Patents

Literature

41results about How to "High repeatability accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

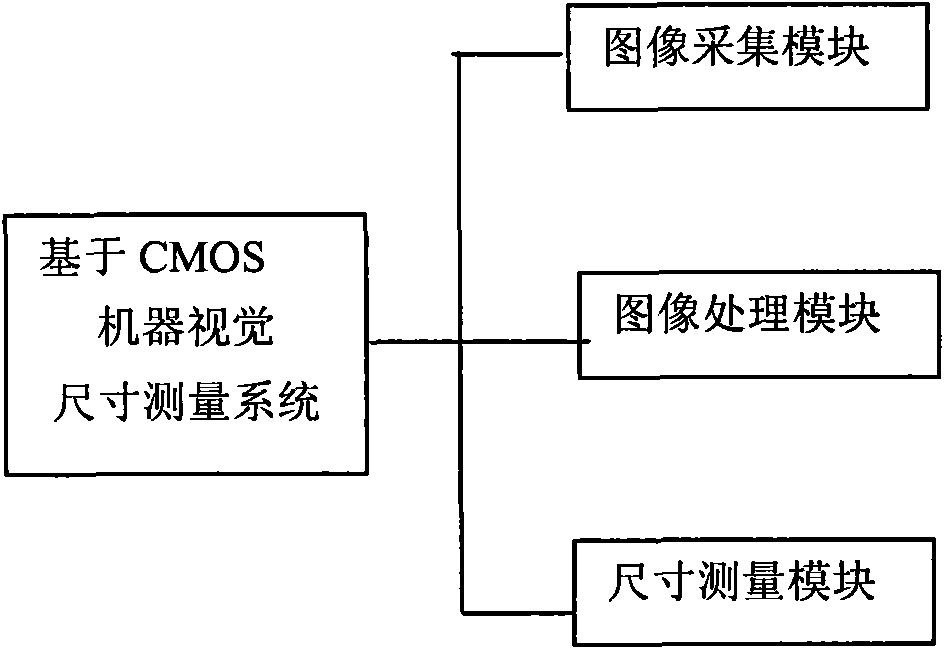

CMOS (complementary metal-oxide-semiconductor)-machine-vision-based component size measuring system and measurement test method

InactiveCN102538672AHigh repeatability accuracyImprove linearityUsing optical meansCMOSMeasurement test

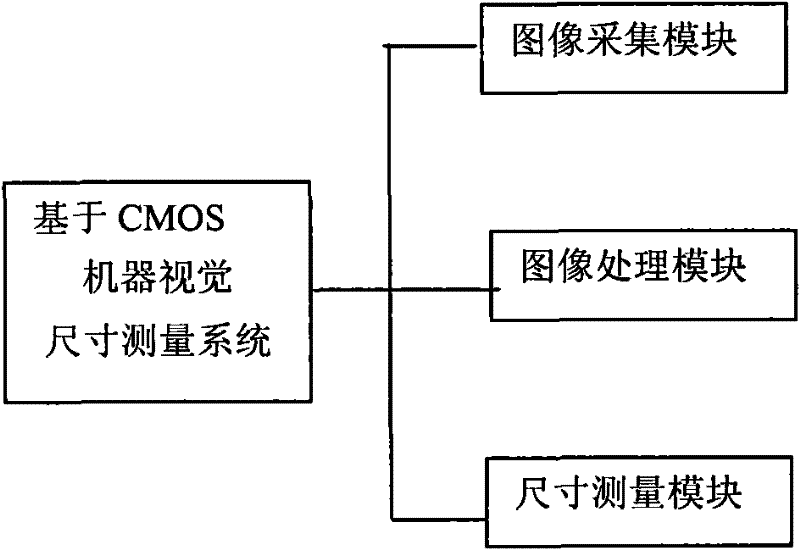

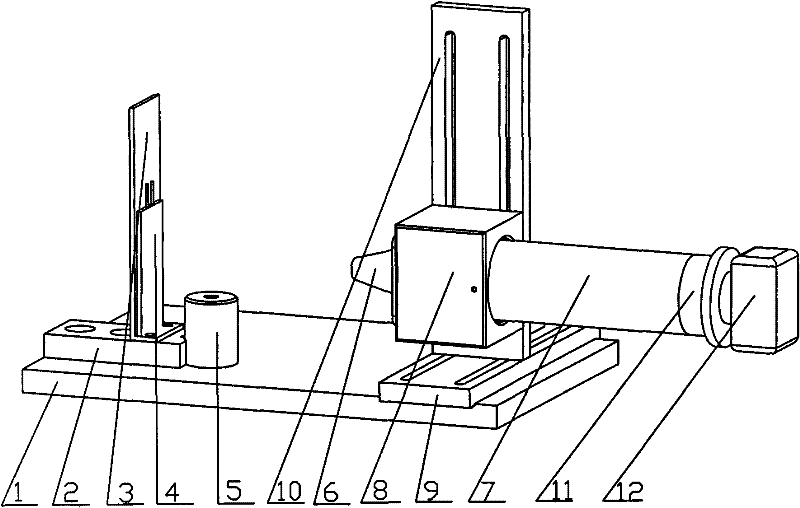

The invention discloses a CMOS (complementary metal-oxide-semiconductor)-machine-vision-based component size measuring system and a measurement test method. The CMOS-machine-vision-based component size measuring system comprises an image acquisition module, an image processing module and a size measuring module, wherein the image acquisition module acquires images of contour edges of a shot component; the image processing module performs binaryzation and filtering processing on the acquired images, and then performs edge detection to obtain edges of the images of the component; and the size measuring module calculates a pixel value of an edge contour of a measured object through feature extraction, and the pixel value can directly reflect the size of the component through calibration. According to the CMOS-machine-vision-based component size measuring system and the measurement test method disclosed by the invention, the measurement of the contour size can be realized, and the measurement of the aperture of a small through hole can be finished; and after a special assistant tool is provided, the measurement of the bottom width of a trumpet-shaped groove can be realized.

Owner:ZHONGBEI UNIV

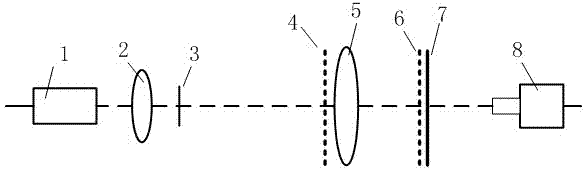

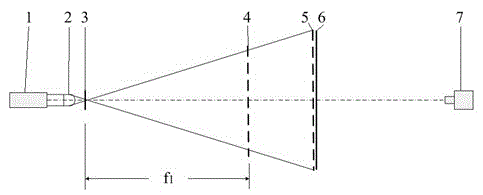

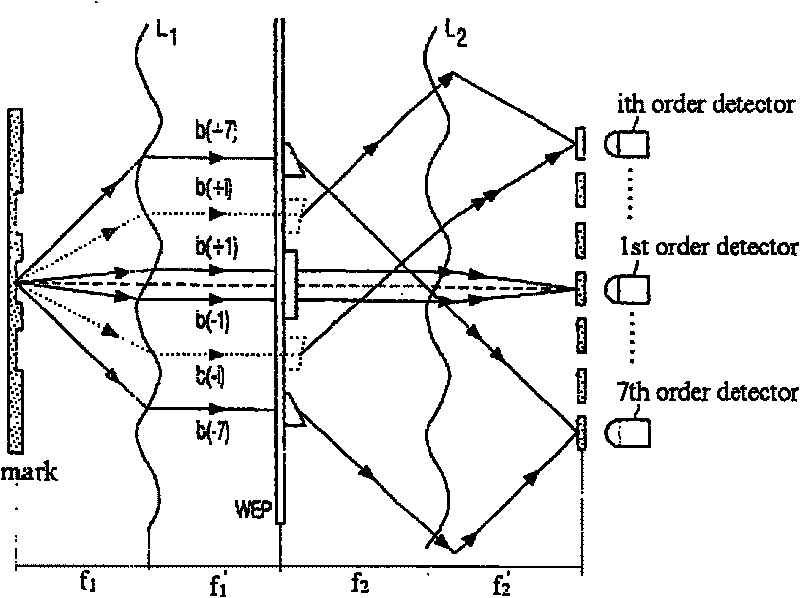

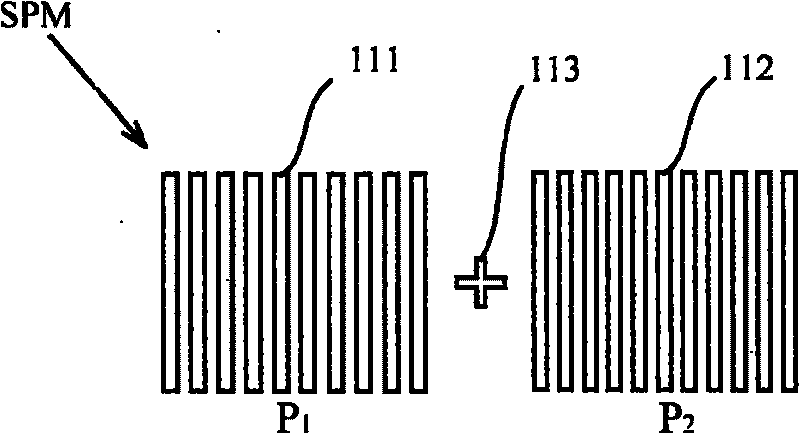

High-precision focus detection device for long-focus lens

ActiveCN102313642ASimple structureRealize high-precision measurementTesting optical propertiesLong-focus lensGrating

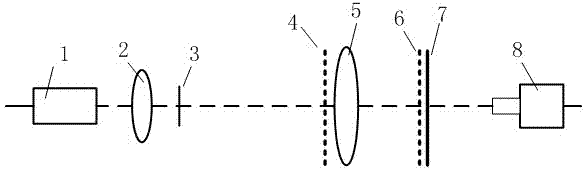

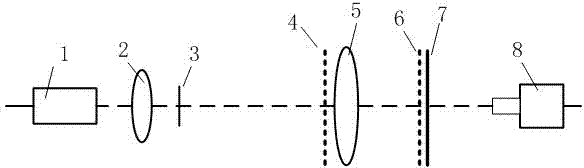

The invention discloses a high-precision focus detection device for a long-focus lens, which comprises a laser, a microscope objective, a pin hole, a first Ronchi grating, the long-focus lens to be detected, a second Ronchi grating, ground glass and a CCD (Charge Coupled Device) camera. Light emitted by the laser passes through the microscope objective and the pin hole to form a divergent beam and the divergent beam enters the first Ronchi grating and then passes through the long-focus lens to be detected and the second Ronchi grating; the second Ronchi grating is placed at a certain talbot-order position of the first Ronchi grating, so that Moire fringes can be formed on a talbot image of the first Ronchi grating and the second Ronchi grating; and the fringes are acquired by the CCD camera and the focus of the lens to be detected can be obtained by calculating angles of the fringes. The high-precision focus detection device has a simple structure, is easy to implement, has high precision, can be used for detecting the long-focus lens and accurately measuring the focus in an optical system and particularly can be used for accurately measuring the focus of the large-caliber long-focus lens (the focus is in the range of meters and dozens of meters), so that an error caused by the scanning detection is avoided.

Owner:ZHEJIANG UNIV

Zero-drive chain digital control gear hobbing machine

InactiveCN101298106AGuaranteed stabilityNo vibrationFeeding apparatusGear-cutting machinesHobbingGear wheel

The invention discloses a numberical control hobbing machine with zero transmission, which comprises a machine body, a main shaft system, a hobbing cutter feeding and angle adjusting system and a control system; the main shaft system comprises a functional part of a hobbing cutter main shaft and a functional part of work-piece main shaft part; the functional part of the hobbing cutter main shaft is an integration of the rotator of the servo motor I and the hobbing cutter main shaft, and the functional part of the work-piece main shaft is an integration of the rotator of the servo motor II and the work-piece main shaft. The numberical control hobbing machine of the invention can remove the manufacturing errors of transmission component of generating motion and the influence on gear process caused by space and assembly error, is able to greatly improve process accuracy and process speed of machine tool. The numberical control hobbing machine of the invention has simple structure, is able to improve overall rigidity of machine tool, solves the wearing problem caused by mechanical transmission chain, improves the retentivity of precision, causes the hobbing speed to be higher than the numberical control hobbing machine with traditional structure, shortens milling time as well as based on which, the hobbing machine is provided with the machine tool conditions required by dry type hobbing through adopting a series of matching technical measures.

Owner:CHONGQING UNIV

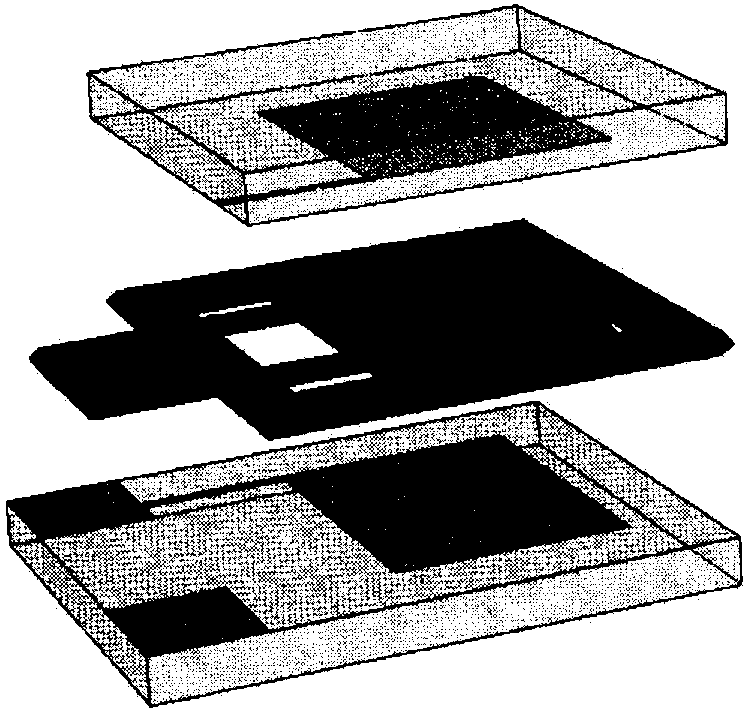

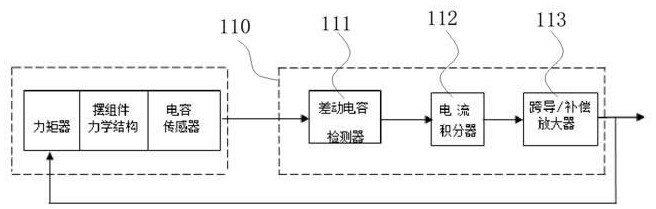

Electrostatic Force Rebalance Pendulum Silicon Micro Accelerometer Sensitive Structure and Manufacturing Method

ActiveCN105659845BHigh repeatability accuracyImprove zero drift problemAcceleration measurementGuidance systemGlass cover

The sensitive structure of the electrostatic force rebalanced pendulum silicon micro accelerometer is the upper and lower glass plates, and the middle is the sensitive mass block of the monocrystalline silicon pendulum structure. The three are connected together by bonding. The double flexible beams of the crystalline silicon sensitive mass are arranged opposite to the lead-out lines of the electrodes. In addition, in order to further reduce the influence of temperature on the monocrystalline silicon pendulum plate, the bonding area is reduced in the design, instead of the overall bonding, three small pieces of bonding are used to ensure that the bonding area of the upper and lower glass plates is completely Consistent, and further reduce the temperature coefficient caused by thermal stress; the manufacturing method of the above-mentioned sensitive structure includes the manufacturing of single crystal silicon pendulum plate and the manufacturing of upper and lower glass cover plates. The invention can reduce the temperature coefficient of the instrument and improve the temperature repeatability, thereby improving the resolution and sensitivity of the silicon micro accelerometer and meeting the requirements of inertial guidance systems such as missiles.

Owner:BEIJING AEROSPACE TIMES OPTICAL ELECTRONICS TECH

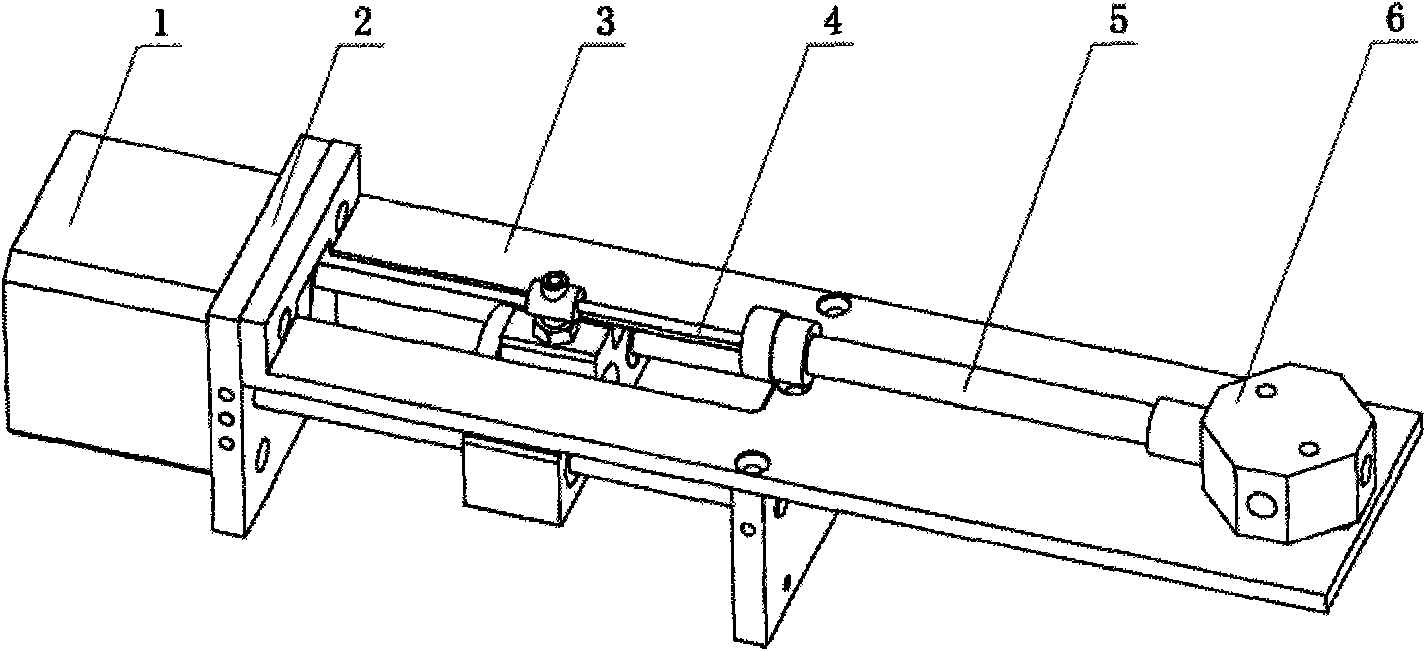

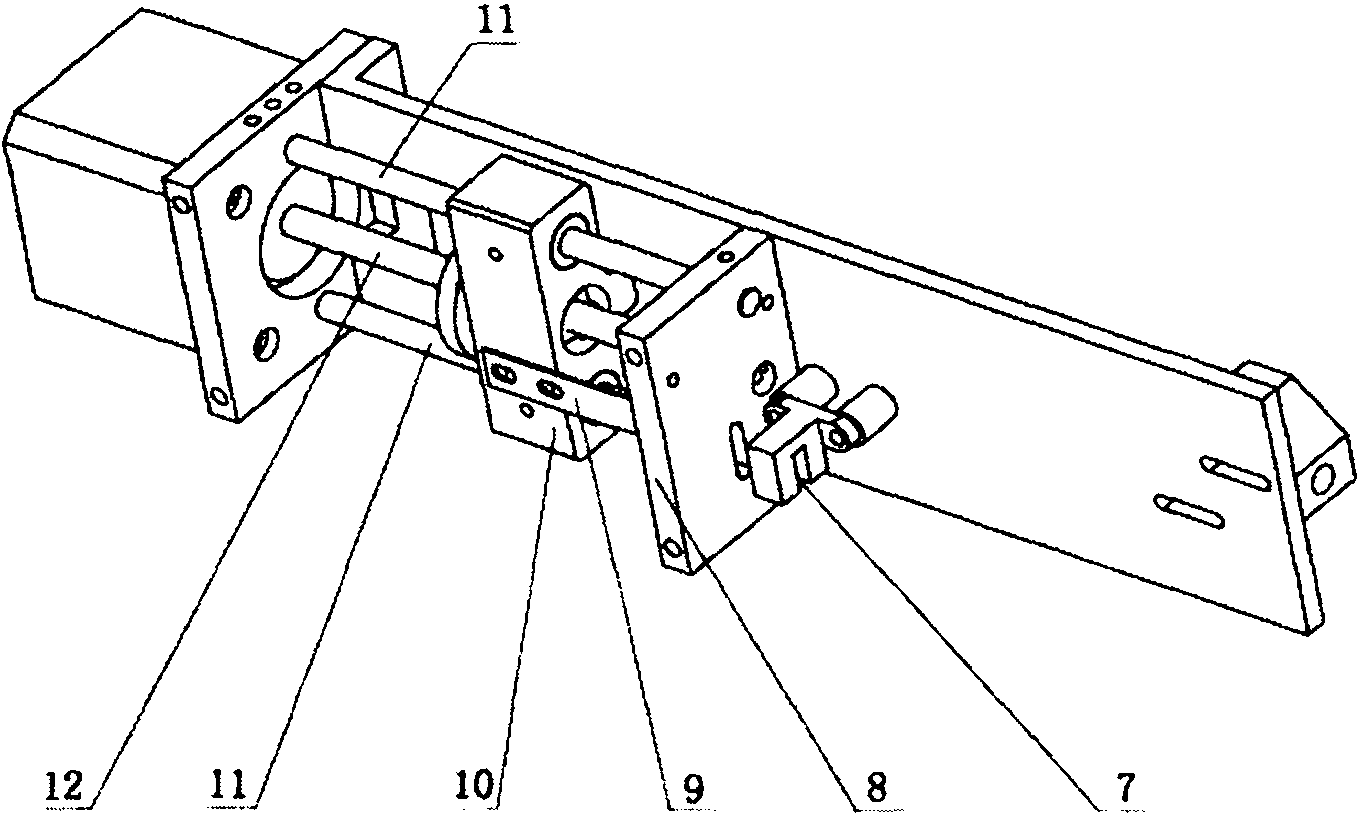

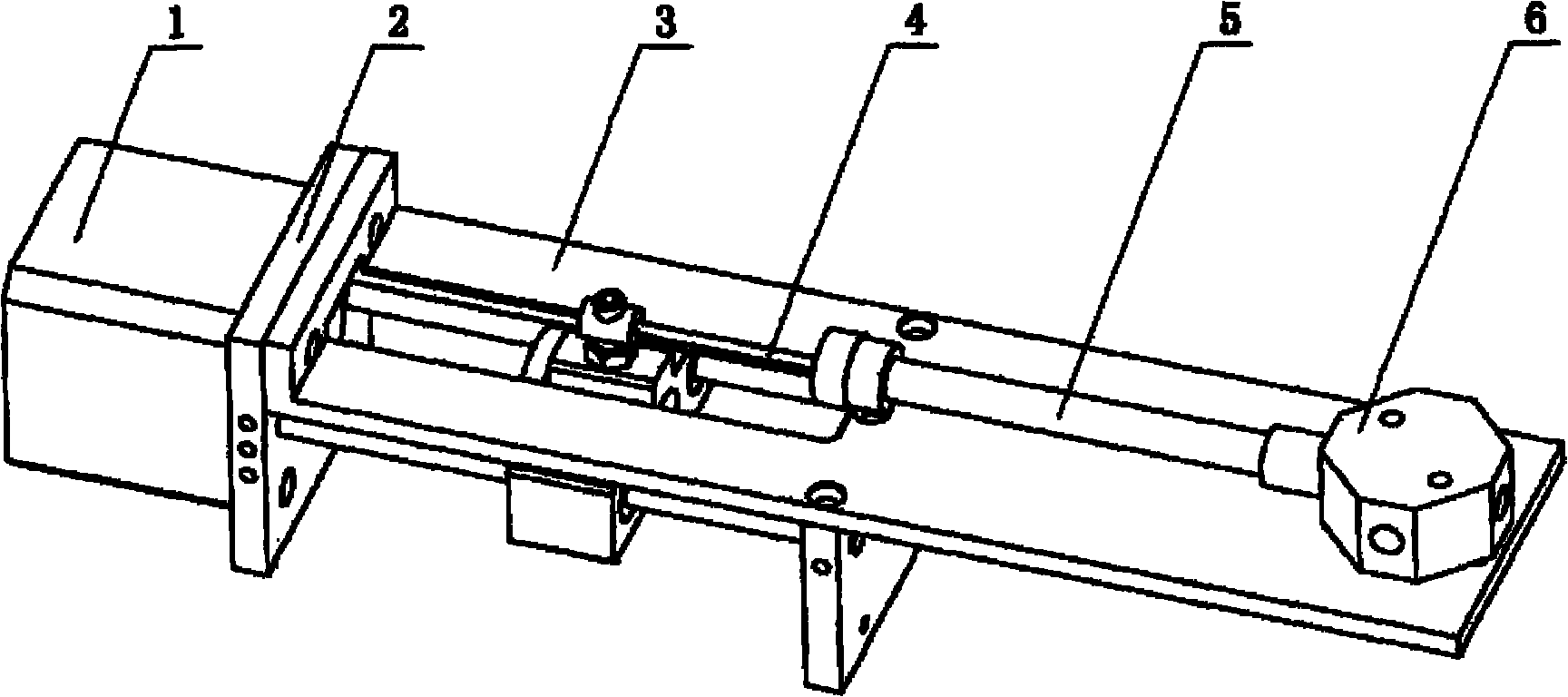

Automatic precision loading device

The invention relates to an automatic precision loading device of immunoassay technology. The automatic precision loading device comprises a stepping motor, a screw, a motor clamping plate, a motor front plate, an optical axis guide rail, an injection sliding block, a motor baffle plate, an injector, an optical coupling sensor, an optical coupling sheet and a three-way block, and is characterized in that: the stepping motor and a precision screw kinematic pair are taken as transmission components; the injection sliding block is connected with a piston of the injector and performs back-and-forth linear motion along the optical axis guide rail; and a trigger point of the optical coupling sensor is taken as a completion point of injection action and an initial point of a next action cycle. The design ensures the precision of the device, and particularly reliably ensures repeated precision; and the automatic precision loading device has a simple structure, is convenient to maintain and can realize full automatic quantitative loading of an instrument. The loading device is widely suitable for loading mechanisms such as luminescence detection analyzers, biochemical analyzers, electrolytic analyzers and the like which need quantitative loading instruments.

Owner:北京量质科技有限公司

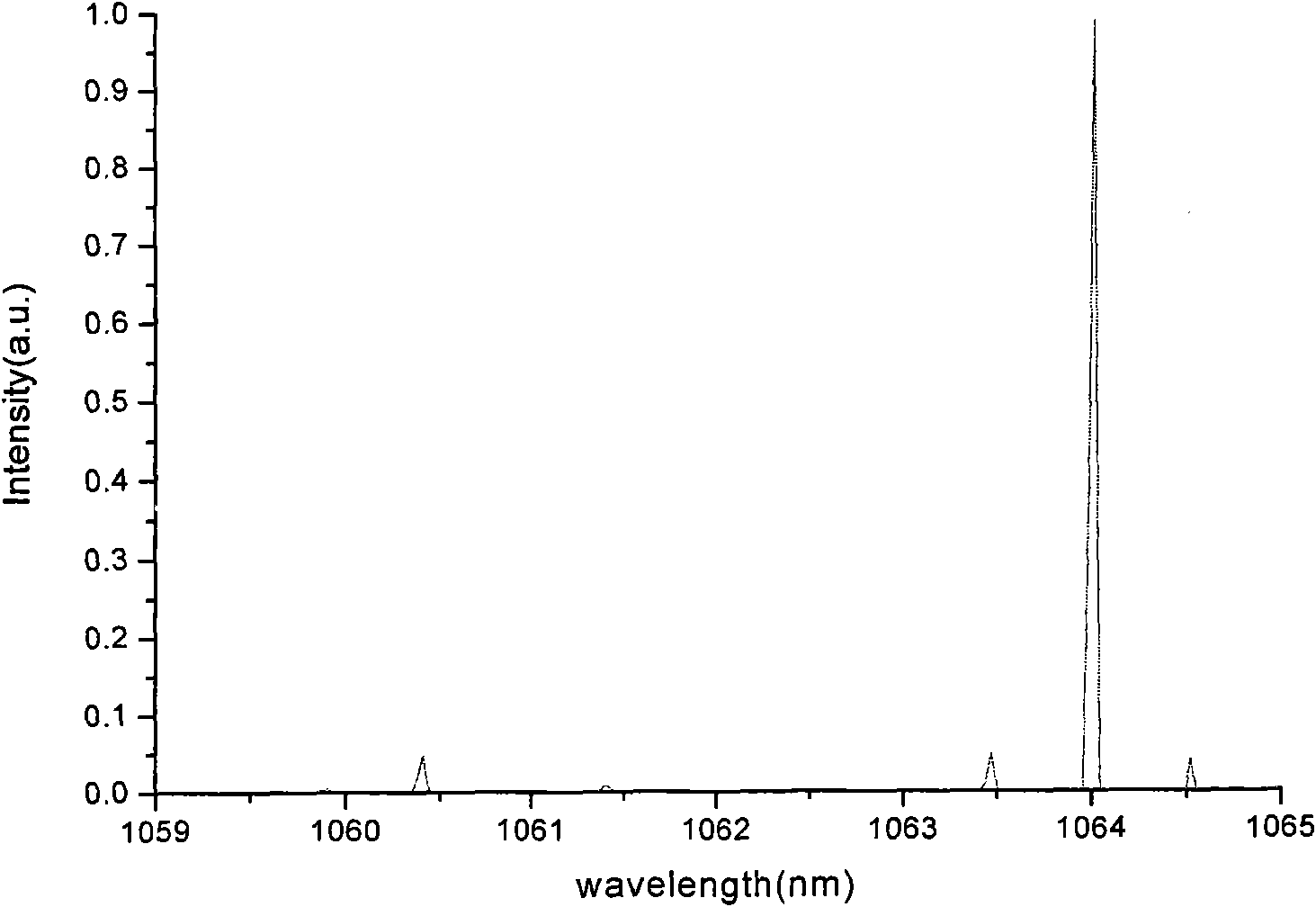

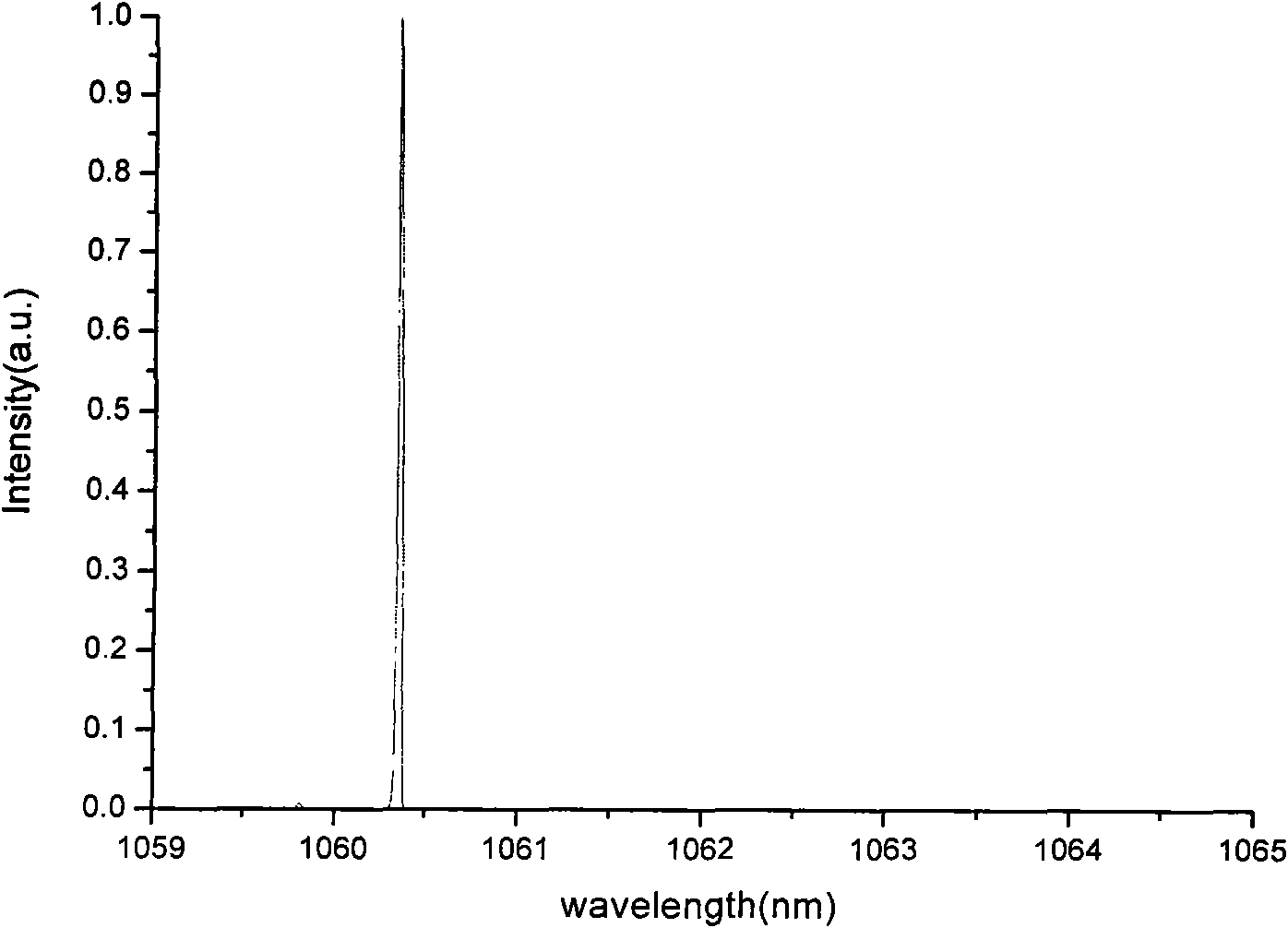

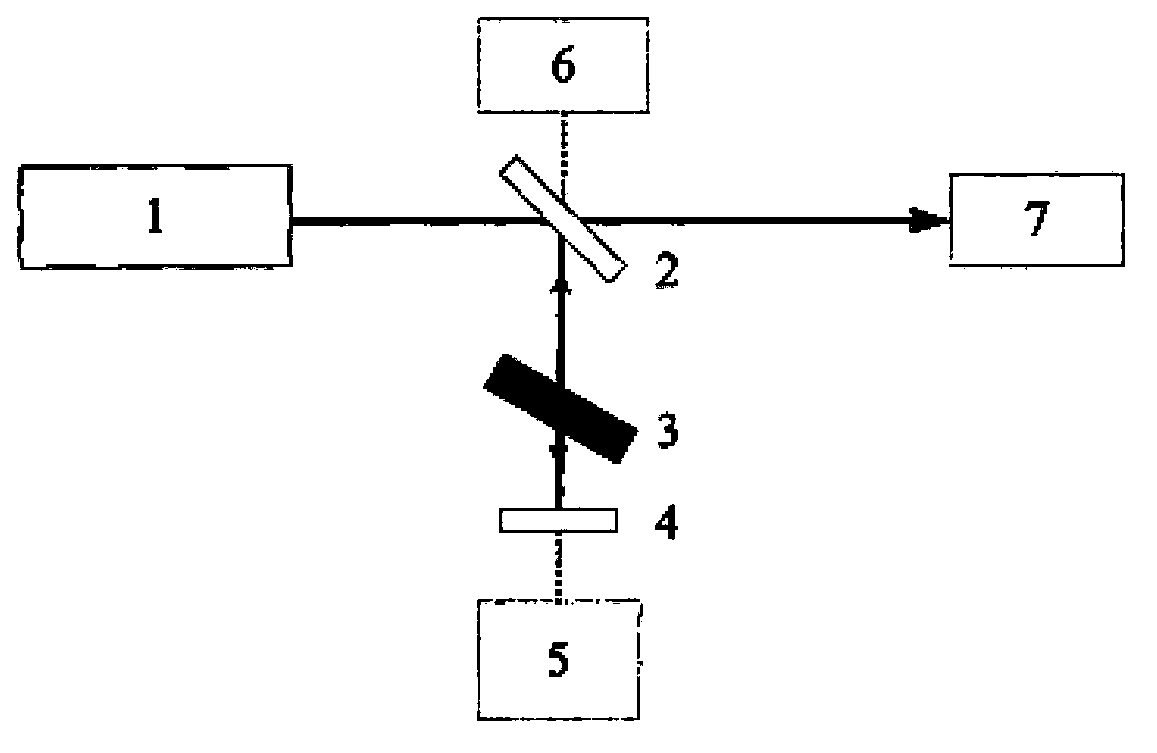

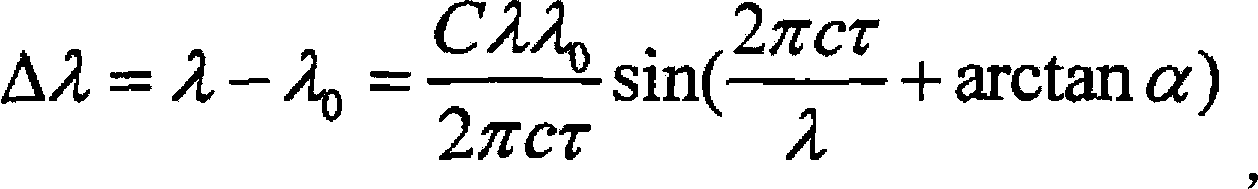

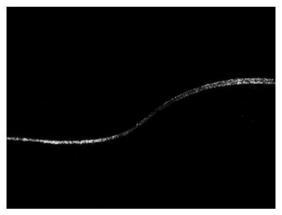

Method for tuning laser output wavelength based on self-mixing effect

InactiveCN101566776ASuppression of Power VariationsStable output optical powerLaser output parameters controlNon-linear opticsUltrasound attenuationPolarizer

A method for tuning laser output wavelength based on self-mixing effect belongs to the field of opto-electrical engineering. The tuning method comprises the following steps of: feeding laser output light back to a laser by an external reflecting mirror; realizing the tuning of the laser output wavelength by changing feedback light intensity by making use of semiconductor laser self-mixing effect. Ways for controlling backward feedback light intensity are as follows: inserting a linear polarizer, an attenuation film and a variable diaphragm between the laser and the reflecting mirror, or adjusting the pitching of the reflecting mirror. The invention provides a new method for tuning laser output wavelength, which can effectively avoid larger power change due to wavelength tuning, thus realizing the purpose of keeping the output light power to be relatively stable during the wavelength tuning. In addition, the method can be applied to conducting external modification to the laser with fixed wavelength, thus causing the wavelength to be adjustable, being simple and easy, and greatly reducing the cost for system modification.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

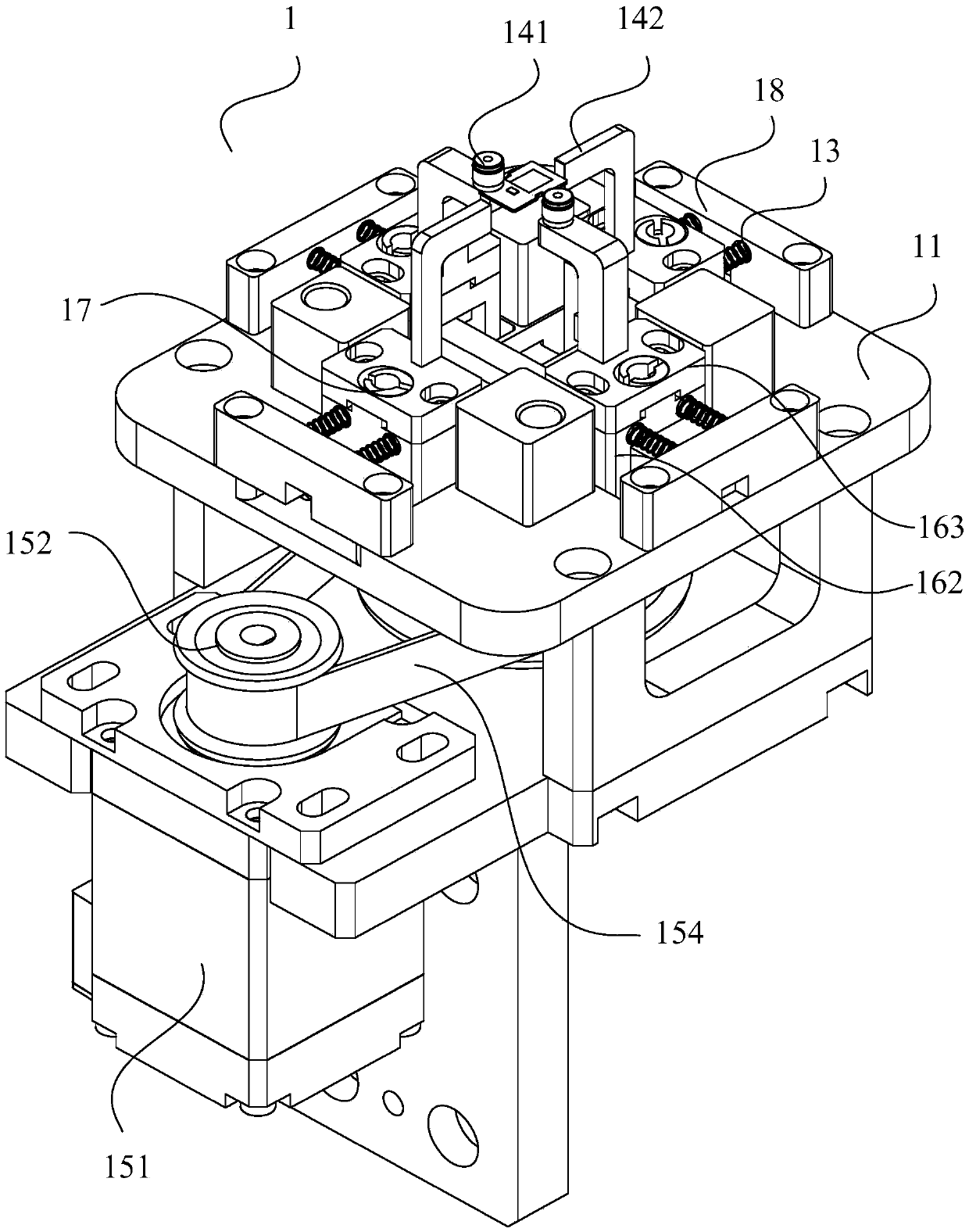

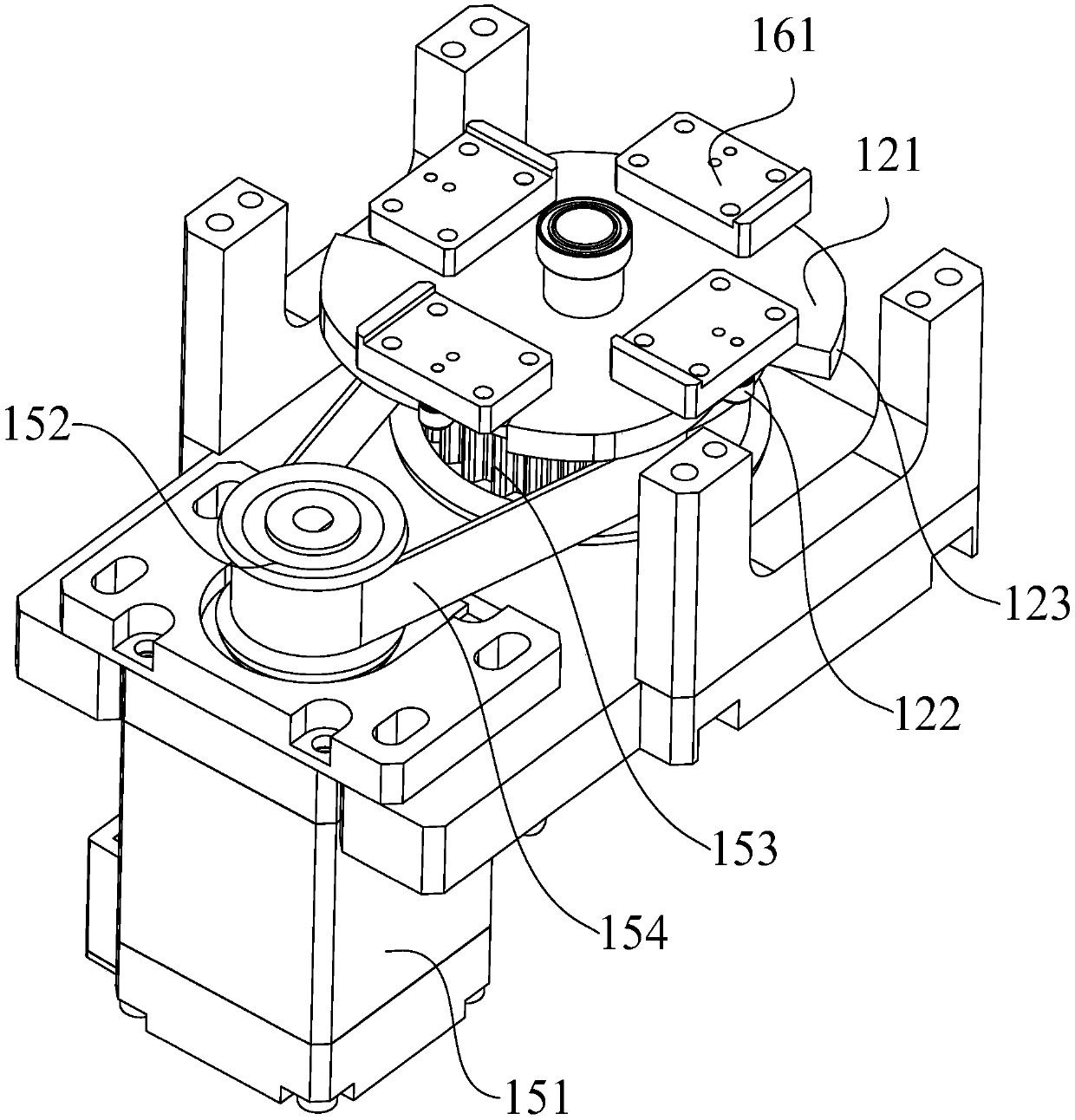

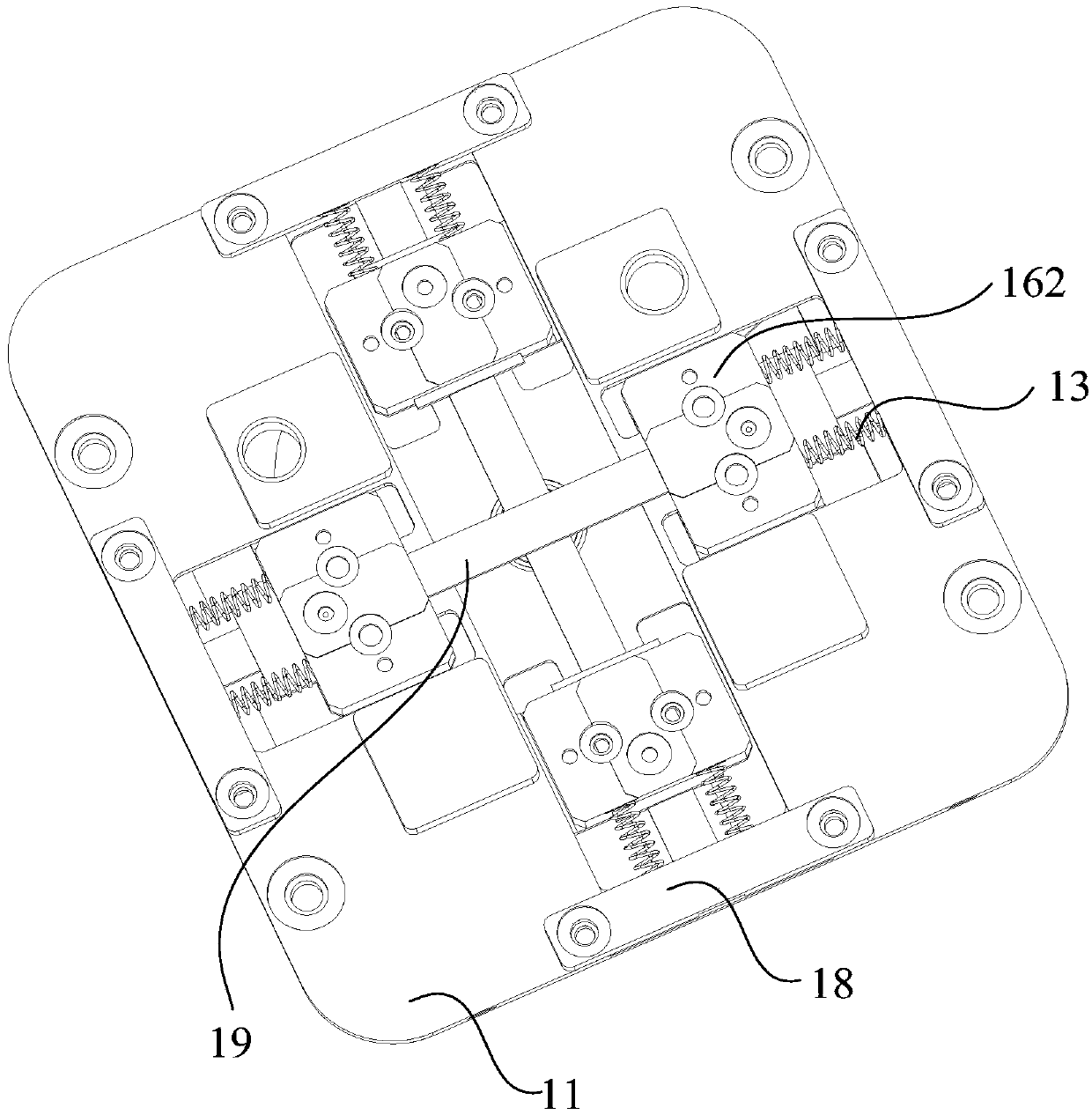

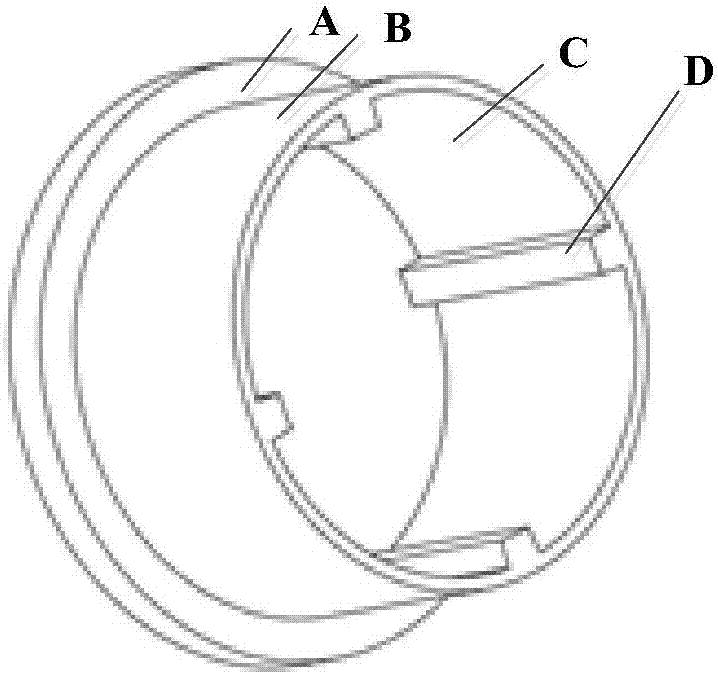

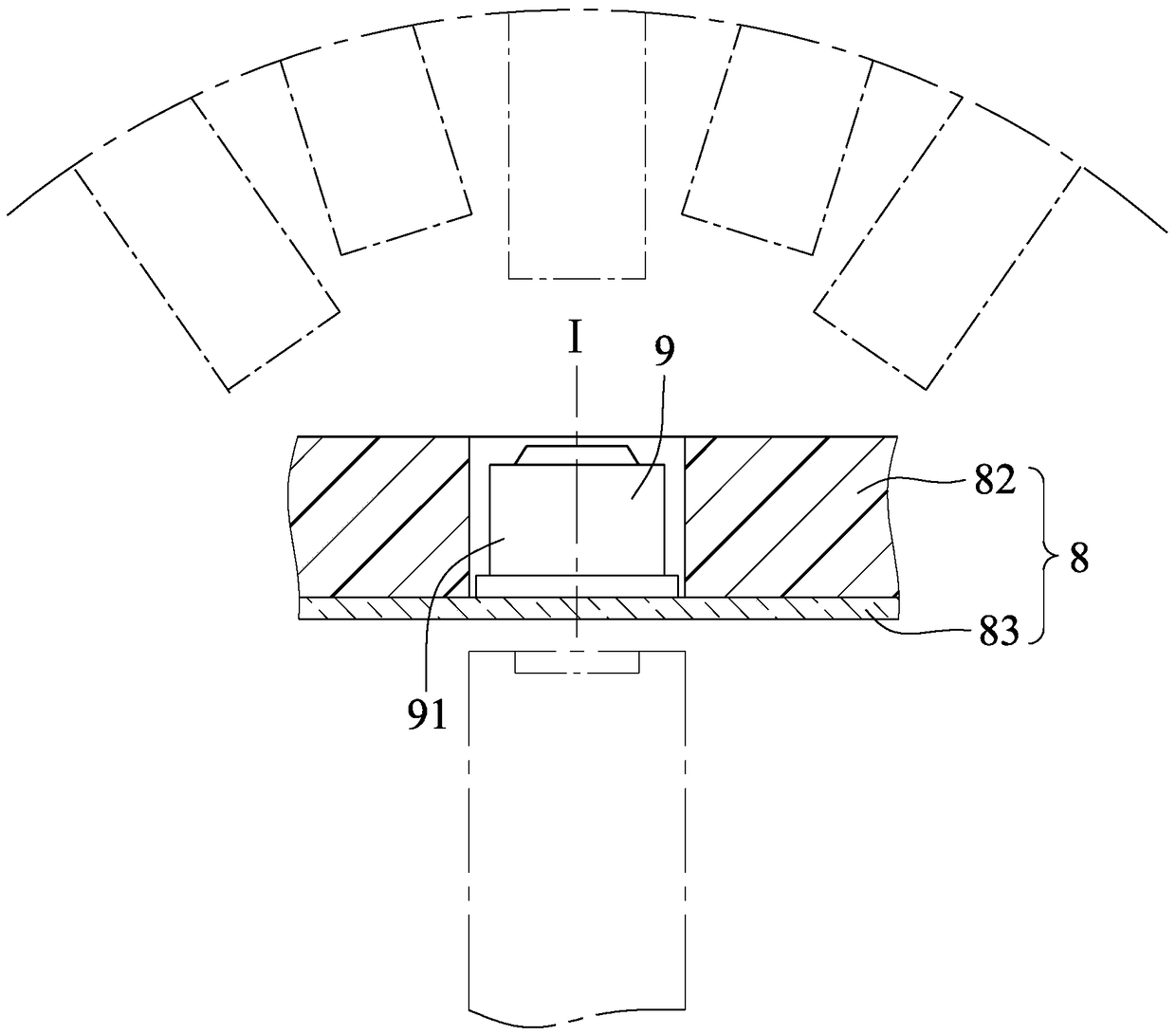

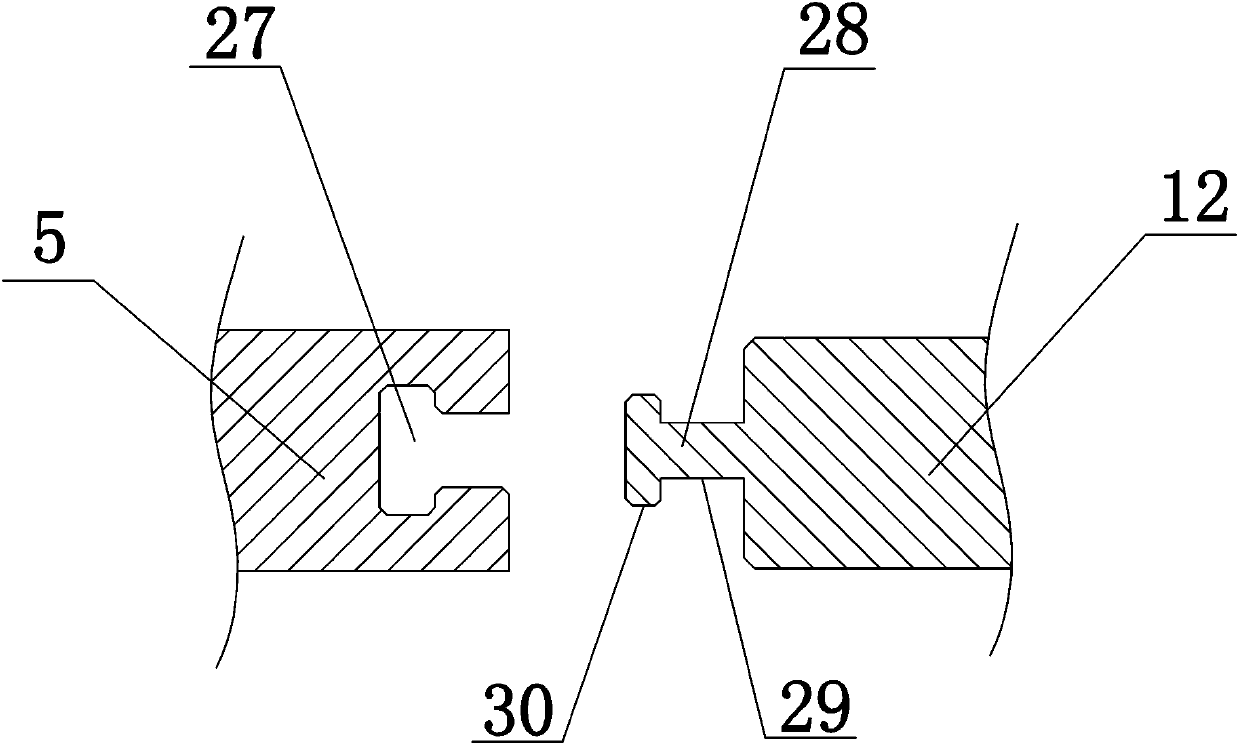

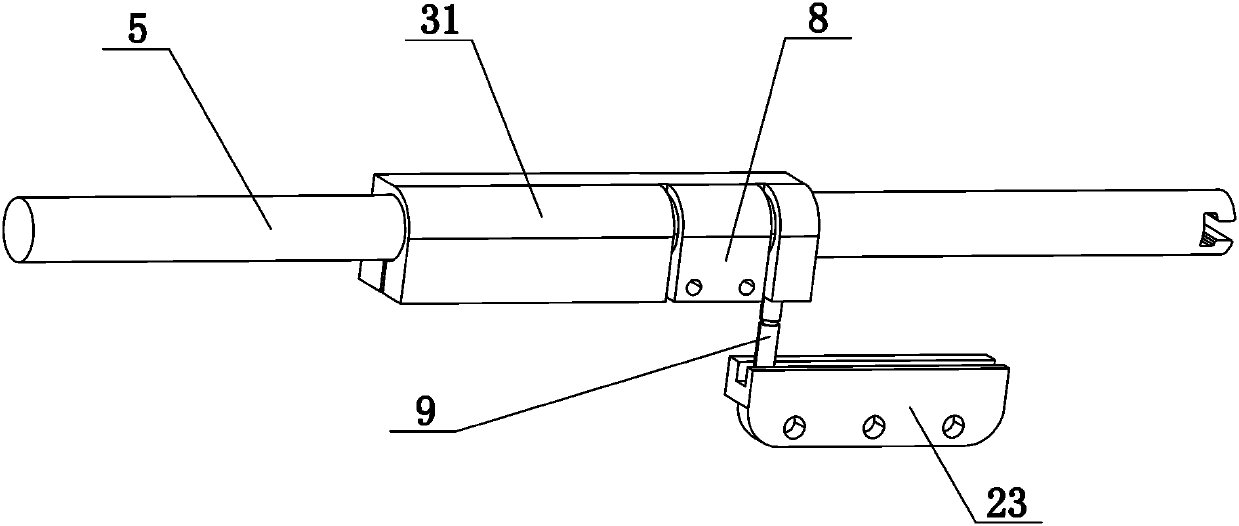

Central locating mechanism and device

PendingCN109605250AHigh repeatability accuracyGuaranteed Stability and ReliabilityWork holdersCamEngineering

The invention provides a central locating mechanism and device, and relates to the technical field of locating of micro parts. The central locating mechanism comprises a power mechanism, a cam mechanism, a base, elastic parts and clamping parts, wherein the cam mechanism comprises a cam and at least two driven parts oppositely arranged on the edge of the outer side of the cam; an output end of thepower mechanism is in transmission connection with a rotating shaft of the cam; the base is erected above the cam; at least two oppositely arranged connecting seats are arranged on the base; each connecting seat is connected with one driven part; the clamping parts which extend in the direction away from the base are arranged on the connecting seats; the elastic parts are arranged on the connecting seats; and the driven parts abut the edge of the outer side of the cam under the action of the elastic parts, and the clamping parts move towards the center to clamp a to-be-detected product. According to the central locating mechanism, precision of a central position of the to-be-detected product can be improved, and stability and reliability of testing data acquisition are guaranteed.

Owner:SHENZHEN JPT OPTO ELECTRONICS CO LTD

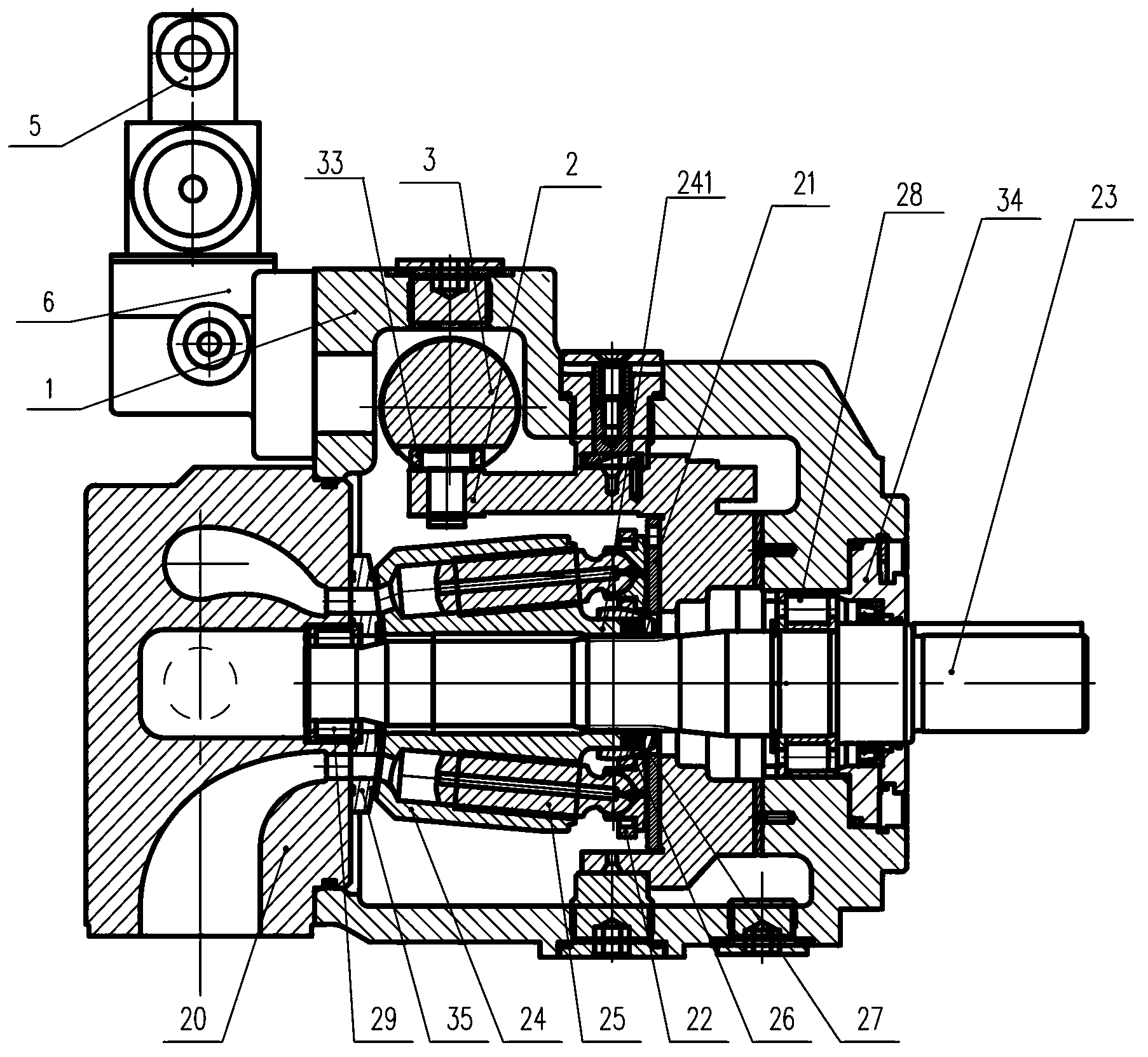

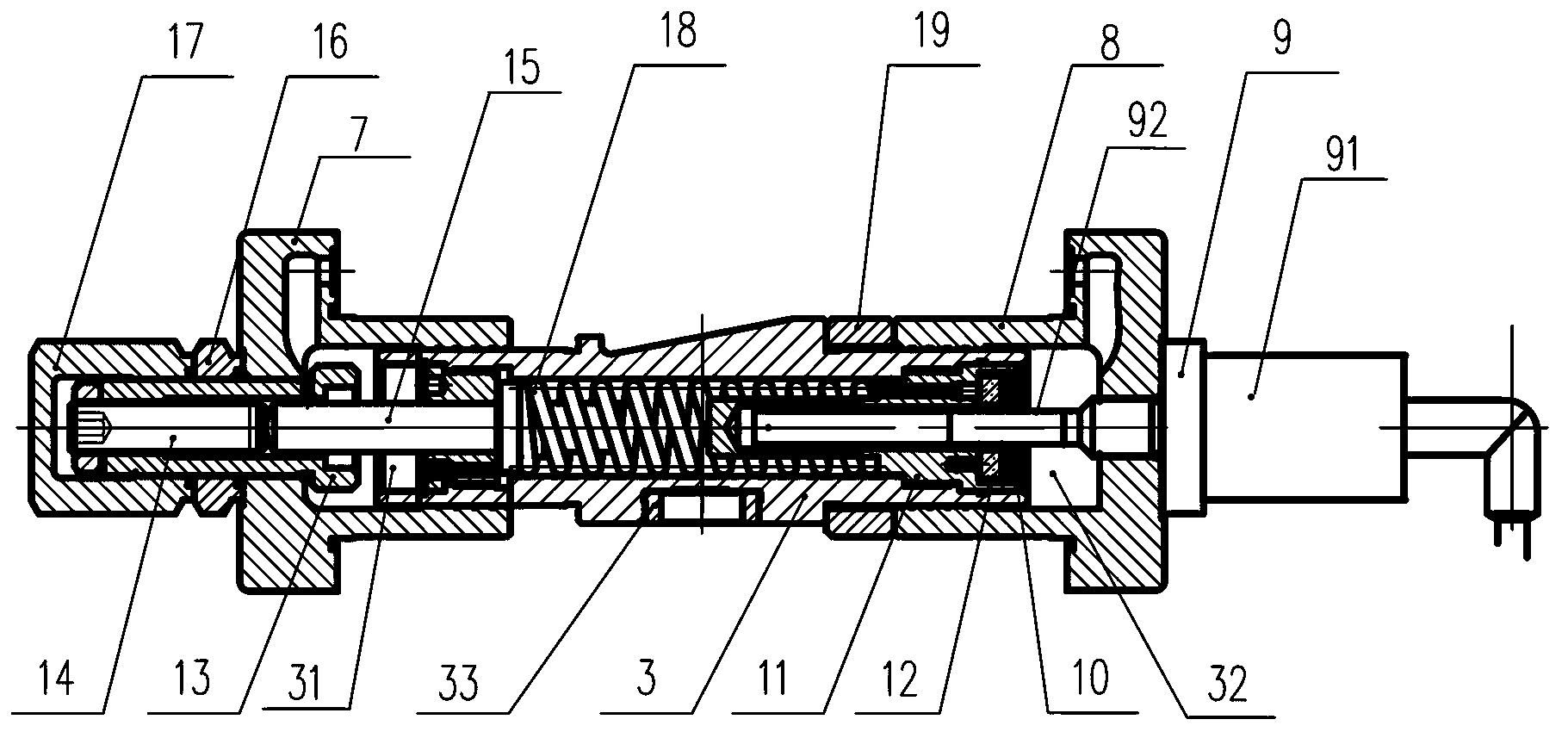

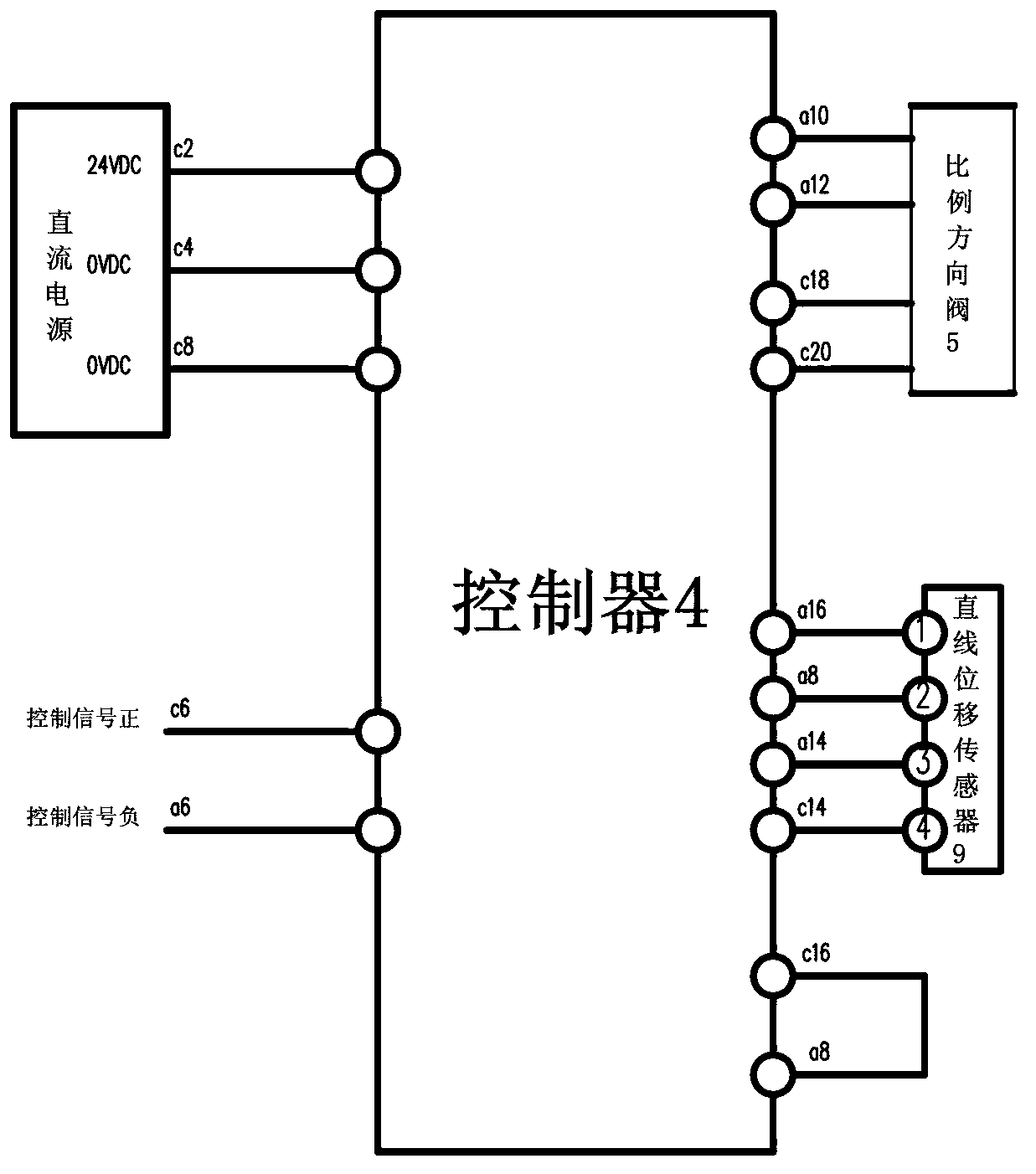

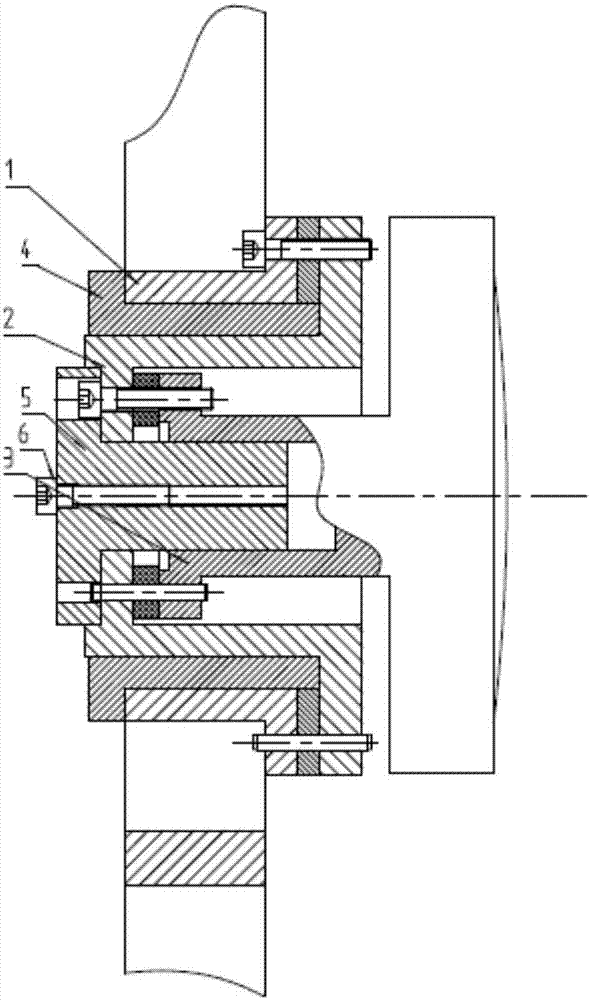

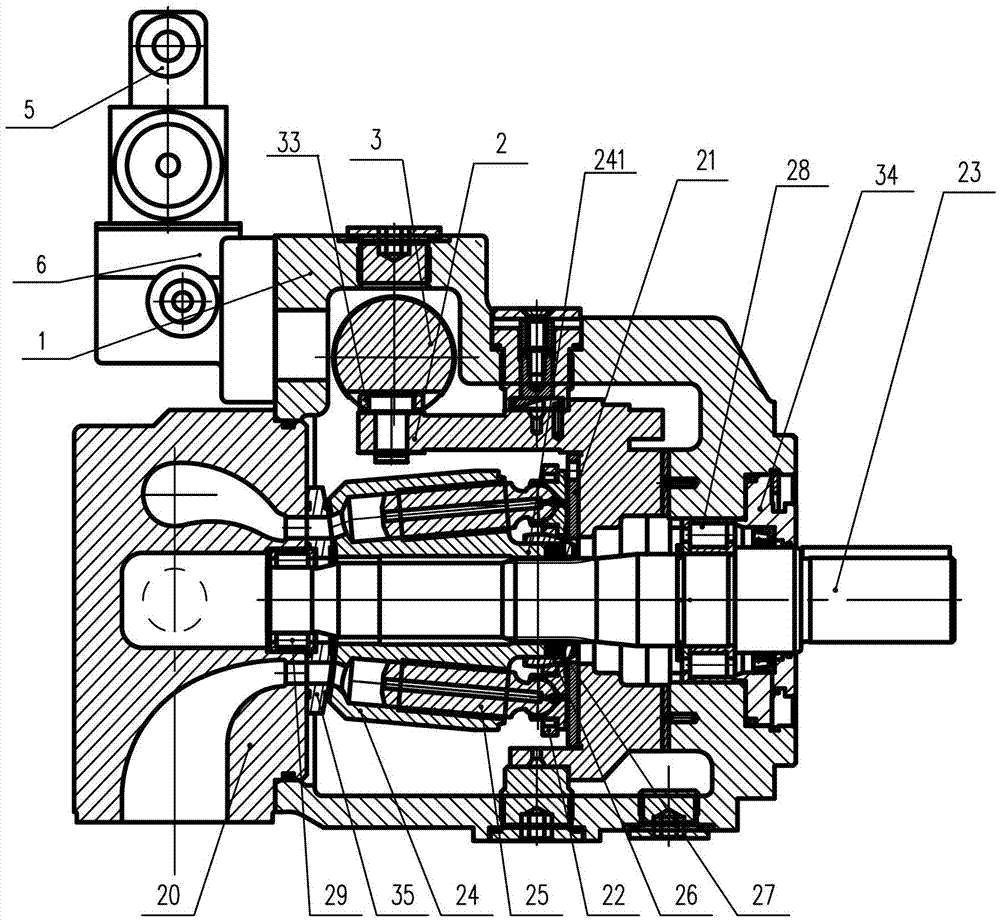

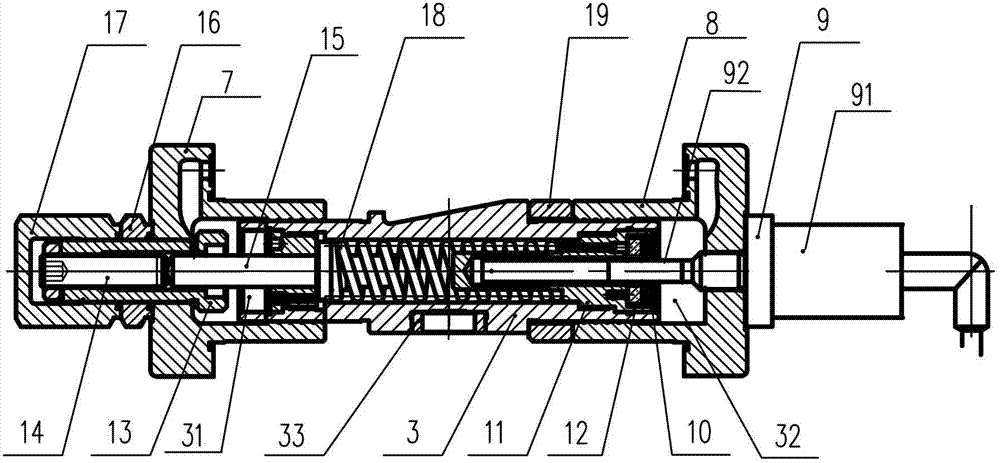

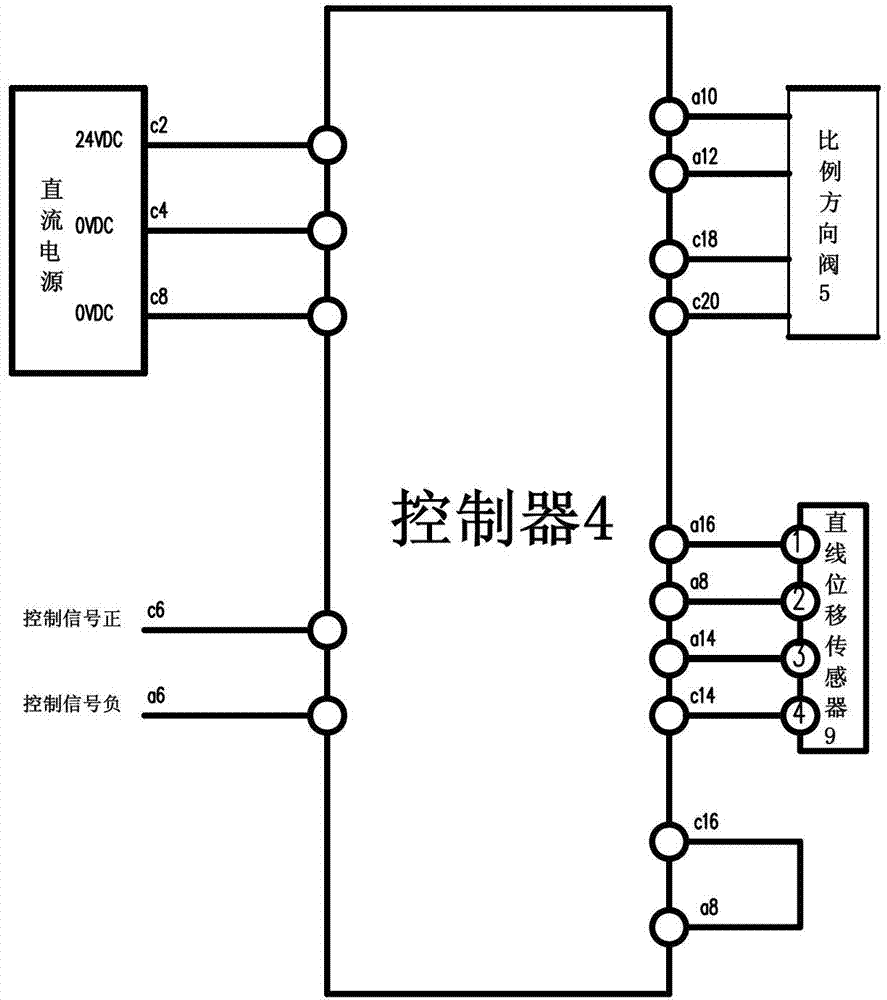

Electric proportional variable axial plunger pump

ActiveCN103291575AOutput displacement adjustmentImprove reliabilityPositive-displacement liquid enginesMulti-cylinder pumpsControl theoryPlunger pump

The invention discloses an electric proportional variable axial plunger pump comprising a plunger pump body and a variable mechanism arranged on one side of the plunger pump body. The plunger pump body comprises a pump body and a variable tray arranged inside the pump body. The variable mechanism comprises a variable piston connected with the variable tray and a first oil chamber and a second chamber which are formed at two ends of the variable plunger. A hydraulic control system is further arranged on the outer side of the pump body, and comprises a controller, a proportional direction value, a transition plate and a detection mechanism, wherein the proportional direction value is connected with the controller and used for controlling flow of oil, the detection mechanism is used for detecting the position of the variable piston, the transition plate provided with two oil outlets is mounted on the outer side of the pump body. The two oil outlets are communicated with the first and second oil chambers respectively, the proportional direction valve is mounted on the transition plate, and the detection mechanism is connected with the controller. The electric proportional variable axial plunger pump has the advantages of simplicity in control, high reliability and repeat accuracy, and emission can be regulated in real time during operation.

Owner:宁波恒力液压股份有限公司

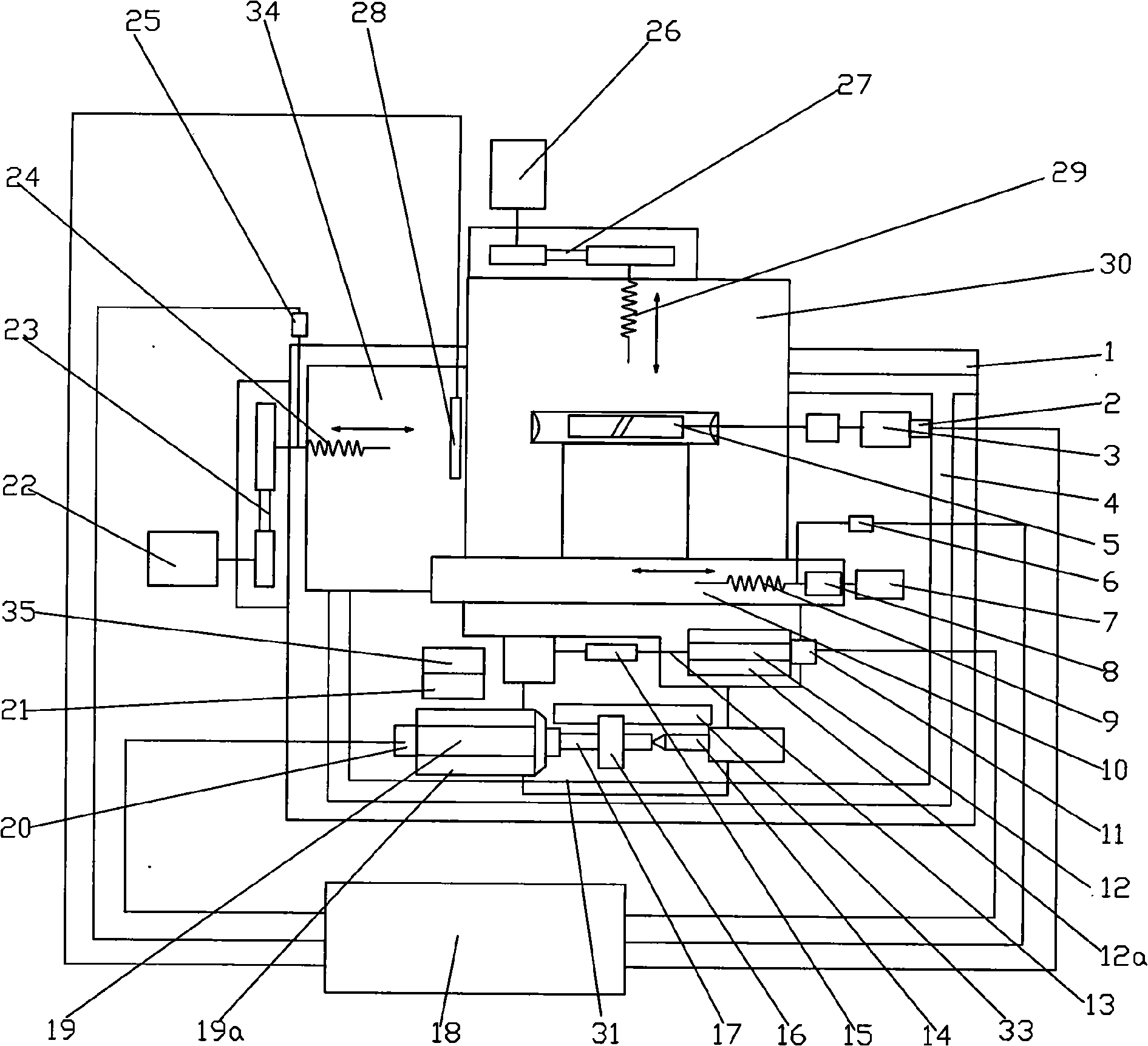

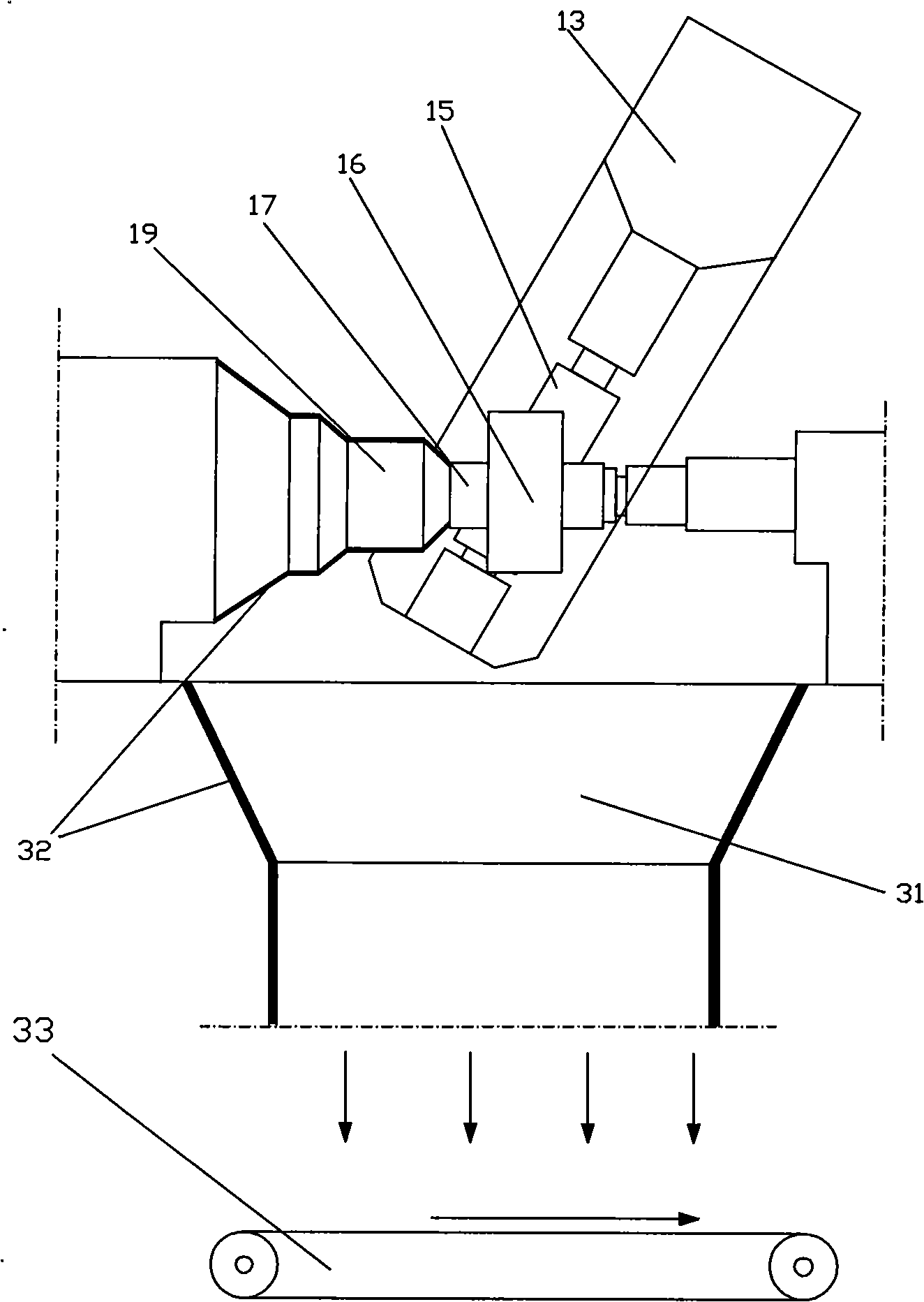

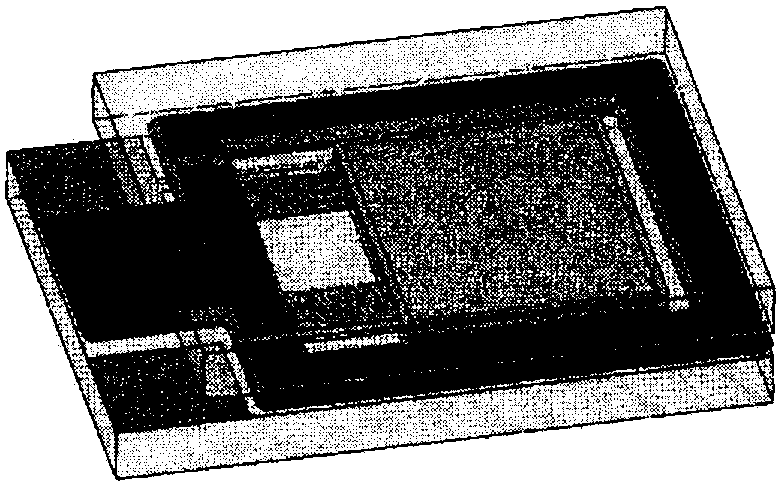

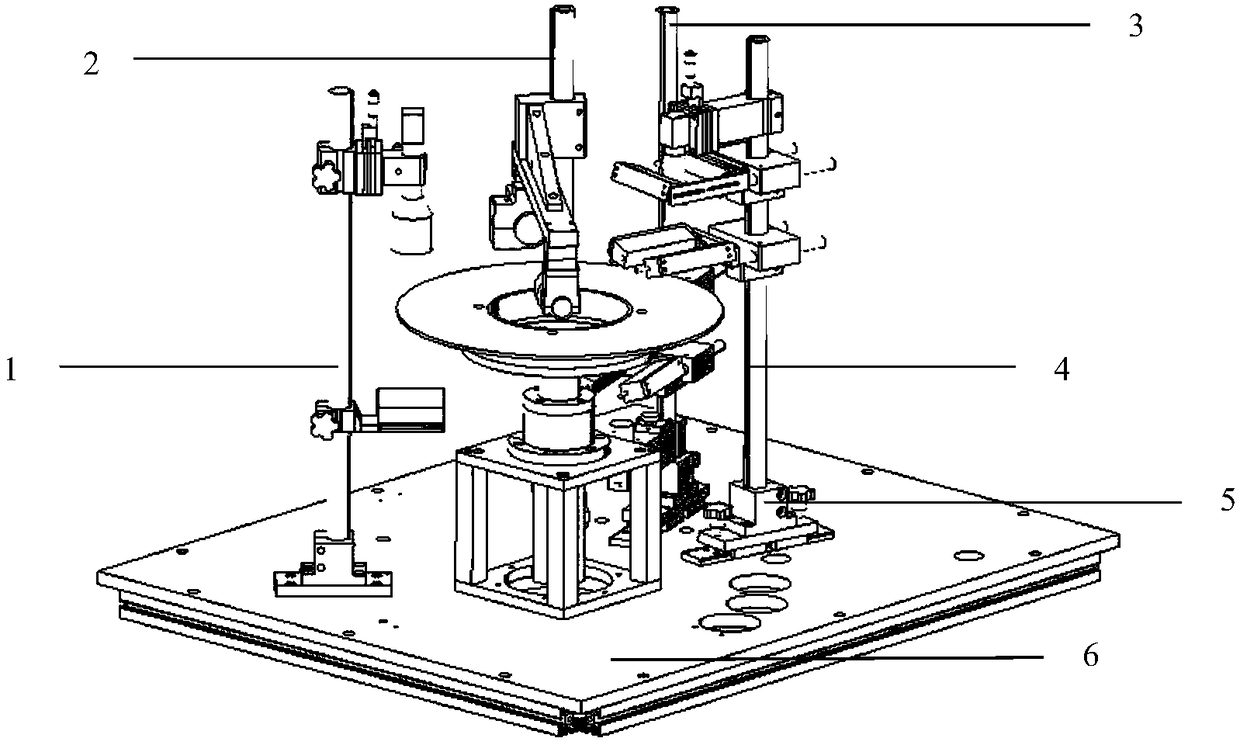

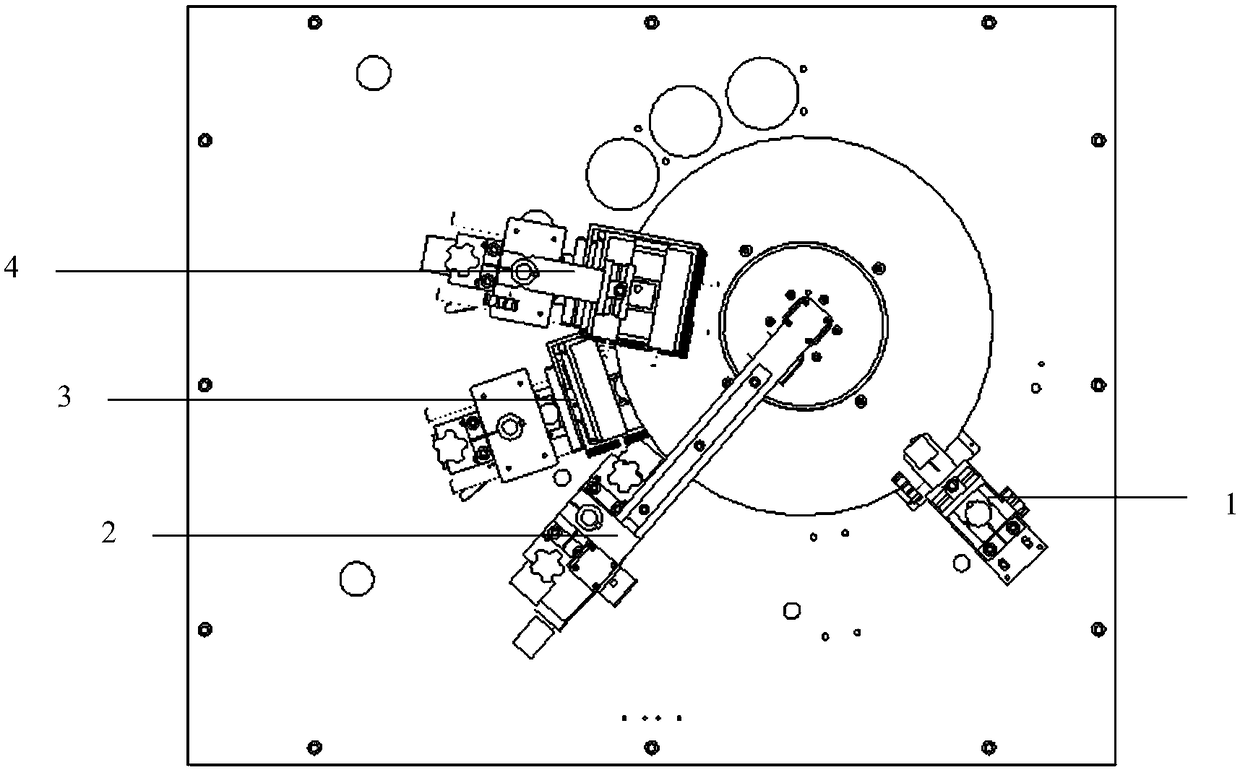

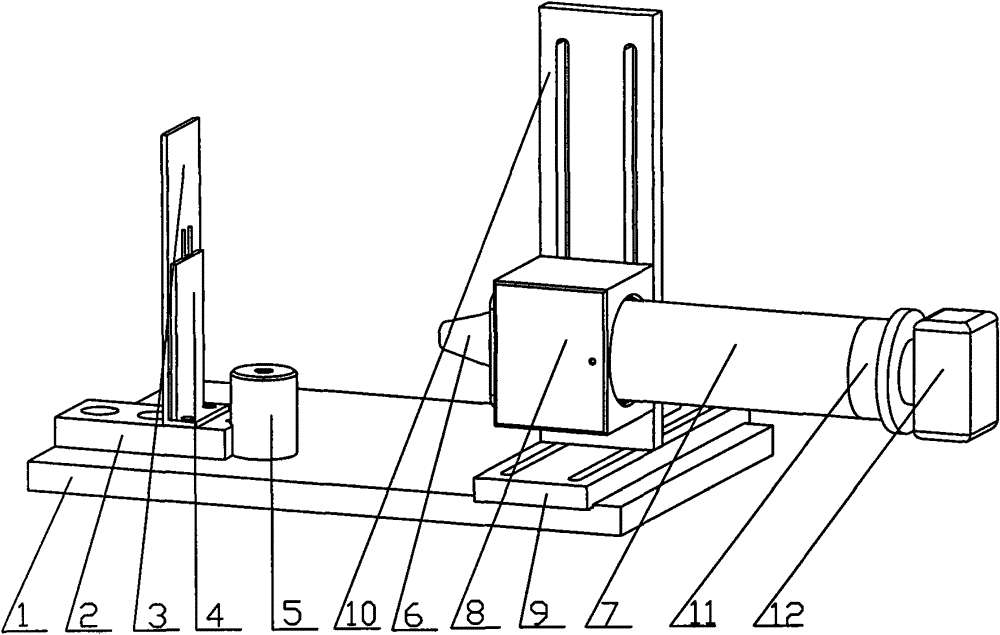

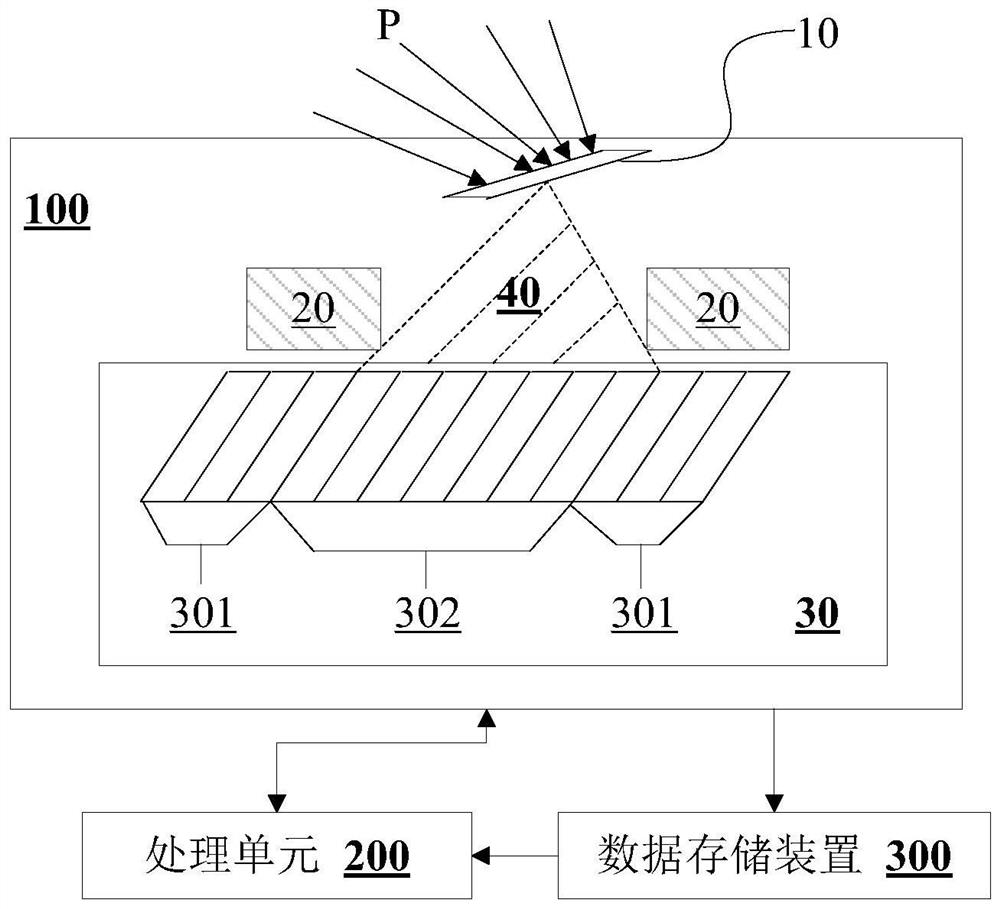

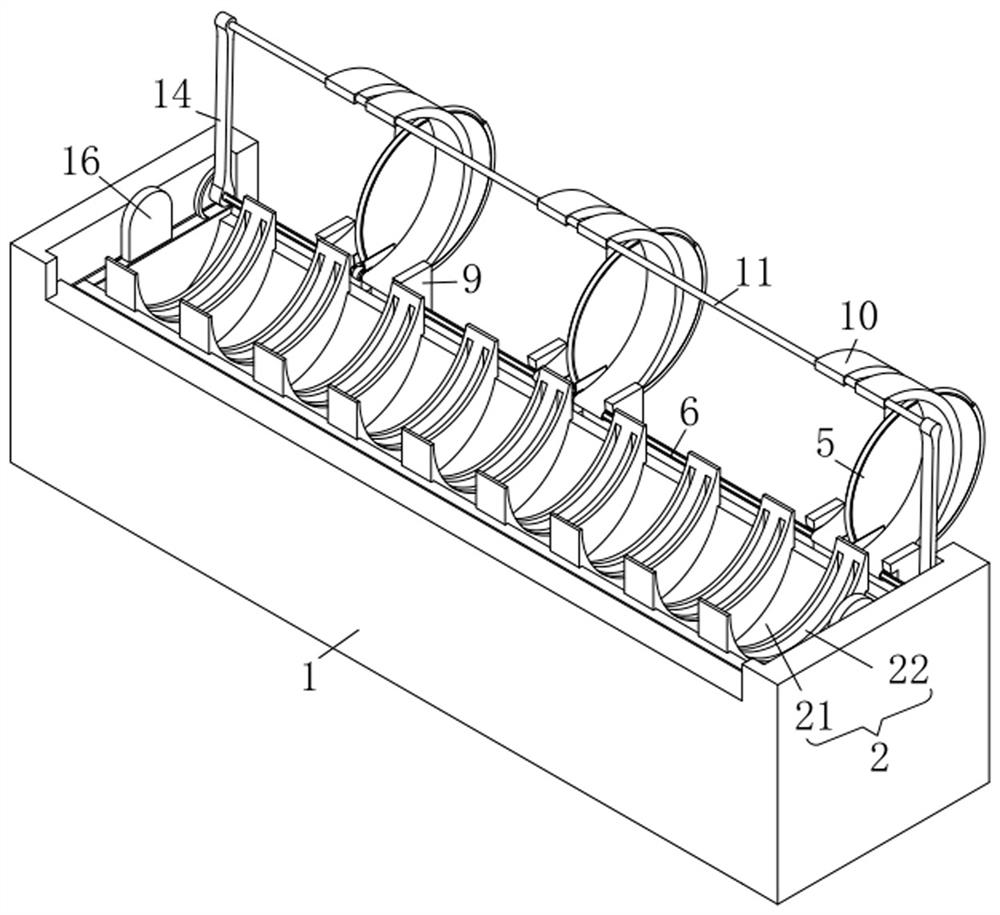

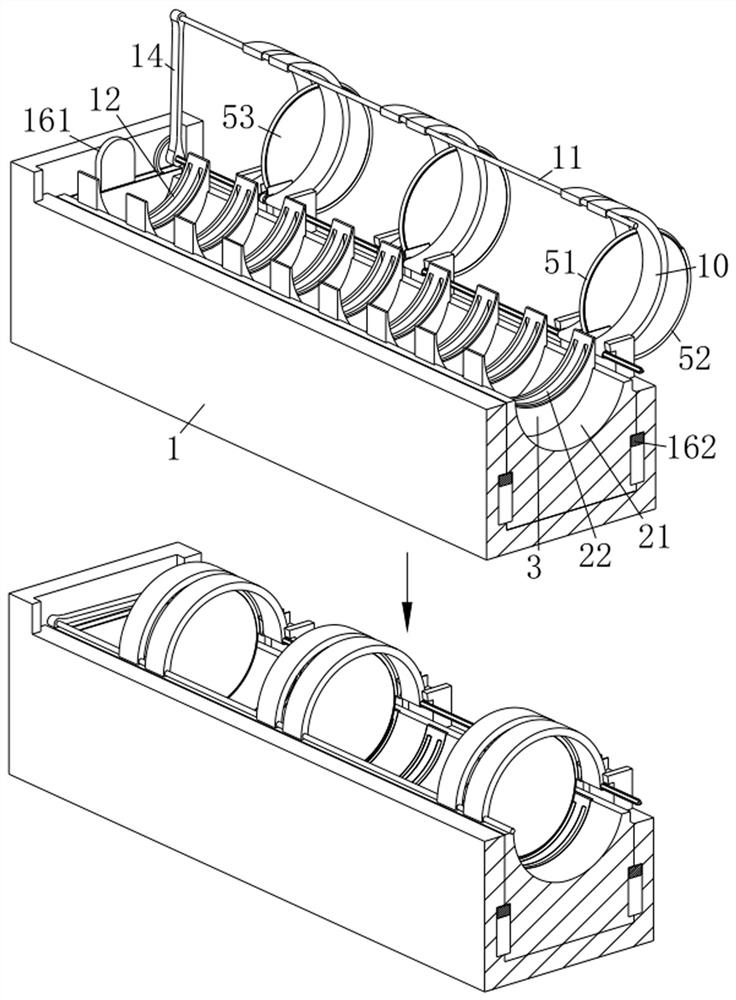

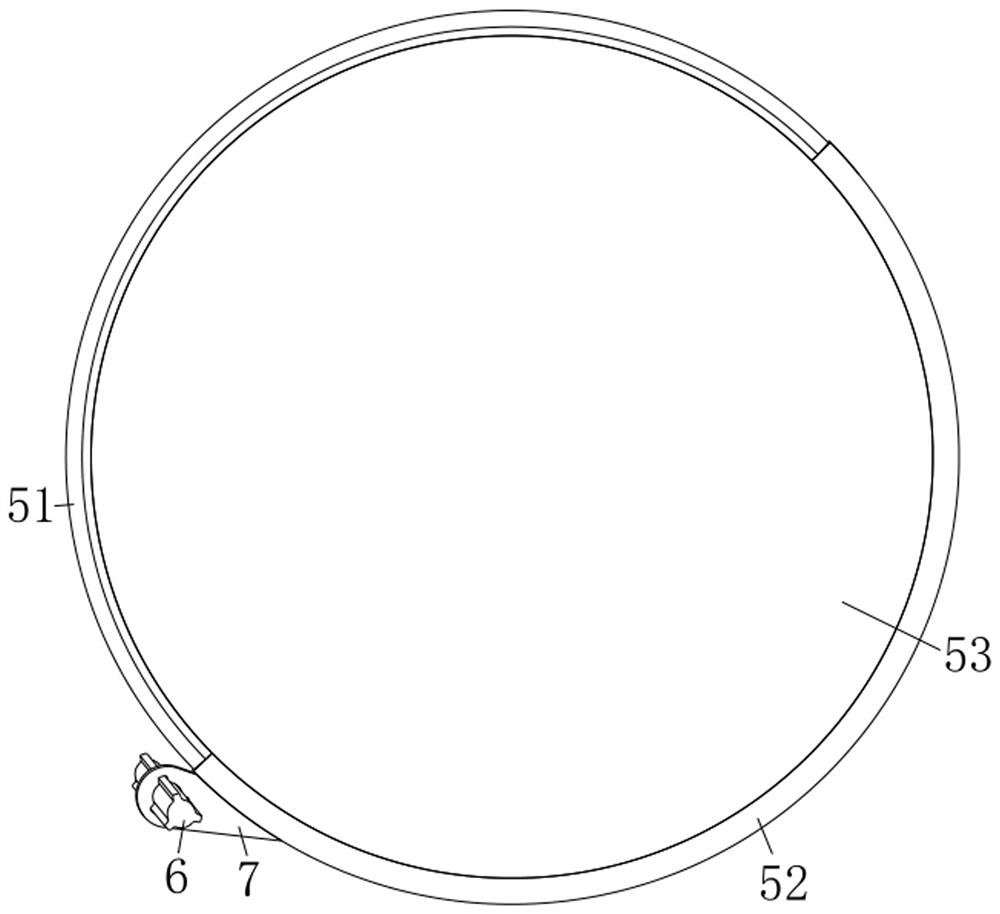

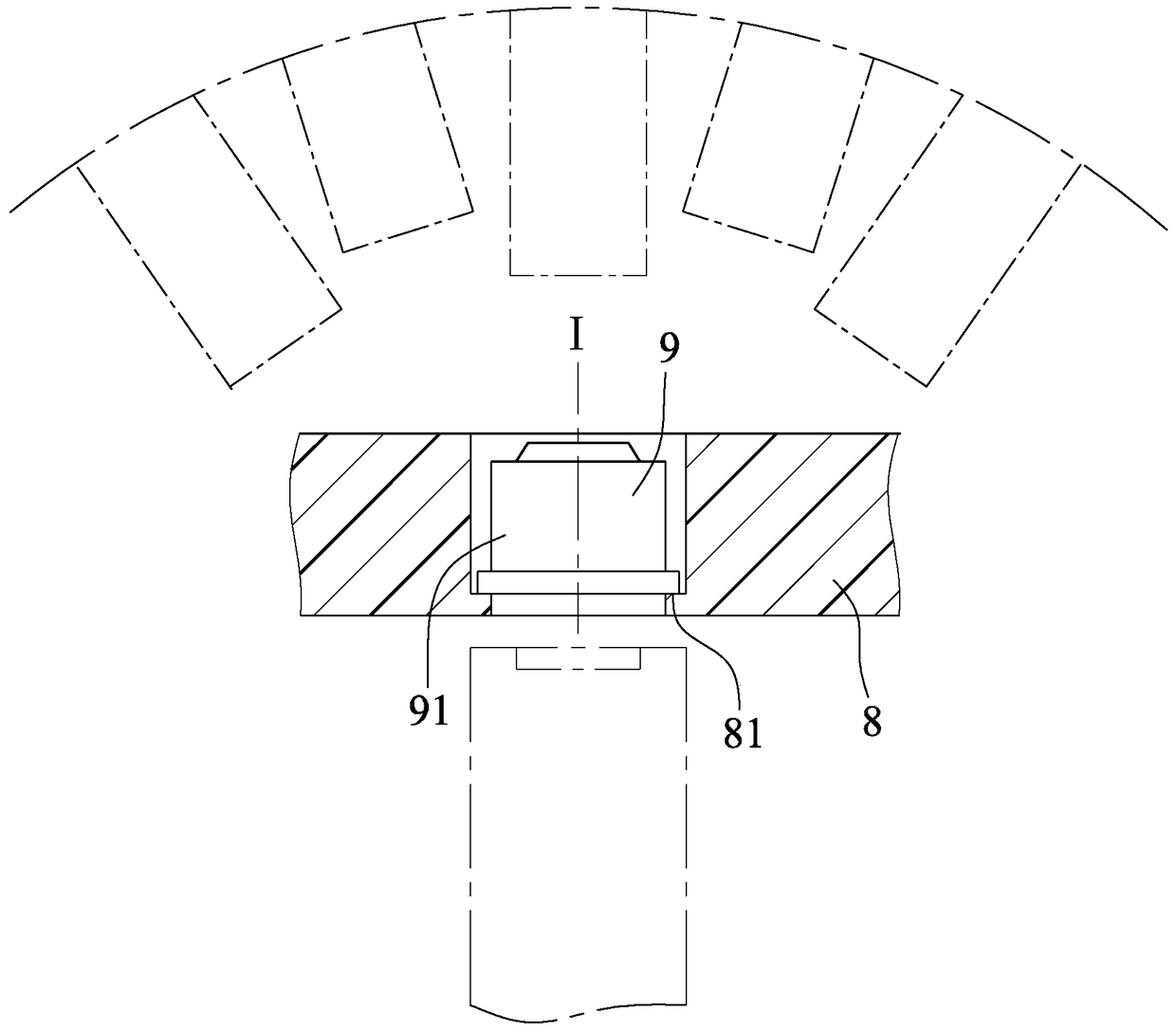

Image acquisition device for small magnetic material part

InactiveCN108593657AHigh repeatability accuracyGood stabilityOptically investigating flaws/contaminationUsing optical meansMicrometerImage acquisition

The invention discloses an image acquisition device for a small magnetic material part, relates to the field of image acquisition devices, and particularly relates to the field of image acquisition ofsmall parts. The device comprises a fixed bottom plate, an objective table, a side length size imaging mechanism, a thickness size imaging mechanism, a top view appearance imaging mechanism and a bottom view appearance imaging mechanism; the objective table comprises a support frame, a motor and a carrier disc, the carrier disc is made of a transparent material, the support frame is mounted on the fixed bottom plate, the motor and the carrier disc are mounted on the support frame, and the motor can drive the carrier disc to rotate; and the side length size imaging mechanism, the thickness size imaging mechanism, the bottom view appearance imaging mechanism and the top view appearance imaging mechanism are arranged on the fixed bottom plate and are located around the objective table. The device has the advantages of high repeatability precision, good stability, small influences of the time and the environment on the system detection precision, realization of the detection accuracy meeting micrometer-level detection accuracy requirements, suitableness for detecting the size and the appearance of parts with different shapes and different specifications, and extensive uses.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

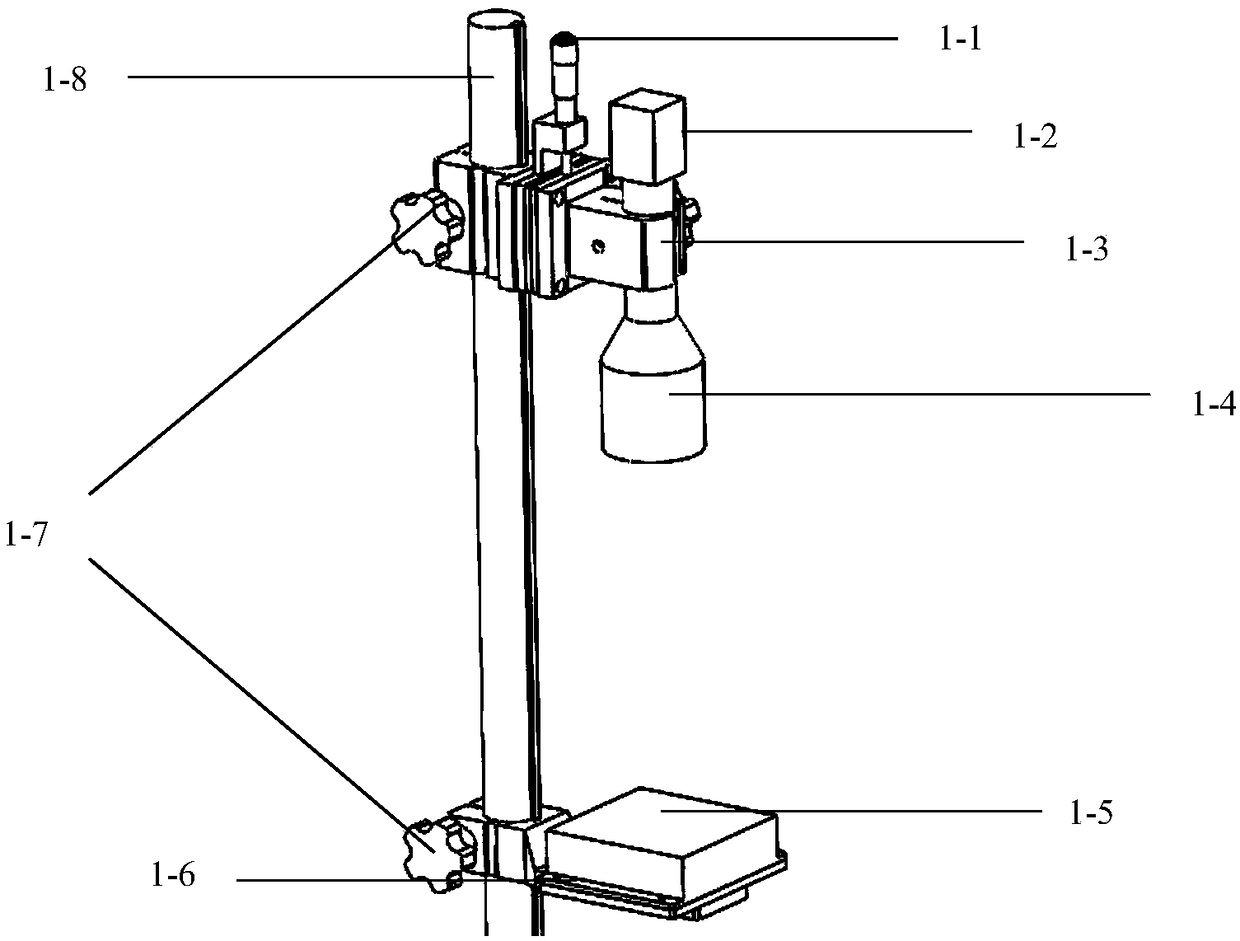

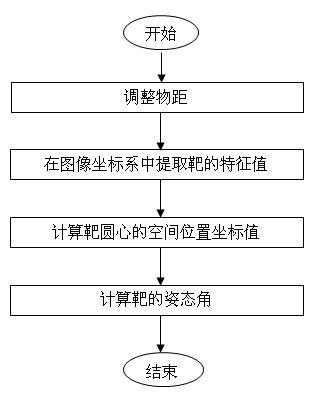

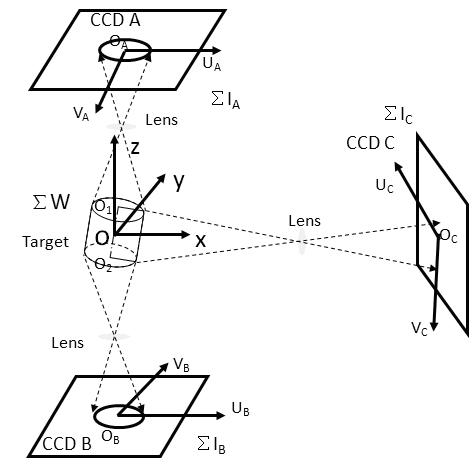

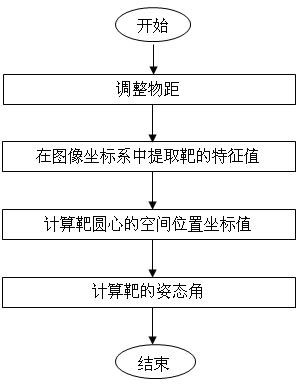

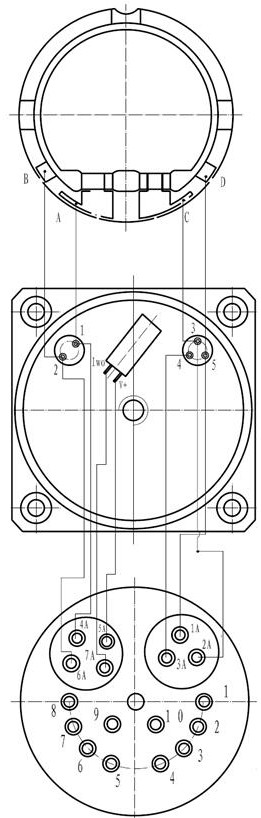

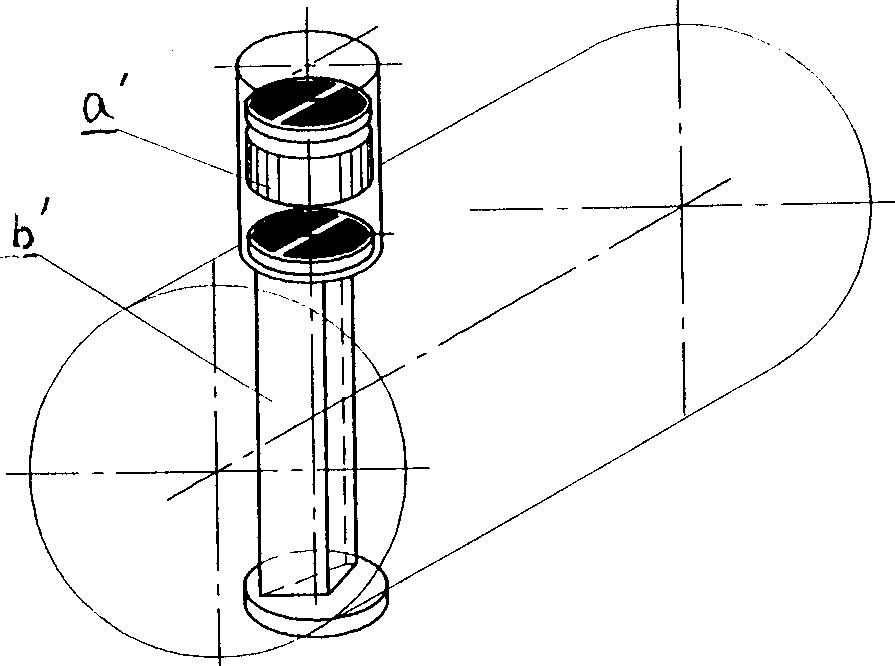

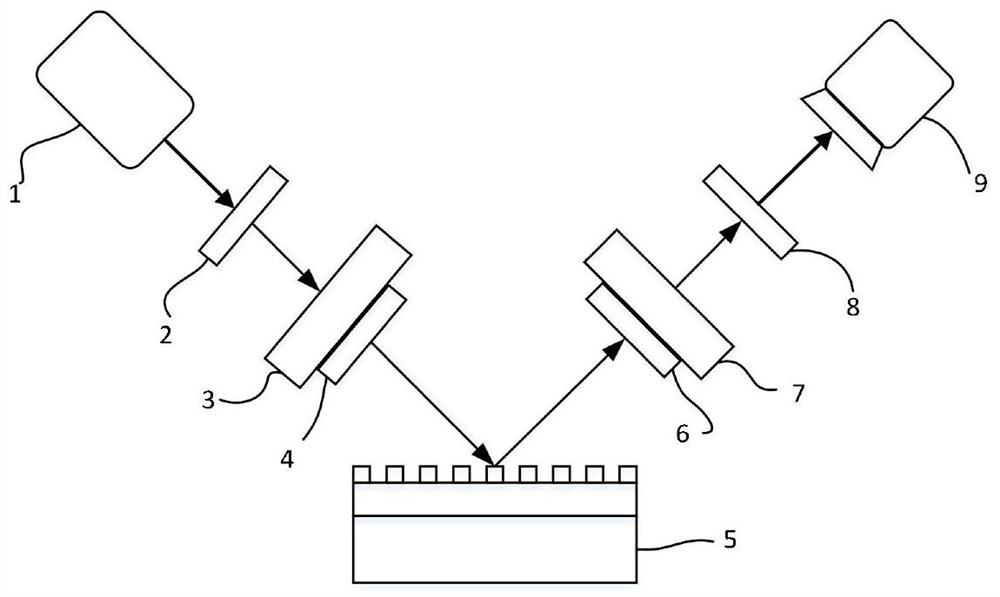

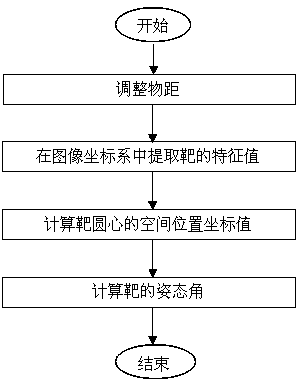

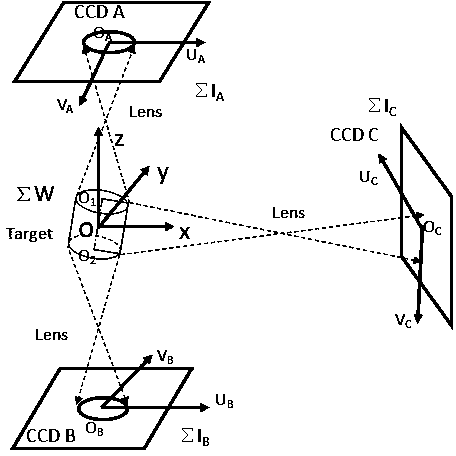

Method for detecting position and attitude of micro cylindrical cavity target by using target collimating sensor

InactiveCN102607410AHigh repeatability accuracyReduce mistakesNuclear energy generationUsing optical meansLocation detectionOptical axis

The invention relates to a method for detecting the position and attitude of a micro cylindrical cavity target by using a target collimating sensor. When the method is used for detection, a target collimating sensor consisting of three CCD (Charge Coupled Device) image sensors which are in orthogonal arrangement is adopted; the intersection point of optical axes of the three CCD image sensors is taken as a reference point for placing a target, and the images of a micro cylindrical cavity target are acquired by the target collimating sensor from different viewing angels; and characteristic values of the images of the images of the micro cylindrical cavity target, which are extracted by the three CCD image sensors are combined, and the space coordinate and azimuth rotation matrix of the micro cylindrical cavity target are calculated according to the characteristic values so as to determine the six-dimensional position and attitude of the micro cylindrical cavity target in space. The new method for detecting the position and attitude of the micro cylindrical cavity target, provided by the invention, has the advantages of improving repeatability accuracy in position detection for the micro cylindrical cavity target and especially reducing errors in attitude direction for the micro cylindrical cavity target, is convenient to operate and has good in stability and has a high detection speed.

Owner:SHANGHAI UNIV

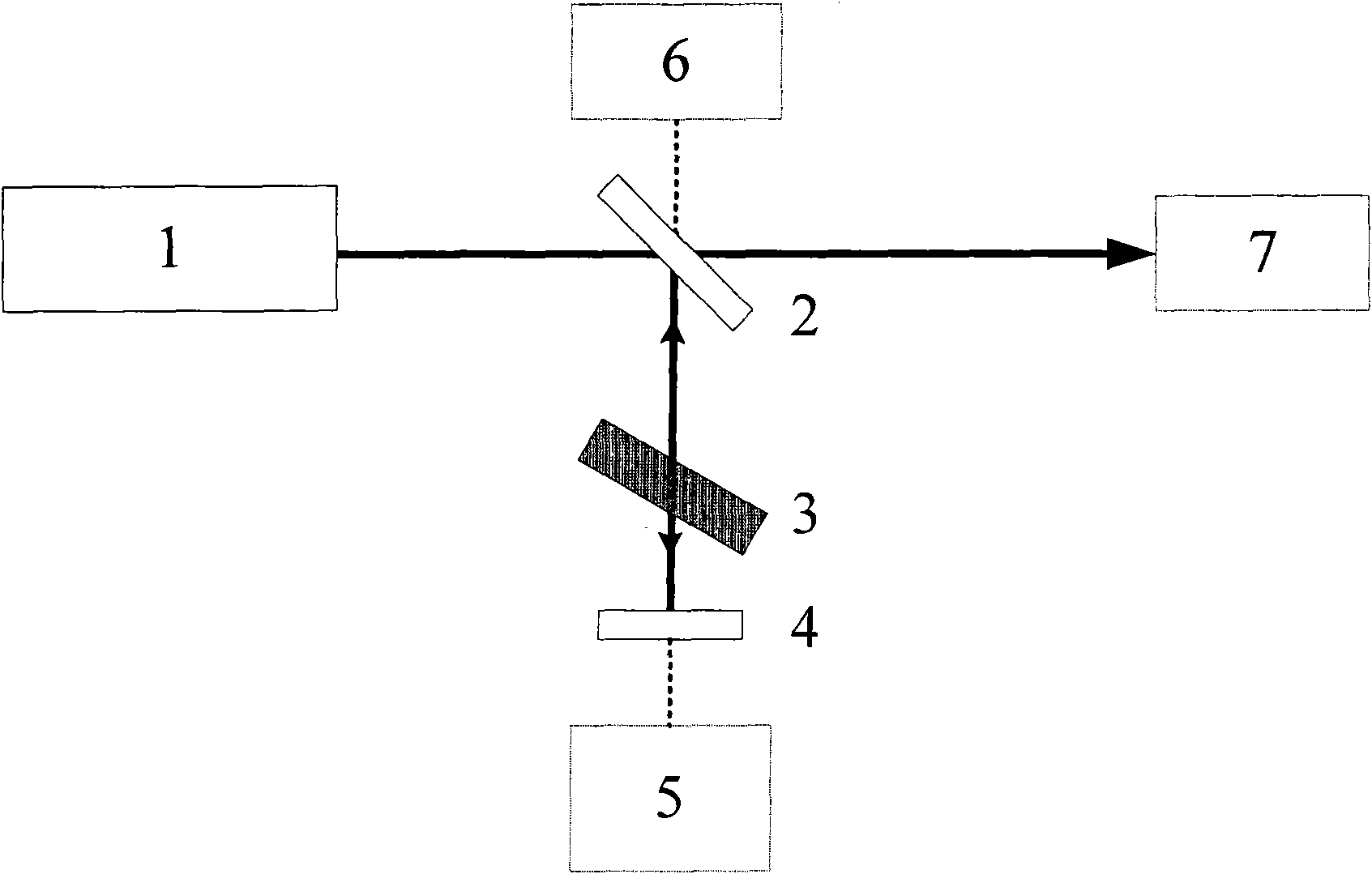

Tuning device of optical signal transmitting device for communication

InactiveCN103812572ASuppression of Power VariationsStable output optical powerElectromagnetic transmittersOptoelectronicsOptical pathlength

The invention provides a tuning device of an optical signal transmitting device. The turning device comprises a laser (1), a spectroscope (2), a variable attenuator (3) and a reflection mirror (4). The outer cavity of the laser is formed by the reflection mirror (4). The turning device is characterized in that the outer cavity is also provided with an optical device (8) with an adjustable optical length, and through adjusting the variable attenuator (3) and the optical device (8) with the adjustable optical length at the same time, the turning output of the optical signal is realized by using a self mixing effect.

Owner:WUXI CINSEC INFORMATION TECH

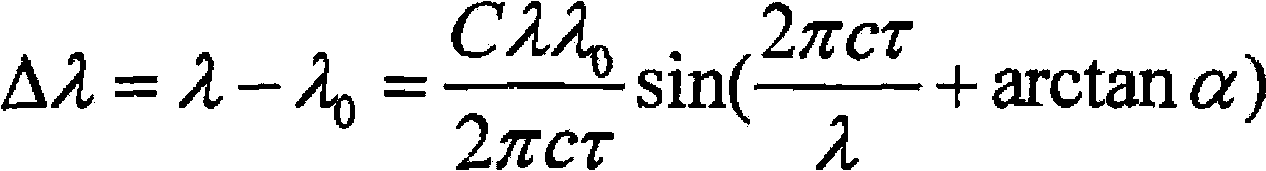

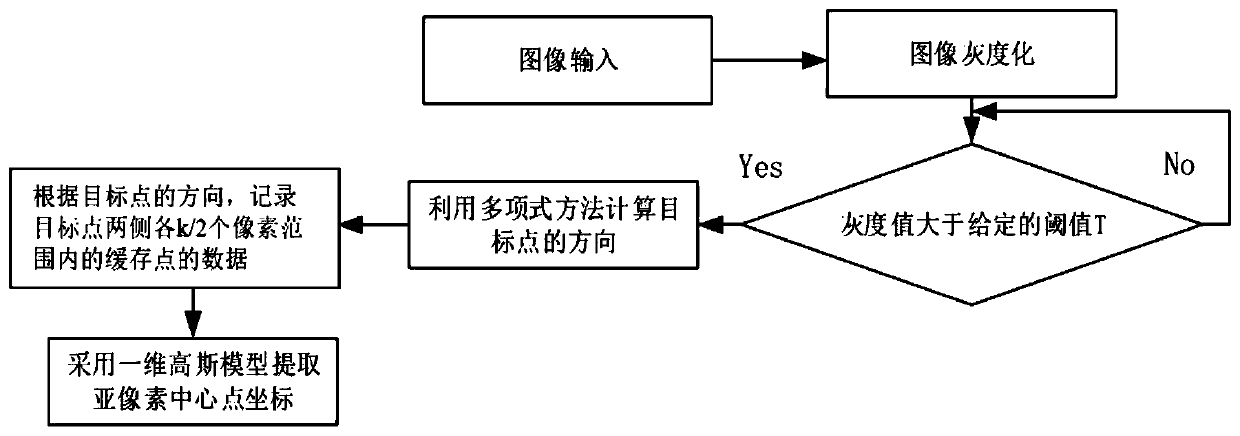

Line laser center extraction method

The invention discloses a line laser center extraction method, and belongs to the technical field of industrial measurement. The method comprises the following steps: firstly performing threshold processing to remove most of redundant calculation and improve the calculation speed and efficiency; calculating the direction of a target point by using a polynomial technology; and according to the direction of the target point, recording the data of the cache points in the k / 2 pixel ranges on the two sides of the target point; and finally, adopting a one-dimensional Gaussian model to extract coordinates of a line laser sub-pixel center point. The method has the advantages of high calculation speed, interference resistance, convenience in hardware implementation and the like.

Owner:苏州中科行智智能科技有限公司

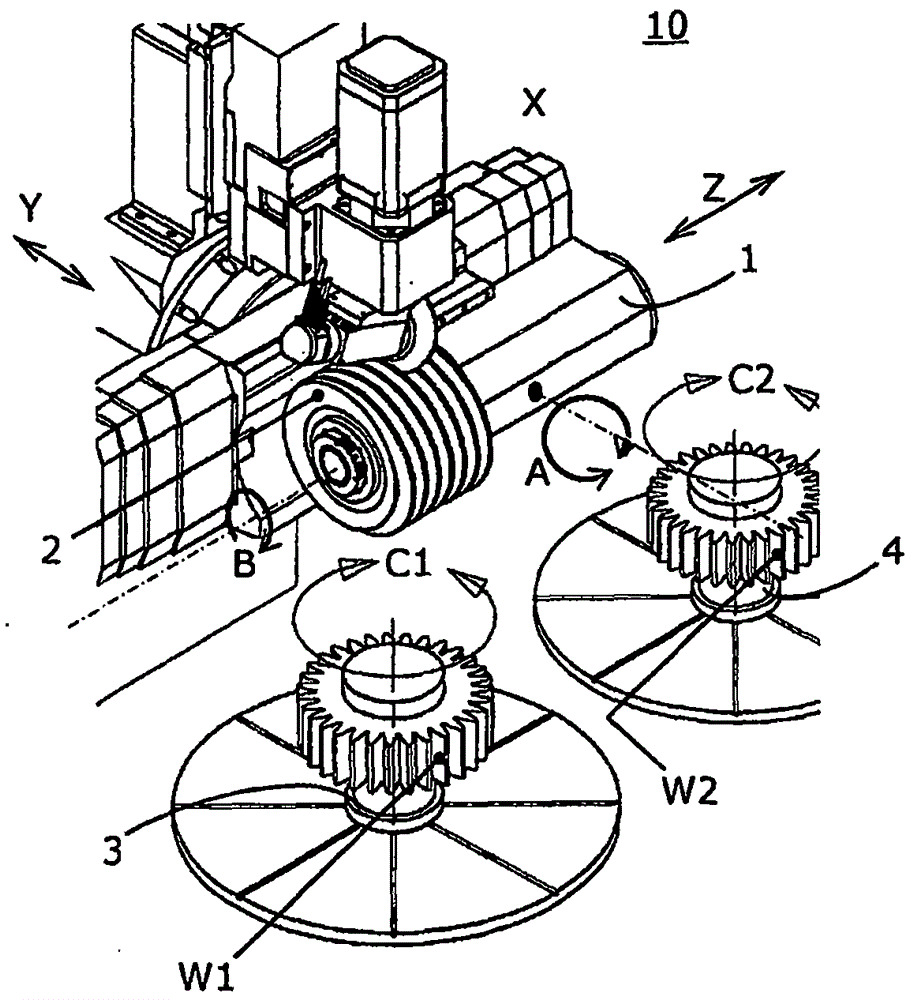

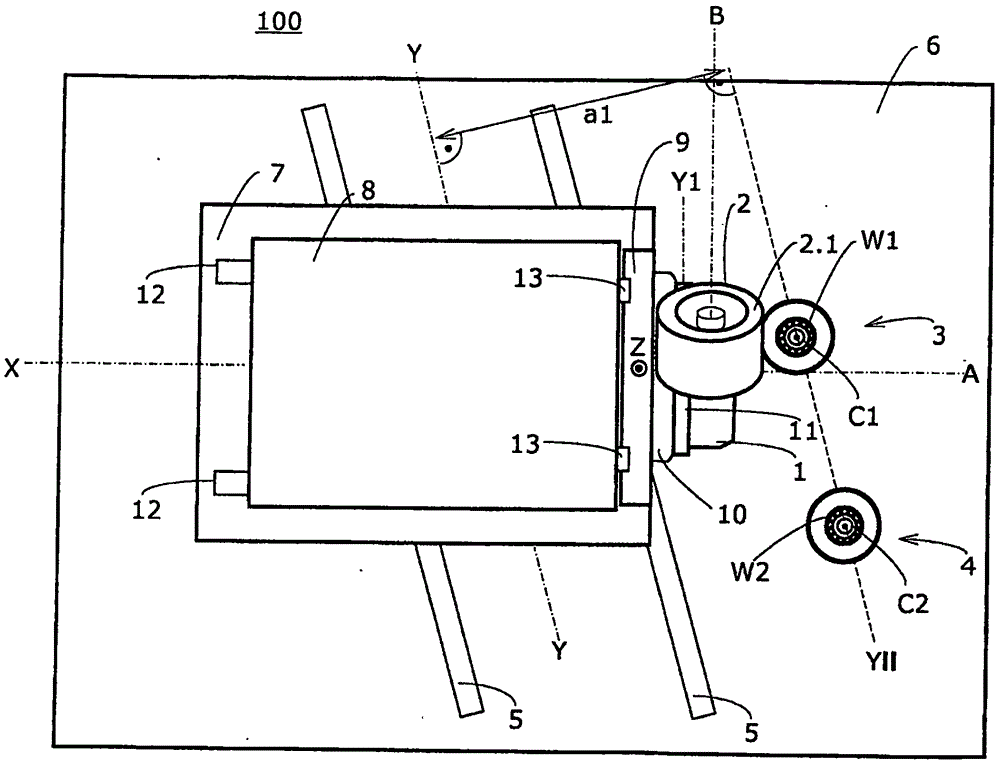

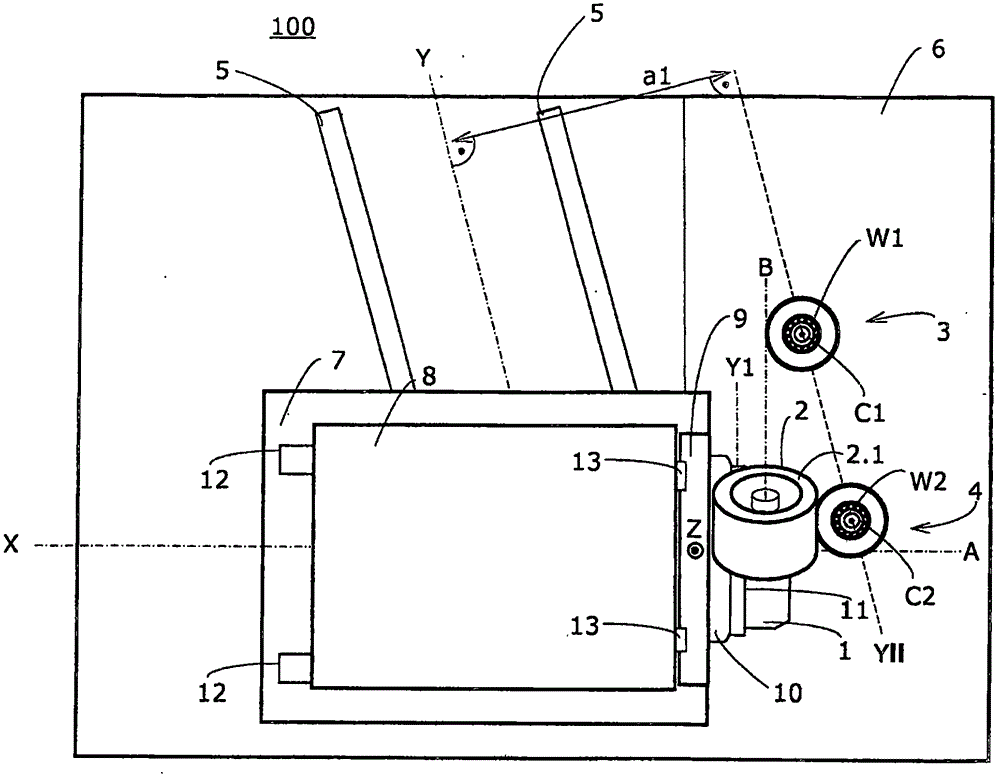

Grinding machine with a grinding tool for roller grinding two workpieces

InactiveCN105772867AMuch spaceGood precisionGrinding carriagesGrinding machinesClosed angleHorizontal projection

Grinding machine (100) includes a tool spindle (1, 1.1) for receiving and rotationally driving a grinding tool (2) about a tool axis (B) of rotation, a first workpiece spindle (3) for receiving a first workpiece (W1), and a second workpiece spindle (4) for receiving a second workpiece (W2), wherein the first workpiece spindle (3) and the second workpiece spindle (4) are arranged on one longitudinal side of the grinding tool (2) received on the tool spindle (1, 1.1); both workpiece spindles (3, 4) are arranged parallel to one another; the tool spindle (1) is configured to be able to move along a first linear guiding piece (5) parallel to a horizontal inclined axis (Y); the first workpiece spindle (3) and the second workpiece spindle (4) are separated from the horizontal inclined axis (Y) with the same vertical horizontal distance (a1); and the tool rotation axis (B) and the horizontal inclined axis (Y) form a closed angle (W) being greater than 0 DEG in the horizontal projection.

Owner:KLINGELNBERG AG

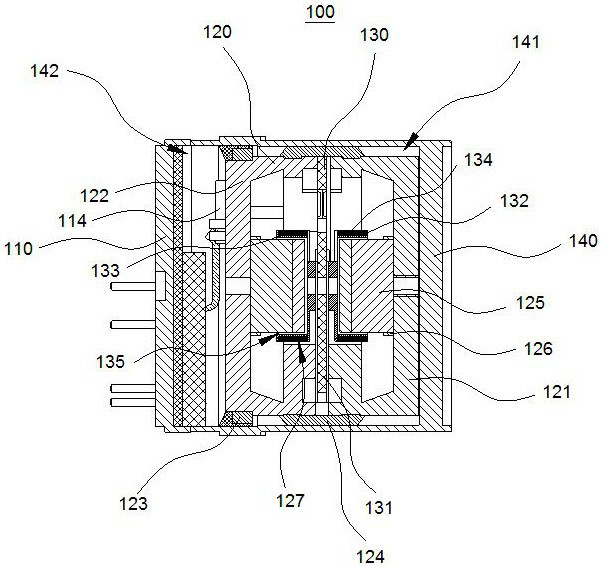

High-precision accelerometer

PendingCN112162113AImprove stabilityHigh repeatability accuracyThermometer detailsAcceleration measurement using interia forcesAccelerometerHemt circuits

A high-precision accelerometer relates to the technical field of acceleration measurement and comprises a servo circuit board, a torquer stator assembly, a pendulum assembly and a shell. The shell isprovided with a cylindrical inner cavity, one end of the inner cavity is closed, and the other end of the inner cavity is opened to form an opening; the torquer stator assembly is located in the innercavity, and the torquer stator assembly and the opening are arranged at intervals to form a hanging meter structure; and the servo circuit board is positioned at the opening and is bonded and weldedwith the shell to seal the inner cavity. The high-precision accelerometer adopts multiple new technologies such as a unique hanging meter structure, a precise flexible supporting structure, a pendulumassembly mechanical structure, a high-sensitivity capacitive sensor and a feedback type integrated servo circuit, so the high-precision accelerometer has the characteristics of high product stability, high repeatability precision, small temperature coefficient, accurate temperature measurement, quick starting, strong environmental adaptability and the like, and is particularly suitable for high-precision systems with high requirements on accelerometer precision, temperature and starting time, such as inertial navigation, navigation attitude, platform stability, missile steering engine controland the like.

Owner:AVIC SHAANXI HUAYAN AERO INSTR

Temperature measurement method based on image data normalization technology

ActiveCN111207833AImprove temperature measurement accuracyHigh repeatability accuracyRadiation pyrometryComputational physicsTemperature measurement

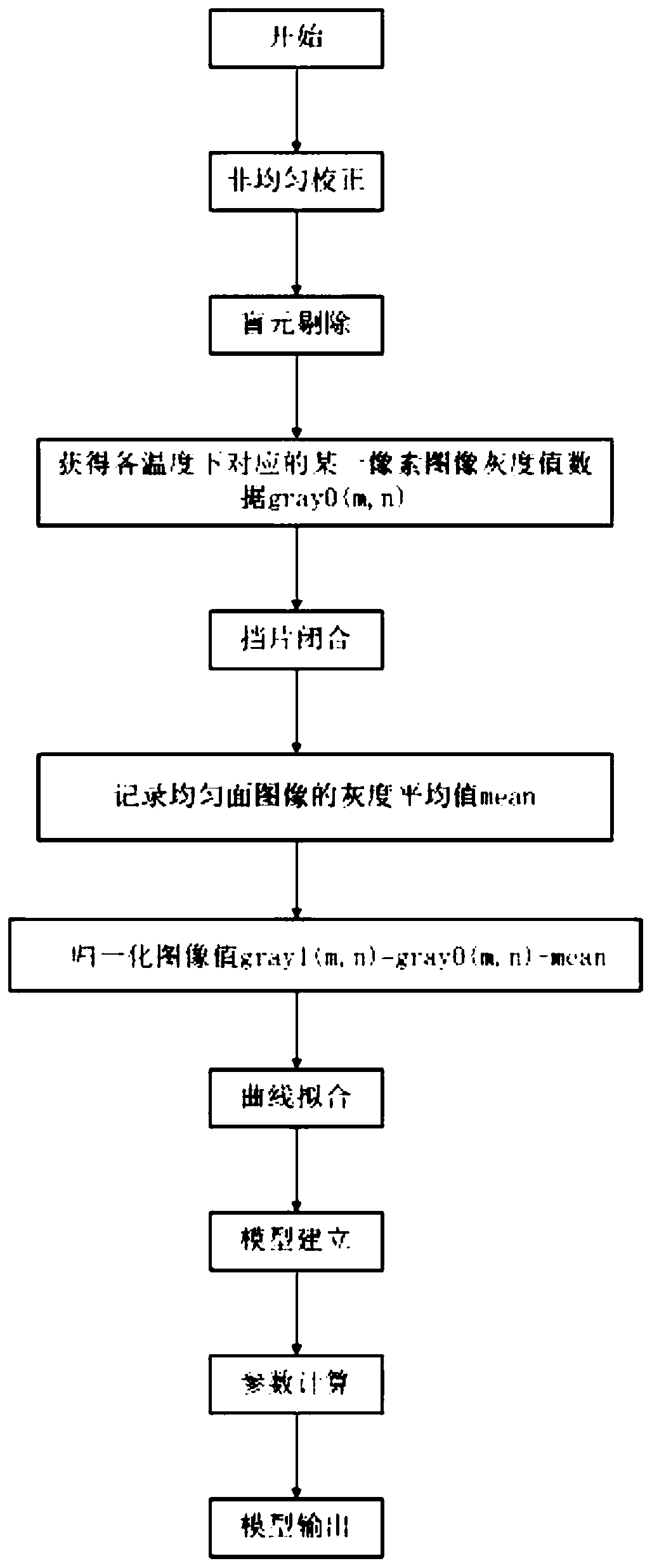

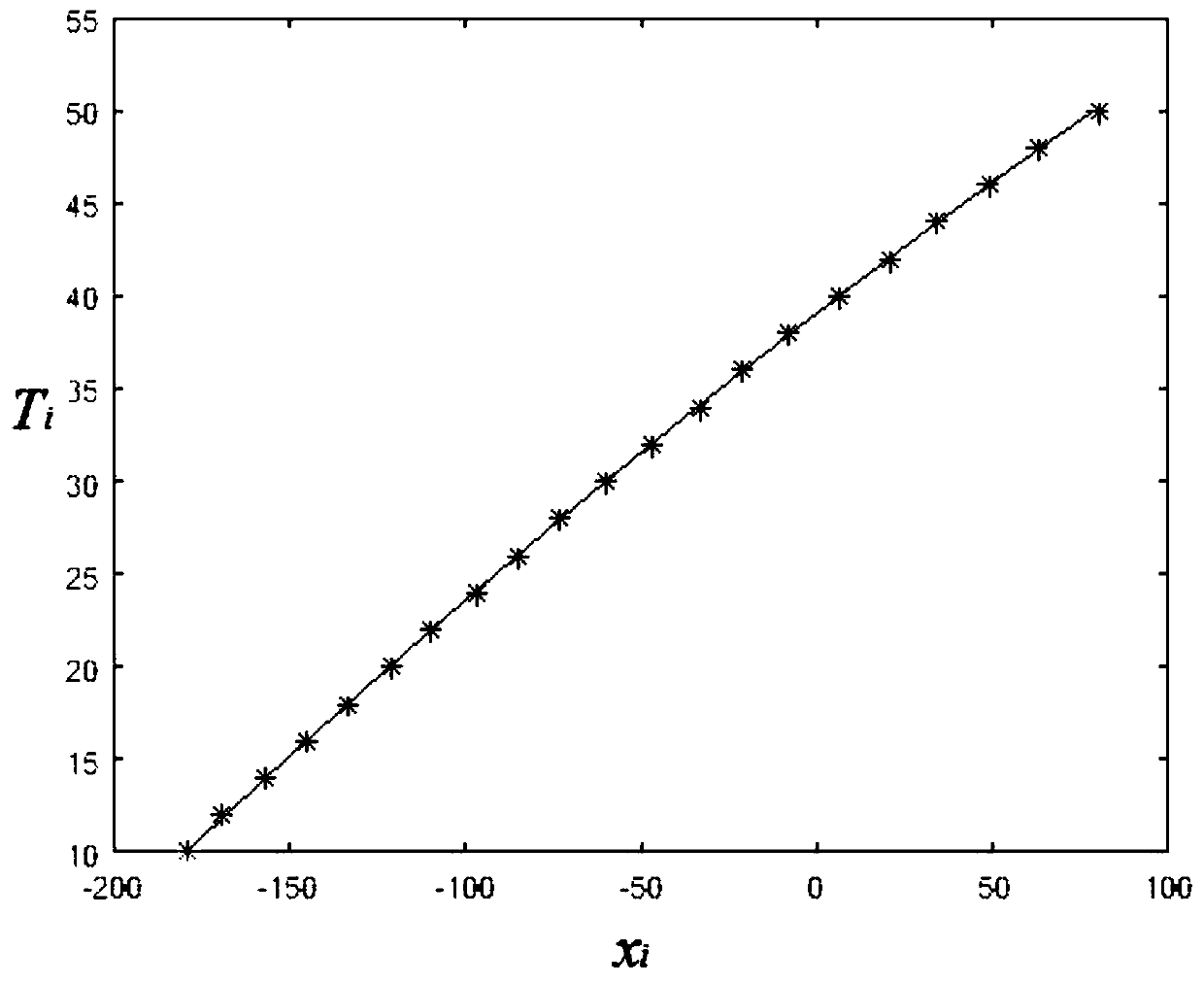

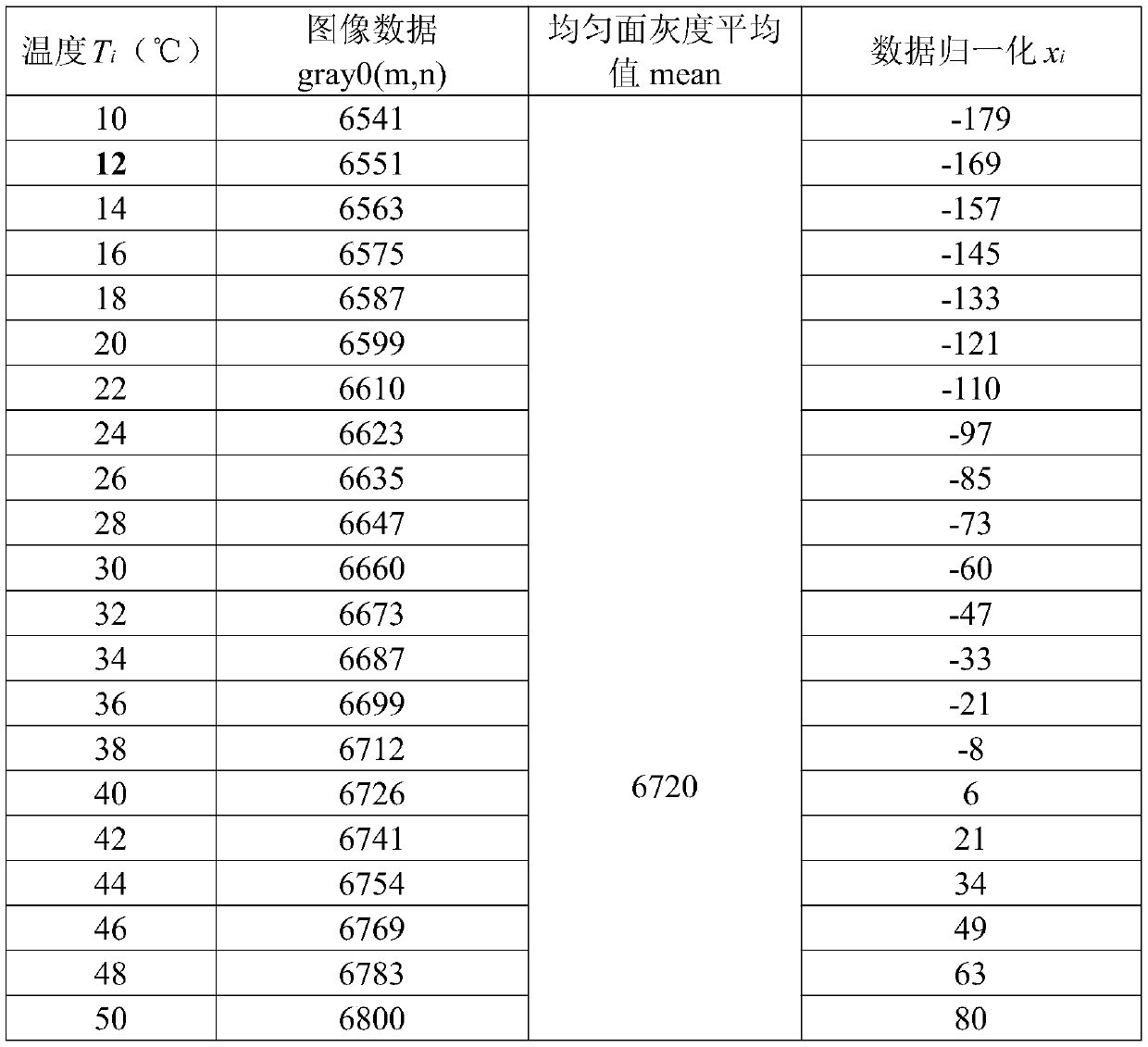

The invention relates to a temperature measurement method based on an image data normalization technology. The temperature measurement method comprises steps of (1) starting an uncooled thermal infrared imager to reach thermal balance; (2) obtaining an image after non-uniform correction; (3) removing blind pixels; (4) measuring black body radiation by using the uncooled thermal infrared imager toobtain gray value data of a certain pixel image corresponding to each temperature Ti; (5) normalizing the gray value data of the image; (6) establishing a temperature measurement mathematical model ofthe relationship between the normalized image gray value and the temperature; and (7) calculating a temperature value corresponding to each gray scale by utilizing the temperature measurement mathematical model, wherein an image gray scale value inputted into the temperature measurement mathematical model needs to be normalized according to the step (5). The temperature measurement method is advantaged in that the relation between the normalized image data and the temperature is used for fitting the curve model, the model is used for temperature measurement so that the temperature measurementprecision can be improved, repeatability precision can further be improved, that is to say, the temperature measurement result of the same pixel used for each startup is not greatly changed.

Owner:HARGLO APPLIED LASER TECH INST CO LTD

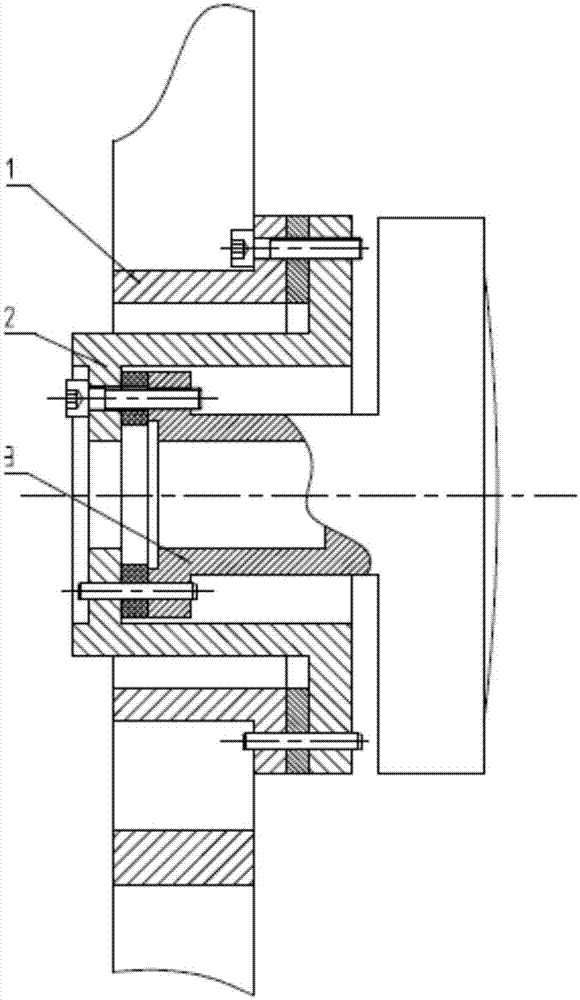

Thermal control focusing assistance adjustment device and method

ActiveCN106969754ASimple structureEasy to operatePicture taking arrangementsEngineeringService condition

The invention relates to a thermal regulator focusing assistance adjustment device and method. The device comprises a first adjustment locating ring, a second adjustment locating ring and a mounting and dismounting screw, wherein the first adjustment locating ring is mounted between an aluminum ring and a secondary mirror component of a thermal regulator focusing device; the second adjustment locating ring is mounted on the aluminum ring; the mounting and dismounting screw is located in the middle of the second adjustment locating ring; and the device is convenient to dismount after the aluminum ring and the secondary mirror component are mounted. According to the thermal regulator focusing assistance adjustment device meeting space service conditions and having stable performance, high precision and a reliable structure, and the method, the mounting precision of the thermal regulator focusing device is ensured.

Owner:ACAD OF OPTO ELECTRONICS CHINESE ACAD OF SCI

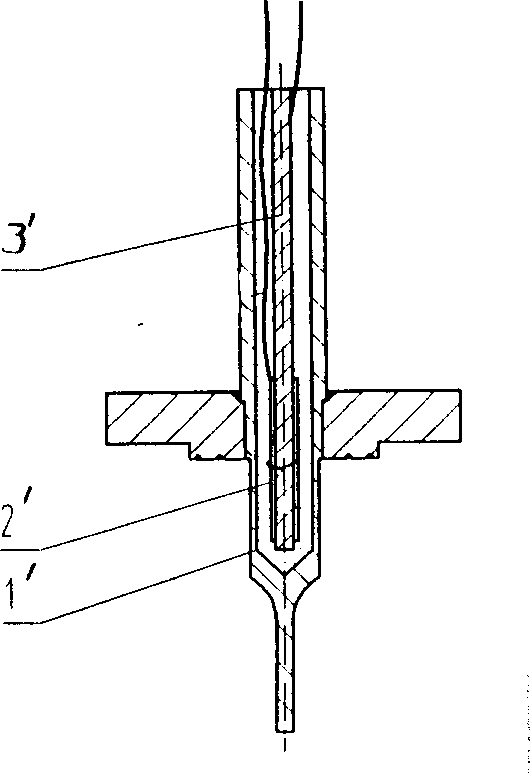

Novel vortex street flowmeter sensor

InactiveCN1335488AImprove seismic performanceImprove high temperature resistanceVolume/mass flow by dynamic fluid flow effectElectricityFilling materials

The novel vortex street flowmeter sensor has piezoelectric ceramic wafer vibration membrane structure as signal detecting element, and has piezoelectric ceramic wafer inside the casing cavity of probe. One end of the piezoelectric ceramic wafer is adhered directly to the bottom of the casing and the other end to the connection board. The piezoelectric ceramic wafer is pressed by one holddown block with insulating material in between. The wires are led out from the holddown block and the connection board. The probe is one rod structure, has planar top and the casing of the probe has one ring groove. The present invention has the advantages of simple production, high sensitivity, high vibration resistance, high precision repetition, etc.

Owner:陈宝荣

CMOS (complementary metal-oxide-semiconductor)-machine-vision-based component size measuring system and measurement test method

InactiveCN102538672BHigh repeatability accuracyImprove linearityUsing optical meansCMOSMeasurement test

The invention discloses a CMOS (complementary metal-oxide-semiconductor)-machine-vision-based component size measuring system and a measurement test method. The CMOS-machine-vision-based component size measuring system comprises an image acquisition module, an image processing module and a size measuring module, wherein the image acquisition module acquires images of contour edges of a shot component; the image processing module performs binaryzation and filtering processing on the acquired images, and then performs edge detection to obtain edges of the images of the component; and the size measuring module calculates a pixel value of an edge contour of a measured object through feature extraction, and the pixel value can directly reflect the size of the component through calibration. According to the CMOS-machine-vision-based component size measuring system and the measurement test method disclosed by the invention, the measurement of the contour size can be realized, and the measurement of the aperture of a small through hole can be finished; and after a special assistant tool is provided, the measurement of the bottom width of a trumpet-shaped groove can be realized.

Owner:ZHONGBEI UNIV

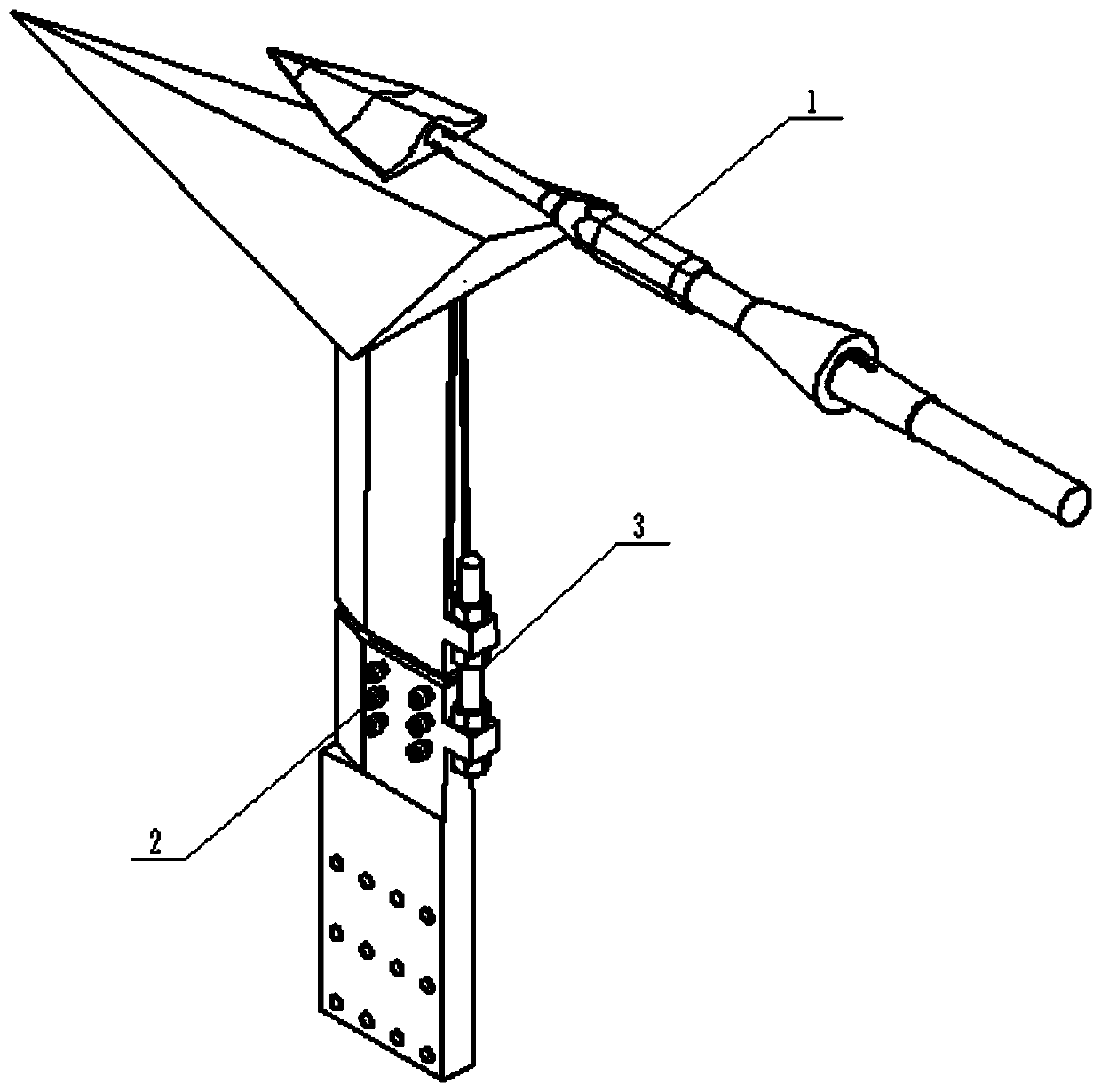

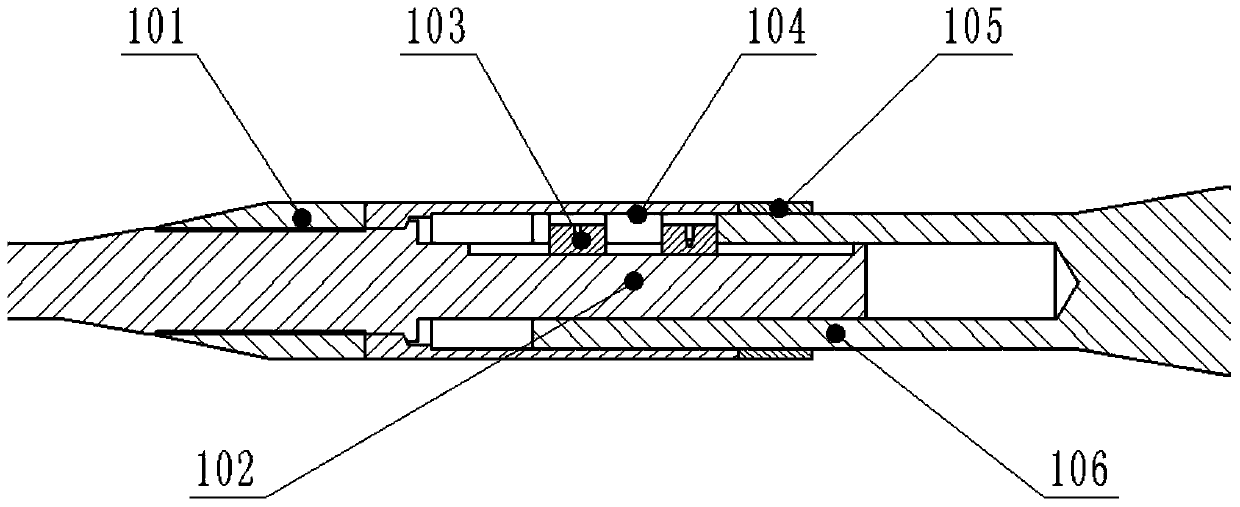

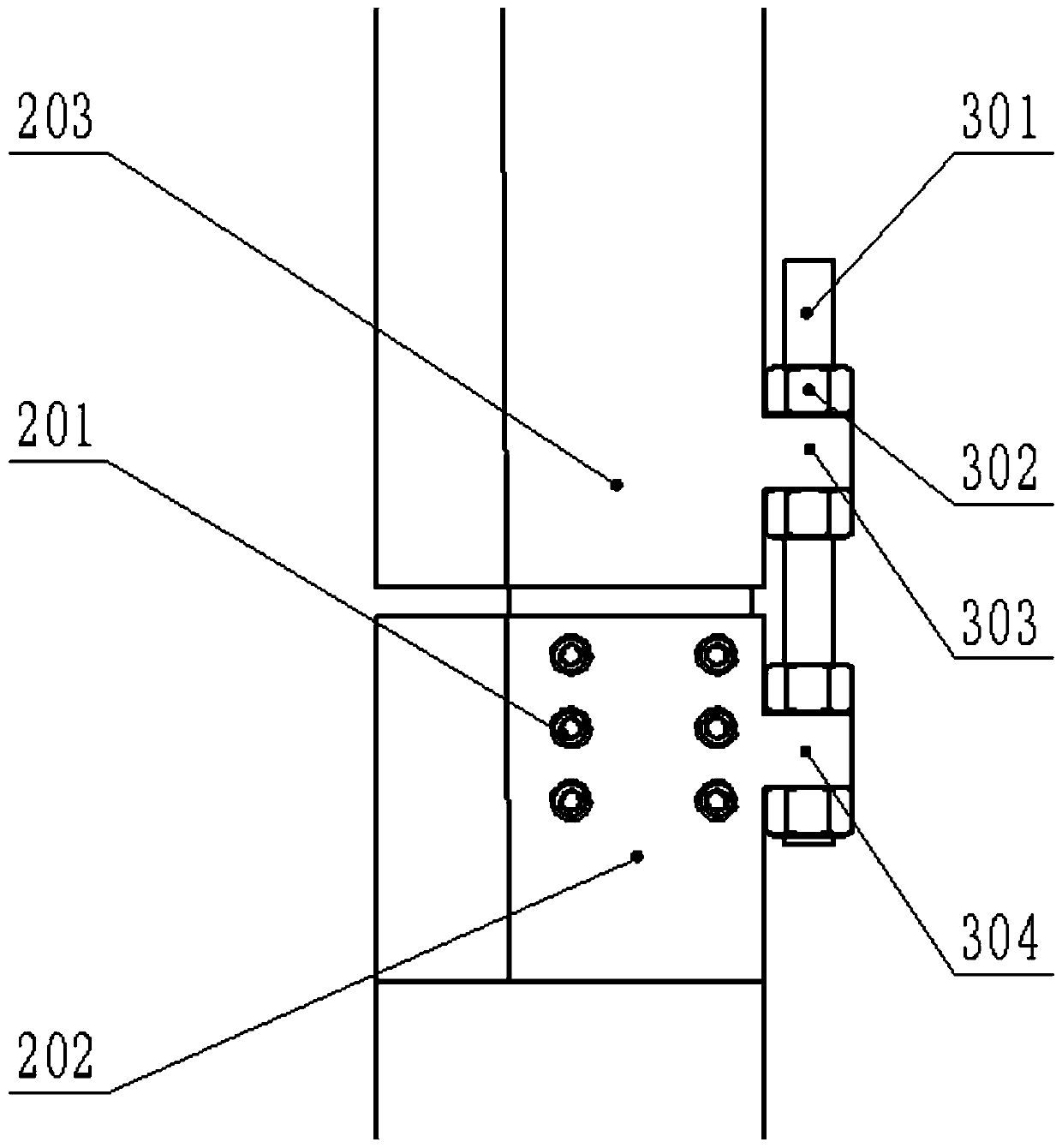

Hypersonic wind tunnel parallel type separation model relative position continuous adjustment device

PendingCN110595731AReduce distractionsRealize positioning in front, back, left, and right directionsAerodynamic testingTest efficiencyEngineering

The invention discloses a hypersonic wind tunnel parallel type separation model relative position continuous adjustment device. A model X direction relative position adjustment device of the adjustment device is horizontally placed, the front end of the model X direction relative position adjustment device is fixedly connected with the tail end of a secondary test model, and the rear end is fixedly connected with a tail supporting mechanism of a hypersonic wind tunnel; a model Y direction relative position adjustment device is vertically placed, the upper end of the model Y direction relativeposition adjustment device is fixedly connected with an abdominal supporting connector below a primary test model, and the lower end is fixedly connected with an abdominal supporting mechanism of thehypersonic wind tunnel; and a Y direction locking and auxiliary adjustment device is vertically placed, fixed on a leeward surface of the model Y direction relative position adjustment device and in charge of Y direction locking and auxiliary adjustment. The adjustement device disclosed by the invention is simple in structure, processing cost is low, test model state can be easily changed, labor intensity of field staff is reduced, test efficiency is improved, an error caused by processing and installing errors is avoided, reliability precision is improved, and a test state can be temporarilyadded in an adjustable range.

Owner:中国空气动力研究与发展中心超高速空气动力研究所

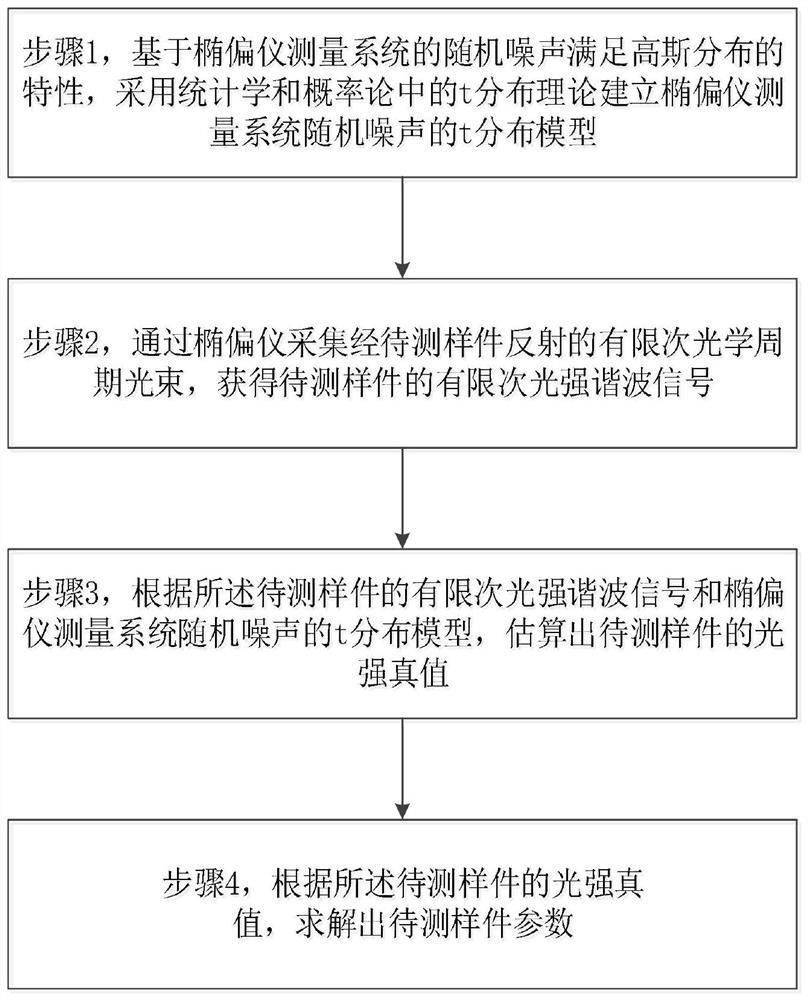

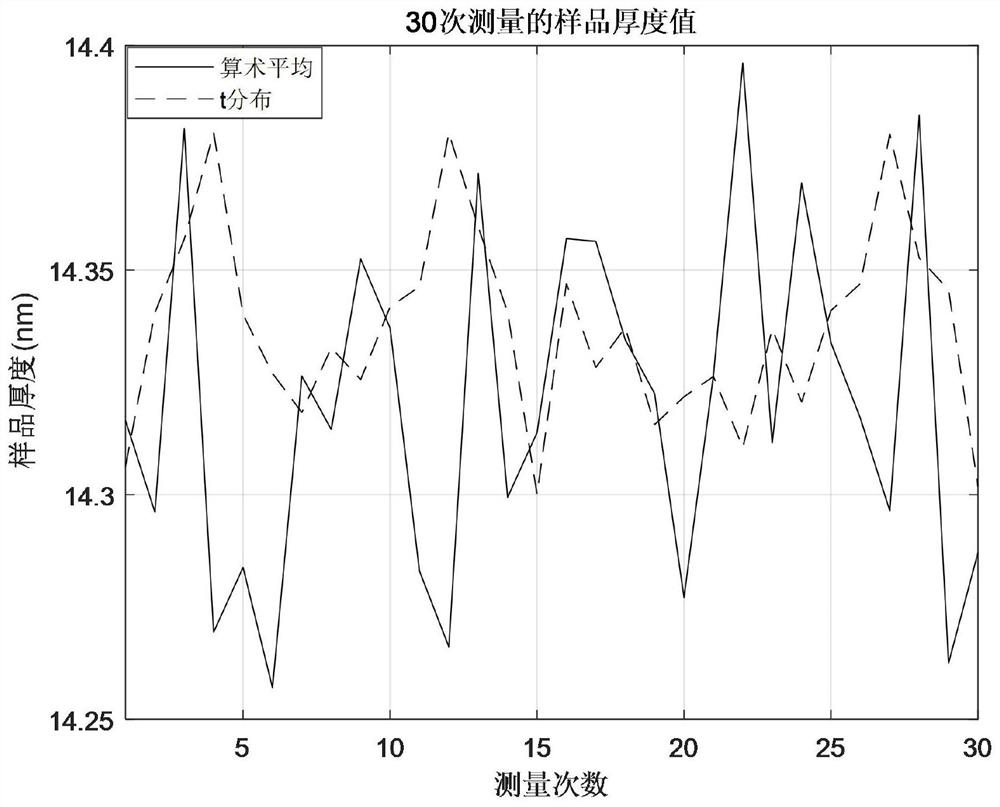

To-be-measured sample piece parameter measuring method based on ellipsometer

ActiveCN112345463AHigh repeatability accuracyDoes not reduce detection efficiencyPolarisation-affecting propertiesUsing optical meansLight beamPhysical model

The invention provides a to-be-measured sample piece parameter measuring method based on an ellipsometer. The method comprises the following steps: building a t distribution model based on a characteristic that random noise in an ellipsometer measurement system meets Gaussian distribution; collecting a finite-order optical periodic light beam reflected by the to-be-measured sample piece to obtaina light intensity harmonic signal of the sample piece; eliminating random noise contained in the light intensity harmonic signal through the established t distribution model, estimating a light intensity true value reflected by the sample piece, and further calculating to obtain a corresponding Fourier coefficient true value; and finally, according to calculation formulas such as a specific physical model, solving parameters such as the thickness and the optical constant of the sample piece. Based on the fact that light intensity random noise meets Gaussian distribution, the collected light intensity is subjected to data processing through the t distribution theory in statistics, the true value of the light intensity is estimated, then the parameters of the to-be-detected sample piece areestimated, and the repeatability precision of the ellipsometer detection system is improved while the detection efficiency is not reduced.

Owner:WUHAN EOPTICS TECH CO LTD

High-precision focus detection device for long-focus lens

ActiveCN102313642BSimple structureRealize high-precision measurementTesting optical propertiesGratingLong-focus lens

Owner:ZHEJIANG UNIV

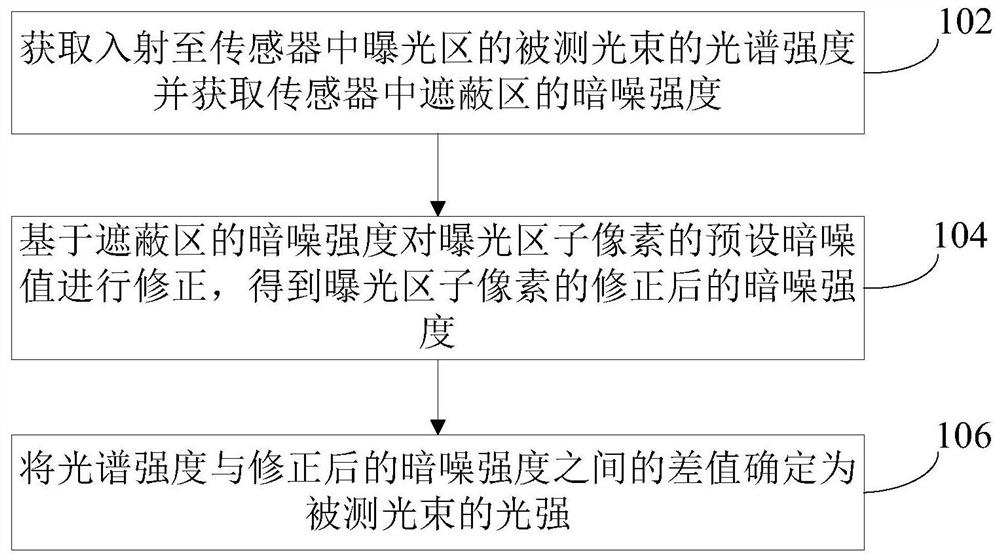

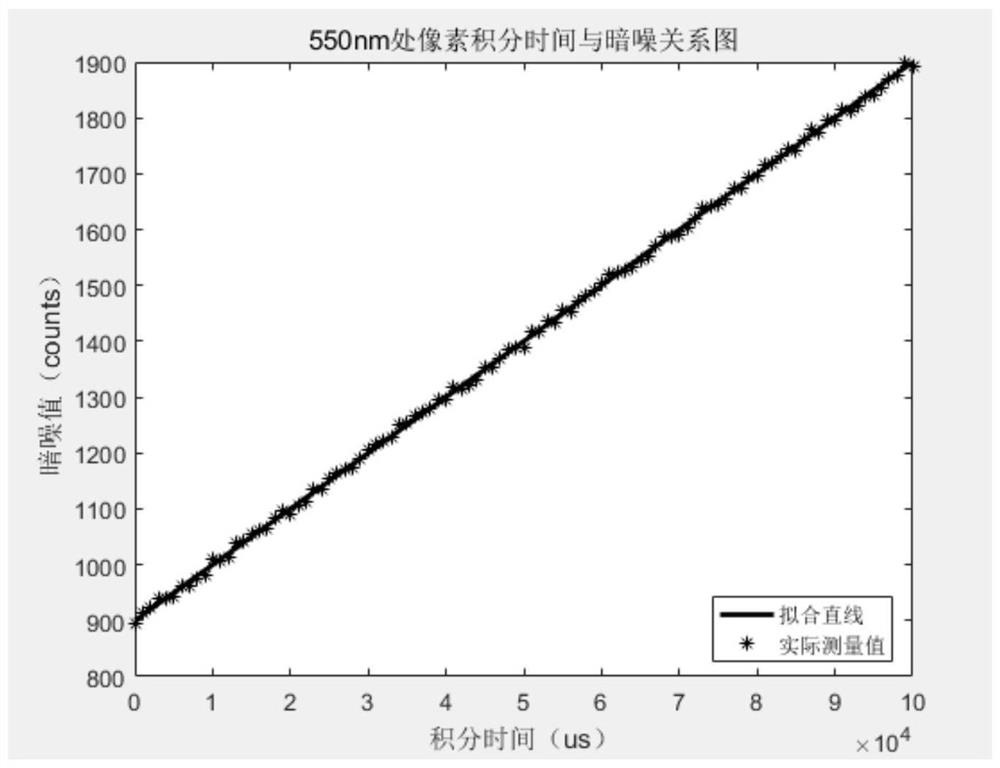

Colorimeter dark noise signal processing method and system

ActiveCN111614916AReduce the extreme difference in light intensityHigh repeatability accuracyTelevision system detailsColor television detailsLight beamExposure

The invention provides a colorimeter dark noise signal processing method and system. The colorimeter dark noise signal processing method comprises: acquiring the spectral intensity of a measured lightbeam entering an exposure area in a sensor, and acquiring the dark noise intensity of a shielding area in the sensor; correcting the preset dark noise value of the exposure area sub-pixel based on the dark noise intensity of the shielding area to obtain the corrected dark noise intensity of the exposure area sub-pixel; and determining the difference between the spectral intensity and the light intensity corresponding to the corrected dark noise intensity as the light intensity of the measured light beam. The method is used for solving the problem that the measured spectral intensity has a large error due to the change of the dark current intensity.

Owner:SHANGHAI PRECISION MEASUREMENT SEMICON TECH INC

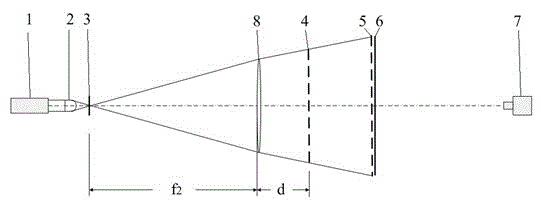

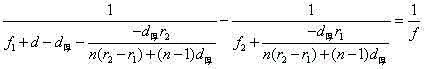

A Method for Measuring the Focal Length of Long Focal Length Lens Based on Moiré Fringe Matching

ActiveCN103063415BAccurate measurementHigh repeatability accuracyTesting optical propertiesGratingLong-focus lens

The invention discloses a long-focus lens focus distance measuring method based on moire fringe matching. According to the long-focus lens focus distance measuring method based on the moire fringe matching, divergent light is adopted to serve as a light source, a moire fringe is collected firstly through a charge coupled device (CCD) camera when a long-focus lens to be measured focus is not added, focus distance between the light source to an initial divergent beam of the first Lang grating, the light source is moved forward and backward after the long-focus lens to be measured focus is added until a present moire fringe collected by the CCD camer is the same as the first moire fringe, combined focal distance between a new divergent beam and the lens to be measured is the same as the focus distance of the initial divergent beam, and then the focus distance of the long-focus lens to be measured is obtained. The long-focus lens focus distance measuring method based on the moire fringe matching has the advantages that focus distance of the long-focus lens (focus distance can be several meters to tens of meters) with a heavy caliber can be measured accurately, uniqueness is achieved by using a moire fringe angle as a criterion, measurement of an included angle between grating lines of two gratings is not needed, and error of the moire fringe angle caused by installation of an imaging system is avoided.

Owner:ZHEJIANG UNIV

Electric proportional variable axial plunger pump

ActiveCN103291575BOutput displacement adjustmentImprove reliabilityPositive-displacement liquid enginesMulti-cylinder pumpsControl theoryPlunger pump

The invention discloses an electric proportional variable axial plunger pump comprising a plunger pump body and a variable mechanism arranged on one side of the plunger pump body. The plunger pump body comprises a pump body and a variable tray arranged inside the pump body. The variable mechanism comprises a variable piston connected with the variable tray and a first oil chamber and a second chamber which are formed at two ends of the variable plunger. A hydraulic control system is further arranged on the outer side of the pump body, and comprises a controller, a proportional direction value, a transition plate and a detection mechanism, wherein the proportional direction value is connected with the controller and used for controlling flow of oil, the detection mechanism is used for detecting the position of the variable piston, the transition plate provided with two oil outlets is mounted on the outer side of the pump body. The two oil outlets are communicated with the first and second oil chambers respectively, the proportional direction valve is mounted on the transition plate, and the detection mechanism is connected with the controller. The electric proportional variable axial plunger pump has the advantages of simplicity in control, high reliability and repeat accuracy, and emission can be regulated in real time during operation.

Owner:宁波恒力液压股份有限公司

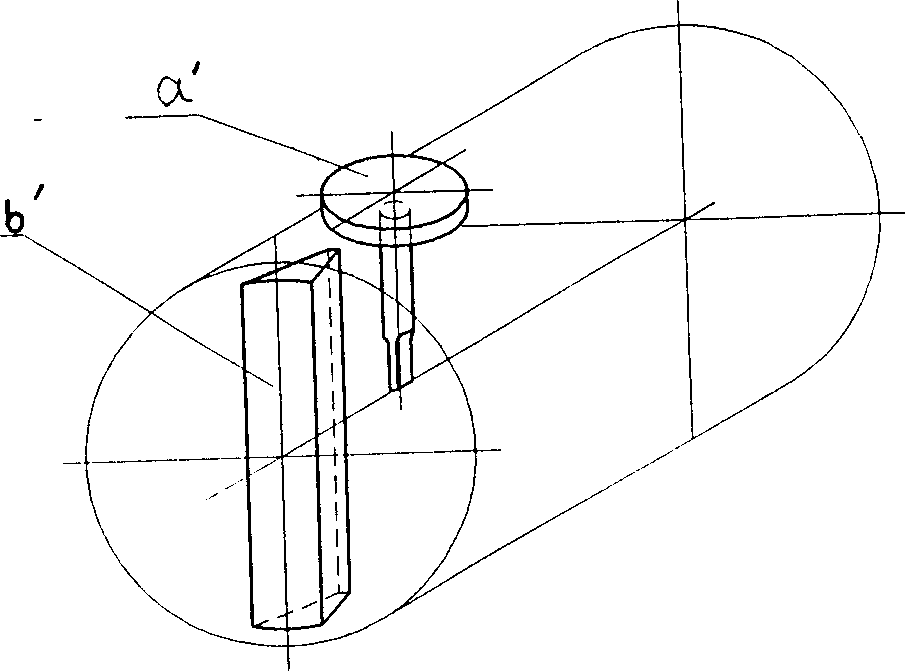

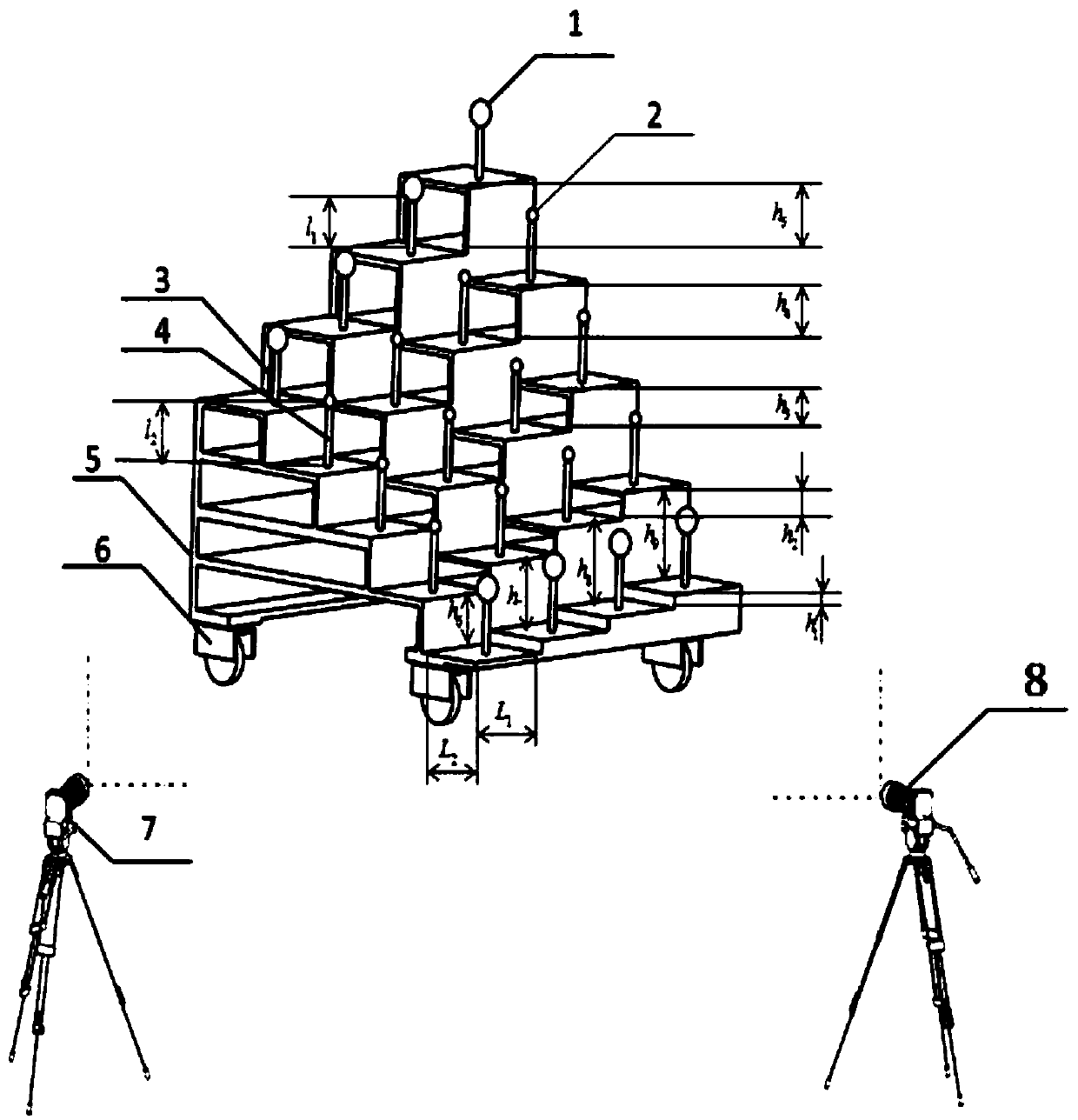

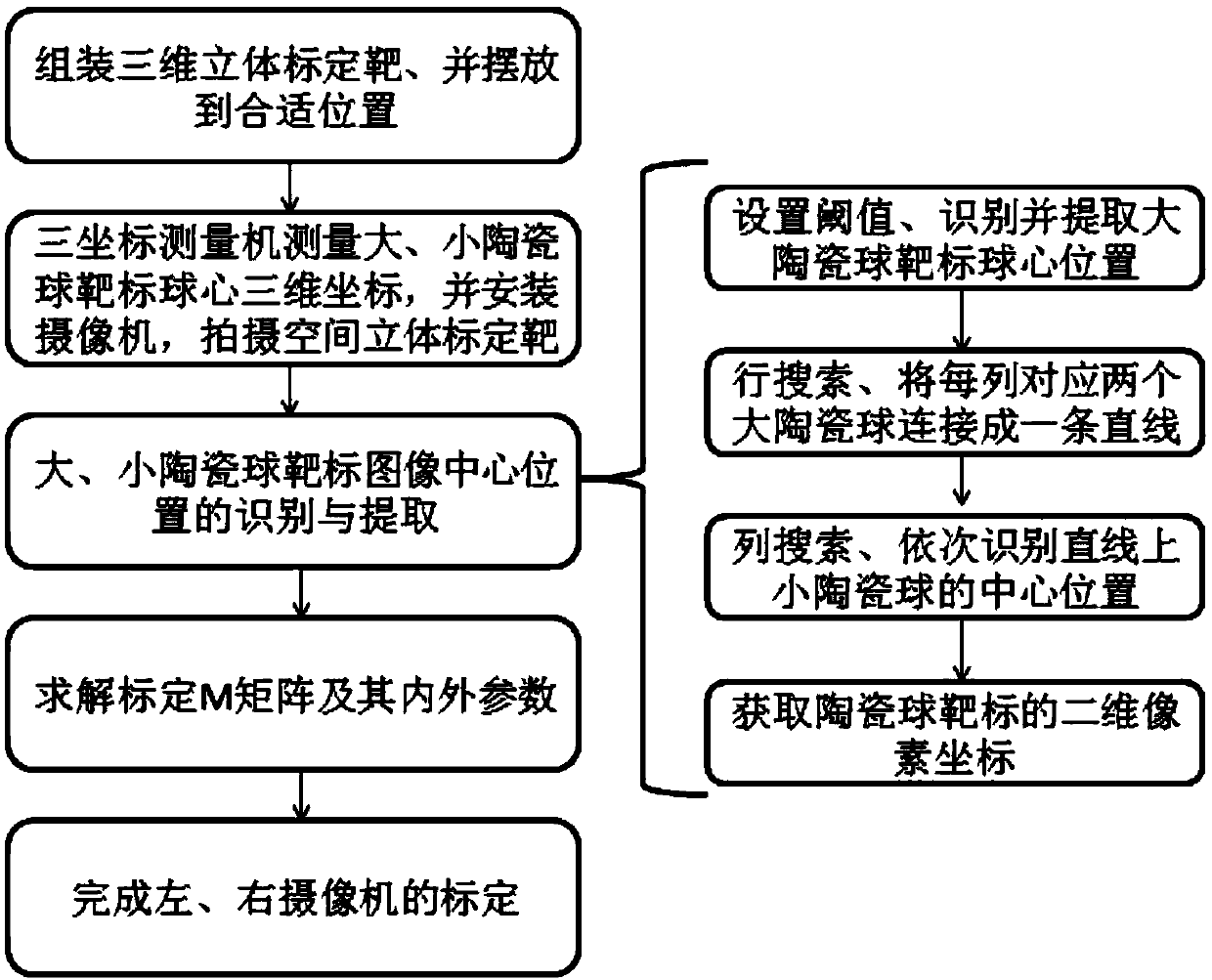

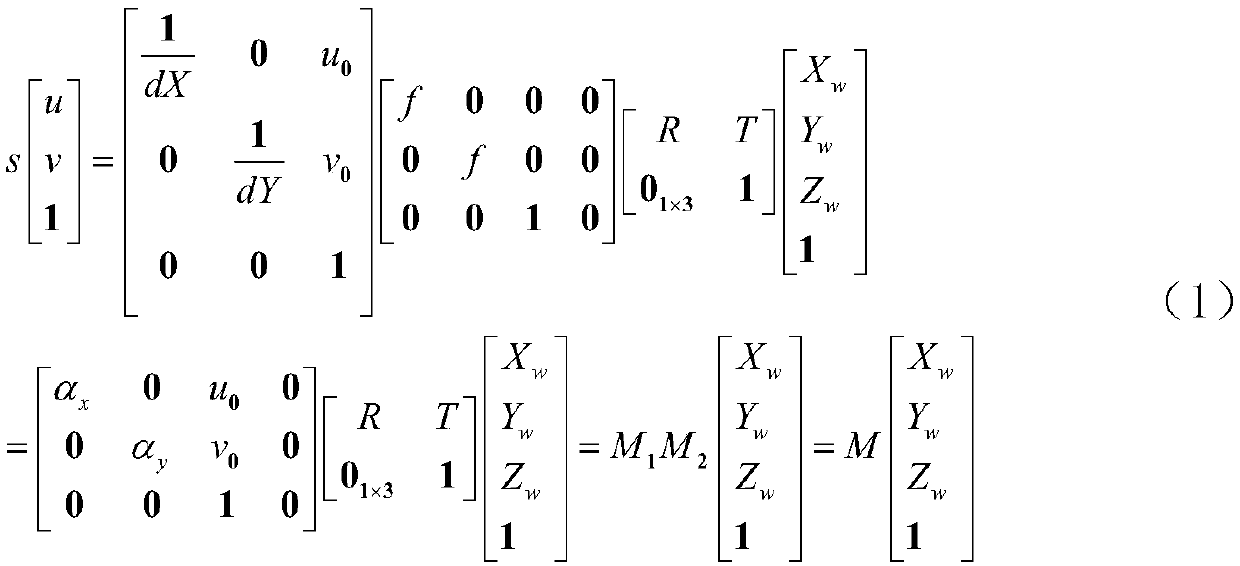

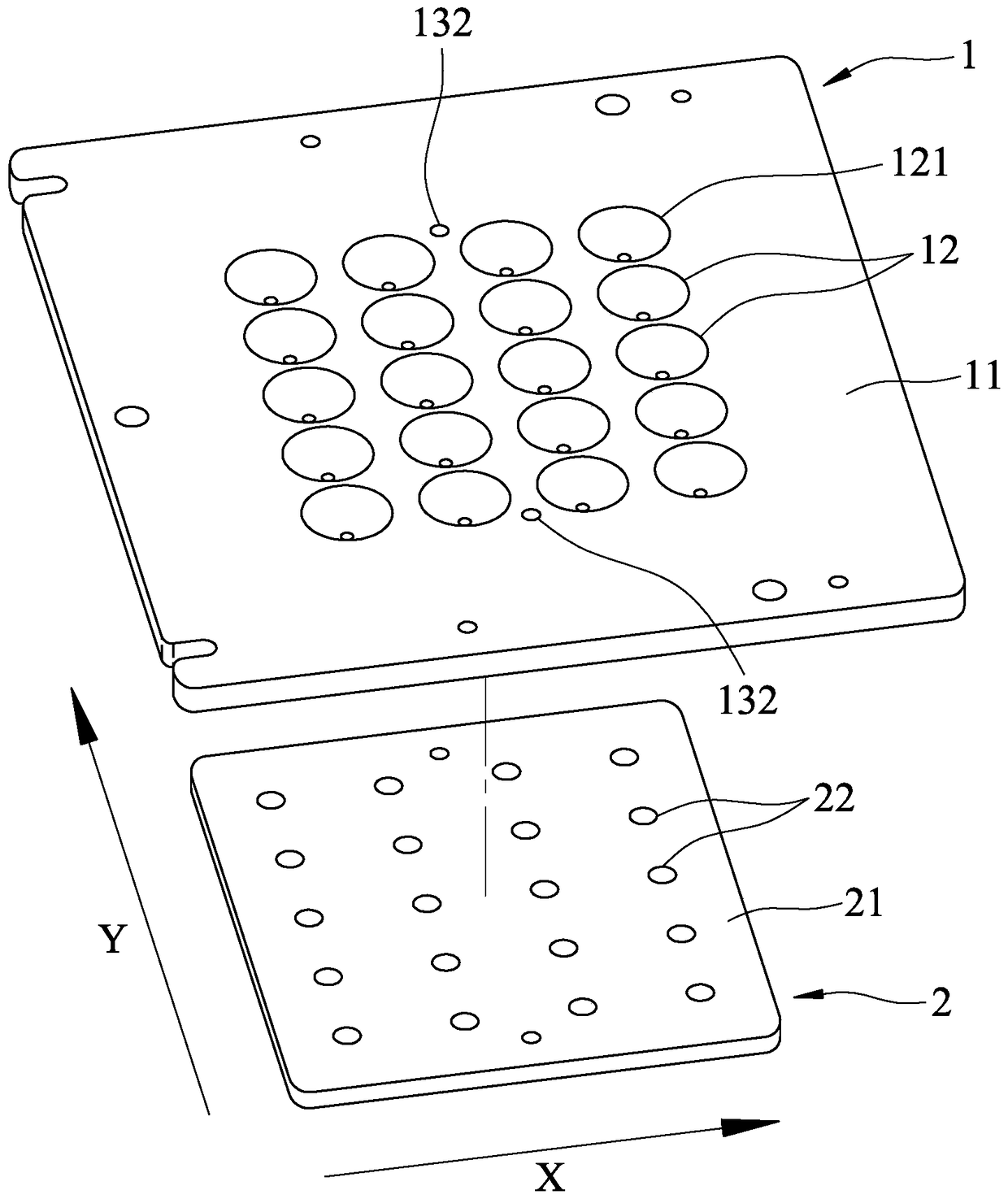

A Fast Extraction Method for Camera Space Stereo Calibration

InactiveCN106600645BEasy to disassembleEasy to carryImage enhancementImage analysisCamera auto-calibrationThree-dimensional space

The invention belongs to the field of visual measurement, and relates to a quick extraction method for the space three-dimensional calibration of a camera. The method comprises the steps: installing a space three-dimensional calibration target before calibration, employing a three-coordinate measuring machine for measurement, and determining the precise three-dimensional position information of the centers of big and small ceramic ball targets; photographing the big and small ceramic ball targets through left and right cameras in a binocular visual system, extracting the feature information of the centers of the big and small ceramic ball targets in images, and solving two-bit pixel coordinates of the centers of the ceramic ball targets; finally solving the internal and external parameters of the left and right cameras on the basis of a direct linear conversion method, and achieving the three-dimensional calibration of the cameras in a three-dimensional space. On the basis of the direct linear conversion method, the method employs the binocular visual measurement system to overcome the limits of a conventional three-dimensional calibration method in the calibration process of the cameras, and achieves the high-precision calibration of the cameras.

Owner:DALIAN UNIV OF TECH

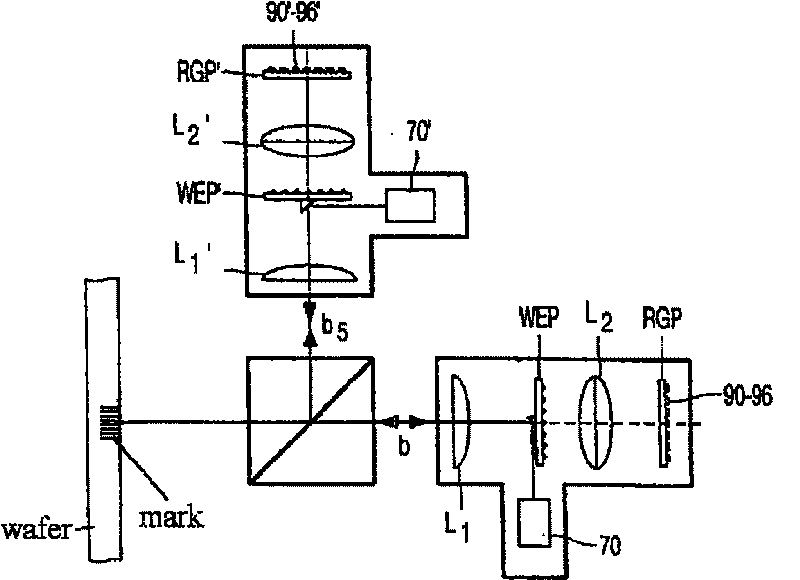

Aligning system and lightscribing device using the system

ActiveCN101165597BHigh sensitivityImprove signal-to-noise ratioPhotomechanical exposure apparatusMicrolithography exposure apparatusGratingLight spot

After the modulation of reference grating, the light intemsity variation of diffracted light coherent imaging in +-1 stage of the alignment mark is detected at image surface; meanwhile at the pupil surface, the variation of interference signal intensity in each stage being coherent and stacking with the positive, negative diffracted light spot in same stage with the high stage diffracted light ofthe alignment light is detected. The generated signals have high process versatility, high sensitivity and high S / N ratio.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

Method for detecting position and attitude of micro cylindrical cavity target by using target collimating sensor

InactiveCN102607410BHigh repeatability accuracyReduce mistakesNuclear energy generationUsing optical meansLocation detectionOptical axis

The invention relates to a method for detecting the position and attitude of a micro cylindrical cavity target by using a target collimating sensor. When the method is used for detection, a target collimating sensor consisting of three CCD (Charge Coupled Device) image sensors which are in orthogonal arrangement is adopted; the intersection point of optical axes of the three CCD image sensors is taken as a reference point for placing a target, and the images of a micro cylindrical cavity target are acquired by the target collimating sensor from different viewing angels; and characteristic values of the images of the images of the micro cylindrical cavity target, which are extracted by the three CCD image sensors are combined, and the space coordinate and azimuth rotation matrix of the micro cylindrical cavity target are calculated according to the characteristic values so as to determine the six-dimensional position and attitude of the micro cylindrical cavity target in space. The new method for detecting the position and attitude of the micro cylindrical cavity target, provided by the invention, has the advantages of improving repeatability accuracy in position detection for the micro cylindrical cavity target and especially reducing errors in attitude direction for the micro cylindrical cavity target, is convenient to operate and has good in stability and has a high detection speed.

Owner:SHANGHAI UNIV

A kind of layered sample processing device for muddy soil core column sample detection

ActiveCN114199651BImprove efficiencyImprove slitting accuracyWithdrawing sample devicesPreparing sample for investigationSoil scienceGeological survey

Owner:山东省地质矿产勘查开发局第四地质大队

Optical auxiliary measuring device and measuring method using the device

InactiveCN104748943BGood measurement stabilityHigh repeatability accuracyOptical apparatus testingEngineeringElectrical and Electronics engineering

The invention relates to an optical auxiliary measuring device comprising a suction unit and a carrying unit. The suction unit includes a main body, at least one measuring hole through the main body, and a gas flow channel arranged in the main body. The measuring hole has a first port and a second port formed on the surface of the body and oppositely arranged. The gas channel has at least one suction port formed on the surface of the body near the second port, and at least one suction port formed on the surface of the body. A contact surface is formed on the body surface close to the suction opening. The carrying unit includes a base plate and at least one placement groove formed by a downward depression of the top surface of the base plate, and the placement slot can be used for placing the object to be tested. The measurement method using the device includes a preparation step, a suction step, a measurement step and a detachment step.

Owner:GENIUS ELECTRONICS OPTICAL XIAMEN

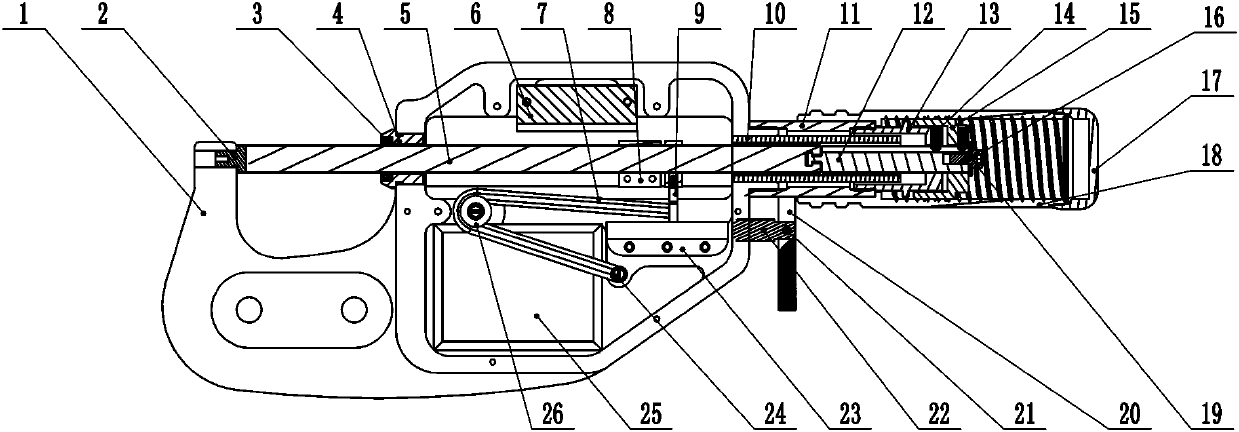

Non-rigid connection rapid-drive high-precision displacement measuring device

PendingCN110296672AHigh repeatability accuracyDoes not affect force measurementMeasurement devicesThreaded pipeDegrees of freedom

The invention discloses a non-rigid connection rapid-drive high-precision displacement measuring device comprising a support, a threaded pipe, a threaded column, and a measuring anvil; internal threads of the threaded pipe are matched with external threads of the threaded column, a measuring shaft, an elastic element and a measuring element used for measuring the displacement of the measuring shaft are arranged in the support, one end of the measuring shaft is a measuring head, the measuring head is matched with the measuring anvil, the measuring shaft is connected with the threaded column, the threaded column only has the degree of freedom in the axial direction under the action of a guiding mechanism, the measuring shaft is connected with the support through a linear guide rail, one endof the elastic element is connected with the support, the other end of the elastic element is connected with the measuring shaft, and the elastic element is used for exerting restoring force towards the direction of a measured point on the measuring shaft. According to the non-rigid connection rapid-drive high-precision displacement measuring device in the invention, the measuring shaft and the driving structure are connected in a non-rigid mode, the measuring rod only provides constant measuring force at the same deformation position by a spring, thereby improving the repeatability precisionand preventing too large external force from acting on the measuring rod to affect the precision of the measuring tool and damage the measured piece, a rotating and stirring mode is adopted, the requirement for fast switching size is met, and the measuring efficiency is high.

Owner:CHENGDU HUALIANG SENSOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com