Central locating mechanism and device

A technology of center positioning and power mechanism, which is applied in the direction of workpiece clamping devices and manufacturing tools, can solve the problems that the center position accuracy cannot meet the test requirements and the substrate size tolerance is large, so as to improve repeatability accuracy, ensure stability and reliability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

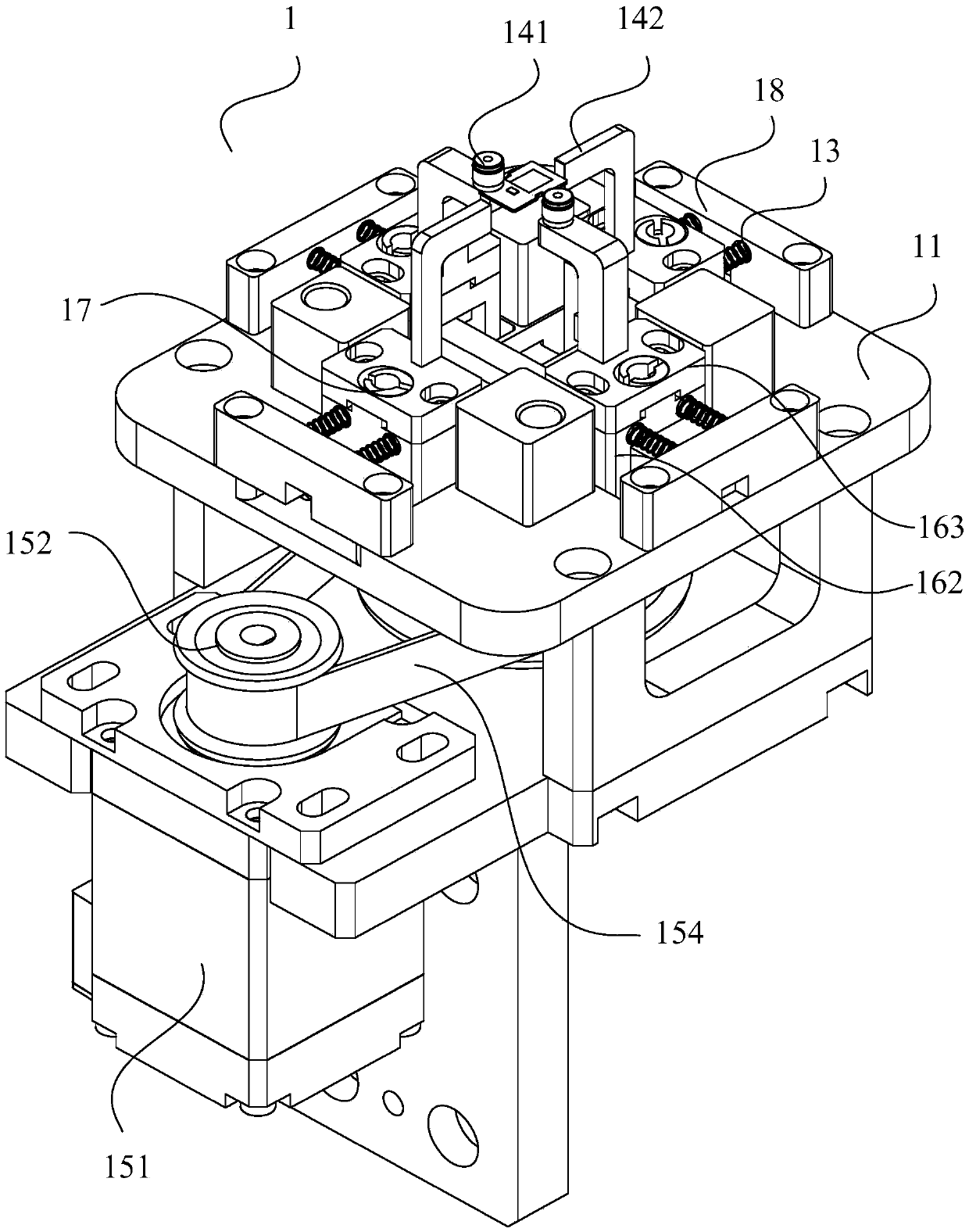

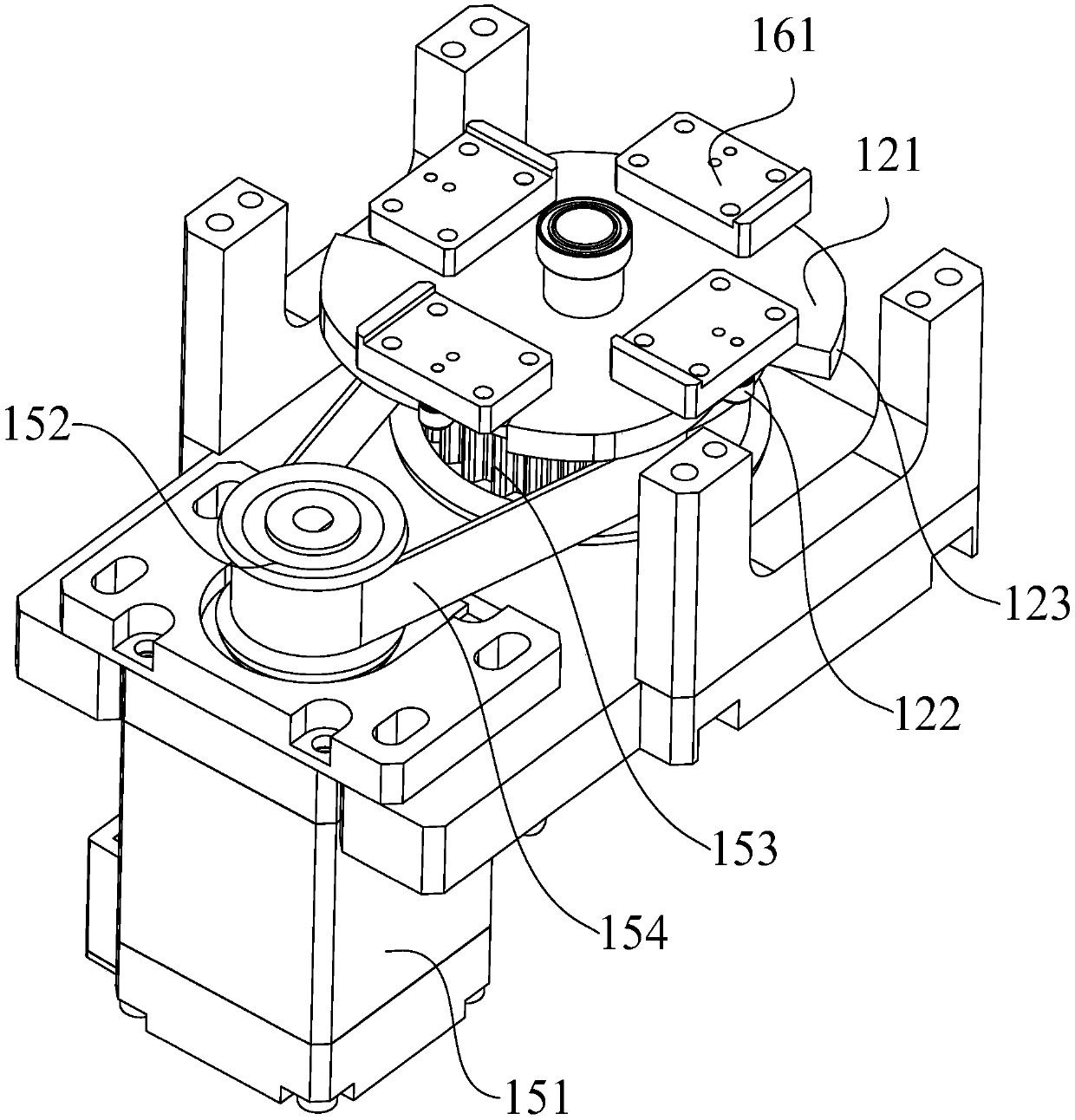

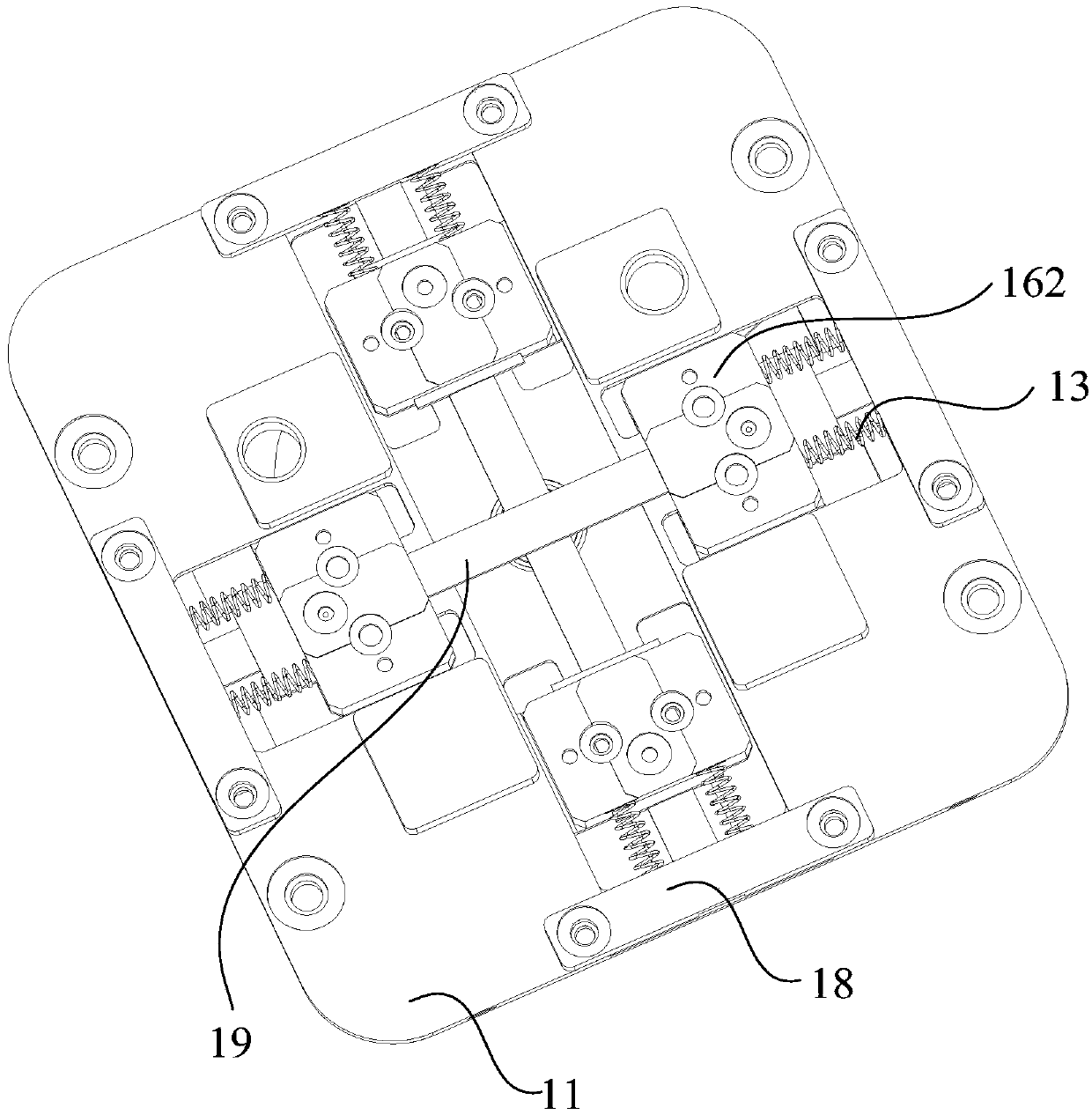

[0040] Such as figure 1 , figure 2 , image 3 , Figure 4 as shown, figure 1 A schematic structural view of the central positioning mechanism provided by the embodiment of the present application is shown; figure 2 It shows the first partial schematic diagram of the central positioning mechanism provided by the embodiment of the present application; image 3 A second partial schematic diagram of the central positioning mechanism provided by the embodiment of the present application is shown; Figure 4 A schematic structural view of the base provided by the embodiment of the present application is shown.

[0041] A center positioning mechanism 1, comprising: a power mechanism, a cam mechanism, a base 11, an elastic member 13, and a clamping part;

[0042] The cam mechanism includes a cam 121 and at least two followers arranged on the outer edge of the cam 121 oppositely, and the output end of the power mechanism is connected with the rotating shaft of the cam 121;

[0...

Embodiment 2

[0078] Based on the same technical idea, the embodiment of the present application also provides a central positioning device, such as Figure 5 as shown, Figure 5 A partial schematic diagram of the central positioning device provided by the embodiment of the present application is shown.

[0079] A center positioning device, comprising a lifting mechanism 2 and a center positioning mechanism 1;

[0080] The lifting mechanism 2 is connected with the central positioning mechanism 1 and is used for adjusting the horizontal height of the clamping part of the central positioning mechanism 1 .

[0081] Specifically, the lifting mechanism 2 is used to lift the entire center positioning mechanism 1 so that the clamping part is located at the position height of the corresponding plane of the VCSEL module. In the implementation of this application, the lifting mechanism 2 adopts a lifting cylinder. It should be noted that the lifting mechanism 2 can also be a hydraulic cylinder, an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com