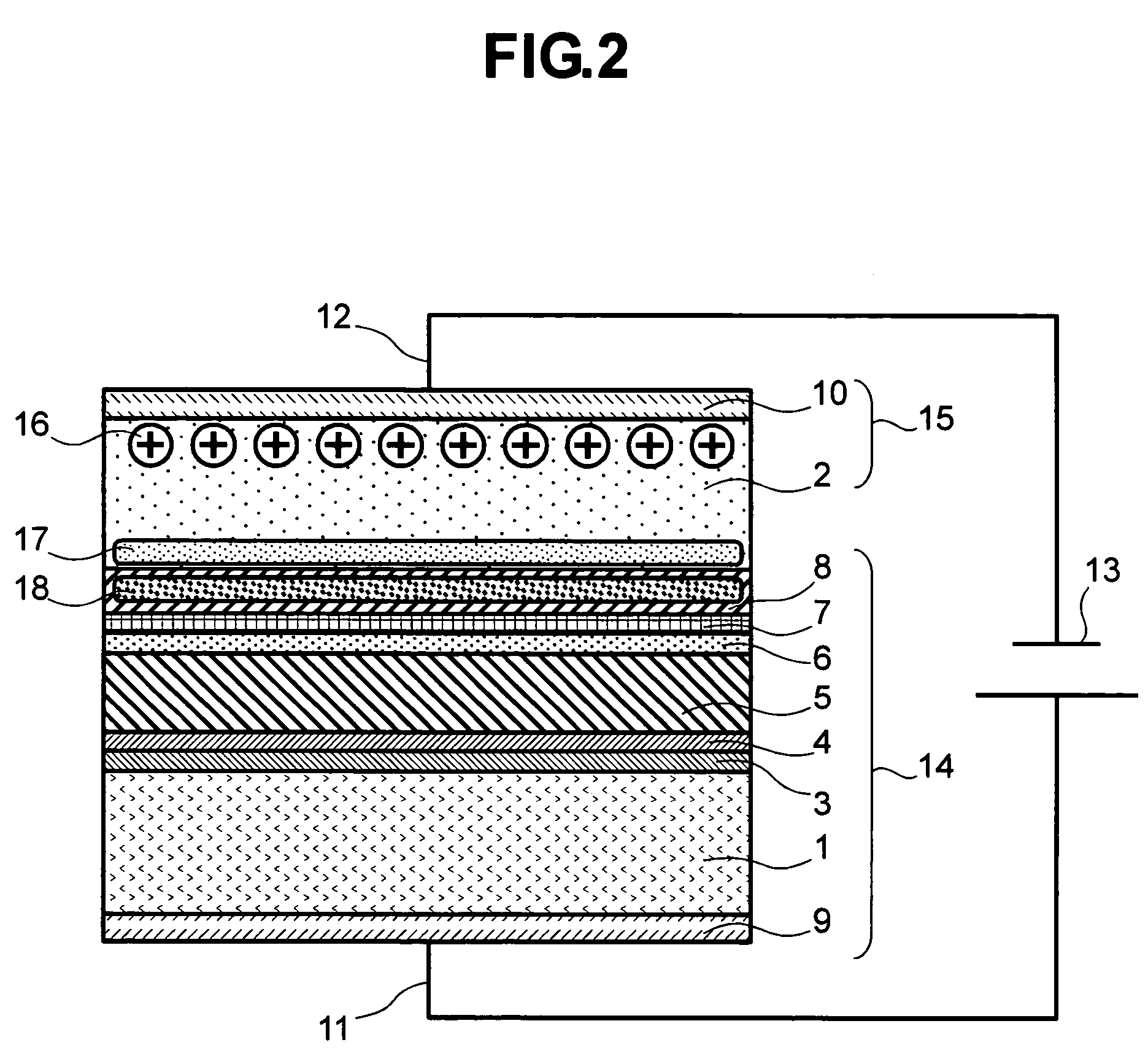

Semiconductor device

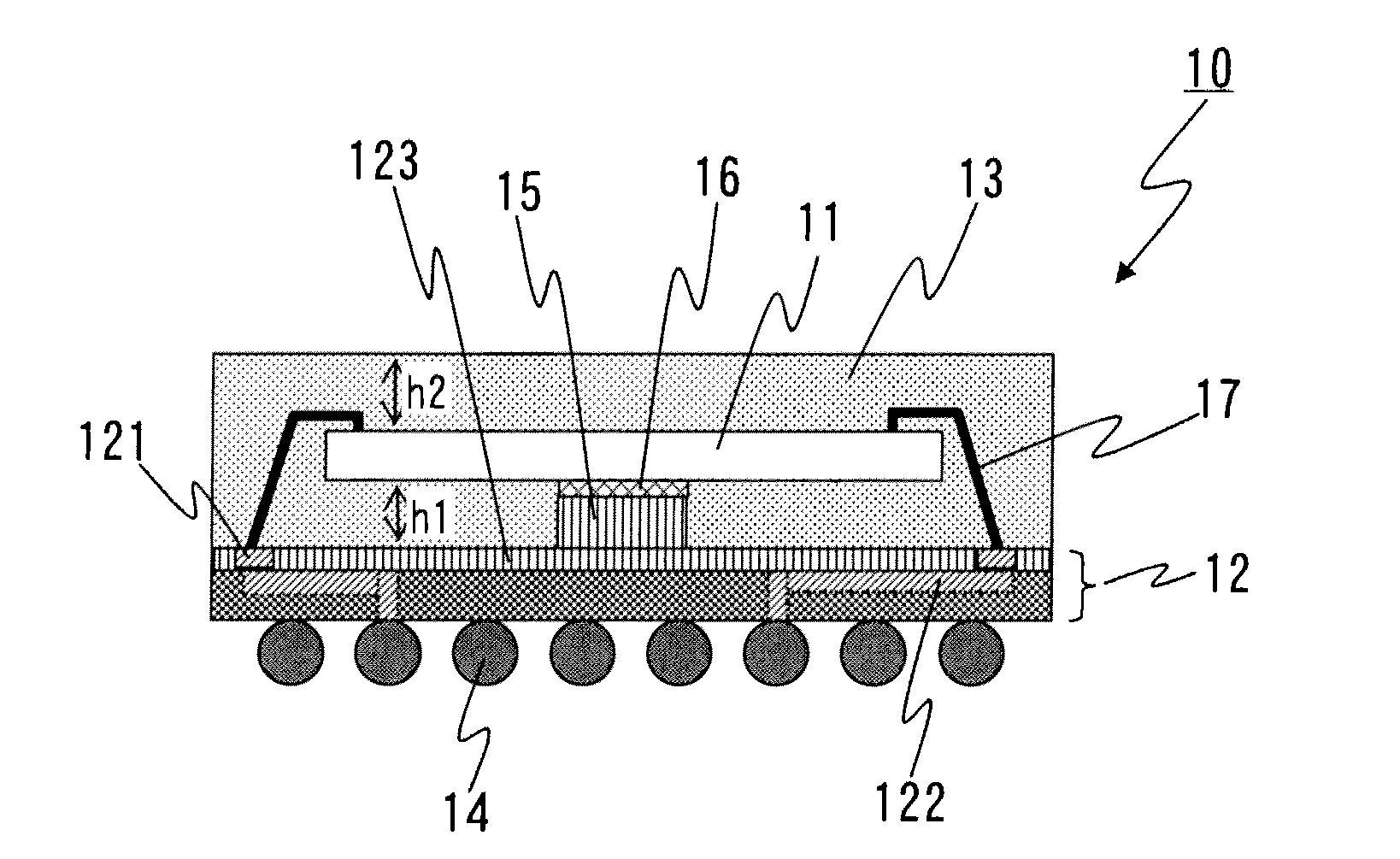

InactiveUS20110074037A1Avoid warpingIncreased problem of deteriorationSemiconductor/solid-state device detailsPrinted circuit aspectsSemiconductor chipSemiconductor device modeling

A device has a semiconductor chip, a wiring board, a support which supports the semiconductor chip on the wiring board and forms a gap between the semiconductor chip and the wiring board, and a sealing resin injected into the gap and covering the semiconductor chip.

Owner:ELPIDA MEMORY INC

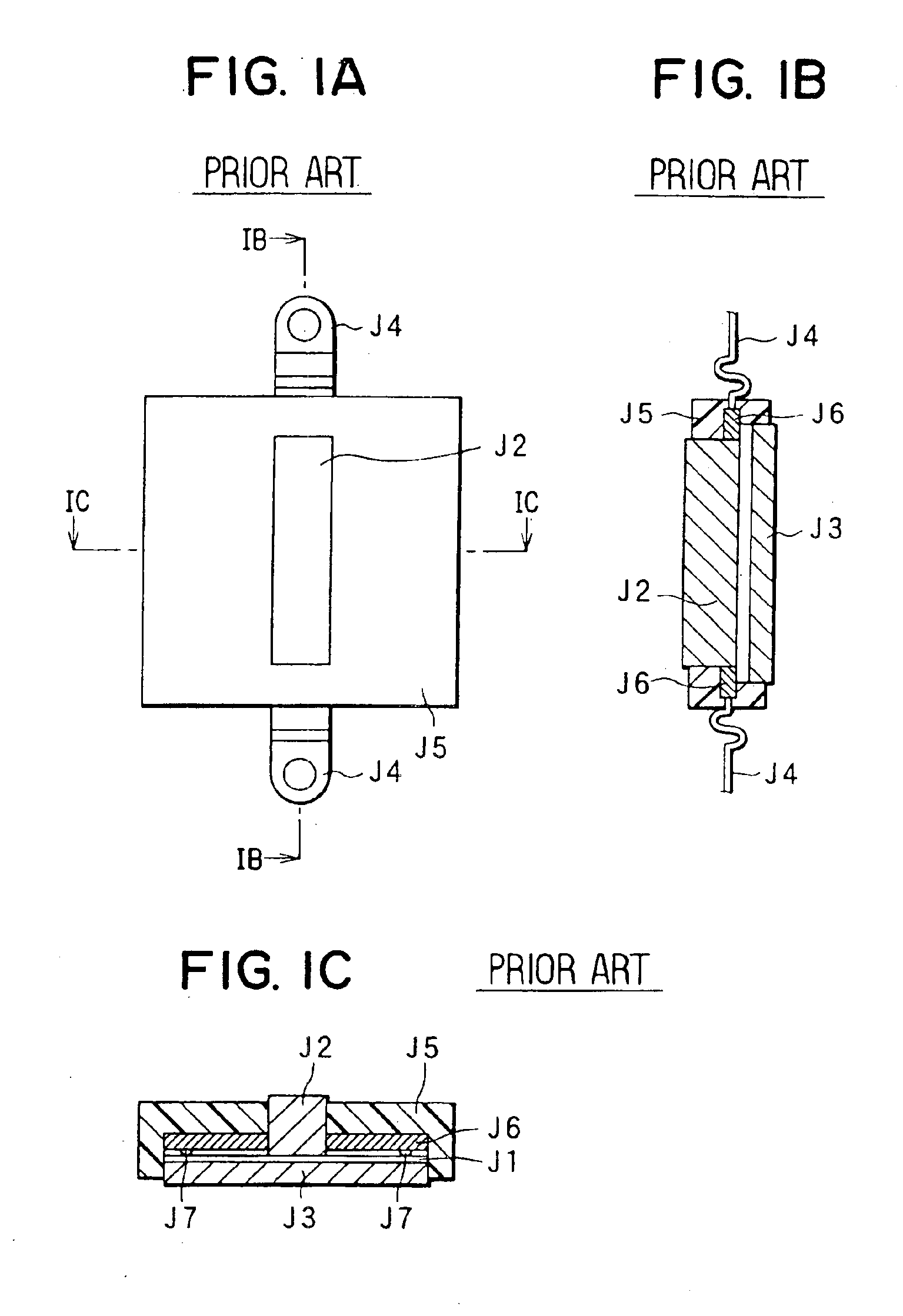

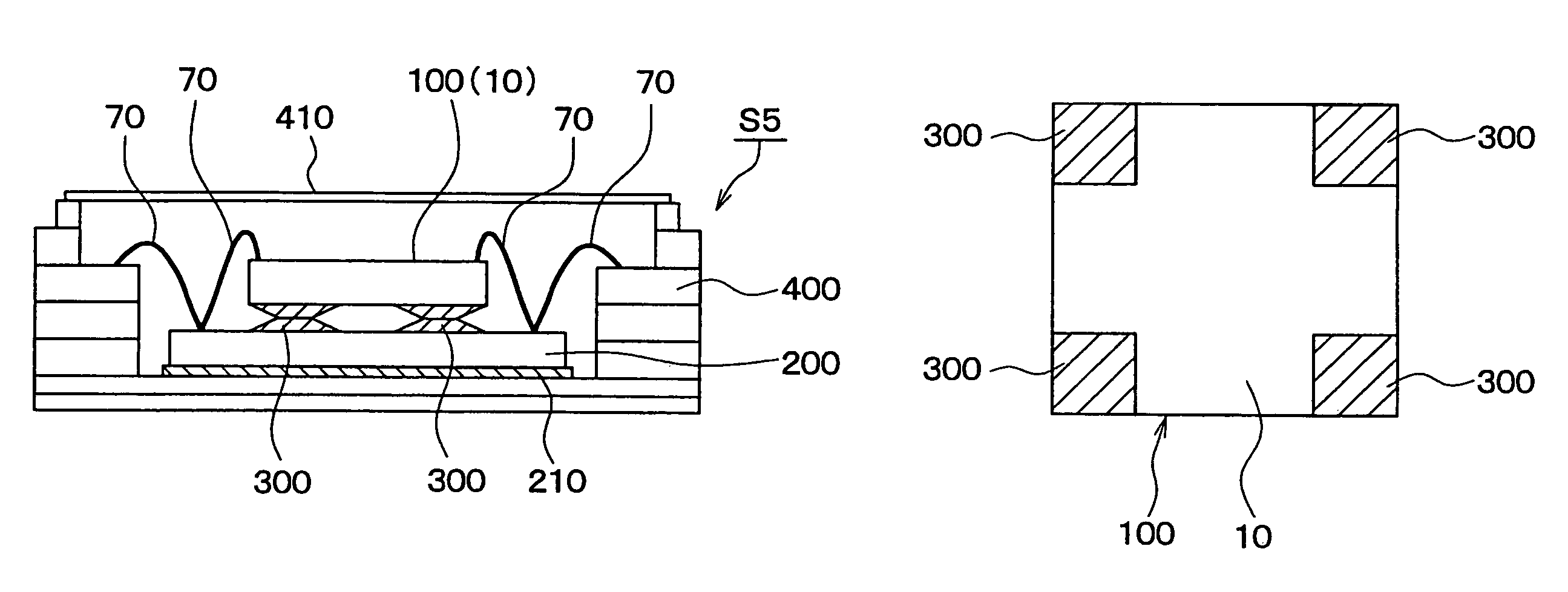

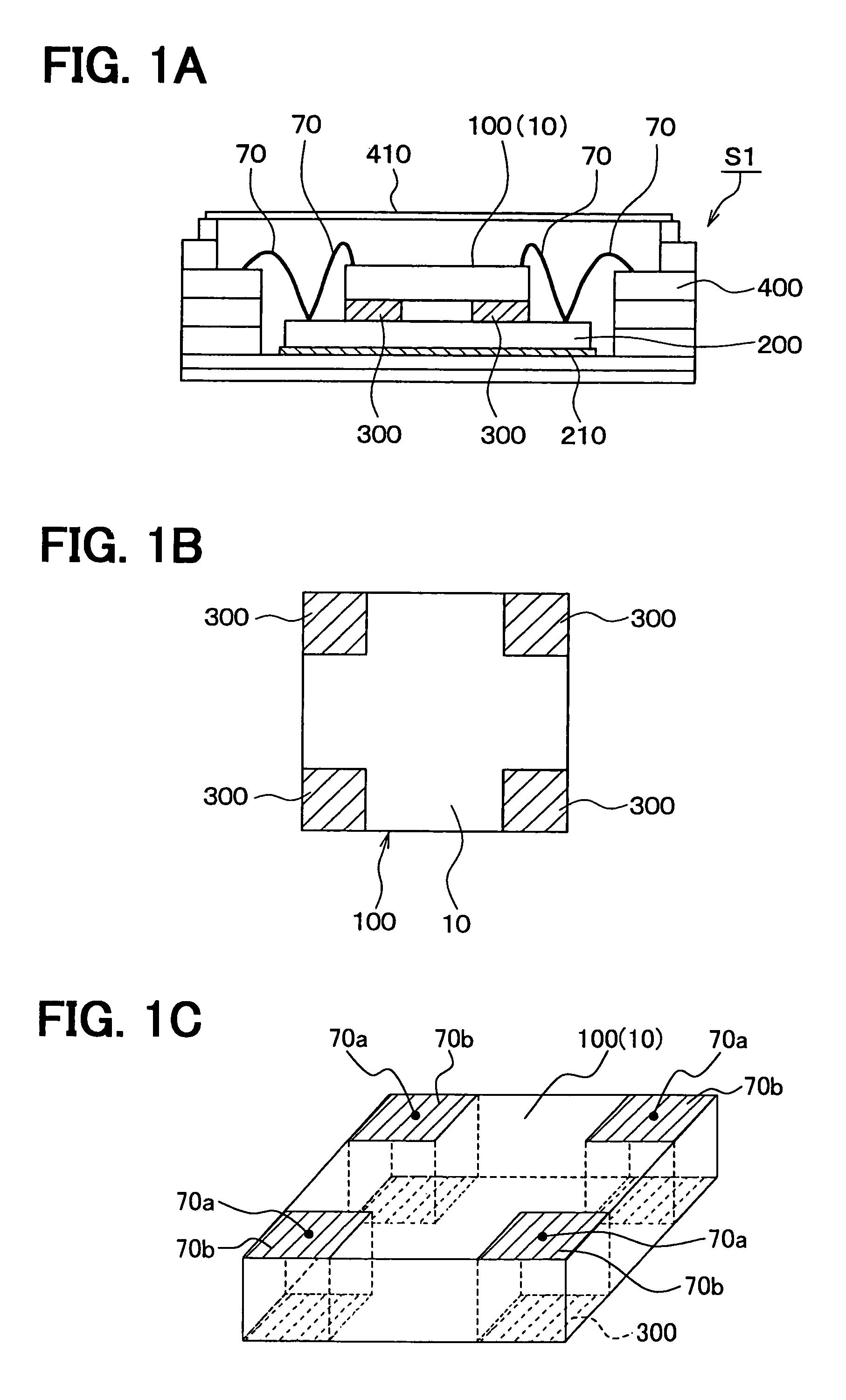

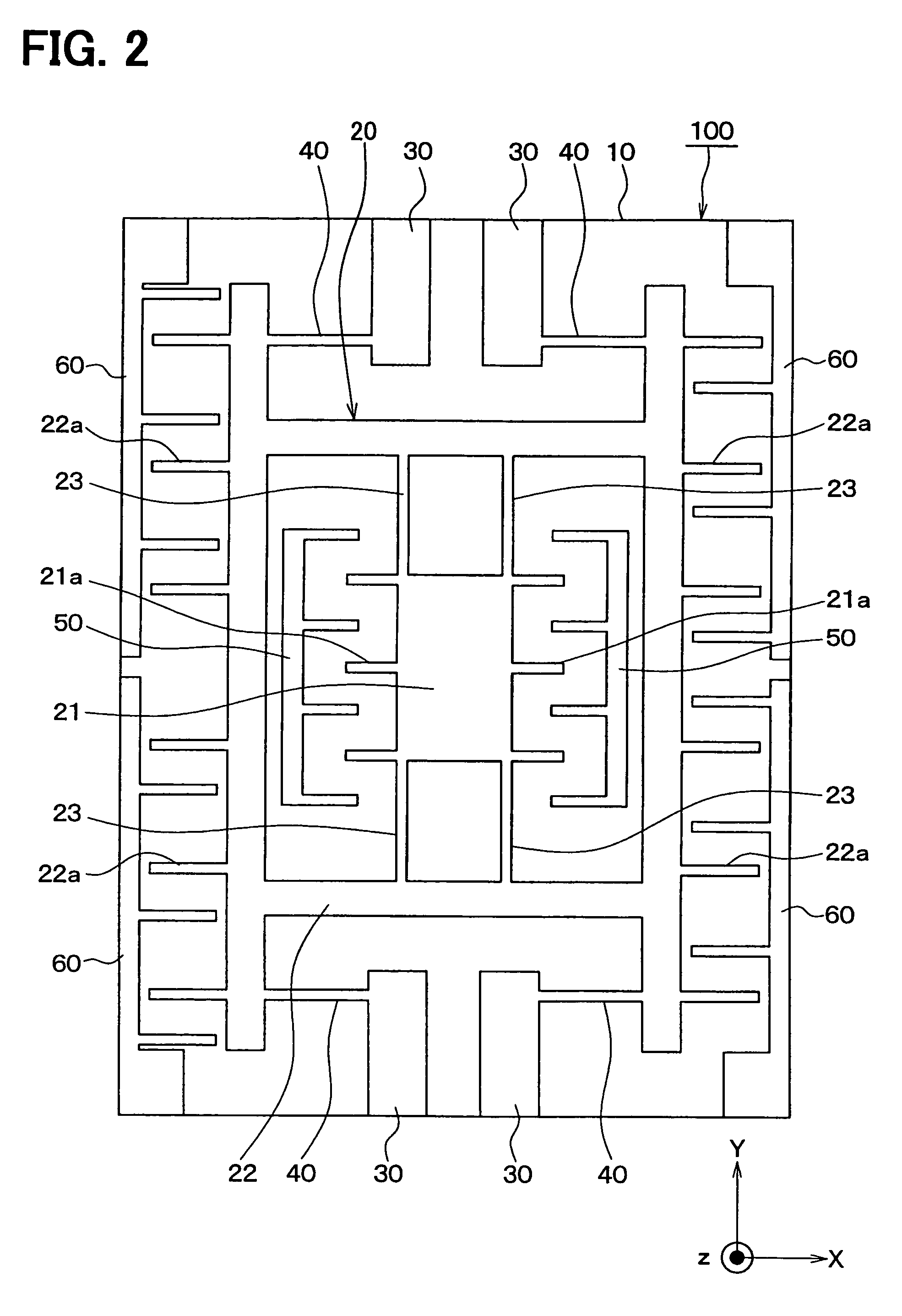

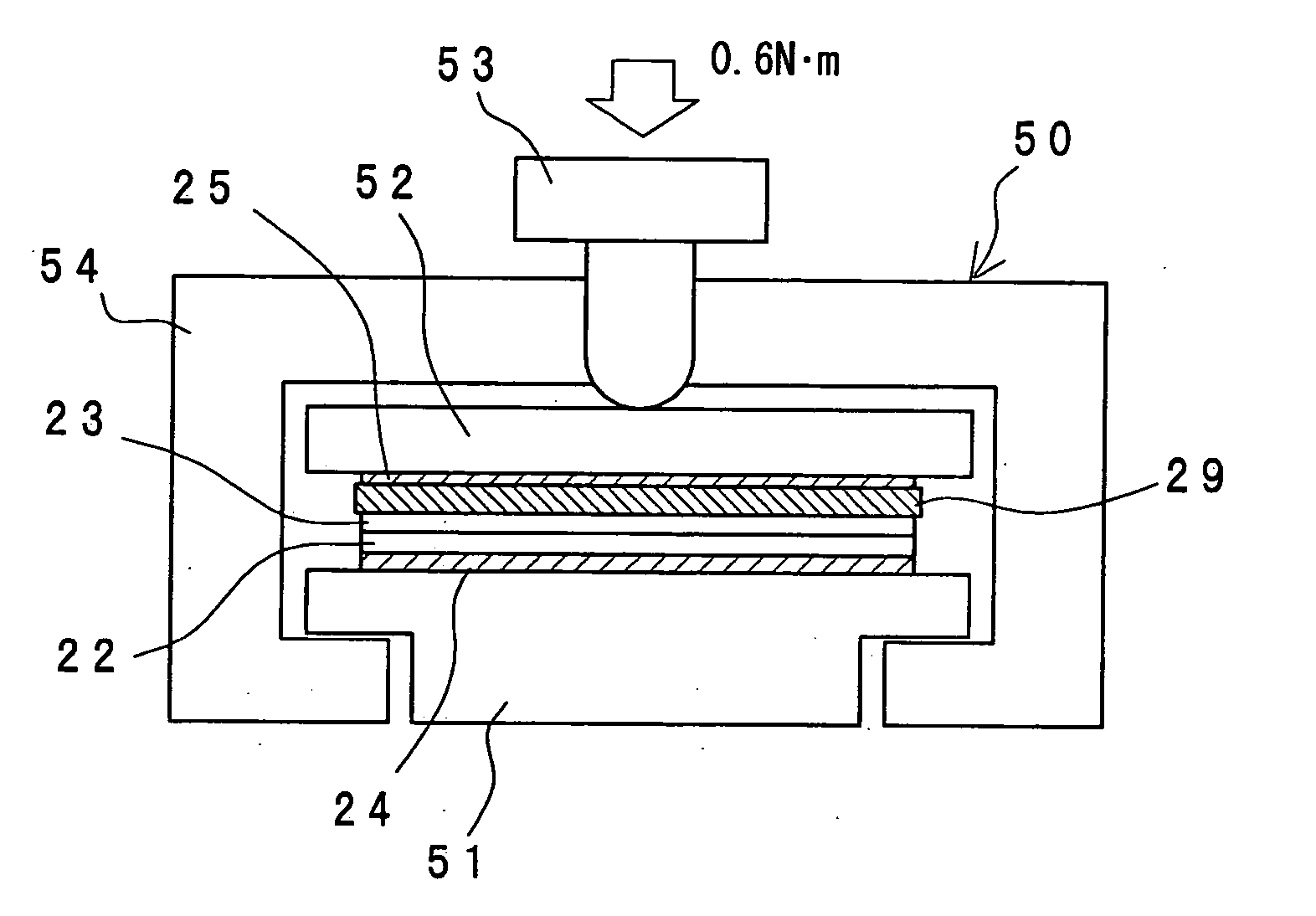

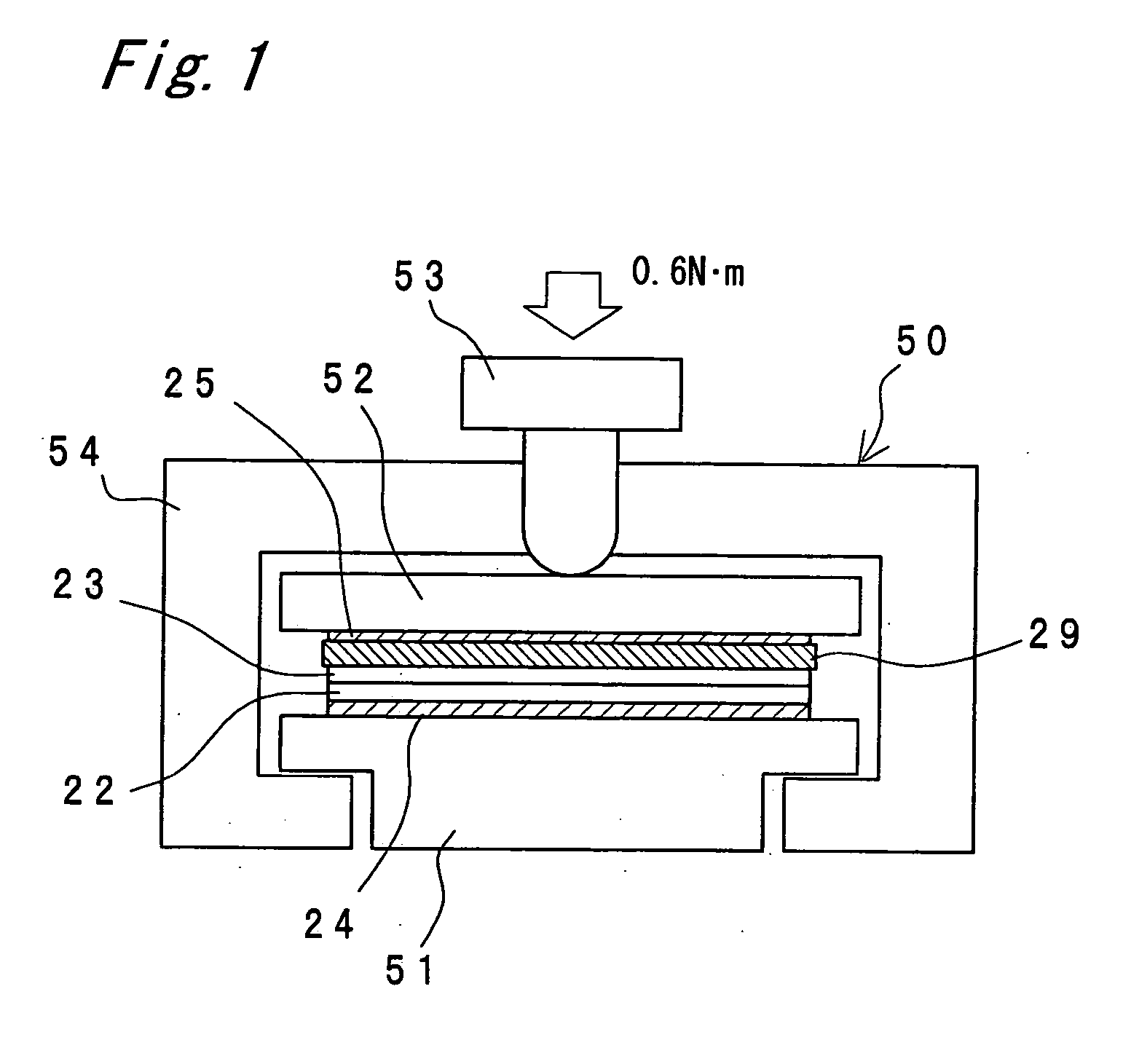

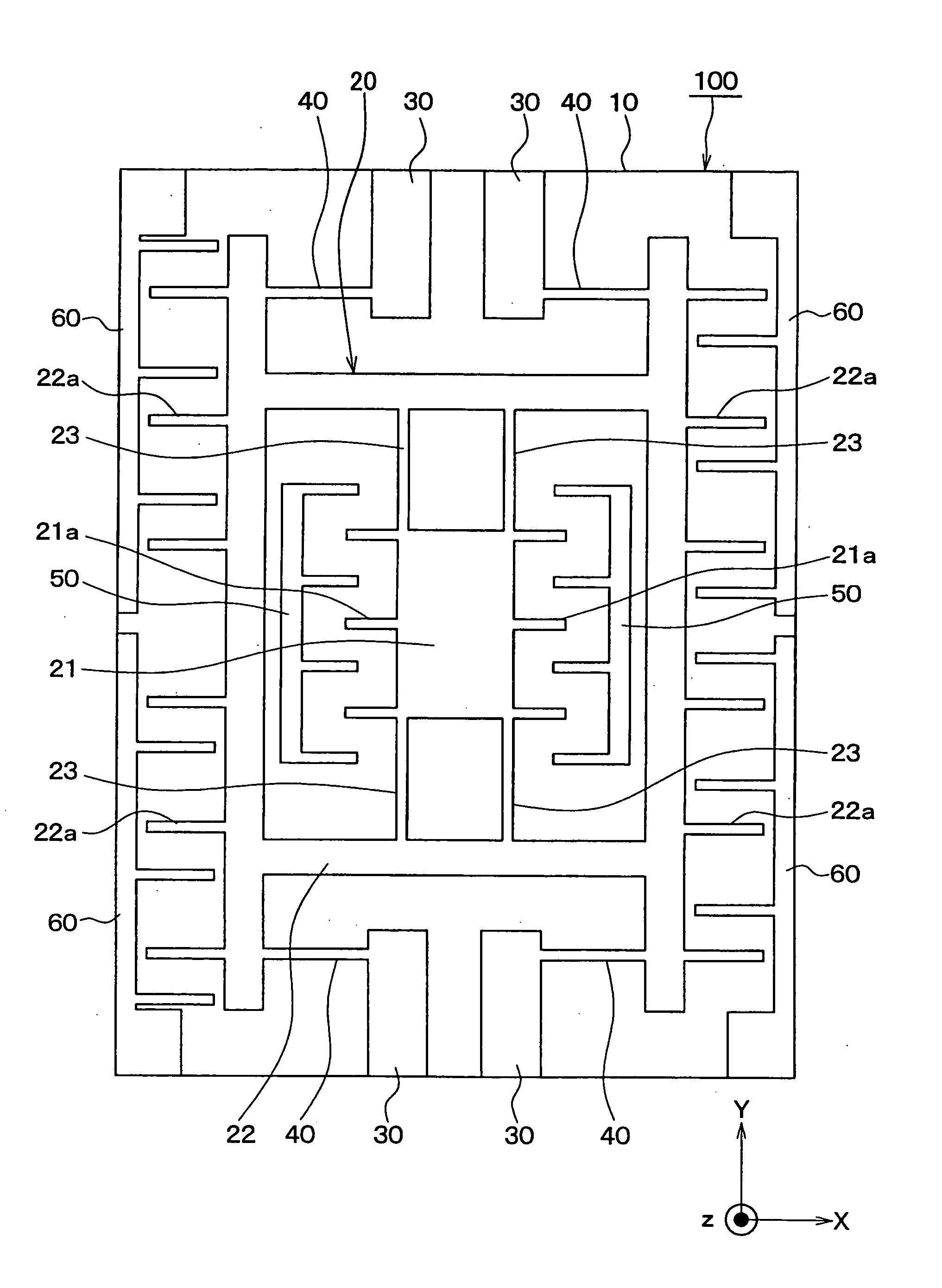

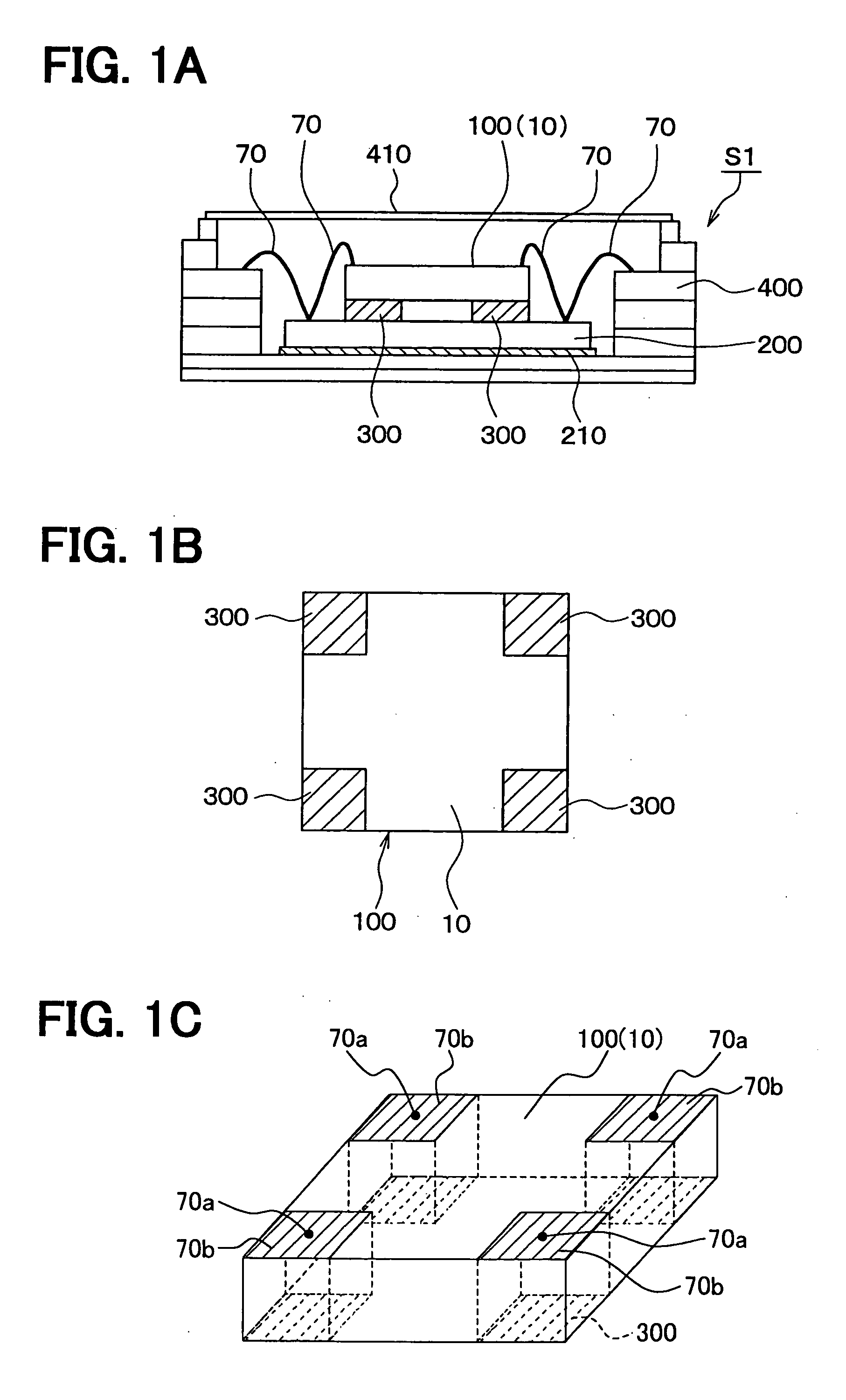

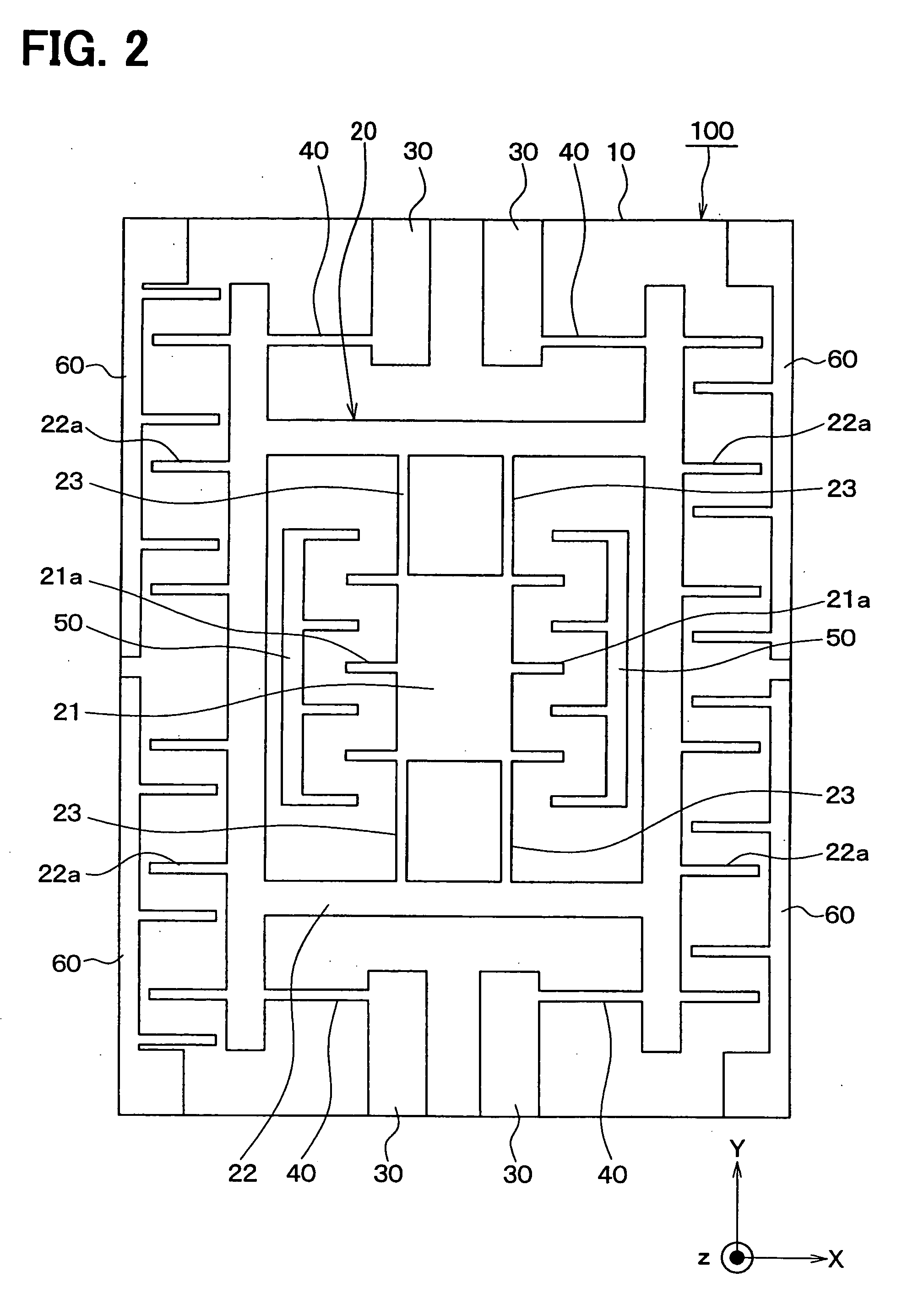

Angular velocity detector

InactiveUS7249509B2Improve accuracyLower resonance frequencyAcceleration measurement using interia forcesSolid-state devicesAngular velocityWire bonding

An angular velocity detector includes an angular velocity detecting element having a vibrating body arranged in a base substrate to be vibrated on a surface horizontal with respect to the base substrate. The angular velocity detecting element detects an angular velocity around an axis perpendicular to the base substrate based on a vibration of the vibrating body. In the angular velocity detector, a circuit substrate is bonded to a first surface of the base substrate through an adhesive, and a second surface of the angular velocity detecting element is electrically connected to the circuit substrate through a bonding wire. Furthermore, the adhesive is partially arranged on the first surface of the base substrate at least at a portion corresponding to a bonding portion of the bonding wire on the second surface of the base substrate. Therefore, a wire bonding can be easily accurately performed.

Owner:DENSO CORP

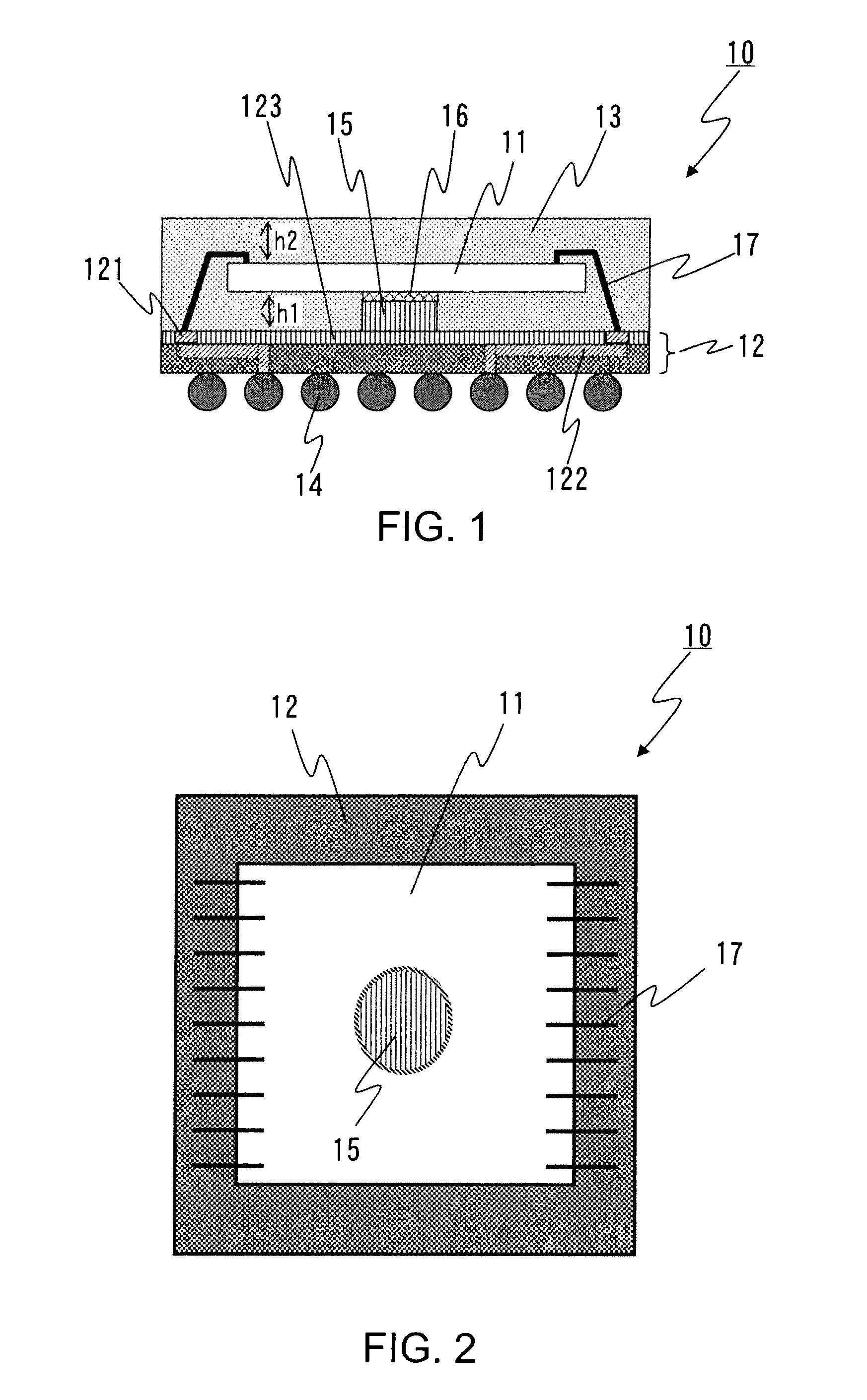

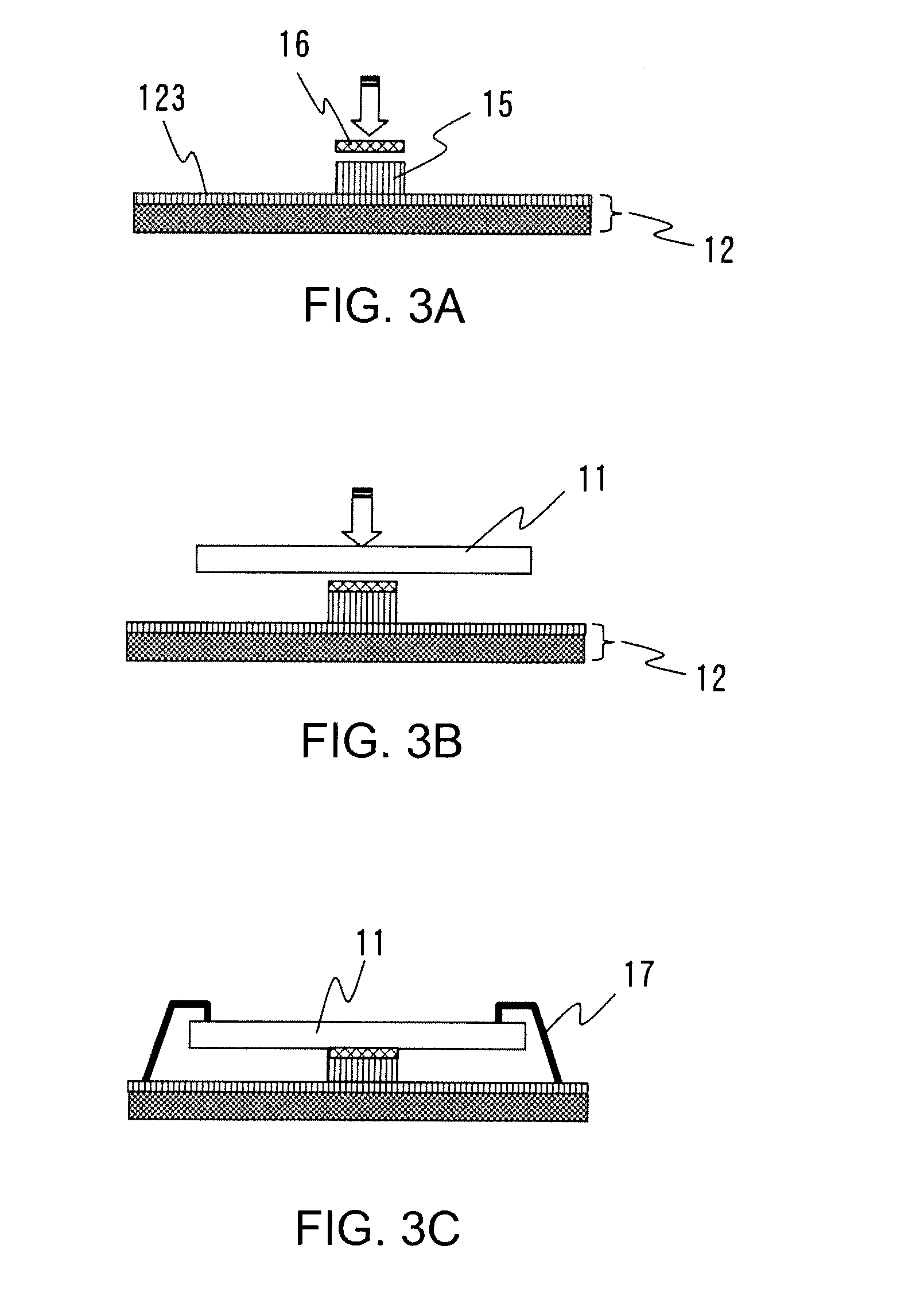

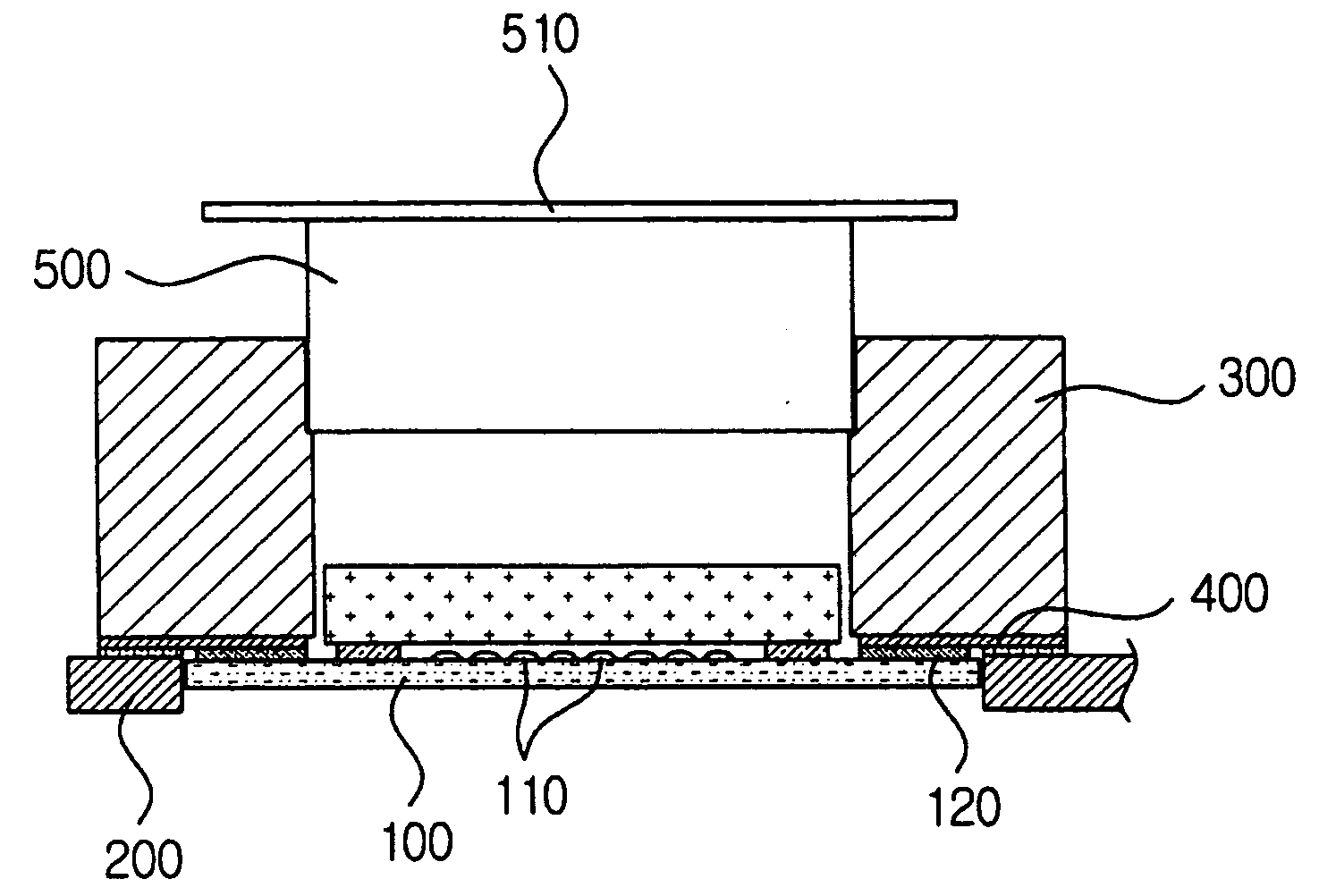

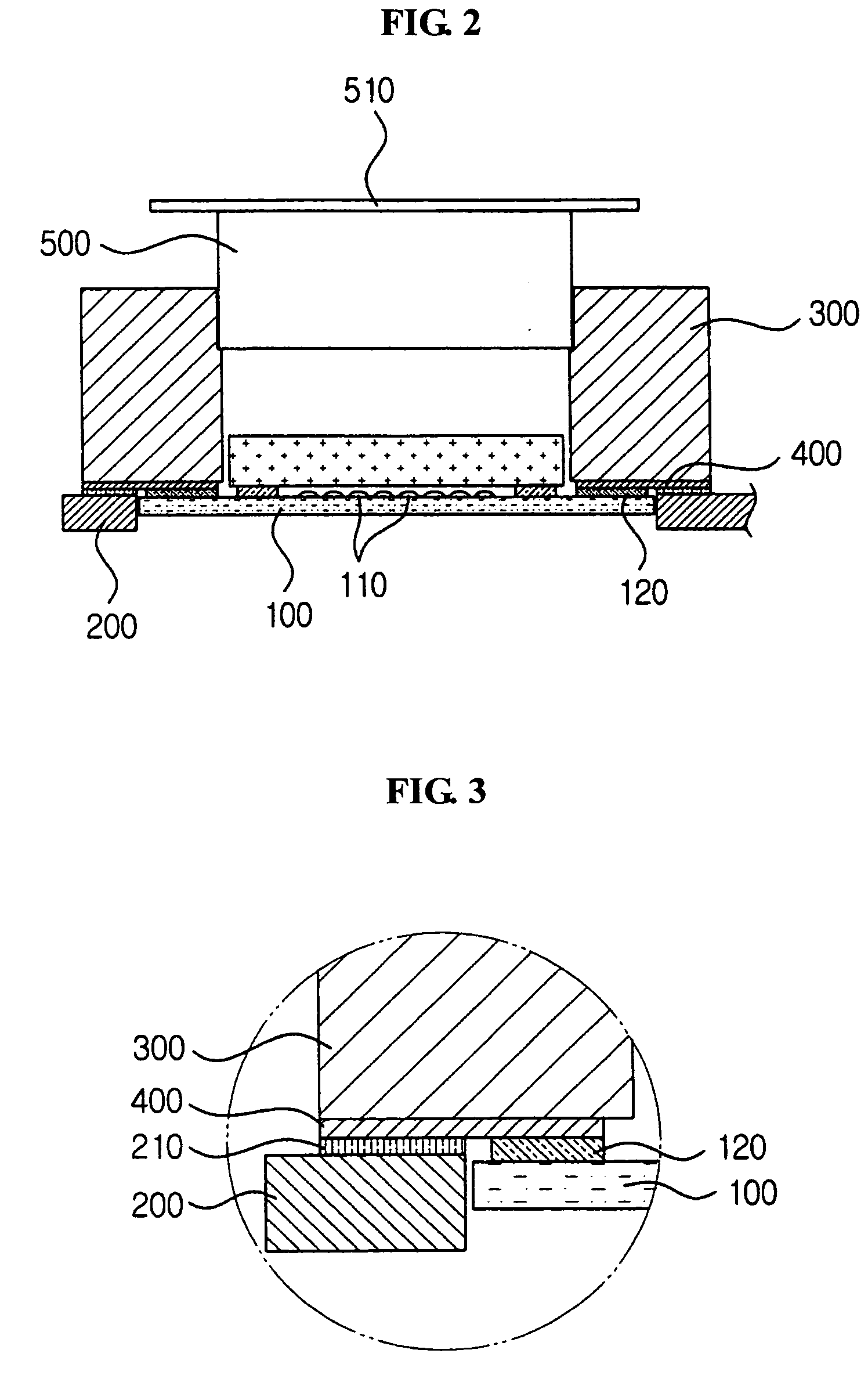

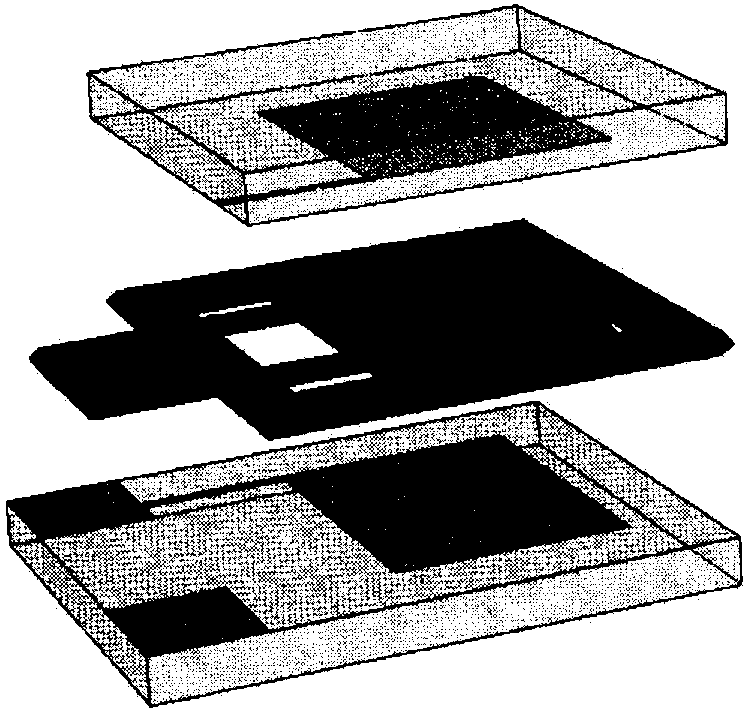

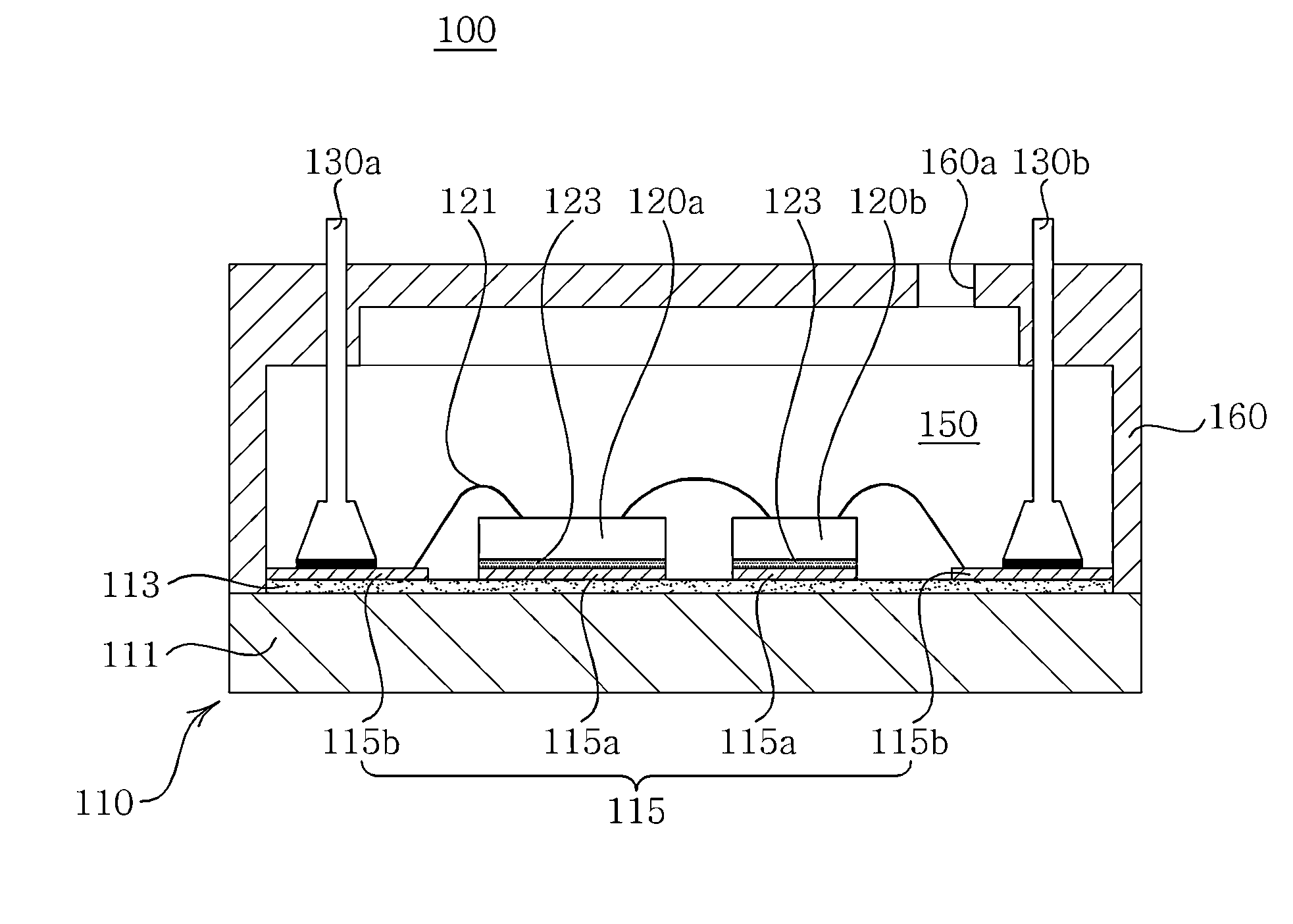

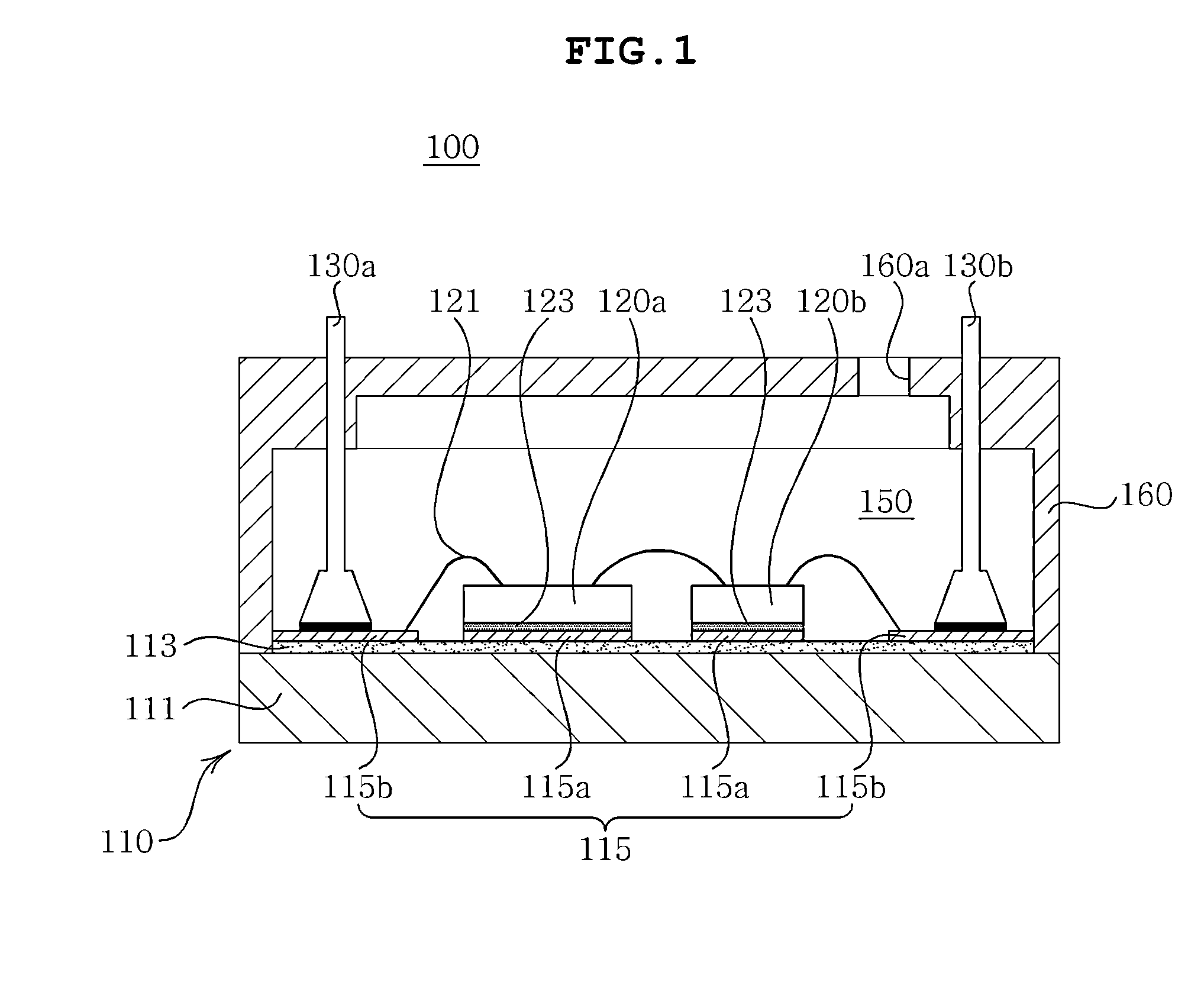

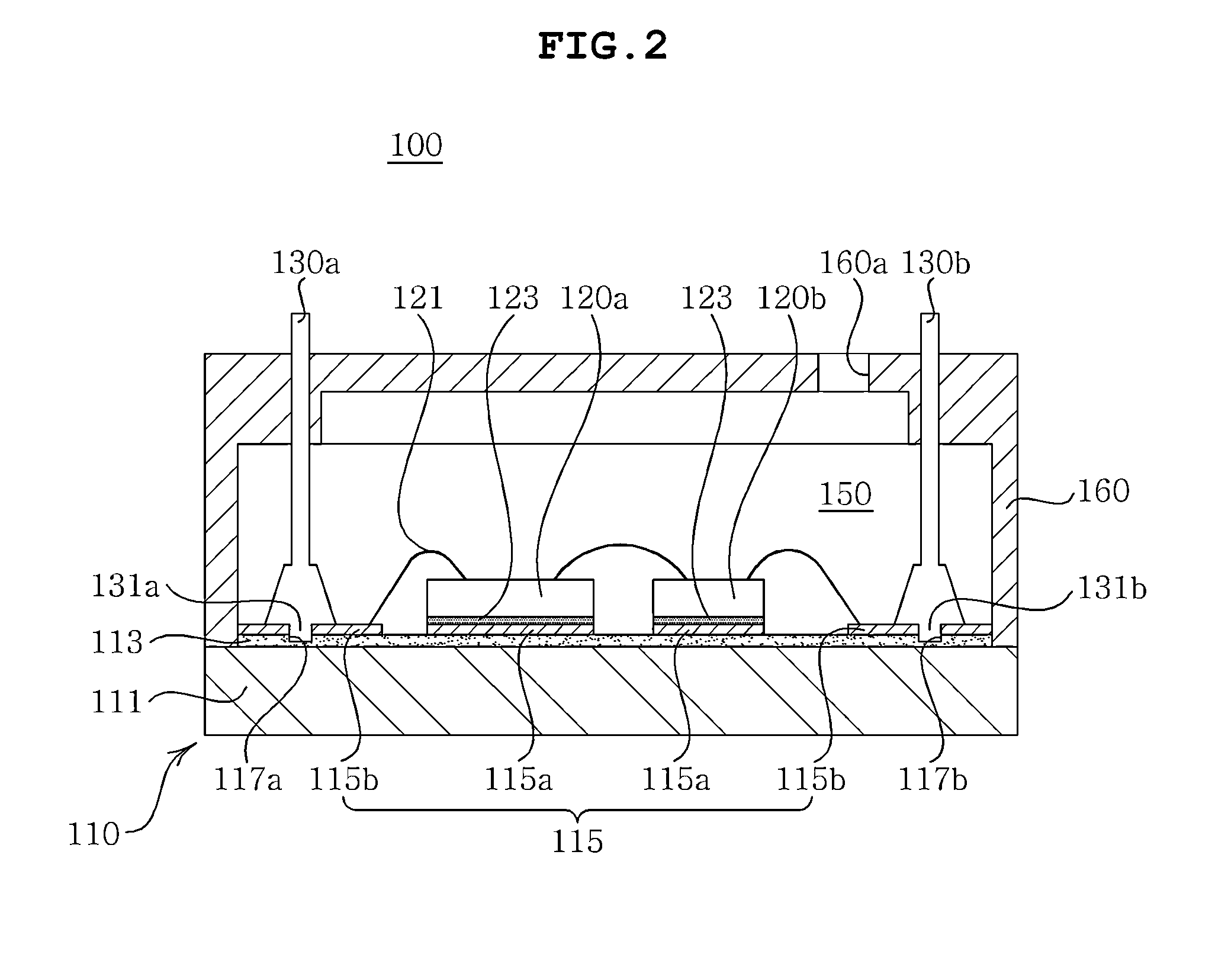

Micro-element package module and manufacturing method thereof

InactiveUS20070228403A1Small sizeReduce the bonding areaSolid-state devicesRadiation controlled devicesManufacturing cost reductionMiniaturization

A micro-element package module which can reduce manufacturing costs and can be advantageous for mass production due to simplifying its structure and manufacturing process, and also can facilitate miniaturization and promote thinness, and a method of manufacturing the micro-element package module. The micro-element package module includes: an element substrate having a micro-element on a top surface of the element substrate; a circuit substrate that is provided around the element substrate; and an element housing that is provided above the element substrate and the circuit substrate, and includes a connecting section for electrically connecting the micro-element and the circuit substrate.

Owner:SAMSUNG ELECTRONICS CO LTD

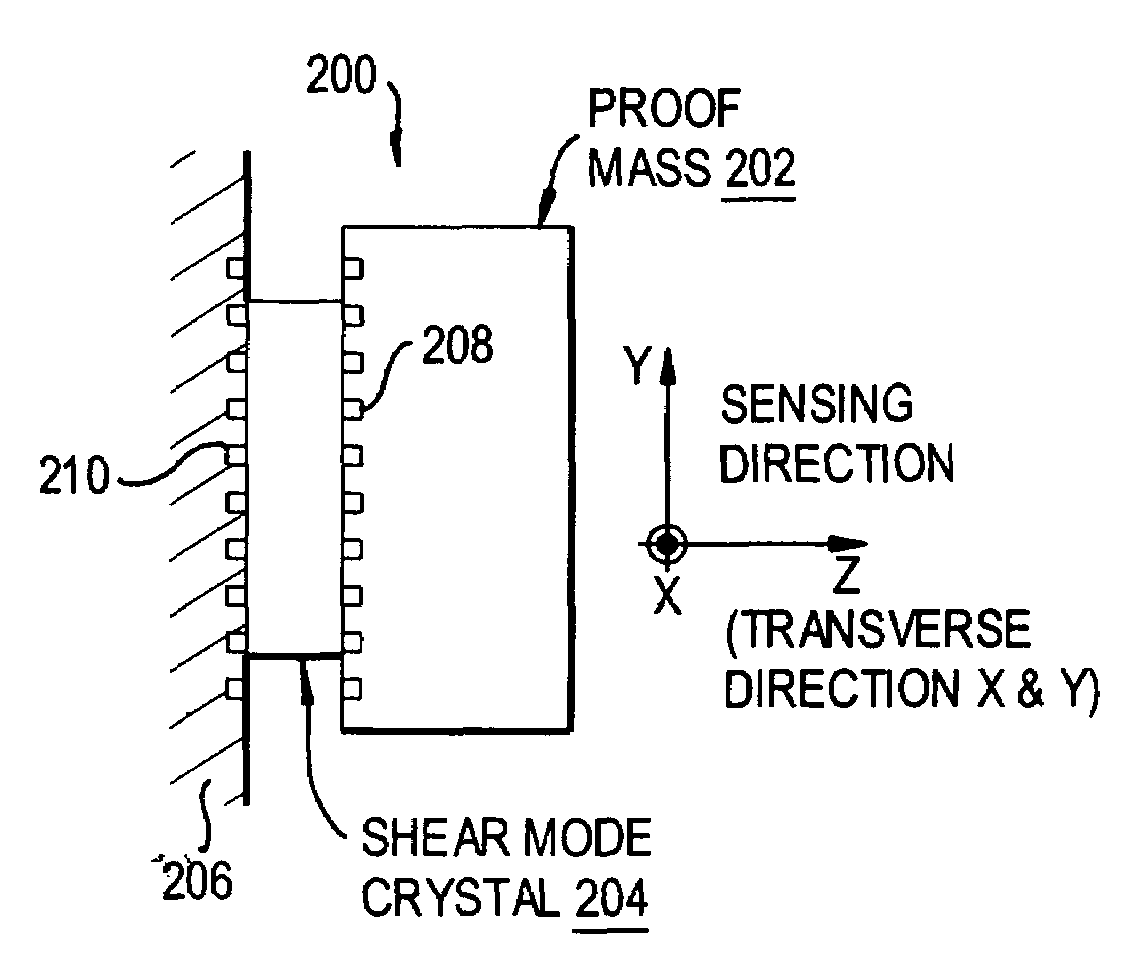

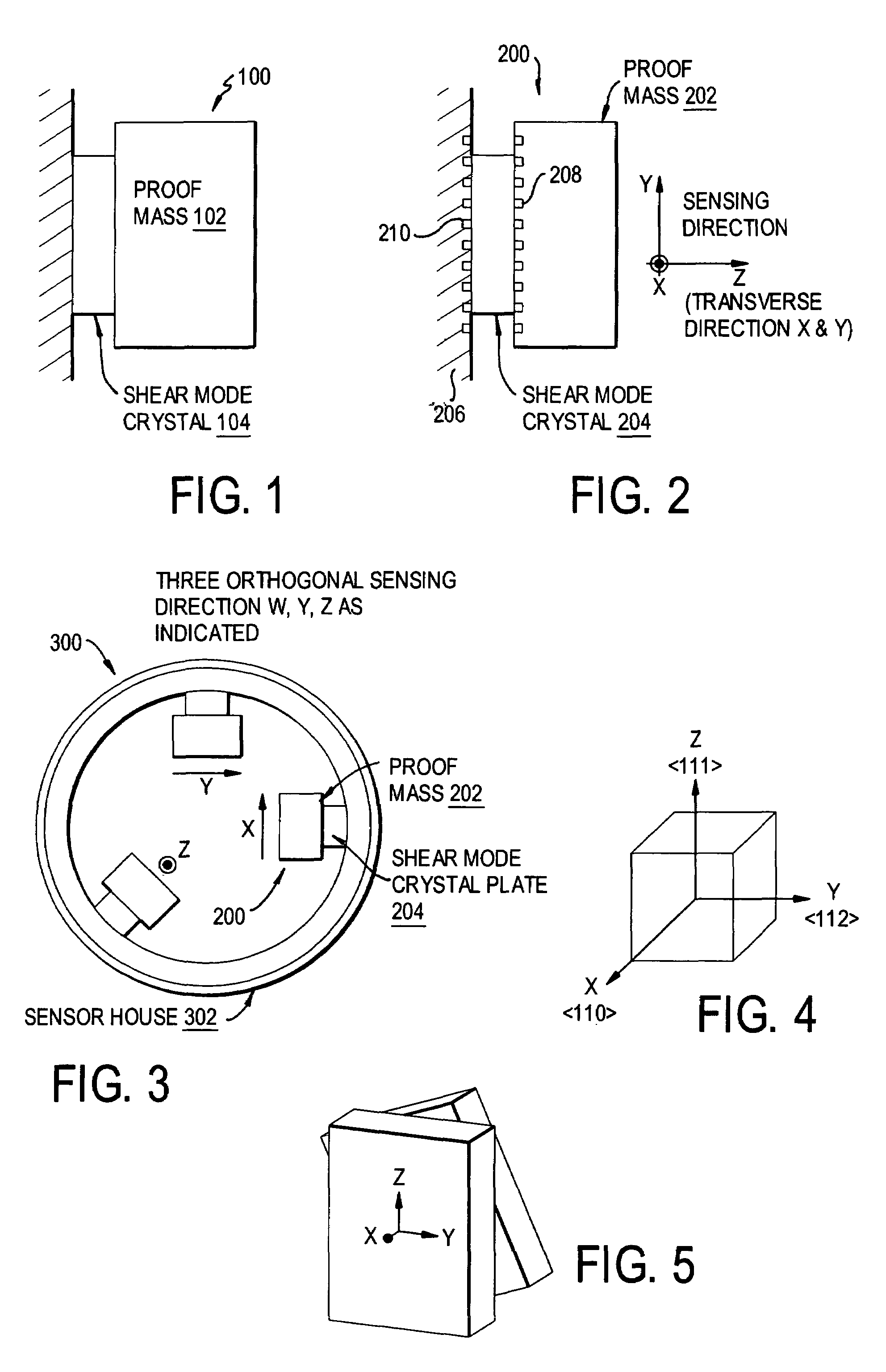

Underwater acoustic vector sensor using transverse-response free, shear mode, PMN-PT crystal

InactiveUS7066026B2Improve noise levelNarrow bandwidthAnalysing fluids using sonic/ultrasonic/infrasonic wavesAcceleration measurement using interia forcesElectricityFree state

The present invention is directed to an acoustic vector sensor, also called particle velocity sensor. <111> direction poled, shear mode, relaxor single crystals are used as the sensing elements. In addition, these crystal plates are cut at a special orientation such that they provide zero or minimum responses in the transverse directions, but have a maximum piezoelectric response in sensing direction. The piezoelectric sensor contains a proof mass, a base, and an aforementioned relaxor crystal. Three of the sensors are mounted orthogonally with a rigid case, and they are designated to sense the acoustic particle velocity in three designated directions, say X, Y, and Z. To solve the adverse lateral constraint problem (also known as clamping effect) associated with the relaxor crystal; reduced bonding area between the proof mass and the relaxor crystal are introduced. This feature greatly reduced the percentage of the bonding area for the crystal; consequently the free-state piezoelectric properties of the relaxor crystals are preserved.

Owner:AMPHENOL MARYLAND INC

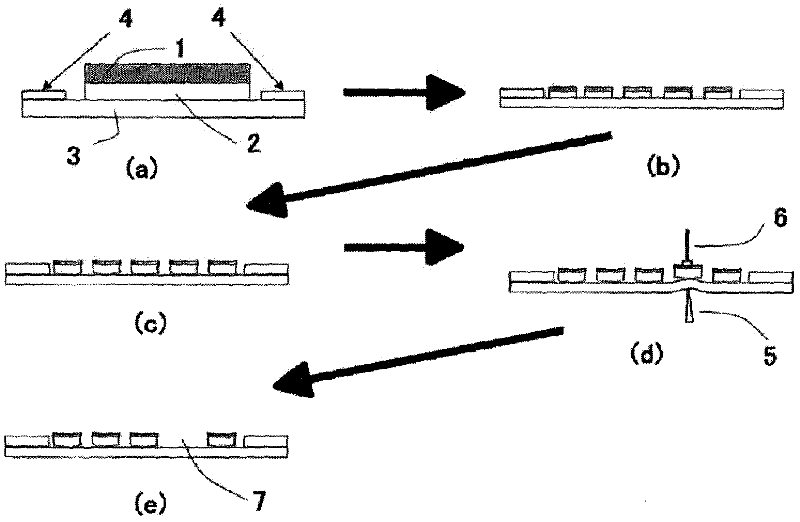

Manufacturing method for semiconductor light emitting device

InactiveUS20060094140A1Prevent stress distributionReduce contact areaSemiconductor/solid-state device manufacturingSemiconductor devicesFailure preventionLength wave

A manufacturing method for a semiconductor light emitting device is provided. The method includes preparing a first wafer in which at least one semiconductor layer including the emitter layer is formed; disposing a second wafer transparent to an emission wavelength of the emitter layer on the surface of the first wafer; providing a bonding failure prevention structure to at least either the first wafer or the second wafer for preventing bonding failures of the first wafer and the second wafer; and applying compressive force to a contact face between the first wafer and the second wafer while at the same time, heating the contact face. The first and second wafers can be bonded across their entire surfaces without causing bonding failure.

Owner:SHARP KK

Solder preform and a process for its manufacture

ActiveUS20110068149A1Constant gapImprove reliabilityTransportation and packagingWelding/cutting media/materialsAlloyMetal

A mixed mother alloy is prepared from a solder mixture comprising a pyrolyzable flux and high melting point metal particles, the mixed mother alloy is charged into a large amount of molten solder and stirred, and a billet is prepared. The billet can then be extruded, rolled, and punched to form a pellet or a washer, for example.

Owner:SENJU METAL IND CO LTD +1

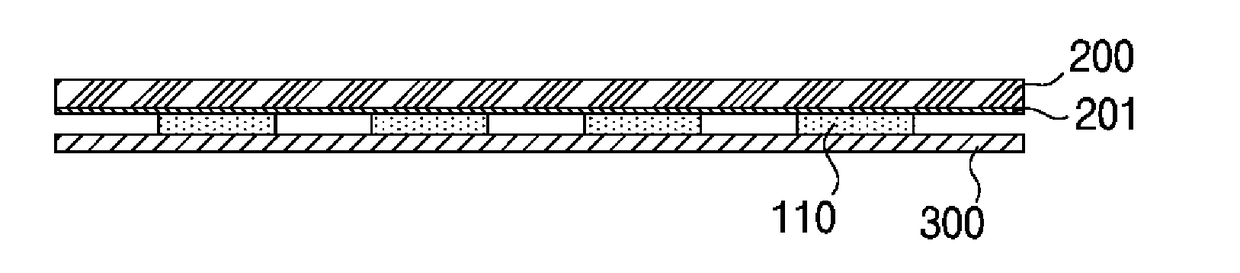

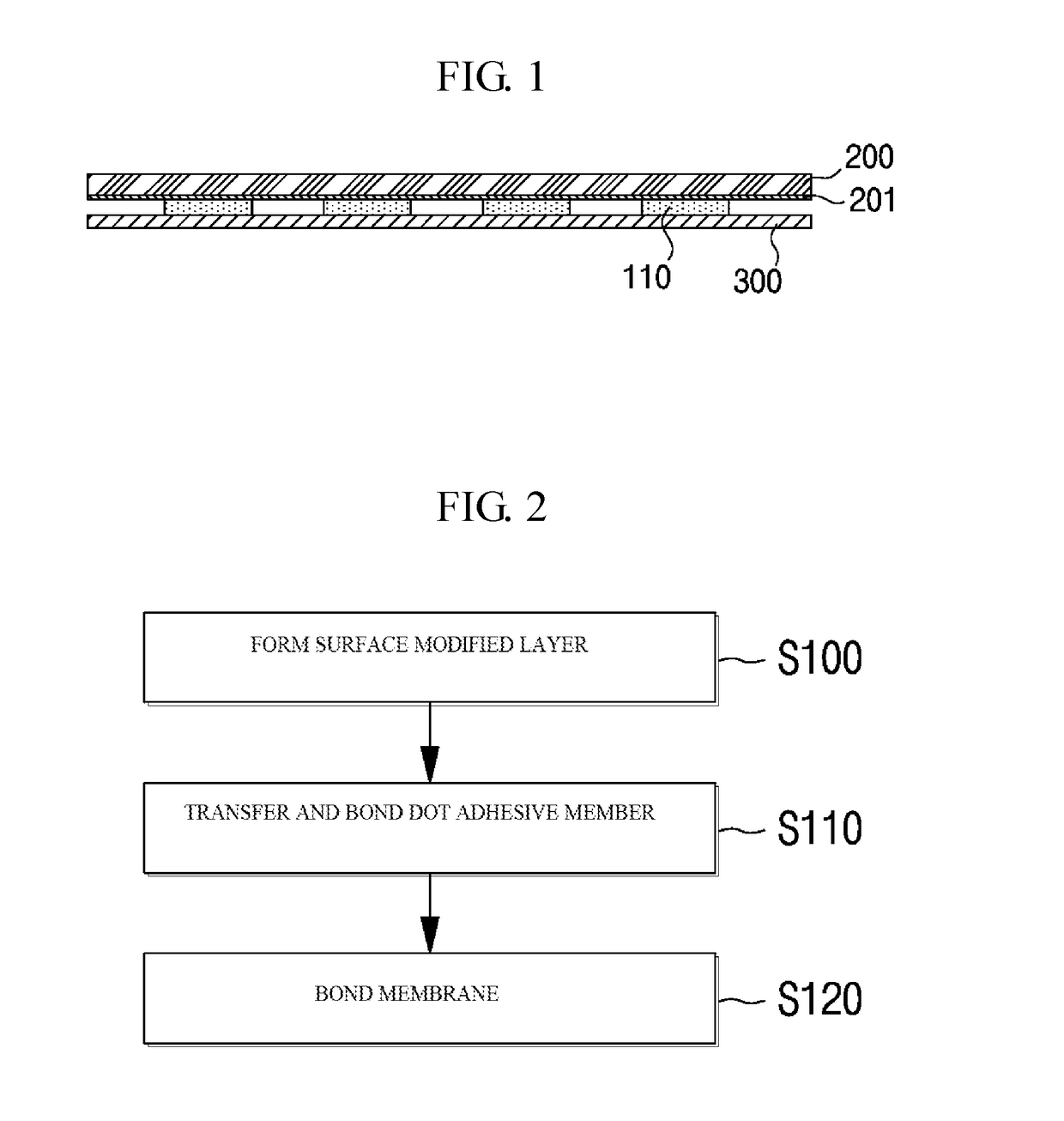

Waterproof and moisture permeable fabric, and manufacturing method therefor

ActiveUS20170266919A1Reduction in bond areaIncrease areaLamination ancillary operationsFibre treatmentBiomedical engineeringMoisture

Owner:AMOGREENTECH CO LTD

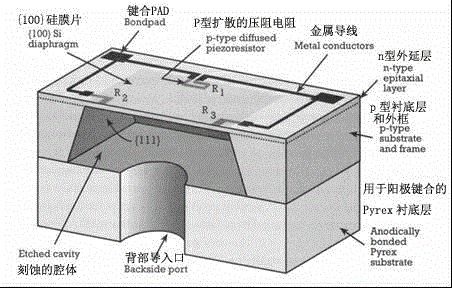

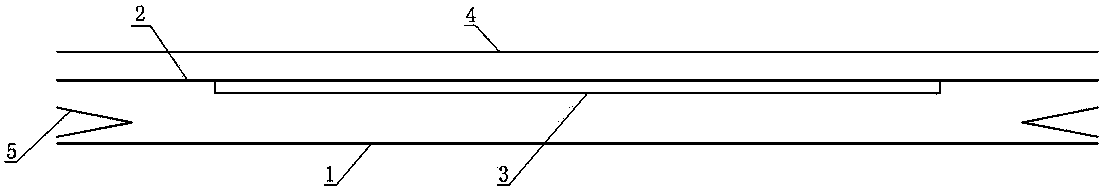

Silicon-silicon-bonding-based pressure sensor capable of isolating packaging stress

ActiveCN104132768AReduce bonding areaReduce thermal stressFluid pressure measurement using ohmic-resistance variationThermal isolationAdhesive

The invention discloses a silicon-silicon-bonding-based pressure sensor capable of isolating a packaging stress. The pressure sensor includes a chip layer and a support layer. A lug used for silicon-silicon bonding is etched on the surface of the support layer. Gaps exist between other areas of the support layer and the chip layer. The structure is capable of avoiding too much consideration of material selection (such as a packing substrate of low stress and an adhesive of low stress) so that high-efficiency thermal isolation is realized comparatively easily and larger shock can be resisted and thus the pressure sensor is wider in application occasions.

Owner:SUZHOU UNIV

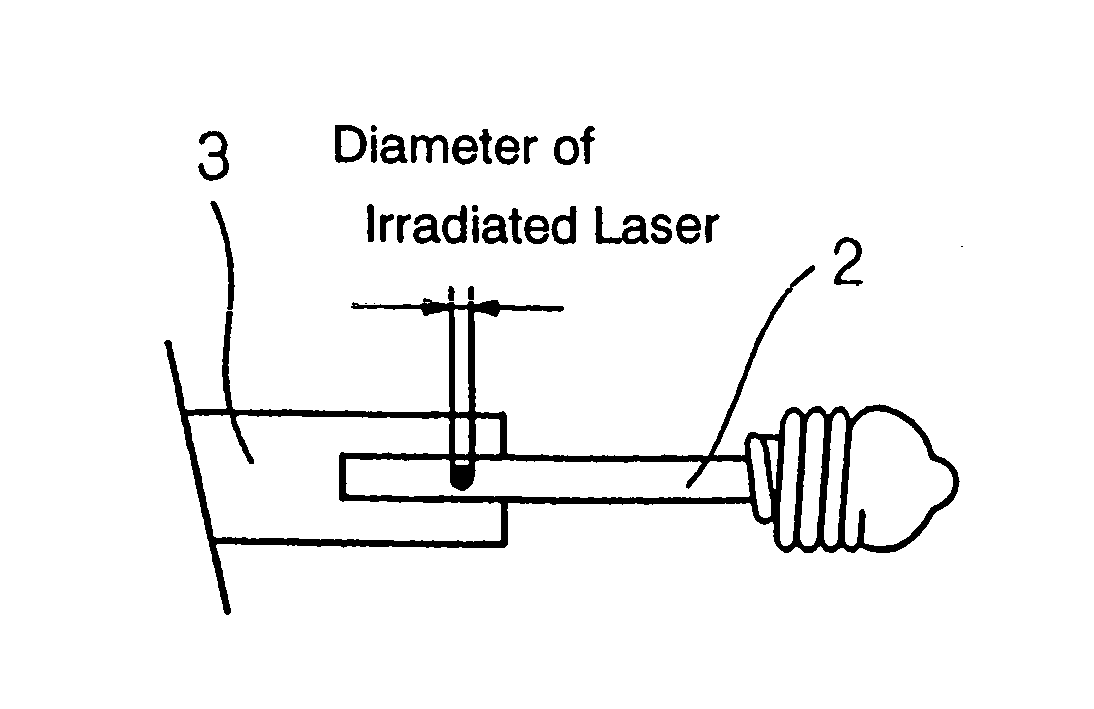

Method of manufacturing a high-pressure discharge lamp

InactiveUS20050003729A1Improve reliabilityEliminate disadvantagesTube/lamp screens manufactureElectroluminescent light sourcesLaser lightLength wave

For manufacturing a high-pressure discharge lamp, a tungsten electrode is welded to a molybdenum foil by bringing a shaft of tungsten electrode into close contact with the molybdenum foil, and by irradiating a laser light, having a metal melting wavelength, to a junction of the molybdenum foil with the tungsten electrode from a location closer to the molybdenum foil to melt both the molybdenum foil and the shaft of the tungsten electrode for bonding.

Owner:USHIO DENKI KK

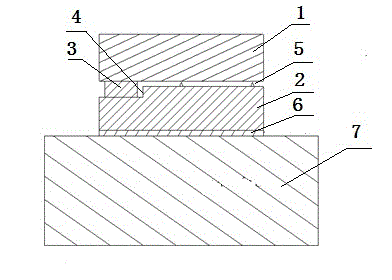

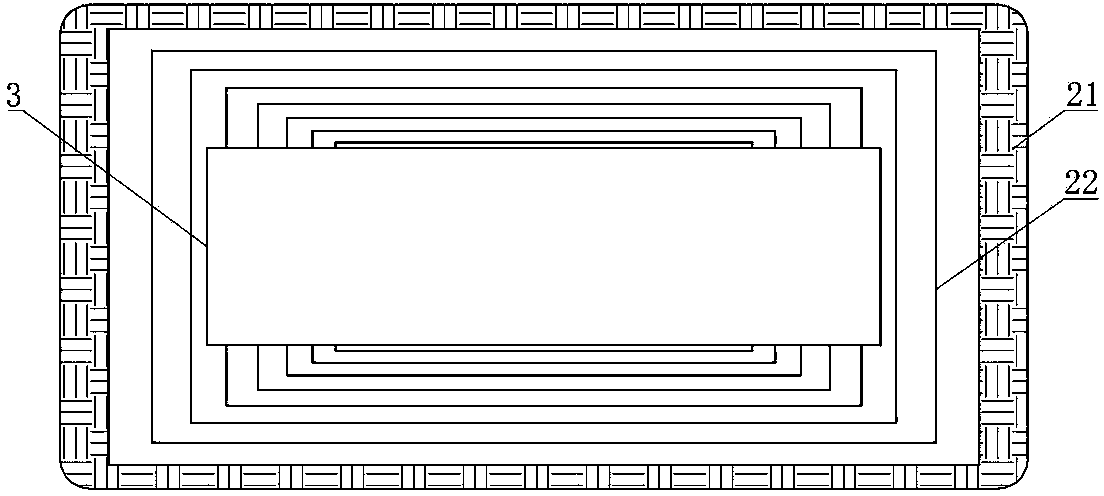

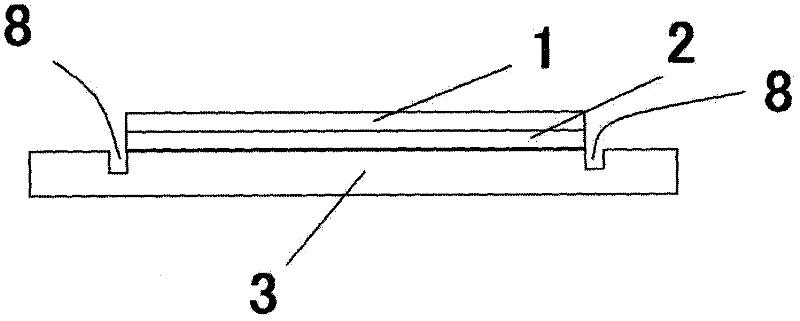

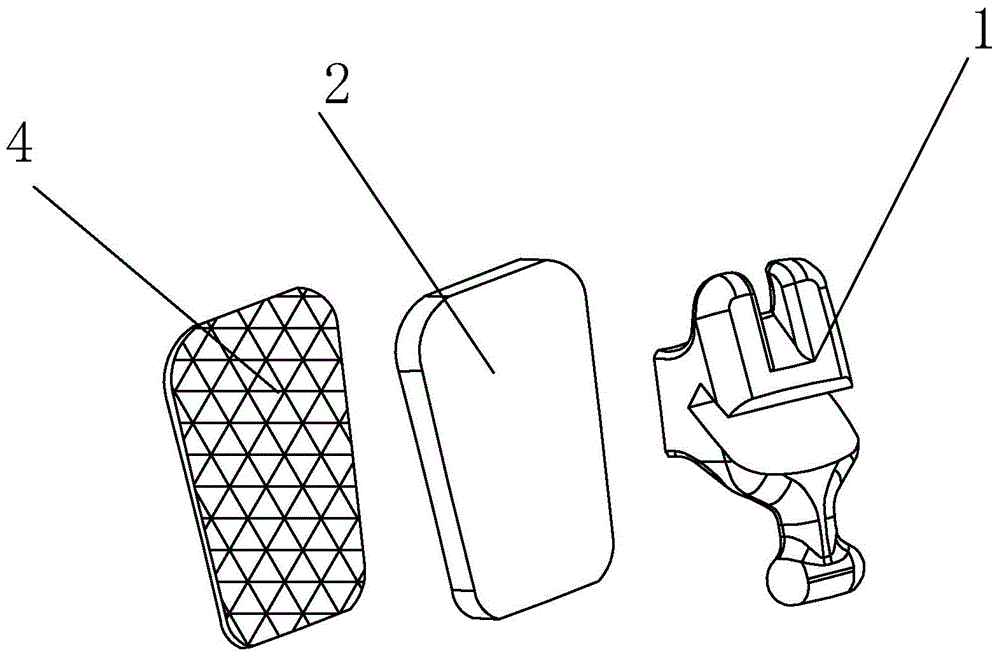

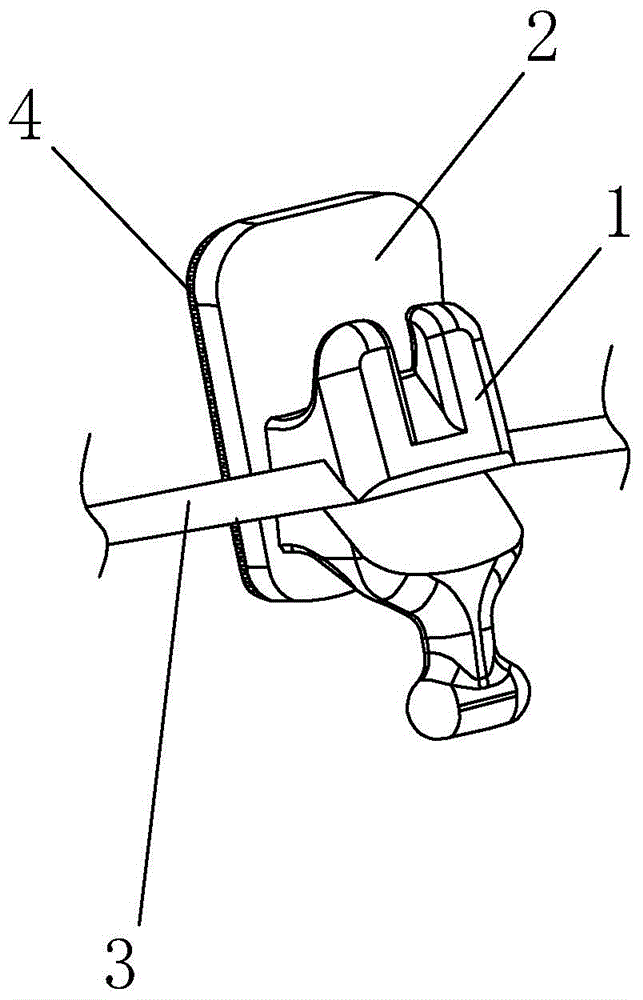

Functional dressing (film)

ActiveCN103505322AReduce the bonding areaPromote healingAdhesive dressingsDiagnostic recording/measuringEngineeringSurgery

A functional dressing (film) comprises an edge remaining film 1 and a fixed pasting film 2 which are convenient to separate from each other, wherein a functional pad 3 is arranged between the edge remaining film 1 and the fixed pasting film 2, a protective film 4 is arranged on the face, with the back towards the functional pad, of the fixed pasting film, and a plurality of layers of annular adhesive tape or adhesive tape shaped like a Chinese character 'hui' is arranged on the fixed pasting film. Thus, on the one hand, the binding area of the fixed pasting film and the skin is reduced, and on the other hand, sweat can volatilize through reserved gap; due to the fact that a functional layer and a moisture-preserving layer are arranged in the functional pad, medicine ingredients in the functional layer and the moisture-preserving layer act on wounds and peripheral tissue, and the functional dressing (film) has the functions of stopping bleeding, resisting and preventing bacteria, diminishing inflammation, easing pain, promoting healing, reducing scar formation and accelerating local blood circulation.

Owner:SHAANXI YUANGUANG HI TECH

Angular velocity detector

InactiveUS20060005624A1Preventing reduction in accuracy of angularImprove accuracyAcceleration measurement using interia forcesSolid-state devicesAngular velocityWire bonding

An angular velocity detector includes an angular velocity detecting element having a vibrating body arranged in a base substrate to be vibrated on a surface horizontal with respect to the base substrate. The angular velocity detecting element detects an angular velocity around an axis perpendicular to the base substrate based on a vibration of the vibrating body. In the angular velocity detector, a circuit substrate is bonded to a first surface of the base substrate through an adhesive, and a second surface of the angular velocity detecting element is electrically connected to the circuit substrate through a bonding wire. Furthermore, the adhesive is partially arranged on the first surface of the base substrate at least at a portion corresponding to a bonding portion of the bonding wire on the second surface of the base substrate. Therefore, a wire bonding can be easily accurately performed.

Owner:DENSO CORP

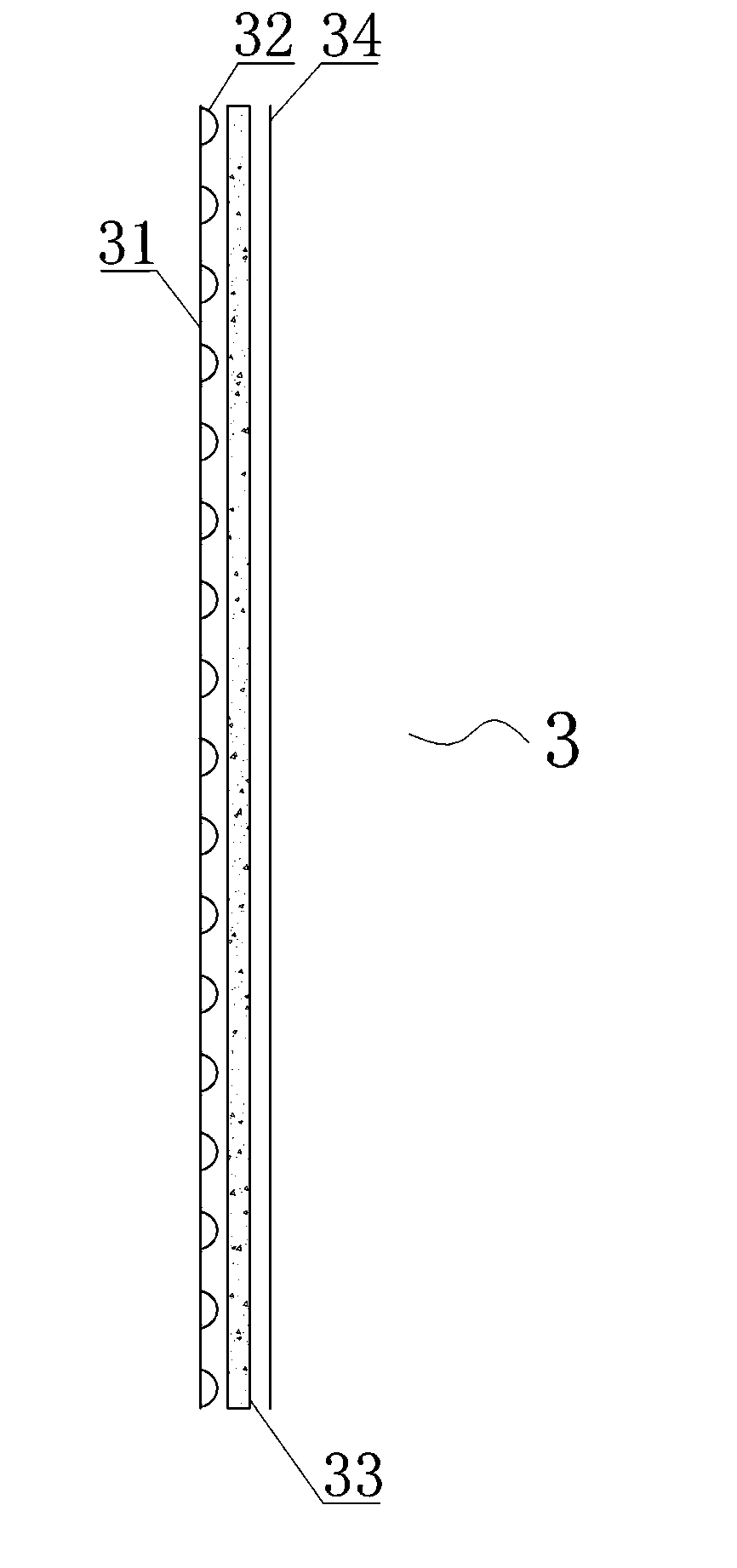

Electrostatic Force Rebalance Pendulum Silicon Micro Accelerometer Sensitive Structure and Manufacturing Method

ActiveCN105659845BHigh repeatability accuracyImprove zero drift problemAcceleration measurementGuidance systemGlass cover

The sensitive structure of the electrostatic force rebalanced pendulum silicon micro accelerometer is the upper and lower glass plates, and the middle is the sensitive mass block of the monocrystalline silicon pendulum structure. The three are connected together by bonding. The double flexible beams of the crystalline silicon sensitive mass are arranged opposite to the lead-out lines of the electrodes. In addition, in order to further reduce the influence of temperature on the monocrystalline silicon pendulum plate, the bonding area is reduced in the design, instead of the overall bonding, three small pieces of bonding are used to ensure that the bonding area of the upper and lower glass plates is completely Consistent, and further reduce the temperature coefficient caused by thermal stress; the manufacturing method of the above-mentioned sensitive structure includes the manufacturing of single crystal silicon pendulum plate and the manufacturing of upper and lower glass cover plates. The invention can reduce the temperature coefficient of the instrument and improve the temperature repeatability, thereby improving the resolution and sensitivity of the silicon micro accelerometer and meeting the requirements of inertial guidance systems such as missiles.

Owner:BEIJING AEROSPACE TIMES OPTICAL ELECTRONICS TECH

Method for processing wafer

InactiveCN102208366AGood adhesionReduce the bonding areaSemiconductor/solid-state device detailsSolid-state devicesWaferingDicing tape

A method for processing wafer includes sticking a surface protection sheet for dicing onto a surface of a wafer and cutting the sheet together with the wafer to protect the surface of the wafer from being contaminated by deposition of a dust such as swarf and the like, and picking up a chip without causing cracking or chipping in the chip after a dicing step, in the steps of dicing the wafer and then picking up the chip. The method includes: sticking the surface protection sheet for dicing onto the surface of the wafer; cutting the sheet together with the wafer; subsequently giving a stimulus to the surface protection sheet for dicing to peel the end of the chip from the dicing tape; and then picking up the chip.

Owner:NITTO DENKO CORP

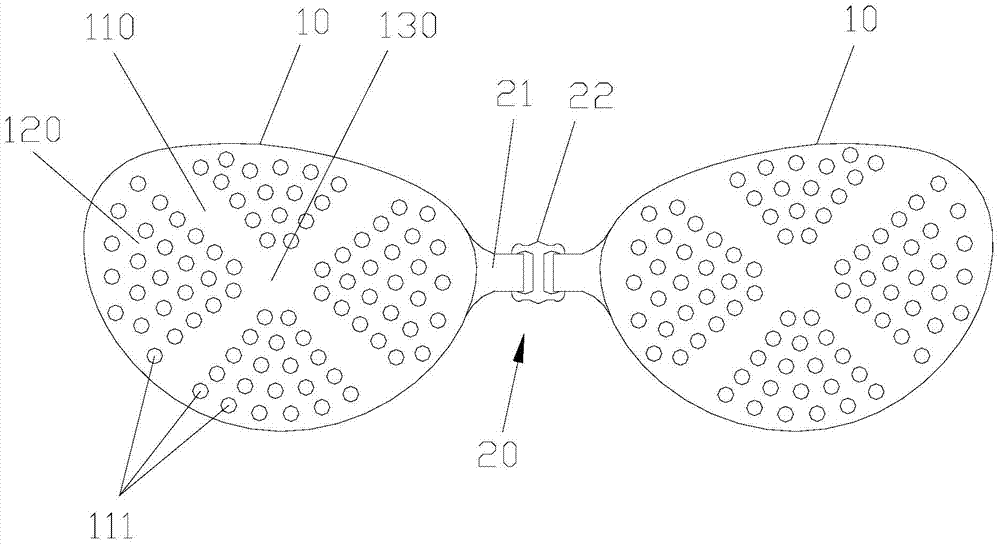

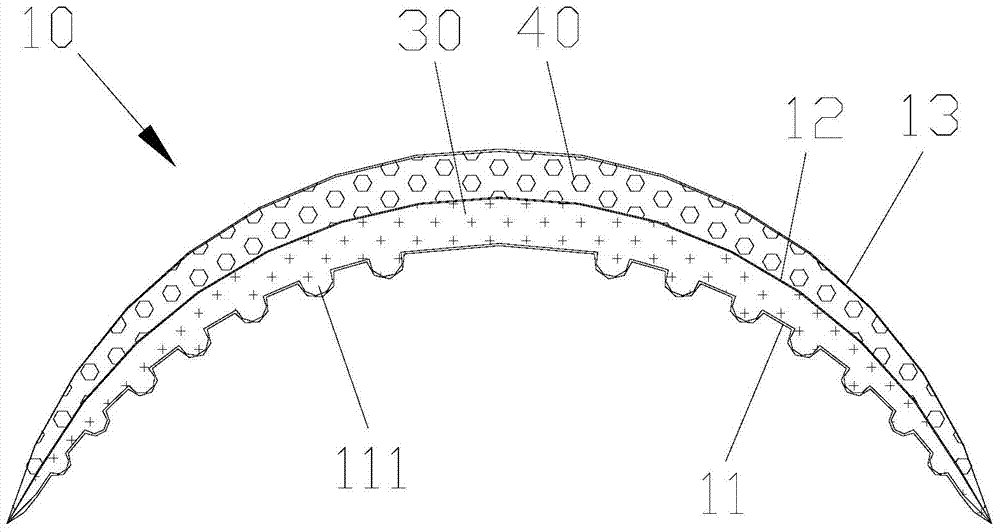

Silica gel bra in multi-layer combination as well as preparation method of silica gel bra

ActiveCN103689820AReduce weightImproves breathability and wicking performanceBrassieresCorsetsViscoseEngineering

The invention provides a silica gel bra in multi-layer combination as well as a preparation method of the silica gel bra. The silica gel bra comprises two bra cup bodies and a connecting element for connecting the two bra cup bodies, wherein each bra cup body comprises a silica gel bag formed by at least three layers of plastic films which are laminated and combined together along the periphery; each silica gel bag at least comprises a first plastic film, a second plastic film and a third plastic film sequentially from inside to outside; a first silica gel containing cavity is formed between the first plastic film and the second plastic film; a second silica gel containing cavity is formed between the second plastic film and the third plastic film; the first silica gel containing cavity is filled with a first silica gel body; the second silica gel containing cavity is filled with a second silica gel body; the specific gravity of the first silica gel body is less than that of the second silica gel body; the inner side surface of the first plastic film is provided with a plurality of salient point regions at intervals; each salient point region is internally provided with salient points which are raised outward at intervals; the surfaces of the salient points are coated with pressure-sensitive viscose. The silica gel bra provided by the invention is light, breathable, and firm and comfortable to wear.

Owner:SUZHOU MEISHANZI GARMENTS CO LTD

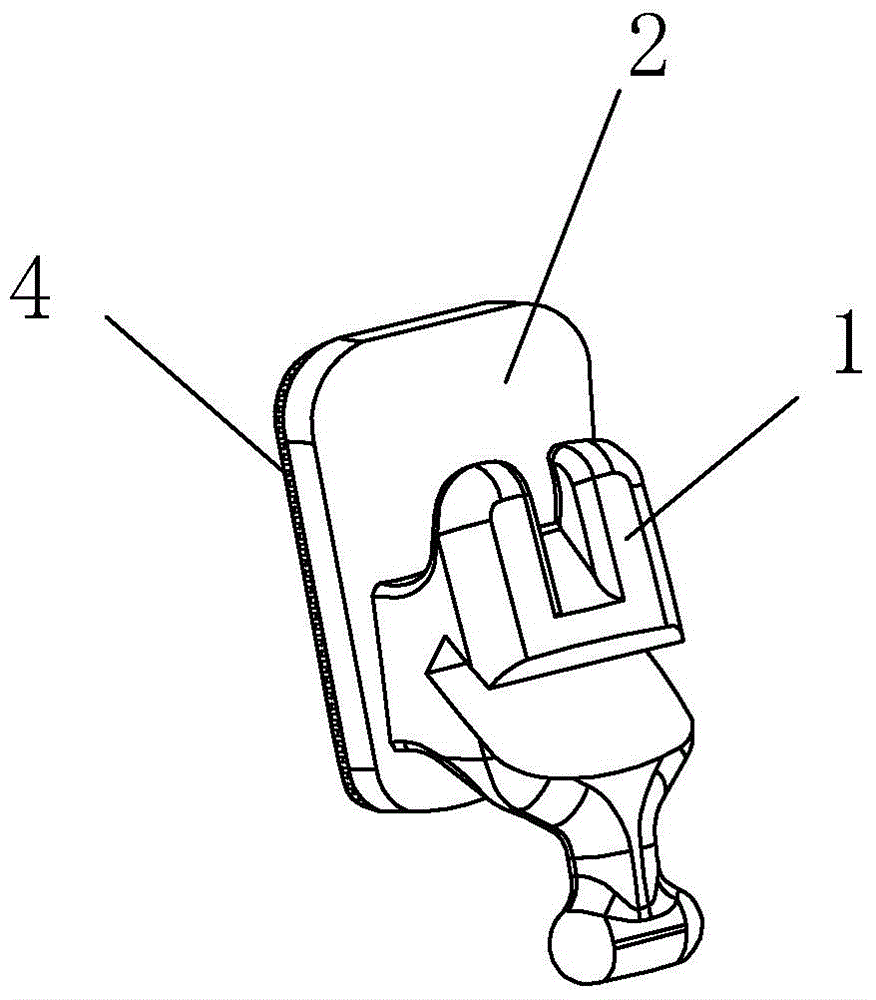

Manufacturing method of customized tongue-side invisible aligner

InactiveCN104970891AHigh precisionReduce bonding areaBracketsThree dimensional modelComputer Aided Design

Disclosed is a manufacturing method of a customized tongue-side invisible aligner, and belongs to the technical field of orthodontic treatment. The manufacturing method comprises steps of: performing three-dimensional scanning of a patient's teeth via laser to obtain image information; performing simulative alignment of teeth on a computer to obtain an ideal tooth alignment effect, and determining a tooth model scheme; printing the tooth model scheme of simulative alignment by using a 3D printer; designing three-dimensional models of an aligning bracket, a bracket baseplate, and an aligning steel wire, which are special for each tooth, by computer aided design and manufacturing technology. The manufacturing method is characterized by further comprising: carving the aligning bracket by adopting stainless steel via a numerically-controlled machine tool; selecting a stainless steel board, and carving a shape, identical to the teeth, at the lower surface of the stainless steel board via the numerically-controlled machine tool; and selecting a stainless steel mesh and welding the stainless steel mesh to the lower surface of the stainless steel board. According to the manufacturing method, an integrate bracket is manufactured by directly adopting three-dimensional image information, so that the bracket is high in precision and good in comfort during an orthodontic treatment process.

Owner:JINHUA KEDIFU MEDICAL TECH CO LTD

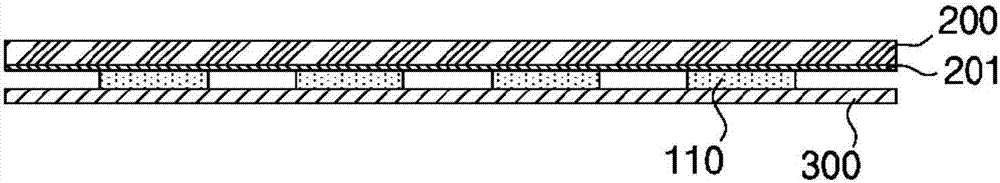

Adhesive sheet comprising hollow parts and method for preparing the same

ActiveUS20050276963A1Reduce noiseReduce vibrationNon-macromolecular adhesive additivesLayered productsPolymer scienceMicrosphere

Disclosed herein are an adhesive sheet comprising a cured acrylic polymer, hollow polymeric microspheres dispersed and ruptured in the cured acrylic polymer, and hollow parts formed by rupturing the hollow polymeric microspheres dispersed in the cured acrylic polymer, and a preparation method thereof.

Owner:LG CHEM LTD

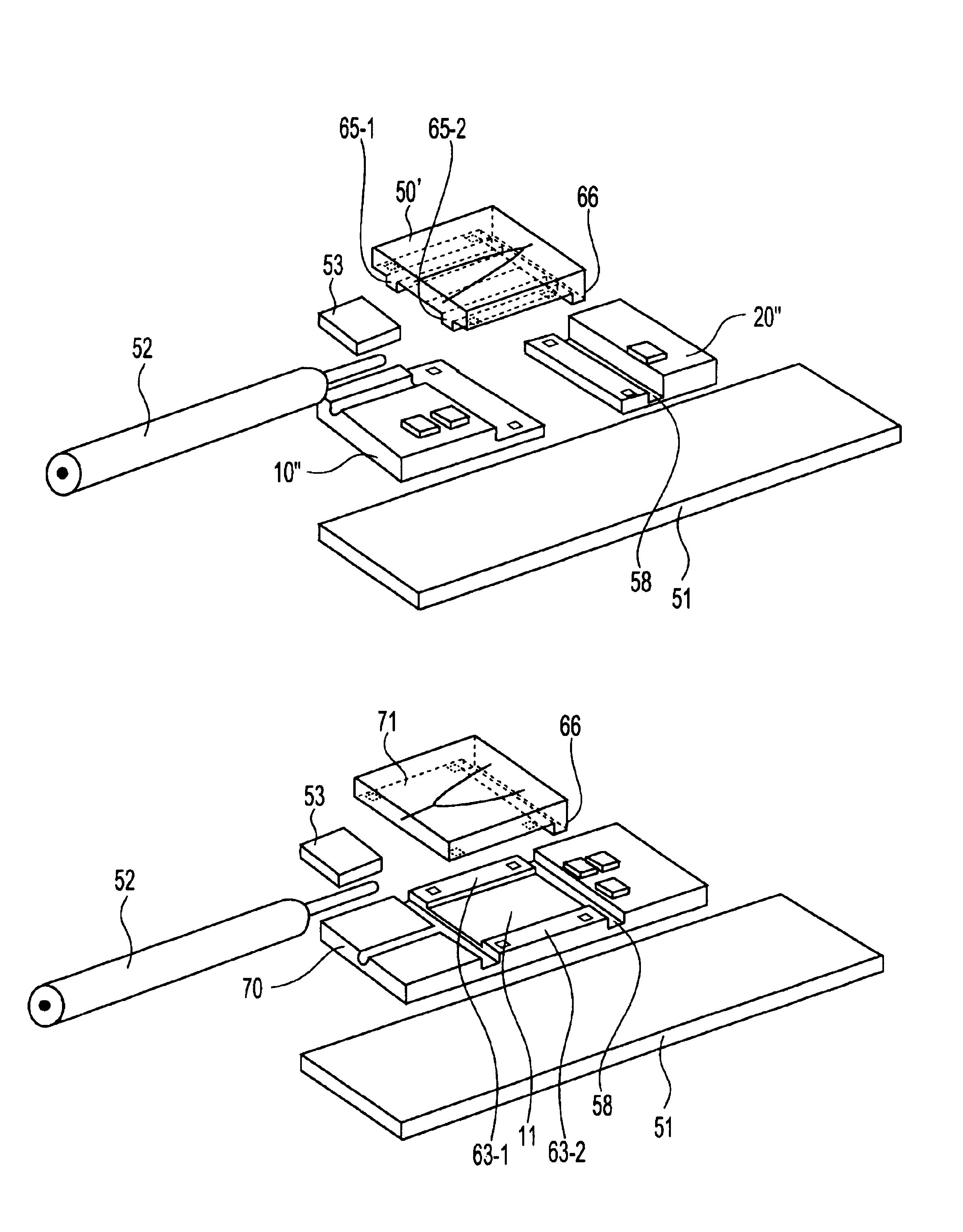

Optical waveguide transmitter-receiver module

InactiveUS7046868B2Reducing electrical crosstalkMade smallCoupling light guidesOptical waveguide light guideWaveguideOptical coupling

Owner:NEOPHOTONICS CORP

Power module package

InactiveUS20140110833A1Saving process costEasy to manufactureSemiconductor/solid-state device detailsSolid-state devicesComputer moduleSemiconductor chip

Disclosed herein is a power module package. The power module package includes a substrate having one surface formed with a circuit pattern including a chip mounting pad and an external connection pad and the other surface; a semiconductor chip mounted on the chip mounting pad; and an external connection terminal having one terminal and the other terminal, the one terminal being connected to the external connection pad and the other terminal protruding to the outside, in which the external connection pad and the external connection terminal are bonded to each other by welding.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

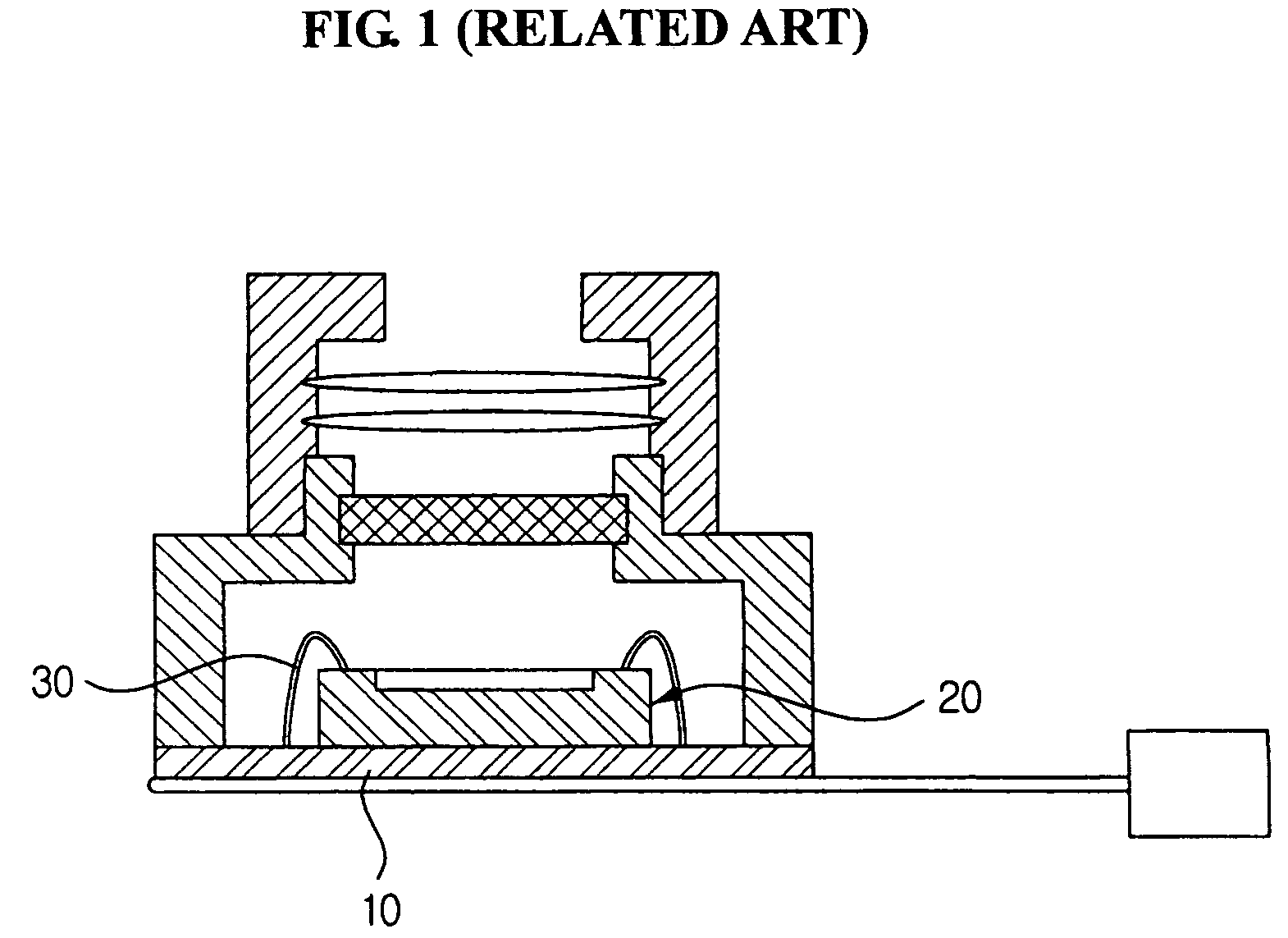

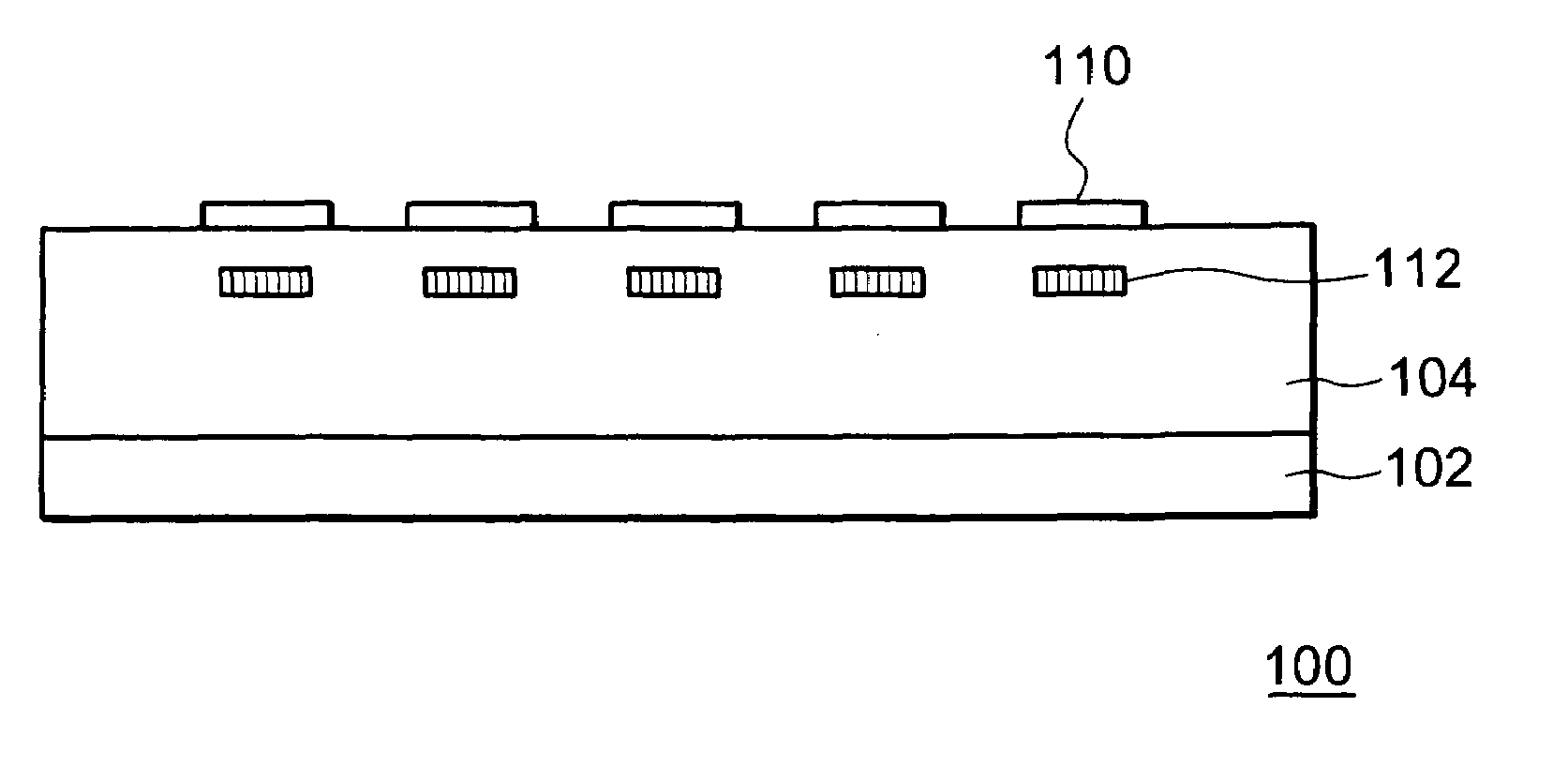

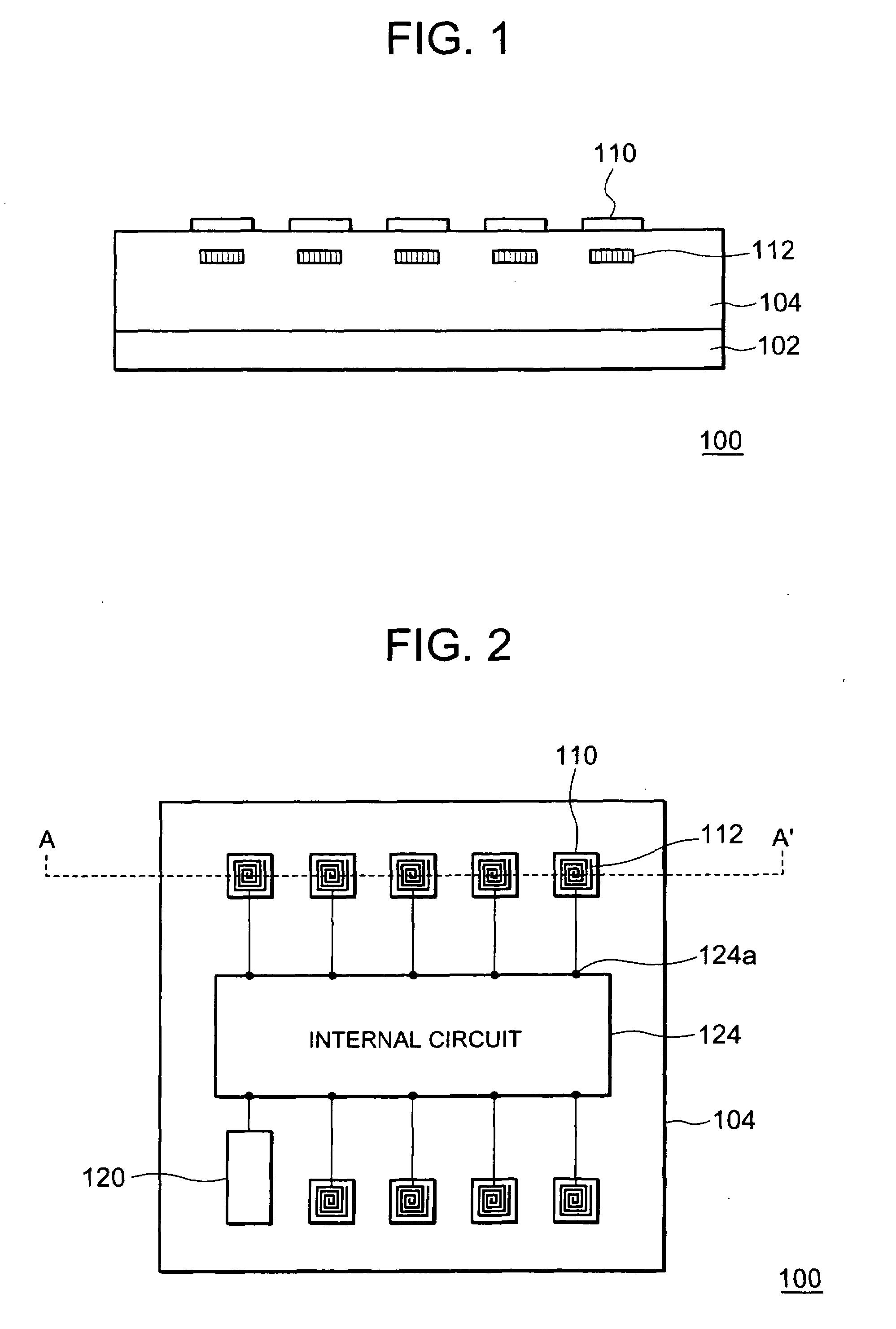

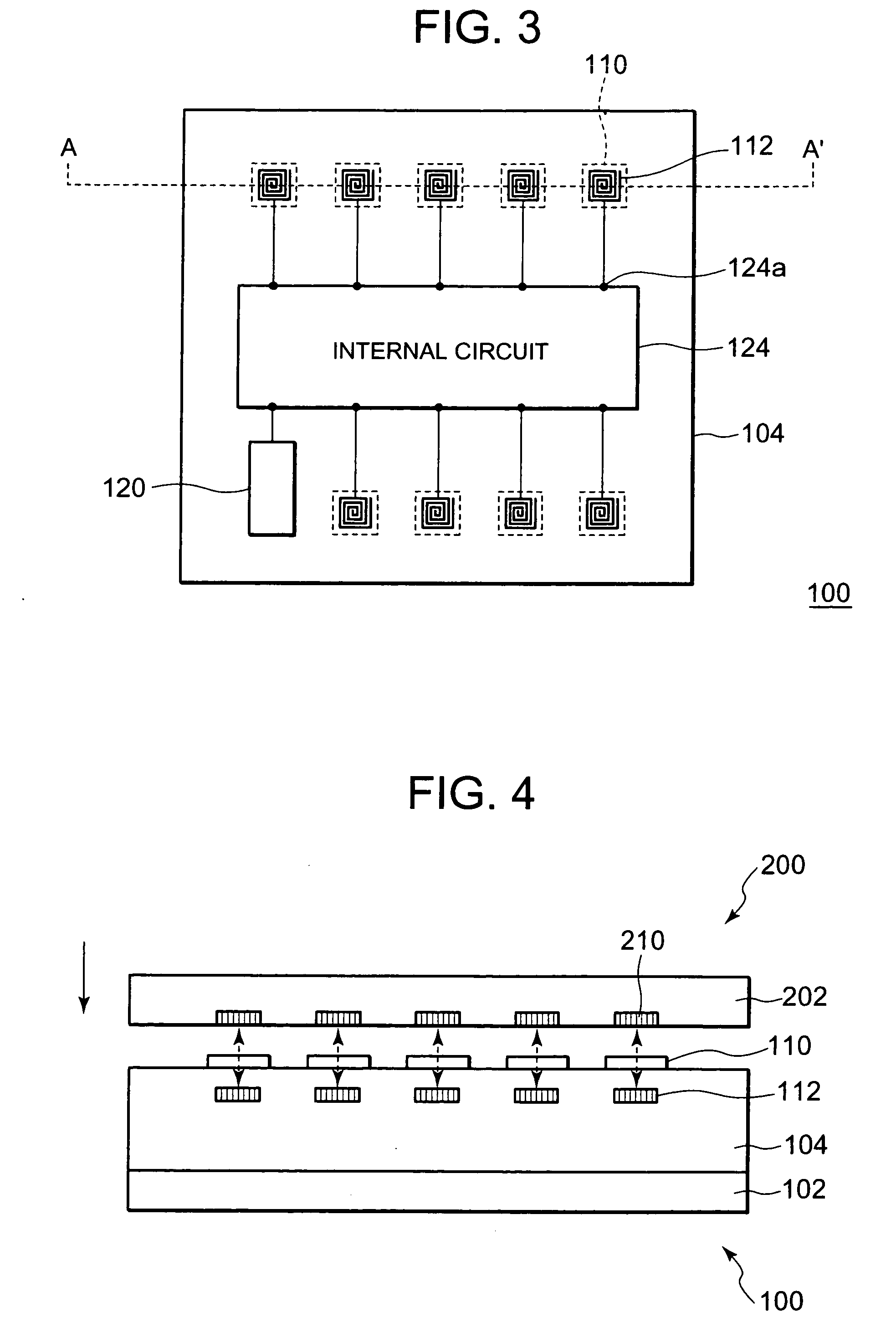

Semiconductor device, method of manufacturing thereof, signal transmission/reception method using such semiconductor device, and tester apparatus

ActiveUS20090189745A1Increase in chip size can be suppressedIncrease in sizeSemiconductor/solid-state device detailsSolid-state devicesDevice materialInductor

A semiconductor device (100) includes: a substrate (102); a bonding pad (110) provided above the substrate (102); and an inductor (112) provided above the substrate (102) and below the bonding pad (110) for carrying out signal transmission / reception to / from the external in a non-contact manner by electromagnetic induction.

Owner:RENESAS ELECTRONICS CORP

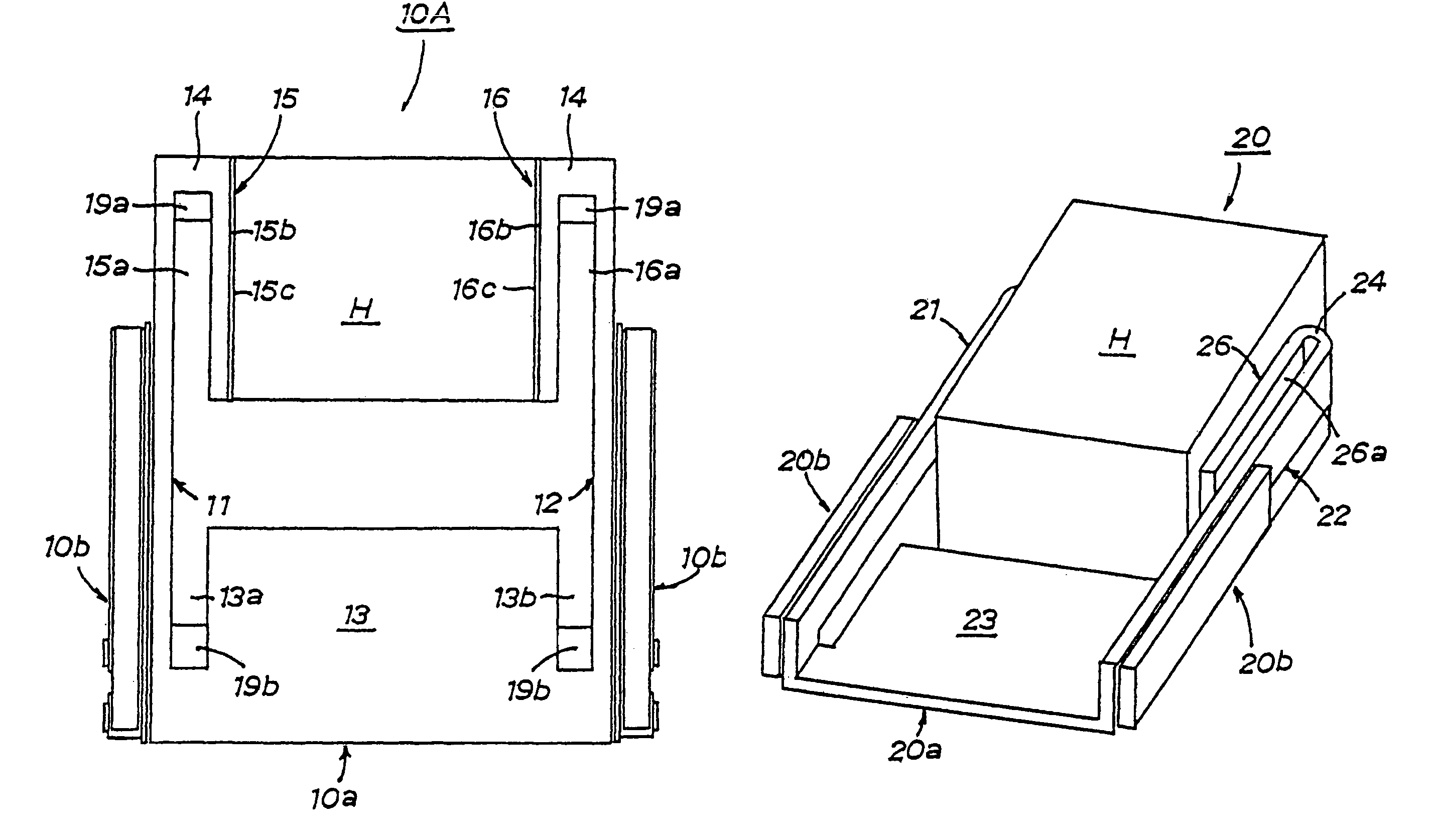

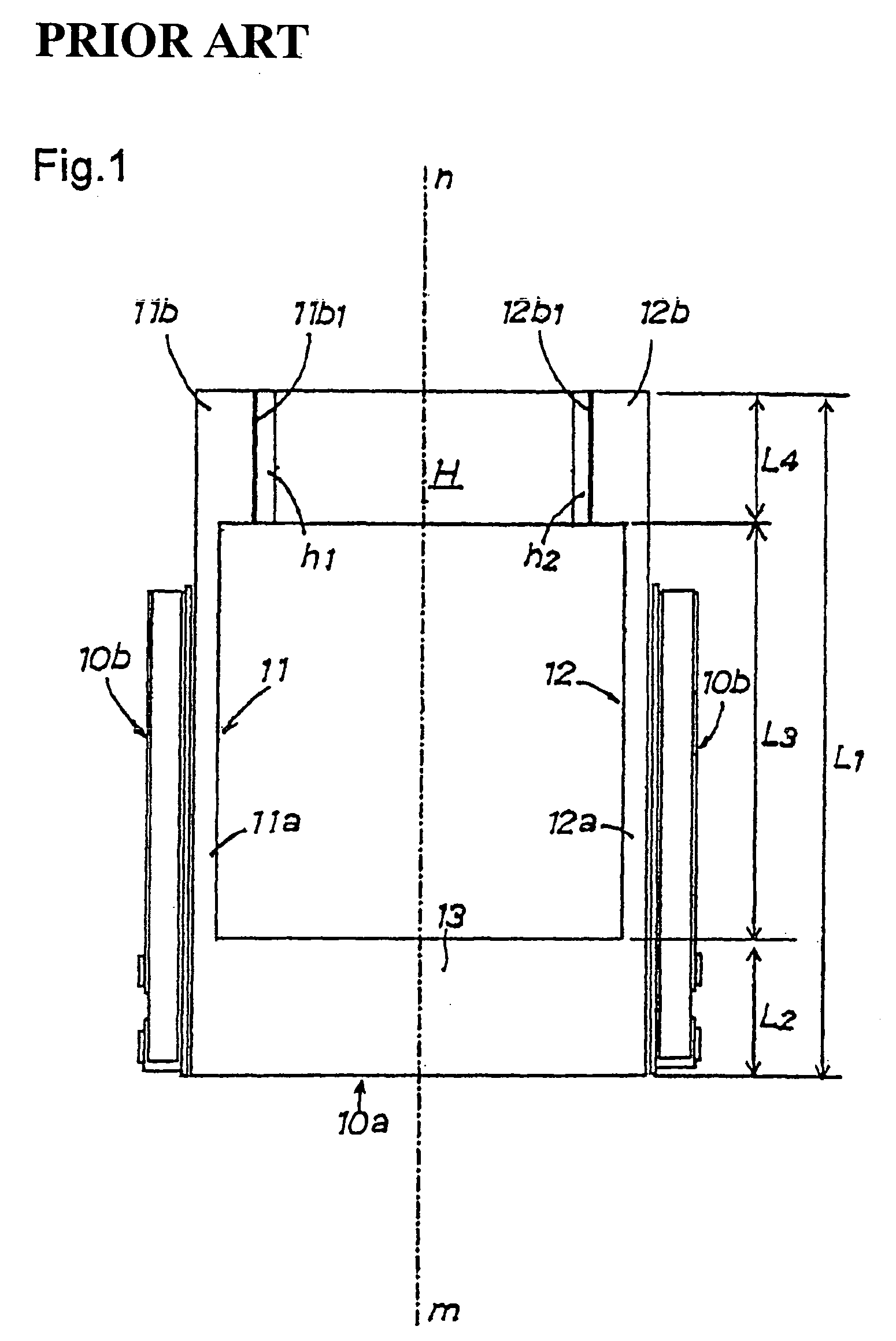

Punching knife mold of touch screen protecting film and fitting process of touch screen protecting film

InactiveCN103935111AImprove fitGuaranteed YieldLamination ancillary operationsLaminationTectorial membranePunching

The invention provides a punching knife mold of a touch screen protecting film and a fitting process of the touch screen protecting film. The punching knife mold is characterized in that a knife point consists of an outer-layer knife point and an inner-layer knife point, wherein the outer-layer knife point and the inner-layer knife point are annular, and punching edges of the outer-layer knife point and the inner-layer knife point are located in the same plane; the inner-layer knife point is arranged in the outer-layer knife point, and a gap is formed between the outer-layer knife point and the inner-layer knife point. The punching knife mold is designed in a double-layer annular knife point structure can be used for annularly cutting the protecting film, and a punched annular glue layer exposed outside only needs to fit an peripheral region outside a visible region of a touch screen, so that the fitting process can be simplified, and the rate of finished products is beneficially guaranteed.

Owner:NANCHANG O FILM OPTICAL TECH +3

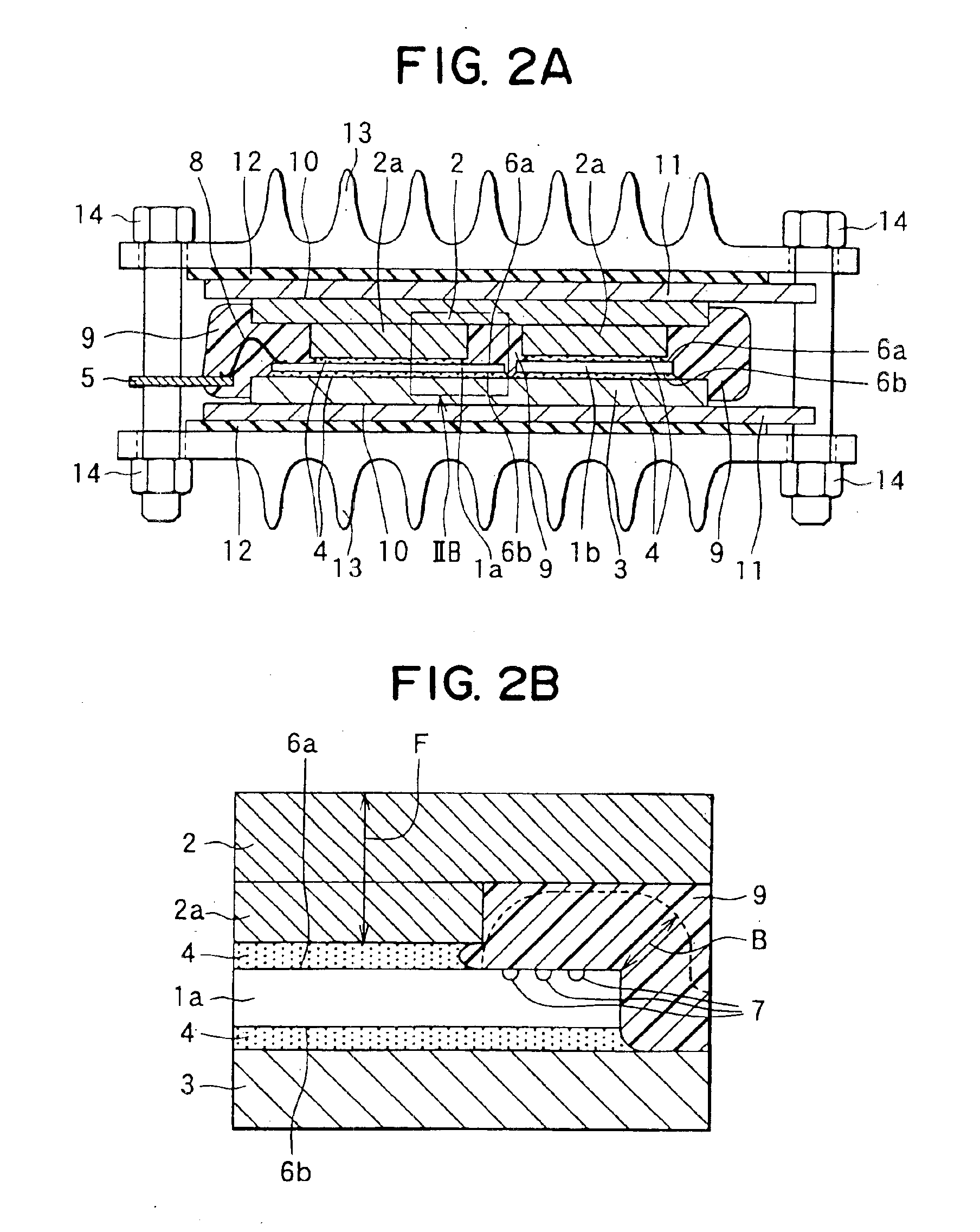

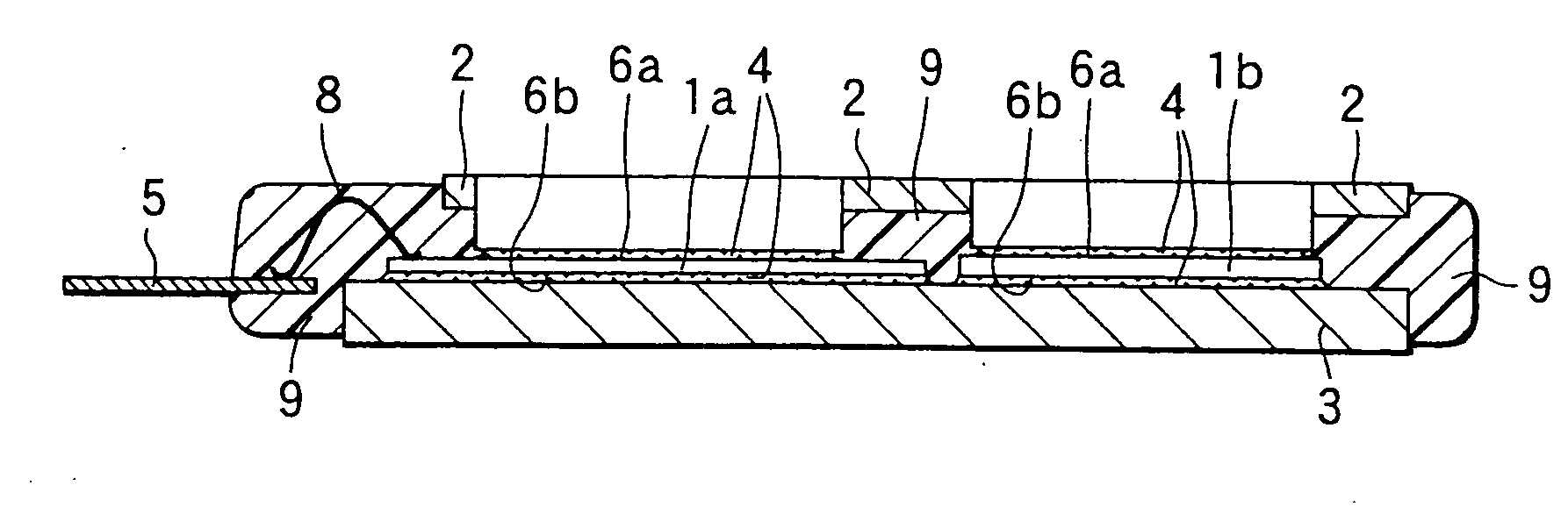

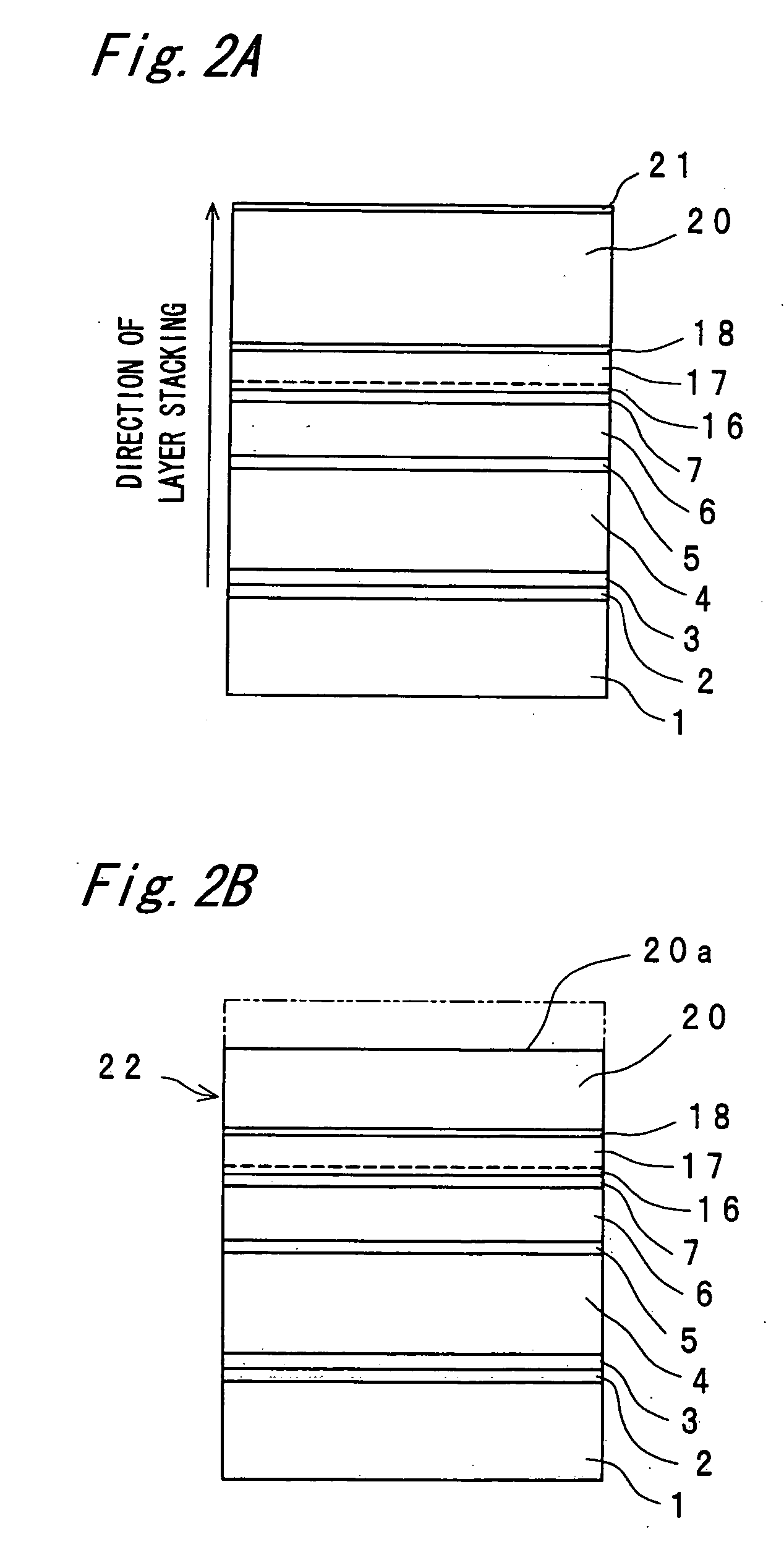

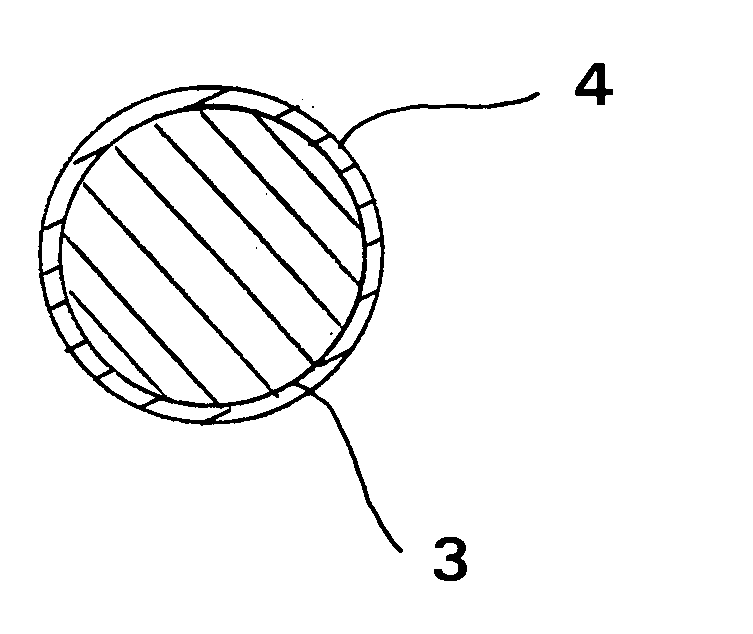

Method of producing a piezoelectric/electrostrictive device

InactiveUS7089637B2Increase displacementReduce the bonding areaPrinted circuit assemblingPiezoelectric/electrostrictive device manufacture/assemblyEngineeringMechanical engineering

A method of producing a piezoelectric / electrostrictive device having a base including a pair of movable parts opposing each other, a fixing part that connects the movable parts with each other at one end thereof, and mounting parts that extend for a predetermined length while holding slit-shaped gaps of a predetermined width along inside surfaces of said movable parts by being turned around at the other end of said movable parts, said piezoelectric / electrostrictive device having a piezoelectric / electrostrictive element disposed on at least one outside surface of said movable parts of said base, wherein a base block obtained by laminating and calcining a large number of ceramic green sheets is adopted as a material for forming said base, and the base including said movable parts, said fixing part, and said mounting parts is formed by cutting said base block at a predetermined site along a lamination direction of said ceramic green sheets.

Owner:NGK INSULATORS LTD

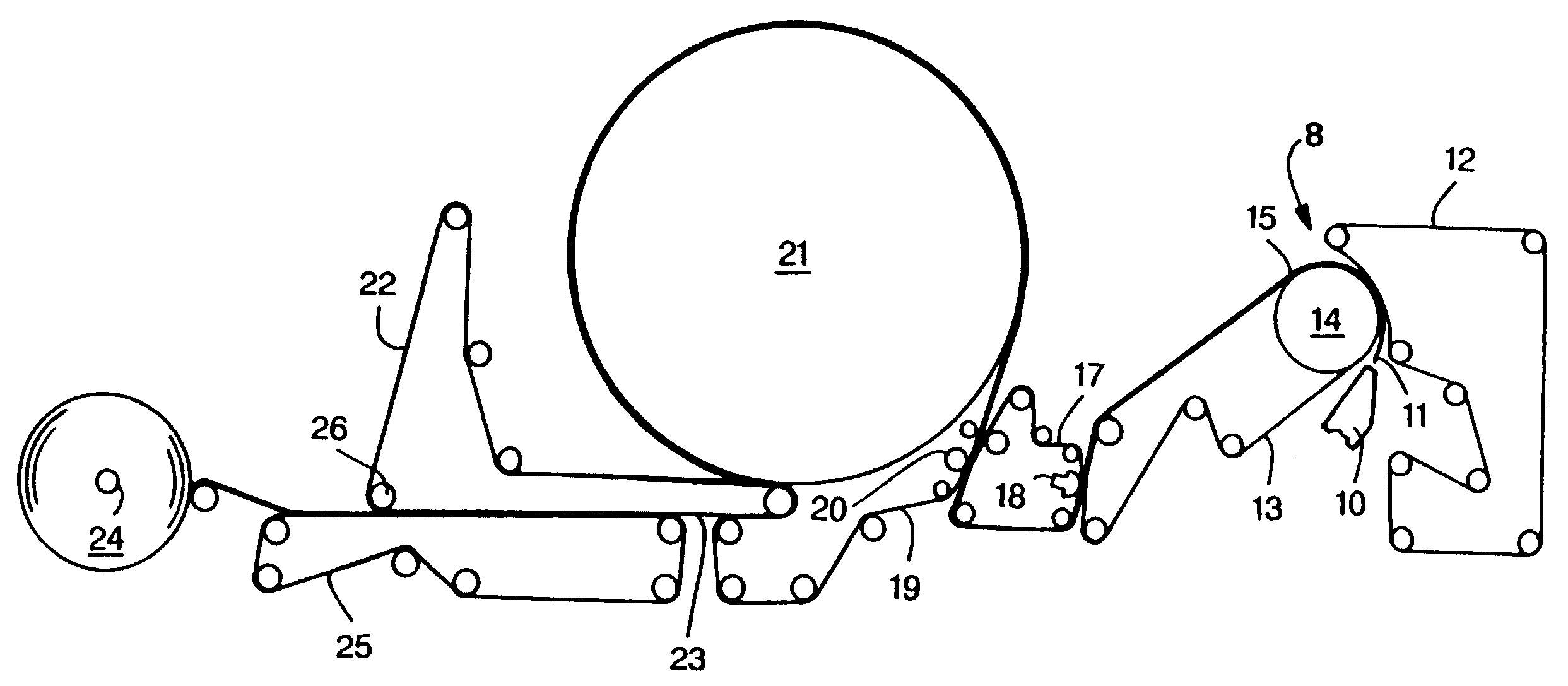

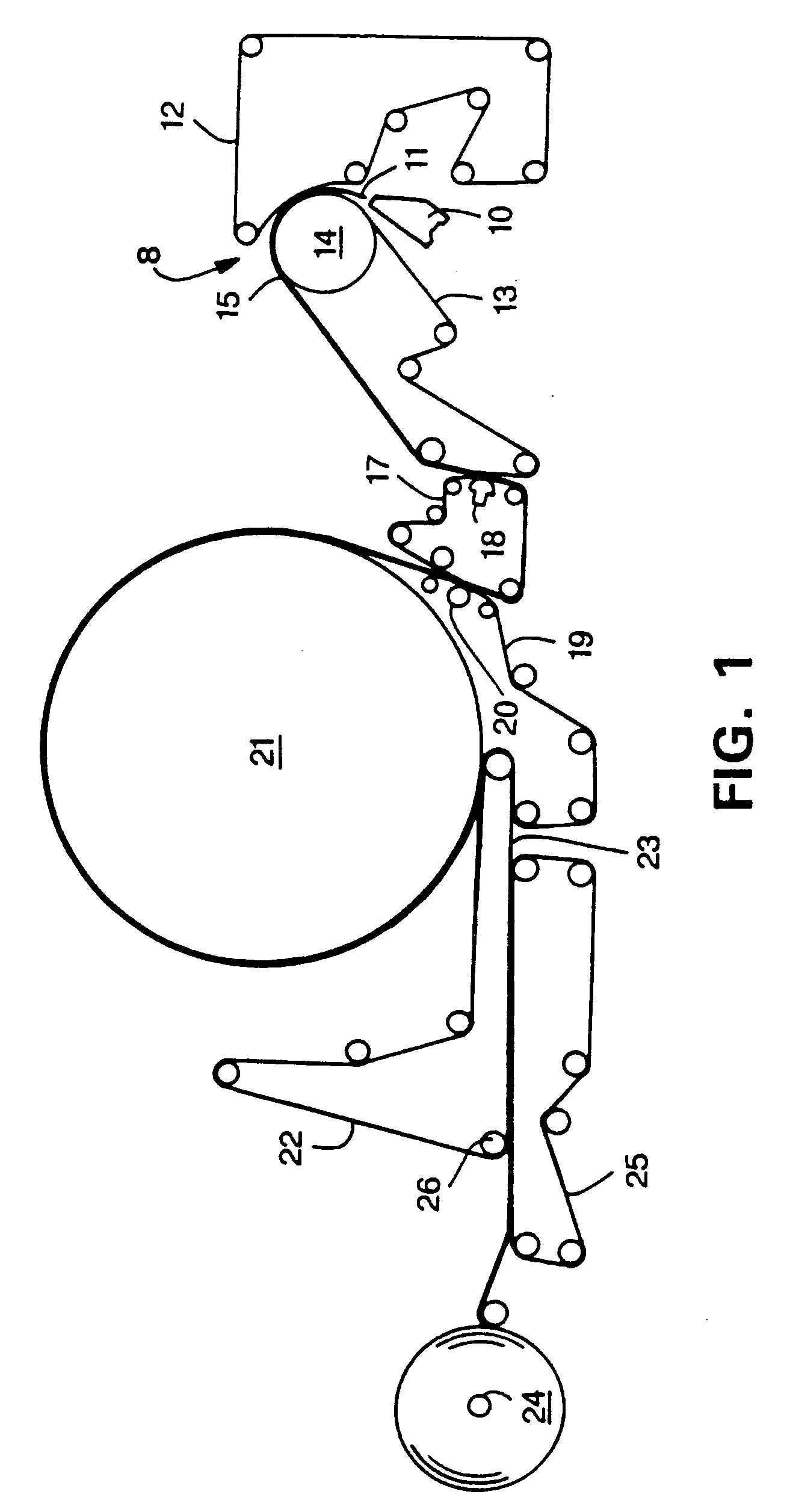

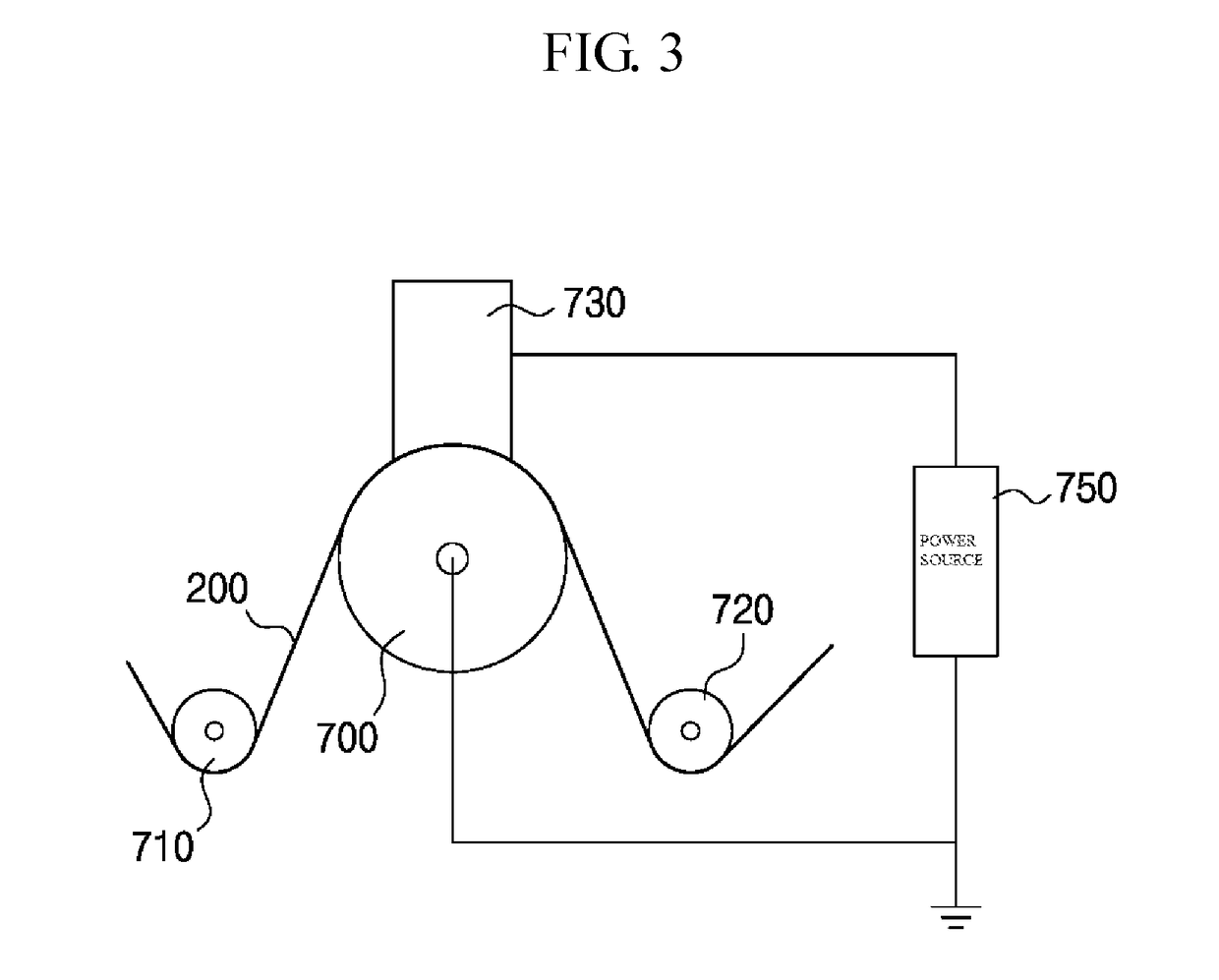

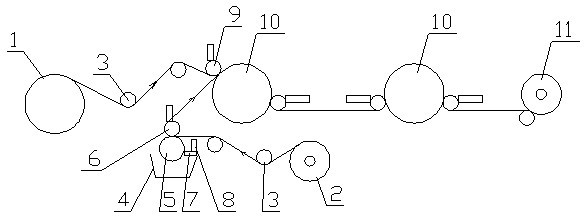

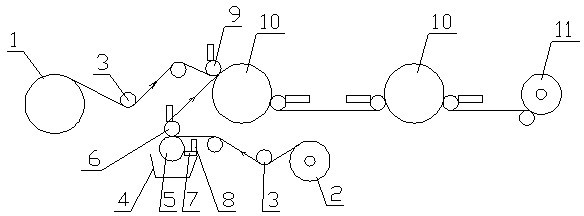

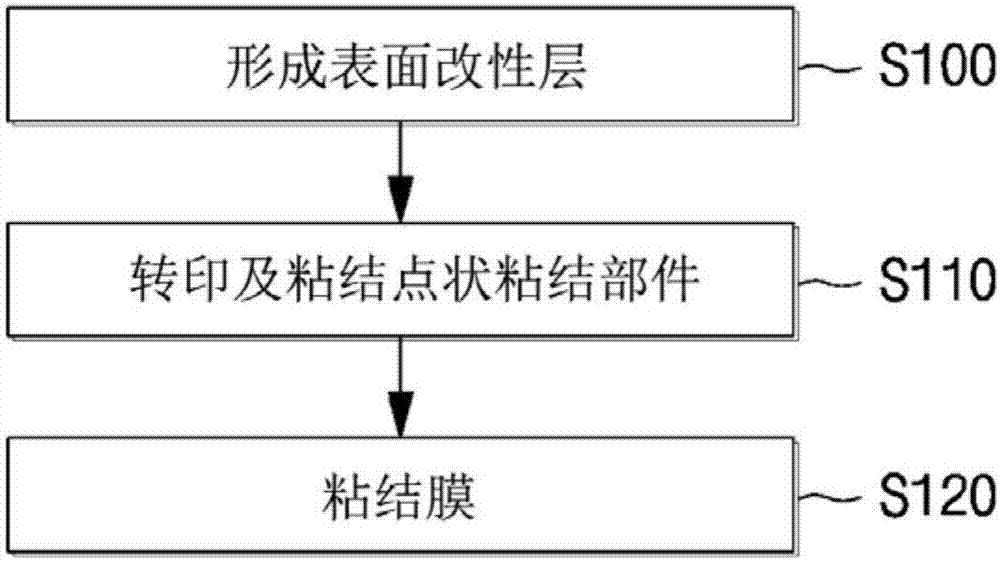

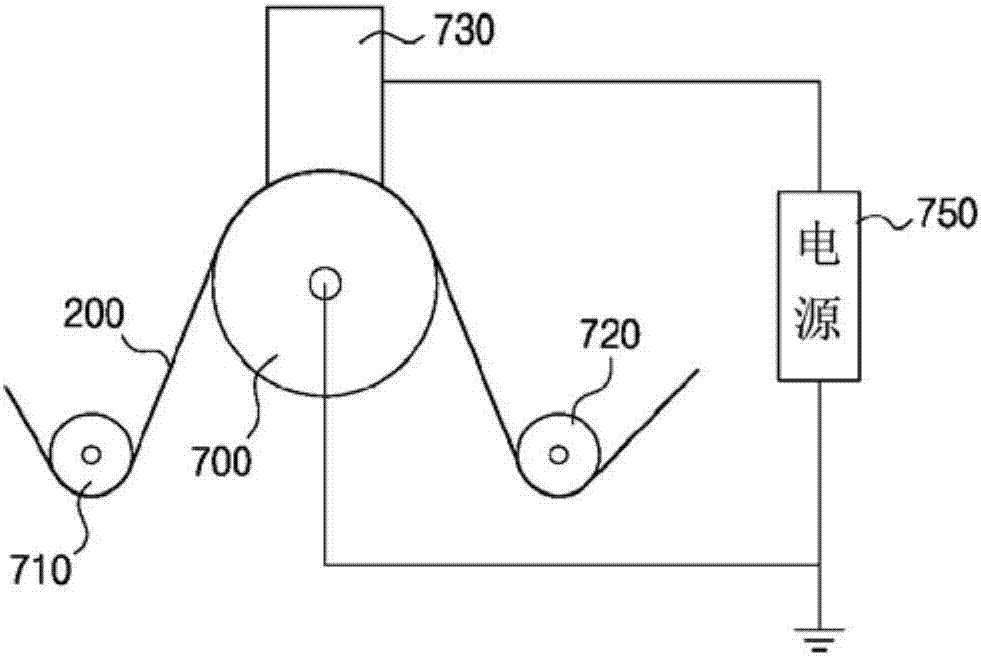

Transfer method for glueing spunbonded nonwovens

InactiveCN102350854AReduce the bonding areaSoft touchLaminationLamination apparatusEngineeringMechanical engineering

The invention relates to a transfer method for glueing spunbonded nonwovens. Spunbonded nonwovens and a ventilated membrane are placed at two uncoiling machines respectively and are rotating simultaneously for uncoiling. A transfer gluing system comprises a transfer embossing roll, a scraper and pressure rollers; the transfer embossing roll is an engraving roll with a plurality of pits engraved on a roll surface, and a lower part of the transfer embossing roll immerses into a glue tank and rotates continuously; the scraper is a device parallel to the transfer embossing roll and arranged behind the transfer embossing roll to scrape superfluous glue on the transfer embossing roll surface. The transfer embossing roll with scraped surface is closely bonded with the ventilated membrane; under stitching effect of the pressure roller above the transfer embossing roll, glue in the pits of the transfer embossing roll transfers to a surface of the ventilated membrane. The ventilated membrane with glue and the spunbonded nonwovens are stitched by a pressure roller above a drying cylinder and attached on a drying cylinder surface. The glue is solidified during the period, and solidified gluedspunbonded nonwovens are rolled by a winder.

Owner:江阴金凤特种纺织品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com