Transfer method for glueing spunbonded nonwovens

A technology of spun-bonded nonwovens and transfer method, which is applied in the direction of chemical instruments and methods, layered products, lamination devices, etc., which can solve the problems of irregular bonding points, large bonding area, hard hand feeling, etc. The effect of softness and small bonding area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

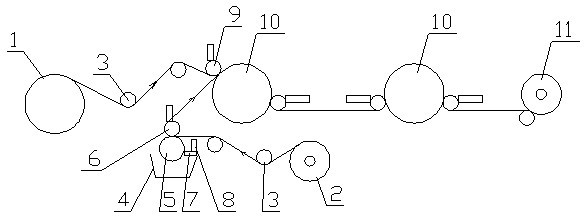

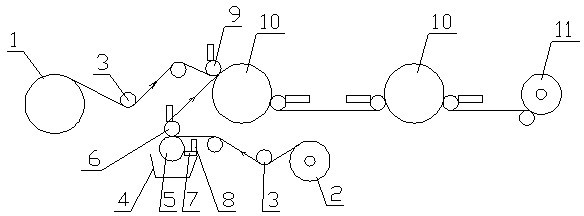

[0042] see figure 1 , the method for gluing spunbond nonwovens by transfer method that the present invention relates to, said method includes unwinding, transfer gluing, bonding and drying and winding processes,

[0043] Step 1. Unwind

[0044] The spunbonded nonwoven fabric and breathable film are respectively placed on two unwinders, and the spunbond nonwoven fabric and breathable film are rotated and unrolled at the same time. The unwinder adopts a constant tension control system to ensure that the fabric surface tension is evenly controlled throughout the process.

[0045] Step 2. Transfer gluing

[0046] The transfer gluing system consists of a transfer pattern roller, a scraper and a pressure roller. The transfer pattern roller is an engraved roller with several concave points on the roller surface. The pattern on the final product is formed by the glue in the concave points of the pattern roller. . The lower part of the transfer pattern roller is immersed in the glue...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com