Manufacturing method of customized tongue-side invisible aligner

A technology for invisible orthodontics and manufacturing method, applied in the field of orthodontics, can solve the problems of large bonding area of the bottom plate, insufficient elasticity, poor bonding strength, etc., achieve good safety and stability, reduce gingival inflammation, and reduce the possibility of Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

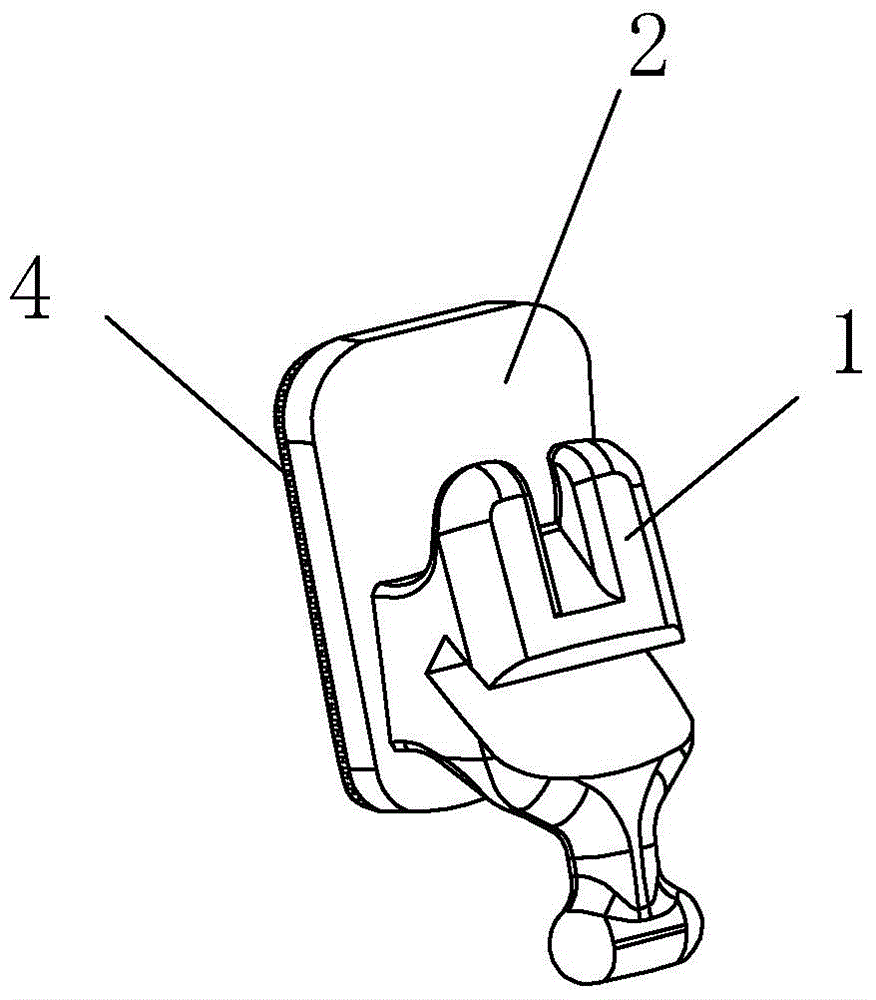

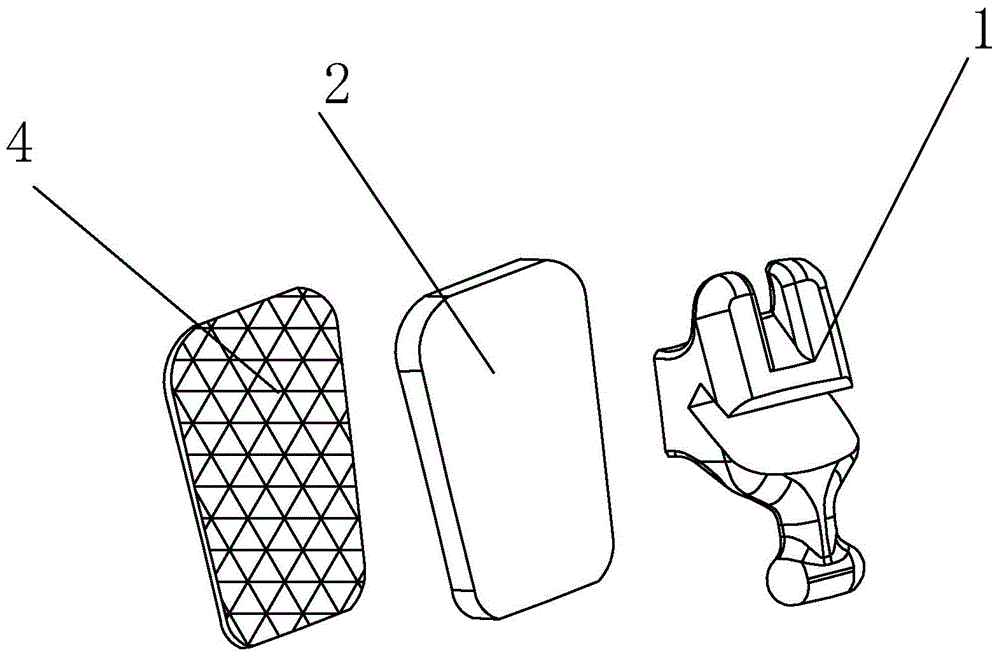

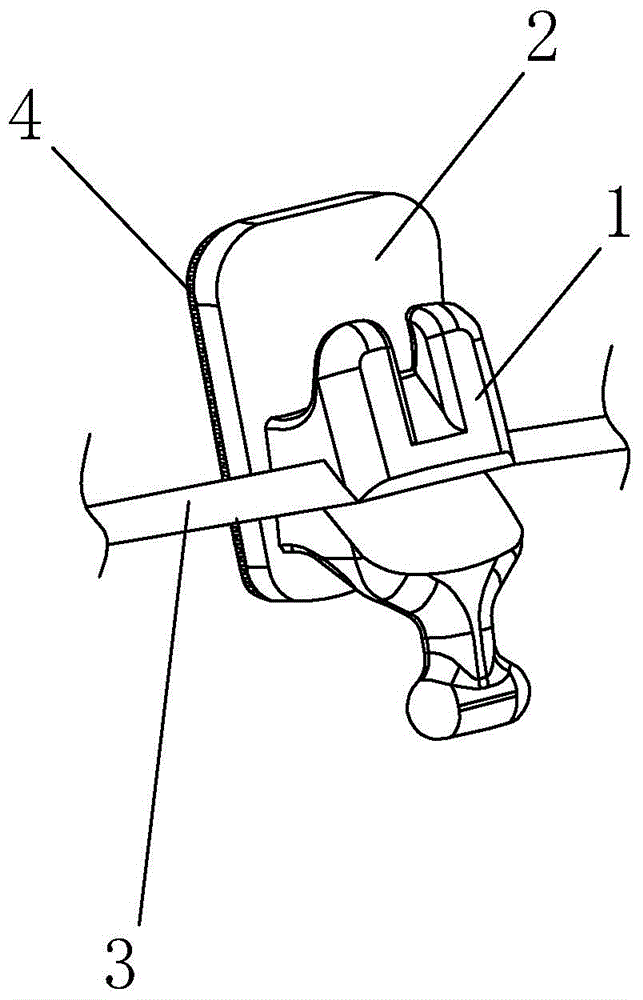

[0027] Attached below Figure 1-6 The represented embodiment further describes the present invention:

[0028] Steps include:

[0029] a) Three-dimensional scanning of the patient's teeth by laser to obtain three-dimensional imaging information including the patient's teeth, dentition, alveolar bone and cranio-maxillofacial bone structure;

[0030] b) Combining the obtained 3D imaging information, use computer-aided design and manufacturing technology (CAD / CAM technology) to simulate and correct the teeth on the computer, and determine the tooth model plan after obtaining the ideal dentition effect and matching the arch diagram of the dentition ;

[0031] c) Use a 3D printer to print out the simulated orthodontic tooth model plan;

[0032] d) Use computer-aided design and manufacturing technology (CAD / CAM technology) based on the center point of the dentition on the printed tooth model, the space between the teeth, the slope of the tooth surface, the surface shape of the ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com