Silicon-silicon-bonding-based pressure sensor capable of isolating packaging stress

A technology of pressure sensor and packaging stress, which is applied in the direction of measuring fluid pressure, measuring fluid pressure, instruments, etc. by changing the ohmic resistance. It can solve the problems of complex etching process and increase chip area, and achieve small chip area and wide application occasions. , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

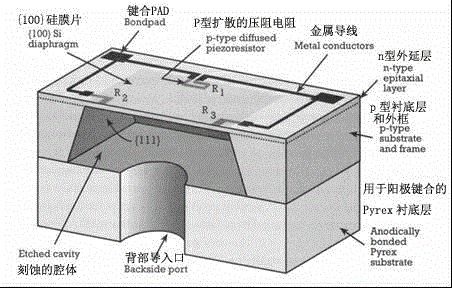

Problems solved by technology

Method used

Image

Examples

Embodiment

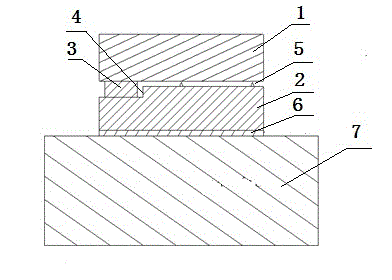

[0028] Example: such as image 3 The pressure sensor based on the silicon-silicon bonding isolation package stress structure is composed of a chip layer 1 and a support layer 2, and a small square 3 for silicon-silicon bonding is etched on the surface of the support layer 2 (etching The shape of the sensor can be determined according to the structure of the sensor. For example, if the support layer is square, the etched shape can be square; if the support layer is circular, the etched shape can be circular). The deep groove 4 makes the bonding surface smaller than the chip area, and the other areas of the support layer 2 maintain a gap of 0.1-2um with the chip layer 1. In the -2um gap area, a series of small protrusions 5 protective structures are made to prevent the bonded area from breaking due to excessive strain. The support layer 2 is bonded to the packaging package 7 through an adhesive 6, and in view of the harsh environment of high temperature and high pressure, a T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com